吉林大学学报(工学版) ›› 2021, Vol. 51 ›› Issue (4): 1213-1221.doi: 10.13229/j.cnki.jdxbgxb20200347

• 车辆工程·机械工程 • 上一篇

基于SVR的轴向柱塞泵配流盘三角槽结构优化

- 浙江大学 流体动力与机电系统国家重点实验室,杭州 310027

Structure optimization of triangular groove of valve plate in axial piston pump based on SVR

Bin ZHANG( ),Guo-zan CHENG,Hao-cen HONG(

),Guo-zan CHENG,Hao-cen HONG( ),Chun-xiao ZHAO,Da-peng BAI,Hua-yong YANG

),Chun-xiao ZHAO,Da-peng BAI,Hua-yong YANG

- State Key Laboratory of Fluid Power Transmission and Control,Zhejiang University,Hangzhou 310027,China

摘要:

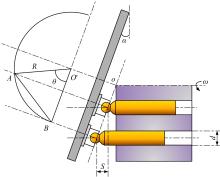

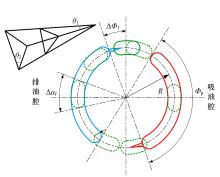

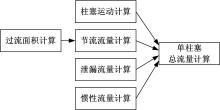

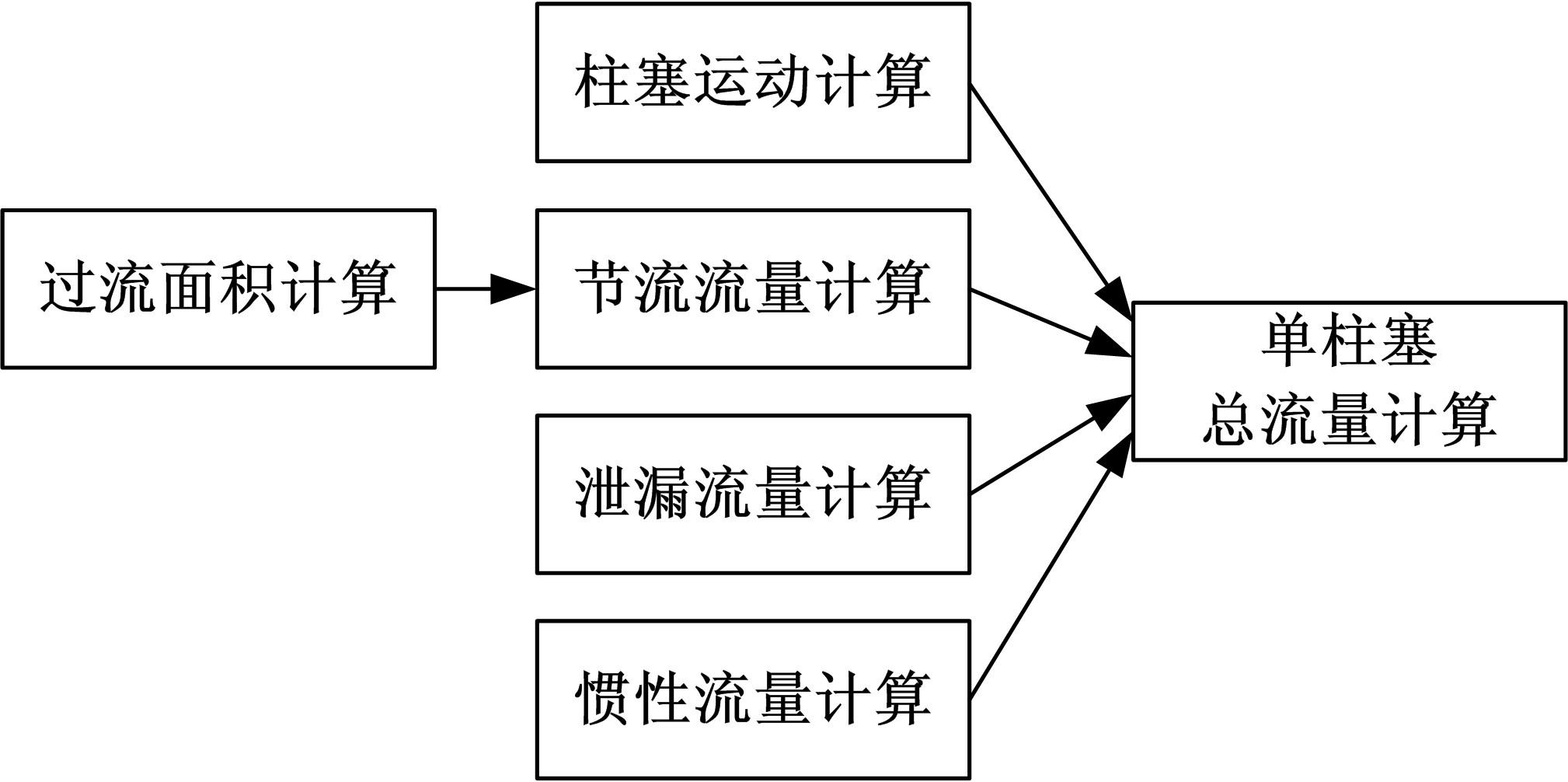

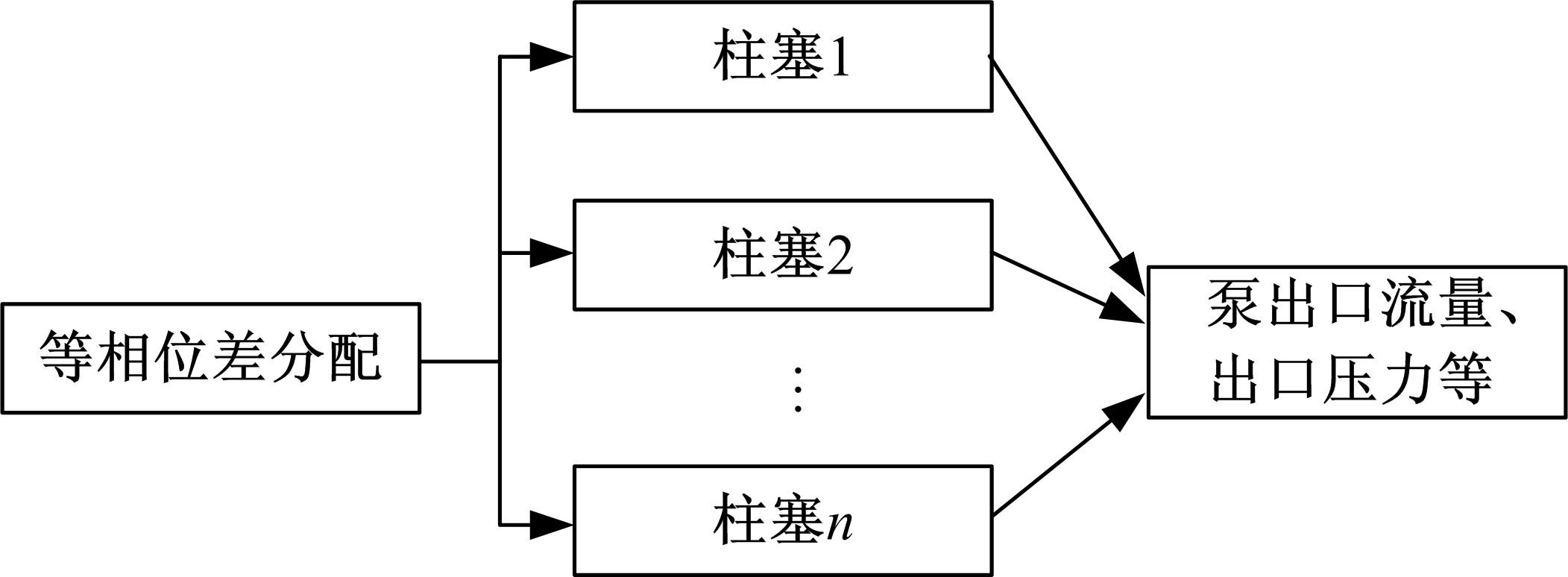

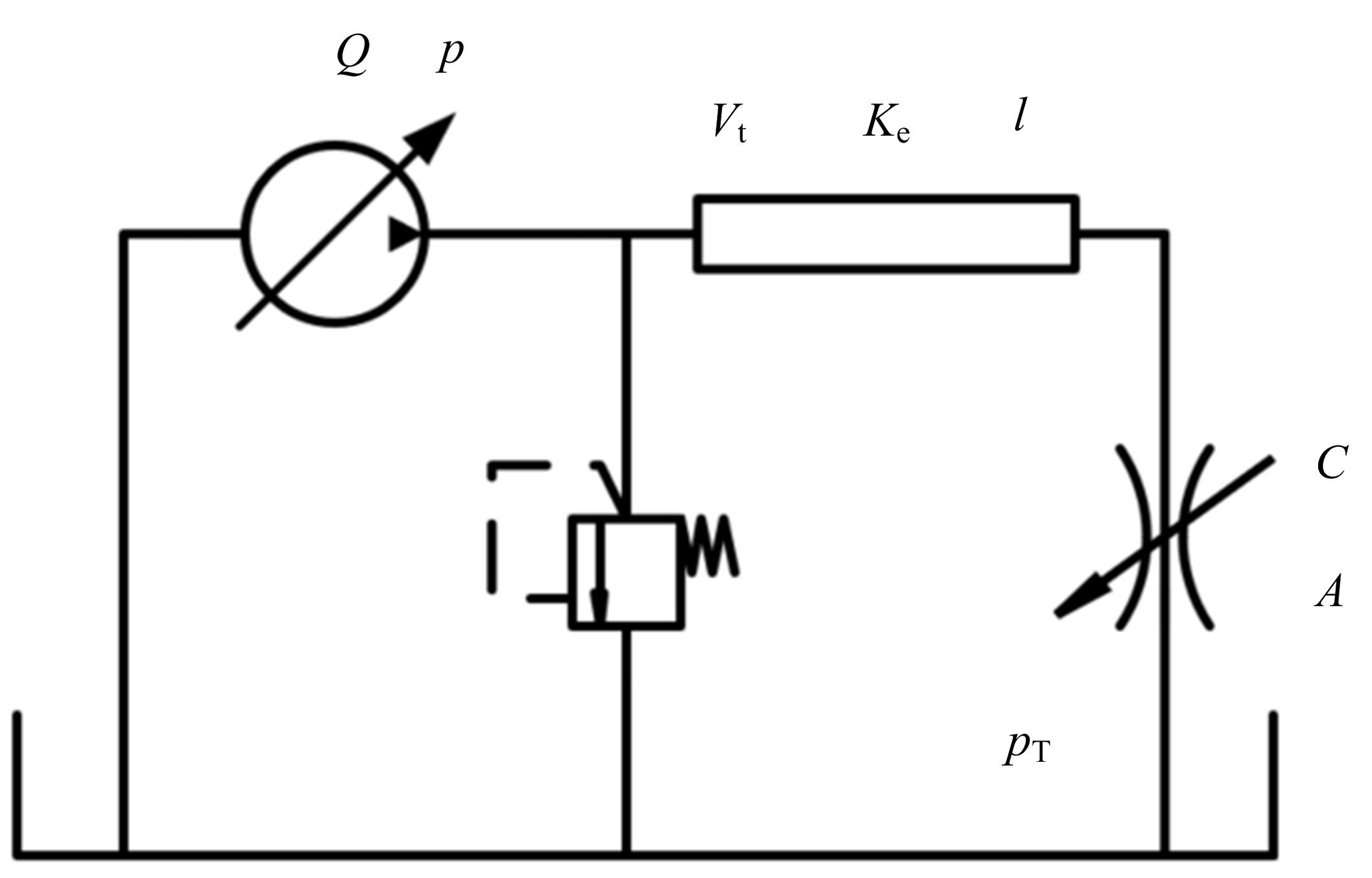

