吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (6): 1501-1511.doi: 10.13229/j.cnki.jdxbgxb.20220951

• 车辆工程·机械工程 •

湿滑路面轮胎接地力学特性模型

刘从臻1( ),陈高1,刘洪柱1,马强1,徐成伟1,孟辉1,王国林2

),陈高1,刘洪柱1,马强1,徐成伟1,孟辉1,王国林2

- 1.山东理工大学 交通与车辆工程学院,山东 淄博 255022

2.江苏大学 汽车与交通工程学院,江苏 镇江 212013

Tire grounding mechanical model on wet roads

Cong-zhen LIU1( ),Gao CHEN1,Hong-zhu LIU1,Qiang MA1,Cheng-wei XU1,Hui MENG1,Guo-lin WANG2

),Gao CHEN1,Hong-zhu LIU1,Qiang MA1,Cheng-wei XU1,Hui MENG1,Guo-lin WANG2

- 1.School of Transportation and Vehicle Engineering,Shandong University of Technology,Zibo 255022,China

2.School of Automotive and Traffic Engineering,Jiangsu University,Zhenjiang 212013,China

摘要:

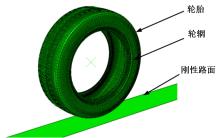

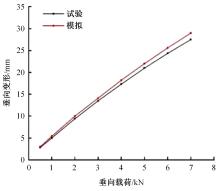

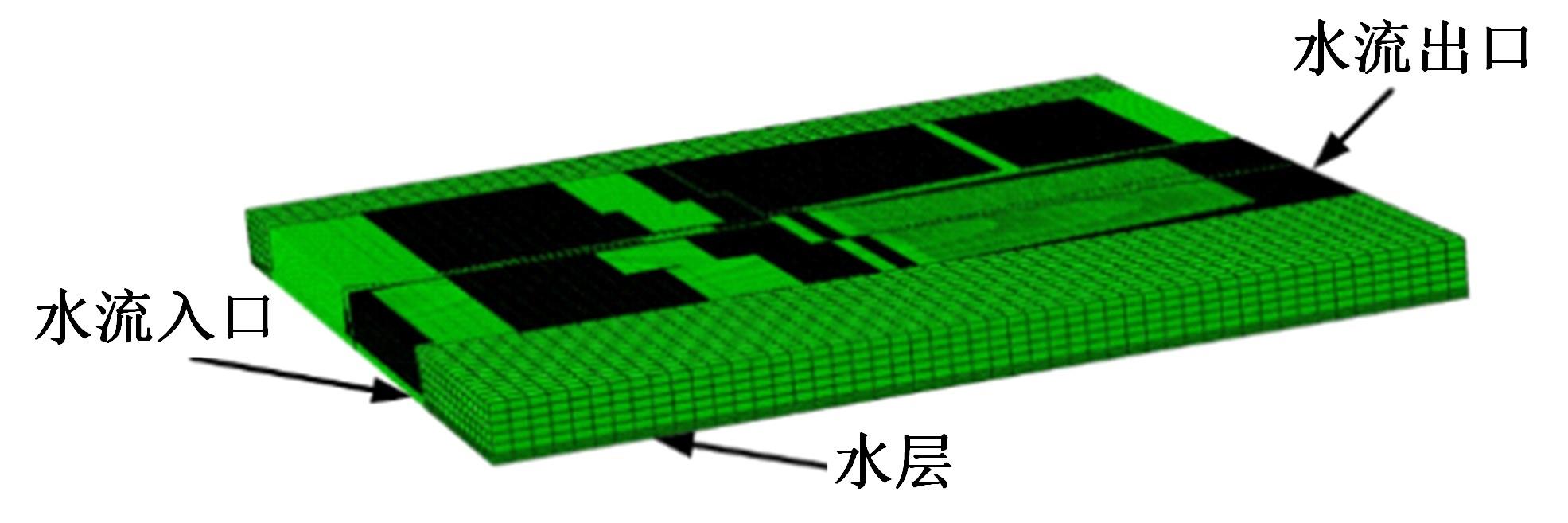

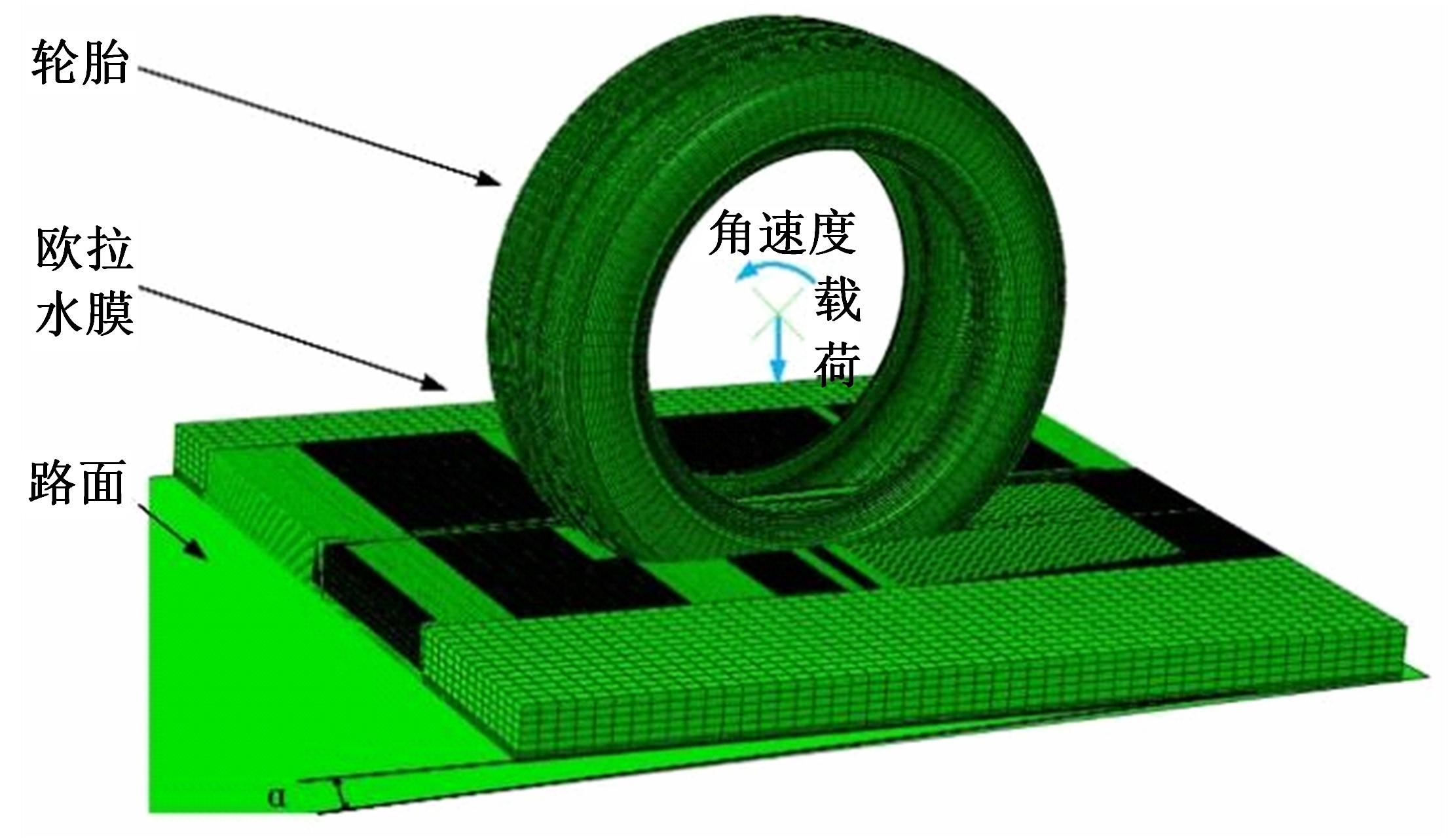

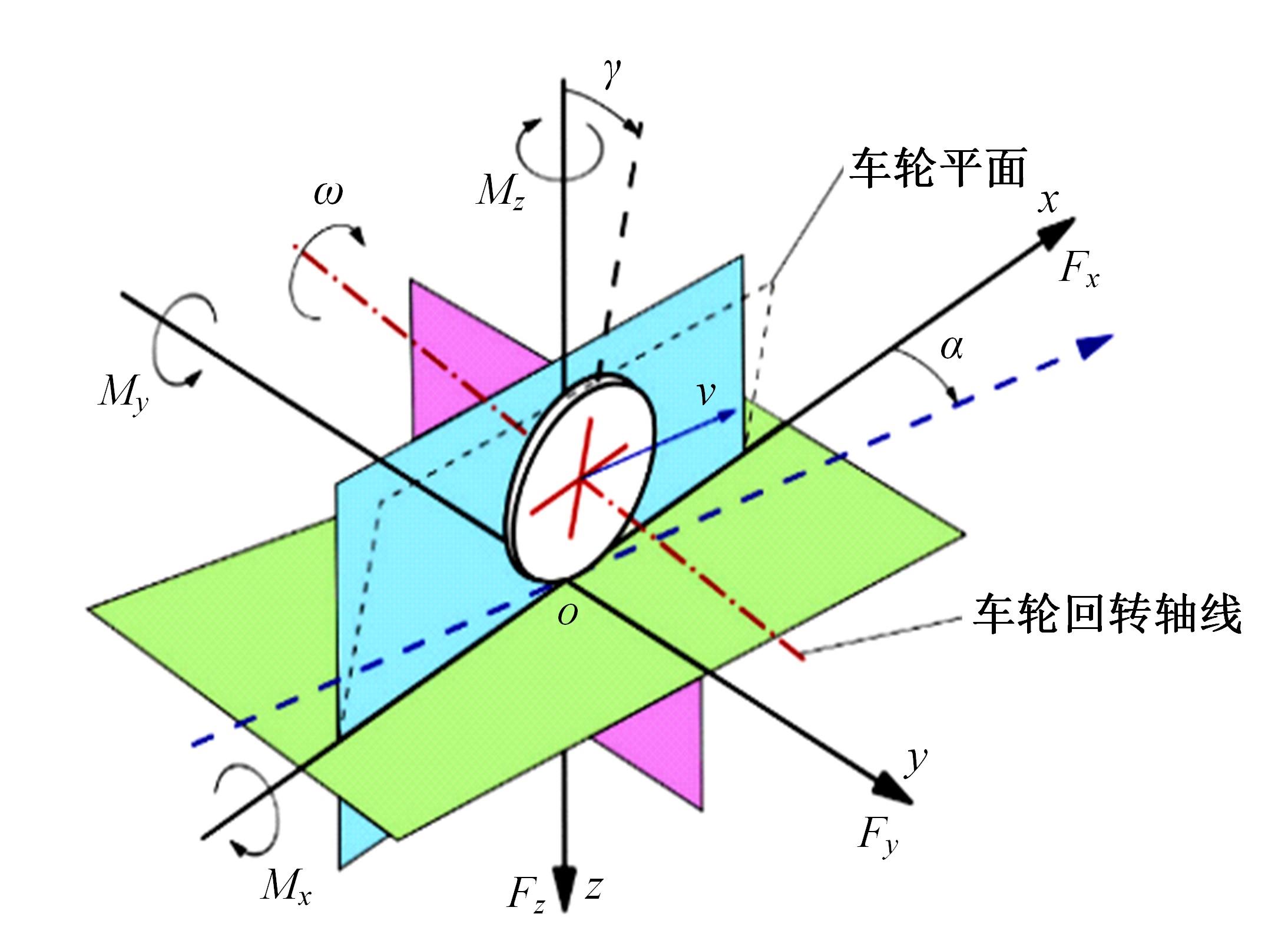

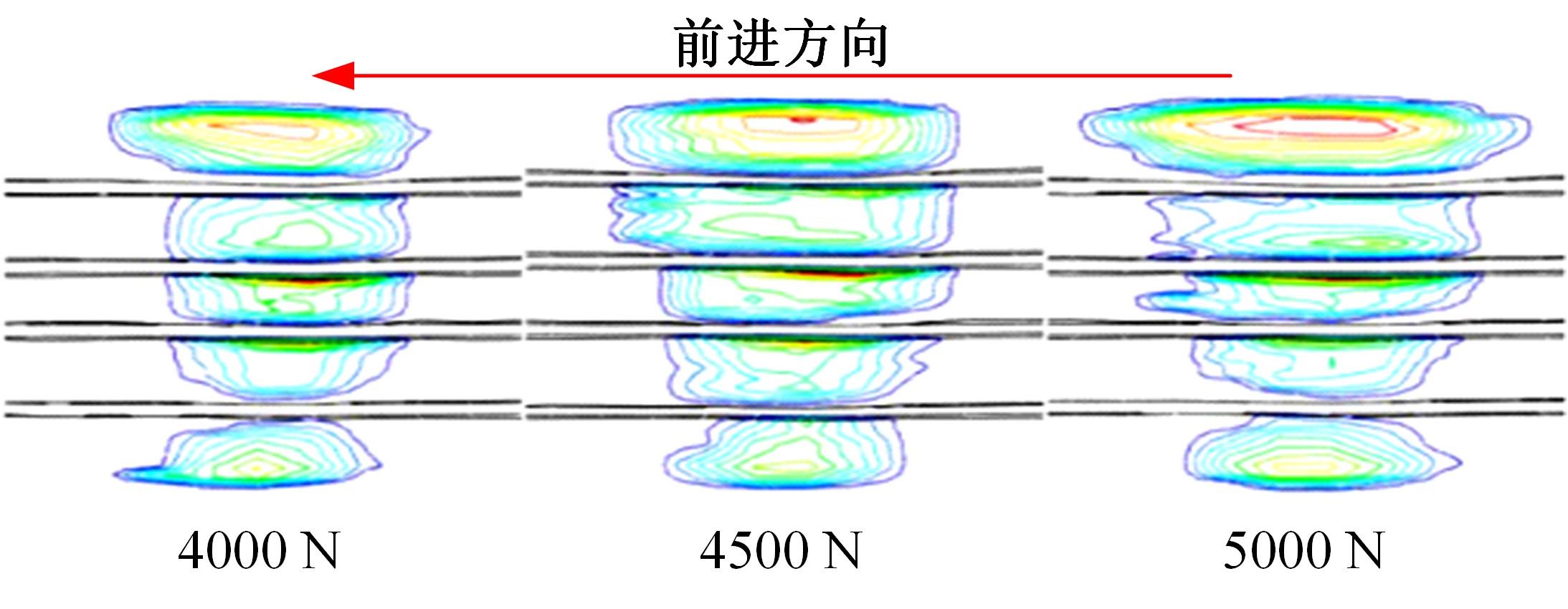

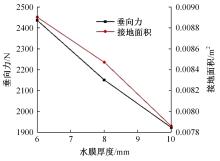

