吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (1): 76-85.doi: 10.13229/j.cnki.jdxbgxb.20220251

基于Ease off的准双曲面齿轮多目标优化

吴骁1( ),史文库1(

),史文库1( ),郭年程2,赵燕燕2,陈志勇1,李鑫鹏1,孙卓1,刘健2

),郭年程2,赵燕燕2,陈志勇1,李鑫鹏1,孙卓1,刘健2

- 1.吉林大学 汽车仿真与控制国家重点实验室,长春 130022

2.中国重汽集团 汽车研究总院,济南 250100

Multi-objective optimization of hypoid gears based on Ease off

Xiao WU1( ),Wen-ku SHI1(

),Wen-ku SHI1( ),Nian-cheng GUO2,Yan-yan ZHAO2,Zhi-yong CHEN1,Xin-peng LI1,Zhuo SUN1,Jian LIU2

),Nian-cheng GUO2,Yan-yan ZHAO2,Zhi-yong CHEN1,Xin-peng LI1,Zhuo SUN1,Jian LIU2

- 1.State Key Laboratory of Automotive Simulation and Control,Jilin University,Changchun 130022,China

2.Automotive Research Institute,China National Heavy Duty Truck (Group Crop. ),Jinan 250100,China

摘要:

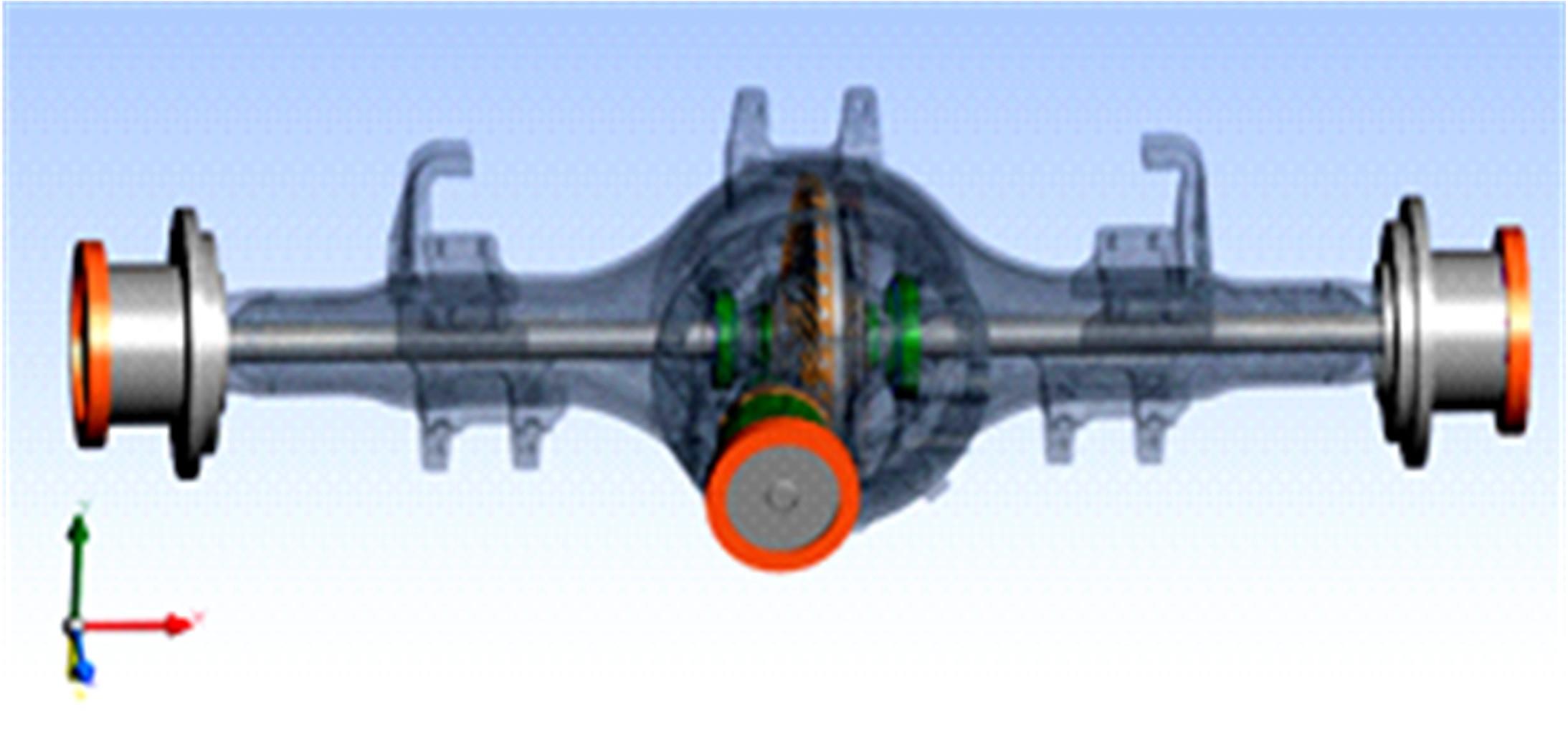

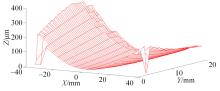

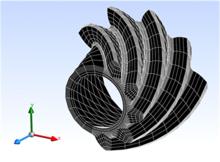

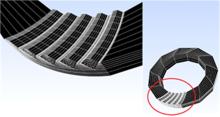

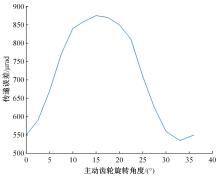

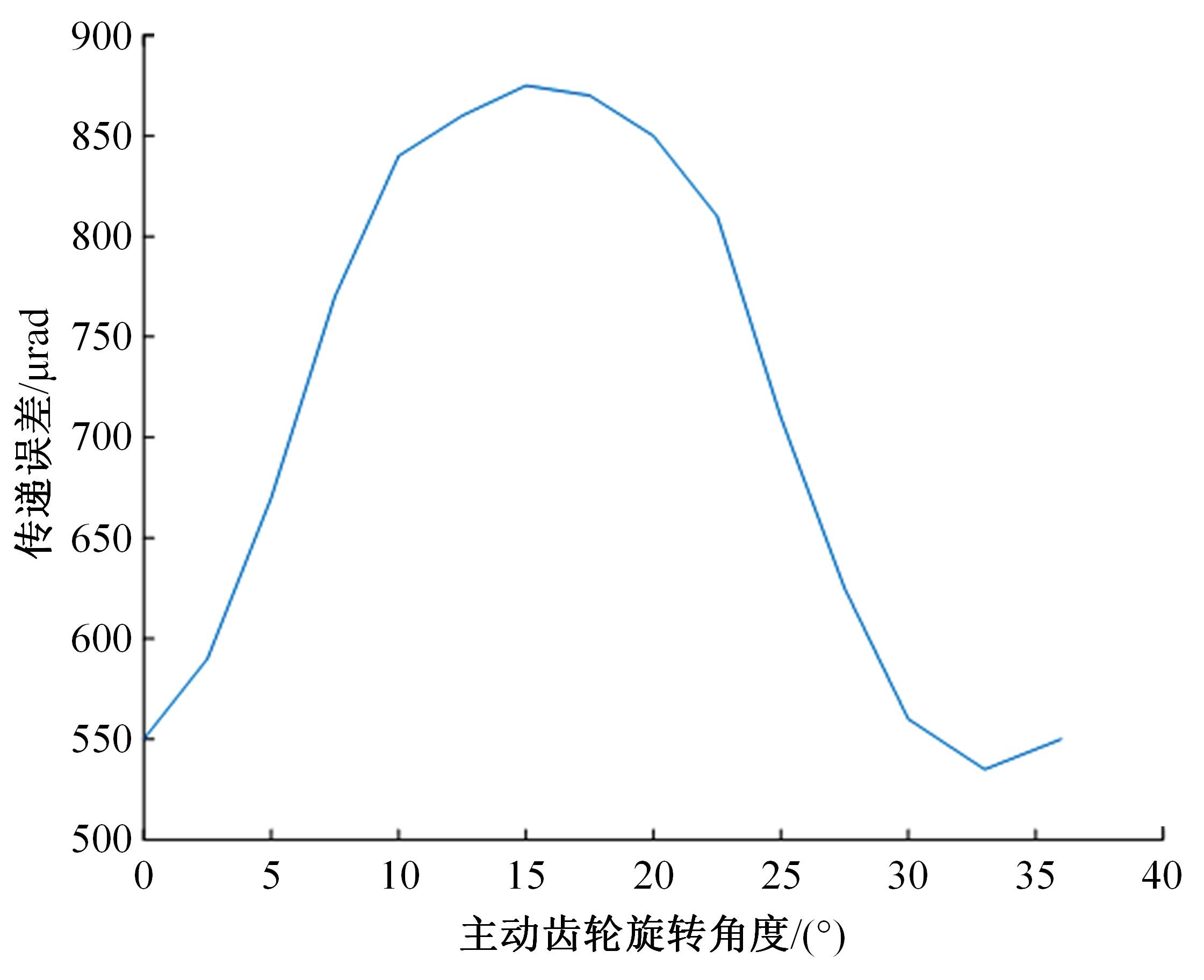

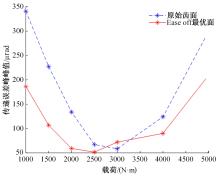