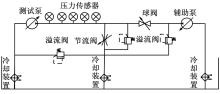

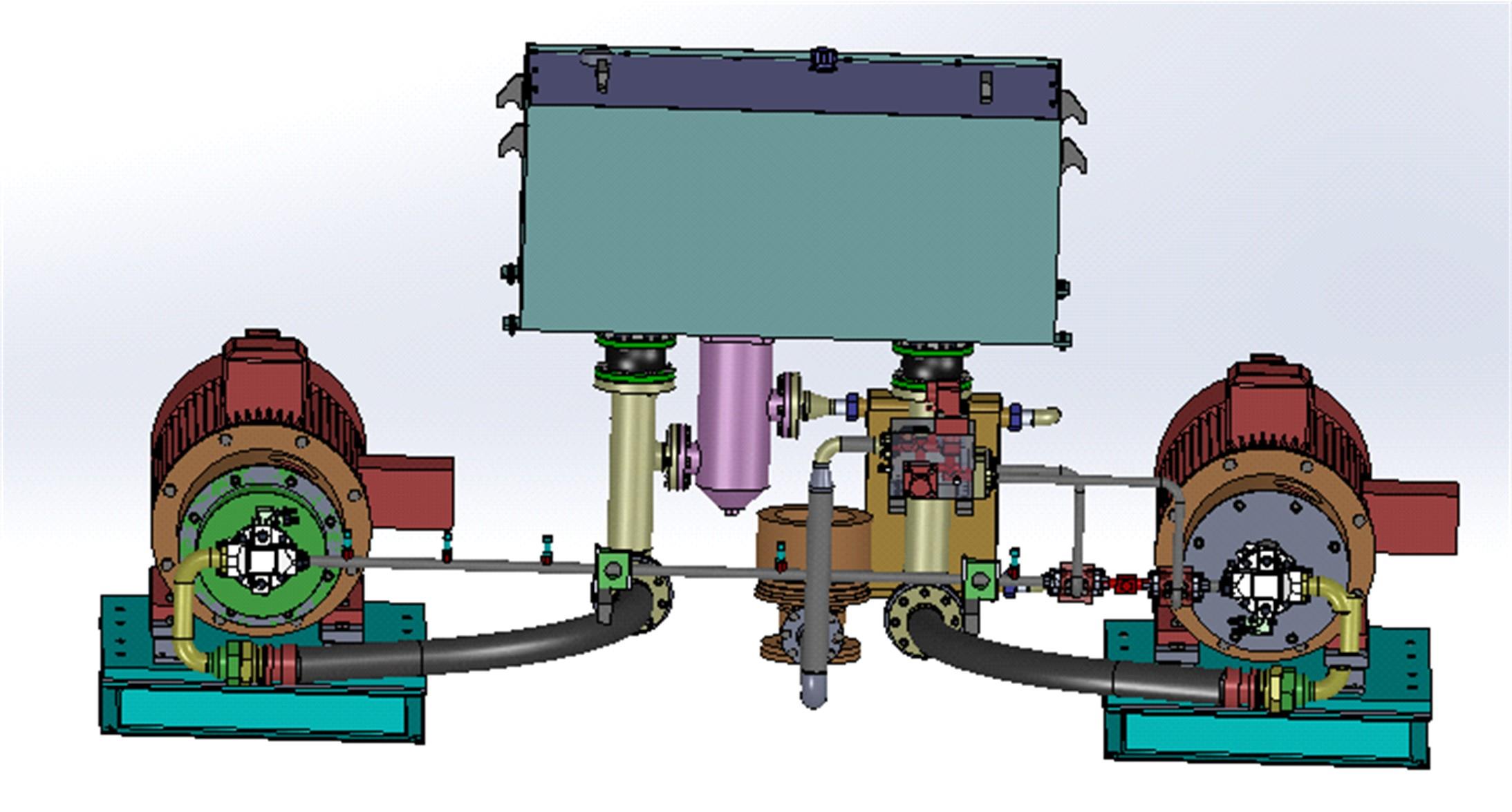

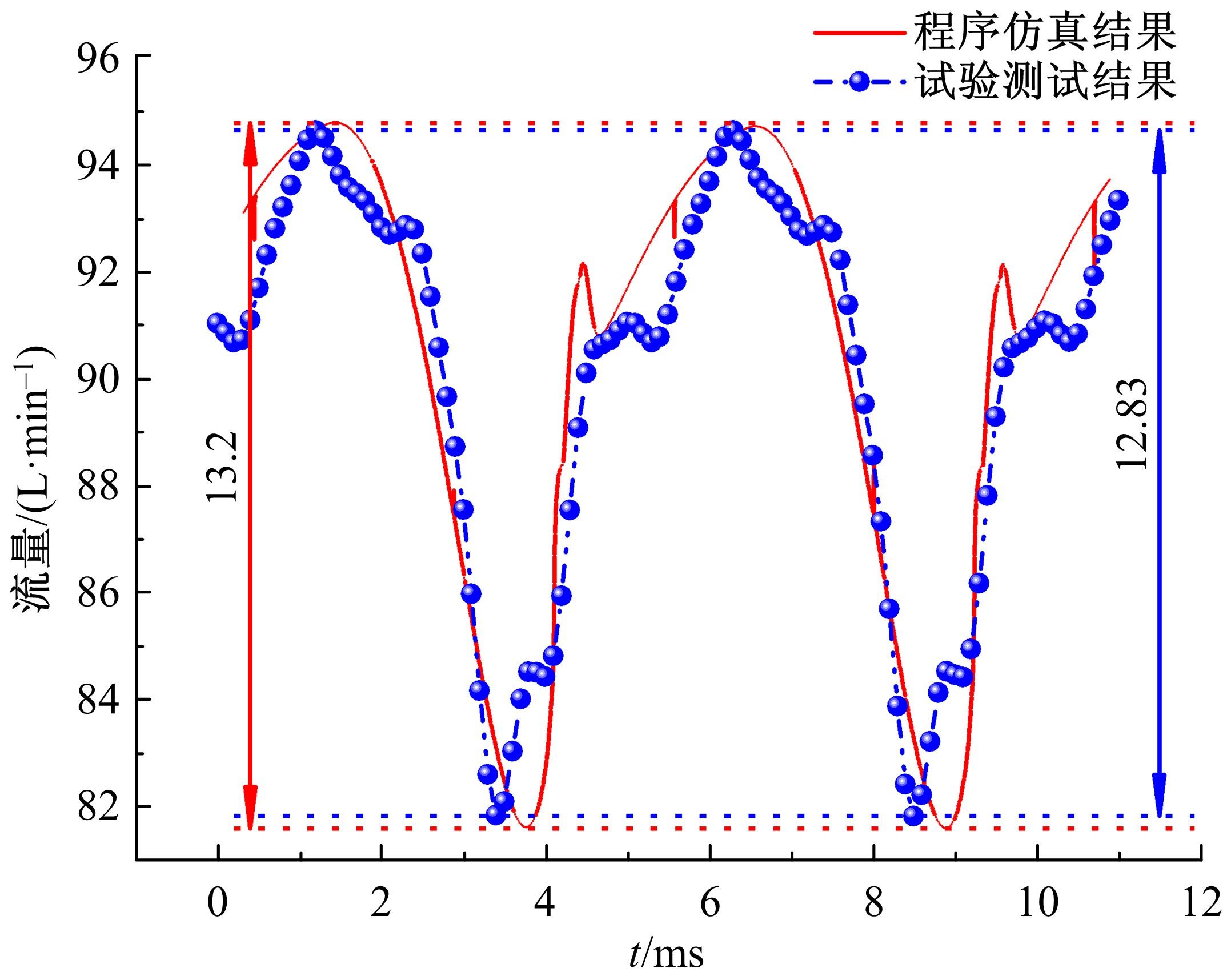

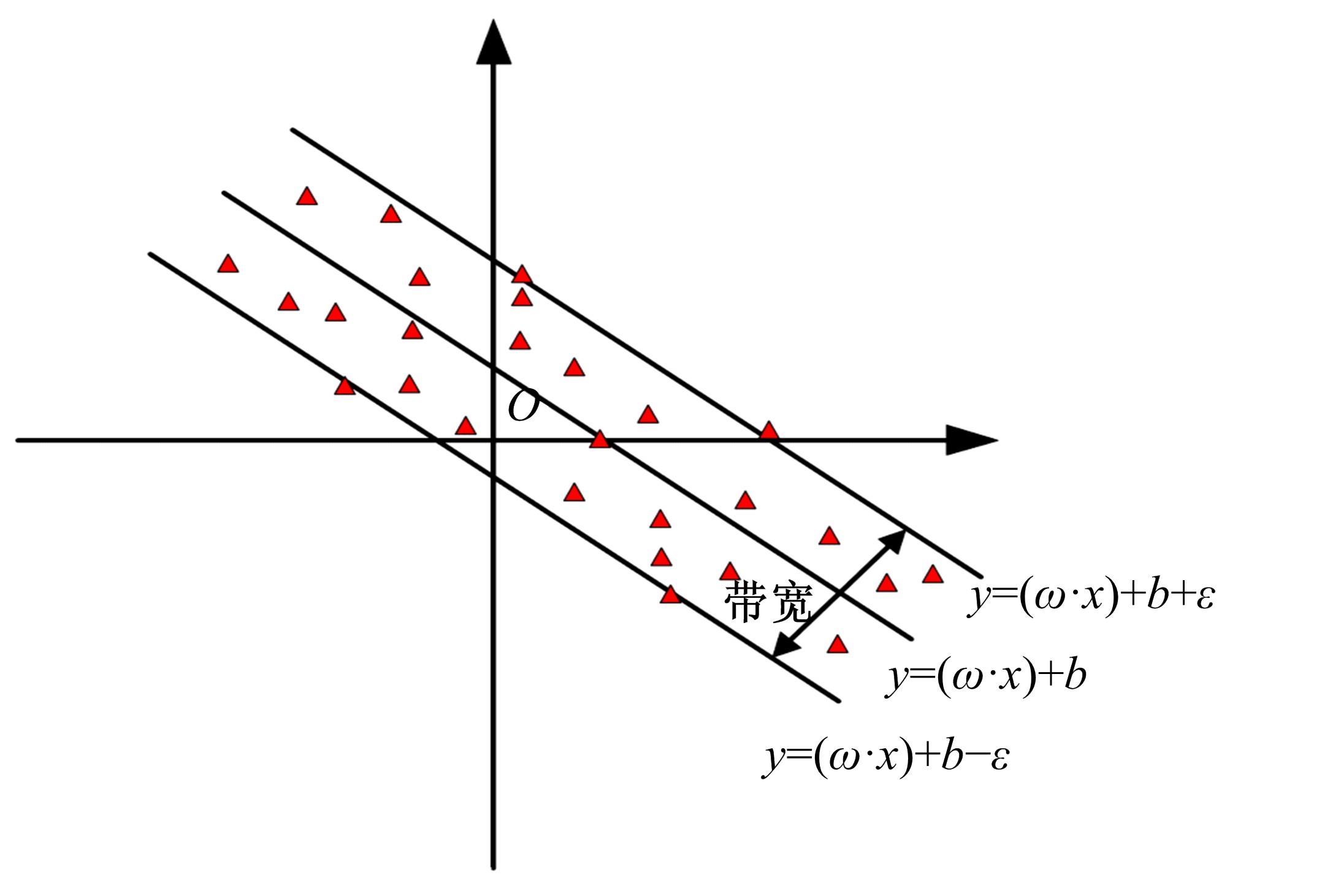

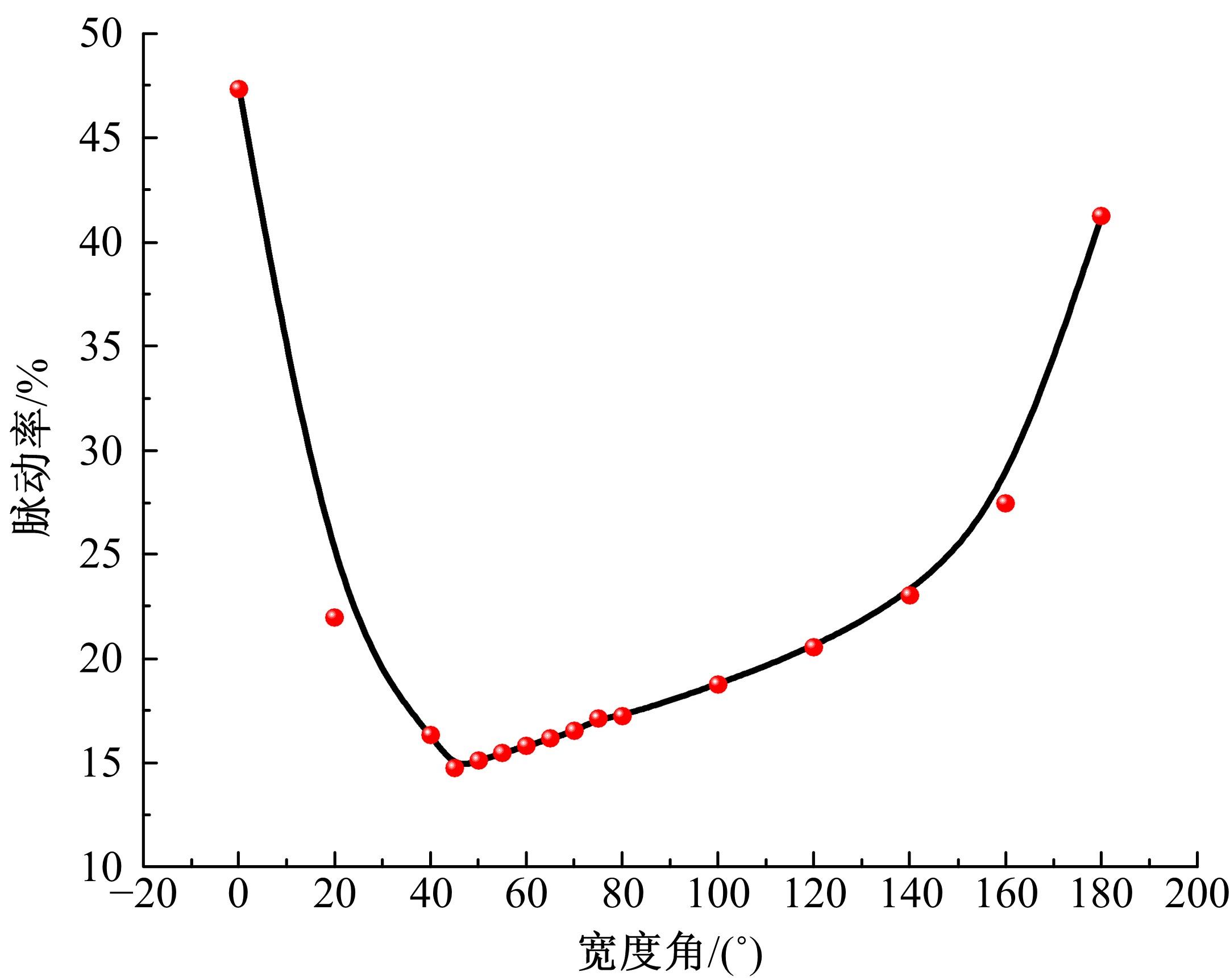

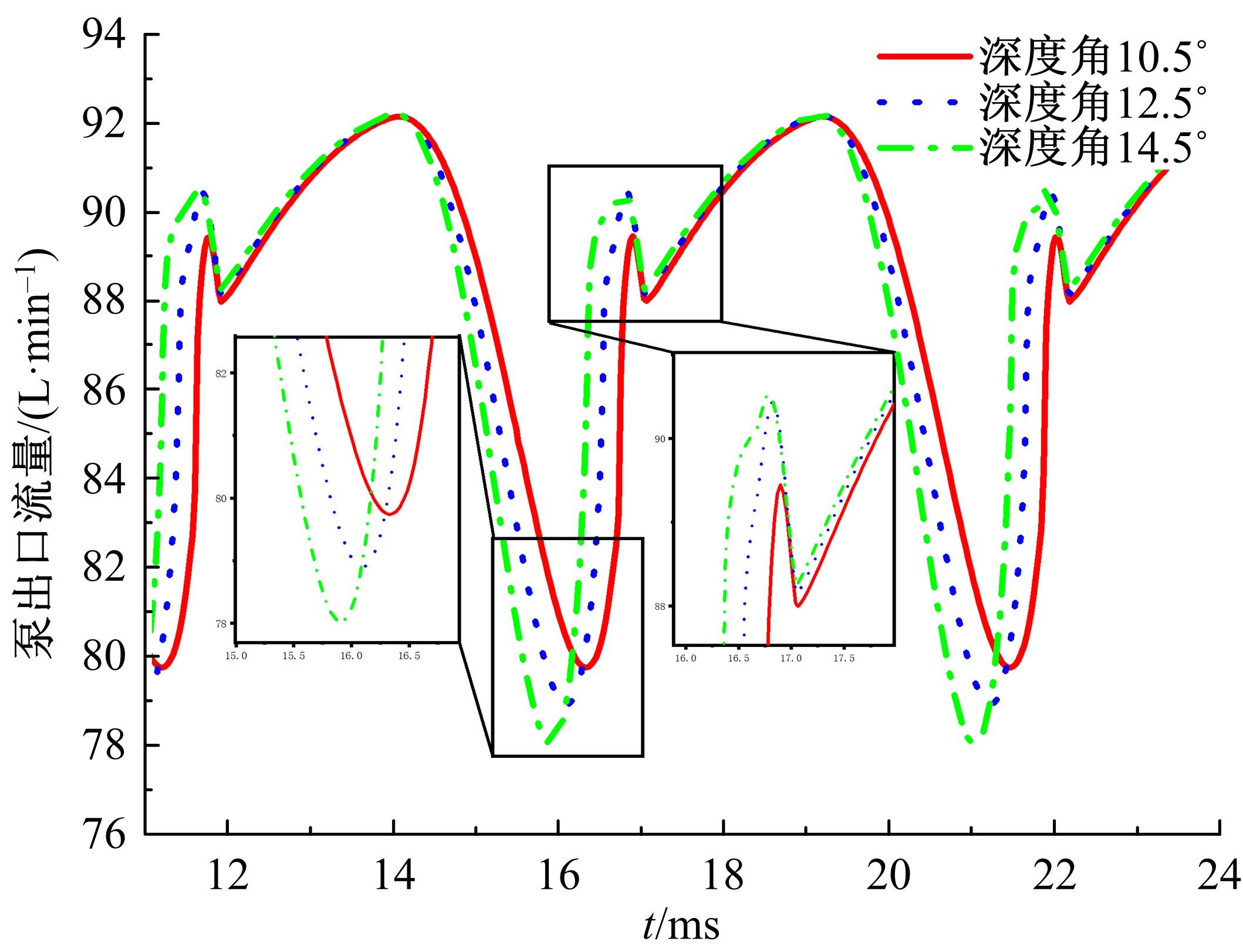

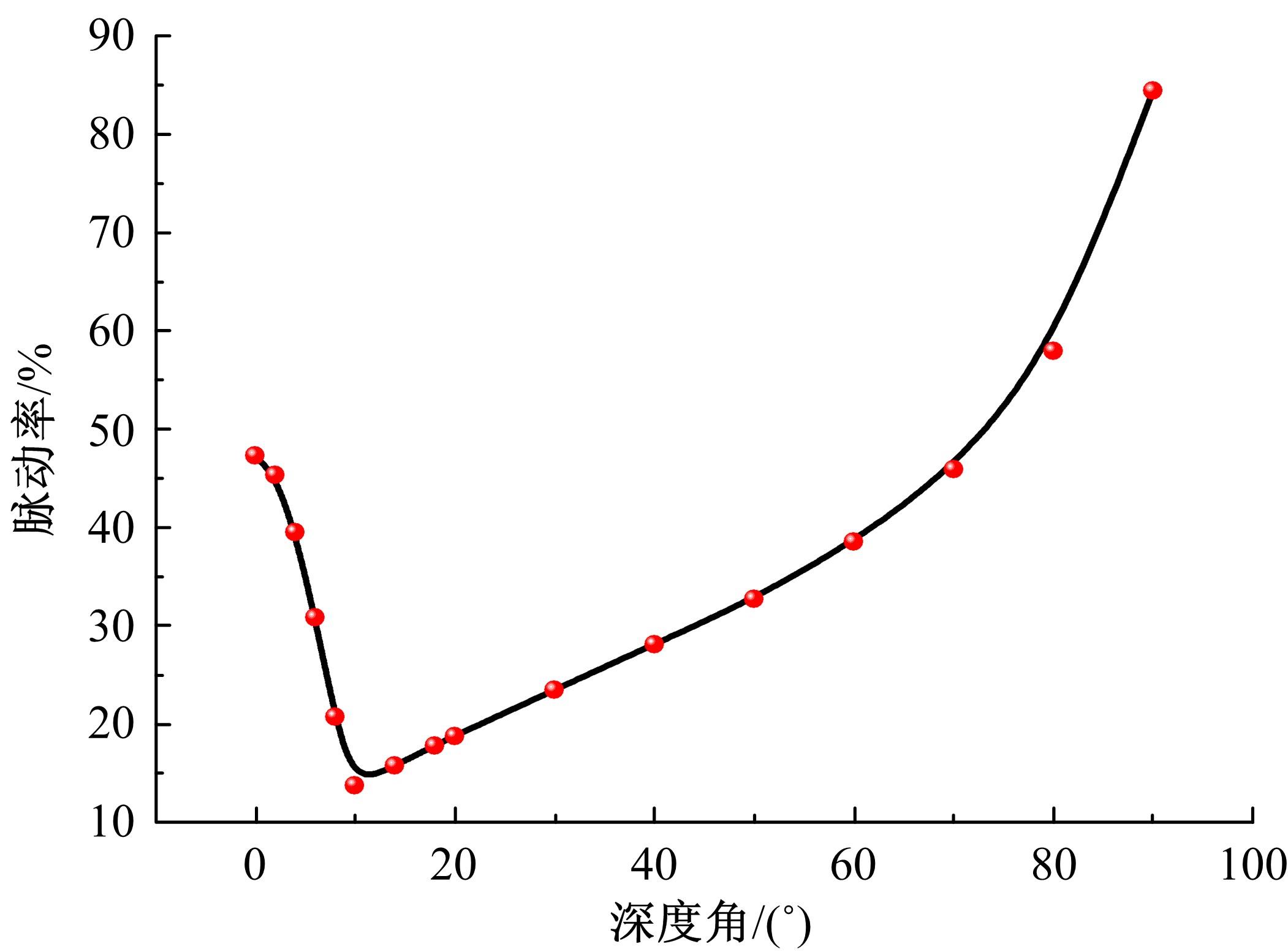

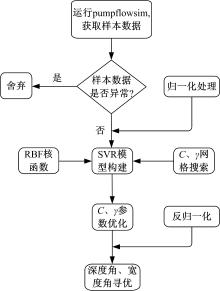

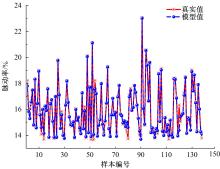

