吉林大学学报(工学版) ›› 2018, Vol. 48 ›› Issue (6): 1653-1660.doi: 10.13229/j.cnki.jdxbgxb20170903

车身钢-铝粘接接头湿热老化性能

- 1. 吉林大学 汽车仿真与控制国家重点实验室,长春 130022

2. 华北水利水电大学 机械学院,郑州 450045

Effect of hygrothermal aging on steel-aluminum adhesive joints for automotive applications

NA Jing-xin1( ),MU Wen-long1,FAN Yi-sa2,TAN Wei1,YANG Jia-zhou1

),MU Wen-long1,FAN Yi-sa2,TAN Wei1,YANG Jia-zhou1

- 1. State Key Laboratory of Automotive Simulation and Control, Jilin University, Changchun 130022, China

2. School of Mechanical Engineering, North China University of Water Resources and Electric Power, Zhengzhou 450045, China

摘要:

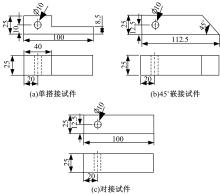

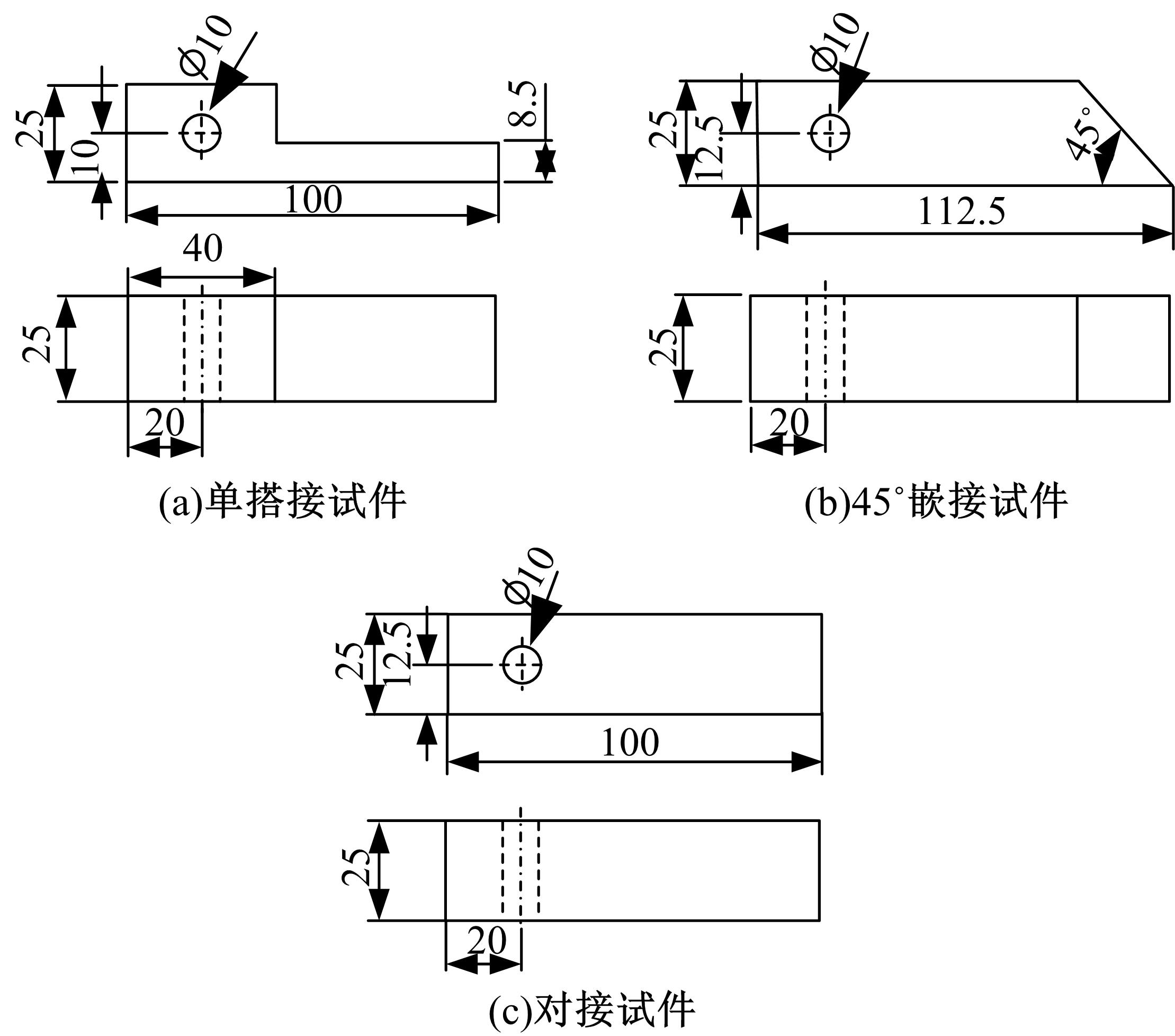

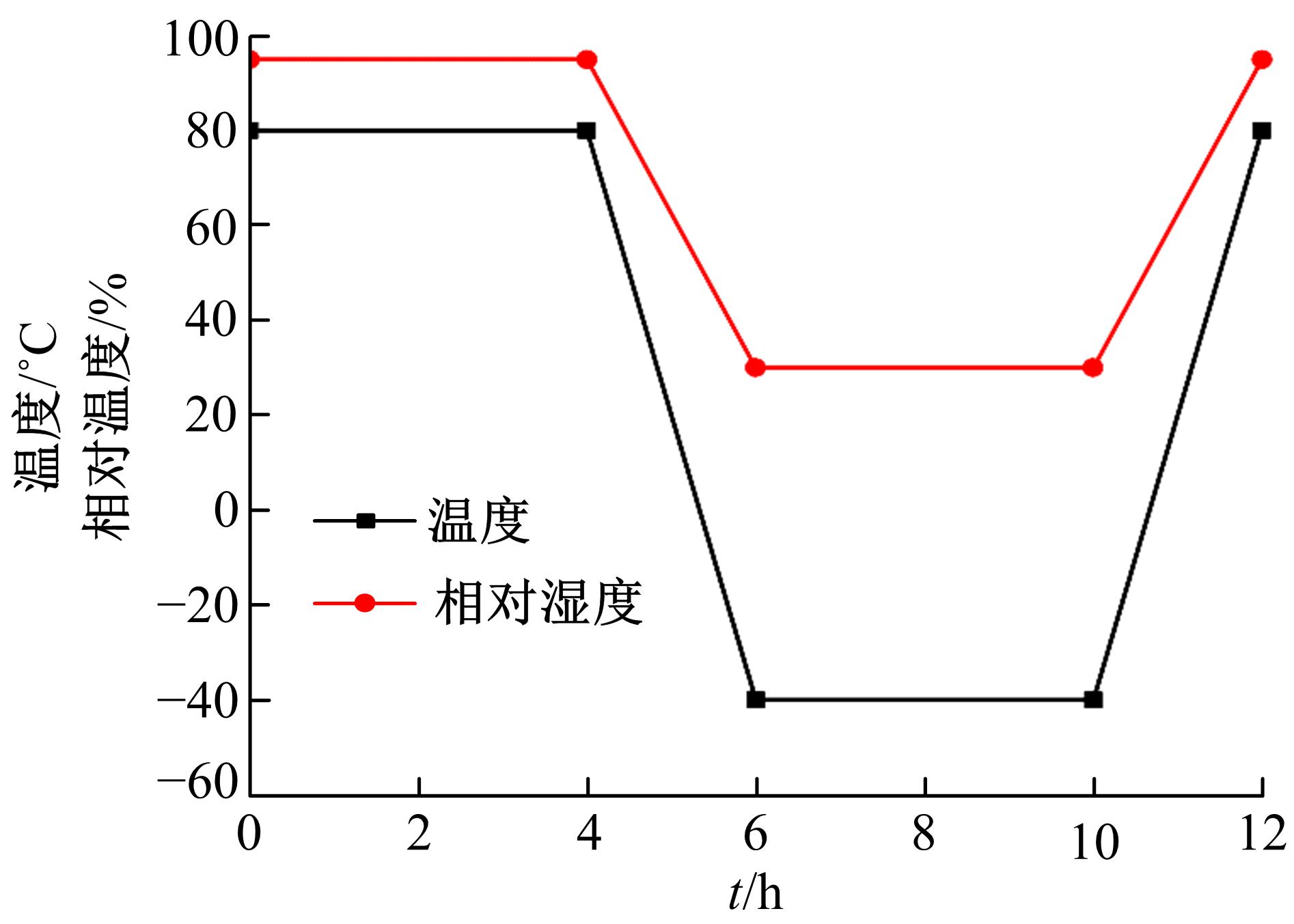

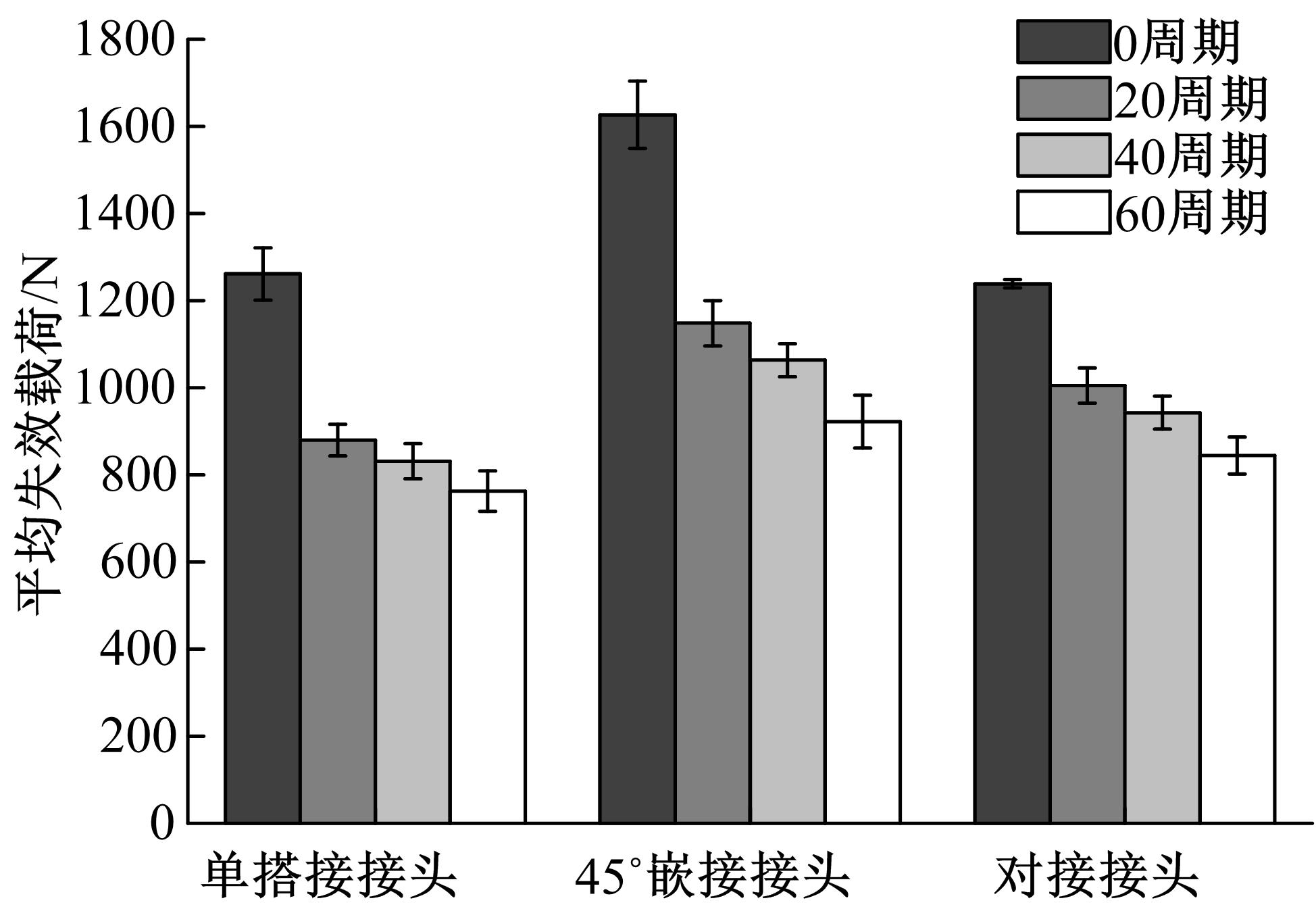

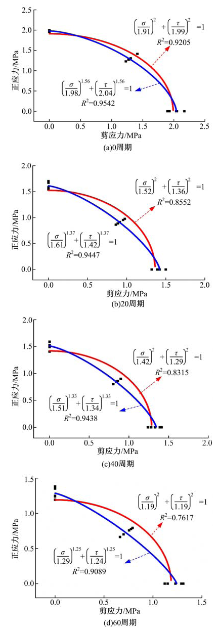