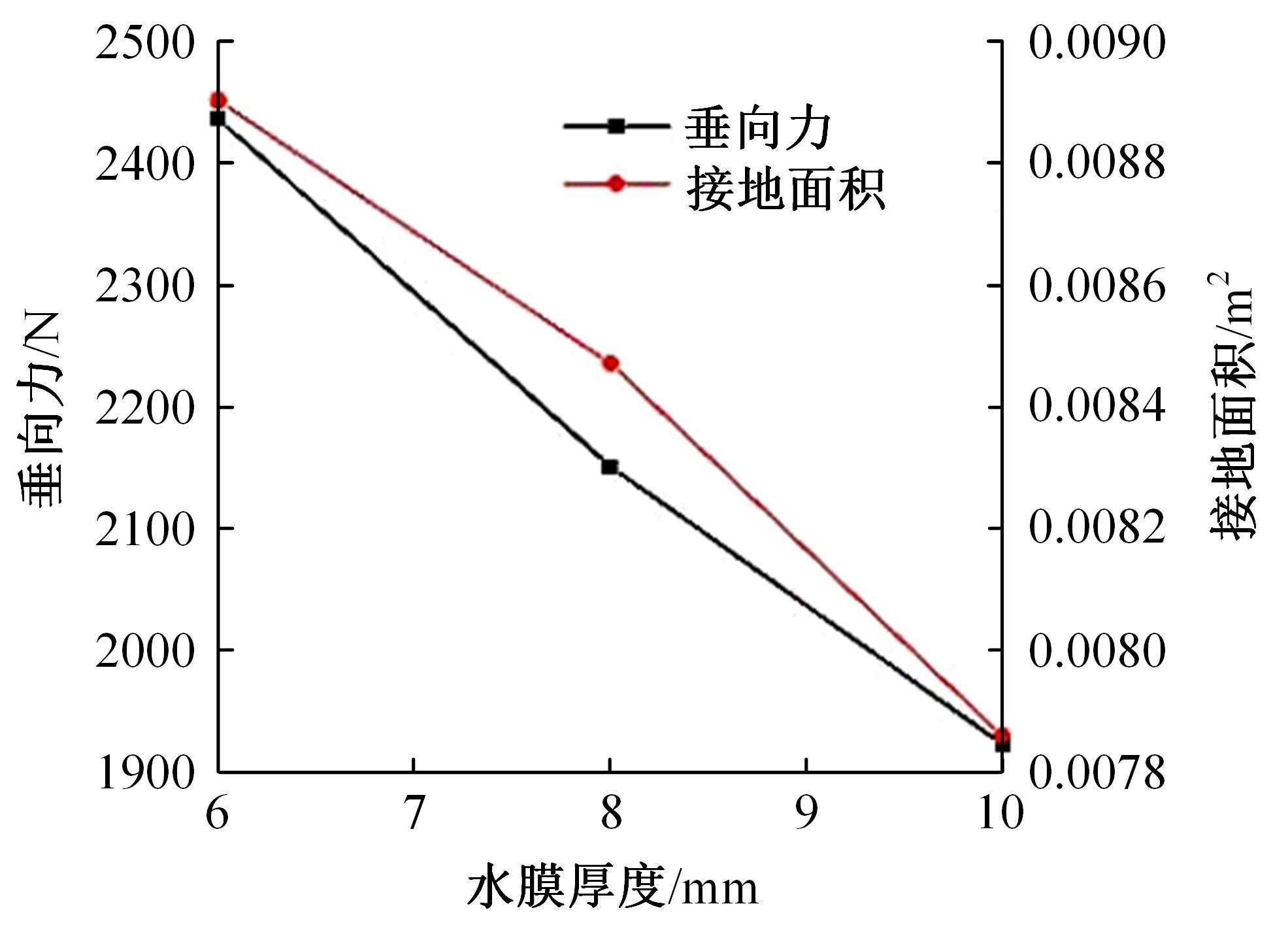

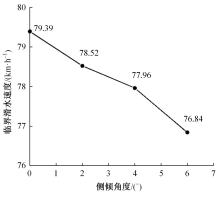

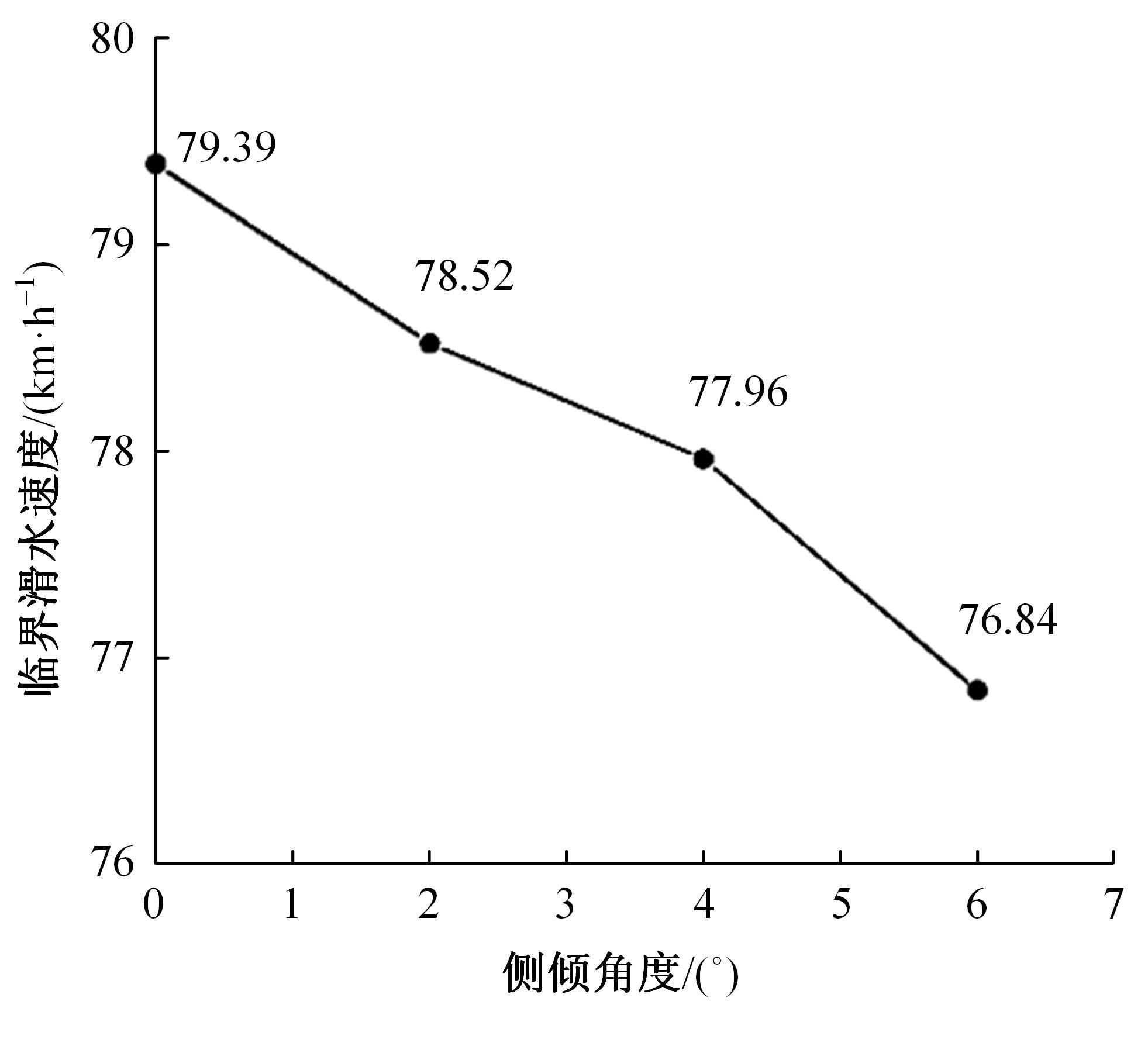

为研究部分滑水状态下轮胎的接地力学特性,以205/55 R16乘用车轮胎为研究对象,建立了耦合欧拉-拉格朗日滑水仿真模型。利用正交试验设计方法创建试验方案,通过极差分析、偏相关分析和多元线性回归分析,建立了适用于不同工况的湿滑路面轮胎侧偏纵滑“亚利桑那大学轮胎模型”。对比分析表明,该模型能够准确预测湿滑路面上的轮胎接地力学特性,可为研究轮胎多工况滑水性能提供理论参考。

中图分类号:

- U463.341

| 1 | Dolwichai P, Limtragool J. The effect of tire treads shape to stick-slip phenomenon in frictional contact[C]∥The 20th Conference of MENETT, Nakorn Ratchasima, Thailand, 2006: 18-20. |

