吉林大学学报(工学版) ›› 2025, Vol. 55 ›› Issue (3): 899-911.doi: 10.13229/j.cnki.jdxbgxb.20230604

预置表面织构对激光熔覆316L涂层的影响

- 长春大学 机械与车辆工程学院,长春 130022

Influence of pre⁃set surface texture on laser cladding of 316L coatings

Chang-long ZHAO( ),Chen MA,Jun-bao YANG,Qin-xiang ZHAO,Xiao-yu JIA,Hong-nan MA

),Chen MA,Jun-bao YANG,Qin-xiang ZHAO,Xiao-yu JIA,Hong-nan MA

- College of Mechanical and Vehicle Engineering,Changchun University,Changchun 130022,China

摘要:

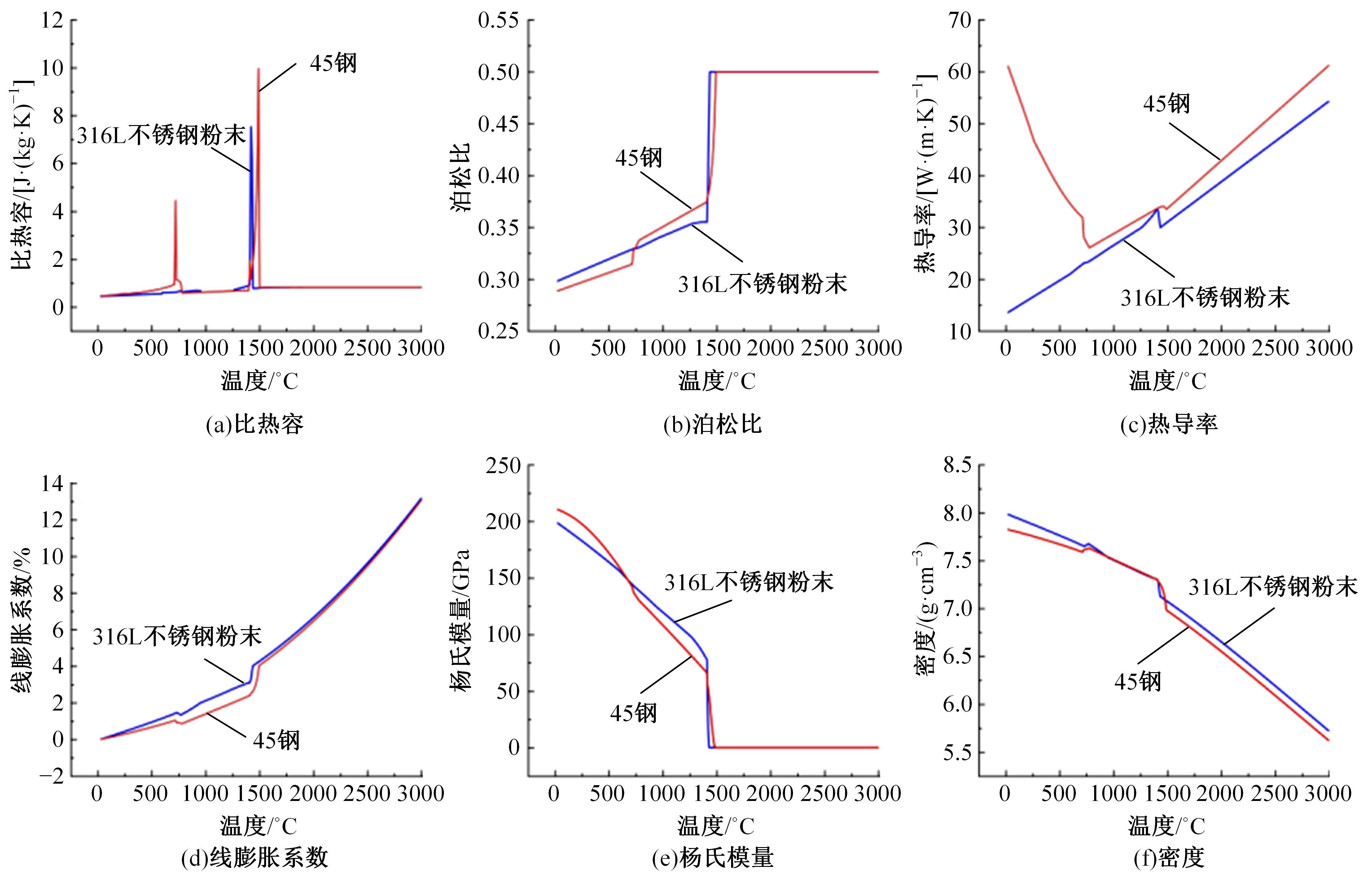

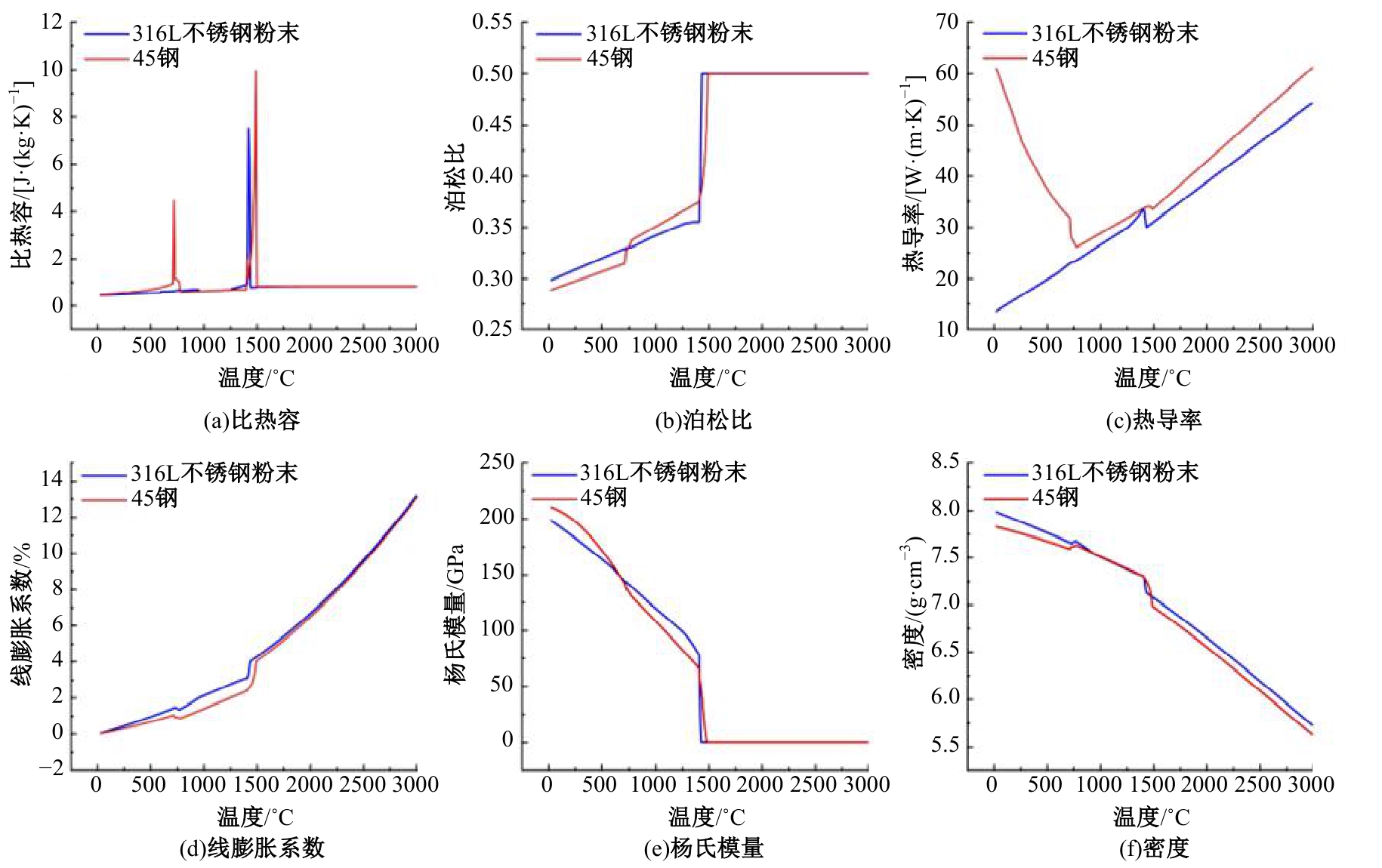

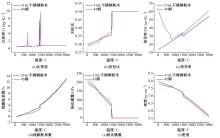

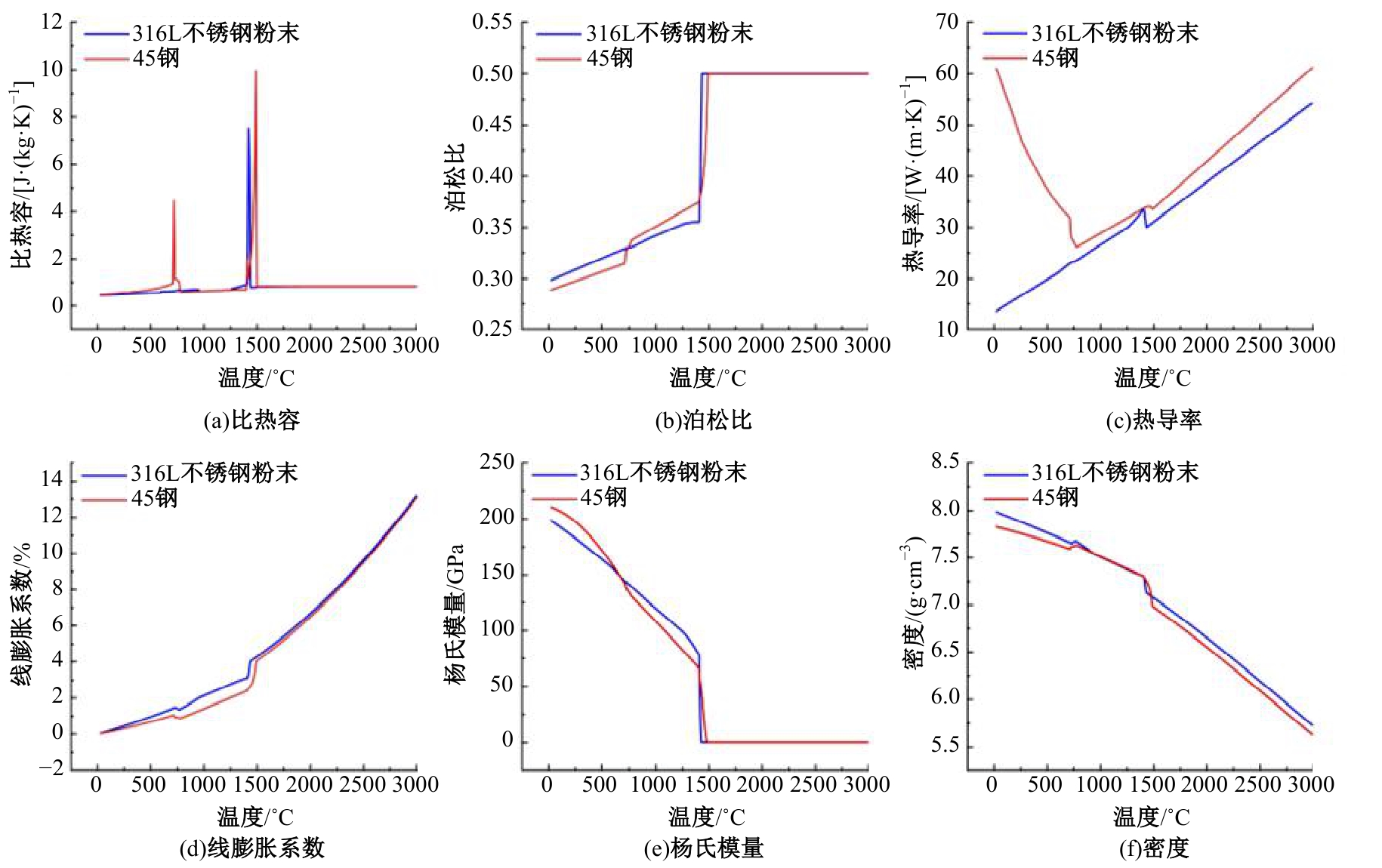

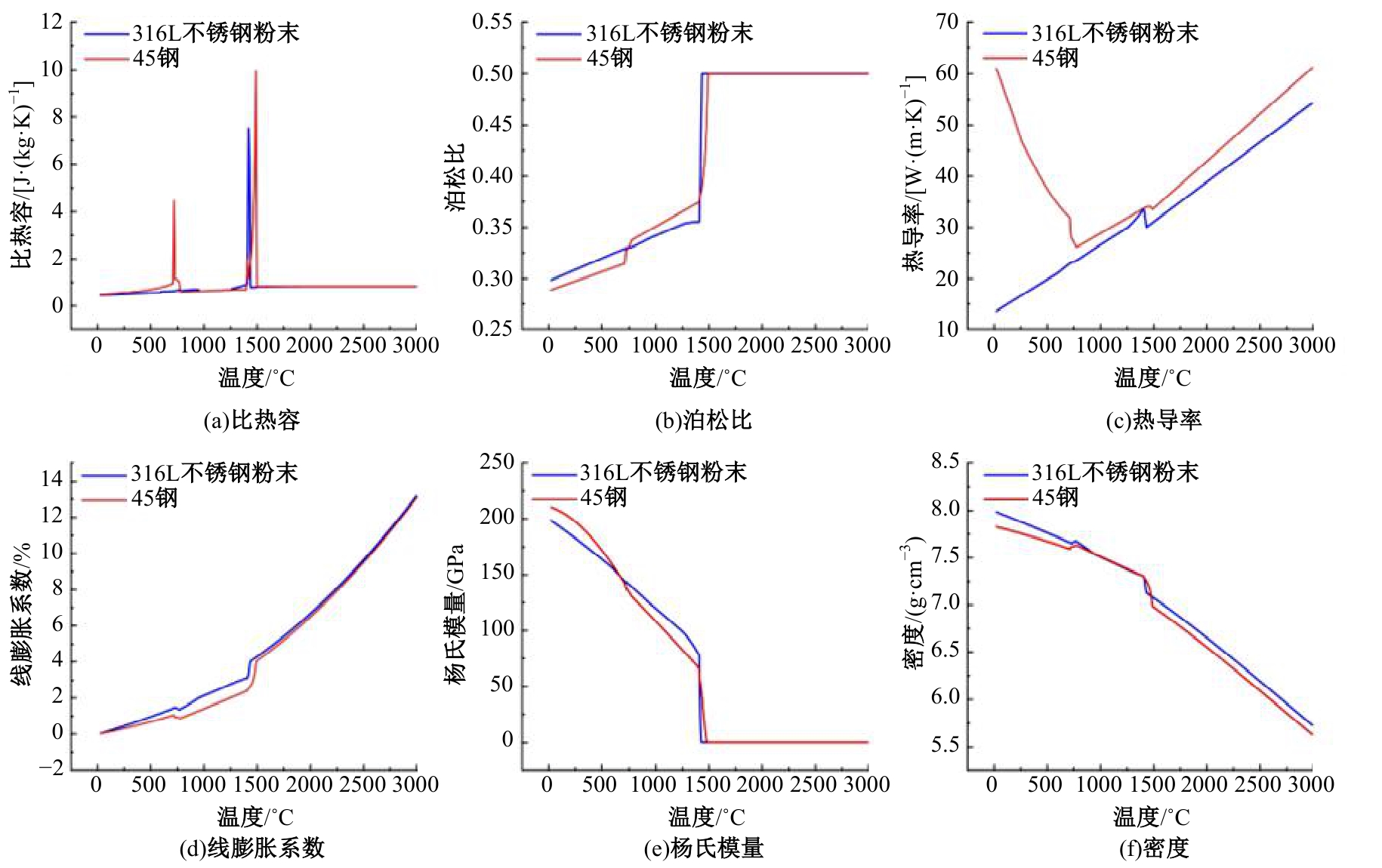

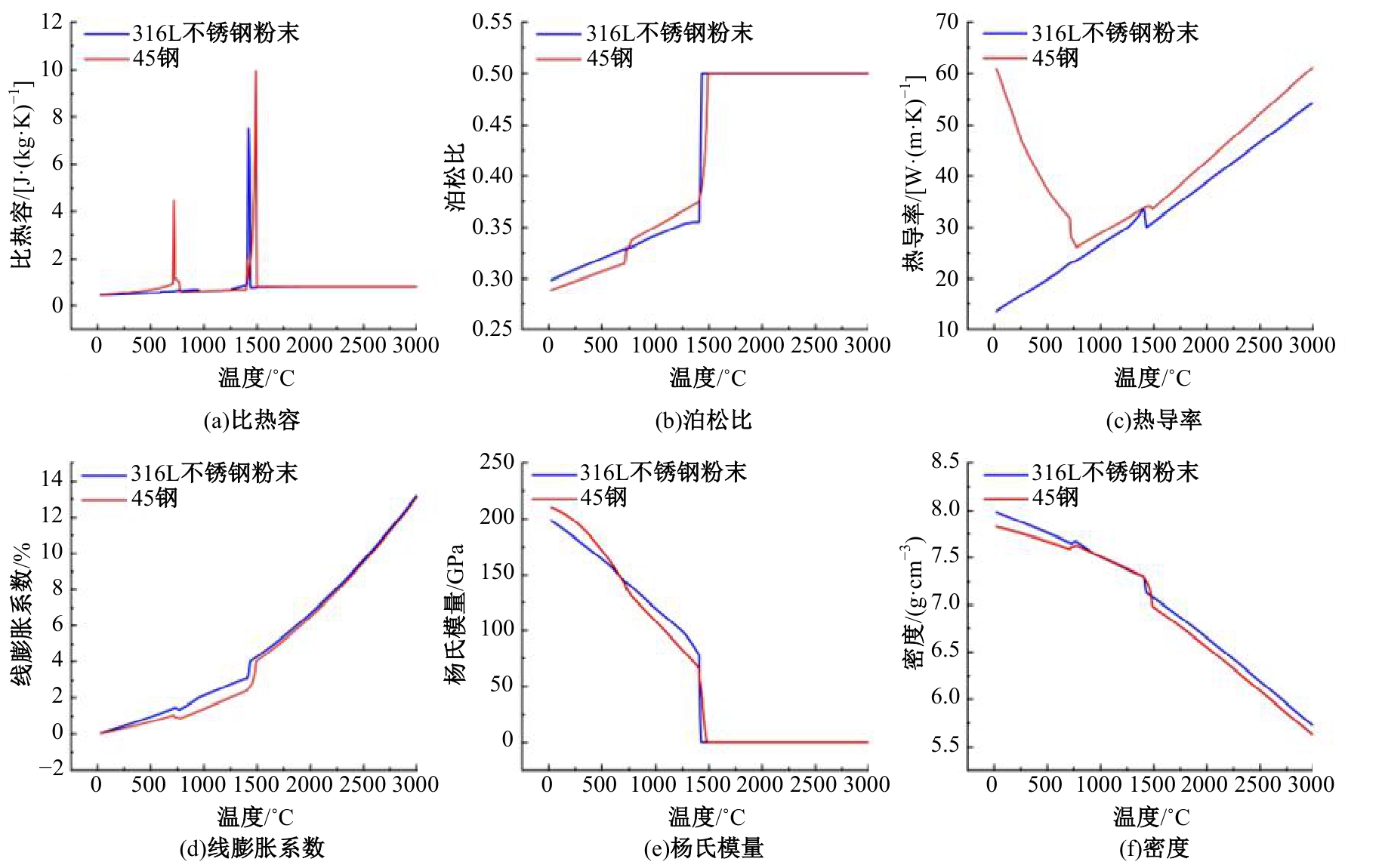

