吉林大学学报(工学版) ›› 2023, Vol. 53 ›› Issue (5): 1400-1410.doi: 10.13229/j.cnki.jdxbgxb.20210883

• 交通运输工程·土木工程 • 上一篇

摩擦耗能型翼缘削弱式钢梁连接的承载性能

王卫华1,2( ),朱勇斌1,3,祁神军1,霍静思1,2(

),朱勇斌1,3,祁神军1,霍静思1,2( ),郭秀泉1,2,钟振安4

),郭秀泉1,2,钟振安4

- 1.华侨大学 土木工程学院,福建 厦门 361021

2.华侨大学 厦门市抗火综合防灾工程技术研究中心,福建 厦门 361021

3.福建省燕城建设工程有限公司,福建 厦门 361016

4.厦门灏森幕墙装饰工程有限公司,福建 厦门 361009

Mechanical behavior on friction energy dissipation reduced beam section connection of steel beams

Wei-hua WANG1,2( ),Yong-bin ZHU1,3,Shen-jun QI1,Jing-si HUO1,2(

),Yong-bin ZHU1,3,Shen-jun QI1,Jing-si HUO1,2( ),Xiu-quan GUO1,2,Zhen-an ZHONG4

),Xiu-quan GUO1,2,Zhen-an ZHONG4

- 1.College of Civil Engineering,Huaqiao University,Xiamen 361021,China

2.Xiamen Engineering Research Center for Fire Resistance and Disaster Prevention,Huaqiao University,Xiamen 361021,China

3.Fujian Yancheng Construction Engineering Co. ,Ltd. ,Xiamen 361016,China

4.Xiamen Hansen Curtain Wall Decoration Engineering Co. ,Ltd. ,Xiamen 361009,China

摘要:

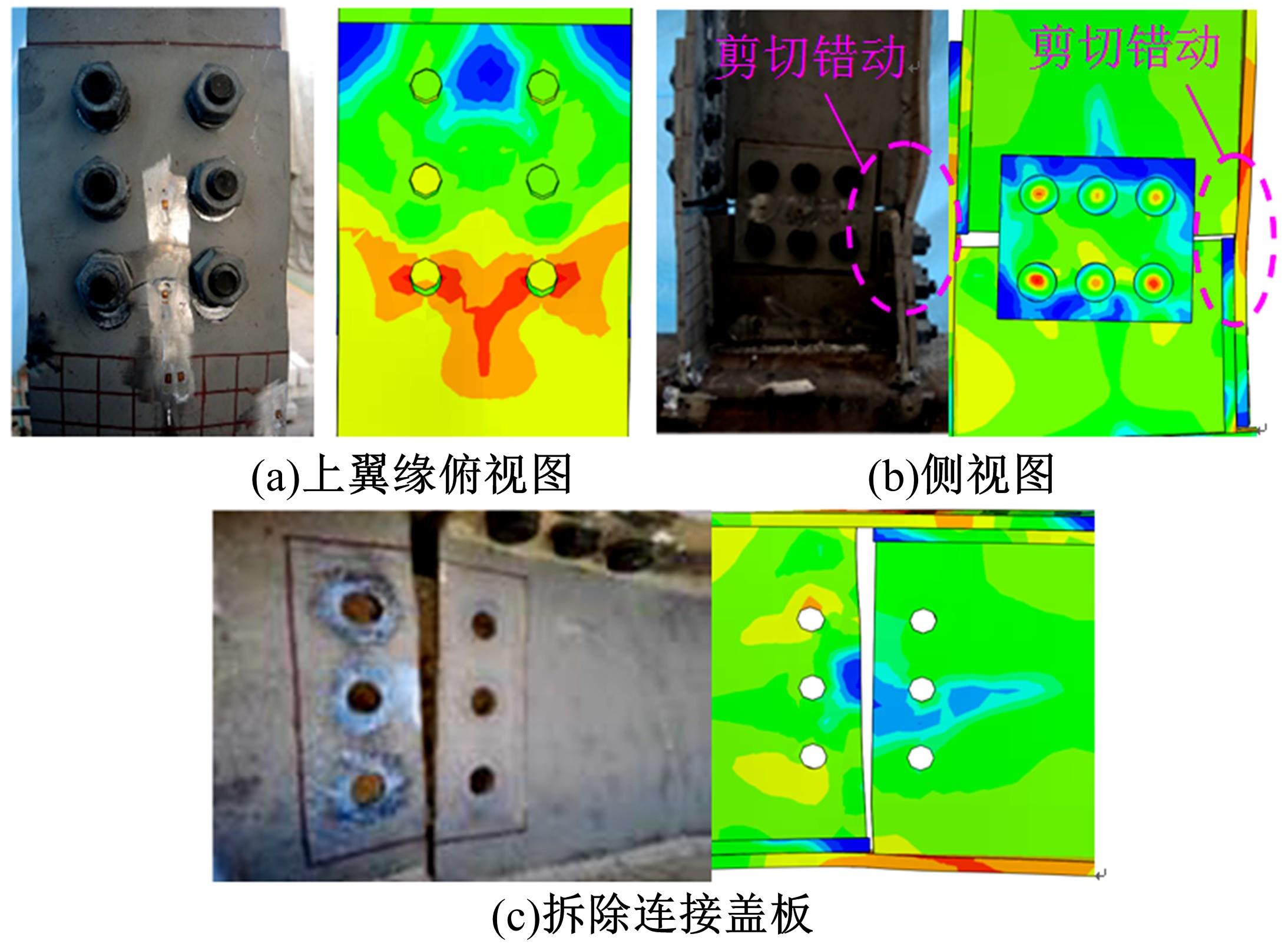

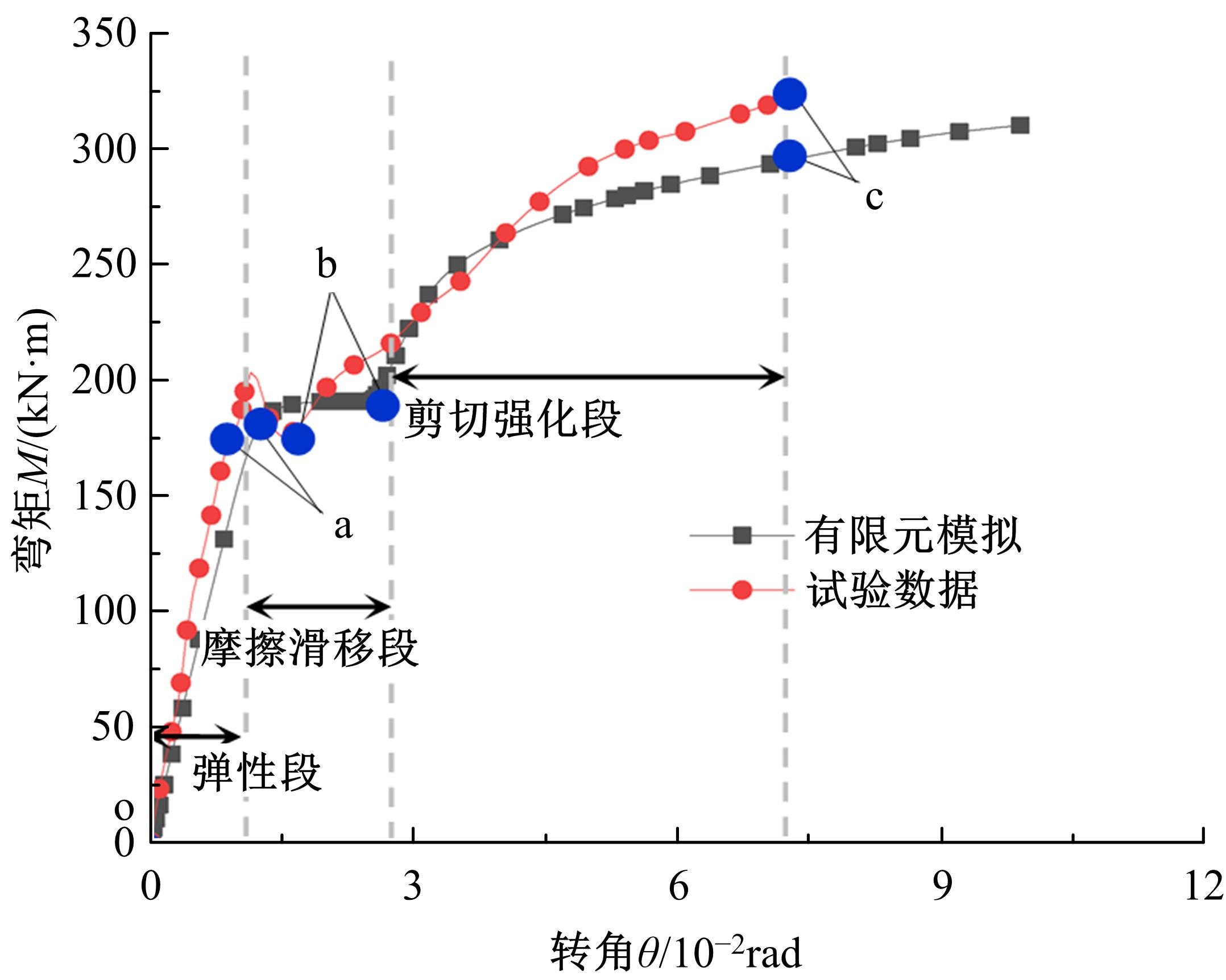

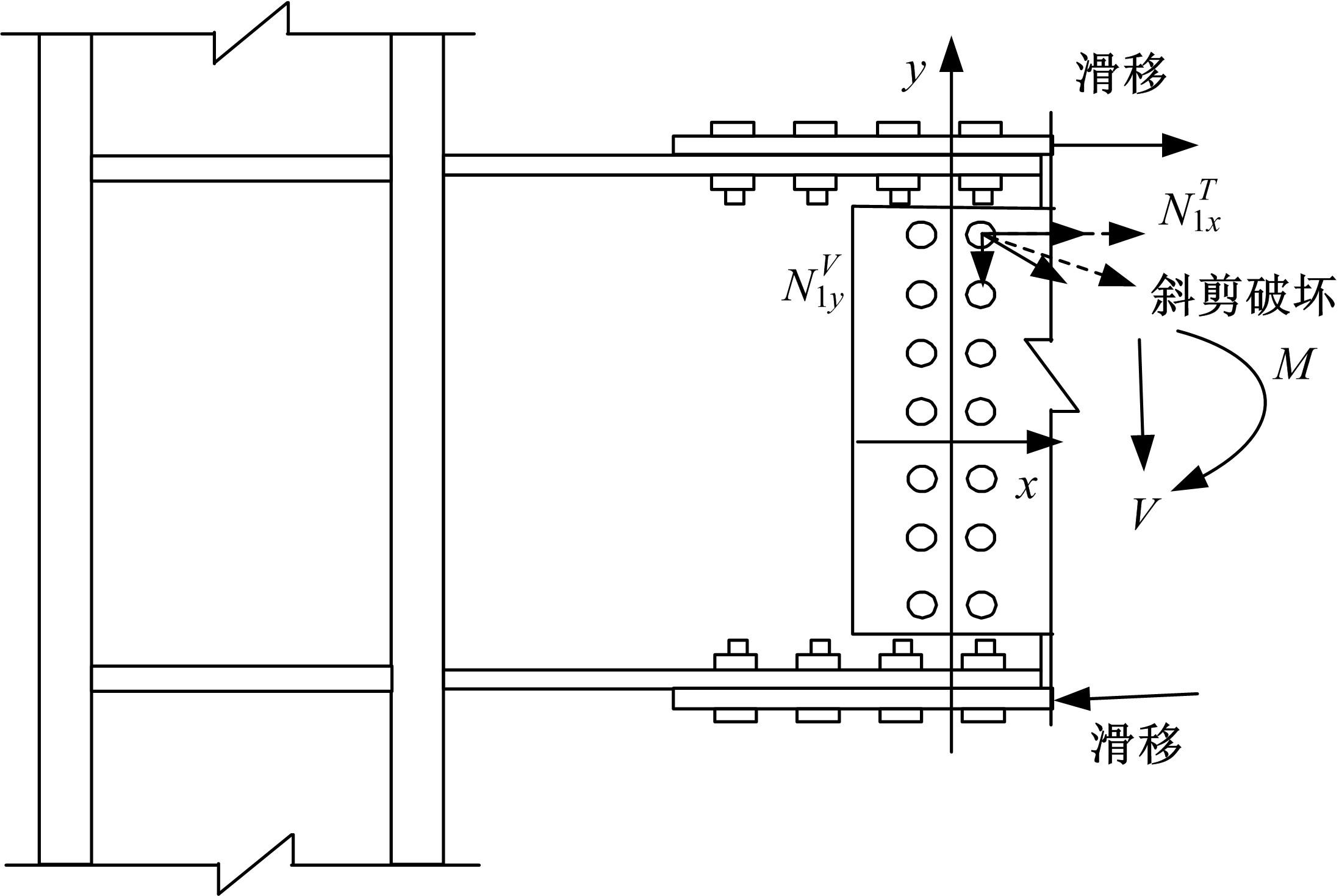

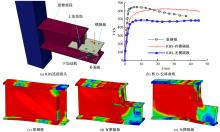

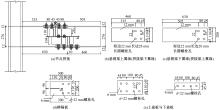