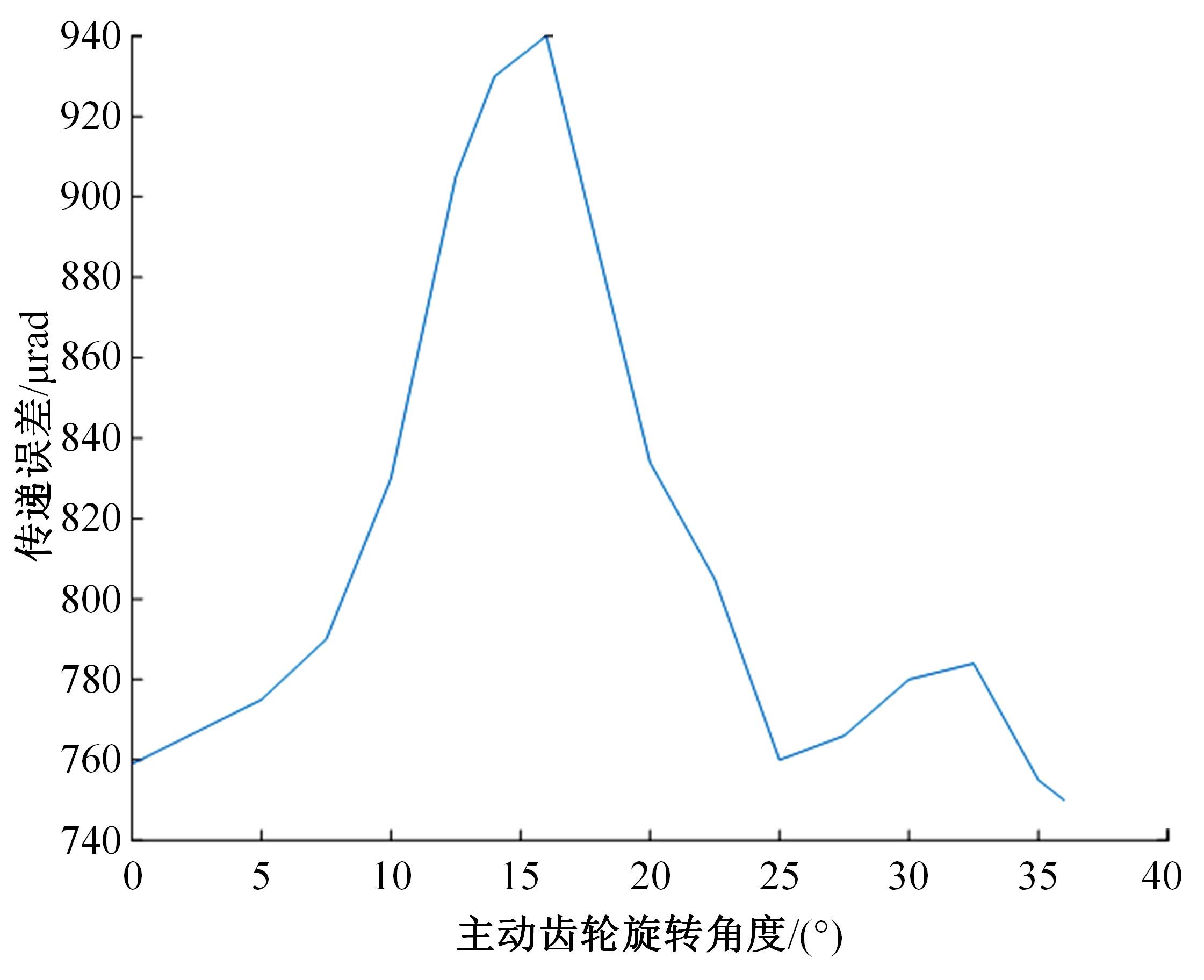

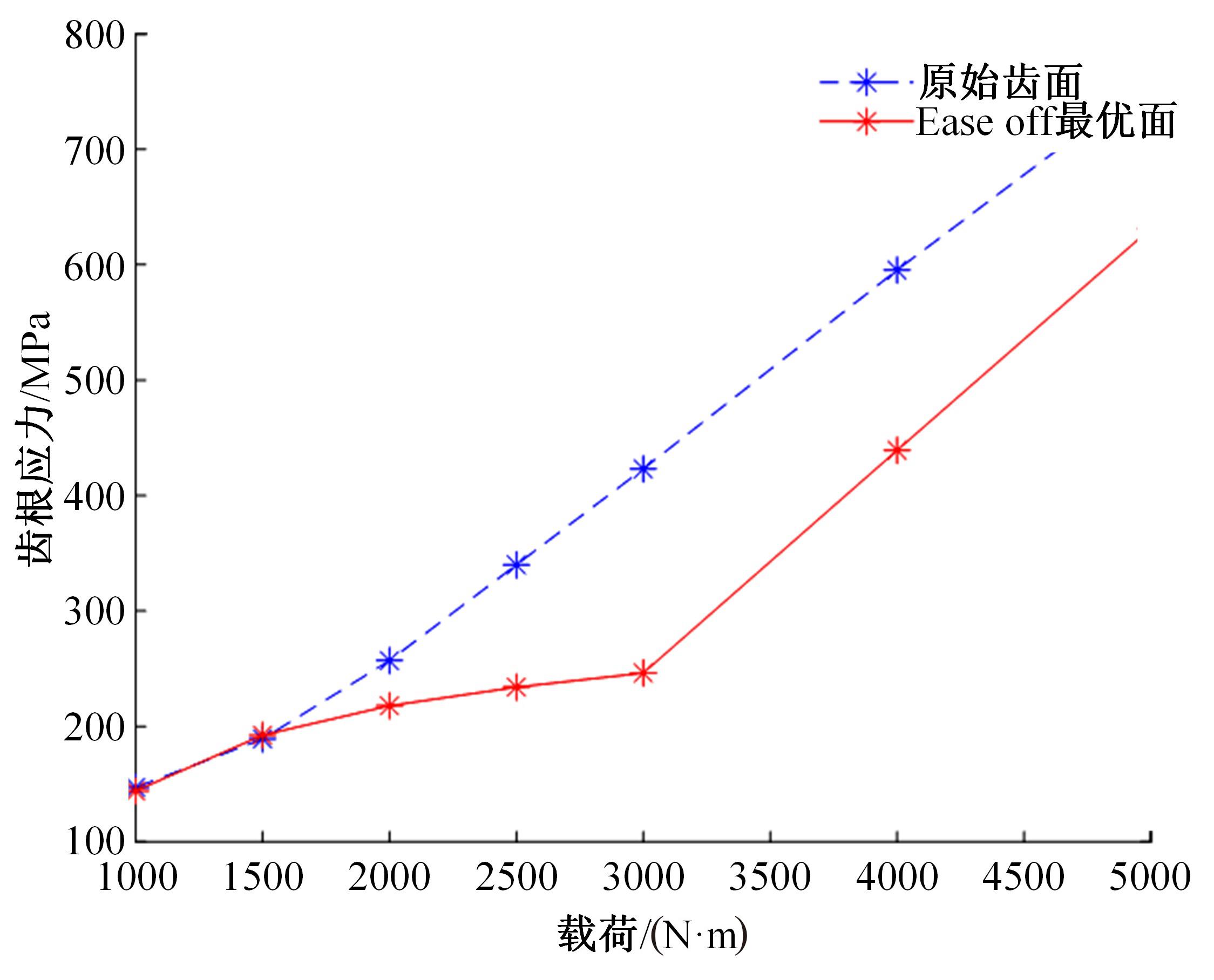

为实现准双曲面齿轮的多目标优化,建立了神经网络代理模型,用以描述Ease off修形参数和传递误差、齿根应力、啮合损失功率的关系。首先,利用动力学软件MASTA建立准双曲面齿轮驱动桥模型,基于敏感度系数矩阵,推导出齿面偏差二阶泰勒展开式对应的机床修形加工参数,建立修形齿轮模型。其次,通过MASTA的加载齿面接触分析功能计算修形齿轮模型的传递误差、齿根应力、啮合损失功率,最终建立神经网络代理模型。最后,采用NSGA-Ⅱ多目标优化算法优化代理模型,进行对比验证。结果表明:采用本多目标优化方法可有效降低准双曲面齿轮的传递误差、齿根应力、啮合损失功率。