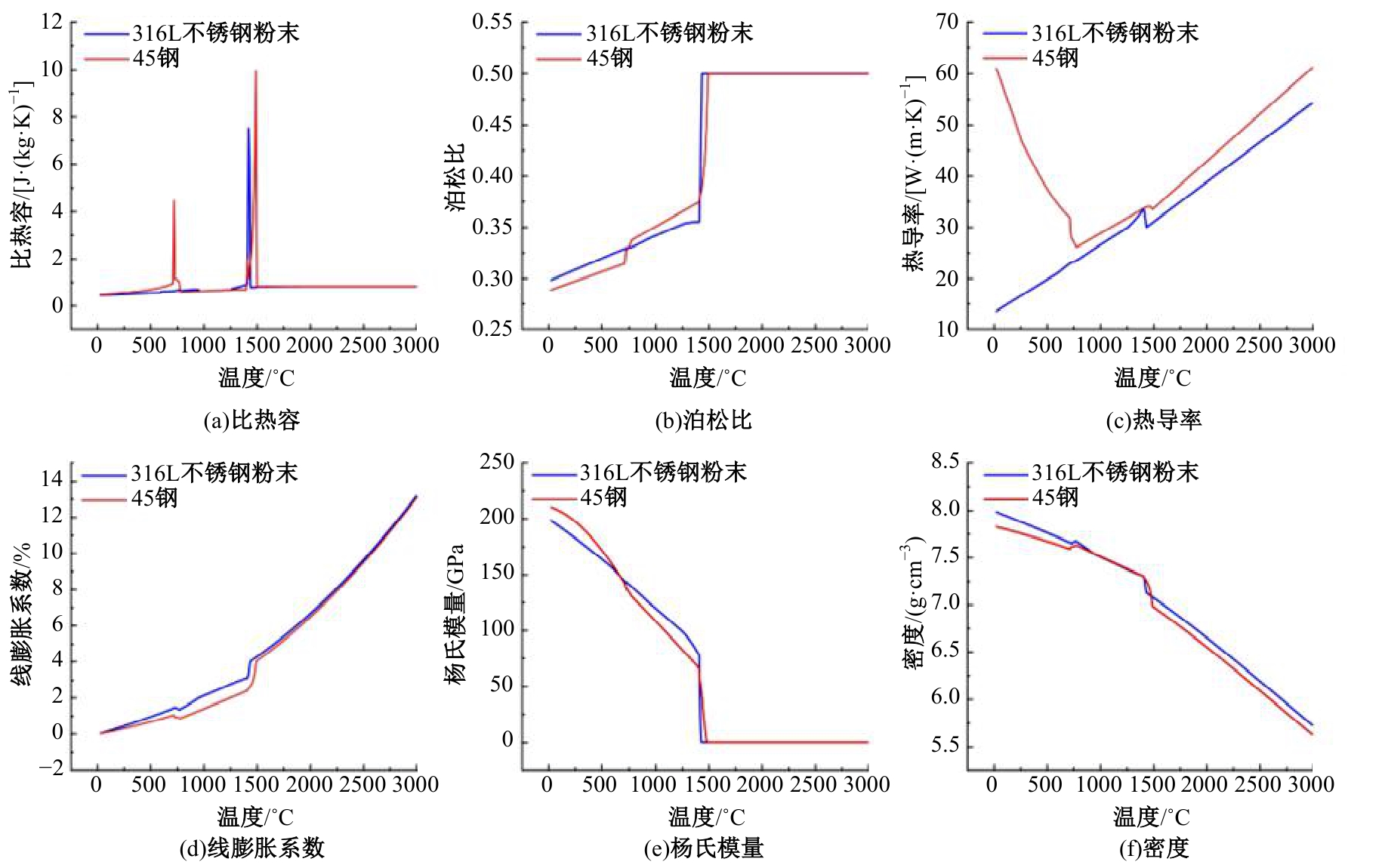

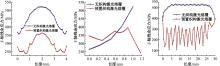

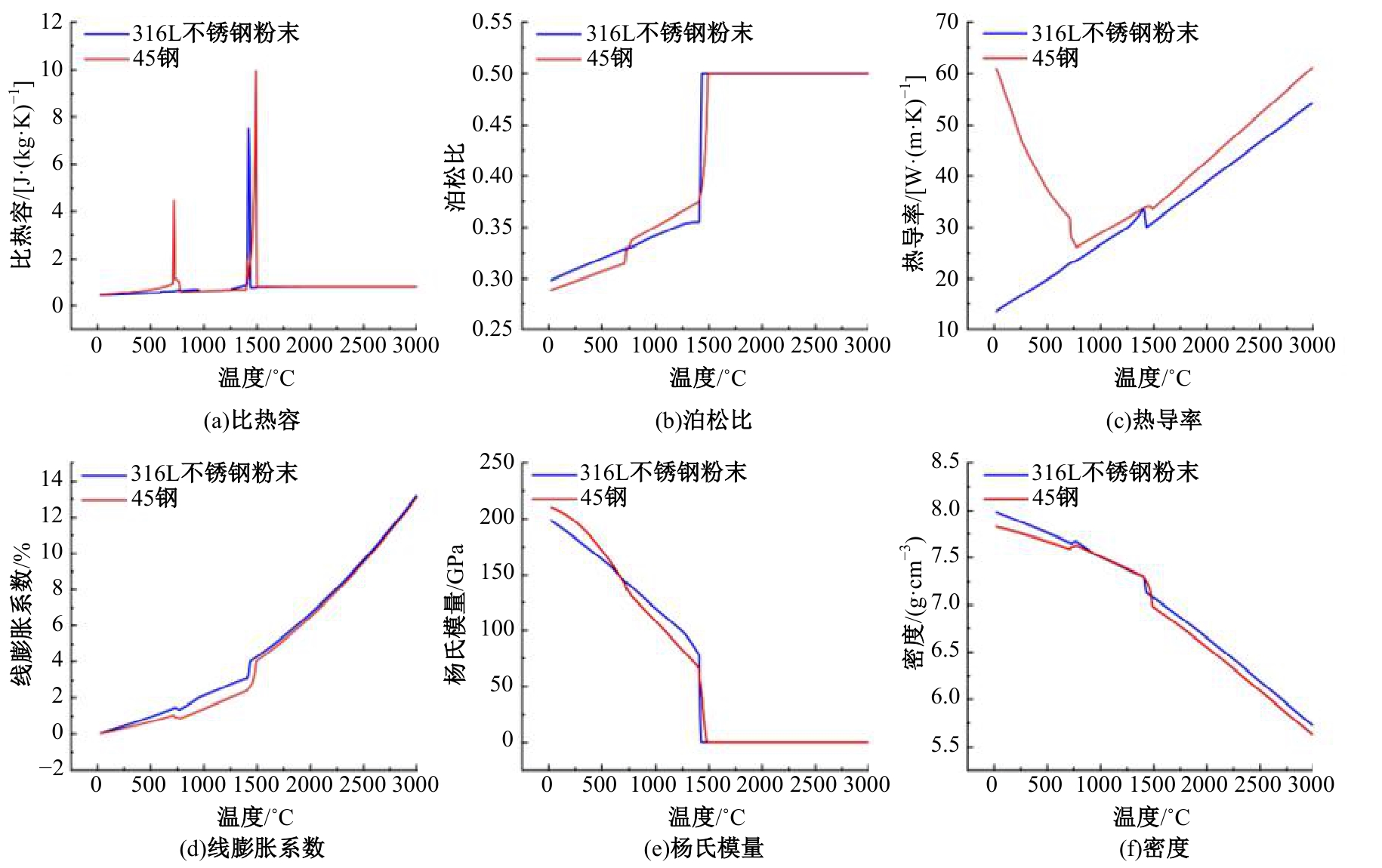

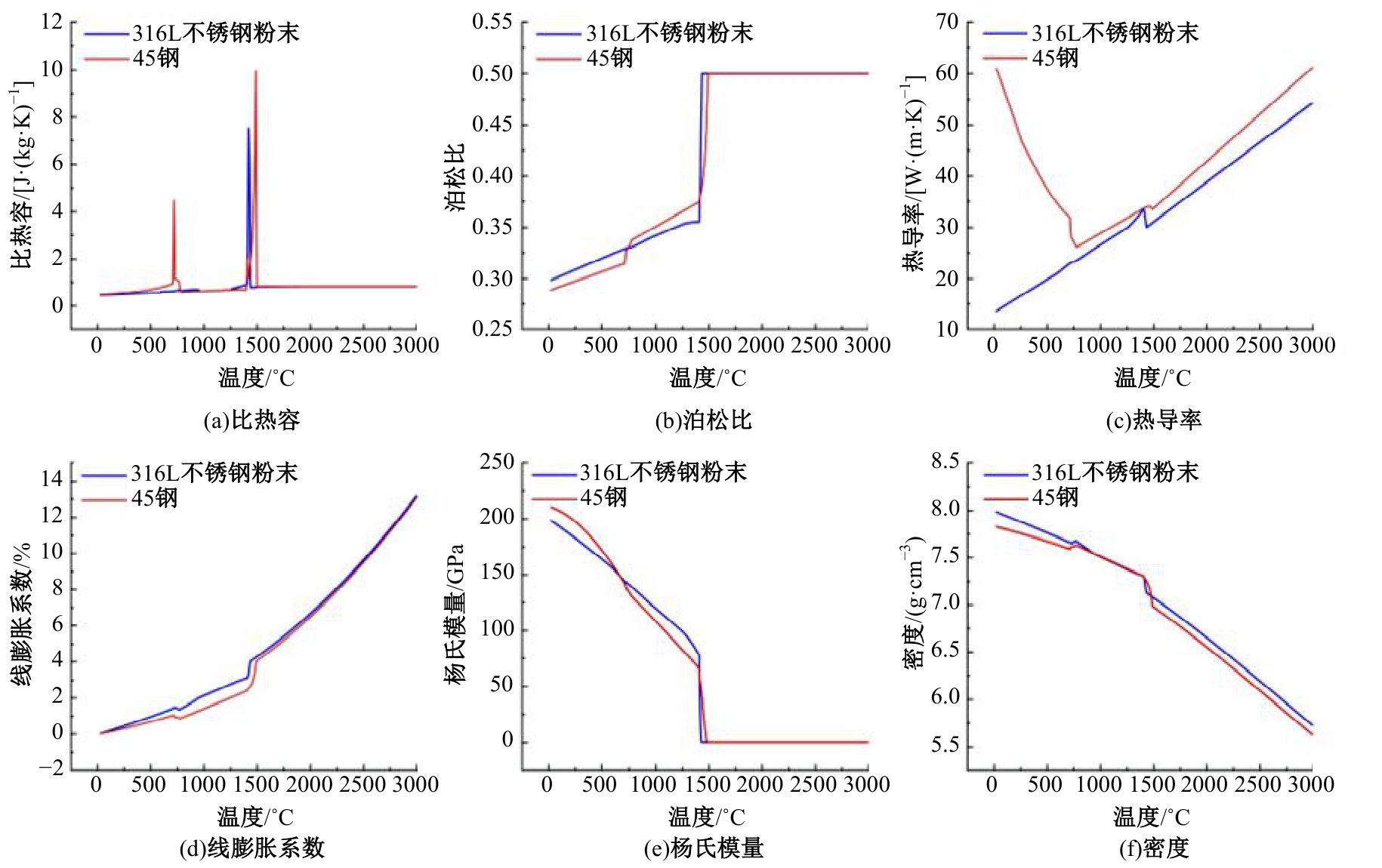

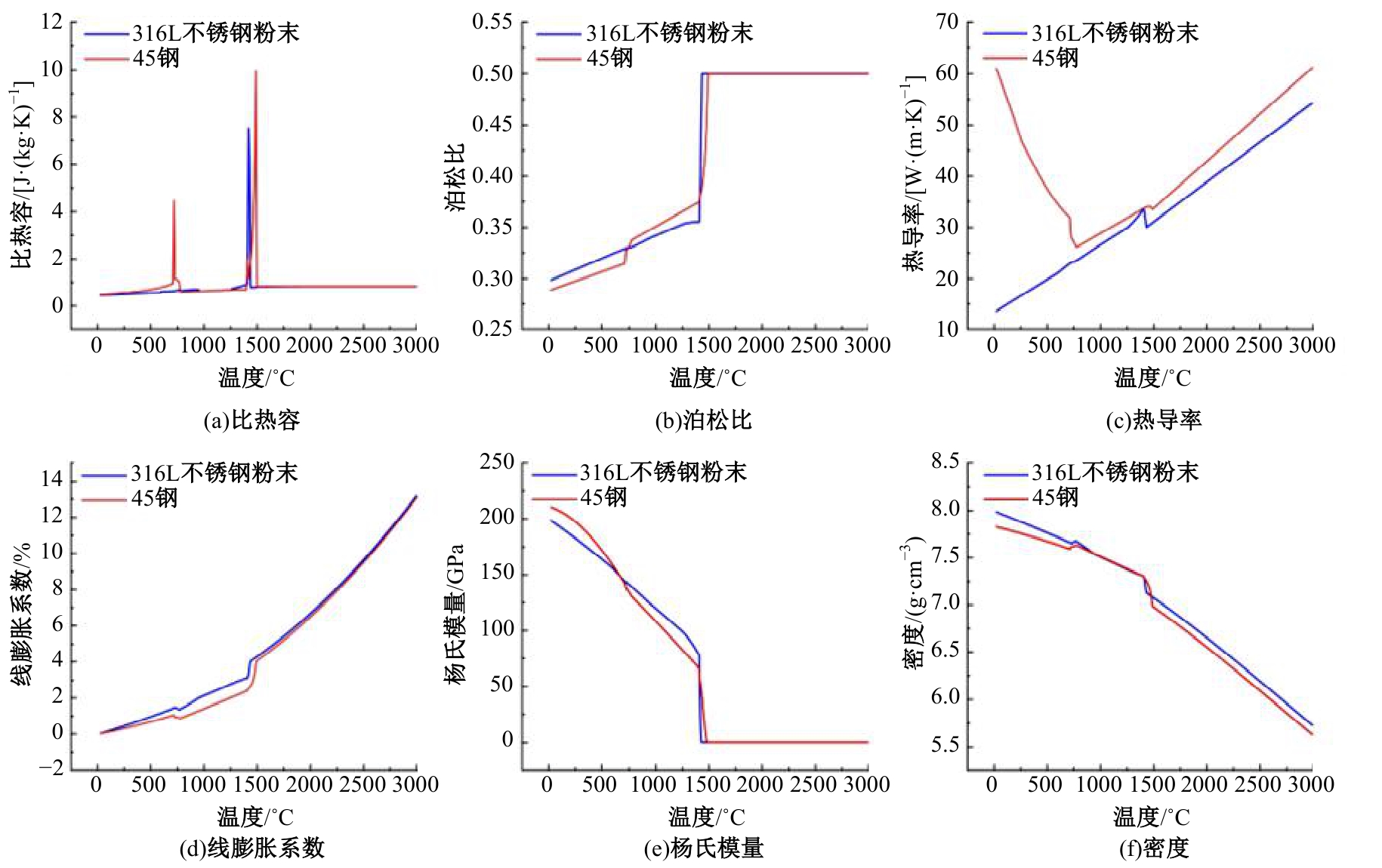

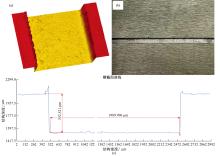

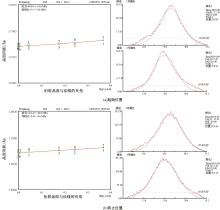

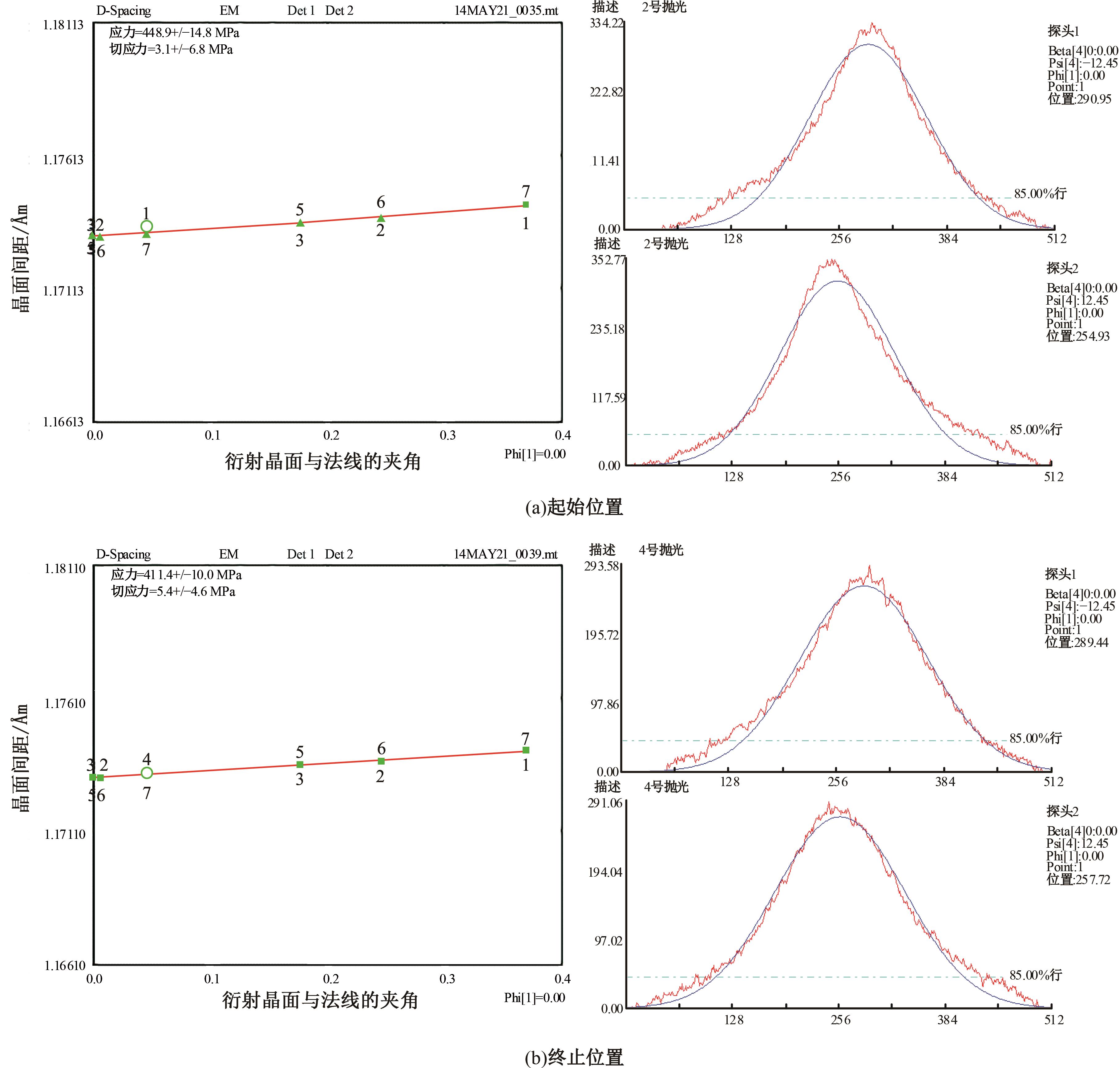

