吉林大学学报(工学版) ›› 2023, Vol. 53 ›› Issue (9): 2695-2705.doi: 10.13229/j.cnki.jdxbgxb.20211178

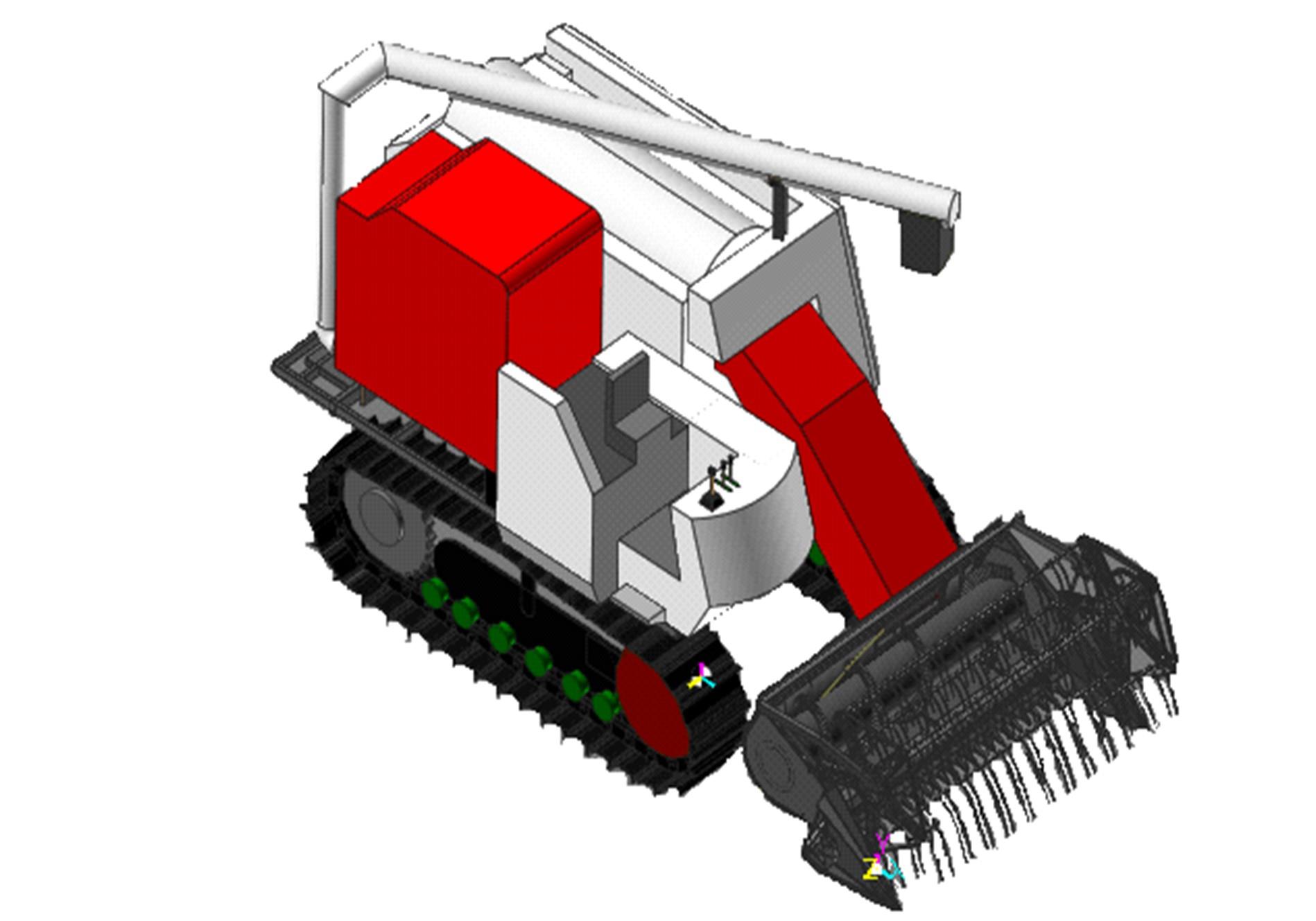

履带式再生稻收获机田间转弯机理和性能试验

- 华南农业大学 南方农业机械与装备关键技术省部共建教育部重点实验室,广州 510642

Field turning mechanism and performance test of crawler reclaimed rice harvester

Wei-jian LIU( ),Xi-wen LUO,Shan ZENG(

),Xi-wen LUO,Shan ZENG( ),Zhi-qiang WEN,Li ZENG

),Zhi-qiang WEN,Li ZENG

- Key Laboratory of Key Technology on Agricultural Machine and Equipment,Ministry of Education,South China Agricultural University,Guangzhou 510642,China

摘要:

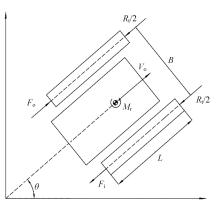

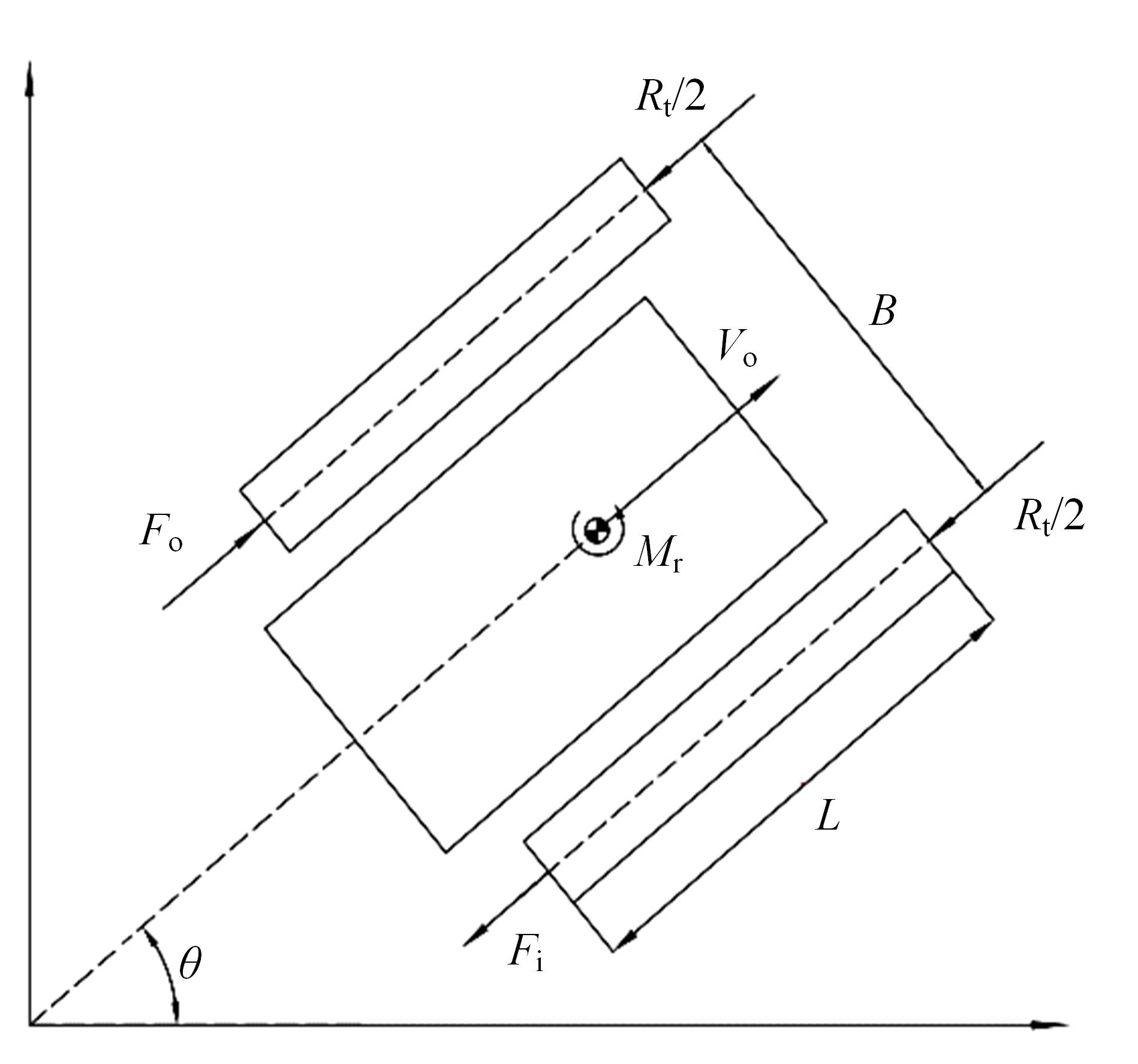

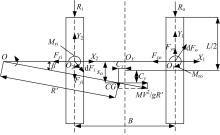

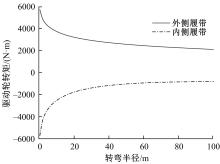