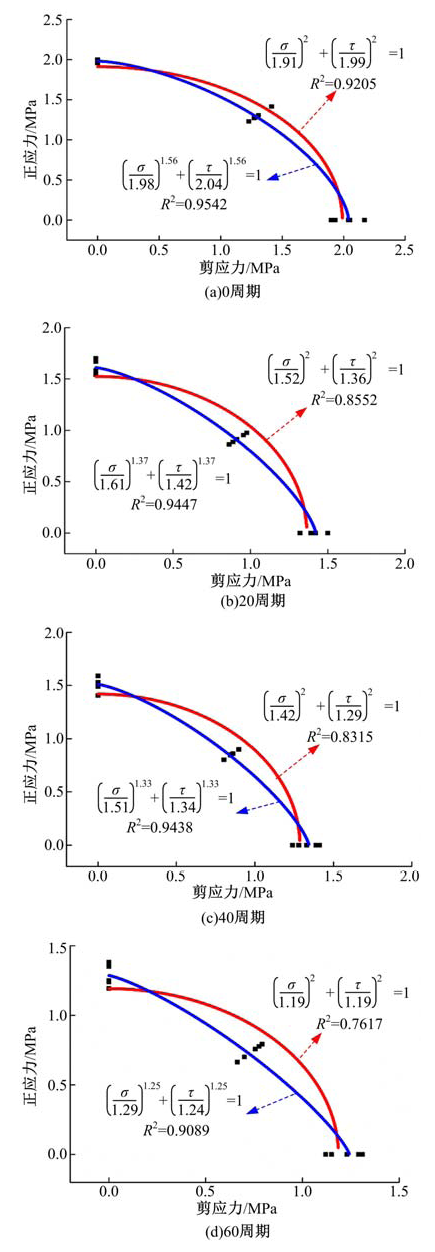

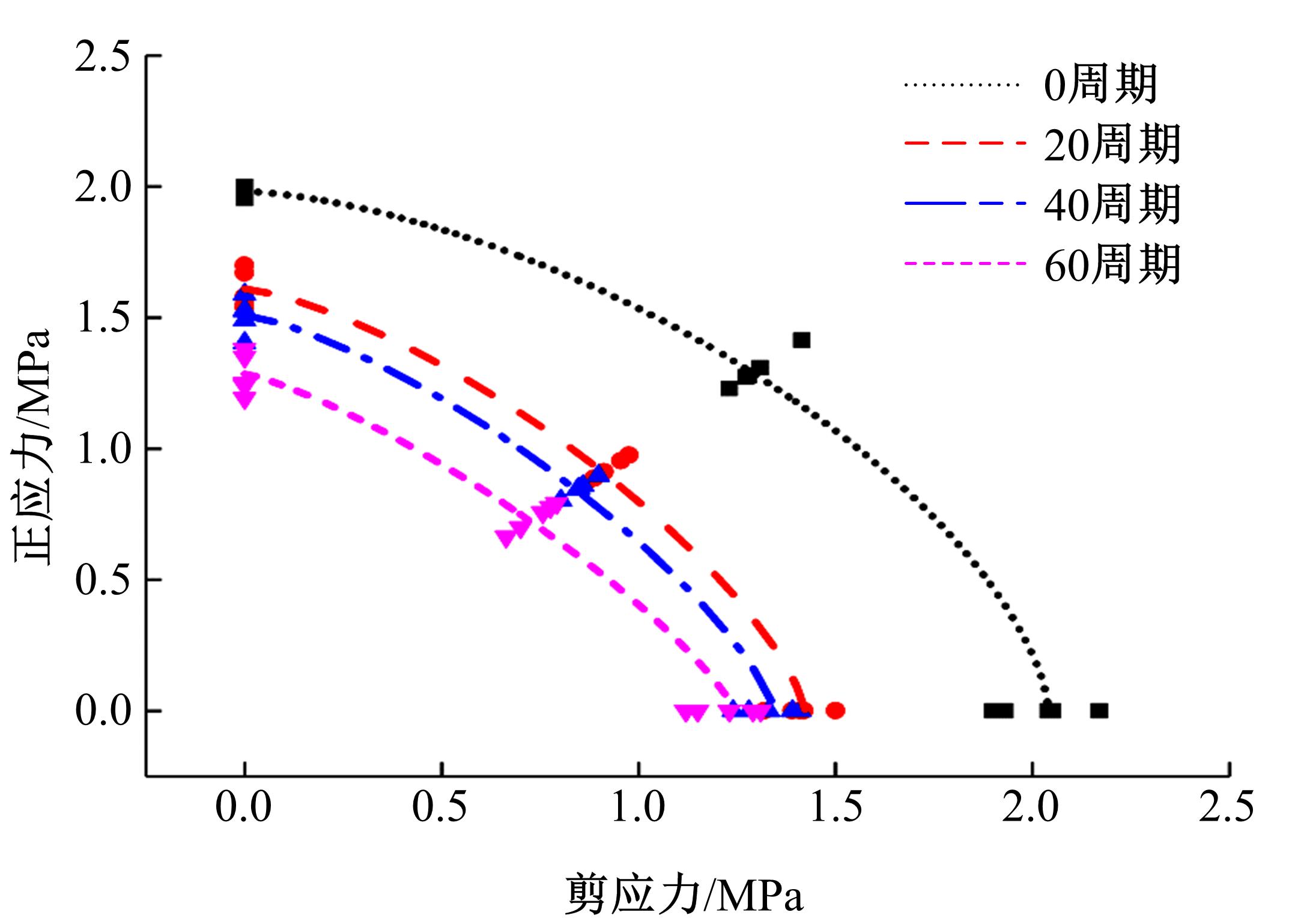

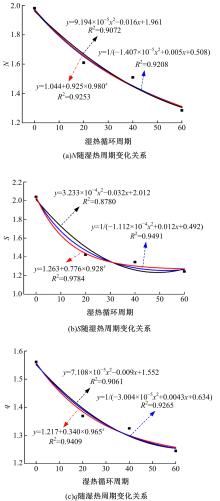

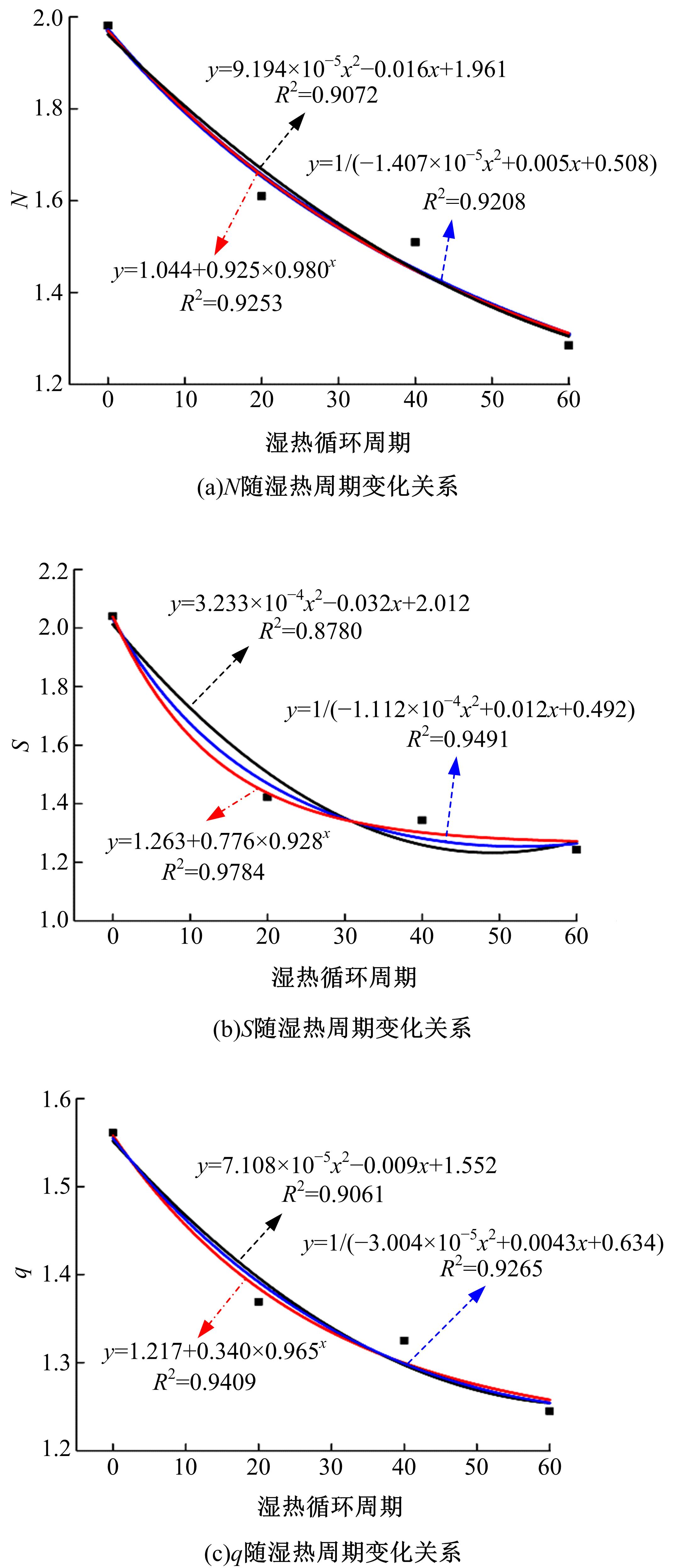

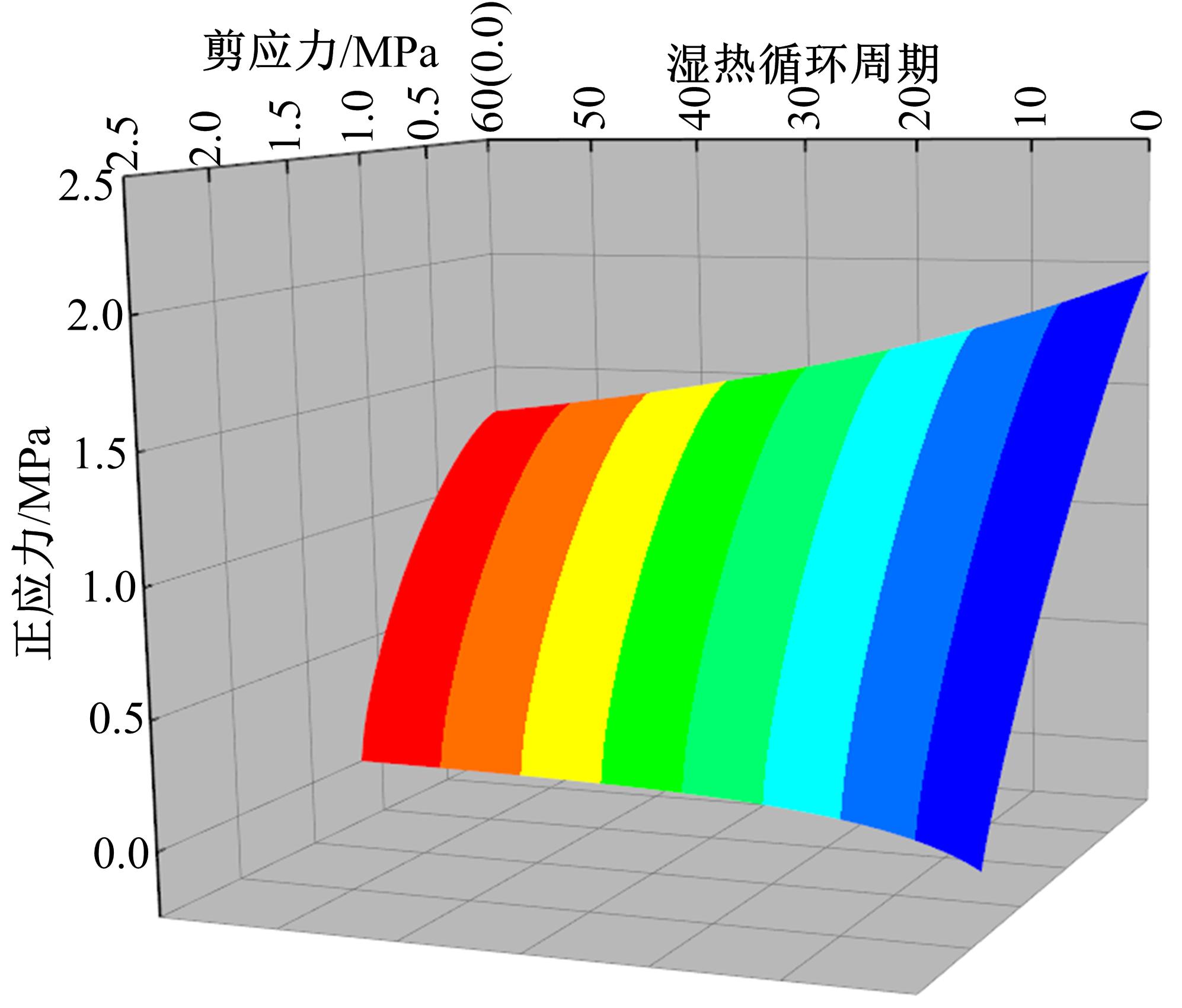

为了给粘接技术在钢-铝车身中的实际应用提供参考依据和技术指导,研究了湿热环境对不同应力状态下钢-铝粘接接头性能的影响。针对所选取的单搭接、45°嵌接、对接钢-铝粘接接头,完成试件的加工及粘接固化,并根据所制定湿热循环谱,进行了20、40、60周期的湿热老化试验。试验结果表明:随着湿热循环周期的增加,3种接头失效载荷均呈下降趋势,在正、剪应力等比状态下,接头失效载荷下降幅度更显著。