吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (6): 1807-1820.doi: 10.13229/j.cnki.jdxbgxb.20220860

• 农业工程·仿生工程 • 上一篇

油菜联合收获导流式双筒旋风分离清选装置设计及试验

- 1.华中农业大学 工学院,武汉 430070

2.农业农村部 长江中下游农业装备重点实验室,武汉 430070

Design and experiment of diversion type double-cylinder cyclone separation system for rapeseed combine harvester

Cai-xia SHU1,2( ),Jia YANG1,Qing-xi LIAO1,2,Xing-yu WAN1,Jia-cheng YUAN1

),Jia YANG1,Qing-xi LIAO1,2,Xing-yu WAN1,Jia-cheng YUAN1

- 1.College of Engineering,Huazhong Agricultural University,Wuhan 430070,China

2.Key Laboratory of Agricultural Equipment in Mid-lower Yangtze River,Ministry of Agriculture and Rural Affairs,Wuhan 430070,China

摘要:

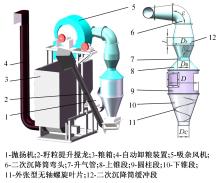

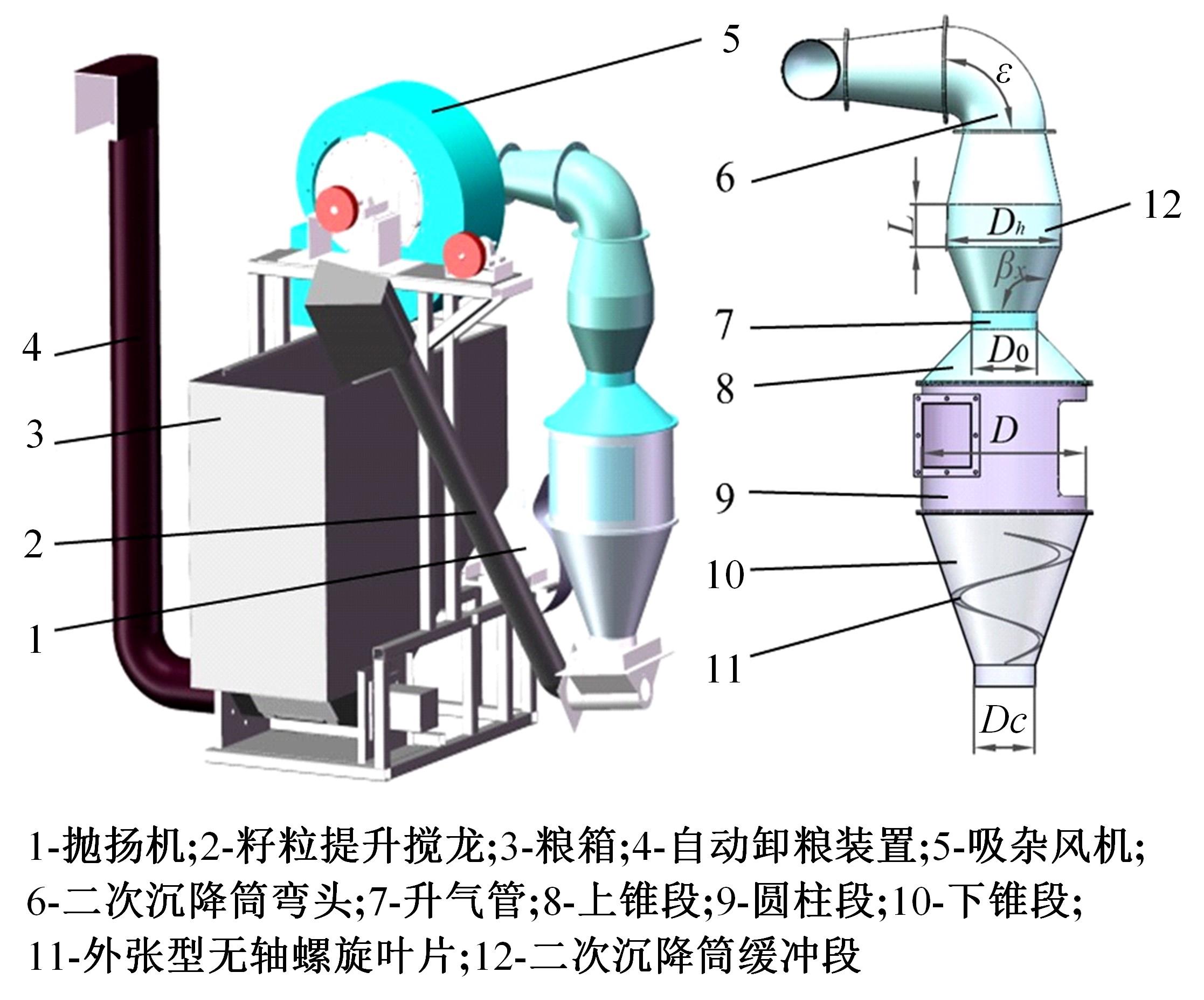

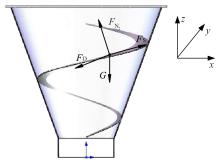

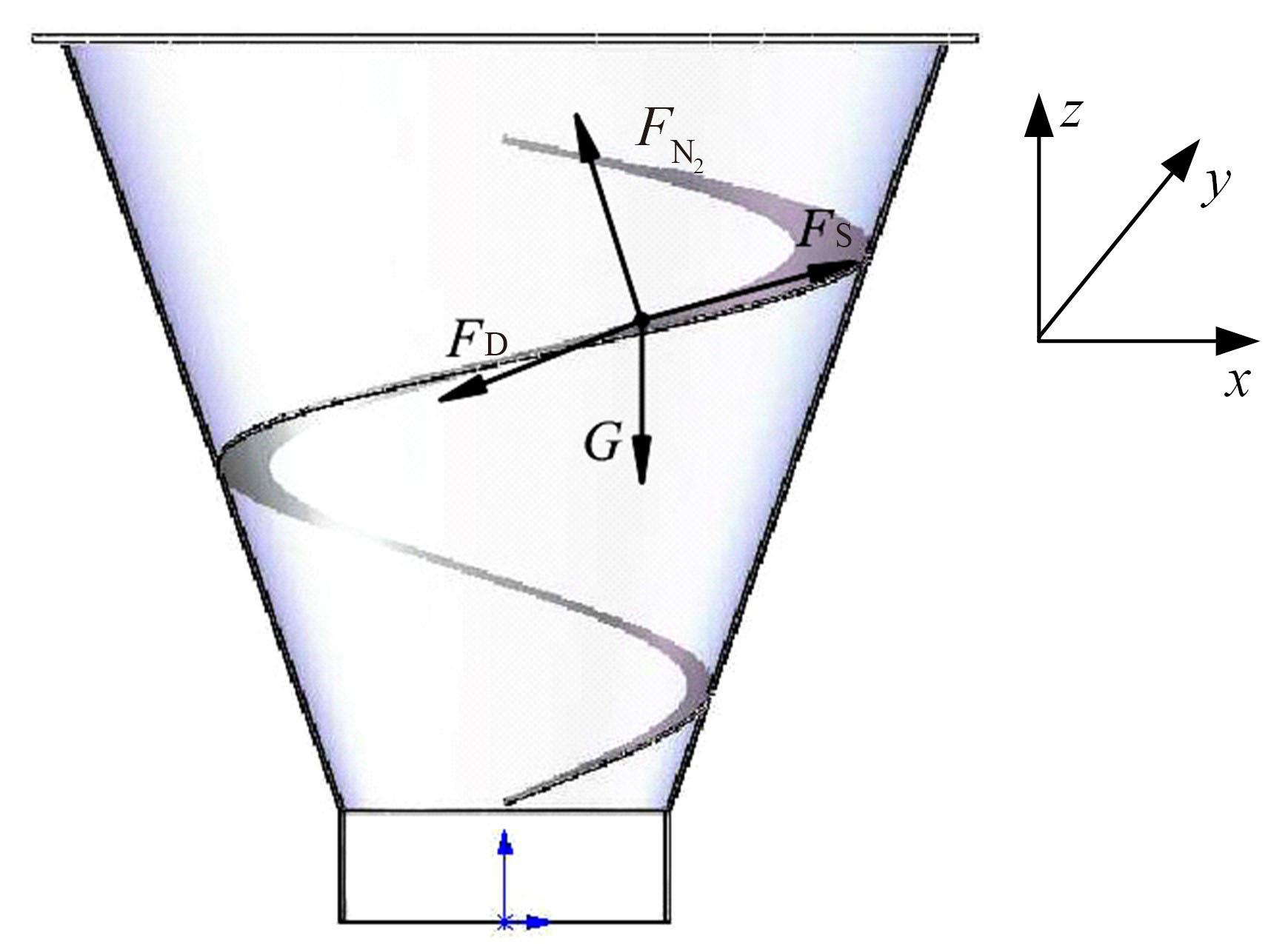

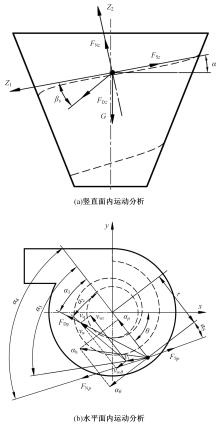

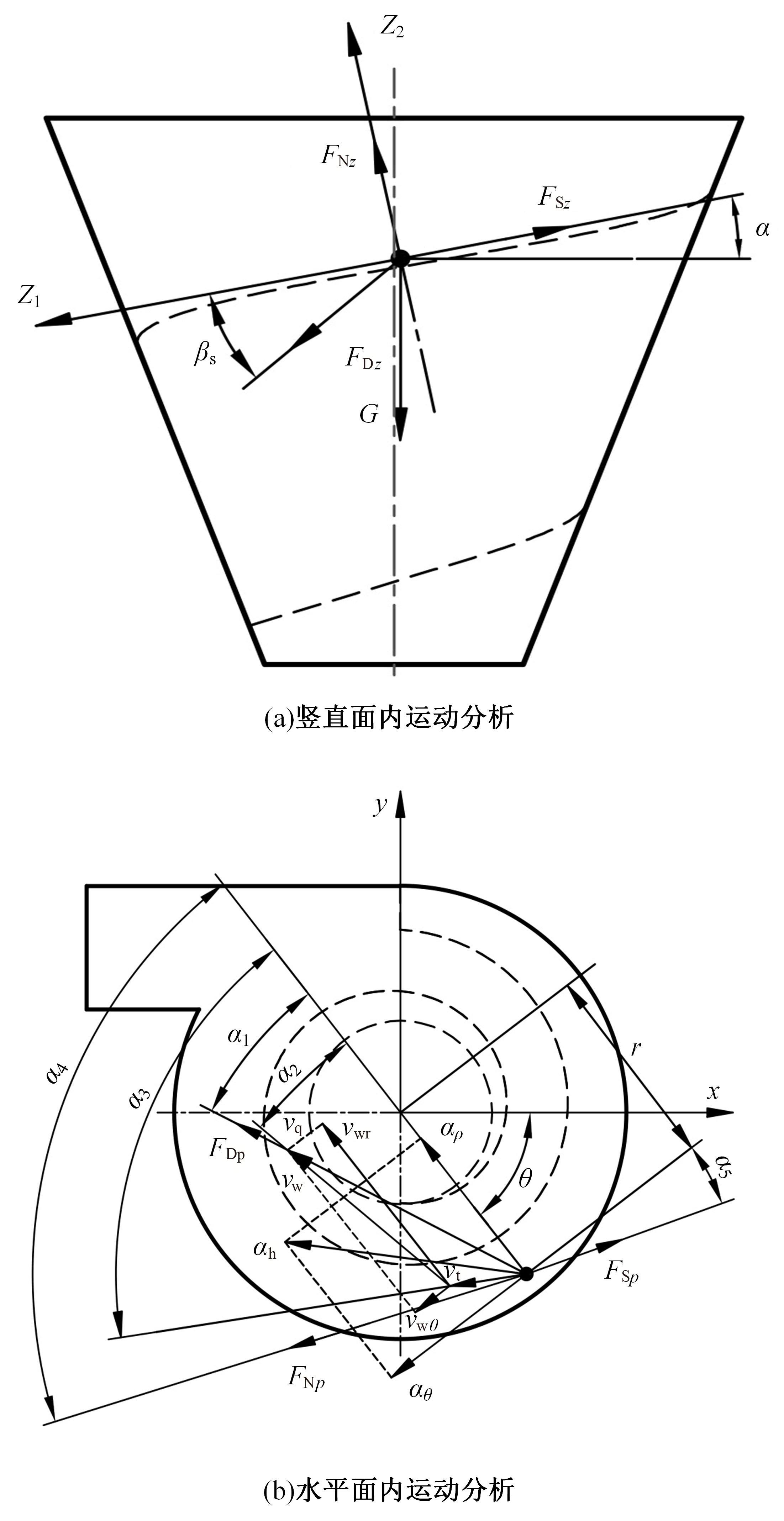

