吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (3): 842-851.doi: 10.13229/j.cnki.jdxbgxb.20220605

• 农业工程·仿生工程 • 上一篇

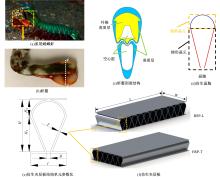

基于虾螯结构的仿生夹层板设计及数值模拟

杨欣1( ),王阳1,2,宋家锋3,4,朱勇2,黄彬兵2,许述财3,5(

),王阳1,2,宋家锋3,4,朱勇2,黄彬兵2,许述财3,5( )

)

- 1.河北农业大学 机电工程学院,河北 保定 071001

2.清华大学 苏州汽车研究院(相城),江苏 苏州 215134

3.清华大学 智能绿色车辆与交通全国重点实验室,北京 100084

4.运输车辆检测、诊断与维修技术交通行业重点实验室,济南 250357

5.清华大学 车辆与运载学院,北京 100084

Design and numerical simulation of bionic sandwich panel based on a shrimp chela structure

Xin YANG1( ),Yang WANG1,2,Jia-feng SONG3,4,Yong ZHU2,Bin-bing HUANG2,Shu-cai XU3,5(

),Yang WANG1,2,Jia-feng SONG3,4,Yong ZHU2,Bin-bing HUANG2,Shu-cai XU3,5( )

)

- 1.College of Mechanical and Electrical Engineering,Hebei Agricultural University,Baoding 071001,China

2.Tsinghua University Suzhou Automobile Research Institute,Suzhou 215134,China

3.State Key Laboratory of intelligent Green Vehicle and Mobility,Tsinghua University,Beijing 100084

4.Key Laboratory of Transportation Industry for Transport Vehicle Detection,Diagnosis and Maintenance Technology,Jinan 250357,China

5.School of Vehicle and Mobility,Tsinghua University,Beijing 100084,China

摘要:

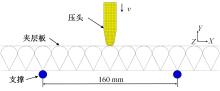

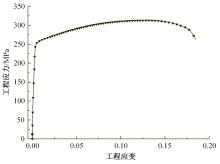

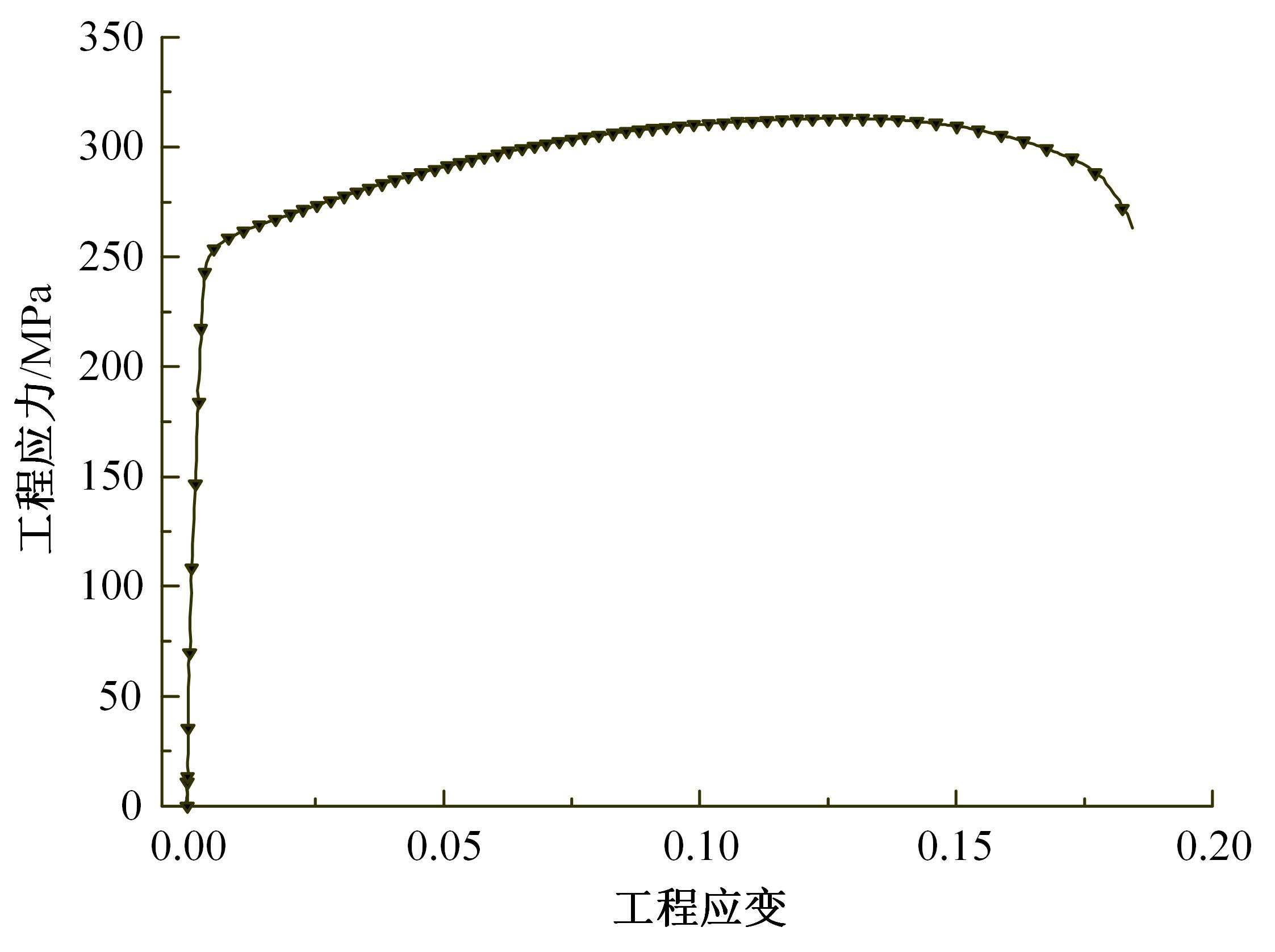

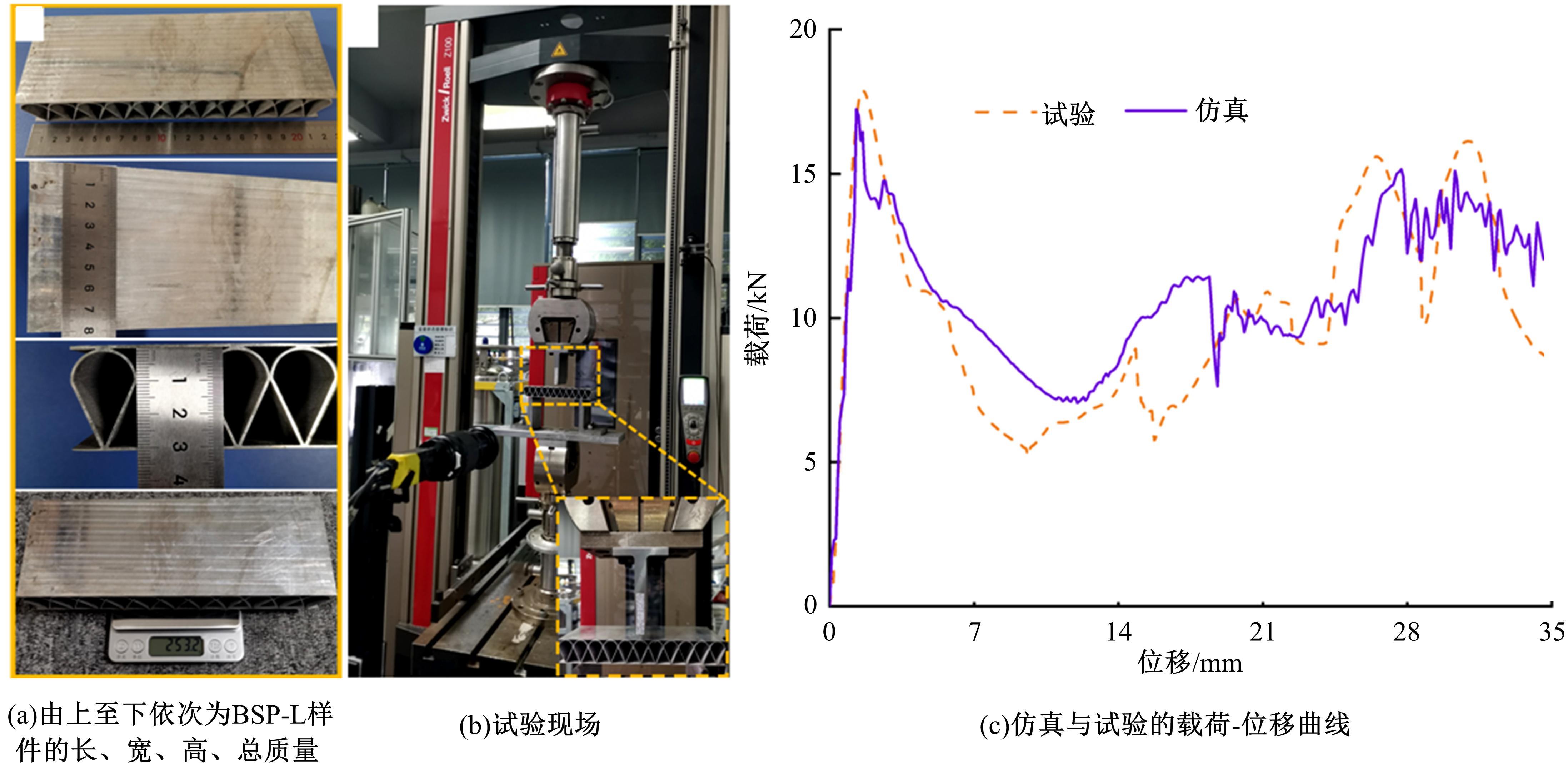

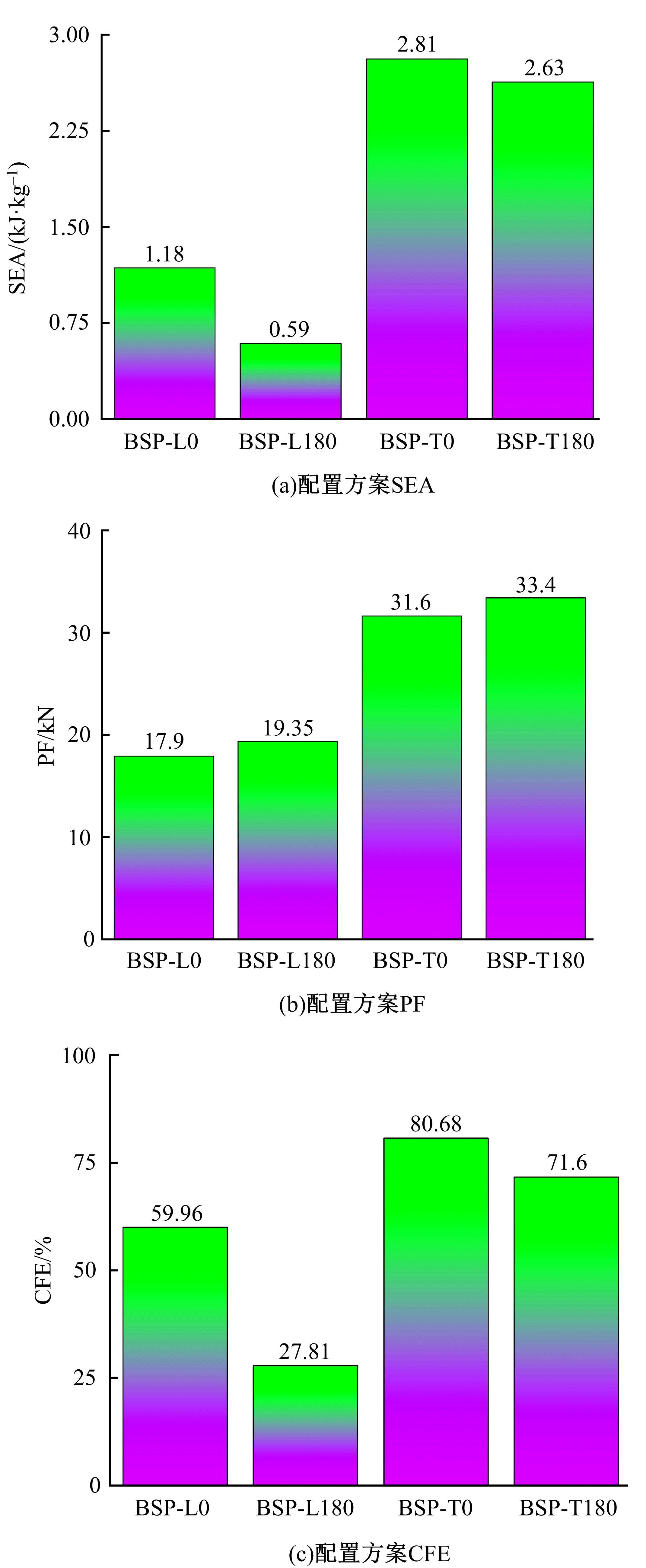

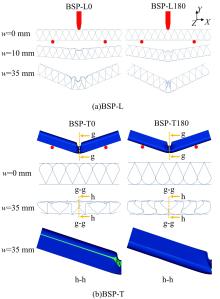

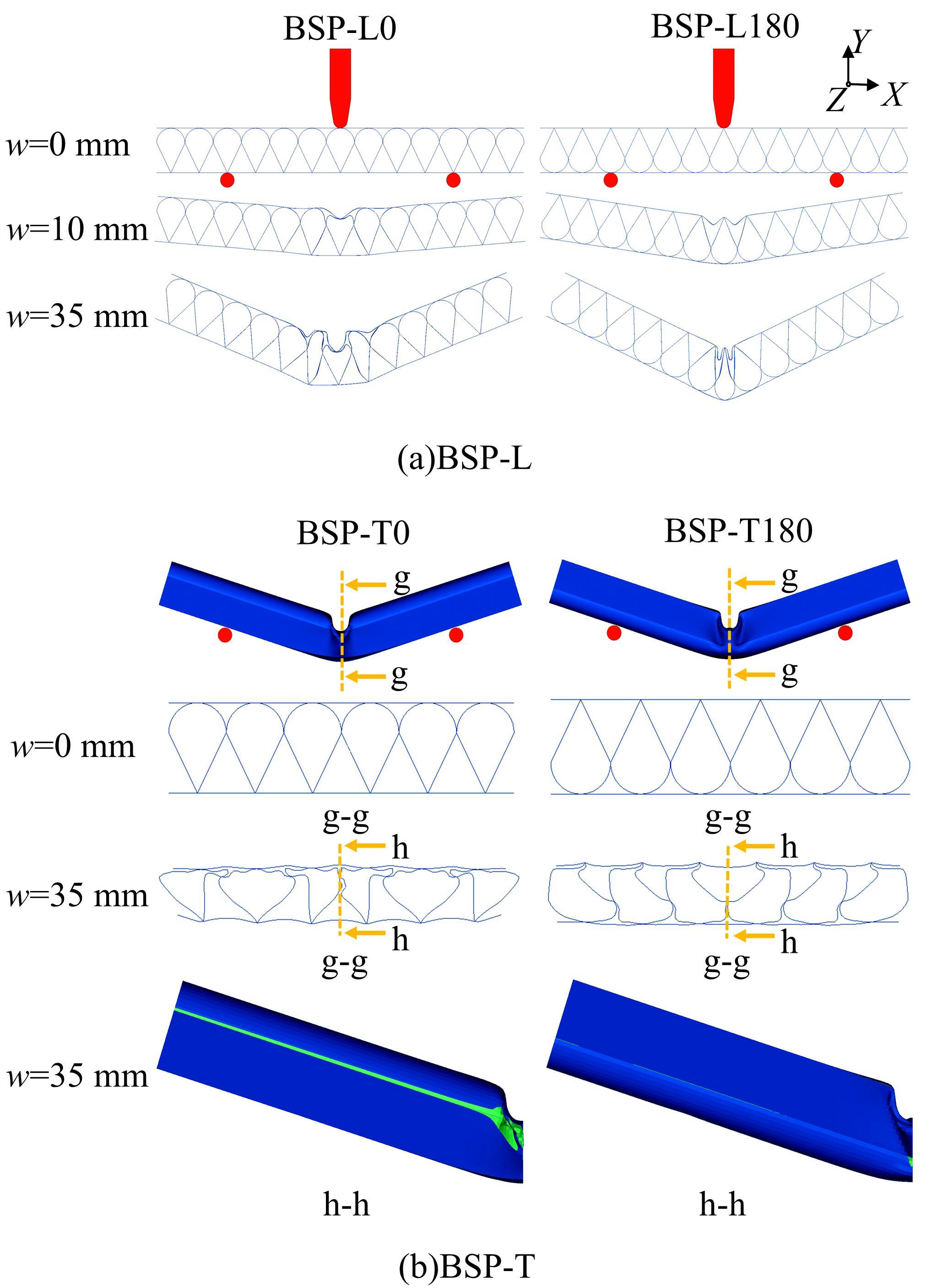

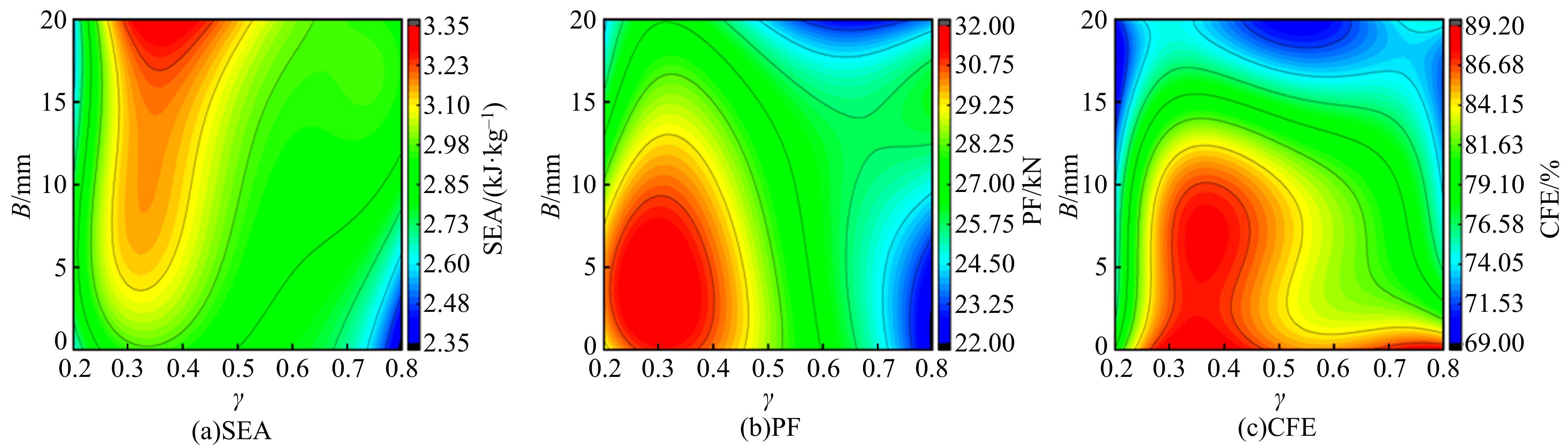

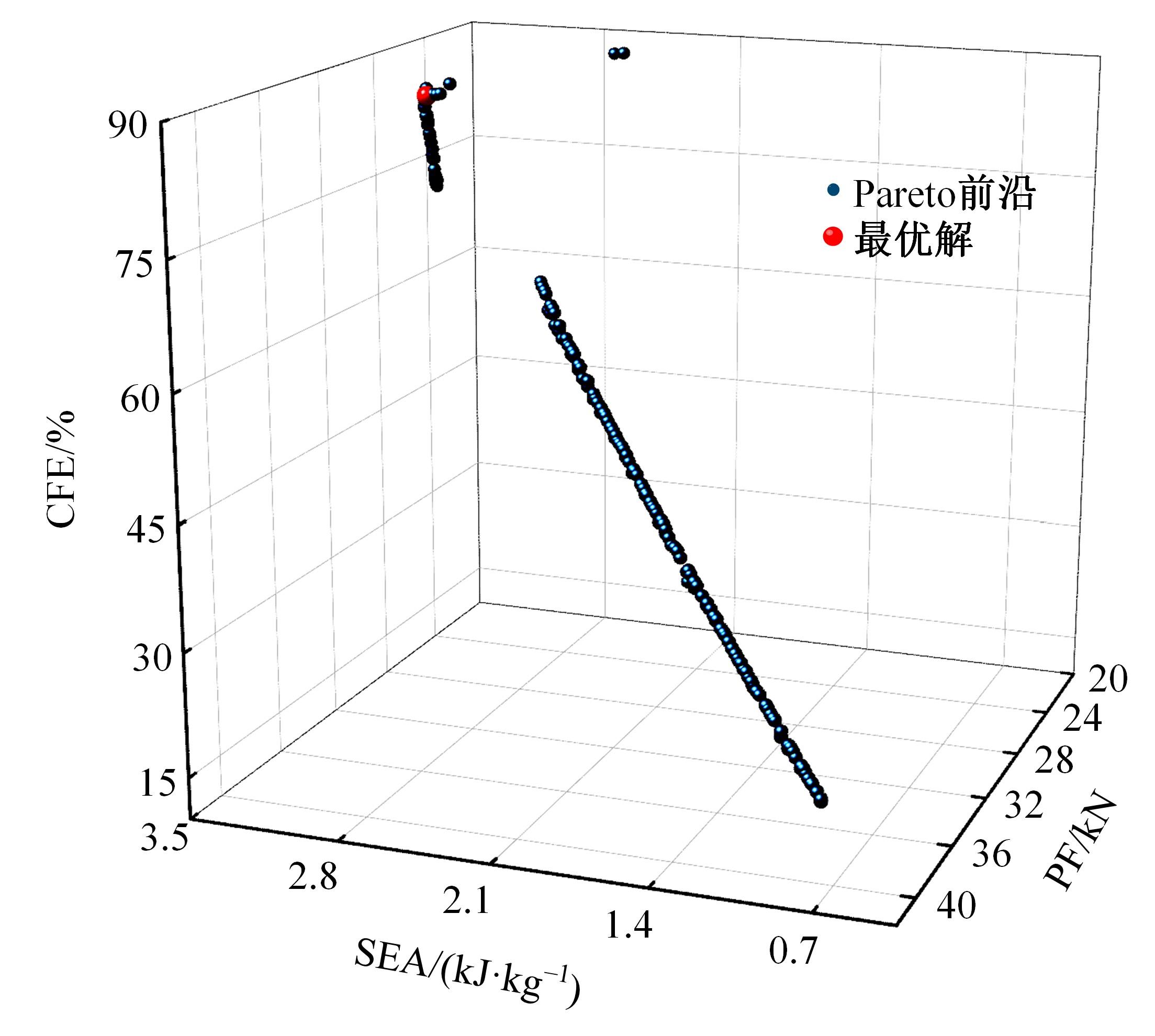

探索了基于虾螯轮廓外形设计的仿生夹层板(BSP)的耐撞性。按照拉伸试验获得的材料本构参数设置了Hyperworks有限元模型,制造了BSP样件,并试验验证了有限元模型有效性。比较了BSP-L0、BSP-L180、BSP-T0、BSP-T180四种配置方案的耐撞性指标,选择BSP-T0方案进一步研究。分析了圆弧高度比γ和梯形晶元窄底宽度B对BSP-T0耐撞性的影响规律,得到γ比B对BSP-T0耐撞性的影响更大。利用遗传学算法进行参数优化,Pareto前沿的一个最优解为比吸能SEA=3.080 kJ/kg、峰值载荷PF=30.700 kN、平均压溃效率CFE=86.884%,相应参数γ=0.355,B=4.23 mm,预测与仿真结果误差均在2%以内,预测效果理想,本文研究成果可为夹层结构设计提供新思路。