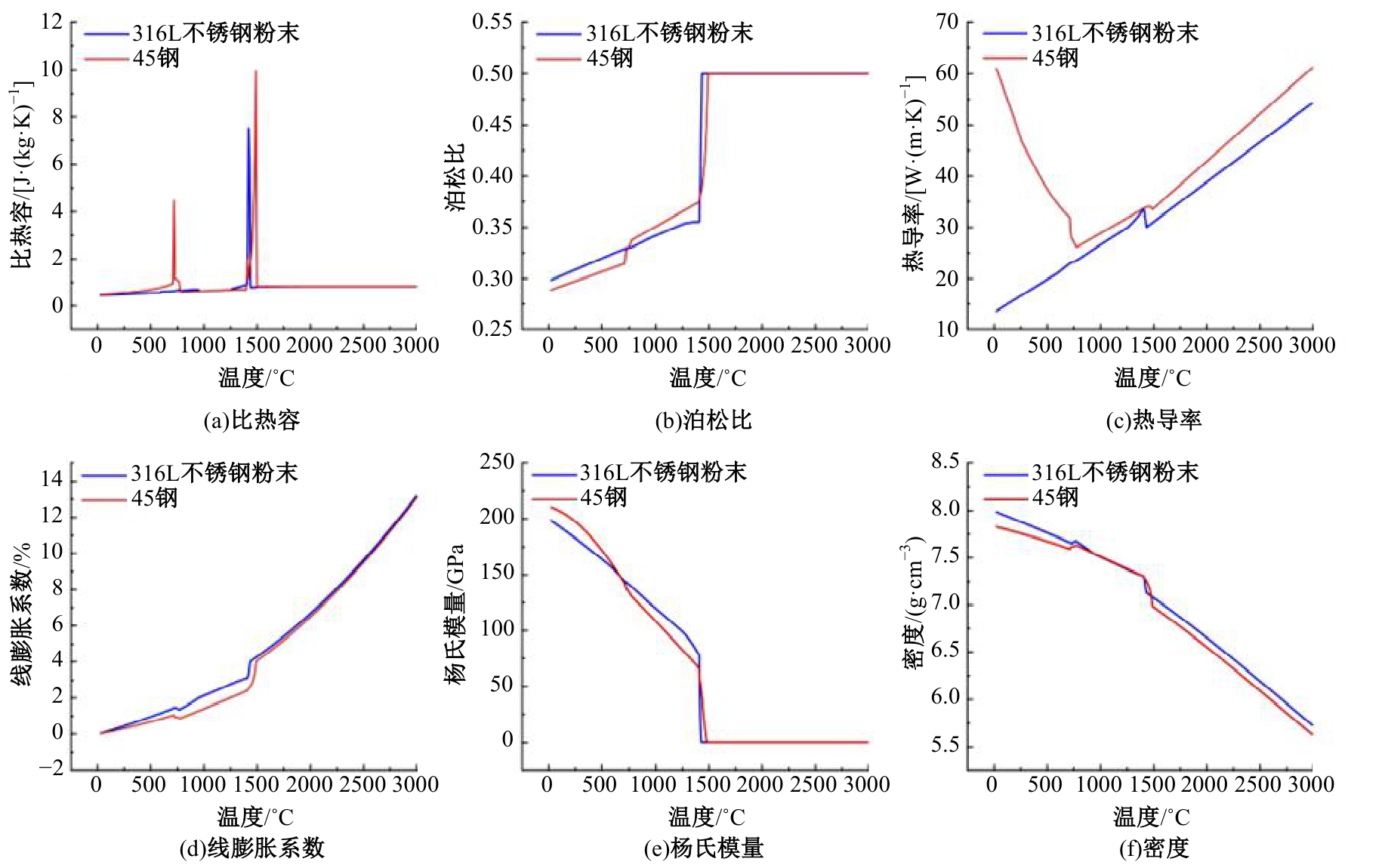

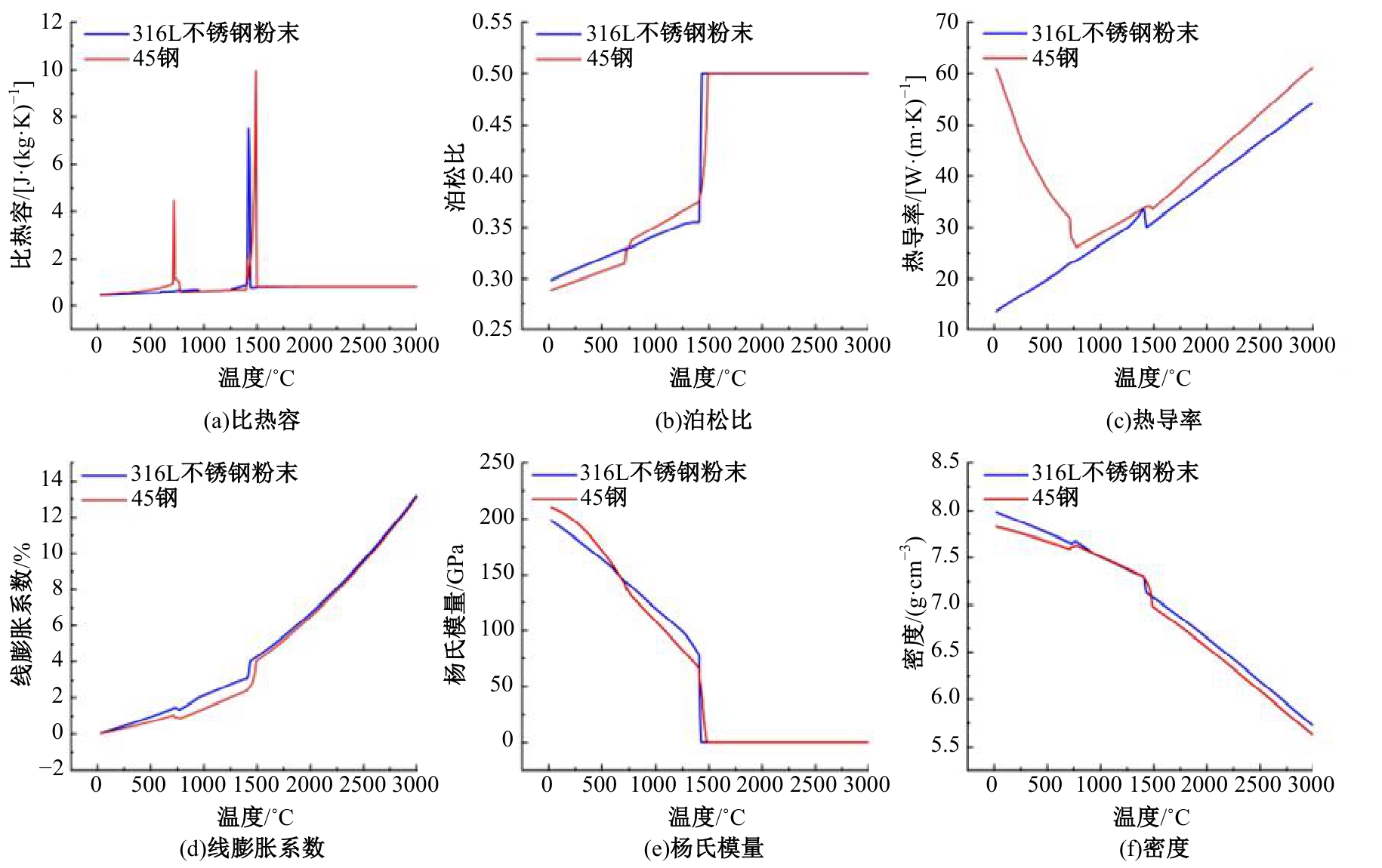

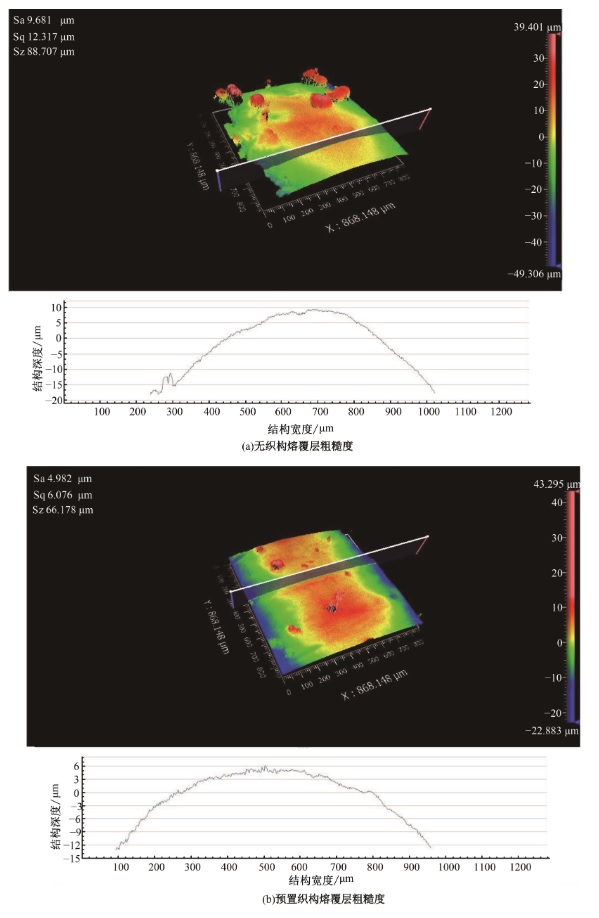

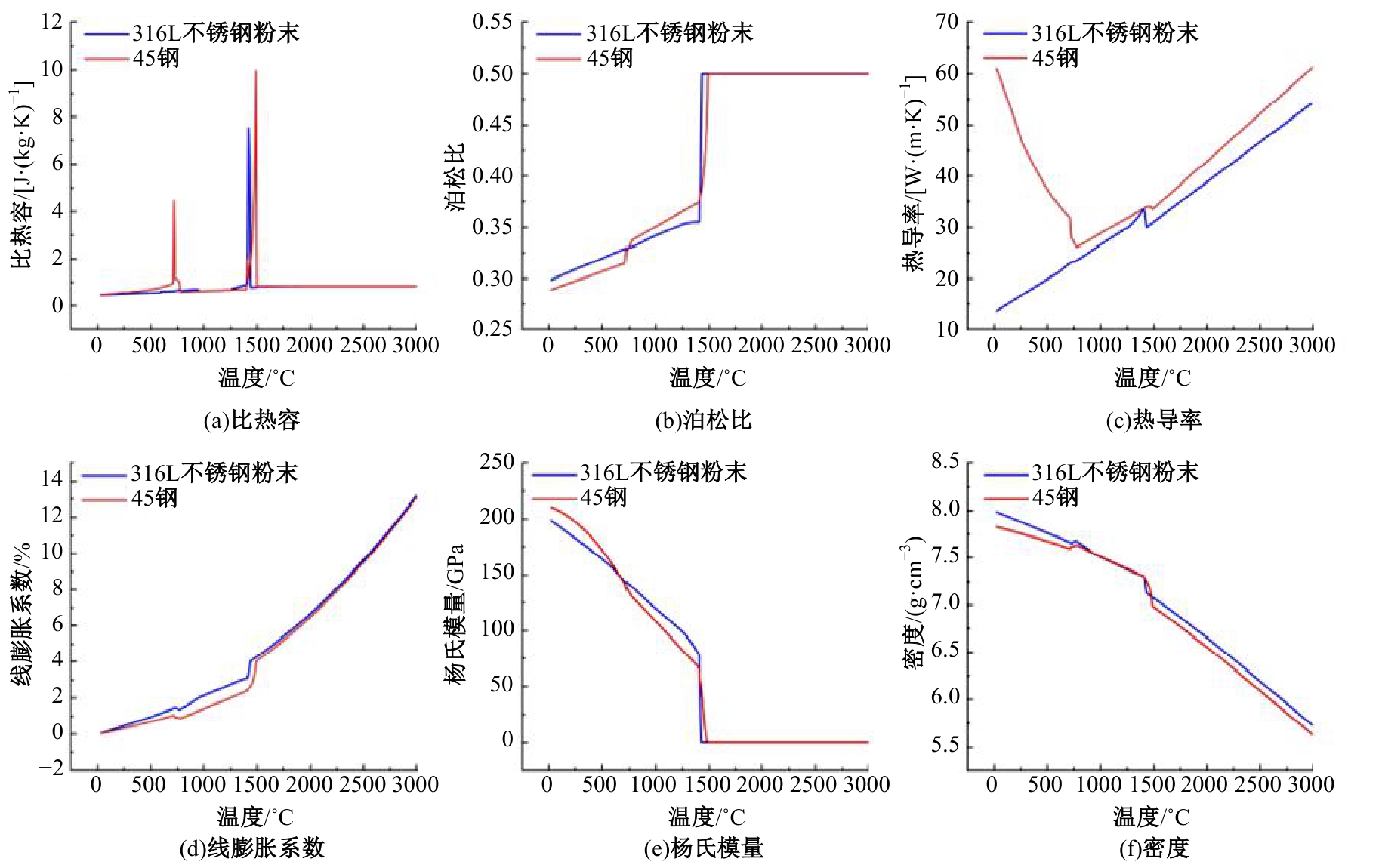

将表面织构技术与激光熔覆相结合,通过建立多场耦合数值模拟模型,针对激光熔覆层易出现的裂纹、气孔等缺陷问题进行解决。预置织构可以平稳温度梯度、降低残余应力、减缓熔池流速,有效避免双涡流效应,提升熔覆层表面质量和晶粒尺寸均匀性。实验结果验证了数值模拟的有效性,为优化激光熔覆参数、改善熔覆层质量、提高熔覆层性能拓展了新思路。

中图分类号:

- TG456.7