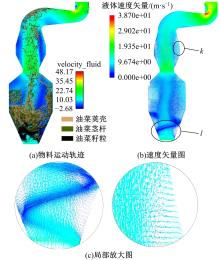

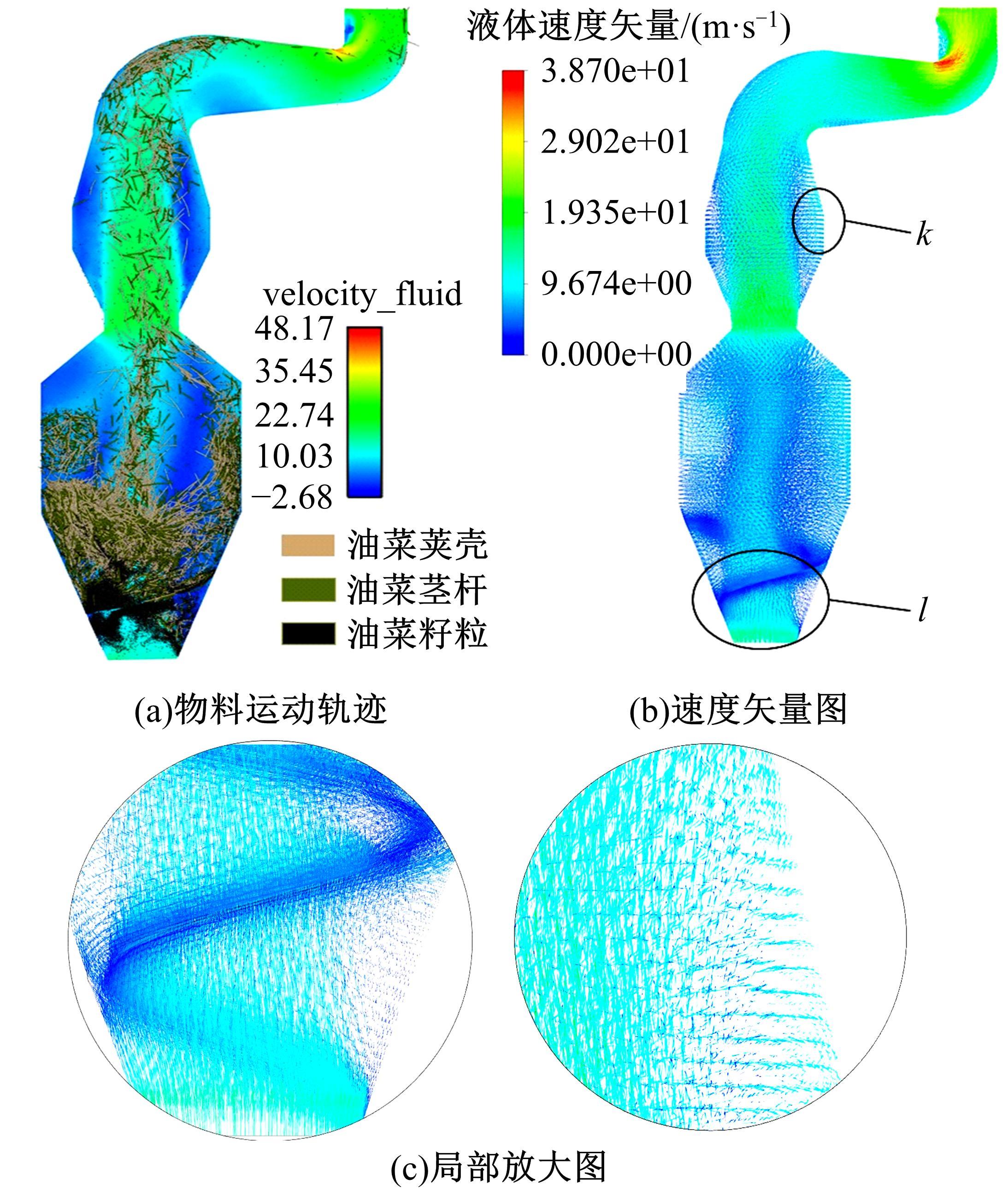

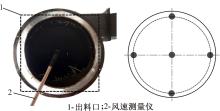

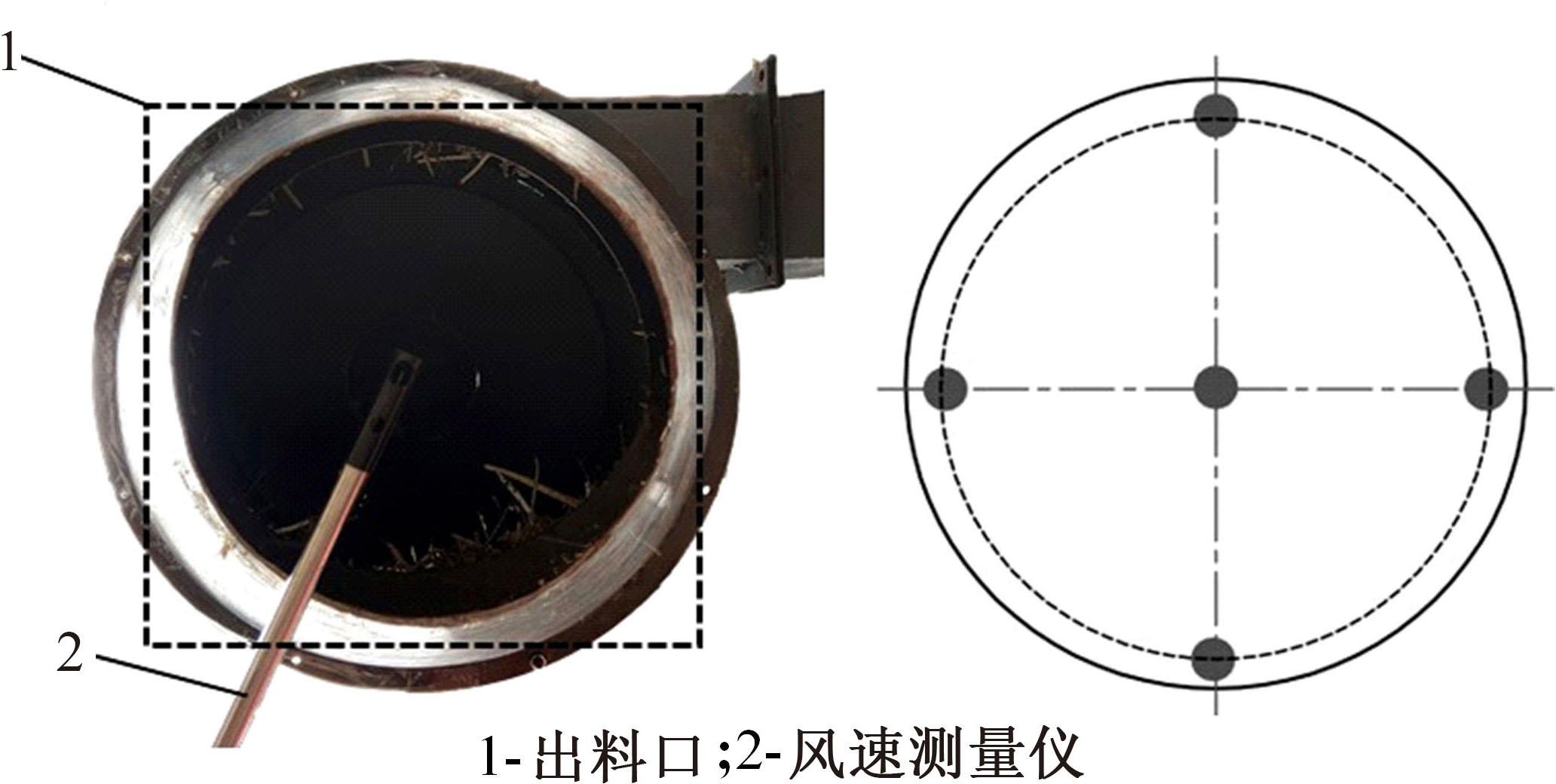

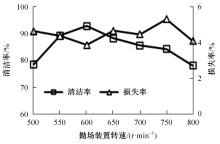

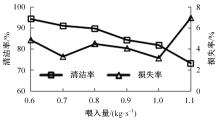

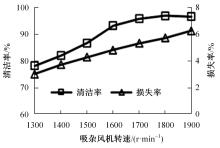

针对油菜联合收获旋风分离清选装置损失率较高、清洁率有待提升的问题,研制了具有导流、二次沉降作用的导流式双筒旋风分离清选装置。通过分析计算确定了旋风分离筒结构参数,基于静力学和运动学分析了油菜籽粒在导流式旋风分离筒内部气流场中的迁移过程,建立了清选筒内油菜籽粒运动微分方程组,确定了外张型无轴螺