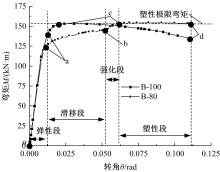

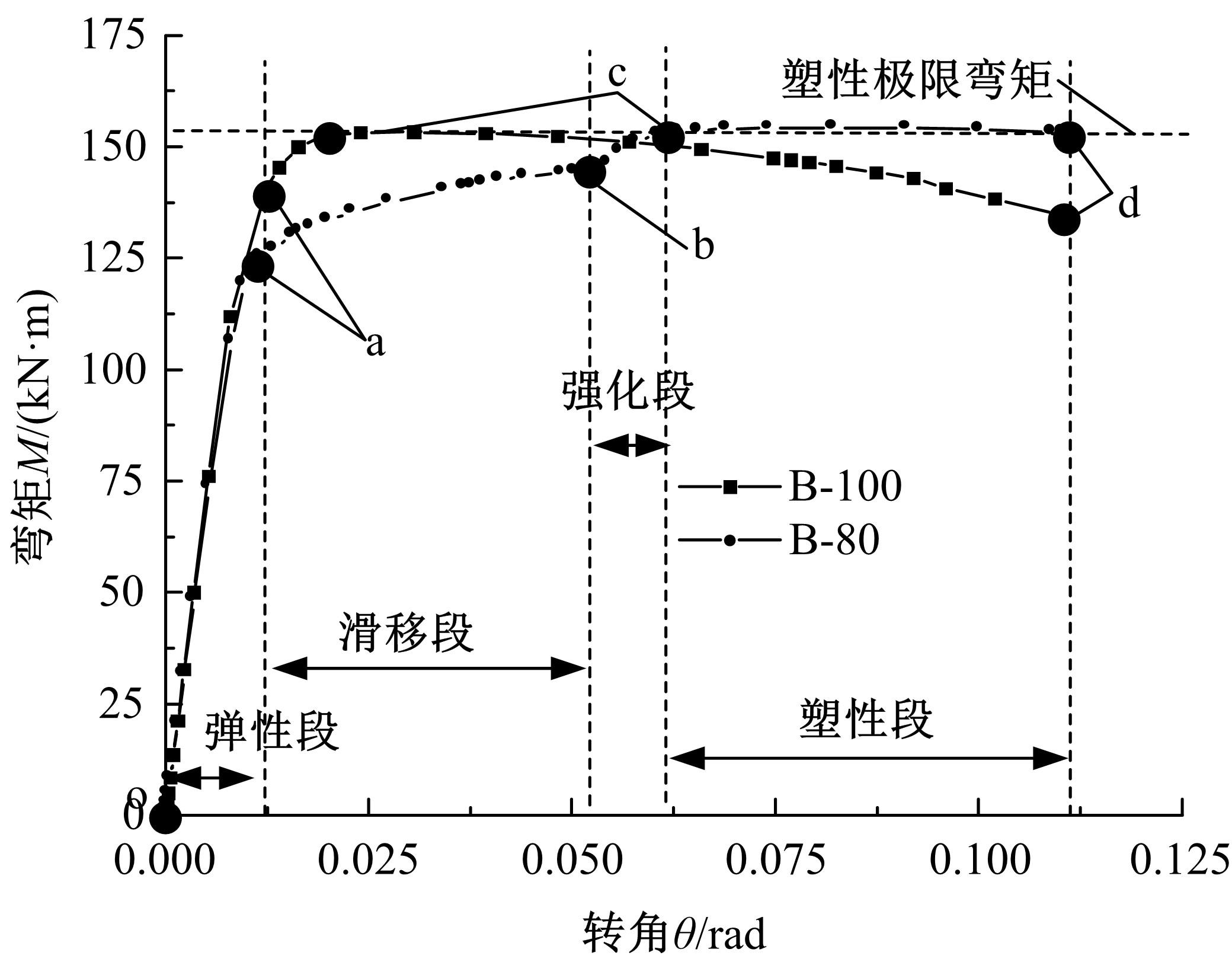

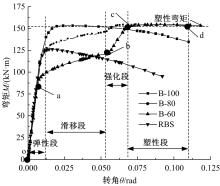

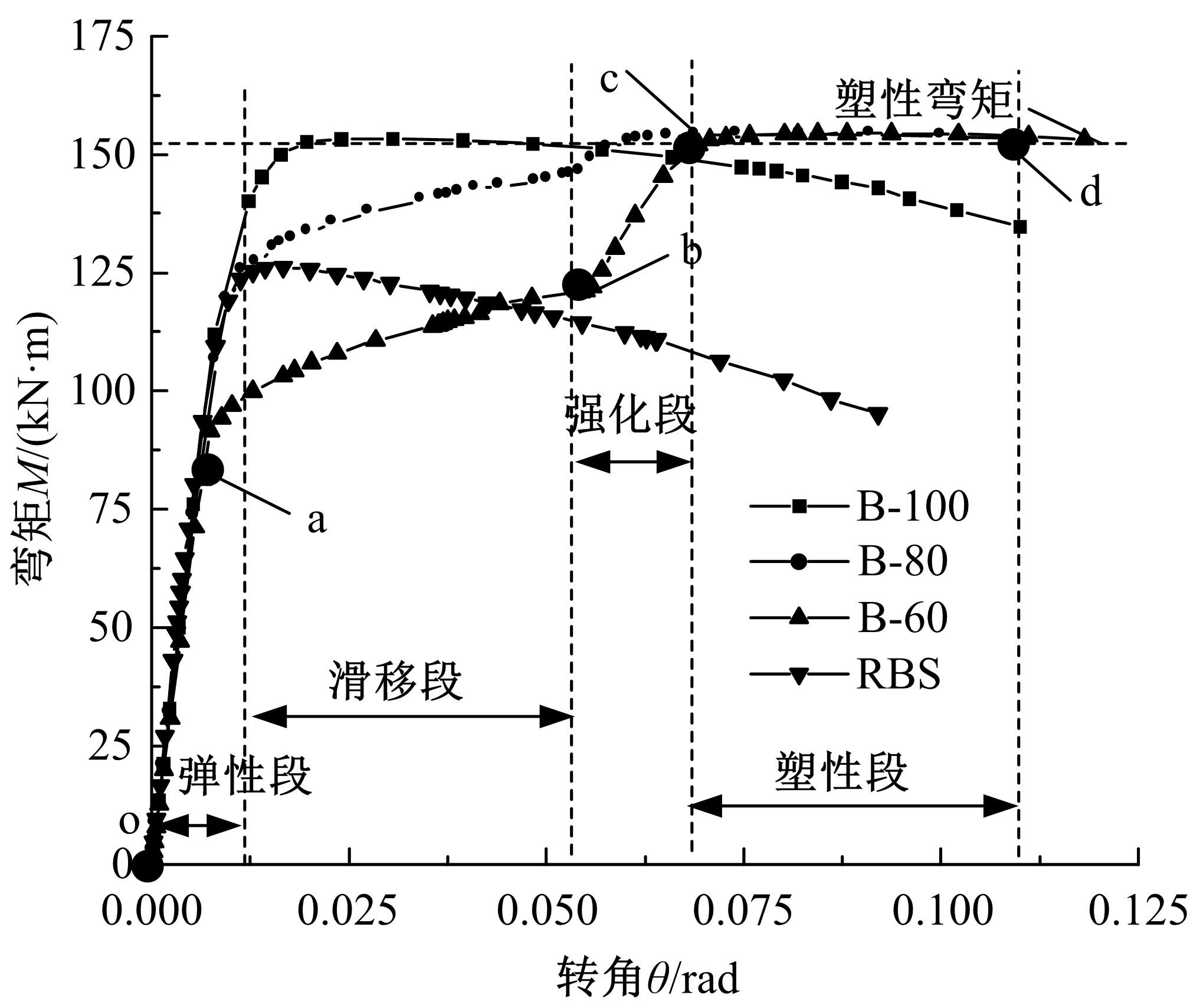