中图分类号:

- TB17

| 1 | Zheng T, Li S, Wang G, et al. Mechanical and energy absorption properties of the composite XX-type lattice sandwich structure[J]. European Journal of Mechanics-A/Solids, 2022, 91: No. 104410. |

| 2 | Jeddi M, Yazdani M, Hasan-nezhad H. Energy absorption characteristics of aluminum sandwich panels with Shear Thickening Fluid (STF) filled 3Dfabric cores under dynamic loading conditions[J]. Thin-Walled Structures, 2021, 168: No. 108254. |

| 3 | Liu P, Liu Y, Zhang X. Simulation of hyper-velocity impact on double honeycomb sandwich panel and its staggered improvement with internal-structure model[J]. International Journal of mechanics and Materials in Design, 2016, 12(2): 241-254. |

| 4 | Sun G, Wang E, Zhang J, et al. Experimental study on the dynamic responses of foam sandwich panels with different facesheets and core gradients subjected to blast impulse[J]. International Journal of Impact Engineering, 2020, 135: No. 103327. |

| 5 | Huo X, Liu H, Luo Q, et al. On low-velocity impact response of foam-core sandwich panels[J]. International Journal of Mechanical Sciences, 2020, 181: No. 105681. |

| 6 | Liu T, Hou S, Nguyen X, et al. Energy absorption characteristics of sandwich structures with composite sheets and bio coconut core[J]. Composites Part B: Engineering, 2017, 114: 328-338. |