旋叶片和二次沉降筒的结构参数范围,明确了影响旋风分离清选装置清选性能的主要因素,计算流体力学(CFD)和离散元法(DEM)耦合模型验证了所设计结构的合理性,并对导流式双筒旋风分离清选装置内部气流速度进行了验证。采用单因素试验与二次旋转正交组合试验研究了清选装置喂入量、抛扬机转速、吸杂风机转速对旋风分离清选装置清选性能的影响,并构建了油菜籽粒清洁率、损失率与清选装置喂入量、抛扬机转速、吸杂风机转速的回归方程,通过优化得出了最佳参数组合。试验结果表明:喂入量为0.6~1.0 kg/s,抛扬机转速为550~750 r/min,吸杂风机转速为1 400~1 800 r/min时,清选性能较好。最佳参数组合如下喂入量为0.71 kg/s、抛扬机转速为616 r/min、吸杂风机转速为1 667 r/min;田间试验表明:旋风分离清选装置清洁率为92.39%,损失率为4.80%。

中图分类号:

- S225.99

| 1 | 陈慧,高丽萍,廖庆喜,等. 肥料减量深施对土壤N2O排放和冬油菜产量的影响[J]. 农业工程学报, 2020, 36(21): 80-87. |

| Chen Hui, Gao Li-ping, Liao Qing-xi, et al. Effects of reduced and deep fertilizer on soil N2O emission and yield of winter rapeseed[J]. Transactions of the Chinese Society of Agricultural Engineering, 2020, 36(21): 80-87. | |

| 2 | 罗海峰,汤楚宙,官春云,等. 适应机械化收获的田间油菜植株特性研究[J].农业工程学报, 2010, 26():61-66. |

| Luo Hai-feng, Tang Chu-zhou, Guan Chun-yun, et al. Plant characteristic research on field rape based on mechanized harvesting adaptability[J]. Transactions of the Chinese Society of Agricultural Engineering, 2010, 26(Sup.1): 61-66. | |

| 3 | 万星宇,廖庆喜,廖宜涛,等. 油菜全产业链机械化智能化关键技术装备研究现状及发展趋势[J].华中农业大学学报, 2021, 40(2): 24-44. |

| Wan Xing-yu, Liao Qing-xi, Liao Yi-tao, et al. Situation and prospect of key technology and equipment in mechanization and intelligentization of rapeseed whole industry chain[J]. Journal of Huazhong Agricultural University, 2021, 40(2): 24-44. | |