| 2 | El-Sayegh Z, El-Gindy M. Cornering characteristics of a truck tire on wet surface using finite element analysis and smoothed-particle hydrodynamics[J]. International Journal of Dynamics and Control, 2018, 6(4): 1567-1576. |

| 3 | El-Sayegh Z, El-Gindy M. Sensitivity analysis of truck tyre hydroplaning speed using FEA-SPH model[J]. International Journal of Vehicle Systems Modelling and Testing, 2017, 12(1/2): 143-161. |

| 4 | Jeong J Y, Jeong H Y. Hydroplaning simulation of a tire in thin water using fem and an estimation method and its application to skid number estimation[J]. International Journal of Automotive Technology, 2013, 14(2): 325-331. |

| 5 | Ong G P, Fwa T F. Mechanistic interpretation of braking distance specifications and pavement friction requirements[J]. Transportation Research Record, 2010, 2155(1): 145-157. |

| 6 | Fwa T F, Anupam K, Ong G P. Relative effectiveness of grooves in tire and pavement for reducing vehicle hydroplaning risk[J]. Transportation Research Record, 2010, 2155(1): 73-81. |

| 7 | 陈磊,周海超,潘公宇. 轮胎花纹凹坑非光滑表面对抗滑水性能的影响分析[J]. 现代制造工程, 2019, 19(1): 23-31. |

| Chen Lei, Zhou Hai-chao, Pan Gong-yu. Influence analysis of bionic pit non-smooth surface pattern on tire hydroplaning performance[J]. Modern Manufacturing Engineering, 2019, (1): 23-31. | |

| 8 | 杨建,王国林,周海超,等. 仿生非光滑花纹沟对轮胎抗滑水性能的影响[J]. 华中科技大学学报: 自然科学版, 2015, 43(2): 21-25. |