| 7 | Flores-Johnson E A, Shen L, Guiamatsia I, et al. A numerical study of bioinspired nacre-like composite plates under blast loading[J]. Composite Structures, 2015, 126: 329-336. |

| 8 | 葛东云, 莫与明, 何柏灵, 等. 复合材料帽型加筋板轴压试验及承载能力预测[J]. 复合材料学报, 2016, 33(7): 1531-1539. |

| Ge Dong-yun, Mo Yu-ming, He Bo-ling, et al. Test and ultimate load capacity prediction of hat-stiffened composite panel under axial compression[J]. Acta Materiae Compositae Sinica, 2016, 33(7): 1531-1539. | |

| 9 | 张保成, 刘晓婷, 杨贵春, 等. 折板截面特征对结构刚度的影响[J]. 机械设计, 2019, 36(4): 27-31. |

| Zhang Bao-cheng, Liu Xiao-ting, Yang Gui-chun, et al. Effect of cross-section characteristics of folded plate on structural stiffness[J]. Journal of Machine Design, 2019,36(4): 27-31. | |

| 10 | 秦勤, 王建伟, 刘星岩, 等. 复合蛋盒型夹层结构动态压缩的力学性能研究[J]. 稀有金属材料与工程, 2021, 50(11): 4103-4112. |

| Qin Qin, Wang Jian-wei, Liu Xing-yan, et al. Study on dynamic compression properties of egg-box sandwich structure[J]. Rare Metal Materials and Engineering, 2021, 50(11): 4103-4112. | |

| 11 | 邓云飞, 周楠, 田锐, 等. S型碳纤维褶皱夹芯结构低速冲击响应特性实验研究[J]. 航空学报, 2022, 43(6): 469-480. |

| Deng Yun-fei, Zhou Nan, Tian Rui, et al. Research on the response characteristics of sandwich structure with S-shaped CFRP folded core under low velocity impact[J]. Acta Aeronautica et Astronautica Sinica, 2022, 43(6): 469-480. | |