| 4 | 徐立章,李洋,李耀明,等. 谷物联合收获机清选技术与装置研究进展[J]. 农业机械学报, 2019, 50(10):1-16. |

| Xu Li-zhang, Li Yang, Li Yao-ming, et al. Research progress on cleaning technology and device of grain combine harvester[J]. Transactions of the Chinese Society for Agricultural Machinery, 2019, 50(10): 1-16. | |

| 5 | Evangelista R L, Hojilla-Evangelista M P, Cermak S C,et al. Dehulling of coriander fruit before oil extraction[J].Industrial Crops and Products, 2015, 69: 378-384. |

| 6 | Innocentini M D M, Barizan W S, Alves M N O, et al. Pneumatic separation of hulls and meats from cracked soybeans[J]. Food and Bioproducts Processing, 2009, 87(4): 237-246. |

| 7 | Dai F, Song X F, Guo W J, et al. Simulation and test on separating cleaning process of flax threshing material based on gas-solid coupling theory[J]. International Journal of Agricultural and Biological Engineering, 2020, 13(1): 73-81. |

| 8 | Wan Xing-yu, Liao Qing-xi, Xu Yang,et al. Design and evaluation of cyclone separation cleaning devices using a conical sieve for rape combine harvesters[J]. Applied Engineering in Agriculture, 2018, 34(4): 677-686. |

| 9 | 王荣东,杜海鸥,王国芝,等. 旋风组钠气溶胶去除系统性能验证[J].原子能科学技术, 2022, 56(6):1078-1084. |

| Wang Rong-dong, Du Hai-ou, Wang Guo-zhi, et al. Performace verification of sodium aerosol removal system in cyclone group[J]. Atomic Energy Science and Technology, 2022, 56(6): 1078-1084. | |

| 10 | Parvaz F, Hosseini S H, Elsayed K, et al. Numerical investigation of effects of inner cone on flow field, performance and erosion rate of cyclone separators[J]. Separation and Purification Technology, 2018,201: 233-237. |

| 11 | 王晨雯. 旋风分离器内短路流的流动特征与形成机理研究[D]. 兰州:兰州大学资源环境学院,2020. |

| Wang Chen-wen. A study on the characteristics and mechanism of short-circuit flow in a gas cyclone[D]. Lanzhou: College of Earth and Enviornmental Science, Lanzhou University, 2020. | |

| 12 | 戴飞. 胡麻脱粒物料分离清选机理与关键技术研究[D].兰州:甘肃农业大学机电工程学院, 2020. |

| Dai Fei. Study on the separating-cleaning mechanism andkey technology of flax threshing material[D]. Lanzhou: Gansu Agricultural University Mechanical and Electrical Engineering college, 2020. | |

| 13 | 谢超,刘大为,李旭,等. 小型水稻联合收割机旋风分离清选装置的结构优化与试验[J].中国农业科技导报,2018, 20(5): 54-63. |

| Xie Chao, Liu Da-wei, Li Xu, et al. Structure optimization and experiment on cyclone separation-purification device for small rice combine harvester[J]. Journal of Agricultural Science and Technology, 2018, 20(5): 54-63. | |

| 14 | 金鑫,杜新武,甘帮兴,等. 小型联合收获机旋风分离系统清选性能试验[J]. 农业机械学报, 2016, 47(5): 99-105. |

| Jin Xin, Du Xin-wu, Gan Bang-xing, et al. Cleaning performance experiment of cyclone separating system in miniature combine harvester[J]. Transactions of the Chinese Society for Agricultural Machinery, 2016, 47(5): 99-105. | |

| 15 | 刘师多,张利娟,师清翔,等. 微型小麦联合收获机旋风分离清选系统研究[J]. 农业机械学报, 2006(6):45-48. |

| Liu Shi-duo, Zhang Li-juan, Shi Qing-xiang, et al. Experimental research on cyclone separating cleaning system used on micro-combine harvester of wheat[J]. Transactions of the Chinese Society for Agricultural Machinery, 2006(6): 45-48. | |