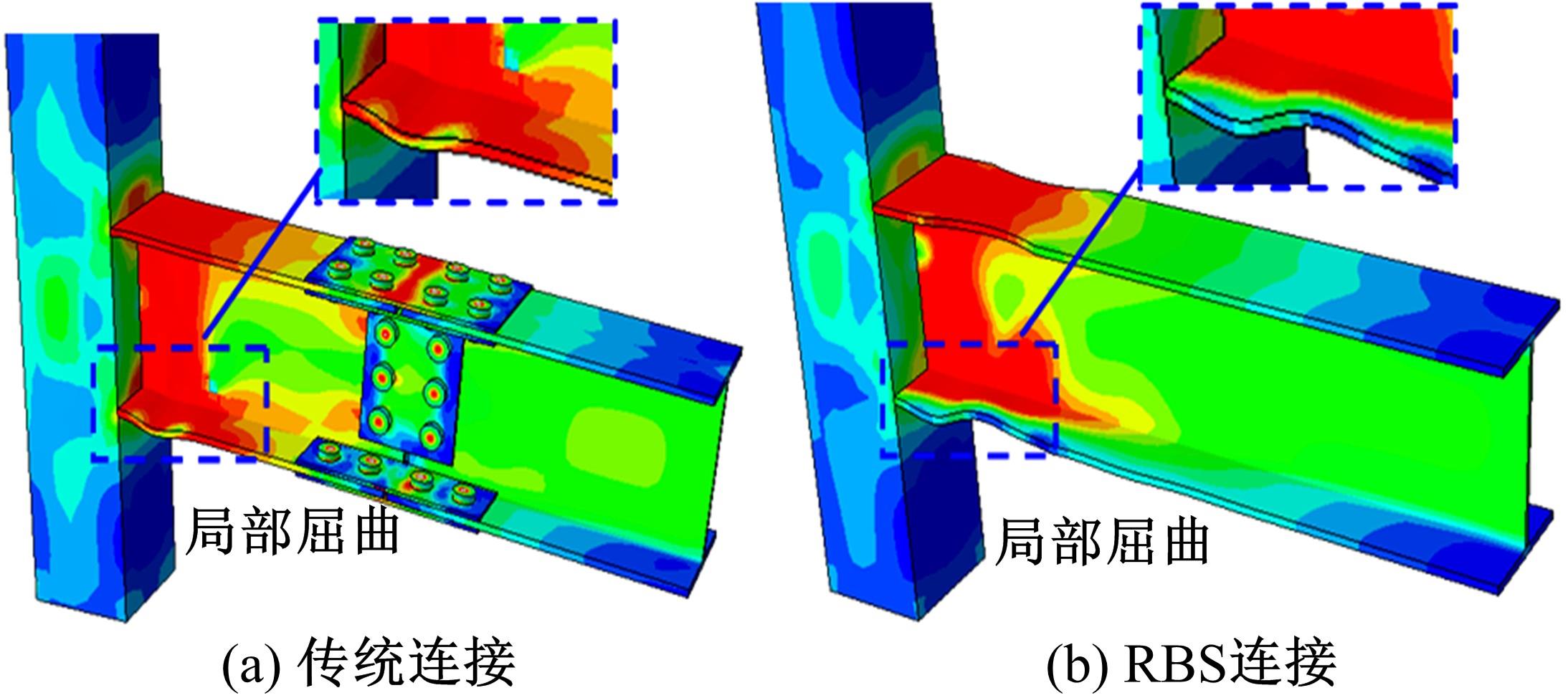

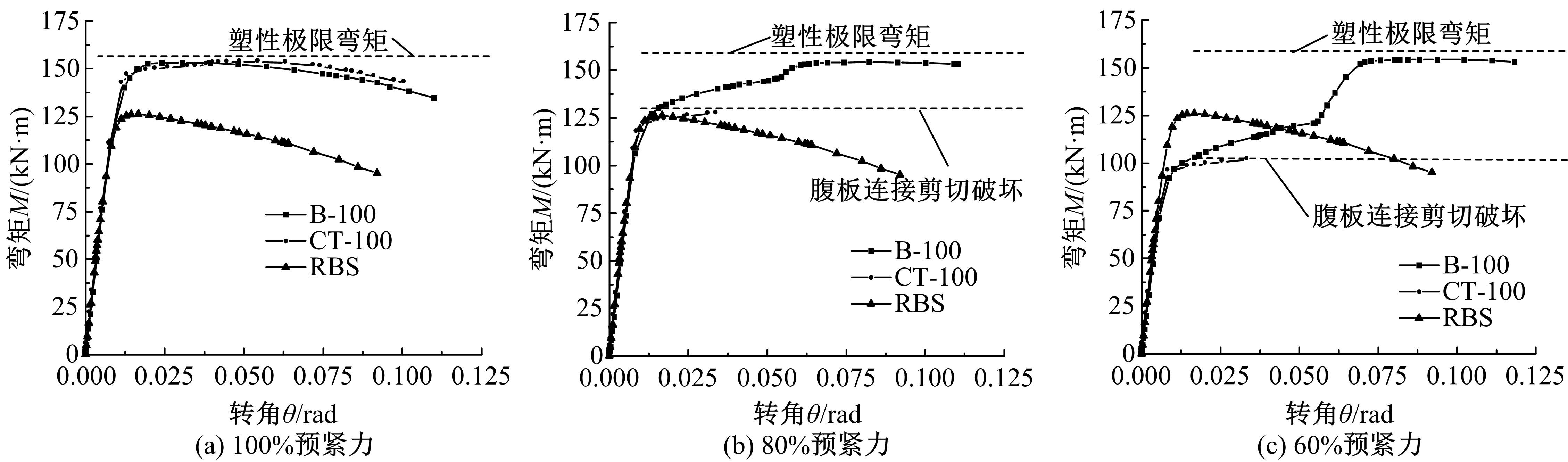

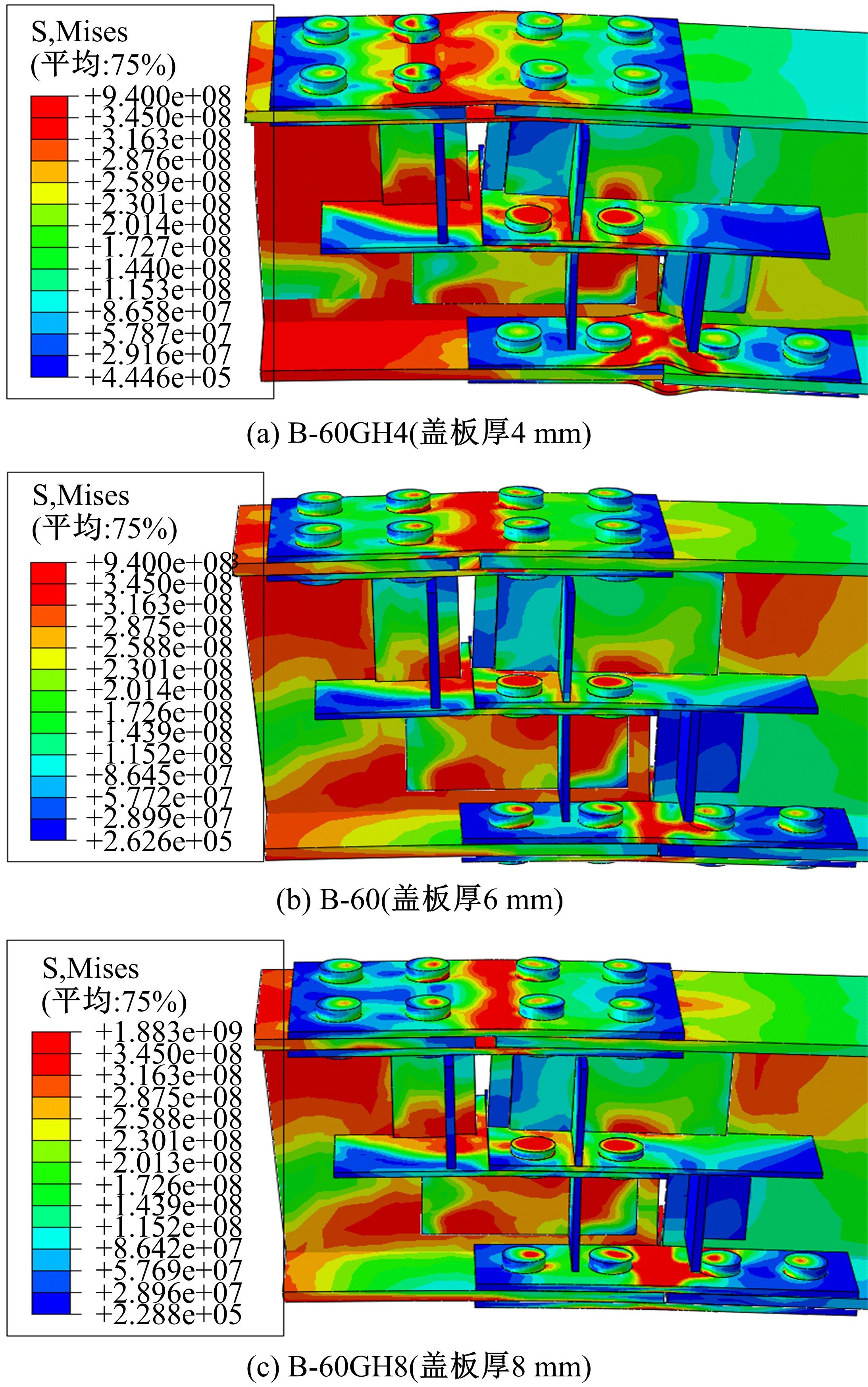

提出一种摩擦耗能型翼缘削弱式(RBS)钢梁高强螺栓的连接形式,可实现塑性铰外移的效果。