中图分类号:

- U463.2

| 1 | Park Nogill. A generalized hypoid gear synthesized with common crown rack positioned between pinion and gear blanks[J]. Journal of Mechanical Design, 2017, 139(8): No. 085001. |

| 2 | 魏冰阳, 杨建军, 仝昂鑫, 等. 基于等距Ease-off曲面的轮齿啮合仿真分析[J]. 航空动力学报, 2017, 32(5): 1259-1265. |

| Wei Bing-yang, Yang Jian-jun, Tong Ang-xin, et al. Simulation analysis of gear tooth meshing based on isometric ease-off surface[J]. Journal of Aerospace Power, 2017, 32(5): 1259-1265. | |

| 3 | Li G, Zhu W. An active ease-off topography modification approach for hypoid pinions based on a modified error sensitivity analysis method[J]. Journal of Mechanical Design, 2019, 141(9): 1-10. |

| 4 | Wang Q, Zhou C, Gui L, et al. An ease-off based approach to designing a high-order transmission motion for face-milled spiral bevel gears[J]. International Journal of Vehicle Design, 2019, 81(3/4): 241-252. |

| 5 | Shih Y P. A novel ease-off flank modification methodology for spiral bevel and hypoid gears[J]. Mechanism & Machine Theory, 2010, 45(8): 1108-1124. |

| 6 | Peng X L, Zhang L, Fang Z D. Manufacturing process for a face gear drive with local bearing contact and controllable unloaded meshing performance based on ease-off surface modification[J]. Journal of Mechanical Design, 2016, 138(4): No.043302. |

| 7 | Fan Q. Ease-Off and Application in Tooth Contact Analysis for Face-Milled and Face-Hobbed Spiral Bevel and Hypoid Gears[M]. Berlin: Springer International Publishing, 2016. |

| 8 | 聂少武, 唐思成, 黄菊花, 等. 基于刀倾法的弧齿锥齿轮齿面失配啮合分析[J]. 机械传动, 2019, 43(9): 96-102. |

| Nie Shao-wu, Tang Si-cheng, Huang Ju-hua, et al. Analysis of tooth surface mismatch meshing of spiral bevel gear based on cutter tilt method[J]. Mechanical Transmission, 2019, 43(9): 96-102. | |

| 9 | 聂少武, 邓静, 邓效忠, 等. 基于齿面Ease off拓扑的弧齿锥齿轮齿面偏差等效修正方法[J]. 中国机械工程, 2017, 28(20): 2434-2440. |

| Nie Shao-wu, Deng Jing, Deng Xiao-zhong, et al. Equivalent correction method for tooth surface deviation of spiral bevel gears based on ease off topology[J]. China Mechanical Engineering, 2017, 28(20): 2434-2440. | |

| 10 | 曹雪梅, 邓效忠, 聂少武. 基于共轭齿面修正的航空弧齿锥齿轮高阶传动误差齿面拓扑结构设计[J]. 航空动力学报, 2015, 30(1): 195-200. |

| Cao Xue-mei, Deng Xiao-zhong, Nie Shao-wu. Topological structure design of aeronautical spiral bevel gear high order transmission error based on conjugate tooth surface modification[J]. Journal of Aerospace Power, 2015, 30(1): 195-200. | |

| 11 | 聂少武, 邓静, 邓效忠, 等. 弧齿锥齿轮齿面拓扑修形及加工参数计算[J]. 航空动力学报, 2017, 32(08): 2009-2016. |

| Nie Shao-wu, Deng Jing, Deng Xiao-zhong, et al. Topological modification and machining parameters calculation of spiral bevel gears[J]. Journal of Aerospace Power, 2017, 32(8): 2009-2016. | |

| 12 | 聂少武, 蒋闯, 邓效忠, 等. Ease-off拓扑修正的准双曲面齿轮齿面修形方法[J]. 中国机械工程, 2019, 30(22): 2709-2715, 2740. |