同时,在湿热循环作用下接头失效形式也发生了一定改变。通过计算接头胶层的正、剪应力值,并进行曲线拟合发现不同湿热循环周期后,接头失效准则均符合应力准则。在此基础上,进一步建立了钢-铝粘接接头在任意老化周期后的失效准则表达式及对应的三维曲面。

中图分类号:

- U463.82

| [1] |

Sakundarini N, Taha Z, Abdul-Rashid S H , et al. Optimal multi-material selection for lightweight design of automotive body assembly incorporating recyclability[J]. Materials & Design, 2013,50(17):846-857.

doi: 10.1016/j.matdes.2013.03.085 |

| [2] |

李永兵, 马运五, 楼铭 , 等. 轻量化多材料汽车车身连接技术进展[J]. 机械工程学报, 2016,52(24):1-23.

doi: 10.3901/JME.2016.24.001 |

|

Li Yong-bing, Ma Yun-wu, Lou Ming , et al. Advances in welding and joining processes of multi-material lightweight car body[J]. Journal of Mechanical Engineering, 2016,52(24):1-23.

doi: 10.3901/JME.2016.24.001 |

|

| [3] |

龙江启, 兰凤崇, 陈吉清 . 车身轻量化与钢铝一体化结构新技术的研究进展[J]. 机械工程学报, 2008,44(6):27-35.

doi: 10.3321/j.issn:0577-6686.2008.06.004 |

|

Long Jiang-qi, Lan Feng-chong, Chen Ji-qing . New technology of lightweight and steel/aluminum hybrid structure car body[J]. Journal of Mechanical Engineering, 2008,44(6):27-35.

doi: 10.3321/j.issn:0577-6686.2008.06.004 |

|

| [4] |

Li Hong, Li Xin . The present situation and the development trend of new materials used in automobile lightweight[J]. Applied Mechanics & Materials, 2012,189(1):58-62.