由设置在钢梁腹板中部的横隔板和腹板共同组成H型凸起抵抗剪力,不仅节省了钢梁腹板位置的大量抗剪螺栓群,在钢梁吊装时还可作为搭接平台,实现钢梁的快速安装。在H型钢梁摩擦型高强螺栓连接试验验证的基础上,利用ABAQUS有限元软件建立了摩擦型RBS钢梁连接的数值模型。与传统钢梁连接形式相比,摩擦型RBS钢梁连接的受力过程可分为:弹性阶段、滑移阶段、强化阶段和塑性阶段,在摩擦滑移阶段和全截面屈服阶段可形成2级耗能机制。改变翼缘螺栓预紧力、盖板厚度、翼缘厚度以及钢材强度等参数,对摩擦型RBS钢梁连接的工作机理和承载性能变化规律进行分析。摩擦型RBS钢梁连接具有良好的承载力和塑性转动能力,可得到与骨式翼缘RBS钢梁相似的塑性铰外移的效果,且转角延性系数由1.7提高到12。摩擦型RBS钢梁连接滑移阶段的抗弯承载力主要与翼缘螺栓群的极限摩阻力相关,而塑性阶段极限抗弯承载力则与螺栓强度、栓杆直径以及钢梁塑性极限弯矩等因素相关。