| Nie Shao-wu, Jiang Chuang, Deng Xiao-zhong, et al. Tooth surface modification method for hypoid gears with ease-off topology modification[J]. China Mechanical Engineering, 2019, 30(22): 2709-2715, 2740. | |

| 13 | Cinelli C, Hazlett C. Making sense of sensitivity: extending omitted variable bias[J]. Journal of the Royal Statistical Society Series B, 2020, 82(1): 39-67. |

| 14 | Deb K, Pratap A, Agarwal S, et al. A fast and elitist multi-objective genetic algorithm: NSGA-II[J]. IEEE Transactions on Evolutionary Computation, 2002, 6(2): 182-197. |

| 15 | Srinivas N, Deb K. Multi-objective function optimization using non-dominated sorting genetic algorithms[J]. Evolutionary Computation, 1994, 2(3): 1301-1308. |

| [1] | 李旭东,王新宇,田程,张新峰,牛治慧,赵志强. 基于用户关联的车辆耐久性载荷谱编制[J]. 吉林大学学报(工学版), 2024, 54(1): 66-75. |

| [2] | 陈兆玮,蒲前华. 弹性车轮对大跨斜拉桥车桥耦合振动的抑制特性[J]. 吉林大学学报(工学版), 2023, 53(9): 2519-2532. |

| [3] | 刘平义,李晓婷,高偌霖,李海涛,魏文军,王亚. 车辆侧倾驱动机构设计与试验[J]. 吉林大学学报(工学版), 2023, 53(8): 2185-2192. |

| [4] | 黄学劲,钟锦星,路京雨,赵霁,肖伟,袁新枚. 基于用户画像的电动汽车充电负荷预测方法[J]. 吉林大学学报(工学版), 2023, 53(8): 2193-2200. |

| [5] | 周晓,梁燚杰,奚中轩,王宇涛. 白车身B柱焊接变形模拟及预变形控制方法[J]. 吉林大学学报(工学版), 2023, 53(8): 2212-2218. |

| [6] | 张树培,夏明悦,张玮,陈钊,陈义祥. 考虑非线性刚度的间隙球铰碰撞动力学建模与仿真[J]. 吉林大学学报(工学版), 2023, 53(8): 2227-2235. |

| [7] | 陈辉,邵亚军. 基于惯性基准多传感器耦合的路面谱测量方法[J]. 吉林大学学报(工学版), 2023, 53(8): 2254-2262. |

| [8] | 陈磊,王杨,董志圣,宋亚奇. 一种基于转向意图的车辆敏捷性控制策略[J]. 吉林大学学报(工学版), 2023, 53(5): 1257-1263. |

| [9] | 陈鑫,张冠宸,赵康明,王佳宁,杨立飞,司徒德蓉. 搭接焊缝对铝合金焊接结构轻量化设计的影响[J]. 吉林大学学报(工学版), 2023, 53(5): 1282-1288. |

| [10] | 张勇,毛凤朝,刘水长,王青妤,潘神功,曾广胜. 基于Laplacian算法的汽车外流场畸变网格优化[J]. 吉林大学学报(工学版), 2023, 53(5): 1289-1296. |

| [11] | 汪少华,储堃,施德华,殷春芳,李春. 基于有限时间扩张状态观测的HEV鲁棒复合协调控制[J]. 吉林大学学报(工学版), 2023, 53(5): 1272-1281. |

| [12] | 尹燕莉,黄学江,潘小亮,王利团,詹森,张鑫新. 基于PID与Q⁃Learning的混合动力汽车队列分层控制[J]. 吉林大学学报(工学版), 2023, 53(5): 1481-1489. |

| [13] | 于贵申,陈鑫,武子涛,陈轶雄,张冠宸. AA6061⁃T6铝薄板无针搅拌摩擦点焊接头结构及性能分析[J]. 吉林大学学报(工学版), 2023, 53(5): 1338-1344. |

| [14] | 田彦涛,黄兴,卢辉遒,王凯歌,许富强. 基于注意力与深度交互的周车多模态行为轨迹预测[J]. 吉林大学学报(工学版), 2023, 53(5): 1474-1480. |

| [15] | 杨红波,史文库,陈志勇,郭年程,赵燕燕. 基于NSGA⁃II的斜齿轮宏观参数多目标优化[J]. 吉林大学学报(工学版), 2023, 53(4): 1007-1018. |

|

||