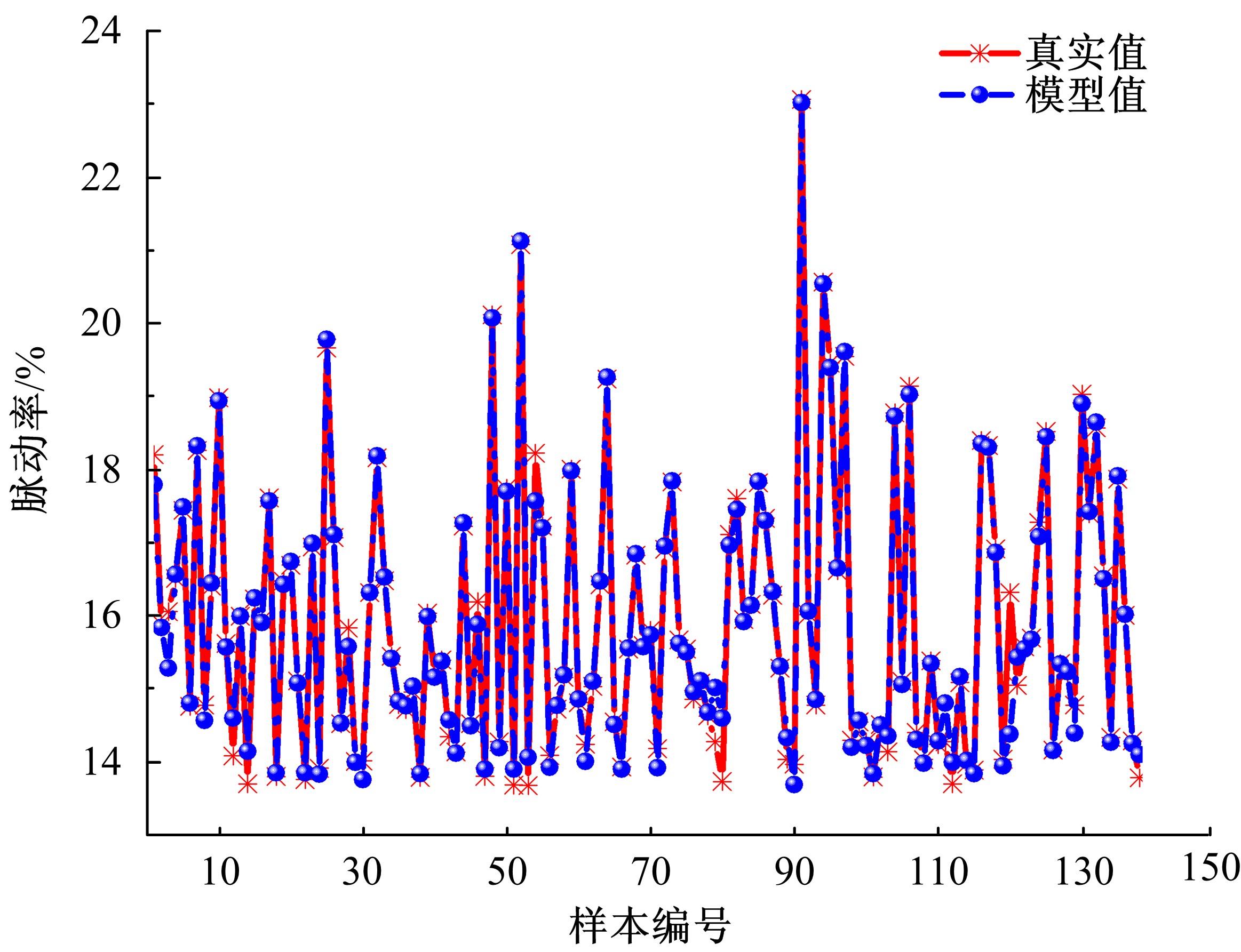

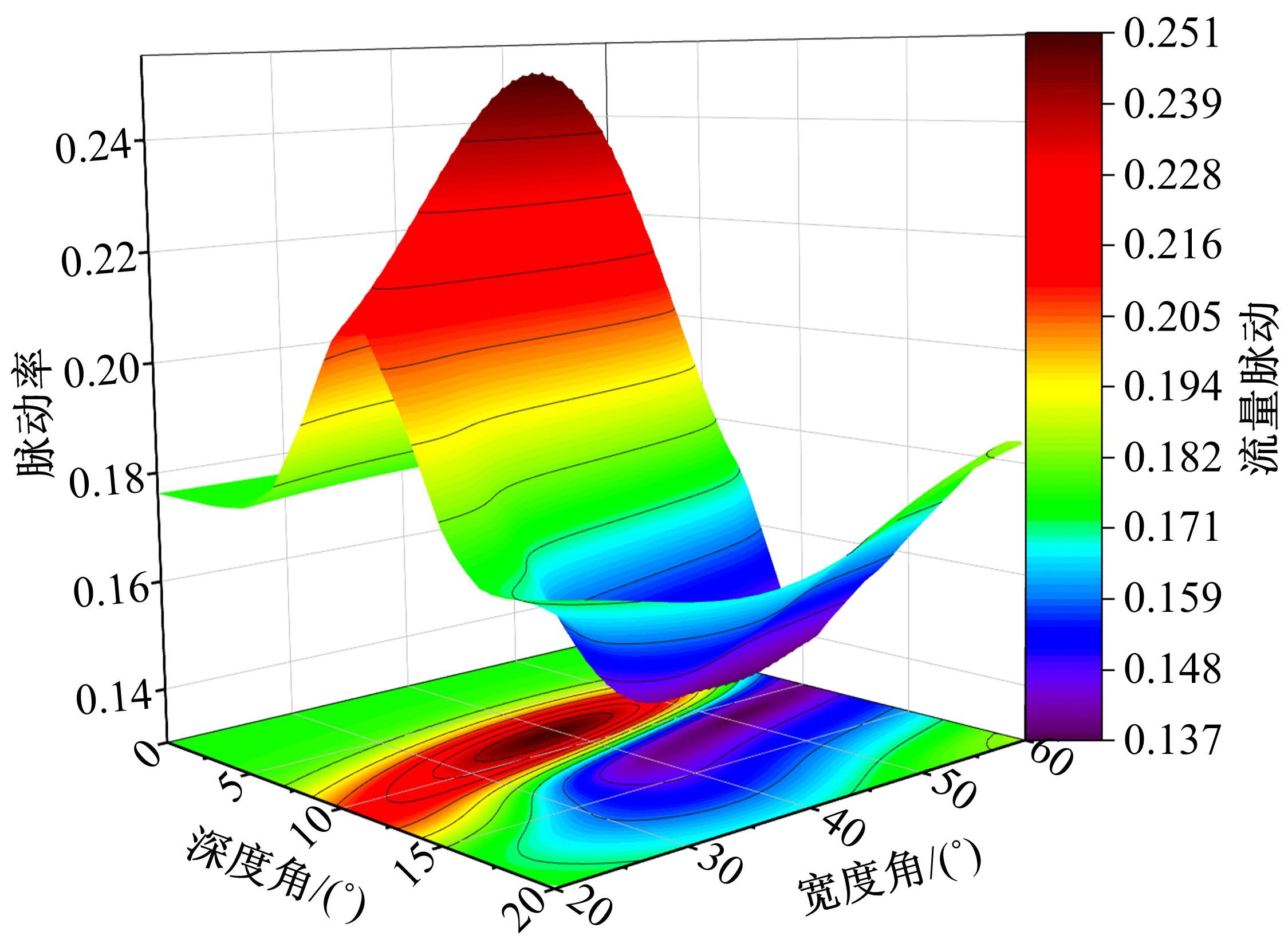

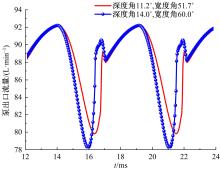

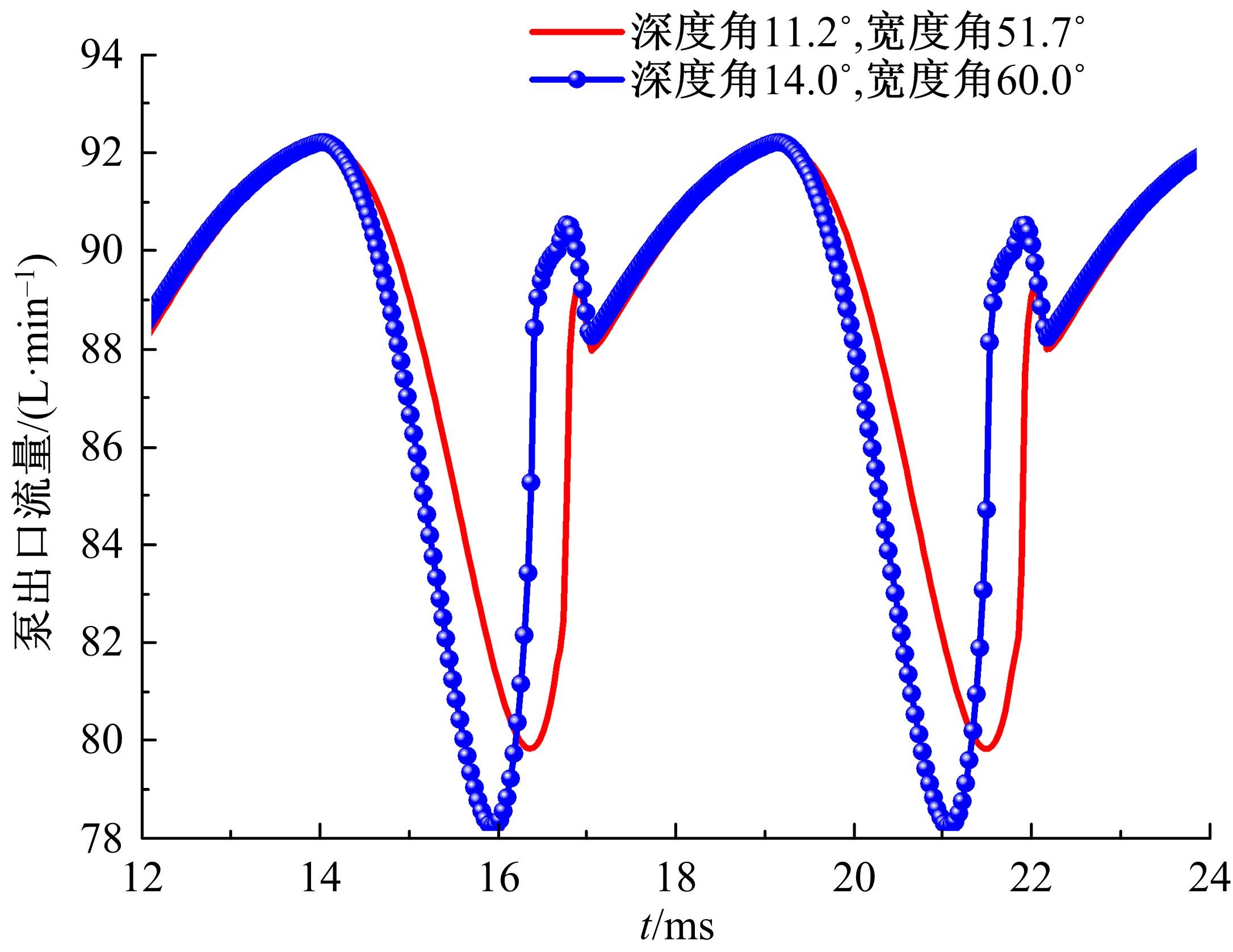

为优化轴向柱塞泵的输出动态特性,提出了一种基于支持向量回归机(SVR)的柱塞泵配流盘三角槽结构优化方法。首先,根据轴向柱塞泵的工作原理对其输出特性进行建模,并通过试验对仿真模型的准确性和可行性进行验证,试验与仿真结果误差约为0.31%,理论模型与试验具有较好的一致性。然后,通过计算获取不同配流盘三角槽结构条件下的样本数据,基于SVR模型找出柱塞泵出口流量脉动与三角槽的深度角、宽度角间的对应关系,计算得到深度角与宽度角的最优解分别为11.2°和51.7°。