吉林大学学报(工学版) ›› 2023, Vol. 53 ›› Issue (5): 1390-1399.doi: 10.13229/j.cnki.jdxbgxb.20220603

• 交通运输工程·土木工程 • 上一篇

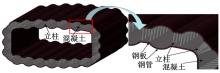

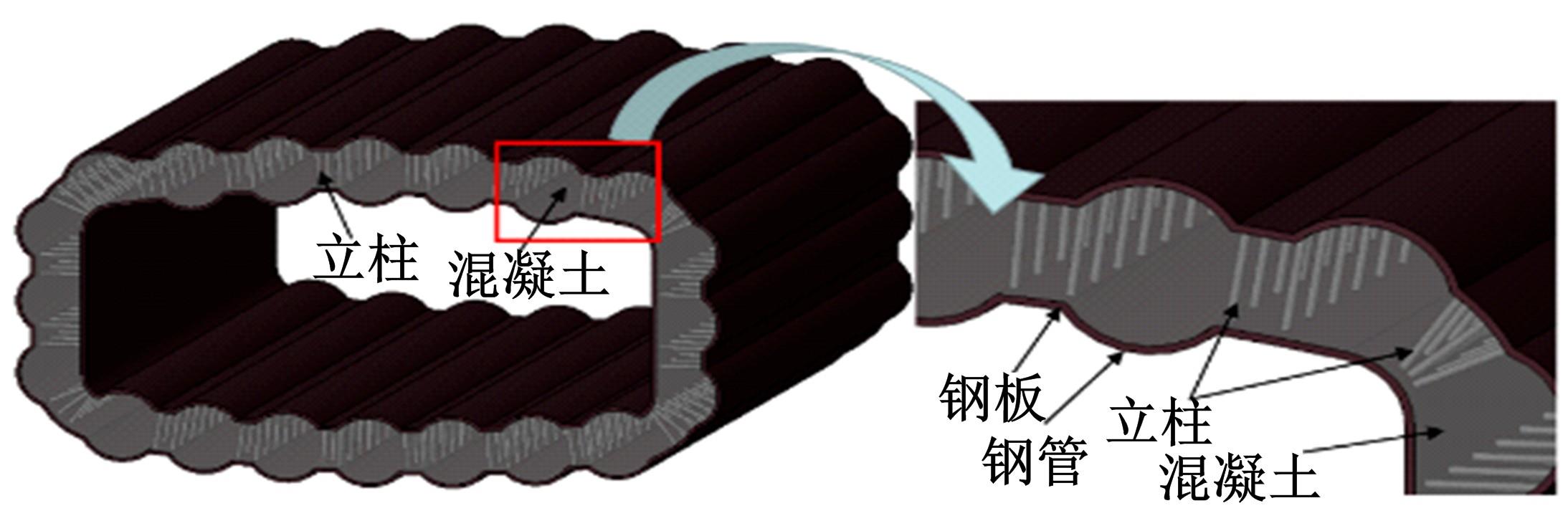

管幕预筑结构构件受弯性能试验

张艳青1,2( ),吕宇宣2,韩石2,3(

),吕宇宣2,韩石2,3( ),尤龙飞2,曾俊2,侯飞阳2

),尤龙飞2,曾俊2,侯飞阳2

- 1.道路与铁道工程安全保障省部共建教育部重点实验室(石家庄铁道大学),石家庄 050043

2.石家庄铁道大学 土木工程学院,石家庄 050043

3.新疆生产建设兵团兴新职业技术学院 建筑与水利工程学院,新疆维吾尔自治区 铁门关 841007

Experimental research on flexural performance of tubular roof prefabricated structural components

Yan-qing ZHANG1,2( ),Yu-xuan LYU2,Shi HAN2,3(

),Yu-xuan LYU2,Shi HAN2,3( ),Long-fei YOU2,Jun ZENG2,Fei-yang HOU2

),Long-fei YOU2,Jun ZENG2,Fei-yang HOU2

- 1.Key Laboratory of Roads and Railway Engineering Safety Control (Shijiazhuang Tiedao University),Ministry of Education,Shijiazhuang 050043,China

2.School of Civil Engineering,Shijiazhuang Tiedao University,Shijiazhuang 050043,China

3.School of Architecture and Water Conservancy Engineering,Bingtuan Xingxin Vocational and Technical College,Tiemenguan 841007,China

摘要:

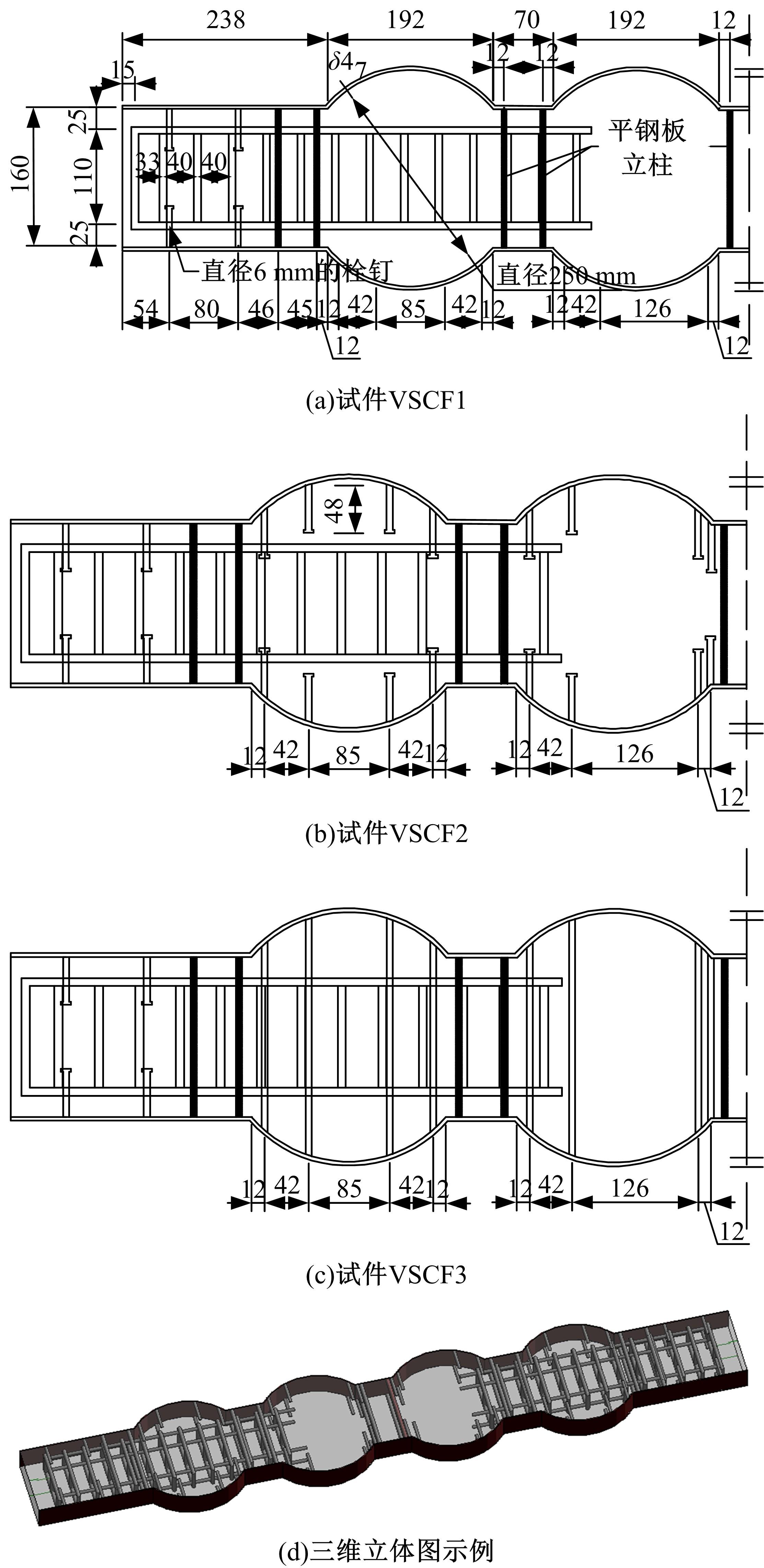

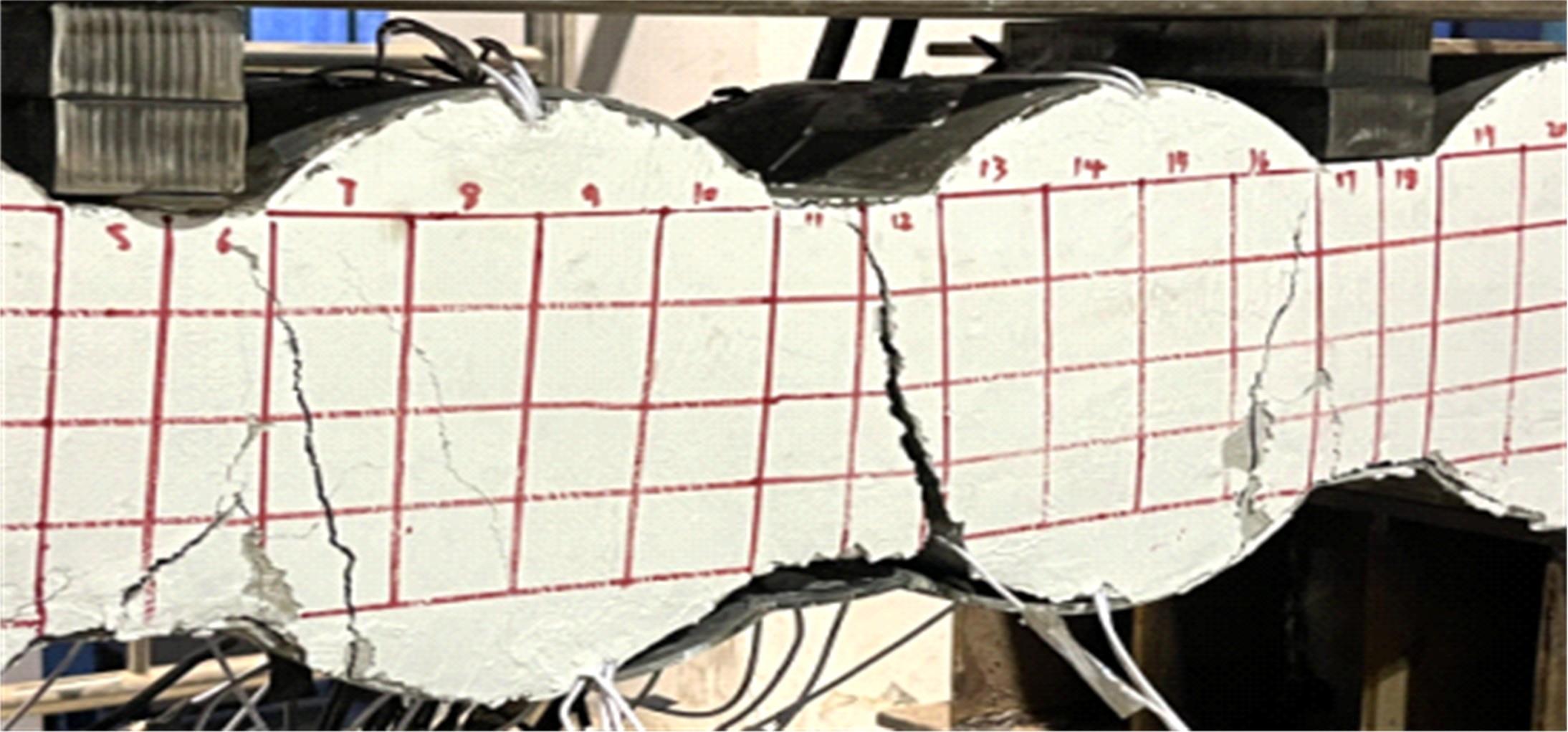

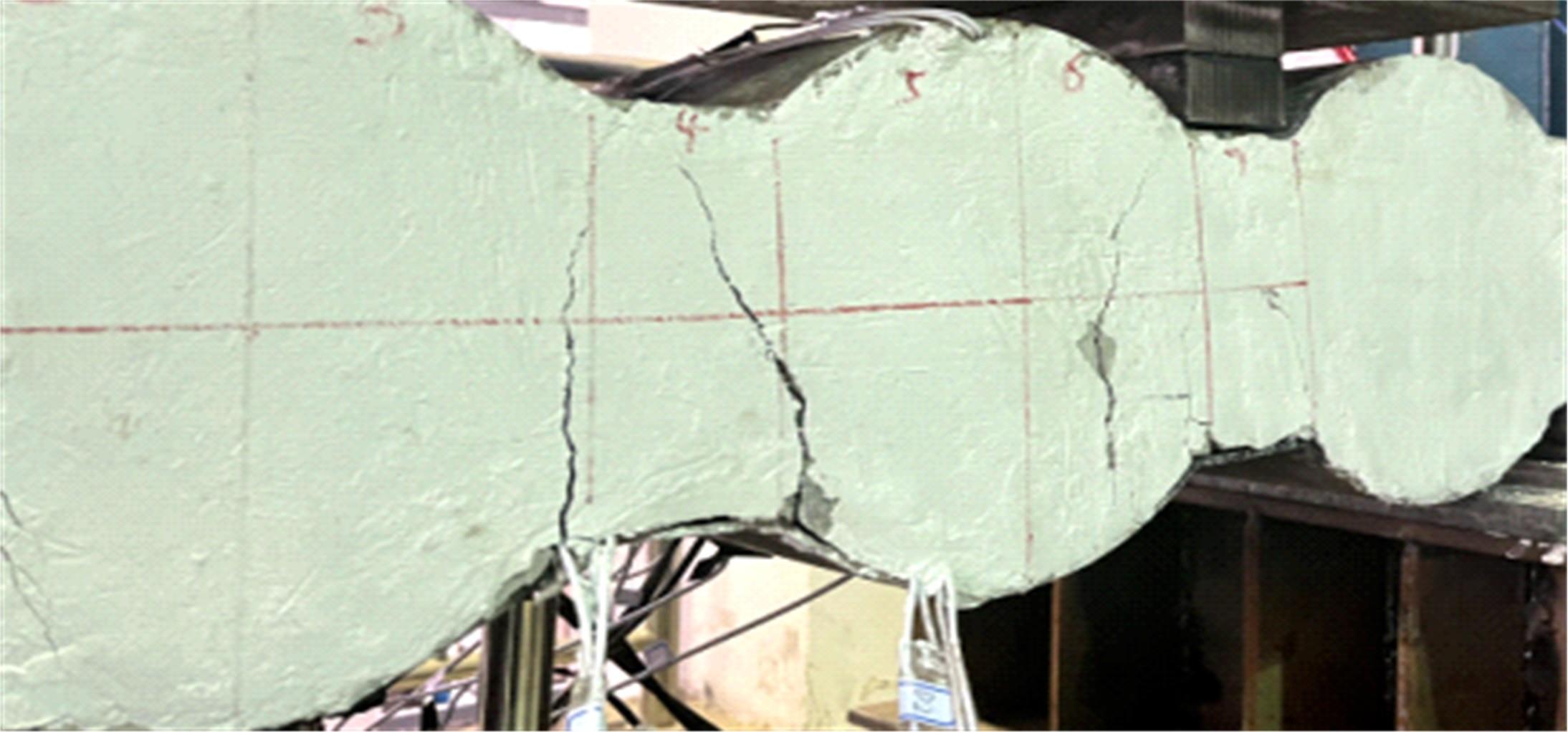

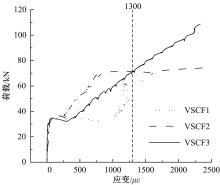

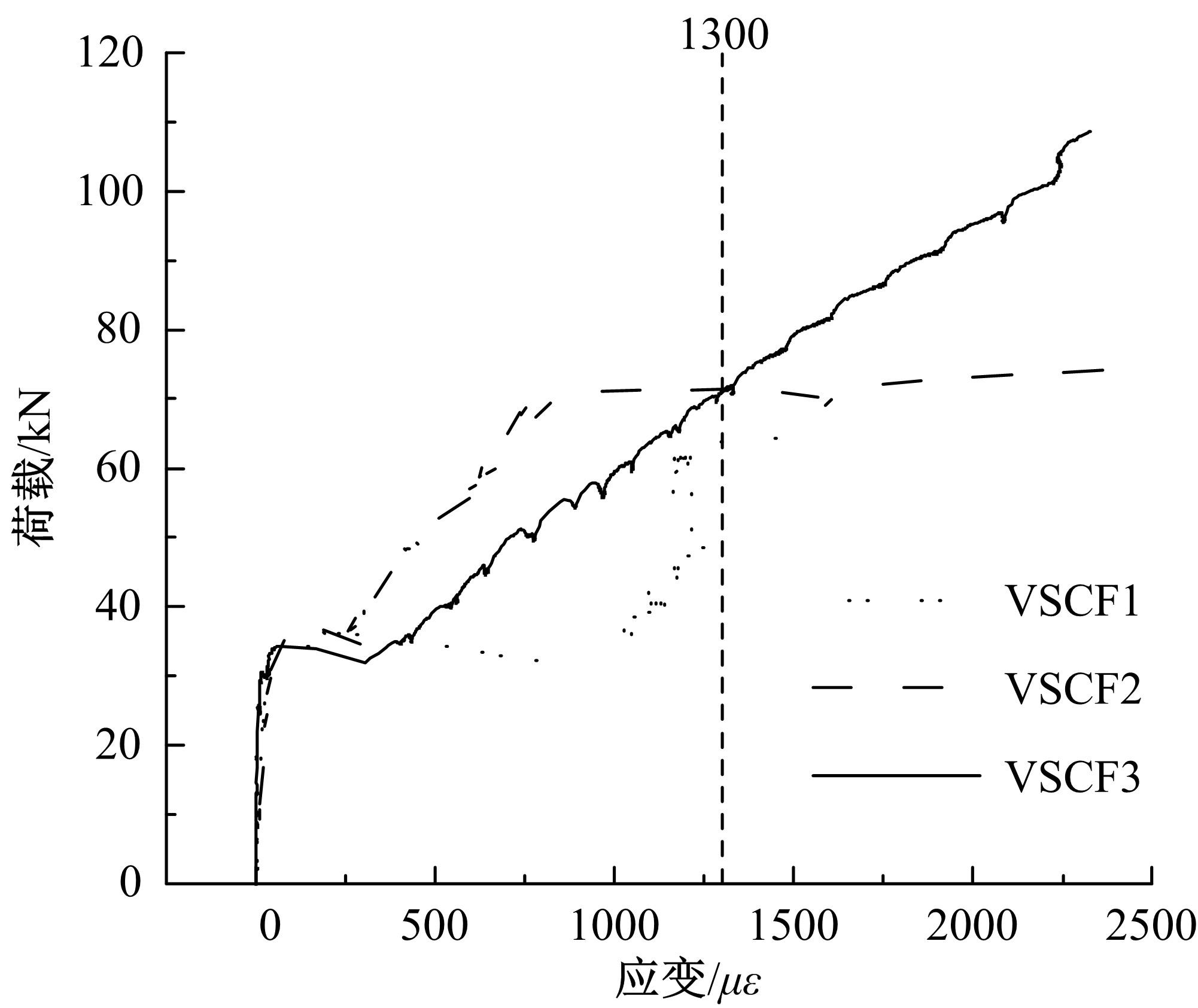

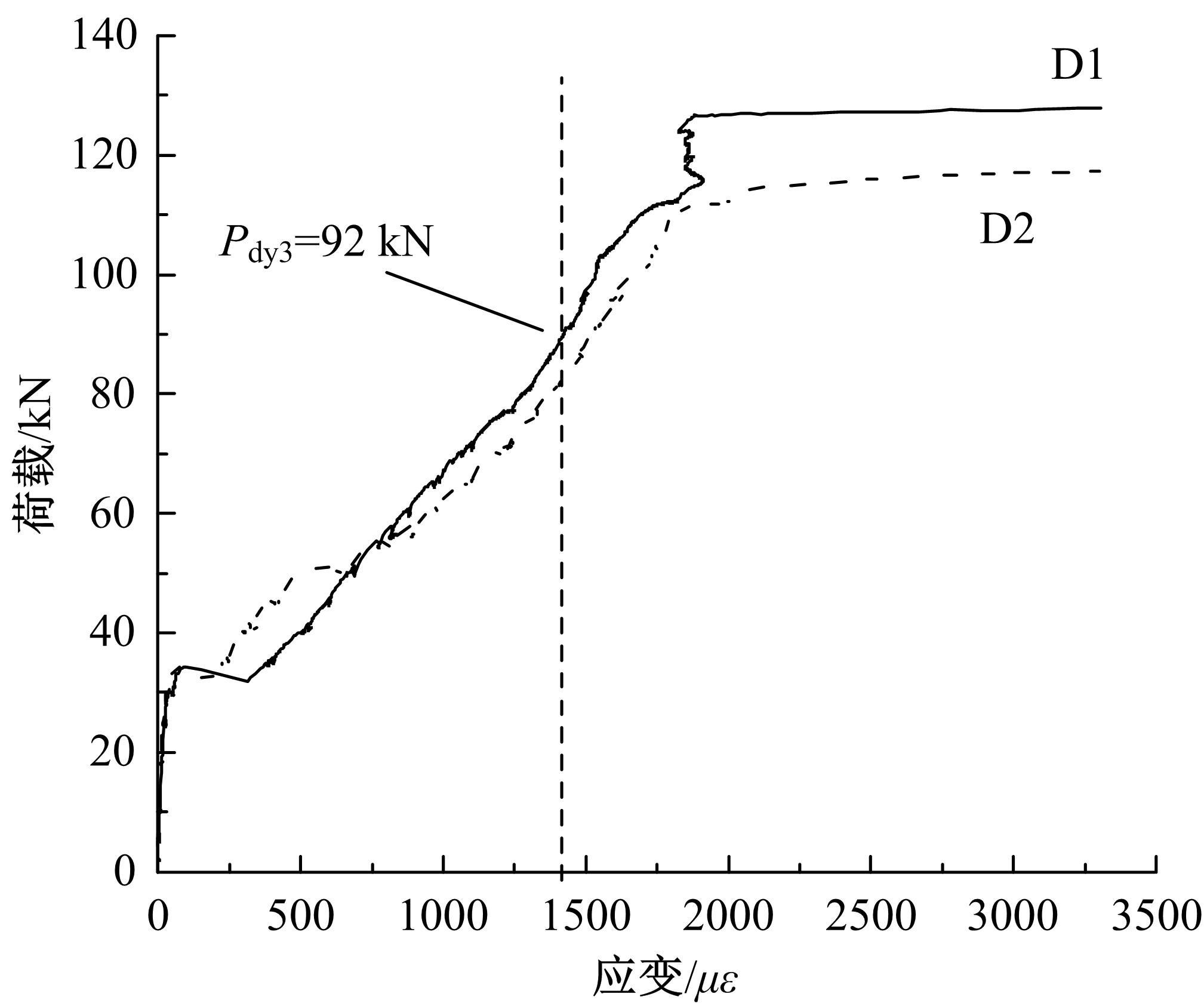

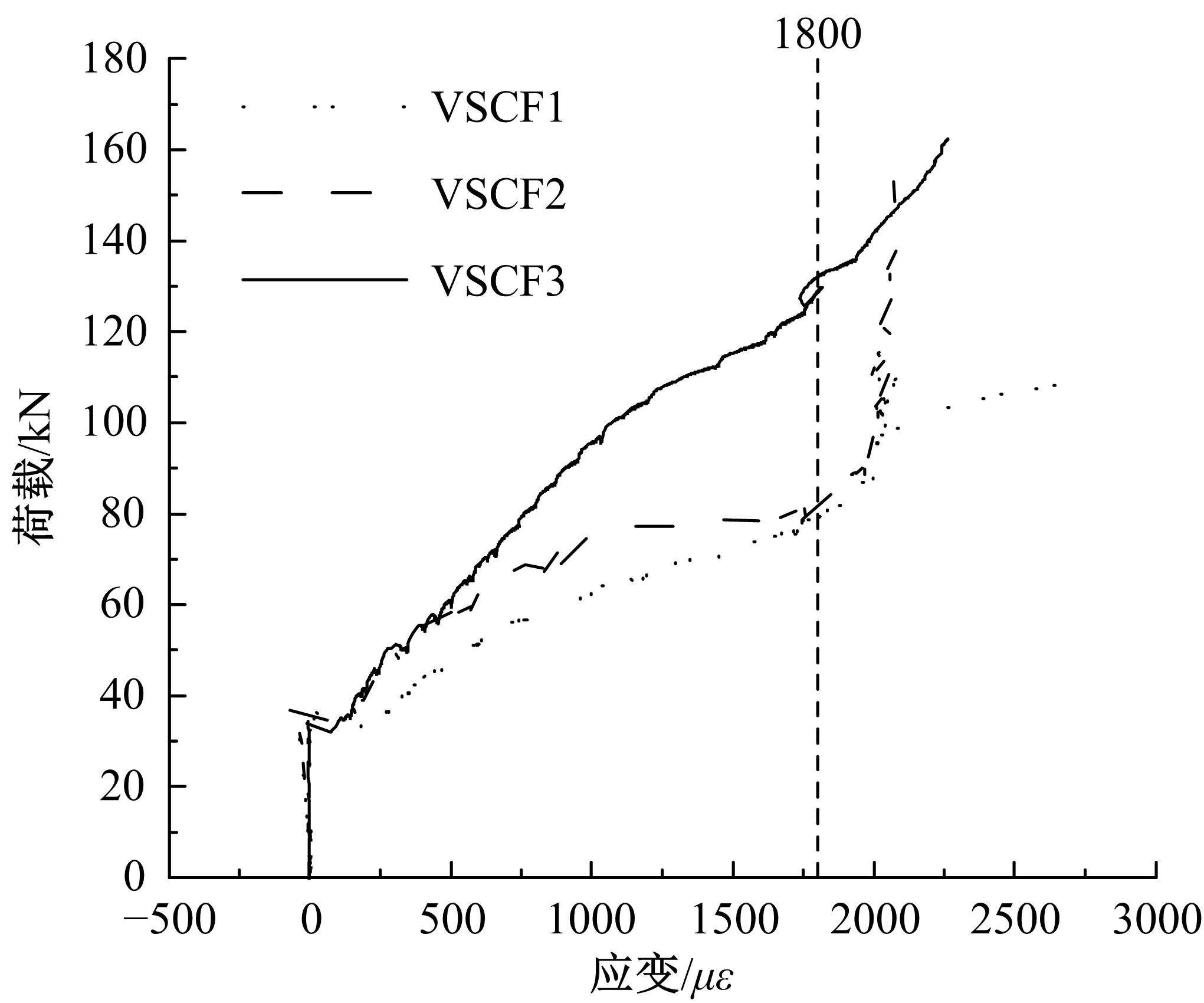

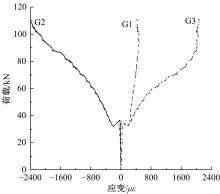

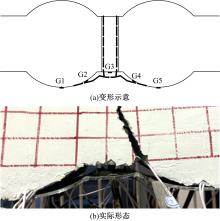

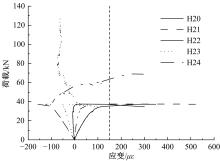

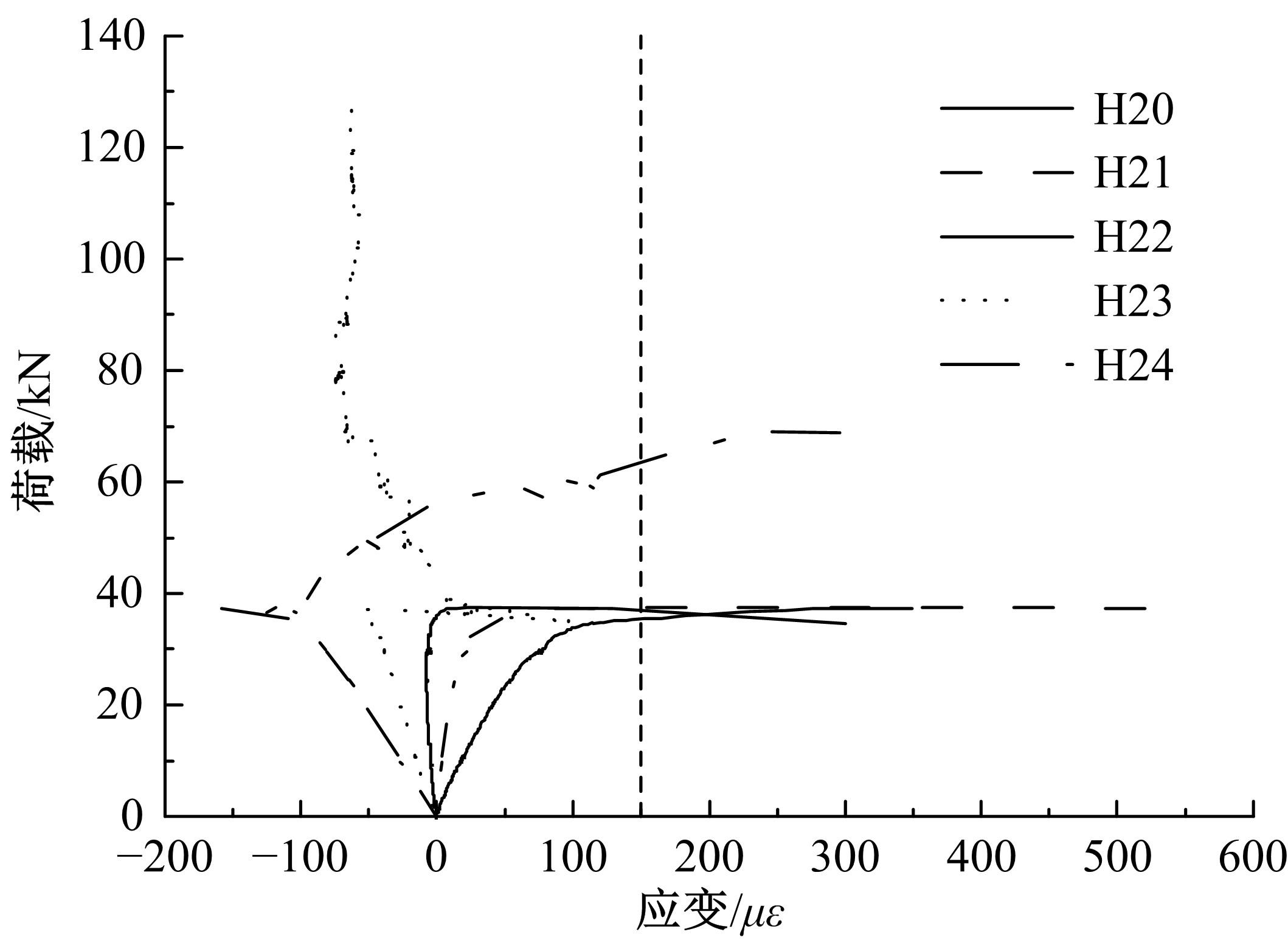