| 12 | Mohammadabadi M, Jarvis J, Yadama V, et al. Predictive models for elastic bending behavior of a wood composite sandwich panel[J]. Forests, 2020, 11(6): No. 624. |

| 13 | Khan M S, Abdul-Latif A, Koloor S S R, et al. Representat-ive cell analysis for damage-based failure model of polymer hexagonal honeycomb structure under the out-of-plane loadings[J]. Polymers, 2020, 13(1): No. 52. |

| 14 | Chen J, Hao N, Pan L, et al. Characteristics of compressive mechanical properties and strengthening mechanism of 3D-printed grid beetle elytron plates[J]. Journal of Materials Science, 2020, 55(20): 8541-8552. |

| 15 | Ha N S, Lu G, Xiang X. Energy absorption of a bio-inspired honeycomb sandwich panel[J]. Journal of Materials Science, 2019, 54(8): 6286-6300. |

| 16 | Song J F, Xu S C, Wang H X, et al. Bionic design and multi-objective optimization for variable wall thickness tube inspired bamboo structures[J]. Thin-Walled Structures, 2018, 125: 76-88. |

| 17 | Song J, Xu S, Liu S, et al. Design and numerical study on bionic columns with grooves under lateral impact[J]. Thin-Walled Structures, 2020, 148: No. 106546. |

| 18 | 霍鹏, 许述财, 范晓文, 等. 鹿角骨单位仿生薄壁管斜向冲击耐撞性研究[J]. 爆炸与冲击, 2020, 40(11): 127-138. |

| Huo Peng, Xu Shu-cai, Fan Xiao-wen, et al. Oblique impact resistance of a bionic thin-walled tube based on antles osteon[J]. Explosion and Shock Waves, 2020, 40(11): 127-138. | |

| 19 | Suksangpanya N, Yaraghi N A, Kisailus D, et al. Twisting cracks in Bouligand structures[J]. Journal of the Mechanical Behavior of Biomedical Materials, 2017, 76: 38-57. |

| 20 | Suksangpanya N, Yaraghi N A, Pipes R B, et al. Crack twisting and toughening strategies in Bouligand architectures[J]. International Journal of Solids and Structures, 2018, 150: 83-106. |

| 21 | Huang H, Yang X, Yan Q, et al. Crashworthiness analysis and multiobjective optimization of bio-inspired sandwich structure under impact load[J]. Thin-Walled Structures, 2022, 172: No. 108840. |

| 22 | 黄晗, 许述财, 陈姮. 仿生波纹夹层结构耐撞性分析及优化[J]. 爆炸与冲击, 2021, 41(8): 36-46. |

| Huang Han, Xu Shu-cai, Chen Heng. Crashworthiness analysis and optimization of bionic corrugated sandwich structures[J]. Explosion and Shock Waves, 2021, 41(8): 36-46. | |

| 23 | 黄晗, 闫庆昊, 向枳昕, 等. 基于虾螯的仿生多胞薄壁管耐撞性分析及优化[J]. 吉林大学学报: 工学版, 2022, 52(3): 716-724. |

| Huang Han, Yan Qing-hao, Xiang Zhi-xin, et al. Crashworthi-ness investigation and optimization of bionic multi-cell tube based on shrimp chela[J]. Journal of Jilin University (Engineering and Technology Edition), 2022, 52(3): 716-724. | |

| 24 | 杨欣, 范晓文, 许述财, 等. 仿虾螯结构薄壁管设计及耐撞性分析[J]. 爆炸与冲击, 2020, 40(4): 62-72. |

| Yang Xin, Fan Xiao-wen, Xu Shu-cai, et al. Design and crashworthiness analysis of thin-walled tubes based on a shrimp chela structure[J]. Explosion and Shock Waves, 2020, 40(4): 62-72. | |

| 25 | Patek S N, Caldwell R L. Extreme impact and cavitation forces of a biological hammer: strike forces of the peacock mantis shrimp Odontodactylus scyllarus[J]. Journal of Experimental Biology, 2005, 208(19): 3655-3664. |

| 26 | Grunenfelder L K, Milliron G, Herrera S, et al. Ecologically driven ultrastructural and hydrodynamic designs in stomatopod cuticles[J]. Advanced Materials, 2018, 30(9): No. 1705295. |

| 27 | Nia A A, Chahardoli S. Optimizing the layout of nested three-tube structures in quasi-static axial collapse[J]. Thin-Walled Structures, 2016, 107: 169-181. |

| 28 | Manes A, Peroni L, Scapin M, et al. Analysis of strain rate behavior of an Al 6061 T6 alloy[J]. Procedia Engineering, 2011, 10: 3477-3482. |