最后,在相同工况条件下,将三角槽结构优化前和优化后计算结果进行对比分析,结果显示,柱塞泵优化后的流量脉动相比优化前降低了1.87%,为制作新产品缩短了研发周期和成本。

中图分类号:

- TH322

| 1 | 张静,谢世聪,杨馥霖,等. 基于PumpLinx柱塞泵配流盘三角槽结构的优化[J]. 液压气动与密封, 2019, 39(12): 14-19. |

| Zhang Jing, Xie Shi-cong, Yang Fu-lin, et al. The optimization of axis pump valve plate triangular groove structure based on pumpLinx[J]. Hydraulics Pneumatics & Seals, 2019, 39(12): 14-19. | |

| 2 | 马吉恩. 轴向柱塞泵流量脉动及配流盘优化设计研究[D]. 杭州:浙江大学机械工程学院, 2009. |

| Ma Ji-en. Study on flow ripple and valve plate optimization of axial piston pump[D]. Hangzhou: School of Mechanical Engineering, Zhejiang University, 2009. | |

| 3 | 杨华勇,马吉恩,徐兵. 轴向柱塞泵流体噪声的研究现状[J]. 机械工程学报, 2009, 45(8): 71-79. |

| Yang Hua-yong, Ma Ji-en, Xu Bing. Research status of axial piston pump fluid-borne noise[J]. Journal of Mechanical Engineering, 2009, 45(8): 71-79. | |

| 4 | 邓海顺,黄坤,王传礼,等. 平衡式两排轴向柱塞泵缸体倾覆力矩[J]. 吉林大学学报:工学版, 2015, 45(5): 1468-1473. |

| Deng Hai-shun, Huang Kun, Wang Chuan-li, et al. Overturning moment of cylinder of balanced two-ring axial piston pump[J]. Journal of Jilin University(Engineering and Technology Edition), 2015, 45(5): 1468-1473. | |