| Yang Jian, Wang Guo-lin, Zhou Hai-chao, et al. Study on influence of bionic non-smooth pattern groove on tire anti-hydroplaning performance[J]. Journal of Huazhong University of Science and Technology (Natural Science Edition), 2015, 43(2): 21-25. | |

| 9 | Zhou H C, Zhai H H, Ding Y M, et al. Numerical investigation of passive control flow to improve tire hydroplaning performance using a V-riblet non-smooth surface[J]. Advances in Mechanical Engineering, 2017, 9(11): 1-13. |

| 10 | 黄晓明,刘修宇,曹青青,等. 积水路面轮胎部分滑水数值模拟[J]. 湖南大学学报: 自然科学版, 2018, 45(9): 113-121. |

| Huang Xiao-ming, Liu Xiu-yu, Cao Qing-qing, et al. Numerical simulation of tire partial hydroplaning on flooded pavement[J]. Journal of Hunan University (Natural Sciences), 2018, 45(9): 113-121. | |

| 11 | 季天剑,黄晓明,刘清泉. 部分滑水对路面附着系数的影响[J]. 交通运输工程学报, 2003, 3(4): 10-12. |

| Ji Tian-jian, Huang Xiao-ming, Liu Qing-quan. Part hydroplaning effect on pavement friction coefficient[J]. Journal of Traffic and Transportation Engineering, 2003, 3(4): 10-12. | |

| 12 | 董斌. 部分滑水条件下高速公路车辆行驶安全性研究[D].重庆: 重庆交通大学土木建筑学院, 2011. |

| Dong Bin. Study of safety drive on expressway under partly hydroplaning[D]. Chongqing: School of Civil Engineering and Architecture, Chongqing Jiaotong University, 2011. | |

| 13 | Fiala E. Seitenkraefte am rollenden Luftreifen[J]. Verein Deutscher Ingenieure, 1954, 96(29): 973-979. |

| 14 | 刘青,郭孔辉,陈秉聪. 轮胎刷子模型分析Ⅰ.稳态侧偏刷子模型[J]. 农业机械学报, 2000, 31(1): 19-22. |

| Liu Qing, Guo Kong-hui, Chen Bing-cong. Review of tire brush models I. Steady state cornering brush models[J]. Transactions of the Chinese Society for Agricultural Machinery, 2000, 31(1): 19-22. | |

| 15 | 郭孔辉. 汽车轮胎动力学[M]. 北京: 科学出版社, 2018. |

| 16 | 郭孔辉,李宁,庄晔. 轮胎侧向力影响因素试验[J]. 农业机械学报, 2011, 42(12): 1-5. |

| Guo Kong-hui, Li Ning, Zhuang Ye. Test on factors of tire lateral force[J]. Transactions of the Chinese Society for Agricultural Machinery, 2011, 42(12): 1-5. | |

| 17 | Horne W B, Joyner U T. Pneumatic tire hydroplaning and some effects on vehicle performance[J]. SAE Transactions, 1966, 74: 623-650. |

| 18 | Horne W B, Yager T J, Ivey D L. Recent studies to investigate effects of tire footprint aspect ratio on dynamic hydroplaning speed[J]. ASTM Special Technical Publication, 1986, 929: 26-46. |

| 19 | Gim G, Nikravesh P E. An analytical model of pneumatic tyres for vehicle dynamic simulations. Part 1: pure slips[J]. International Journal of Vehicle Design, 1990, 11(6): 589-618. |

| 20 | Gim G. An analytical model of pneumatic tyres for vehicle dynamic simulations. Part 2: comprehensive slips[J]. International Journal of Vehicle Design of Vehicle Design, 1991, 12(1): 19-39. |

| 21 | 周海超,陈磊,翟辉辉,等. 基于CFD的轮胎滑水及其性能影响因素分析[J]. 重庆交通大学学报: 自然科学版, 2017, 36(1): 110-116. |

| Zhou Hai-chao, Chen Lei, Zhai Hui-hui, et al. Research on flow field and influencing factors of tire hydroplaning based on CFD method[J]. Journal of Chongqing Jiaotong University (Natural Science), 2017, 36(1): 110-116. | |

