吉林大学学报(工学版) ›› 2023, Vol. 53 ›› Issue (7): 1920-1928.doi: 10.13229/j.cnki.jdxbgxb.20211055

• 车辆工程·机械工程 • 上一篇

利用振动提高熔丝成型制品结合颈的机理分析

- 1.东北大学 机械工程与自动化学院,沈阳 110819

2.北京海纳川汽车部件股份有限公司 技术中心电动化部,北京 100021

3.东北大学 信息科学与工程学院,沈阳 110819

Mechanism analysis on improving bonding neck of fused filament fabrication products by using vibration

Shi-jie JIANG1( ),Pi-feng CHEN1,Ke HU1,Xu-zhen HUANG2,Ming ZHAN3

),Pi-feng CHEN1,Ke HU1,Xu-zhen HUANG2,Ming ZHAN3

- 1.School of Mechanical Engineering and Automation,Northeastern University,Shenyang 110819,China

2.Electrification Department of Technology Center,Beijing Hainachuan Automotive Parts Co. ,Ltd. ,Beijing 100021,China

3.College of Information Science & Engineering,Northeastern University,Shenyang 110819,China

摘要:

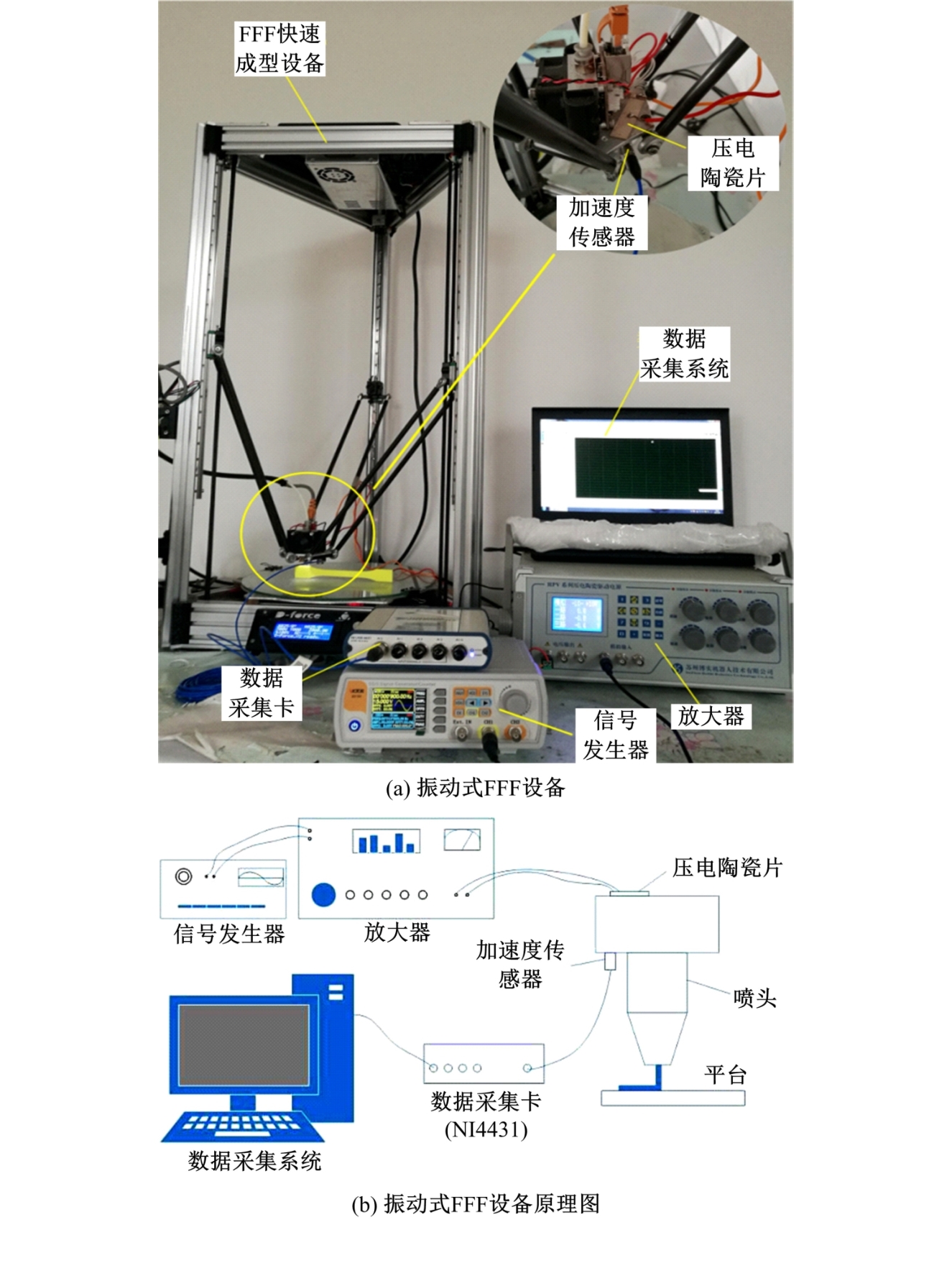

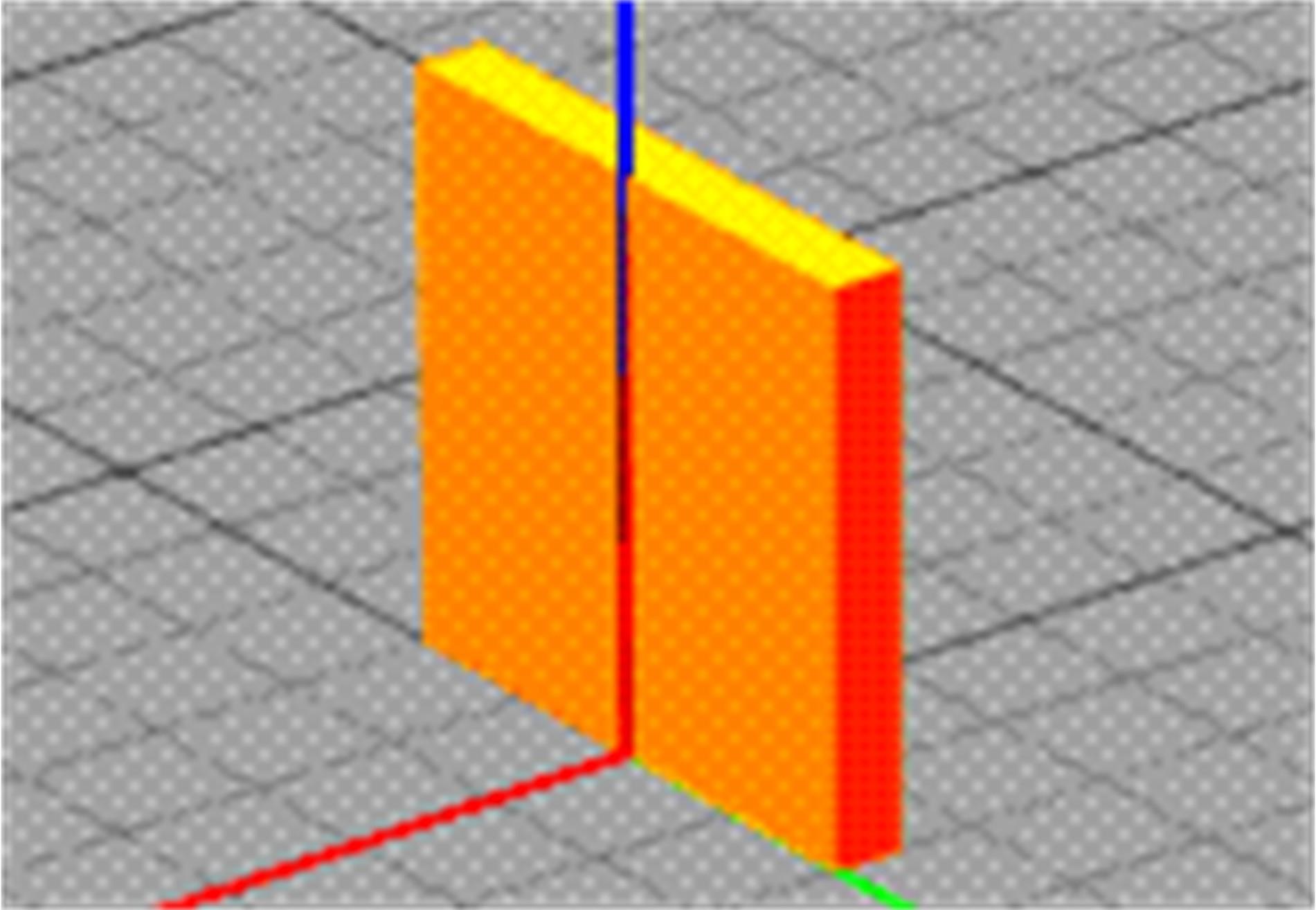

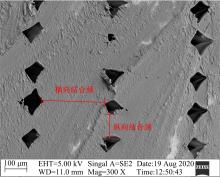

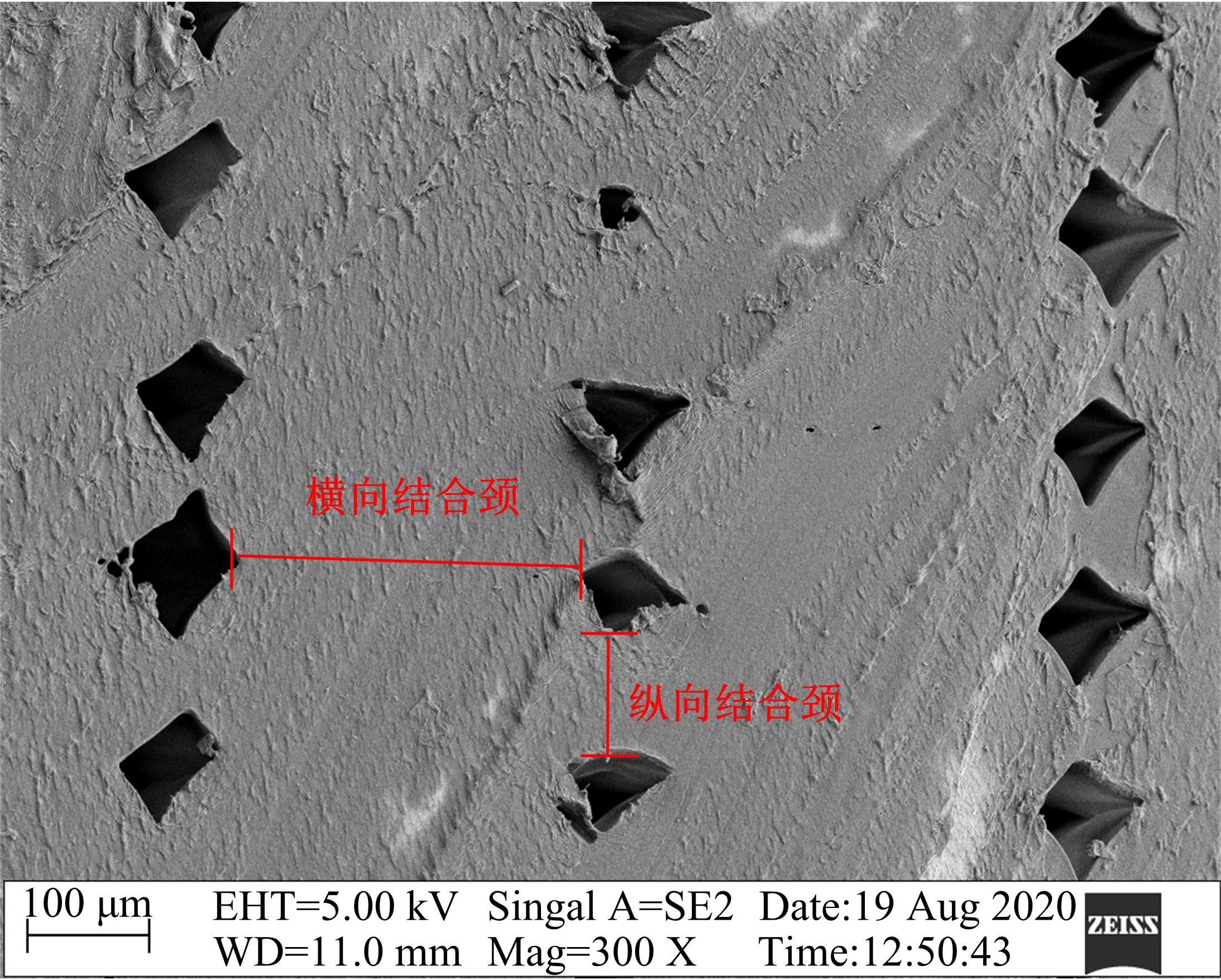

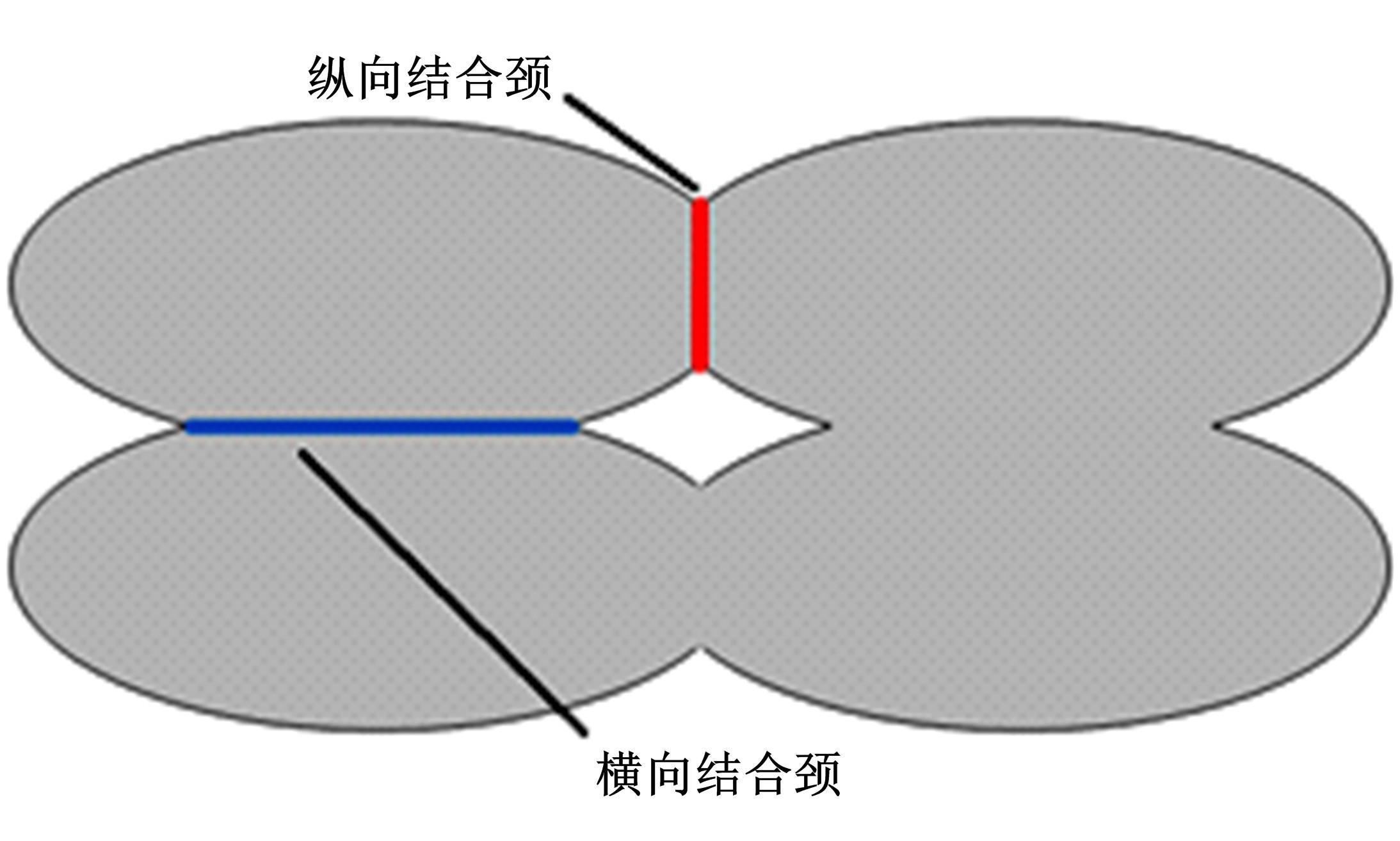