doi: 10.4028/www.scientific.net/AMM.189.58 |

| [5] | 林健, 杨上陆, 雷永平 . 钢/铝异种材料连接接头的强度及失效模式[J]. 北京工业大学学报, 2014,40(3):451-459. |

| Lin Jian, Yang Shang-lu, Lei Yong-ping . Joint strength and failure mode of steel /aluminum dissimilar materials joint used in automobile body assembly[J]. Journal of Beijing University of Technology, 2014,40(3):451-459. | |

| [6] |

Pfestorf M . Manufacturing of high strength steel and aluminum for a mixed material body in white[J]. Advanced Materials Research, 2005, 6-8:109-126.

doi: 10.4028/www.scientific.net/AMR.6-8.109 |

| [7] |

黄健康, 何翠翠, 石玗 , 等. 铝/钢异种金属焊接接头界面Al-Fe金属间化合物生成及其热力学分析[J]. 吉林大学学报:工学版, 2014,44(4):1037-1041.

doi: 10.13229/j.cnki.jdxbgxb201404021 |

|

Huang Jian-kang, He Cui-cui, Shi Yu , et al. Thermodynamic analysis of Al-Fe intermetallic compounds formed by dissimilar joining of aluminium and galvanized steel[J]. Journal of Jilin University (Engineering and Technology Edition), 2014,44(4):1037-1041.

doi: 10.13229/j.cnki.jdxbgxb201404021 |

|

| [8] | 张颖怀, 许立宁, 路民旭 . 表面处理对胶粘剂/金属界面疲劳性能的影响[J]. 北京科技大学学报, 2008,30(12):1338-1341. |

| Zhang Ying-huai, Xu Li-ning, Lu Min-xu . Effect of surface treatment on the fatigue performance of adhesive/metal interface[J]. Journal of University of Science and Technology Beijing, 2008,30(12):1338-1341. | |

| [9] |

王玉奇, 何晓聪, 丁燕芳 , 等. 基于一维梁理论模型的金属单搭粘接贴片接头强度分析[J]. 上海交通大学学报, 2015,49(1):49-55.

doi: 10.16183/j.cnki.jsjtu.2015.01.009 |

|

Wang Yu-qi, He Xiao-cong, Ding Yan-fang , et al. Analysis of strength of adhesive bonding of single lap joints of metal with reinforcements based on one-dimensional beam theory[J]. Journal of Shanghai Jiaotong University, 2015,49(1):49-55.

doi: 10.16183/j.cnki.jsjtu.2015.01.009 |

|

| [10] |

Koricho E G, Verna E, Belingardi G , et al. Parametric study of hot-melt adhesive under accelerated ageing for automotive applications[J]. International Journal of Adhesion & Adhesives, 2016,68:169-181.

doi: 10.1016/j.ijadhadh.2016.03.006 |

| [11] | Nassar S A, Sakai K . Effect of cyclic heat, humidity, and joining methods on the static and dynamic performance of lightweight-material single lap joints[J]. Journal of Manufacturing Science & Engineering, 2015,137(5):2469723. |

| [12] |

王元伍, 王艳, 刘金凤 , 等. 温度对单组分湿固化聚氨酯胶粘剂接头剪切强度的影响[J]. 粘接, 2016(4):59-64.

doi: 10.3969/j.issn.1001-5922.2016.04.011 |

|

Wang Yuan-wu, Wang Yan, Liu Jin-feng , et al. Effect of temperature on the shear strength of one-component moisture curing polyurethane adhesive joints[J]. Adhesion, 2016(4):59-64.

doi: 10.3969/j.issn.1001-5922.2016.04.011 |

|

| [13] |

Wang Ming-xing, Liu Ai-long, Liu Zhong-xia , et al. Effect of hot humid environmental exposure on fatigue crack growth of adhesive-bonded aluminum A356 joints[J]. International Journal of Adhesion & Adhesives, 2013,40:1-10.

doi: 10.1016/j.ijadhadh.2012.08.008 |

| [14] |

Han X, Crocombe A D, Anwar S N R , et al. The effect of a hot-wet environment on adhesively bonded joints under a sustained load[J]. Journal of Adhesion, 2014,90(5/6):420-436.

doi: 10.1080/00218464.2013.853176 |

| [15] |

Datla N V, Papini M, Ulicny J , et al. The effects of test temperature and humidity on the mixed-mode fatigue behavior of a toughened adhesive aluminum joint[J]. Engineering Fracture Mechanics, 2011,78(6):1125-1139.

doi: 10.1016/j.engfracmech.2011.01.028 |

| [16] |

Zhang F, Yang X, Wang H P , et al. Durability of adhesively-bonded single lap-shear joints in accelerated hygrothermal exposure for automotive applications[J]. International Journal of Adhesion & Adhesives, 2013,44:130-137.

doi: 10.1016/j.ijadhadh.2013.02.009 |

| [17] |

Brewer J C, Lagace P A . Quadratic stress criterion for initiation of delamination[J]. Journal of Composite Materials, 1988,22(12):1141-1155.