| 22 | 张丽霞,郑超艺,杨朝会,等. 湿滑路面汽车轮胎滑水性能影响因素仿真[J]. 科学技术与工程, 2020, 20(30): 12589-12595. |

| Zhang Li-xia, Zheng Chao-yi, Yang Chao-hui, et al. Simulation on factors affecting hydroplaning performance of vehicle tire on wet pavement[J]. Science Technology and Engineering, 2020, 20(30): 12589-12595. | |

| 23 | 庄楚强,何春雄. 应用数理统计基础[M]. 广州: 华南理工大学出版社, 2006. |

| 24 | 王婷婷. 严寒地区居民用能行为对住宅能耗影响的偏相关分析[J]. 建筑与文化, 2021, 18(10): 195-197. |

| Wang Ting-ting. Partial correlation analysis of the influence of residents' energy-using behavior on energy consumption in severe cold region[J]. Architecture and Culture, 2021, 18(10): 195-197. |

| [1] | 黄玲,崔躜,游峰,洪佩鑫,钟浩川,曾译萱. 适用于多车交互场景的车辆轨迹预测模型[J]. 吉林大学学报(工学版), 2024, 54(5): 1188-1195. |

| [2] | 郭洪艳,王连冰,赵旭,戴启坤. 考虑侧向运动的整车质量与道路坡度估计[J]. 吉林大学学报(工学版), 2024, 54(5): 1175-1187. |

| [3] | 陆玉凯,袁帅科,熊树生,朱绍鹏,张宁. 汽车漆面缺陷高精度检测系统[J]. 吉林大学学报(工学版), 2024, 54(5): 1205-1213. |

| [4] | 汪少华,张启睿,施德华,殷春芳,李春. 双行星排式混合动力传动系统非线性振动响应特性分析[J]. 吉林大学学报(工学版), 2024, 54(4): 890-901. |

| [5] | 高镇海,蔡荣贵,孙天骏,于桐,赵浩源,班浩. 人机共驾下的驾驶行为数据滤波方法[J]. 吉林大学学报(工学版), 2024, 54(3): 589-599. |

| [6] | 谢宪毅,王禹涵,金立生,赵鑫,郭柏苍,廖亚萍,周彬,李克强. 基于改变控制时域时间步长的智能车轨迹跟踪控制[J]. 吉林大学学报(工学版), 2024, 54(3): 620-630. |

| [7] | 邓小林,杨馥模,覃善甘. 新型仿竹六边形梯度层级多胞管耐撞性对比分析[J]. 吉林大学学报(工学版), 2024, 54(2): 333-345. |

| [8] | 王毅刚,王玉鹏,张昊,赵思安. 高速列车转向架区域气动噪声源识别与分析[J]. 吉林大学学报(工学版), 2024, 54(2): 346-355. |

| [9] | 聂建军,侯军凯,解晓琳,鄢鸿桢. 新型巡检机器人移动底盘设计及越障性能分析[J]. 吉林大学学报(工学版), 2024, 54(2): 356-364. |

| [10] | 胡宏宇,张慧珺,姚荣涵,陈国迎,高菲. L3级自动驾驶接管过程驾驶员情景意识研究[J]. 吉林大学学报(工学版), 2024, 54(2): 410-418. |

| [11] | 吴骁,史文库,郭年程,赵燕燕,陈志勇,李鑫鹏,孙卓,刘健. 基于Ease off的准双曲面齿轮多目标优化[J]. 吉林大学学报(工学版), 2024, 54(1): 76-85. |

| [12] | 王铁,李旭东,田程,赵宏伟. 基于多轴载荷投影构建轮辋双轴疲劳损伤模型[J]. 吉林大学学报(工学版), 2024, 54(1): 99-104. |

| [13] | 李旭东,王新宇,田程,张新峰,牛治慧,赵志强. 基于用户关联的车辆耐久性载荷谱编制[J]. 吉林大学学报(工学版), 2024, 54(1): 66-75. |

| [14] | 陈兆玮,蒲前华. 弹性车轮对大跨斜拉桥车桥耦合振动的抑制特性[J]. 吉林大学学报(工学版), 2023, 53(9): 2519-2532. |

| [15] | 刘平义,李晓婷,高偌霖,李海涛,魏文军,王亚. 车辆侧倾驱动机构设计与试验[J]. 吉林大学学报(工学版), 2023, 53(8): 2185-2192. |

|

||