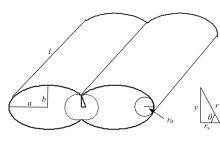

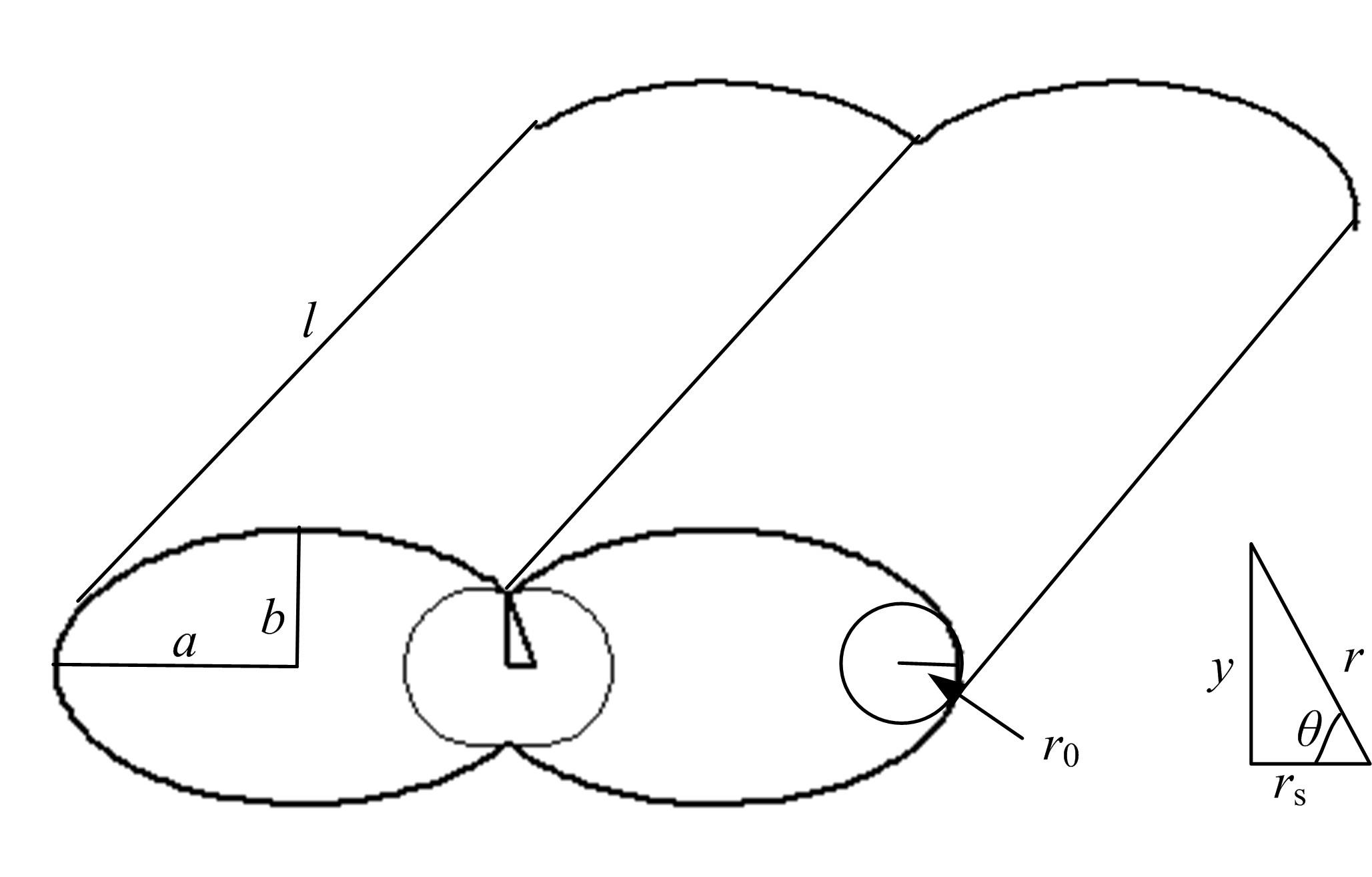

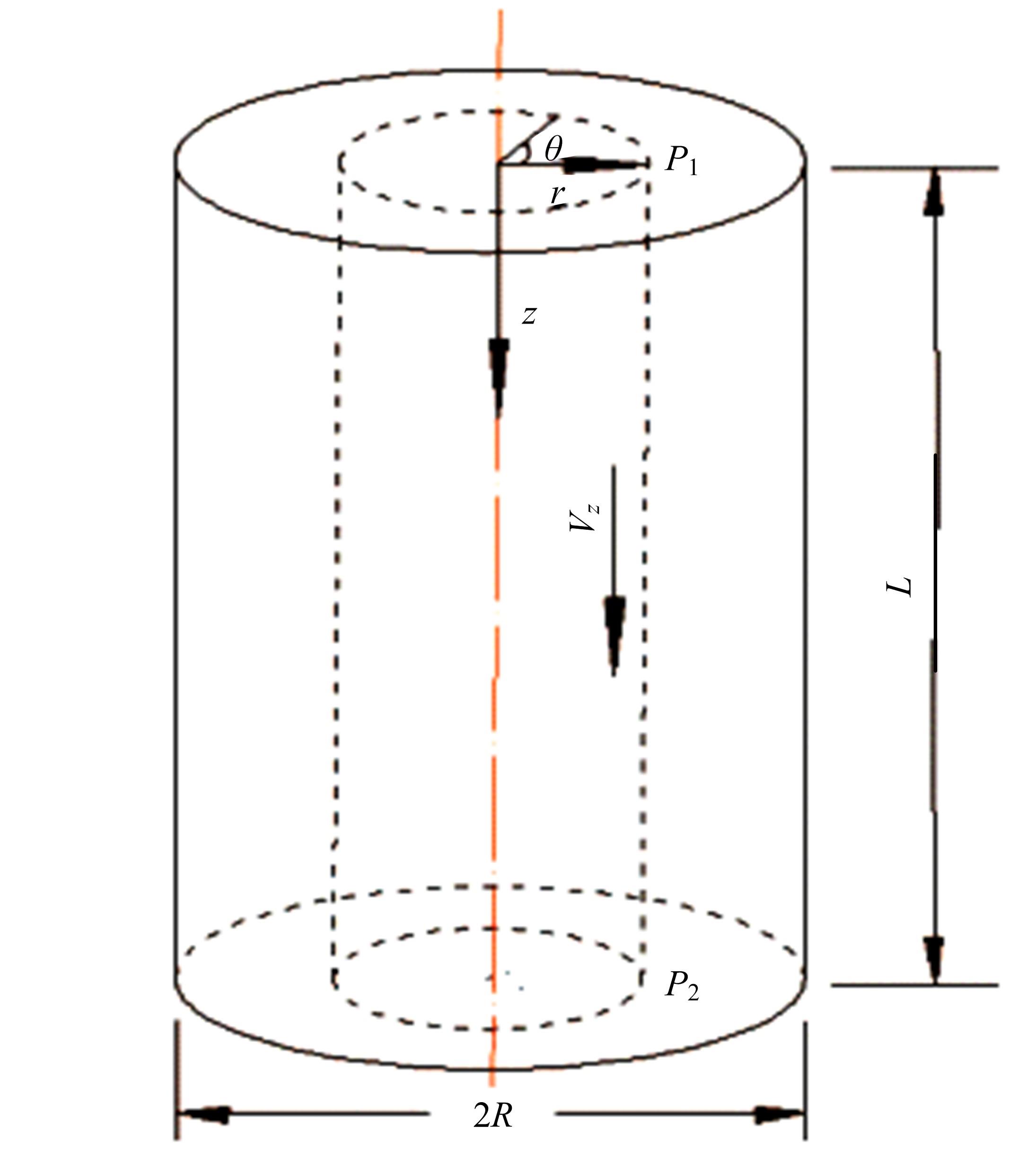

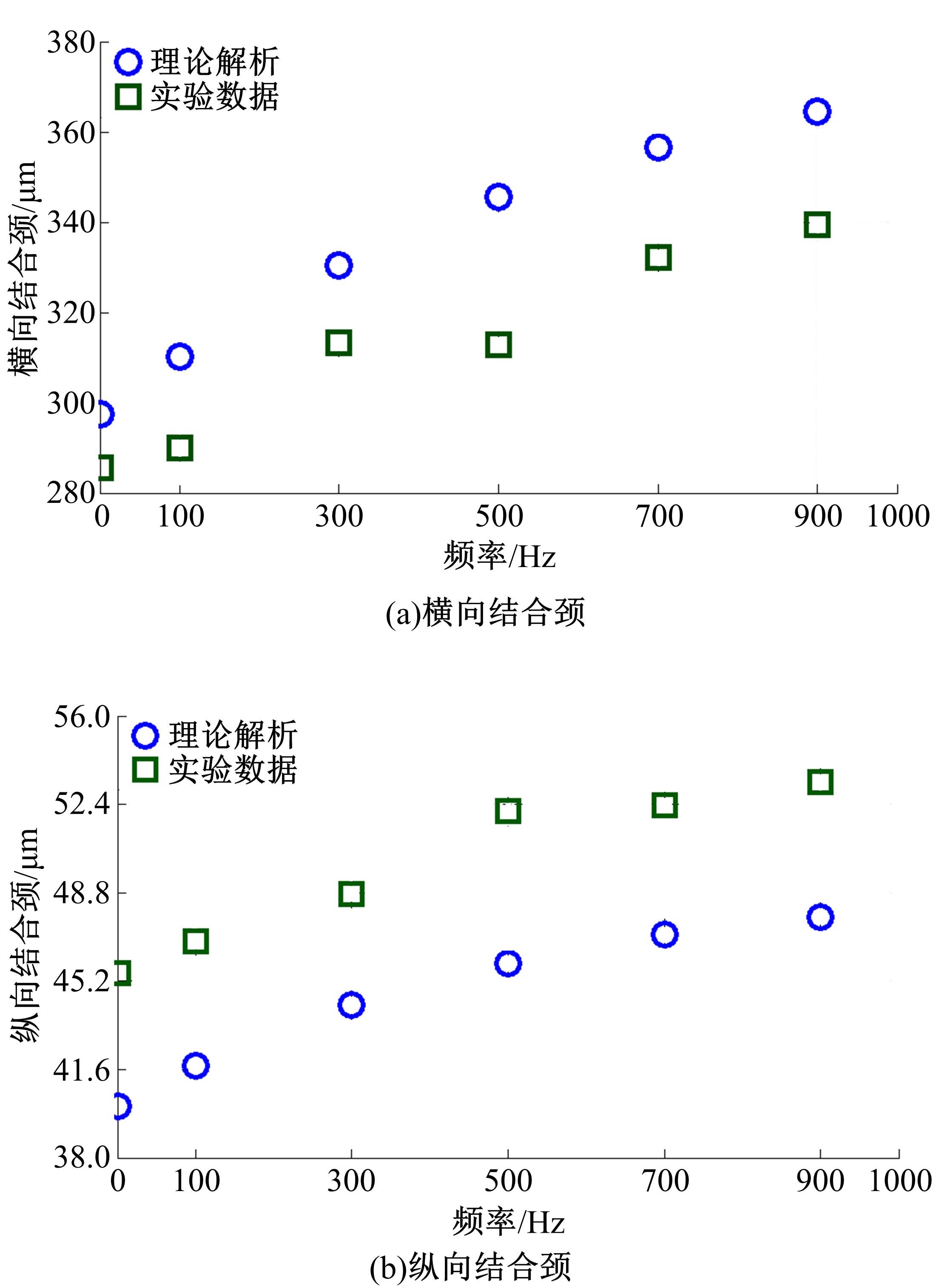

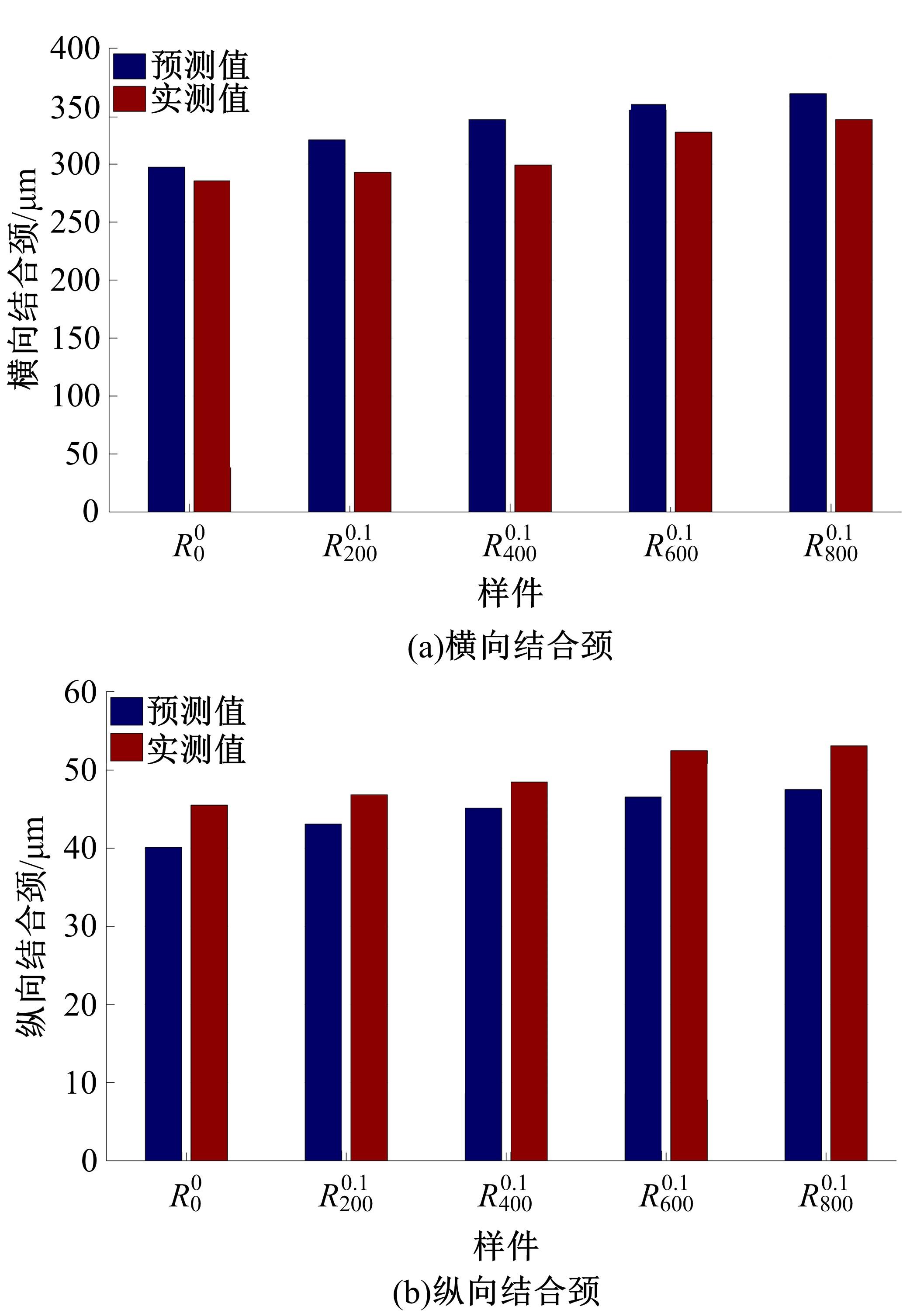

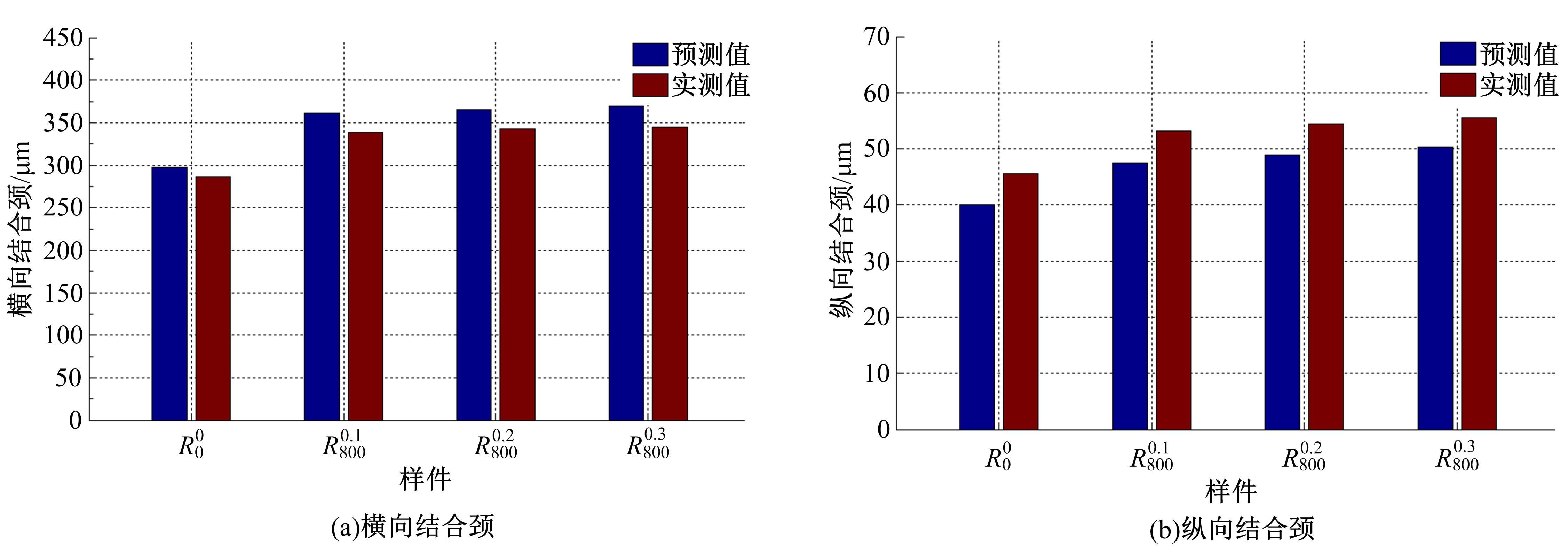

提出利用正弦波振动改善熔丝成型挤出材料丝间的结合颈的新熔丝成型方法,即采用压电陶瓷对熔丝成型热熔喷头施加纵向(沿着熔体流动方向)正弦振动场以增大结合颈尺寸,实现制品成型质量的提升。完成熔丝成型设备的振动改装,基于改装后的设备制备实验样件,并在电子显微镜下对样件结合颈的尺寸进行了测量;建立了结合颈尺寸的理论计算模型,并与实测结果进行了比较。结果表明,辅以振动的新熔丝成型可有效增大结合颈,且结合颈随着振动频率或幅值的增大而进一步增大,横、纵向结合颈最大增幅分别为21.4%和22.3%;结合颈尺寸的理论计算与测量结果比较误差为2%~12%,正确、可靠,能够准确地预测结合颈。

