吉林大学学报(工学版) ›› 2023, Vol. 53 ›› Issue (6): 1601-1611.doi: 10.13229/j.cnki.jdxbgxb.20230095

• 交通运输工程·土木工程 • 上一篇

可“临-永”转换抢修钢墩应急使用极限承载力

刘子玉1,2( ),陈士通1,2,3(

),陈士通1,2,3( ),支墨墨1,2,3,黄晓明4,陈哲心5

),支墨墨1,2,3,黄晓明4,陈哲心5

- 1.石家庄铁道大学 大型基础设施性能与安全省部共建协同创新中心,石家庄 050043

2.石家庄铁道大学 河北省交通应急保障工程技术创新中心,石家庄 050043

3.石家庄铁道大学 省部共建交通工程结构力学行为与系统安全国家重点实验室,石家庄 050043

4.东南大学 交通学院,南京 210096

5.济南金曰公路工程有限公司,济南 250101

Ultimate bearing capacity of temporary⁃permanent conversion rush⁃repair steel pier for emergency use

Zi-yu LIU1,2( ),Shi-tong CHEN1,2,3(

),Shi-tong CHEN1,2,3( ),Mo-mo ZHI1,2,3,Xiao-ming HUANG4,Zhe-xin CHEN5

),Mo-mo ZHI1,2,3,Xiao-ming HUANG4,Zhe-xin CHEN5

- 1.Collaborative Innovation Center for Performance and Security of Large-scale Infrastructure,Shijiazhuang Tiedao University,Shijiazhuang 050043,China

2.Hebei Eng. Research Center for Traffic Emergency and Guarantee,Shijiazhuang Tiedao University,Shijiazhuang 050043,China

3.State Key Laboratory of Mechanical Behavior and System Safety of Traffic Engineering Structures,Shijiazhuang Tiedao University,Shijiazhuang 050043,China

4.School of Transportation,Southeast University,Nanjing 210096,China

5.Jinan Kingyue Highway Engineering Company Limited,Jinan 250101,China

摘要:

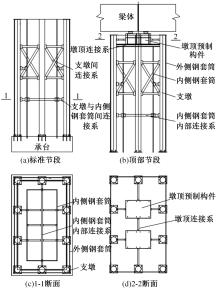

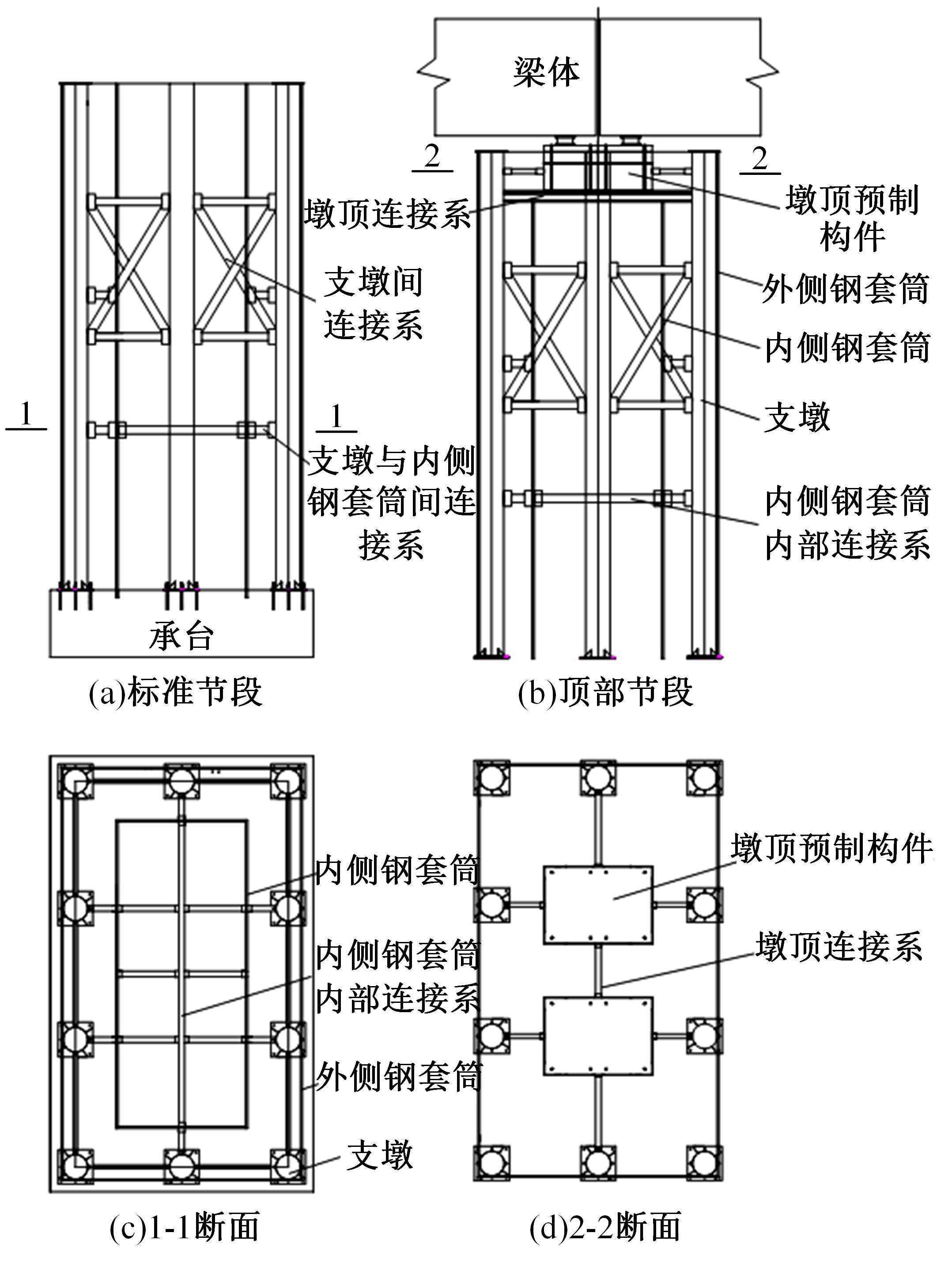

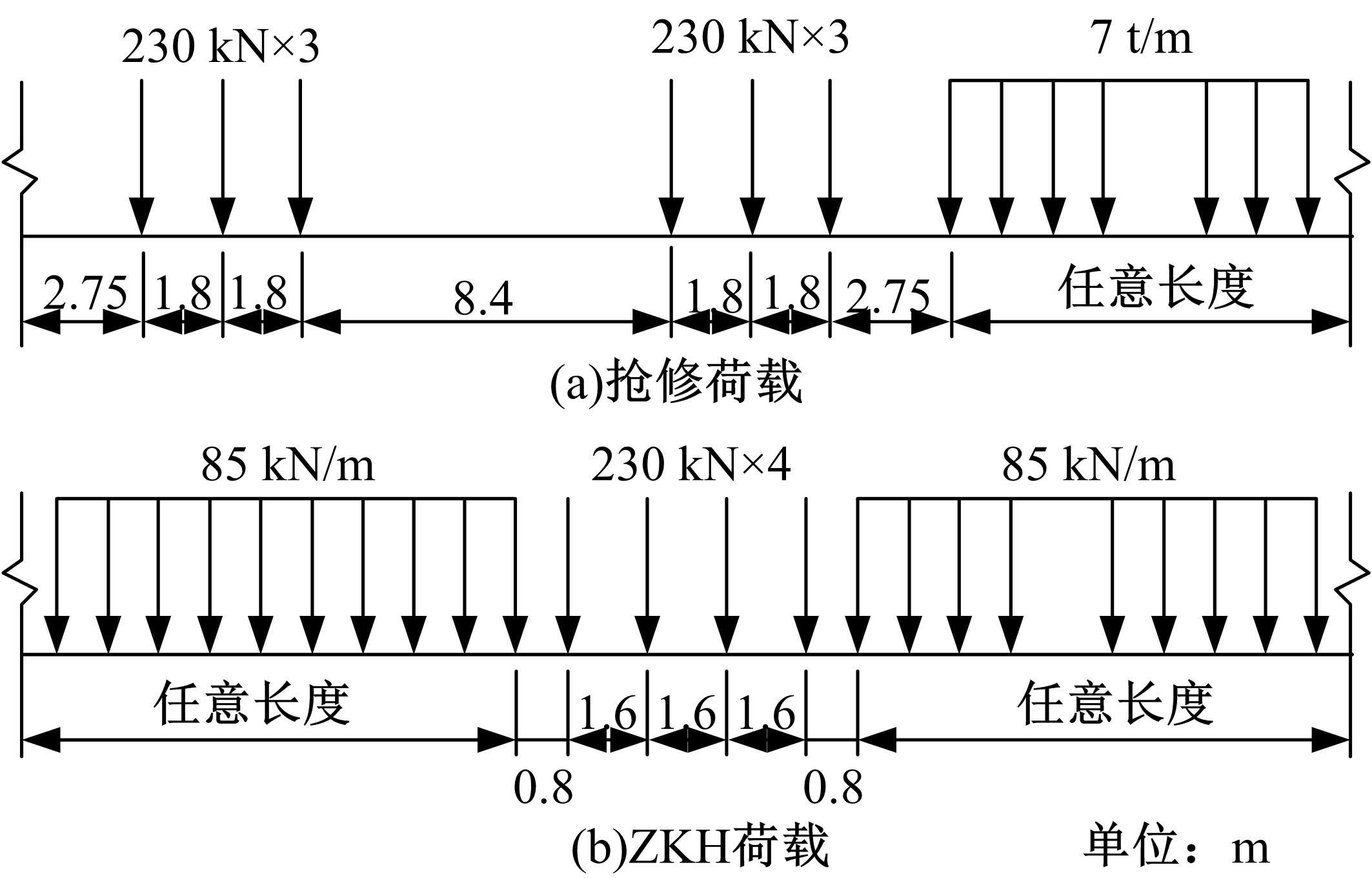

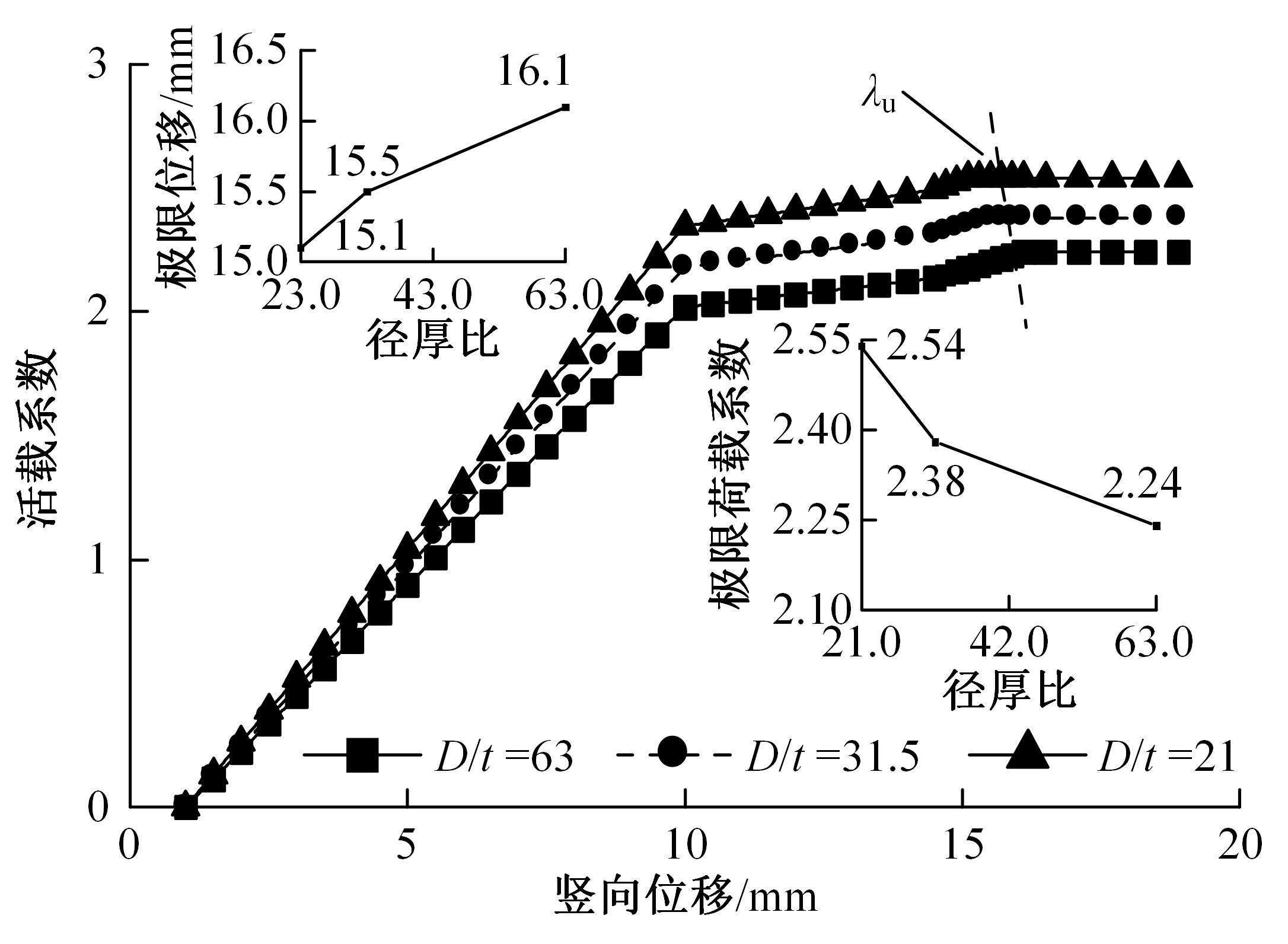

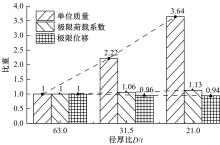

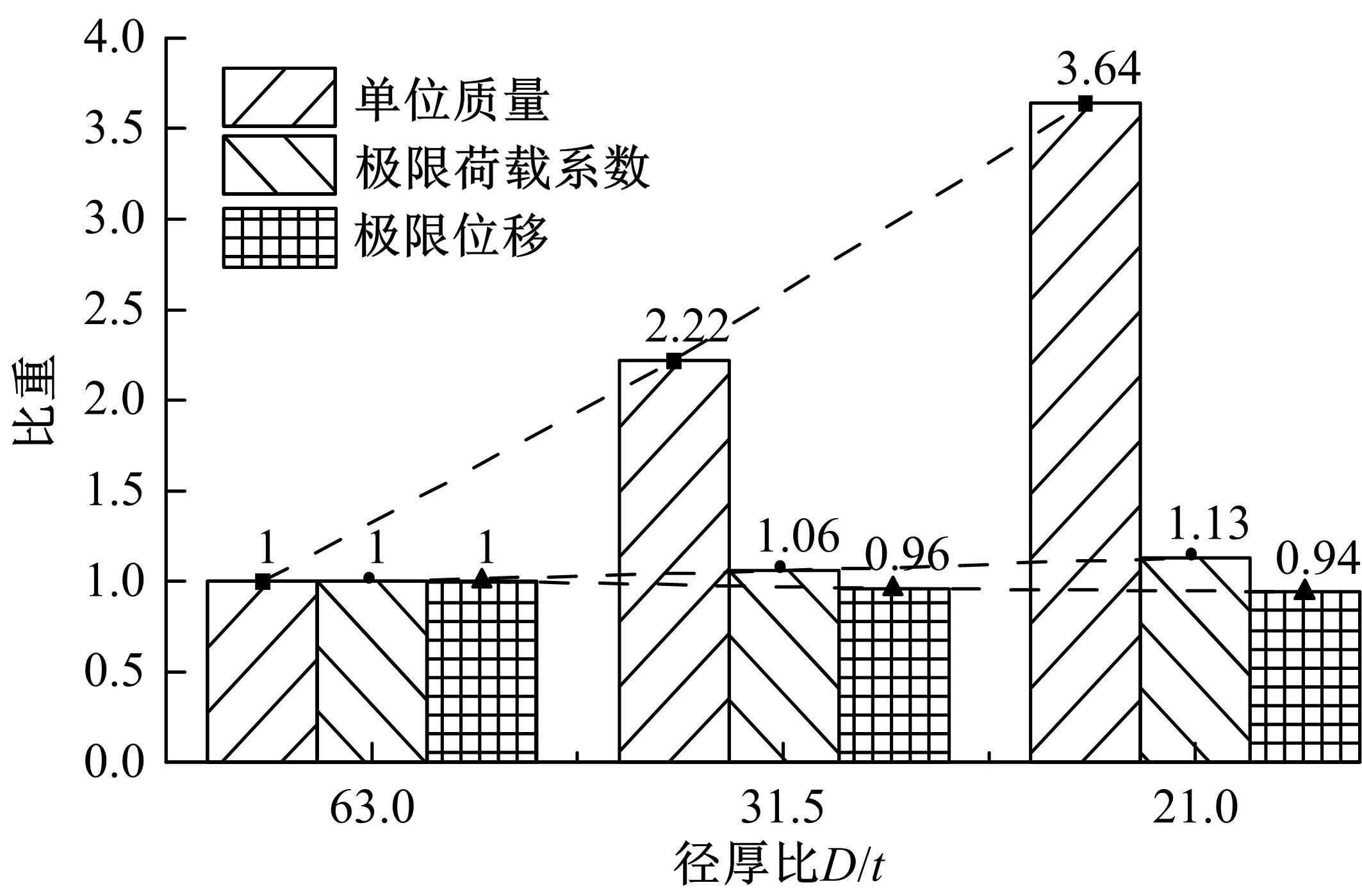

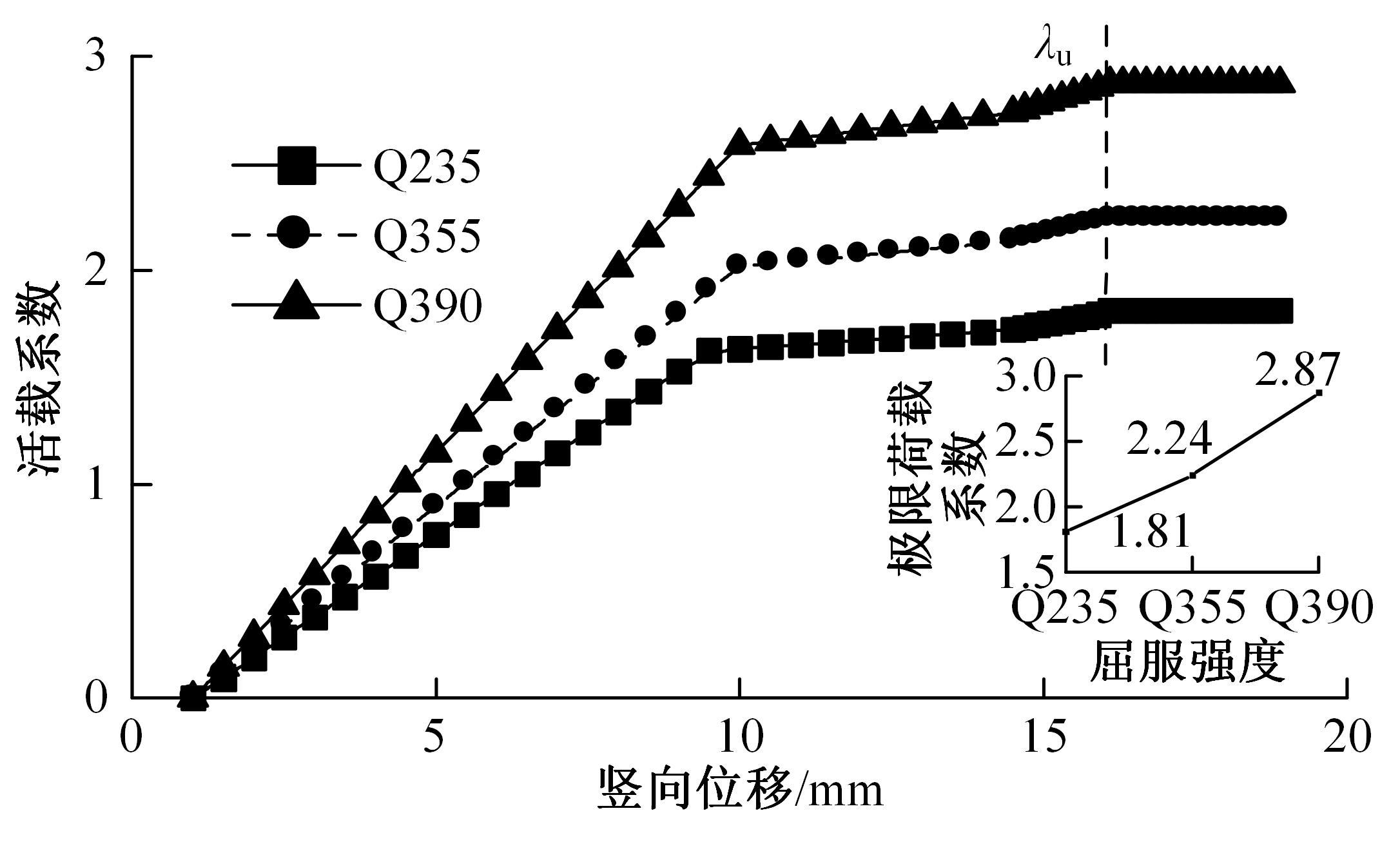

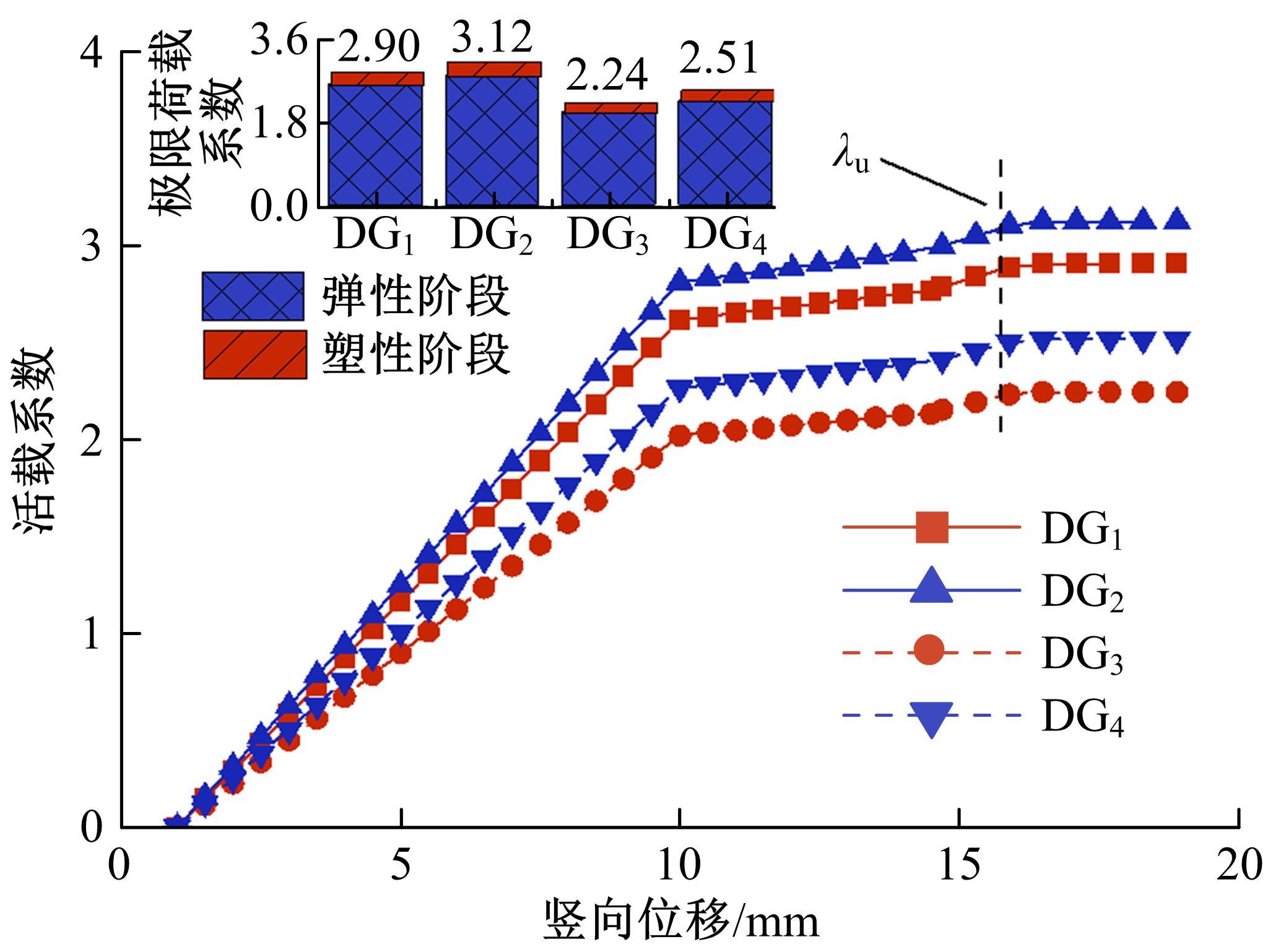

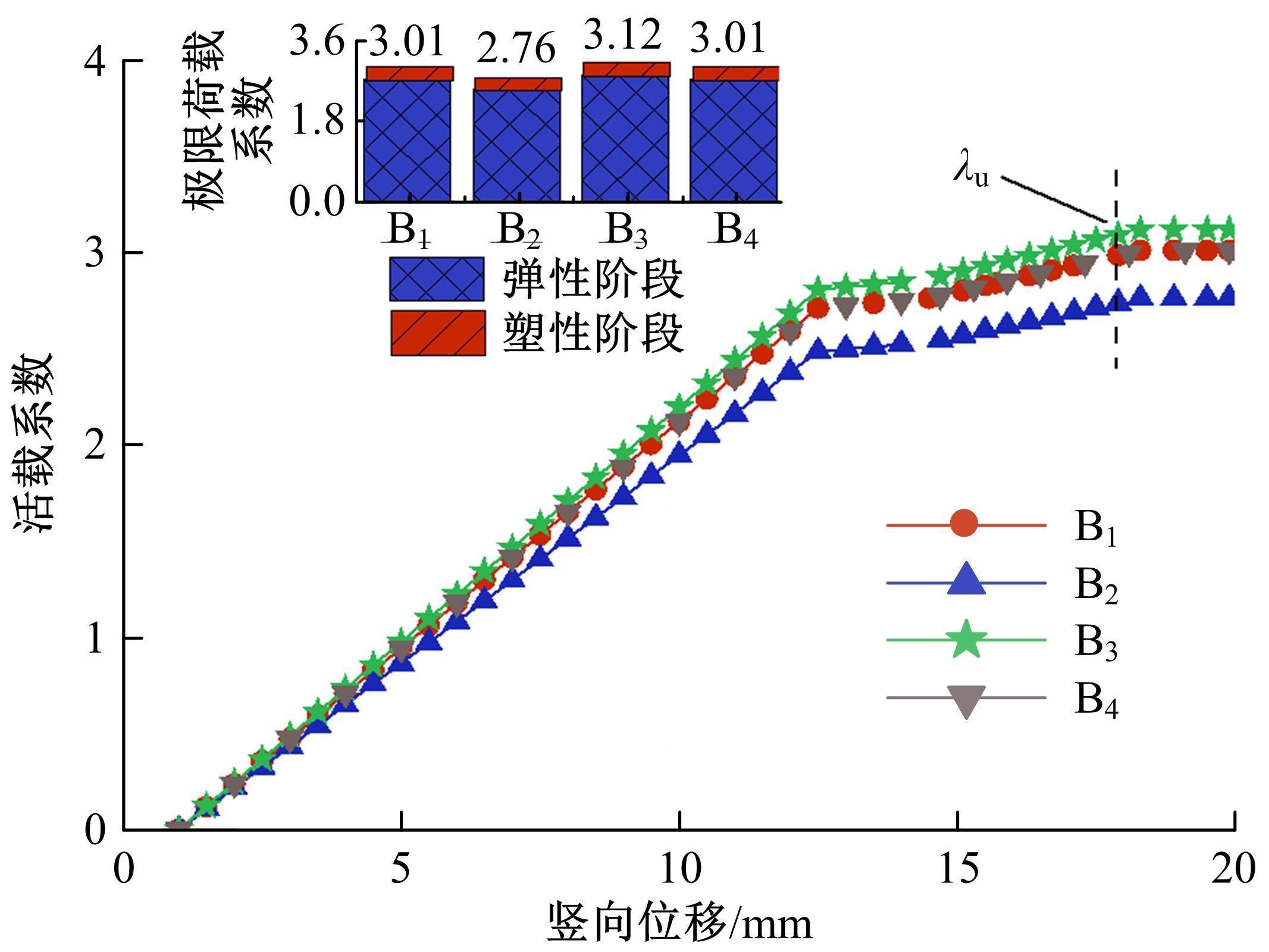