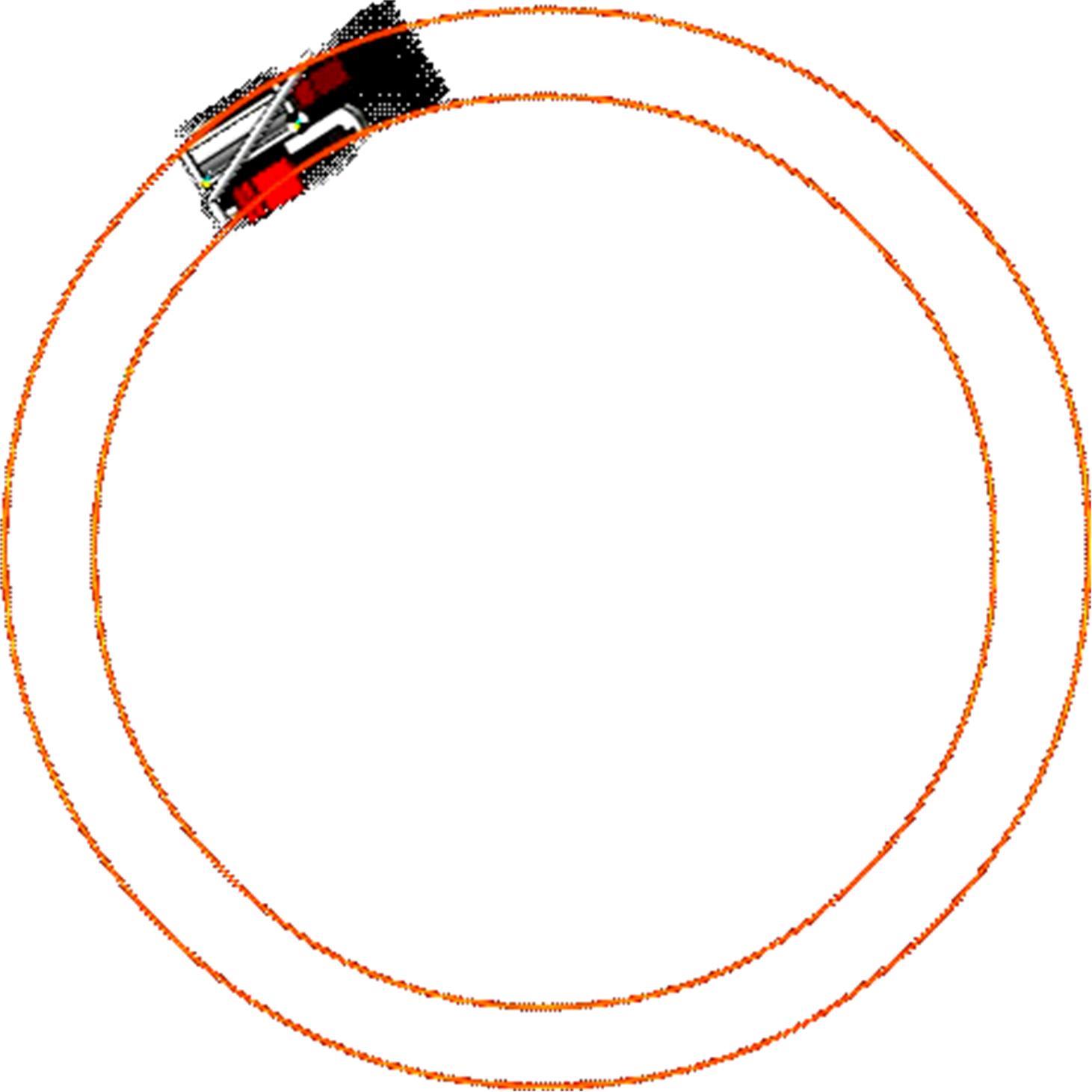

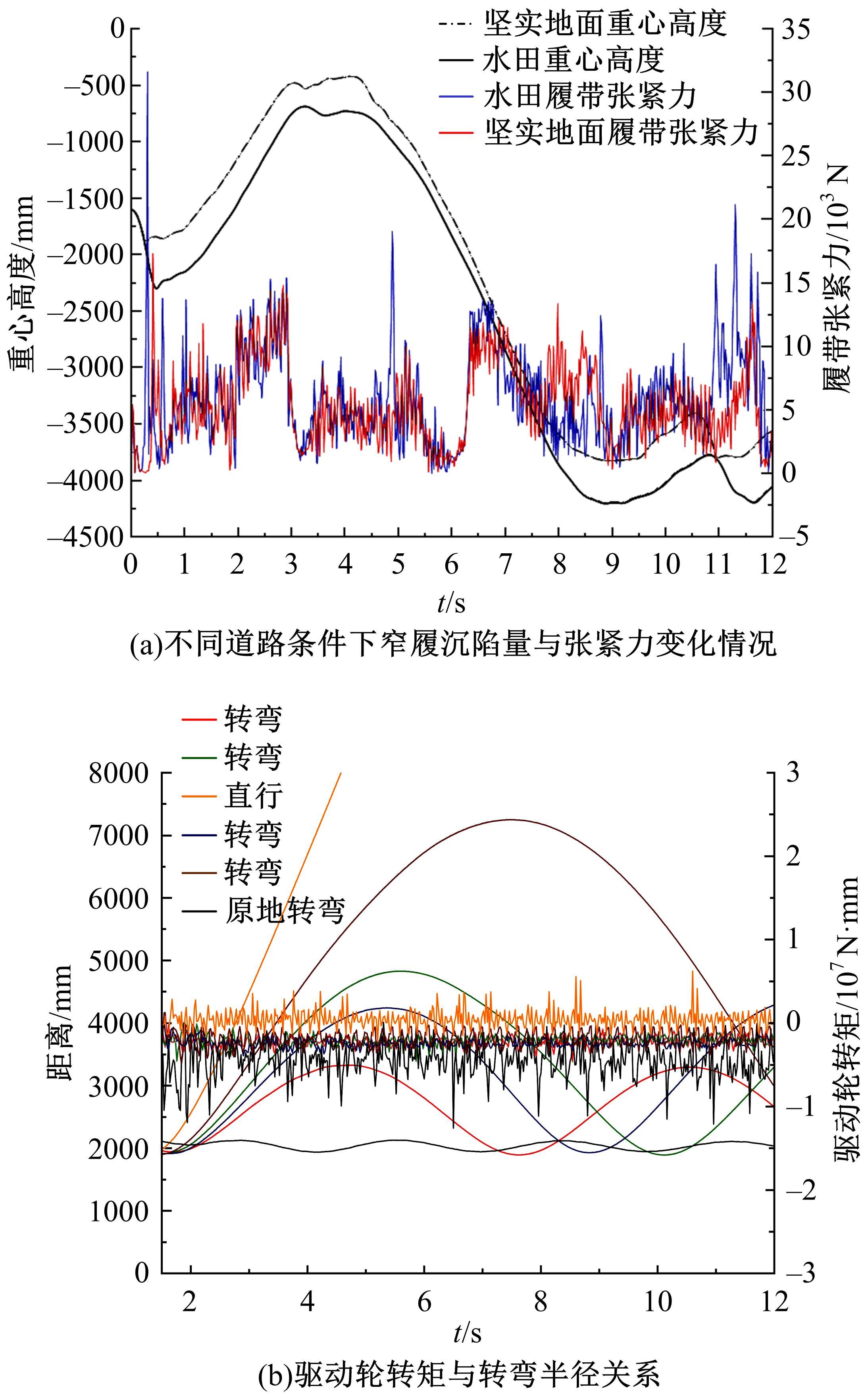

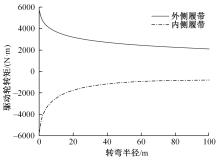

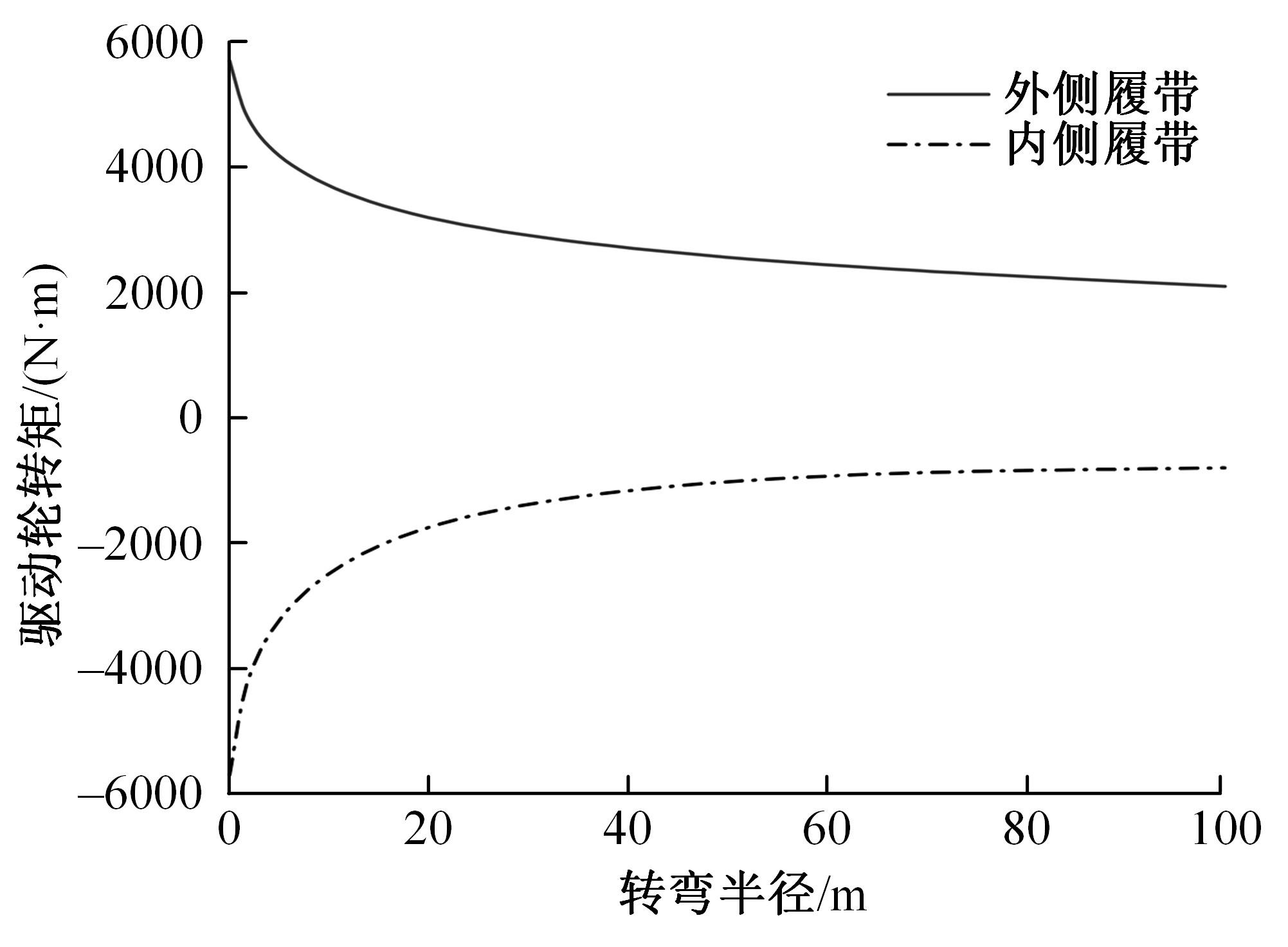