中图分类号:

- TH113.1

| 1 | Vyavahare S, Teraiya S, Panghal D, et al. Fused deposition modelling: a review[J]. Rapid Prototyping Journal, 2020, 26(1): 176-201. |

| 2 | Shahriar B B, France C, Valerie N, et al. Toward improvement of the properties of parts manufactured by FFF (fused filament fabrication) through understanding the influence of temperature and rheological behaviour on the coalescence phenomenon[C]∥ AIP Conference Proceedings, 2017. |

| 3 | Coogan T J, Kazmer D O. Prediction of interlayer strength in material extrusion additive manufacturing[J]. Additive Manufacturing, 2020, 35: 1-17. |

| 4 | Tronvoll S A, Welo T, Elverum C W. The effects of voids on structural properties of fused deposition modelled parts: a probabilistic approach[J]. The International Journal of Advanced Manufacturing Technology, 2018, 97(9): 3607-3618. |

| 5 | Kuznetsov V E, Solonin A N, Tavitov A, et al. Increasing strength of FFF three-dimensional printed parts by influencing on temperature-related parameters of the process[J]. Rapid Prototyping Journal, 2020, 26(1): 107-121. |

| 6 | Vanaei H R, Raissi K, Deligant M, et al. Toward the understanding of temperature effect on bonding strength, dimensions and geometry of 3D-printed parts[J]. Journal of Materials Science, 2020, 55(29): 14677-14689. |

| 7 | Bakrani B S, Chabert F, Nassiet V, et al. Influence of printing parameters on the stability of deposited beads in fused filament fabrication of poly(lactic) acid[J]. Additive Manufacturing, 2019, 25: 112-121. |

| 8 | Vaes D, Coppens M, Goderis B, et al. Assessment of crystallinity development during fused filament fabrication through fast scanning chip calorimetry[J]. Applied Science-basel, 2019, 9(13): 1-20. |

| 9 | He Qing-hao, Ye Lin, Kinloch A J, et al. Characterisation of fusion bonding between filaments of thin 3D printed polyamide 6 using an essential work of fracture method[J]. Journal of Materials Science, 2021, 56(3): 2777-2794. |