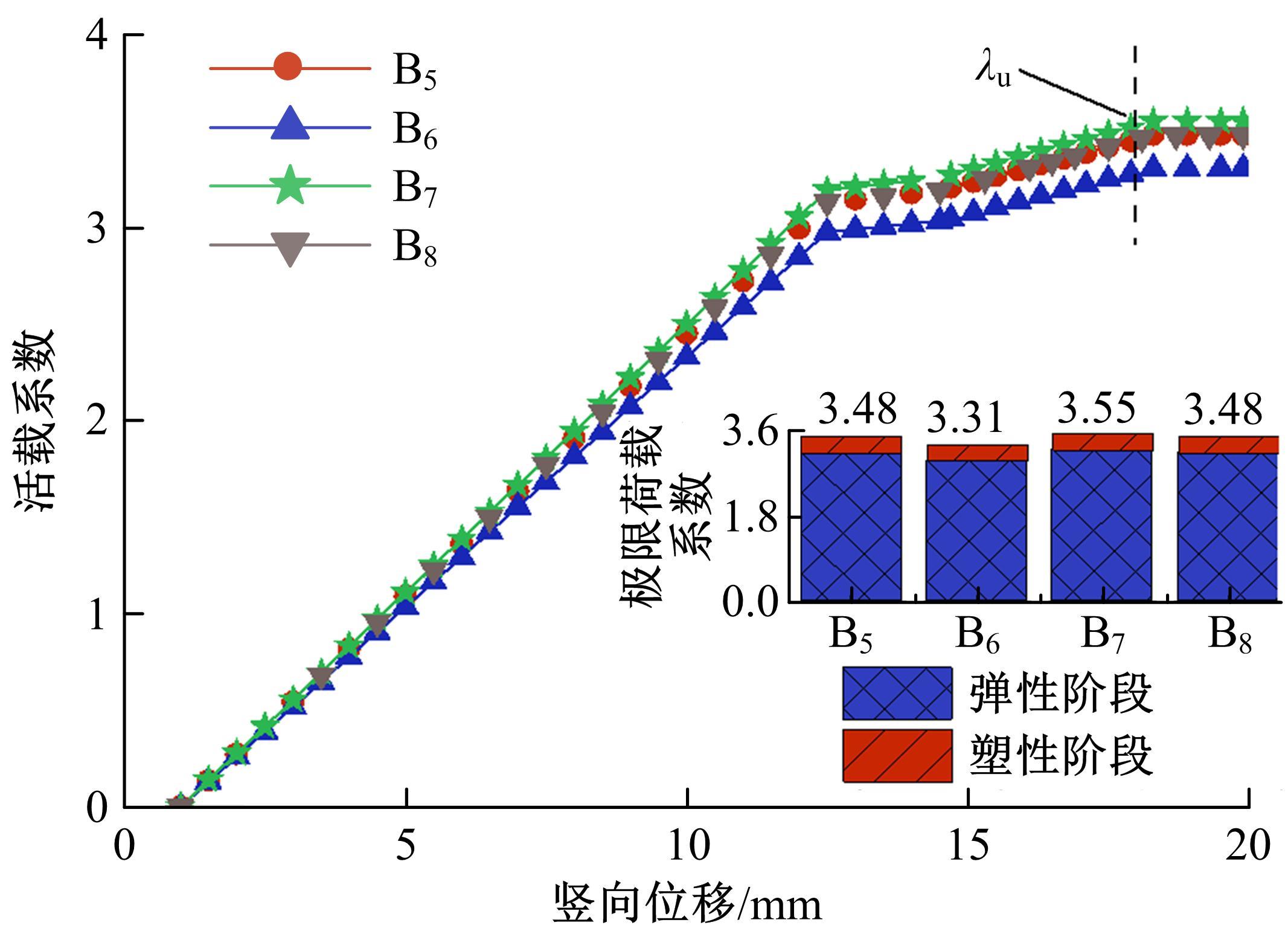

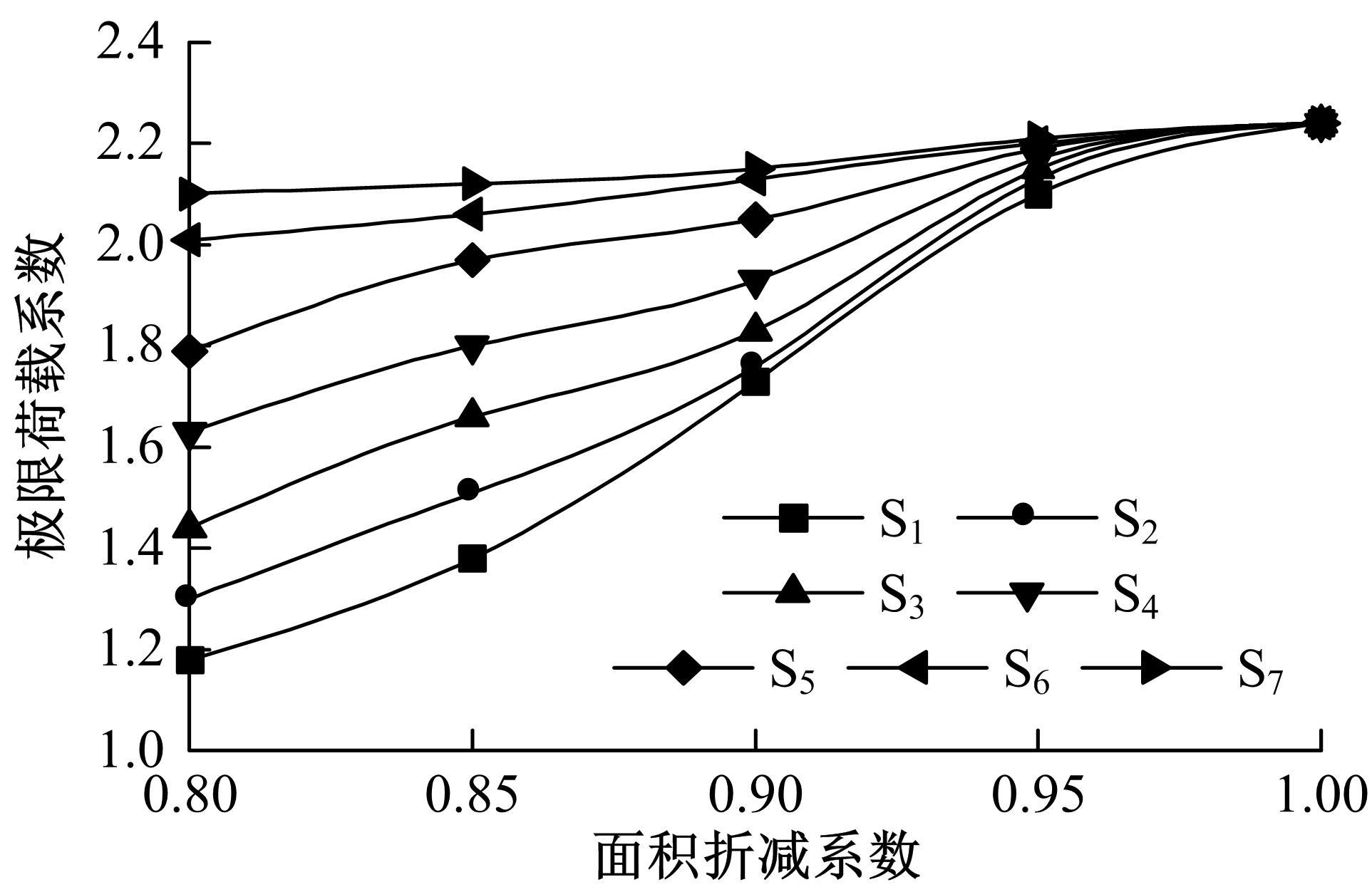

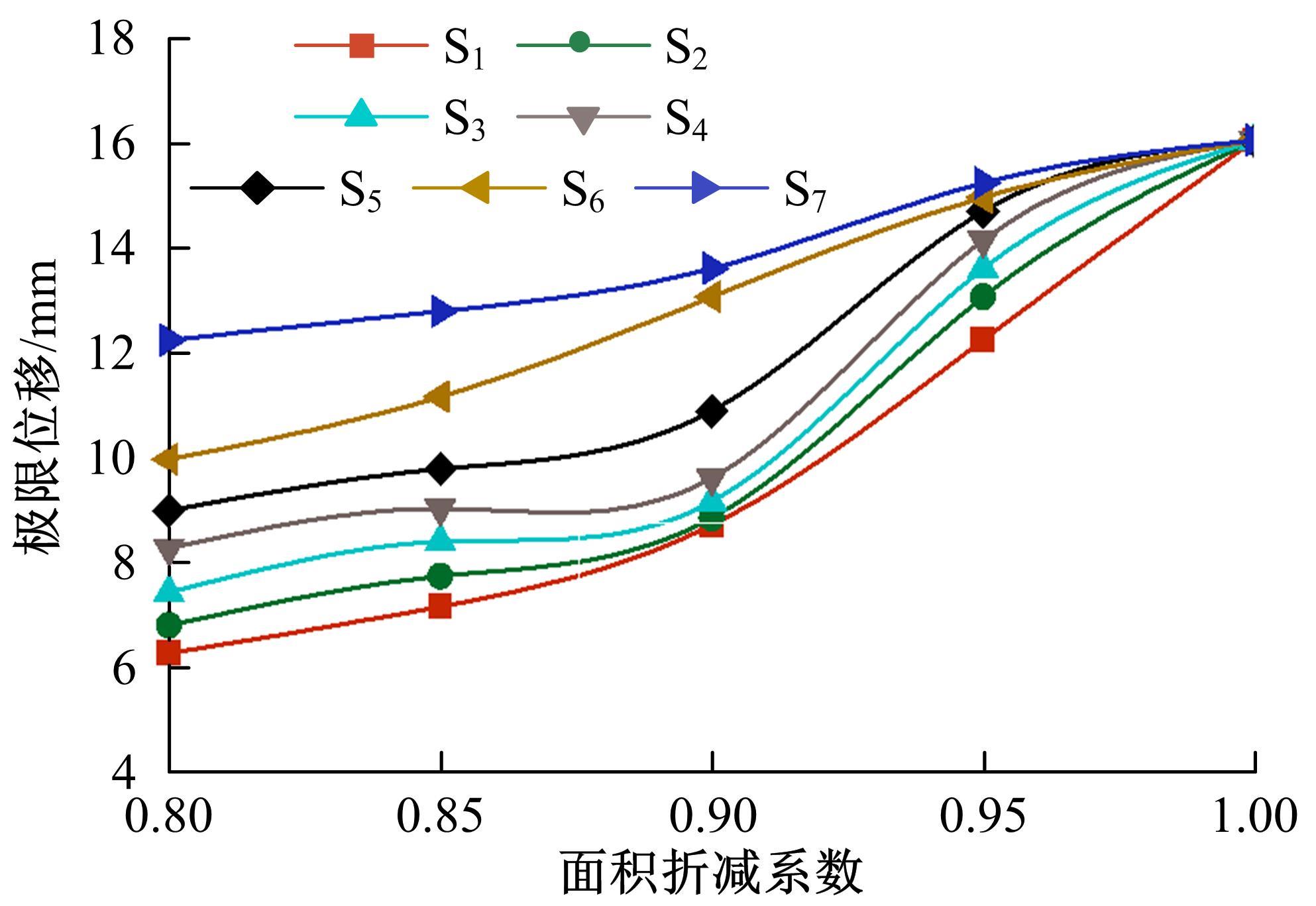

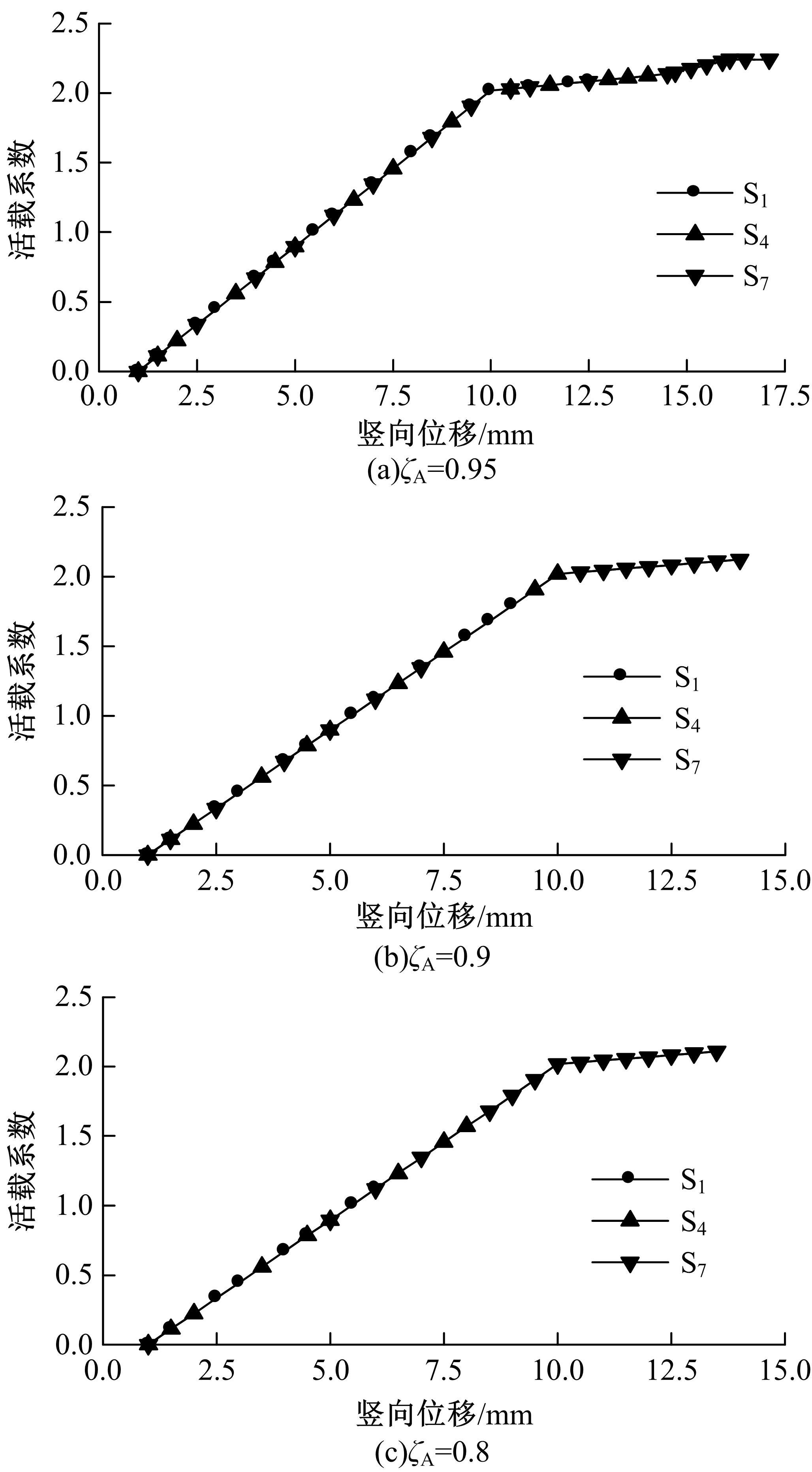

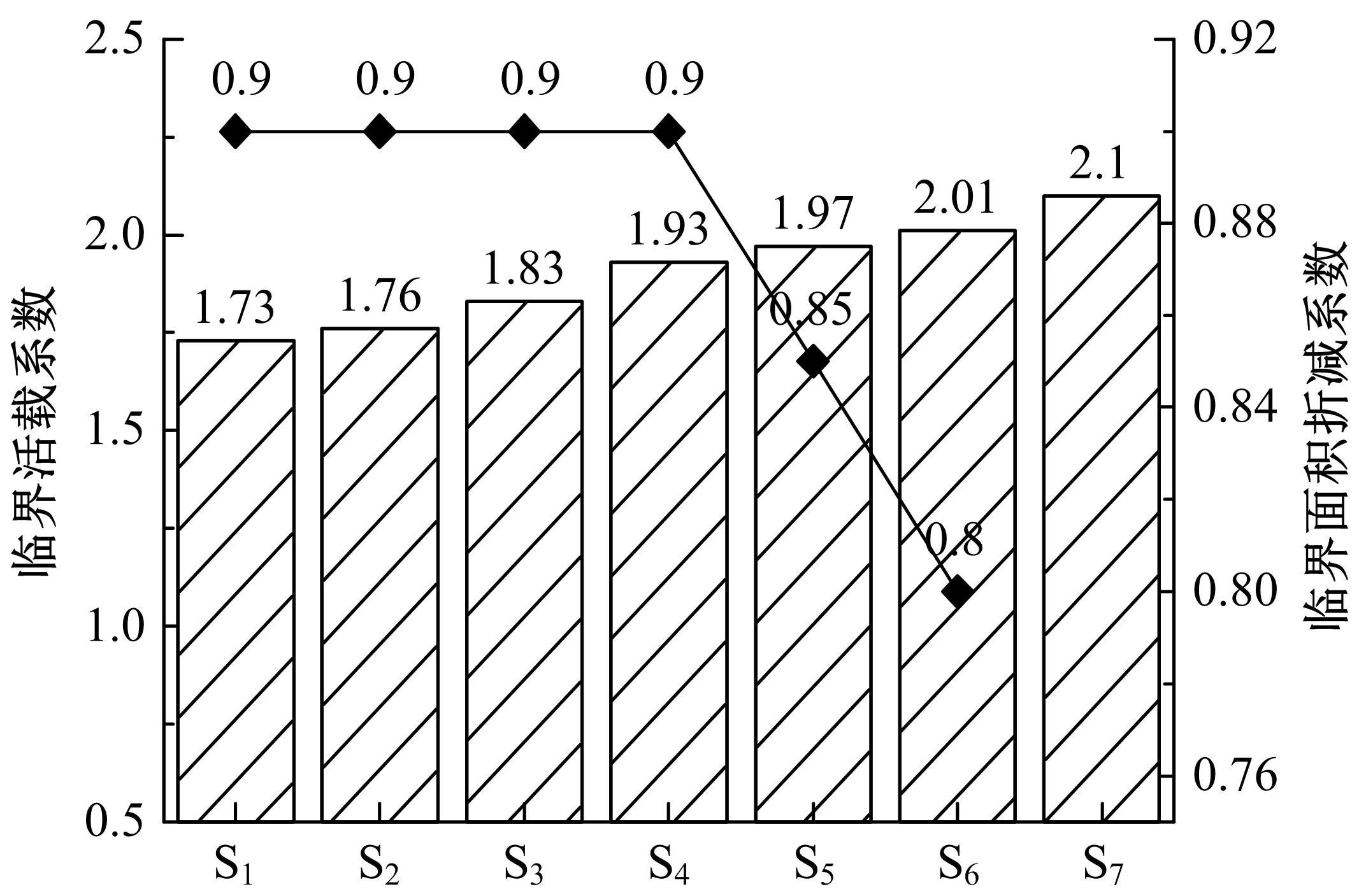

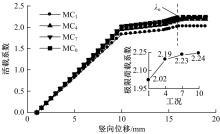

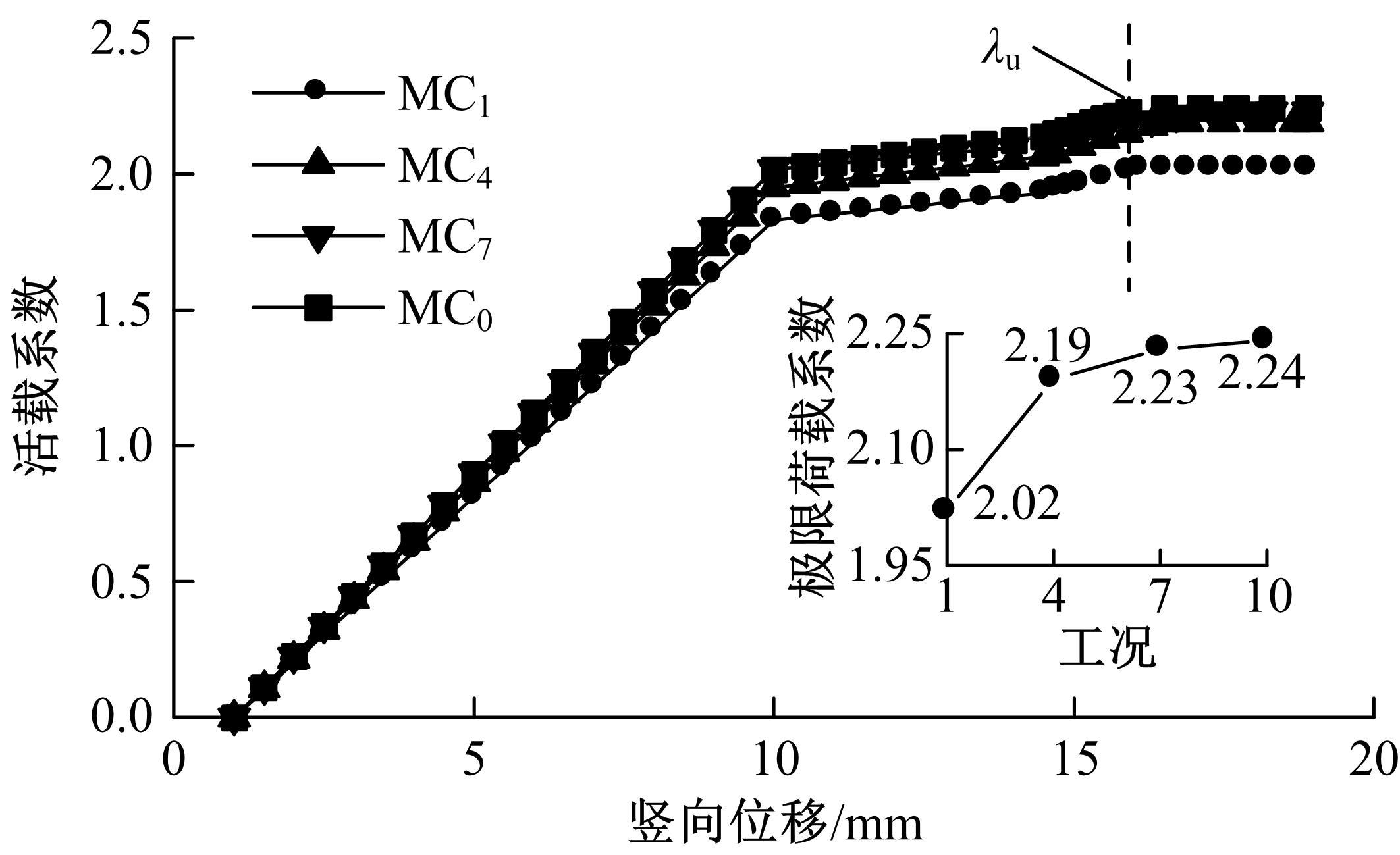

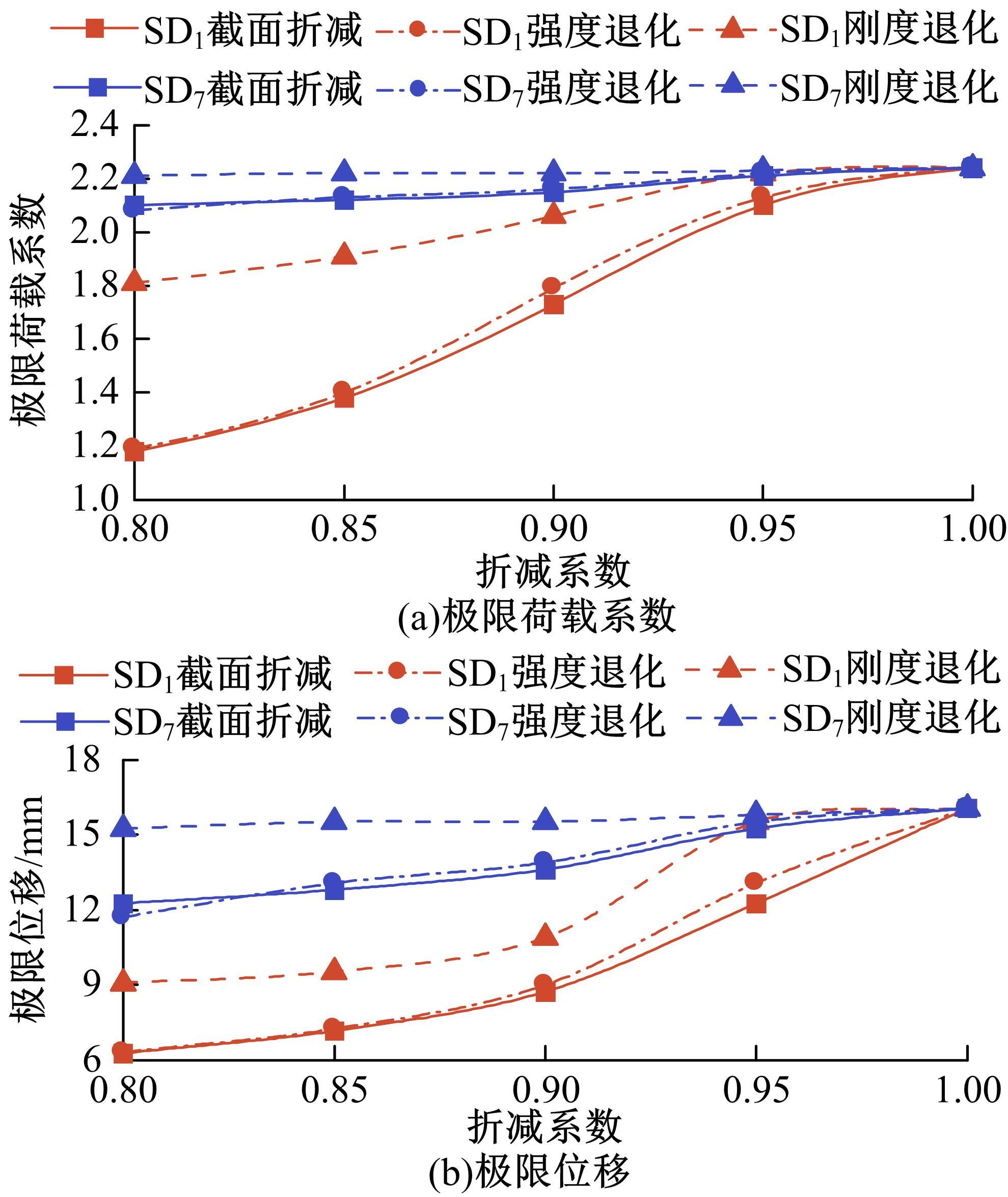

研发了一种可“临-永”转换的抢修钢墩,基于ABAQUS三维仿真模拟,首先通过极限承载力因素影响分析确定主材选型;在此基础上,开展钢墩非损伤及损伤状态结构极限承载力研究。