以连接件设置为参数,对管幕预筑结构构件的受弯性能进行试验研究,通过观察试件的裂缝发展及破坏形态,量测试件的荷载、挠度、应变,研究管幕预筑结构的受力机理,分析连接件的设置对管幕预筑结构构件受弯性能的影响。试验结果表明:管幕预筑结构受弯构件与等截面双钢板混凝土受弯构件的破坏过程及受力机理有较大差别,其破坏一般出现在钢管与平钢板相交的位置,源于钢管幕在弧形钢管与平钢板相交的凹角处有被拉平的趋势,破坏始于对拉筋及立柱的屈服,终于钢管幕与混凝土完全分离后钢板的屈服;设置对拉钢筋连接件可大幅度提升管幕预筑结构受弯构件的力学性能。

中图分类号:

- TU375.1

| 1 | 李积栋, 油新华, 肖龙鸽. 地下工程支护-结构一体管幕预筑法技术及发展[J]. 隧道建设, 2018, 38(3): 456-460. |

| Li Ji-dong, You Xin-hua, Xiao Long-ge. Technology and development of support-structure integral pipe-roofing pre-construction method for underground works[J]. Tunnel Construction, 2018, 38(3): 456-460. | |

| 2 | Wright H D, Oduyemi T O S, Evans H R. The experimental behaviour of double skin composite elements[J]. Journal of Constructional Steel Research, 1991, 19(2): 97-110. |

| 3 | Roberts T M, Dogan O. Fatigue of welded stud shear connectors in steel-concrete-steel sandwich beams[J]. Journal of Constructional Steel Research, 1998, 45(3): 301-320. |

| 4 | 聂建国, 赵洁. 钢板-混凝土组合简支梁的试验研究[J]. 土木工程学报, 2008(12): 28-34. |