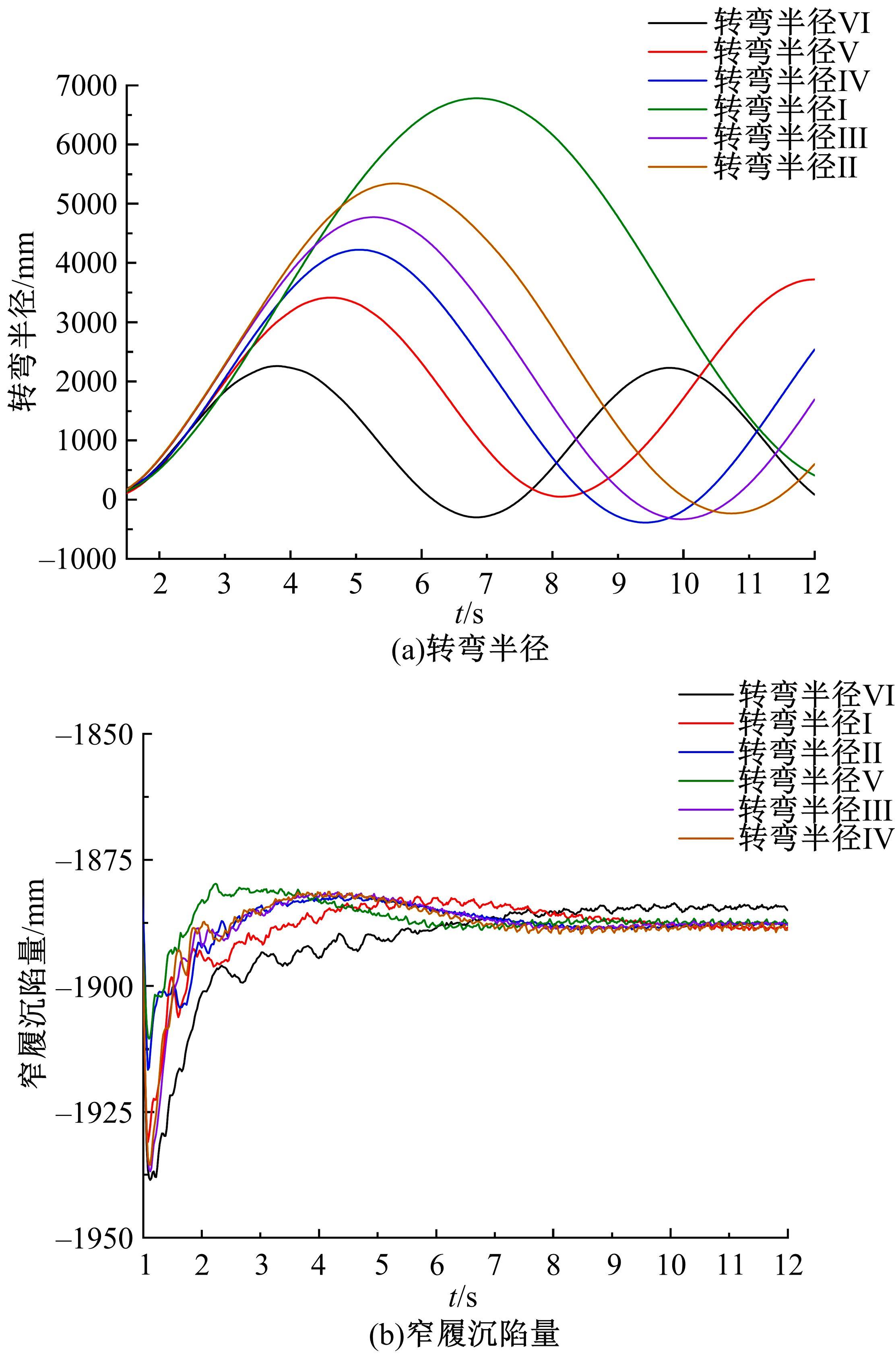

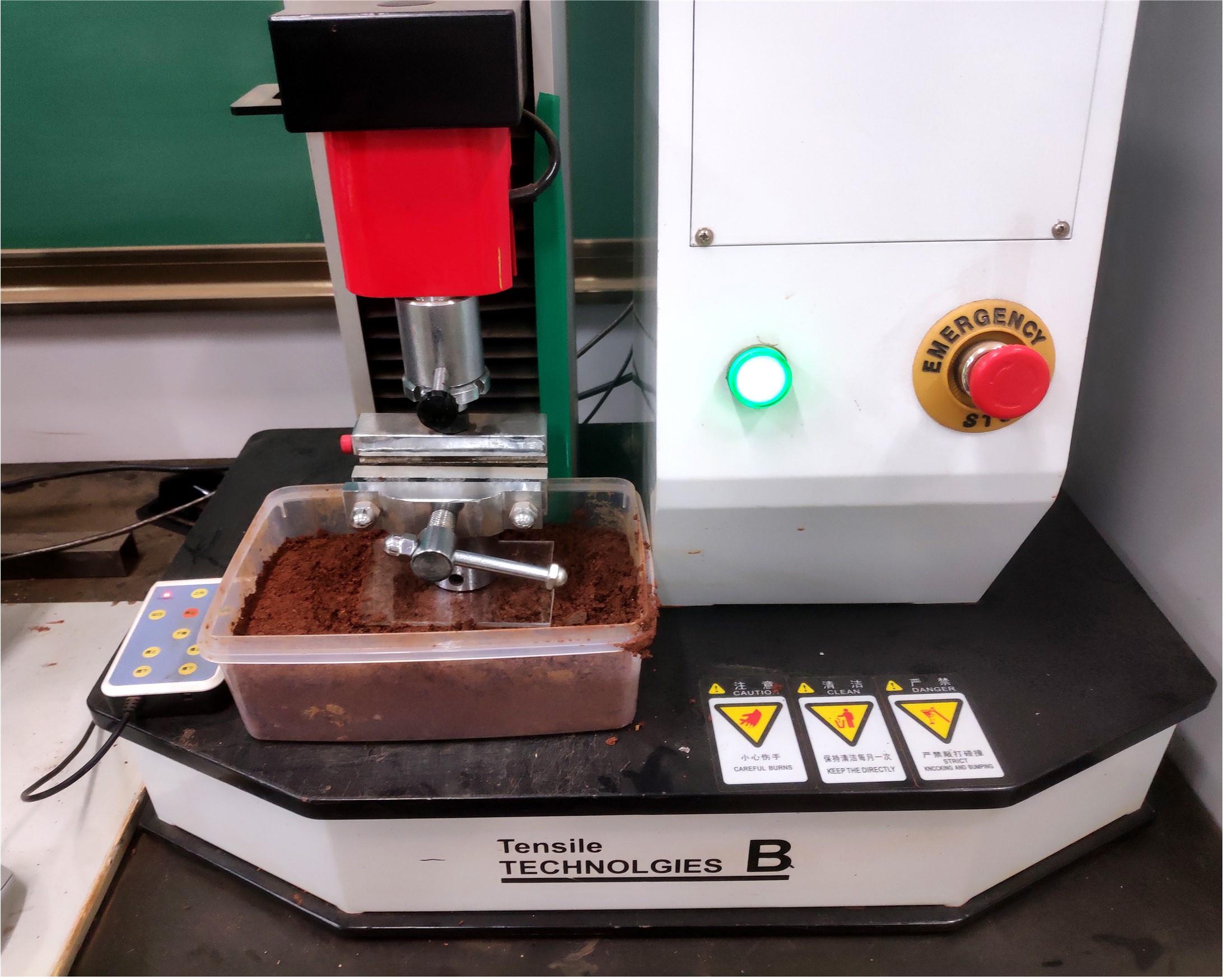

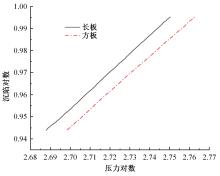

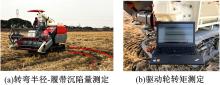

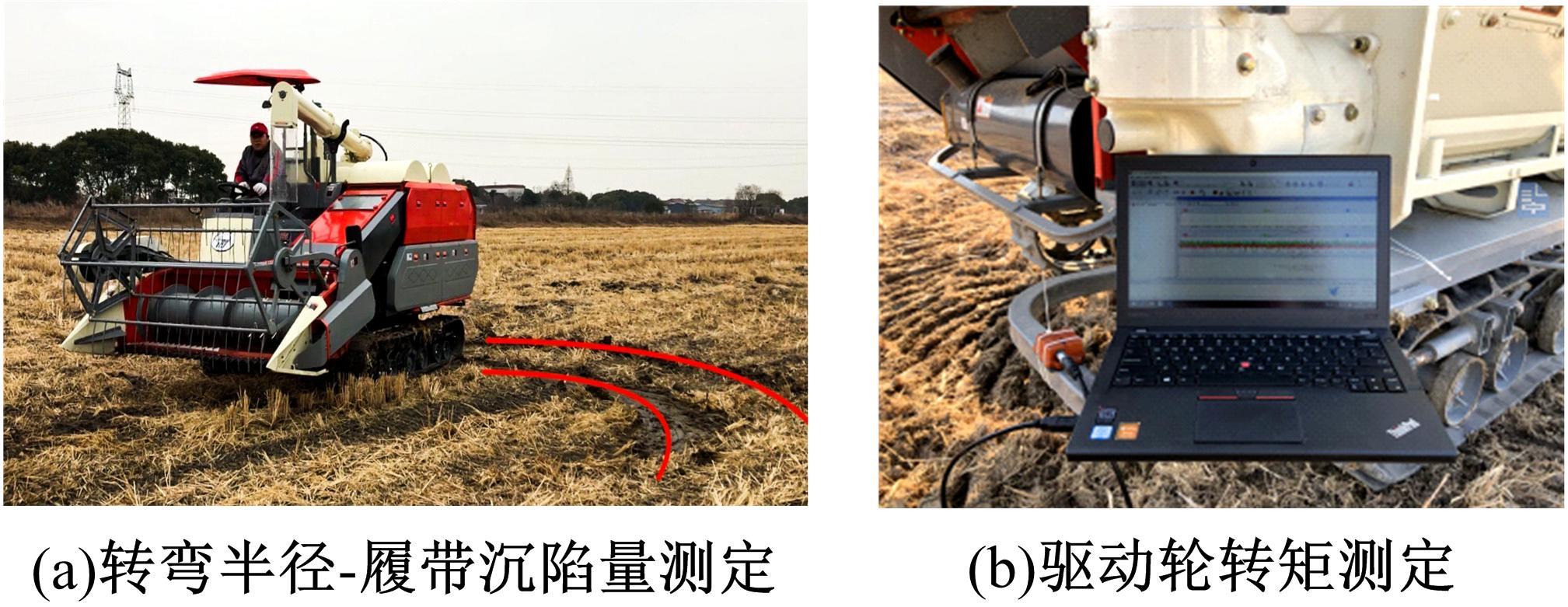

为进一步探究履带式再生稻收获机的田间转弯性能,对转弯半径与窄履沉陷量的关系进行了全面分析。主要分析了再生稻收获机田间转弯的基本原理,对窄履驱动力、滑移率、窄履沉陷量以及行驶阻力进行了计算,使用Recurdyn分析获得转弯半径与窄履沉陷量的函数关系。仿真结果表明:随着转弯半径的增大,两侧驱动轮转矩、窄履沉陷量均减小,驱动轮转矩从5835 N·m减小到672.3 N·m,驱动轮转矩、窄履沉陷量峰值均处于转弯半径为0处。通过田间试验对仿真结果的可靠性进行验证,结果表明:随着转弯半径的增大,沉陷量从186.24 mm减小到103.57 mm,试验现象和计算结果均与Recurdyn仿真吻合,证明仿真结果可靠,该研究可为后期再生稻收获机转弯理论研究提供参考。

中图分类号:

- S225.4

| 1 | 王飞, 彭少兵. 水稻绿色高产栽培技术研究进展[J]. 生命科学, 2018, 30(10): 1129-1136. |

| Wang Fei, Peng Shao-bing. Research progress in rice green and high-yield management practices[J]. Chinese Bulletin of Life Sciences, 2018, 30(10): 1129-1136. | |

| 2 | 徐富贤, 熊洪, 张林, 等. 再生稻产量形成特点与关键调控技术研究进展[J]. 中国农业科学, 2015, 48(9): 1702-1717. |

| Xu Fu-xian, Xiong Hong, Zhang Lin, et al. Progress in research of yield formation of ratooning rice and its high-yielding key regulation technologies[J]. Scientia Agricultura Sinica, 2015, 48(9): 1702-1717. | |

| 3 | 曾山, 黄登攀, 杨文武,等. 三角履带式再生稻收割机底盘的设计与试验[J]. 吉林大学学报: 工学版, 2022, 52(8): 1943-1950. |

| Zeng Shan, Huang Deng-pan, Yang Wen-wu, et al. Design and test of the chassis of triangular crawler reclaiming rice harvester[J]. Journal of Jilin University (Engineering and Technology Edition), 2022, 52(8): 1943-1950. | |

| 4 | 刘伟健, 罗锡文, 曾山, 等. 基于模糊PID控制的再生稻自适应仿形割台性能试验与分析[J]. 农业工程学报, 2022, 38(10): 1-9. |

| Liu Wei-jian, Luo Xi-wen, Zeng Shan, et al. Performance test and analysis of the self-adaptive profiling header for ratooning rice based on fuzzy PID control[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2022, 38(10): 1-9. | |

| 5 | 张国忠, 张翼翔, 黄见良, 等. 再生稻割穗机的设计与性能试验[J]. 华中农业大学学报, 2016, 35(1): 131-136. |

| Zhang Guo-zhong, Zhang Yi-xiang, Huang Jian-liang, et al. Design and performance testing a novel head spike harvester of ratoon rice[J]. Journal of Huazhong Agriculturall University, 2016, 35(1): 131-136. | |

| 6 | 付建伟, 张国忠, 谢干, 等. 双通道喂入式再生稻收获机研制[J]. 农业工程学报,2020, 36(3): 11-20. |

| Fu Jian-wei, Zhang Guo-zhong, Xie Gan, et al. Development of double-channel feeding harvester for ratoon rice[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2020, 36(3): 11-20. | |

| 7 | 雷志强, 张国忠, 彭少兵, 等. 全履带式再生稻收割机行走底盘碾压率的模拟与分析[J]. 安徽农业大学学报, 2017, 44(4): 738-743. |

| Lei Zhi-qiang, Zhang Guo-zhong, Peng Shao-bing, et al. Simulation and analysis of the stubble pushing rate by chassis of the completely tracked harvester for the ratoon rice[J]. Journal of Anhui Agricultural University, 2017, 44(4): 738-743. | |

| 8 | Wong J Y. Theory of Ground Vehicles[M]. New york: John Wiley & Sons, 1993. |

| 9 | Wong J Y, Chiang C F. A general theory for skid steering of tracked vehicles on firm ground[J]. Proceedings of the Institution of Mechanical Engineers, Part D: Journal of Automobile Engineering, 2001, 215(3): 343-355. |

| 10 | Wong J Y, Huang W. "Wheels vs. tracks"-a fundamental evaluation from the traction perspective[J]. Journal of Terramechanics, 2006, 52(43): 27-43. |

| 11 | Rahman A, Yahya A, Zohadie M. Design parameters optimization simulation of a prototype segmented rubber track vehicle for Sepang peat in Malaysia[J]. American Journal of Applied Sciences, 2005, 2(3): 655-671. |

| 12 | 杨聪彬, 董明明, 顾亮, 等. 考虑履刺形状的履带板土壤推力研究[J]. 北京理工大学学报, 2015, 35(11): 22-25. |

| Yang Cong-bin, Dong Ming-ming, Gu Liang, et al. Research on soil shear strength considering the shape of grouse[J]. Trancsactions of Beijing Institute of Technology, 2015, 35(11): 22-25. | |

| 13 | 宋振家. 坚实地面上均布载荷时的履带车辆转弯理论[J]. 装甲兵技术学院教学与科研, 1980, 10(3): 1-10. |

| Song Zhen-jia. Steering theory of tracked vehicle with uniformpressure distribution on hard land[J]. Armored Force Technologi-cal Institute Education and Scientific Reaserch, 1980, 10(3): 1-10. | |

| 14 | 程军伟, 高连华, 王红岩, 等. 履带车辆转弯分析[J]. 兵工学报, 2007, 10(9): 1110-1115. |

| Cheng Jun-wei, Gao Lian-hua, Wang Hong-yan. Analysis on the steering of tracked vehicles[J]. Acta Armamentarii, 2007, 10(9): 1110-1115. | |

| 15 | Laura E Ray. Estimation of terrain forces and parameters for rigid-wheeled vehicles[J]. IEEE Transactions on Robotics and Automation, 2009, 25(3): 717-726. |

| 16 | Pentzer J, Brennan S N, Reichard K M. Model-based prediction of skid-steer robot kinematics using online estimation of track instantaneous centers of rotation[J]. Journal of Field Robotics, 2014, 31(3): 455-476. |

| 17 | Martínez J L, Mandow A, Morales J, et al. Approximating kinematics for tracked mobile robots[J]. The International Journal of Robotics Research, 2005, 24(10): 867-878. |

| 18 | Lyasko Modest. Slip sinkage effect in soil-vehicle mechanics[J]. Journal of Terramechanics, 2010, 47(1): 21-31. |

| 19 | 李西秦, 刘冰, 齐劲峰. 车轮动力半径与滑转率的研究[J]. 拖拉机与农用运输车, 2002, 28(2): 17-20. |

| Li Xi-qin, Liu Bing, Qi Jin-feng. Research on wheel radius and slippage[J]. Tractors & Agricultural Vehicles, 2002, 28(2): 17-20. | |