结果表明:钢墩极限承载力随支墩径厚比增大而减小,随钢材强度等级提高而增大;钢墩损伤位置相同时,损伤程度越深,极限荷载系数越敏感;钢墩损伤程度相同时,损伤位置越靠近下方,对极限荷载系数的影响越显著;节段局部损伤时,相较于材料刚度退化,随着折减系数的变化,截面尺寸缩减和材料强度退化对极限荷载系数的影响趋势相近、程度相当,且影响更加明显;节段整体损伤时,截面尺寸缩减影响最大,材料强度退化次之,材料刚度退化最小。

中图分类号:

- U24

| 1 | 张瞩熹. 铁路桥梁抢修器材应急保障能力现状与思考[J]. 国防交通工程与技术, 2020, 18(6): 30-33. |

| Zhang Zhu-xi. My reflection on the current situation of the emergency support capability of rush-repair equipment of railway bridges[J]. Traffic Engineering and Technology for National Defence, 2020, 18(6): 30-33. | |

| 2 | 陈士通, 刘子玉, 支墨墨. 中国桥墩抢修器材现状及思考[J]. 铁道技术标准: 中英文, 2022, 4(11): 14-19. |

| Chen Shi-tong, Liu Zi-yu, Zhi Mo-mo. Current situation and thinking on rush-repair equipment for bridge piers in China[J]. Railway Technical Standard(Chinese & English), 2022, 4(11): 14-19. | |

| 3 | 刘子玉, 陈士通, 支墨墨. “临-永”转换抢修钢墩应急使用结构稳定因素影响研究[C]∥第31届全国结构工程学术会议, 南宁, 中国,2022: 176-185. |

| 4 | 杨绿峰, 赵玉峰, 解威威. 方形钢管混凝土框架二阶效应下极限承载力的高效线弹性迭代分析[J]. 土木工程学报, 2022, 55(2): 1-10. |

| Yang Lü-feng, Zhao Yu-feng, Xie Wei-wei. Linear elastic iteration with high efficiency for ultimate bearing capacity of square-profile CFST frame with second order effect[J]. China Civil Engineering Journal, 2022, 55(2): 1-10. | |

| 5 | Iman M. The old derrick steel truss structure in linear buckling analysis(eigenvalue)[J]. IOP Conference Series: Earth and Environmental Science, 2021, 832(1): No.12027. |

| 6 | Aziz H Y, Sultan H K, Abbas B J. Simulation and style design of bridge stability supported on large diameter piles[J]. MMEP, 2021, 8(6): 961-966. |