| Nie Jian-guo, Zhao Jie. Experimental study on simply supported steel plate-concrete composite beams[J]. China Civil Engineering Journal, 2008(12): 28-34. | |

| 5 | 吴丽丽, 姜宇鹏, 张栋栋, 等. 简支钢板-混凝土组合板受弯性能及承载力分析[J]. 建筑结构学报, 2015, 36(12): 125-134. |

| Wu Li-li, Jiang Yu-peng, Zhang Dong-dong, et al. Flexural behavior and bearing capacity of simply supported steel plate-concrete composite slab[J]. Journal of Building Structures, 2015, 36(12): 125-134. | |

| 6 | 张彦玲, 孙瞳, 侯忠明, 等. 隔板式钢-混凝土曲线组合梁弯扭性能[J]. 吉林大学学报: 工学版, 2015, 45(4):1107-1114. |

| Zhang Yan-ling, Sun Tong, Hou Zhong-ming, et al. Bending-torsion characteristics of steel-concrete curved composite beams stiffened with diaphragms[J]. Journal of Jilin University(Engineering and Technology Edition), 2015, 45(4): 1107-1114. | |

| 7 | 陈俊, 倪家贵, 刘哲, 等. 拉筋约束薄壁方钢管混凝土短柱轴压性能[J]. 吉林大学学报: 工学版, 2023, 53(1): 170-177. |

| Chen Jun, Ni Jia-gui, Liu Zhe, et al. Axial compression performance of thin⁃walled concrete⁃filled square steel tube short columns confined by stirrup[J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(1): 170-177. | |

| 8 | 雷升祥, 张艳青, 刘勇, 等. 双钢板-混凝土组合构件面外受力性能研究综述[J]. 建筑结构, 2022, 52(13): 32-42. |

| Lei Sheng-xiang, Zhang Yan-qing, Liu Yong, et al. Review of study on the out-of-plane mechanical performance of steel-concrete-steel sandwich composite members[J]. Building Structure, 2022, 52(13): 32-42. | |