| 5 | 潘阳,李毅波,黄明辉,等. 双联轴向柱塞泵配流盘优化与流量脉动特性分析[J]. 农业机械学报, 2016, 47(4): 391-398. |

| Pan Yang, Li Yi-bo, Huang Ming-hui, et al. Valve plate improvement and flow ripple characteristic analysis for double compound axial piston pump[J]. Transactions of the Chinese Society for Agricultural Machinery, 2016, 47(4): 391-398. | |

| 6 | 童水光,王相兵,钟崴,等. 基于虚拟样机技术的轴向柱塞泵动态特性分析[J]. 机械工程学报, 2013, 49(2): 174-182. |

| Tong Shui-guang, Wang Xiang-bing, Zhong Wei, et al. Dynamic characteristics analysis on axial piston pump based on virtual prototype technology[J]. Journal of Mechanical Engineering, 2013, 49(2): 174-182. | |

| 7 | Xu B, Ye S, Zhang Jun-hui. Flow ripple reduction of an axial piston pump by a combination of cross-angle and pressure relief grooves: analysis and optimization[J]. Journal of Mechanical Science and Technology, 2016, 30(6): 2531-2545. |

| 8 | 钟鸣. A4V型轴向柱塞泵的动态特性分析[D]. 哈尔滨:哈尔滨工业大学机电工程学院, 2014. |

| Zhong Ming. Analysis of the dynamic characteristics of A4V axial piston pump[D]. Haerbin: School of Electrical and Mechanical Engineering, Harbin Institute of Technology, 2014. | |

| 9 | Hong Hao-cen, Zhang Bin, Yu Min, et al. Analysis and optimization on U-shaped damping groove for flow ripple reduction of fixed displacement axial-piston pump[J]. International Journal of Fluid Machinery and Systems, 2020, 13(1): 126-135. |

| 10 | 申屠胜男,阮健,钱家圆,等. 2D泵流动特性与配流窗口优化分析[J]. 农业机械学报, 2019, 50(12): 403-410. |

| Shentu Sheng-nan, Ruan Jian, Qian Jia-yuan, et al. Optimization analysis of flow characteristic and distribution window of 2D pump[J]. Transactions of the Chinese Society for Agricultural Machinery, 2019, 50(12): 403-410. | |

| 11 | 郝希阳,王玉林,耿超,等. 轴向柱塞泵配流盘阻尼槽的模拟分析[J]. 农业装备与车辆工程, 2018, 56(7): 48-51. |

| Hao Xi-yang, Wang Yu-lin, Geng Chao,et al. Study on damping groove characteristics of axial plunger pump[J]. Agricultural Equipment & Vehicle Engineering, 2018, 56(7): 48-51. | |

| 12 | 王安麟,吴小锋,马博,等.柱塞泵配流结构与流动特性的动态响应关系[J]. 同济大学学报:自然科学版, 2011,39(4): 586-590. |

| Wang An-lin, Wu Xiao-feng, Ma Bo, et al. Dynamic response relationship between swashplate's structural parameters of piston pump and hydrodynamics features[J]. Journal of Tongji University (Natural Science), 2011, 39(4): 586-590. | |

| 13 | 李鑫, 王少萍,黄伯超. 航空柱塞泵流量脉动仿真分析与结构优化[J]. 兰州理工大学学报, 2010, 36(3): 60-64. |

| Li Xin, Wang Shao-ping, Huang Bo-chao. Simulation analysis of flow fluctuation in aviation piston pump and its structure optimization[J]. Journal of Lanzhou University of Technology, 2010, 36(3): 60-64. | |

| 14 | 王毅翔. 轴向柱塞泵配流盘阻尼槽特性分析及优化设计[D]. 杭州:浙江大学机械工程学院, 2014. |

| Wang Yi-xiang. Study on damping groove characteristics and optimization of axial piston pump[D]. Hangzhou: School of Mechanical Engineering, Zhejiang University, 2014. |

| [1] | 杜常清,曹锡良,何彪,任卫群. 基于混合粒子群算法的双离合变速器参数优化设计[J]. 吉林大学学报(工学版), 2020, 50(5): 1556-1564. |

| [2] | 魏巍,刘旭,韩雪永,闫清东. 液力缓速器全充液工况下本征正交基对流场重构精度的影响规律[J]. 吉林大学学报(工学版), 2019, 49(6): 1959-1968. |

| [3] | 谷远利, 张源, 芮小平, 陆文琦, 李萌, 王硕. 基于免疫算法优化LSSVM的短时交通流预测[J]. 吉林大学学报(工学版), 2019, 49(6): 1852-1857. |

| [4] | 何仁,涂琨. 基于温度补偿气隙宽度的电磁制动器[J]. 吉林大学学报(工学版), 2019, 49(6): 1777-1785. |

| [5] | 刘俊龙,孙冬野,刘小军,尤勇. 基于耦合特性的机电控制无级变速器速比控制[J]. 吉林大学学报(工学版), 2019, 49(6): 1951-1958. |

| [6] | 王晓晶,刘美珍,陈帅,李嵩. 仿真转台用连续回转电液伺服马达预测滑模控制[J]. 吉林大学学报(工学版), 2019, 49(5): 1547-1557. |

| [7] | 卢秀泉,胡春玉,柴亚龙,马文星,张剑楠. 大功率液力偶合器调速工况瞬态流场特性[J]. 吉林大学学报(工学版), 2019, 49(5): 1539-1546. |

| [8] | 闻德生,隋广东,田山恒,王少朋,冯佩坤,刘小雪. 内外啮合齿轮马达泄漏与容积效率分析及试验[J]. 吉林大学学报(工学版), 2019, 49(4): 1186-1193. |

| [9] | 刘建芳, 王记波, 刘国君, 李新波, 梁实海, 杨志刚. 基于PMMA内嵌三维流道的压电驱动微混合器[J]. 吉林大学学报(工学版), 2018, 48(5): 1500-1507. |

| [10] | 姜继海, 葛泽华, 杨晨, 梁海健. 基于微分器的直驱电液伺服系统离散滑模控制[J]. 吉林大学学报(工学版), 2018, 48(5): 1492-1499. |

| [11] | 刘国君, 马祥, 杨志刚, 王聪慧, 吴越, 王腾飞. 集成式三相流脉动微混合芯片[J]. 吉林大学学报(工学版), 2018, 48(4): 1063-1071. |

| [12] | 刘祥勇, 李万莉. 包含蓄能器的电液比例控制模型[J]. 吉林大学学报(工学版), 2018, 48(4): 1072-1084. |

| [13] | 李静, 丁明慧, 李立刚, 陈立军. 基于活塞形状的空气弹簧动特性分析与参数优化[J]. 吉林大学学报(工学版), 2018, 48(2): 355-363. |

| [14] | 胡云峰, 王长勇, 于树友, 孙鹏远, 陈虹. 缸内直喷汽油机共轨系统结构参数优化[J]. 吉林大学学报(工学版), 2018, 48(1): 236-244. |

| [15] | 王佳怡, 刘昕晖, 王昕, 齐海波, 孙晓宇, 王丽. 数字二次元件变量冲击机理及其抑制[J]. 吉林大学学报(工学版), 2017, 47(6): 1775-1781. |

|

||