| 7 | Khaled O, Kathryn F, Deniel P, et al. An in vitro evaluation of resonant frequency analysis to measure fixed bridge stability[J]. BDJ Open, 2015, 1(1): No.15001. |

| 8 | 钟昌均, 王忠彬, 柳晨阳. 悬索桥主索鞍承载力影响因素及结构优化[J]. 吉林大学学报: 工学版, 2021, 51(6): 2068-2078. |

| Zhong Chang-jun, Wang Zhong-bin, Liu Chen-yang. Influencing factors and structural optimization of main cable saddle bearing capacity of suspension bridge[J]. Journal of Jilin University (Engineering and Technology Edition), 2021, 51(6): 2068-2078. | |

| 9 | Song Guo-hua, Li Ming-hui, Che De-lu. Geometrically nonlinear stability of curved continuous rigid frame bridges with initial high pier imperfections at largest cantilever stage[J]. International Journal of Engineering and Technology, 2019, 11(1): 16-22. |

| 10 | 双超, 周东华, 陈旭, 等. 圆形截面柱二阶承载力的简便计算方法[J]. 吉林大学学报: 工学版, 2020, 50(6): 2178 -2185. |

| Shuang Chao, Zhou Dong-hua, Chen Xu, et al. Simplified calculation method for second-order bearing capacity of circular section columns[J]. Journal of Jilin University (Engineering and Technology Edition), 2020, 50(6): 2178-2185. | |

| 11 | 王钧利, 贺拴海. 高墩大跨径弯桥在悬臂施工阶段刚构的非线性稳定分析[J]. 交通运输工程学报, 2006(2): 30-34. |

| Wang Jun-li, He Shuan-hai. Nonlinear stability analysis of long-span curve bridge with high piers during cantilever construction[J]. Traffic and Transportation Engineering, 2006(2): 30-34. | |

| 12 | 施洲, 张勇, 张育智, 等. 大跨度铁路下承式钢桁梁柔性拱桥稳定性研究[J]. 中国铁道科学, 2019, 40(4): 52-58. |

| Shi Zhou, Zhang Yong, Zhang Yu-zhi, et al. Study on stability of long-span railway through bridge with steel truss girder and flexible arch[J]. China Railway Science, 2019, 40(4): 52-58. | |

| 13 | 王紫超, 杨切. 两节段装配式钢筋混凝土桥墩受压极限承载力研究[J]. 中国港湾建设, 2022, 42(7): 17-22. |

| Wang Zi-chao, Yang Qie. Research on ultimate bearing capacity of two segment prefabricated reinforced concrete pier under compression[J]. China Harbour Engineering, 2022, 42(7): 17-22. | |

| 14 | 顾森华. 混凝土薄壁高墩桥梁结构的稳定性分析及试验研究[D]. 杭州: 浙江大学建筑工程学院, 2008. |

| Gu Sen-hua. Experimental research and stability analysis on structure of concrete thin wall-high pier bridge[D]. Hangzhou: School of Civil Engineering, Zhejiang University, 2008. | |

| 15 | 熊志洪. 钢管混凝土叠合柱高墩极限承载力有限元分析[D]. 杭州: 浙江工业大学建筑工程学院, 2012. |

| Xiong Zhi-hong. The analysis of the ultimate bearing capacity of concrete filled steel tubular columns high pier[D]. Hangzhou: School of Civil Engineering, Zhejiang University of Technology, 2012. | |

| 16 | 李海青, 杨万里, 高璇. 预应力混凝土薄壁高墩刚构桥梁极限承载力分析[J]. 中国公路学报, 2013, 26(6): 128-134. |

| Li Hai-qing, Yang Wan-li, Gao Xuan. Analysis of ultimate bearing capacity of pre-stressed concrete frame bridge with high piers[J]. China Journal of Highway and Transport, 2013, 26(6): 128-134. | |

| 17 | 薛鹏飞, 吴光宇, 汪劲丰. 考虑非线性行为的PC结构桥梁极限承载力分析[J]. 公路, 2011(3): 50-54. |

| Xue Peng-fei, Wu Guang-yu, Wang Jin-feng. Ultimate bearing capacity analysis of PC structure bridges considering nonlinear behavior[J]. Highway, 2011(3): 50-54. | |

| 18 | Das D, Ayoub A. Mixed formulation for geometric and material nonlinearity of shear-critical reinforced concrete columns[J]. Engineering Structures, 2021, 229:No.11587. |

| 19 | 崔苗苗. 铁路钢桁梁柔性拱桥极限承载力分析研究[D]. 成都: 西南交通大学土木工程学院, 2011. |

| Cui Miao-miao. Analysis on ultimate carrying capacity of steel truss beam and flexible arch railway bridge[D]. Chengdu: School of Civil Engineering, Southwest Jiaotong University, 2011. | |

| 20 | 赵曼, 陈士通, 孙志星, 等. 128 m大跨度铁路应急钢桁梁极限荷载[J]. 中国铁道科学, 2021, 42(5): 85-93. |

| Zhao Man, Chen Shi-tong, Sun Zhi-xing, et al. Ultimate load of 128 m large span railway emergency steel truss girder[J]. China Railway Science, 2021, 42(5): 85-93. | |

| 21 | . 铁路桥涵设计规范 [S]. |

| [1] | 谭国金,孔庆雯,何昕,张攀,杨润超,朝阳军,杨忠. 基于动力特性和改进粒子群优化算法的桥梁冲刷深度识别[J]. 吉林大学学报(工学版), 2023, 53(6): 1592-1600. |

| [2] | 江辉,李新,白晓宇. 桥梁抗震结构体系发展述评:从延性到韧性[J]. 吉林大学学报(工学版), 2023, 53(6): 1550-1565. |

| [3] | 张玥,刘传森,宋飞. 桥台背墙对连续梁桥地震易损性的影响[J]. 吉林大学学报(工学版), 2023, 53(5): 1372-1380. |

| [4] | 兰树伟,周东华,陈旭,莫南明. 双柱式高墩桥梁整体稳定性的实用算法[J]. 吉林大学学报(工学版), 2023, 53(4): 1105-1111. |

| [5] | 孙琪凯,张楠,刘潇,周子骥. 基于Timoshenko梁理论的钢-混组合梁动力折减系数[J]. 吉林大学学报(工学版), 2023, 53(2): 488-495. |

| [6] | 叶华文,段智超,刘吉林,周渝,韩冰. 正交异性钢⁃混组合桥面的轮载扩散效应[J]. 吉林大学学报(工学版), 2022, 52(8): 1808-1816. |

| [7] | 王立峰,肖子旺,于赛赛. 基于Bayesian网络的多塔斜拉桥挂篮系统风险分析的新方法[J]. 吉林大学学报(工学版), 2022, 52(4): 865-873. |

| [8] | 张彦玲,王灿,张旭,王昂洋,李运生. 不同吊杆形式悬索桥人致振动分析及舒适度评价[J]. 吉林大学学报(工学版), 2022, 52(11): 2644-2652. |

| [9] | 周靖,黎亚军,赵卫锋,罗宗健,补国斌. 胶合竹板-钢管约束收尘石粉混凝土柱的偏压性能[J]. 吉林大学学报(工学版), 2021, 51(6): 2096-2107. |

| [10] | 钟昌均,王忠彬,柳晨阳. 悬索桥主索鞍承载力影响因素及结构优化[J]. 吉林大学学报(工学版), 2021, 51(6): 2068-2078. |

| [11] | 陈巍,万田保,王忠彬,厉萱,沈锐利. 悬索桥主缆除湿的内部送气管道设计与性能[J]. 吉林大学学报(工学版), 2021, 51(5): 1749-1755. |

| [12] | 郭殊伦,钟铁毅,闫志刚. 大跨度斜拉桥拉索的抖振响应计算方法[J]. 吉林大学学报(工学版), 2021, 51(5): 1756-1762. |

| [13] | 高凯,刘纲. 全局临界强度分枝-约界法的有效强度改进[J]. 吉林大学学报(工学版), 2021, 51(2): 597-603. |

| [14] | 宫亚峰,宋加祥,谭国金,毕海鹏,刘洋,单承新. 多车桥梁动态称重算法[J]. 吉林大学学报(工学版), 2021, 51(2): 583-596. |

| [15] | 孔庆雯,谭国金,王龙林,王勇,魏志刚,刘寒冰. 基于有限元方法的裂缝箱梁桥自振特性分析[J]. 吉林大学学报(工学版), 2021, 51(1): 225-232. |

|

||