| 10 | Papon E A, Haque A. Fracture toughness of additively manufactured carbon fiber reinforced composites-Sciencedirect[J]. Additive Manufacturing, 2019, 26: 41-52. |

| 11 | Ravi A K, Deshpande A, Hsu K H. An in-process laser localized pre-deposition heating approach to inter-layer bond strengthening in extrusion based polymer additive manufacturing[J]. Journal of Manufacturing Processes, 2016, 24: 179-185. |

| 12 | Abbott A C, Tandon G P, Bradford R L, et al. Process-structure-property effects on abs bond strength in fused filament fabrication[J]. Additive Manufacturing, 2018, 19: 29-38. |

| 13 | Yin Jun, Lu Chao-hua, Fu Jian-zhoug, et al. Interfacial bonding during multi-material fused deposition modeling (FDM) process due to inter-molecular diffusion[J]. Materials & Design, 2018, 150: 104-112. |

| 14 | Jiang S J, Siyajeu Y, Shi Y F, et al. Improving the forming quality of fused filament fabrication parts by applied vibration[J]. Rapid Prototyping Journal, 2020, 26(1): 202-212. |

| 15 | Farah S, Anderson D G, Langer R. Physical and mechanical properties of PLA, and their functions in widespread applications―a comprehensive review[J]. Advanced Drug Delivery Reviews, 2016, 107: 367-392. |

| 16 | Pokluda O, Bellehumeur C T, Vlachopoulos J. Modification of frenkel's model for sintering[J]. Aiche Journal, 1997, 43(12): 3253-3256. |

| 17 | Frenkel. Viscous flow of crystalline bodies under the action of surface tension[J]. 1945, 9(5): 501-559. |

| 18 | Jiang Shi-jie, Chen Pi-feng, Zhan Yang, et al. Theoretical and computational analysis on the melt flow behavior of polylactic acid in material extrusion additive manufacturing under vibration field[J]. Applied Science, 2020, 10(11): 1-19. |

| 19 | Sun Q, Rizvi G M, Bellehumeur C T, et al. Effect of processing conditions on the bonding quality of FDM polymer filaments[J]. Rapid Prototyping Journal, 2008, 14(2): 72-80. |

| [1] | 杨艳,侍玉青,张晓蓉,罗冠炜. 一类多刚性限幅振动系统的动态稳定性分析[J]. 吉林大学学报(工学版), 2023, 53(2): 364-375. |

| [2] | 宋震,柳杰. 旋转机械振动频率时间序列预测算法[J]. 吉林大学学报(工学版), 2022, 52(8): 1764-1769. |

| [3] | 李杰,陈涛,郭文翠,赵旗. 汽车非平稳随机振动空间域虚拟激励法及应用[J]. 吉林大学学报(工学版), 2022, 52(4): 738-744. |

| [4] | 高文英,林静,李宝筏,王伟,谷士艳. 秸秆深埋还田机振动特性分析与结构优化[J]. 吉林大学学报(工学版), 2022, 52(4): 970-980. |

| [5] | 张彦玲,王灿,张旭,王昂洋,李运生. 不同吊杆形式悬索桥人致振动分析及舒适度评价[J]. 吉林大学学报(工学版), 2022, 52(11): 2644-2652. |

| [6] | 杨建,夏琦,周海超,王国林. 修正胎体弦轮廓载重子午线轮胎的降噪机理[J]. 吉林大学学报(工学版), 2021, 51(4): 1198-1203. |

| [7] | 李卫,张怀亮,瞿维. 随机振动环境下液压直管道设计方法[J]. 吉林大学学报(工学版), 2021, 51(4): 1222-1229. |

| [8] | 魏海斌,王相焱,王富玉,张勇. 基于振动成型AC-25沥青混合料力学性能及细观分析[J]. 吉林大学学报(工学版), 2021, 51(4): 1269-1276. |

| [9] | 于萍,穆特,朱黎辉,周子业,宋杰. 钻具输送装置非线性动力学分析及稳定性控制[J]. 吉林大学学报(工学版), 2021, 51(3): 820-830. |

| [10] | 刘钊,程江琳,朱玉田,郑立辉. 轨道车辆垂向振动建模及运动关联分析[J]. 吉林大学学报(工学版), 2020, 50(5): 1600-1607. |

| [11] | 张云龙,郭阳阳,王静,梁东. 钢-混凝土组合梁的固有频率及其振型[J]. 吉林大学学报(工学版), 2020, 50(2): 581-588. |

| [12] | 程超,付君,唐心龙,陈志,任露泉. 振动形式对水稻脱出物界面粘附规律的影响[J]. 吉林大学学报(工学版), 2019, 49(4): 1228-1235. |

| [13] | 史文库, 刘国政, 宋海生, 陈志勇, 张宝. 纯电动客车振动噪声特性[J]. 吉林大学学报(工学版), 2018, 48(2): 373-379. |

| [14] | 陈忠敏, 侯力, 段阳, 张祺, 杨忠学, 蒋易强. 新型摆线针轮行星减速器传动系统的振动特性[J]. 吉林大学学报(工学版), 2018, 48(1): 174-185. |

| [15] | 毛钰, 左曙光, 林福, 曹佳楠, 郑玉平. 基于弹性连接结构的电动轮纵向振动特性[J]. 吉林大学学报(工学版), 2018, 48(1): 74-82. |

|

||