| 1 | 魏德强, 刘科, 王荣. 45钢电子束扫描相变硬化组织和硬度的研究[J]. 机械工程学报, 2012, 48(2): 127-132. |

| Wei De-qiang, Liu Ke, Wang Rong. Research on the microstructure and hardness of transformation hardening of 45 steel during electron beam scanning[J]. Journal of Mechanical Engineering,2012, 48(2): 127-132. | |

| 2 | Wang S, Zheng S, Liu W J, et al. Optimization of process parameters for laser cladding Fe35A alloy on 45 steel surface[J]. Laser & Optoelectronics Progress, 2021, 58(6): 157-168. |

| 3 | Wu J, Zhu D D, Yang R C, et al. Parameters optimization and friction and wear properties for laser cladding Ni60AA coating on 45 steel shaft surface[J]. Laser & Optoelectronics Progress, 2021, 58(3): 101-110. |

| 4 | 王红颖, 崔承云, 周杰. 工具钢表面激光熔覆Co基合金涂层的组织及性能[J]. 吉林大学学报:工学版, 2010, 40(4): 1000-1004. |

| Wang Hong-ying, Cui Cheng-yun, Zhou Jie. Microstructure and properties of cobalt-based alloy coating on tool steel surface prepared by laser cladding[J]. Journal of Jilin University (Engineering and Technology Edition), 2010, 40(4): 1000-1004. | |