中图分类号:

- TU391

| 1 | 黄炳生.日本神户地震中建筑钢结构的震害及启示[J]. 建筑结构, 2000, 30(9): 24-25. |

| Huang Bing-sheng. Earthquake damage of steel structure in Kobe earthquake and its enlightenment[J]. Building Structure, 2000, 30(9): 24-25. | |

| 2 | 周福霖, 李振宝, 安部重孝, 等. 东日本大地震灾害考察报告[J]. 建筑结构, 2012, 42(4): 1-20. |

| Zhou Fu-lin, Li Zhen-bao, Shigetakas A B E, et al. Inspection report of the disaster of the east Japan earthquake by Sino-Japanese joint mission[J]. Building Structure, 2012, 42(4): 1-20. | |

| 3 | Lee C H, Kim J H. Seismic design of reduced beam section(RBS) steel moment connections with bbolted web attachment[J]. Journal of Constructional Steel Research, 2007, 63(4): 522-531. |

| 4 | Chen C C, Lin C C. Seismic performance of steel beam-to-column moment connections with tapered beam flanges[J]. Engineering Structures, 2013, 48: 588-601. |

| 5 | 刘占科, 苏明周, 申林, 等. 钢结构梁端翼缘腋形扩大式刚性梁柱连接试验研究[J]. 建筑结构学报, 2007, 28(3): 8-14. |

| Liu Zhan-ke, Su Ming-zhou, Shen Lin, et al. Experimental study on steel moment resistant frame connections with enlarged beam flange welded to column[J]. Journal of Building Structures, 2007, 28(3): 8-14. | |

| 6 | 戴岩, 聂少锋, 周天华.带环梁的方钢管约束钢骨混凝土柱-钢梁节点滞回性能有限元分析[J].吉林大学学报: 工学版, 2018, 48(5): 1426-1435. |

| Dai Yan, Nie Shao-feng, Zhou Tian-hua. Finite element analysis of hysteretic behavior of square steel tube confined steel reinforced concrete column steel frame ring beam joint[J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(5): 1426-1435. | |

| 7 | 苟海刚, 刘杰, 卢林枫. 箱形节点域H形柱弱轴削弱型连接的设计方法[J]. 钢结构, 2018, 33(8): 62-66. |

| Gou Hai-gang, Liu Jie, Lu Lin-feng. Design method of weak axis RBS connection of H-section column with box-shaped panel zone[J]. Steel Construction, 2018, 33(8): 62-66. | |

| 8 | 郁有升, 王燕. 钢框架梁翼缘削弱型节点力学性能的试验研究[J]. 工程力学, 2009, 26(2): 168-175. |

| Yu You-sheng, Wang Yan. Experimental study on the mechanical property of reduced beam section connections of steel frames[J]. Engineering Mechanics, 2009, 26(2): 168-175. | |

| 9 | FEMA 350. Recommended seismic design criteria for new steel moment-frame buildings[R]. Washington DC: SAC Joint Venture, 2000. |

| 10 | 高强, 黄天立, 陈龙, 等. 螺栓超欠拧对钢桁梁桥节点拼接接头受力的影响[J]. 中南大学学报: 自然科学版, 2019, 50(10): 163-173. |

| Gao Qiang, Huang Tian-li, Chen Long, et al. Influence of over-under-tightening of bolts on mechanical properties of connections of steel truss girder bridge[J]. Journal of Central South University(Science and Technology), 2019, 50(10): 163-173. | |

| 11 | 廖静平, 张建富,郁鼎文, 等.基于虚拟梯度材料的螺栓结合面建模方法[J].吉林大学学报: 工学版, 2016, 46(4): 1149-1155. |

| Liao Jing-ping, Zhang Jian-fu, Yu Ding-wen, et al. Modeling method of bolted joint interface based on gradient virtual materials[J]. Journal of Jilin University(Engineering and Technology Edition), 2016, 46(4): 1149-1155. | |

| 12 | 兰志文, 林新鹏, 吕超, 等. 预紧力变化对高强螺栓摩擦型连接板应变分布的影响[J]. 南昌大学学报: 工科版, 2017, 39(1): 43-49. |

| Lan Zhi-wen, Lin Xin-peng, Lv Chao, et al. Influence of friction high-strength bolt connection strain distribution under varietal preload[J]. Journal of Nanchang University(Engineering&Technology), 2017, 39(1): 43-49. | |

| 13 | 张德莹. 摩擦型高强螺栓传力性能及缺失的非线性分析[J]. 广西大学学报: 自然科学版, 2015, 40(1): 19-27. |

| Zhang De-ying. Nonlinear analysis on load-transfer performance and bolt missing of frictional high strength bolted connections[J]. Journal of Guangxi University(Natural Science Edition), 2015, 40(1): 19-27. | |

| 14 | Astaneh-Asl A. Seismic Design of Steel Column-Tree Moment-Resisting Frames[M]. Moraga: Structural Steel Educational Council, 1997. |

| 15 | 李启才, 苏明周, 顾强, 等. 带悬臂梁段拼接的梁柱连接循环荷载试验研究[J]. 建筑结构学报, 2003, 24(4): 54-59. |

| Li Qi-cai, Su Ming-zhou, Gu Qiang, et al. Experimental study of beam-to-column connection with cantilever beam splicing under cyclic loading[J]. Journal of Building Structures, 2003, 24(4): 54-59. | |