| 9 | 阎石, 王健, 金春福, 等. 新管幕肋梁结构体系抗弯性能试验[J]. 沈阳建筑大学学报: 自然科学版, 2011, 27(2): 242-246. |

| Yan Shi, Wang Jian, Jin Chun-fu, et al. Experimental study on flexural behavior of NTR structures[J]. Joumal of Shenyang Jianzhu University(Natural Science), 2011, 27(2): 242-246. | |

| 10 | 贾鹏蛟, 赵文, 关永平, 等. STS新管幕构件抗弯性能试验研究及数值模拟[J]. 中南大学学报: 自然科学版, 2016, 47(8): 2738-2746. |

| Jia Peng-jiao, Zhao Wen, Guan Yong-ping, et al. Numerical simulation and experimental study on flexural behavior of steel tube slab members[J]. Journal of Central South University(Science and Technology), 2016, 47(8): 2738-2746. | |

| 11 | 贾鹏蛟, 史培新, 关永平, 等. STS管幕结构横向抗弯刚度计算模型及参数优化[J]. 东北大学学报: 自然科学版, 2021, 42(8): 1159-1165. |

| Jia Peng-jiao, Shi Pei-xin, Guan Yong-ping, et al.Calculation model of flexural stiffness of STS structure and parameters optimization[J]. Journal of Northeastern University(Natural Science), 2021, 42(8): 1159-1165. | |

| 12 | , 核电站钢板混凝土结构技术标准 [S]. |

| 13 | Yang Y, Liu J, Fan J. Buckling behavior of double-skin composite walls: an experimental and modeling study[J]. Journal of Constructional Steel Research, 2016, 121: 126-135. |

| 14 | , 混凝土结构试验方法标准 [S]. |

| [1] | 匡亚川,陈立斌,李超举,贺宇豪. 栓钉剪力连接件力学性能分析[J]. 吉林大学学报(工学版), 2023, 53(2): 538-546. |

| [2] | 王毅红,田桥罗,兰官奇,姚圣法,张建雄,刘喜. 630 MPa高强钢筋混凝土大偏压柱受力性能试验[J]. 吉林大学学报(工学版), 2022, 52(11): 2626-2635. |

| [3] | 王有志,赵文帅,刘金樟,邱凯,贾森. 斜拉体系加固桥梁桥下连接件力学性能[J]. 吉林大学学报(工学版), 2022, 52(10): 2376-2384. |

| [4] | 许博,李传习. 基于灰色理论的大跨度钢管混凝土拱桥承载能力检测方法[J]. 吉林大学学报(工学版), 2022, 52(10): 2360-2366. |

| [5] | 周靖,黎亚军,赵卫锋,罗宗健,补国斌. 胶合竹板-钢管约束收尘石粉混凝土柱的偏压性能[J]. 吉林大学学报(工学版), 2021, 51(6): 2096-2107. |

| [6] | 钟昌均,王忠彬,柳晨阳. 悬索桥主索鞍承载力影响因素及结构优化[J]. 吉林大学学报(工学版), 2021, 51(6): 2068-2078. |

| [7] | 戴岩,聂少锋,周天华. 环梁式圆钢管约束H型钢混凝土柱-钢梁节点抗剪承载力[J]. 吉林大学学报(工学版), 2021, 51(3): 977-988. |

| [8] | 张广泰,张路杨,邢国华,曹银龙,易宝. 钢-聚丙烯混杂纤维混凝土剪力墙抗震性能[J]. 吉林大学学报(工学版), 2021, 51(3): 946-955. |

| [9] | 熊二刚,徐涵,谭赐,王婧,丁若愚. 基于弹塑性应力场理论的钢筋混凝土梁受剪承载力[J]. 吉林大学学报(工学版), 2021, 51(1): 259-267. |

| [10] | 李碧雄,廖桥,章一萍,周练,隗萍,刘侃. 超高强钢筋工程用水泥基复合材料梁受弯计算理论[J]. 吉林大学学报(工学版), 2019, 49(4): 1153-1161. |

| [11] | 万世成,黄侨,关健,郭赵元. 预应力碳纤维板加固钢⁃混凝土组合连续梁负弯矩区试验[J]. 吉林大学学报(工学版), 2019, 49(4): 1114-1123. |

| [12] | 刘志峰, 赵代红, 王语莫, 浑连明, 赵永胜, 董湘敏. 重载静压转台承载力与油垫温度场分布的关系[J]. 吉林大学学报(工学版), 2018, 48(3): 773-780. |

| [13] | 刘志峰, 浑连明, 殷亚文, 王建华, 罗宗兰, 董湘敏. 考虑离心力的定量式扇形静压转台承载力建模[J]. 吉林大学学报(工学版), 2017, 47(6): 1791-1795. |

| [14] | 郭楠, 张平阳, 左煜, 左宏亮. 竹板增强胶合木梁受弯性能[J]. 吉林大学学报(工学版), 2017, 47(3): 778-788. |

| [15] | 杨昕卉, 薛伟, 郭楠. 钢板增强胶合木梁的抗弯性能[J]. 吉林大学学报(工学版), 2017, 47(2): 468-477. |

|

||