doi: 10.1177/002199838802201205 |

| [18] |

Campilho R, Moura M D, Domingues J . Using a cohesive damage model to predict the tensile behaviour of CFRP single-strap repairs[J]. International Journal of Solids & Structures, 2008,45(5):1497-1512.

doi: 10.1016/j.ijsolstr.2007.10.003 |

| [19] | Vallée T, Keller T. Strength prediction of adhesively bonded joints of pultruded GFRP [C]//International Conference Composites in Construction, Lyon, France, 2005: 389-391. |

| [20] | Jiang Xu, Qiang Xu-hong, Kolstein H , et al. Analysis on adhesively-bonded joints of FRP-steel composite bridge under combined loading: arcan test study and numerical modeling[J]. Polymers, 2016,8(1):1-18. |

| [21] |

Moura M F S F D, Campilho R D S G, Gonçalves J P M . Crack equivalent concept applied to the fracture characterization of bonded joints under pure mode I loading[J]. Composites Science & Technology, 2008,68(10/11):2224-2230.

doi: 10.1016/j.compscitech.2008.04.003 |

| [22] |

Zhang F, Wang H P, Hicks C , et al. Experimental study of initial strengths and hygrothermal degradation of adhesive joints between thin aluminum and steel substrates[J]. International Journal of Adhesion & Adhesives, 2013,43(2):14-25.

doi: 10.1016/j.ijadhadh.2013.01.001 |

| [23] |

Lee M, Yeo E, Blacklock M , et al. Predicting the strength of adhesively bonded joints of variable thickness using a cohesive element approach[J]. International Journal of Adhesion & Adhesives, 2015,58:44-52.

doi: 10.1016/j.ijadhadh.2015.01.006 |

| [1] | 常成,宋传学,张雅歌,邵玉龙,周放. 双馈电机驱动电动汽车变频器容量最小化[J]. 吉林大学学报(工学版), 2018, 48(6): 1629-1635. |

| [2] | 席利贺,张欣,孙传扬,王泽兴,姜涛. 增程式电动汽车自适应能量管理策略[J]. 吉林大学学报(工学版), 2018, 48(6): 1636-1644. |

| [3] | 何仁,杨柳,胡东海. 冷藏运输车太阳能辅助供电制冷系统设计及分析[J]. 吉林大学学报(工学版), 2018, 48(6): 1645-1652. |

| [4] | 刘玉梅,刘丽,曹晓宁,熊明烨,庄娇娇. 转向架动态模拟试验台避撞模型的构建[J]. 吉林大学学报(工学版), 2018, 48(6): 1661-1668. |

| [5] | 宋大凤, 吴西涛, 曾小华, 杨南南, 李文远. 基于理论油耗模型的轻混重卡全生命周期成本分析[J]. 吉林大学学报(工学版), 2018, 48(5): 1313-1323. |

| [6] | 朱剑峰, 张君媛, 陈潇凯, 洪光辉, 宋正超, 曹杰. 基于座椅拉拽安全性能的车身结构改进设计[J]. 吉林大学学报(工学版), 2018, 48(5): 1324-1330. |

| [7] | 金立生, 谢宪毅, 高琳琳, 郭柏苍. 基于二次规划的分布式电动汽车稳定性控制[J]. 吉林大学学报(工学版), 2018, 48(5): 1349-1359. |

| [8] | 王德军, 魏薇郦, 鲍亚新. 考虑侧风干扰的电子稳定控制系统执行器故障诊断[J]. 吉林大学学报(工学版), 2018, 48(5): 1548-1555. |

| [9] | 赵伟强, 高恪, 王文彬. 基于电液耦合转向系统的商用车防失稳控制[J]. 吉林大学学报(工学版), 2018, 48(5): 1305-1312. |

| [10] | 那景新, 浦磊鑫, 范以撒, 沈传亮. 湿热环境对Sikaflex-265铝合金粘接接头失效强度的影响[J]. 吉林大学学报(工学版), 2018, 48(5): 1331-1338. |

| [11] | 王炎, 高青, 王国华, 张天时, 苑盟. 混流集成式电池组热管理温均特性增效仿真[J]. 吉林大学学报(工学版), 2018, 48(5): 1339-1348. |

| [12] | 隗海林, 包翠竹, 李洪雪, 李明达. 基于最小二乘支持向量机的怠速时间预测[J]. 吉林大学学报(工学版), 2018, 48(5): 1360-1365. |

| [13] | 胡满江, 罗禹贡, 陈龙, 李克强. 基于纵向频响特性的整车质量估计[J]. 吉林大学学报(工学版), 2018, 48(4): 977-983. |

| [14] | 张曼, 施树明. 典型汽车运行工况的状态转移特征分析[J]. 吉林大学学报(工学版), 2018, 48(4): 1008-1015. |

| [15] | 刘国政, 史文库, 陈志勇. 考虑安装误差的准双曲面齿轮传动误差有限元分析[J]. 吉林大学学报(工学版), 2018, 48(4): 984-989. |

|