| 5 | Raj D, Maity S R, Das B. State-of-the-art review on laser cladding process as an in-situ repair technique[J]. Proceedings of the Institution of Mechanical Engineers Part E-Journal of Process Mechanical Engineering, 2022 (236): 1194-1215. |

| 6 | Siddiqui A A, Dubey A K. Recent trends in laser cladding and surface alloying[J]. Optics and Laser Technology, 2021, 134(5): 959-970. |

| 7 | Chang L, Yang Y P, Liu Z T, et al. Differential analysis of the influence mechanism of ultrasonic vibrations on laser cladding[J]. Cirp Journal of Manufacturing Science and Technology, 2022 (38): 16-37. |

| 8 | Chai Q, Zhang H, Fang C, et al. Numerical and experimental investigation into temperature field and profile of Stellite6 formed by ultrasonic vibration-assisted laser cladding[J]. Journal of Manufacturing Processes, 2023 (85): 80-89. |

| 9 | Hu G F, Yang Y, Lu X, et al. A study on the influence mechanism and optimization of physical field parameters of electromagnetic-ultrasonic compound field-assisted laser cladding technology[J]. Welding in the World, 2021 (65): 1687-1700. |

| 10 | 任思学, 李景彬, 史亚盟, 等. 工艺参数对20CrMnTi基激光熔覆Ni60A-TiC涂层组织及耐磨性能的影响[J]. 中国激光, 2023, 50(8): 1-20. |

| Ren Si-xue, Li Jing-bin, Shi Ya-meng, et al. Effect of process parameters on microstructure and wear resistance of 20CrMnTi-based laser cladding Ni60A-TiC coating[J]. Chinese Journal of Lasers, 2023, 50(8): 1-20. | |

| 11 | 史亚盟, 李景彬, 张杰, 等. 工艺参数对65Mn基熔覆Ni60a/SiC涂层的微观组织与耐磨性能影响[J]. 机械工程学报, 2022, 58(16): 197-205. |

| Shi Ya-meng, Li Jing-bin, Zhang Jie, et al. Effect of process parameters on microstructure and wear resistance of 65Mn-based cladding Ni60a/SiC coating[J]. Journal of Mechanical Engineering, 2022, 58(16): 197-205. | |

| 12 | Todaro C J, Easton M A, Qiu D, et al. Grain refinement of stainless steel in ultrasound-assisted additive manufacturing[J]. Additive Manufacturing, 2021, 37: 456-466. |

| 13 | Todaro C J, Easton M A, Qiu D, et al. Grain structure control during metal 3D printing by high-intensity ultrasound[J]. Nature Communications, 2020, 11: 345-360. |

| 14 | Xu J M, Liu N, Zhang F, et al. Frictional behaviors of 3D-printed polylactic acid components with spiral-groove surface textures under oil lubrication[J]. Journal of Tribology-Transactions of the Asme, 2023, 145: 858-869. |

| 15 | Bai L Q, Bai S X. Frictional performance of a textured surface with elliptical dimples: geometric and distribution effects[J]. Tribology Transactions, 2014(57): 1122-1128. |

| 16 | Wang H T, Zhu H, Zhou Y K, et al. Experimental study on the friction characteristics of textured steel surface with ring-shaped pits under lubricated sliding conditions[J]. Tribology Transactions, 2015(58): 712-717. |

| 17 | Vignesh G, Barik D. An experimental investigation of dimple-texturing on the tribological performance of hardened AISI H-13 steel[J]. International Journal of Automotive and Mechanical Engineering, 2022(19): 9391-9402. |

| 18 | Bijani D, Deladi E L, Akchurin A, et al. The influence of surface texturing on the frictional behaviour of parallel sliding lubricated surfaces under conditions of mixed lubrication[J]. Lubricants, 2018, 6: 168-175. |

| 19 | Pei S Y, Xu H, Yun M, et al. Effects of surface texture on the lubrication performance of the floating ring bearing[J]. Tribology International, 2016(102): 143-153. |

| 20 | 黄志强, 熊辰, 钱韦吉, 等. 采油液力马达转子表面织构参数对其摩擦副摩擦学性能的影响[J]. 表面技术, 2022, 51(2): 176-184, 231. |

| Huang Zhi-qiang, Xiong Chen, Qian Wei-ji, et al.The effect of surface texture parameters of the rotor surface texture of oil production hydraulic motor on the tribological performance of the friction pair[J]. Surface Technology, 2022, 51(2): 176-184, 231. |

| [1] | 董长斌,李龙坤,刘永平,裴王鹏. 非圆齿轮传动误差及齿侧间隙的数值模拟与试验[J]. 吉林大学学报(工学版), 2024, 54(4): 865-873. |

| [2] | 卫星,高亚杰,康志锐,刘宇辰,赵骏铭,肖林. 低温环境下栓钉环焊缝焊接残余应力场数值模拟[J]. 吉林大学学报(工学版), 2024, 54(1): 198-208. |

| [3] | 吴飞,农皓业,马晨浩. 基于粒子群优化算法⁃长短时记忆模型的刀具磨损预测方法[J]. 吉林大学学报(工学版), 2023, 53(4): 989-997. |

| [4] | 宋林,王立平,吴军,关立文,刘知贵. 基于信息物理融合和数字孪生的可靠性分析[J]. 吉林大学学报(工学版), 2022, 52(2): 439-449. |

| [5] | 罗开玉,陈俊成,王长雨,鲁金忠. 光斑直径对激光冲击强化铝合金腐蚀性能的影响[J]. 吉林大学学报(工学版), 2021, 51(2): 501-510. |

| [6] | 李国龙,陶小会,徐凯,李喆裕. 数控机床转台位置相关几何误差的快速测量与辨识[J]. 吉林大学学报(工学版), 2021, 51(2): 458-467. |

| [7] | 刘纯国,于晓彤,岳韬,李东来,张明哲. 双曲率筋条壁板铣削回弹预测[J]. 吉林大学学报(工学版), 2021, 51(1): 188-199. |

| [8] | 段春争,张方圆,寇文能,魏斌. 高速硬切削表面白层马氏体相变[J]. 吉林大学学报(工学版), 2019, 49(5): 1575-1583. |

| [9] | 徐戊矫,刘承尚,鲁鑫垚. 喷丸处理后6061铝合金工件表面粗糙度的模拟计算及预测[J]. 吉林大学学报(工学版), 2019, 49(4): 1280-1287. |

| [10] | 鲁金忠,周婉婷,张圣洋,邵亦锴,王长雨,罗开玉. 激光冲击强化层数对6061⁃T6铝合金抗腐蚀性能的影响[J]. 吉林大学学报(工学版), 2019, 49(3): 842-849. |

| [11] | 赵爽,沈继红,张刘,赵晗,陈柯帆. 微细电火花加工表面粗糙度快速高斯评定[J]. 吉林大学学报(工学版), 2018, 48(6): 1838-1843. |

| [12] | 郑孝义, 孙大千, 李欣, 都桂刚, 辛伟达, 任振安. NbAl3强化Al-Nb熔覆层的组织与性能[J]. 吉林大学学报(工学版), 2018, 48(5): 1531-1536. |

| [13] | 刘子武, 李剑峰. 叶片材料FV520B再制造熔覆层冲蚀损伤行为及评价[J]. 吉林大学学报(工学版), 2018, 48(3): 835-844. |

| [14] | 杨晓红, 杭文先, 秦绍刚, 刘勇兵, 刘利萍. H13钢激光熔覆钴基复合涂层的组织及耐磨性[J]. 吉林大学学报(工学版), 2017, 47(3): 891-899. |

| [15] | 杨慧艳, 何晓聪, 周森. 压印接头强度的有限元模型及理论计算方法[J]. 吉林大学学报(工学版), 2015, 45(3): 864-871. |

|

||