| 20 | 杨财, 宋健, 周艳霞. 车辆转弯时牵引力控制系统前轮滑转率算法[J]. 农业机械学报, 2008,39(8): 38-40. |

| Yang Cai, Song Jian, Zhou Yan-xia. Algorithm for front wheel slip ratio in the traction control system when turning[J]. Transactions of the Chinese Society of Agricultural Machinery, 2008, 39(8): 38-40. | |

| 21 | Bekker M G. Introduction to Terrain-vehicle Systems[M]. Michigan: The University of Michigan Press, 1969. |

| 22 | Karafiath L L, Nowatzki E A. Soil Mechanics for Off-road Vehicle Engineering[M]. Clausthal: Transportation Technology Publications, 1978. |

| 23 | 杜小强, 宁晨, 杨振华, 等. 跨式油茶果收获机履带底盘行走液压系统设计与试验[J]. 农业机械学报, 2023, 54(3): 139-147. |

| Du Xiao-qiang, Ning Chen, Yang Zhen-hua, et al. Design and experiment of hydraulic system for crawler chassis of straddle type camellia oleifera fruit harvester[J]. Transactions of the Chinese Society for Agricultural Machinery, 2023, 54(3): 139-147. | |

| 24 | 宋朋, 吕金庆. 基于EDEM-RecurDyn的自激式振动深松铲耦合仿真研究[J]. 东北农业大学学报,2023,54(2):87-94. |

| Song Peng, Lv Jin-qing. Effects of coupling simulation of self-excited vibratory subsoiler based on EDEM-RecurDyn[J]. Journal of Northeast Agricultural University, 2023, 54(2): 87-94. | |

| 25 | 刘汉光,王国强,孟东阁,等. 液压挖掘机履带行走装置的合理预张紧力[J]. 吉林大学学报:工学版,2018,48(2):486-491. |

| Liu Han-guang, Wang Guo-qiang, Meng Dong-ge, et al. Reasonable pre-tension reaserch of crawler traveling gear of hydraulic excavator[J]. Journal of Jilin University (Engineering and Technology Edition), 2018, 48(2): 486-491. |

| [1] | 周鹏飞,陈学庚,蒙贺伟,梁荣庆,张炳成,坎杂. 滚筒式机收膜杂除土装置设计及试验[J]. 吉林大学学报(工学版), 2023, 53(9): 2718-2731. |

| [2] | 张茂健,金敬福,陈奕颖,陈廷坤. 轮式拖拉机对称结构的振动特性[J]. 吉林大学学报(工学版), 2023, 53(7): 2136-2142. |

| [3] | 朱光强,李天宇,周福君,王文明. 鲜食玉米仿生摘穗装置设计与试验[J]. 吉林大学学报(工学版), 2023, 53(4): 1231-1244. |

| [4] | 顿国强,刘文辉,毛宁,吴星澎,纪文义,马洪岩. 交替换岗式大豆小区育种排种器优化设计与试验[J]. 吉林大学学报(工学版), 2023, 53(1): 285-296. |

| [5] | 曾山,黄登攀,杨文武,刘伟健,文智强,曾力. 三角履带式再生稻收割机底盘的设计与试验[J]. 吉林大学学报(工学版), 2022, 52(8): 1943-1950. |

| [6] | 魏国粱,张青松,王彪,何坤,廖庆喜. 油菜直播机扣垡犁体参数分析与试验[J]. 吉林大学学报(工学版), 2022, 52(7): 1709-1718. |

| [7] | 刘洋. 动臂塔机卸载冲击仿真及试验[J]. 吉林大学学报(工学版), 2022, 52(6): 1292-1300. |

| [8] | 刘佳杰,马兰,向伟,颜波,文庆华,吕江南. 4QM-4.0型麻类青饲料联合收获机研制[J]. 吉林大学学报(工学版), 2022, 52(12): 3039-3048. |

| [9] | 曾百功,黎奎良,叶进,任丽丽,Rashidov Jaloliddin,张明. 工厂化上海青流水线收割装置的设计与试验[J]. 吉林大学学报(工学版), 2022, 52(11): 2756-2764. |

| [10] | 万星宇,廖庆喜,蒋亚军,单伊尹,周宇,廖宜涛. 饲用油菜机械化收获切碎过程离散元仿真与试验[J]. 吉林大学学报(工学版), 2022, 52(11): 2735-2745. |

| [11] | 朱光强,李天宇,周福君. 鲜食玉米仿生摘穗柔性夹持输送装置设计与试验[J]. 吉林大学学报(工学版), 2022, 52(10): 2486-2500. |

| [12] | 梁荣庆,钟波,蒙贺伟,孙志民,坎杂. 4QJ⁃3型青贮燕麦捡拾割台的研制[J]. 吉林大学学报(工学版), 2021, 51(5): 1887-1896. |

| [13] | 王新彦,江泉,吕峰,易政洋. 基于参数化模型的零转弯半径割草机侧翻稳定性[J]. 吉林大学学报(工学版), 2021, 51(5): 1908-1918. |

| [14] | 袁佳诚,王昌,何坤,万星宇,廖庆喜. 油菜联合收获机筛下物组分质量比对清选性能的影响[J]. 吉林大学学报(工学版), 2021, 51(5): 1897-1907. |

| [15] | 王刚,刘慧力,贾洪雷,郭春江,丛永健,屈明浩. 触碰定位式玉米行间除草装置的设计与试验[J]. 吉林大学学报(工学版), 2021, 51(4): 1518-1527. |

|