| 29 | Gong C, Bai Z, Lv J, et al. Crashworthiness analysis of bionic thin-walled tubes inspired by the evolution laws of plant stems[J]. Thin-Walled Structures, 2020, 157: No. 107081. |

| 30 | 马芳武, 梁鸿宇, 赵颖, 等. 内凹三角形负泊松比结构耐撞性多目标优化设计[J]. 吉林大学学报: 工学版, 2020, 50(1): 29-35. |

| Ma Fang-wu, Liang Hong-yu, Zhao Ying, et al. Multi-objective crashworthiness optimization design of concave triangles cell structure with negative Poisson′s ratio[J]. Journal of Jilin University (Engineering and Technology Edition), 2020,50(1): 29-35. | |

| 31 | 马超, 高云凯, 刘哲, 等. 骨架式车身多材料及梁截面形状和尺寸优化[J]. 吉林大学学报: 工学版, 2021, 51(5): 1583-1592. |

| Ma Chao, Gao Yun-kai, Liu Zhe, et al. Optimization of multi-material and beam cross-sectional shape and dimension of skeleton-type body[J]. Journal of Jilin University (Engineering and Technology Edition), 2021, 51(5): 1583-1592. |

| [1] | 邓小林,杨馥模,覃善甘. 新型仿竹六边形梯度层级多胞管耐撞性对比分析[J]. 吉林大学学报(工学版), 2024, 54(2): 333-345. |

| [2] | 吴骁,史文库,郭年程,赵燕燕,陈志勇,李鑫鹏,孙卓,刘健. 基于Ease off的准双曲面齿轮多目标优化[J]. 吉林大学学报(工学版), 2024, 54(1): 76-85. |

| [3] | 周晓,梁燚杰,奚中轩,王宇涛. 白车身B柱焊接变形模拟及预变形控制方法[J]. 吉林大学学报(工学版), 2023, 53(8): 2212-2218. |

| [4] | 陈鑫,张冠宸,赵康明,王佳宁,杨立飞,司徒德蓉. 搭接焊缝对铝合金焊接结构轻量化设计的影响[J]. 吉林大学学报(工学版), 2023, 53(5): 1282-1288. |

| [5] | 龙海波,杨家其,尹靓,赵学彧,向子权. 基于鲁棒优化的不确定需求下应急物资配送多目标决策模型[J]. 吉林大学学报(工学版), 2023, 53(4): 1078-1084. |

| [6] | 何颖,樊俊松,王巍,孙庚,刘衍珩. 无人机空地安全通信与航迹规划的多目标联合优化方法[J]. 吉林大学学报(工学版), 2023, 53(3): 913-922. |

| [7] | 刘汉武,雷雨龙,阴晓峰,付尧,李兴忠. 增程式电动汽车增程器多点控制策略优化[J]. 吉林大学学报(工学版), 2022, 52(8): 1741-1750. |

| [8] | 陈昭明,邹劲松,王伟,石明全. 改进粒子群神经网络融合有限元分析的铸锻双控动态成型多目标优化[J]. 吉林大学学报(工学版), 2022, 52(7): 1524-1533. |

| [9] | 马永杰,陈敏. 基于卡尔曼滤波预测策略的动态多目标优化算法[J]. 吉林大学学报(工学版), 2022, 52(6): 1442-1458. |

| [10] | 姜斌祥,姜彤彤,王永雷. 基于文化遗传算法的毒品检验区块链共识算法优化[J]. 吉林大学学报(工学版), 2022, 52(3): 684-692. |

| [11] | 黄晗,闫庆昊,向枳昕,杨鑫涛,陈金宝,许述财. 基于虾螯的仿生多胞薄壁管耐撞性分析及优化[J]. 吉林大学学报(工学版), 2022, 52(3): 716-724. |

| [12] | 张立杰,阿喜塔,田笑,李稳. 基于Gamma过程的加速退化试验多目标优化设计[J]. 吉林大学学报(工学版), 2022, 52(2): 361-367. |

| [13] | 陈奕颖,金敬福,丛茜,陈廷坤,任露泉. 不同冰点介质对冰黏附强度的影响[J]. 吉林大学学报(工学版), 2021, 51(5): 1926-1932. |

| [14] | 于征磊,陈立新,徐泽洲,信仁龙,马龙,金敬福,张志辉,江山. 基于增材制造的仿生防护结构力学及回复特性分析[J]. 吉林大学学报(工学版), 2021, 51(4): 1540-1547. |

| [15] | 于征磊,信仁龙,陈立新,朱奕凝,张志辉,曹青,金敬福,赵杰亮. 仿蜂窝防护结构的承载特性[J]. 吉林大学学报(工学版), 2021, 51(3): 1140-1145. |

|

||