| 16 | 周殿文. 树状柱框架钢梁拼接处产生塑性铰的设计方法研究[D].西安: 西安建筑科技大学土木工程学院, 2008. |

| Zhou Dian-wen. A study on design method of plastic hinge appear in the splicing location of beam in column-tree frame[D]. Xi'an: College of Civil Engineering, Xi'an University of Architecture and Technology, 2008. | |

| 17 | 张爱林, 郭志鹏, 刘学春, 等. 带Z字形悬臂梁段拼接的装配式钢框架节点抗震性能试验研究[J]. 工程力学, 2017, 34(8): 31-41. |

| Zhang Ai-lin, Guo Zhi-peng, Liu Xue-chun, et al. Experimental study on aseismic behavior of prefabricated steel-frame-joints with Z-shaped cantilever-beam splicing[J]. Engineering Mechanics, 2017, 34(8): 31-41. | |

| 18 | . 钢结构设计标准 [S]. |

| 19 | 张耀春. 钢结构设计原理[M]. 北京: 高等教育出版社, 2004. |

| 20 | 童根树, 任涛. 工字梁的抗剪极限承载力[J]. 土木工程学报, 2006(8): 60-67. |

| Tong Gen-shu, Ren Tao. Shear resistance of slender webs in I-girders[J]. China Civil Engineering Journal, 2006(8): 60-67. | |

| 21 | 冯鹏, 强翰霖, 叶列平. 材料,构件,结构的"屈服点"定义与讨论[J]. 工程力学, 2017(3): 36-46. |

| Feng Peng, Qiang Han-lin, Ye Lie-ping. Discussion and definition on yield points of materials, members and structures[J]. Engineering Mechanics, 2017(3): 36-46. | |

| 22 | 纪晓东, 马琦峰, 王彦栋, 等. 钢连梁可更换消能梁段抗震性能试验研究[J]. 建筑结构学报, 2014, 35(6): 1-11. |

| Ji Xiao-dong, Ma Qi-feng, Wang Yan-dong, et al. Cyclic tests of replaceable shear links in steel coupling beams[J]. Journal of Building Structures, 2014, 35(6): 1-11. |

| [1] | 张艳青,吕宇宣,韩石,尤龙飞,曾俊,侯飞阳. 管幕预筑结构构件受弯性能试验[J]. 吉林大学学报(工学版), 2023, 53(5): 1390-1399. |

| [2] | 闫清峰,张纪刚,王涛,陈德刚,郁有升,杨迎春. 预制预装修模块化建筑连接节点抗震性能[J]. 吉林大学学报(工学版), 2023, 53(2): 505-514. |

| [3] | 匡亚川,陈立斌,李超举,贺宇豪. 栓钉剪力连接件力学性能分析[J]. 吉林大学学报(工学版), 2023, 53(2): 538-546. |

| [4] | 陈雪云,贝学宇,姚渠,金鑫. 基于G⁃UNet的多场景行人精确分割与检测[J]. 吉林大学学报(工学版), 2022, 52(4): 925-933. |

| [5] | 王秀芳,孙双,丁春阳. 基于1D⁃RSCNN的嵌入式轴承故障实时检测[J]. 吉林大学学报(工学版), 2022, 52(2): 310-317. |

| [6] | 王有志,赵文帅,刘金樟,邱凯,贾森. 斜拉体系加固桥梁桥下连接件力学性能[J]. 吉林大学学报(工学版), 2022, 52(10): 2376-2384. |

| [7] | 庄蔚敏,陈沈,王楠. 温度对车身钢铝胶铆连接结构热应力变化的影响[J]. 吉林大学学报(工学版), 2022, 52(1): 70-78. |

| [8] | 陈剑斌,周宋泽,费峰永,陈永龙,凌国平. 过盈量及滚花方式对装配式凸轮轴压装失效的影响[J]. 吉林大学学报(工学版), 2021, 51(6): 1959-1966. |

| [9] | 院老虎,连冬杉,张亮,刘义. 基于密集连接卷积网络和支持向量机的飞行器机械部件故障诊断[J]. 吉林大学学报(工学版), 2021, 51(5): 1635-1641. |

| [10] | 郭继昌,吴洁,郭春乐,朱明辉. 基于残差连接卷积神经网络的图像超分辨率重构[J]. 吉林大学学报(工学版), 2019, 49(5): 1726-1734. |

| [11] | 马芳武,陈实现,韩露,梁鸿宇,蒲永锋. 金属表面特征与金属⁃塑料直接连接强度的相关性[J]. 吉林大学学报(工学版), 2019, 49(3): 816-821. |

| [12] | 王露,刘玉雯,陈红. 侧风下峡谷桥隧连接段汽车的行驶特性[J]. 吉林大学学报(工学版), 2019, 49(3): 736-748. |

| [13] | 庄蔚敏, 赵文增, 解东旋, 李兵. 超高强钢/铝合金热铆连接接头性能[J]. 吉林大学学报(工学版), 2018, 48(4): 1016-1022. |

| [14] | 毛钰, 左曙光, 林福, 曹佳楠, 郑玉平. 基于弹性连接结构的电动轮纵向振动特性[J]. 吉林大学学报(工学版), 2018, 48(1): 74-82. |

| [15] | 谷晓燕, 刘亚俊, 孙大千, 徐锋, 孟令山, 高帅. S355钢/6005A铝合金瞬间液相扩散连接接头组织与性能[J]. 吉林大学学报(工学版), 2017, 47(5): 1534-1541. |

|

||