| 16 | 万星宇,廖宜涛,袁佳诚,等. 油菜联合收获机组合式旋风分离清选参数分析与试验[J].农业机械学报, 2020, 51(): 202-211. |

| Wan Xing-yu, Liao Yi-tao, Yuan Jia-cheng, et al. Parameters analysis and experiment of cyclone separation cleaning system with replaceable parts for rapeseed combine harvester[J]. Transactions of the Chinese Society for Agricultural Machinery, 2020, 51(Sup.2): 202-211. | |

| 17 | 万星宇.油菜联合收获机旋风分离清选系统设计及其工作机理[D]. 武汉:华中农业大学工学院, 2019. |

| Wan Xing-yu. Design and working mechanical study on the cyclone separation cleaning system for rapeseed combine harvester[D].Wuhan:College Of Engineering, Huazhong Agricultural University, 2019. | |

| 18 | 刘正怀,郑一平,王志明,等. 微型稻麦联合收获机气流式清选装置研究[J].农业机械学报, 2015, 46(7): 102-108. |

| Liu Zheng-huai, Zheng Yi-ping, Wang Zhi-ming, et al. Design on air-flowing cleaning unit of micro rice-wheat combine harvester[J]. Transactions of the Chinese Society for Agricultural Machinery, 2015, 46(7):102-108. | |

| 19 | 迟媛,李蒙福,杨月斌,等. 禽蛋壳膜旋风式气流清选装置研究[J].农业机械学报, 2019, 50(8): 339-350. |

| Chi Yuan, Li Meng-fu, Yang Yue-bin, et al. Cyclone device collecting eggshell membranes and eggshells separately from eggshells mixture[J]. Transactions of the Chinese Society for Agricultural Machinery, 2019, 50(8): 339-350. | |

| 20 | El-Batsh H M. Improving cyclone performance by proper selection of the exit pipe[J]. Applied Mathematical Modelling, 2013, 37(7): 5286-5303. |

| 21 | 侯华铭,崔清亮,郭玉明,等. 气吹式粮油作物脱出物清选悬浮速度测量装置设计与试验[J]. 农业工程学报,2018,34(16):43-49. |

| Hou Hua-ming, Cui Qing-liang, Guo Yu-ming, et al. Design and test of air-sweeping suspension velocity testing device for cleaning threshed materials of grain and oil crops[J]. Transactions of the Chinese Society of Agricultural Engineering, 2018, 34(16): 43-49. | |

| 22 | 陈立,廖庆喜,宗望远,等. 油菜联合收获机脱出物空气动力学特性测定[J]. 农业机械学报, 2012, 43(): 125-130. |

| Chen Li, Liao Qing-xi, Zong Wang-yuan, et al. Aerodynamic characteristics measurement of extraction components for rape combine harvester[J]. Transactions of the Chinese Society for Agricultural Machinery, 2012, 43(Sup.1): 125-130. | |

| 23 | 马振. 大输量旋风分离器优化设计研究[D].北京:中国石油大学机械与存储工程学院, 2018. |

| Ma Zhen. Study on optimal design of cyclone separator with large mass transmission[D]. Beijing: College of Mechanical and Transportation Engineering, China University of Petroleum, 2018. | |

| 24 | 王修善,刘大为,谢方平,等. 旋风清选分离筒中脱出物籽粒的运动分析[J]. 时代农机, 2019, 46(3): 104-108. |

| Wang Xiu-shan, Liu Da-wei, Xie Fang-ping,et al. Motion analysis of the grains of the separated materials in the cyclone cleaning and separating cylinder[J]. Times Agricultural Machinery, 2019, 46(3): 104-108 | |

| 25 | 彭才望,孙松林,贺喜,等. 双向螺旋黑水虻虫沙收集装置设计与试验[J]. 浙江大学学报: 农业与生命科学版, 2020, 46(5): 637-646. |

| Peng Cai-wang, Sun Song-lin, He Xi, et al. Design and experiment of bidirectional spiral collecting device for Hermetia illucens insect sand[J]. Journal of Zhejiang University Agriculture and Life Sciences, 2020, 46(5): 637-646. | |

| 26 | 廖庆喜,王昌,何坤,等. 油菜联合收获后含杂油菜籽复清机设计与试验[J]. 农业机械学报, 2021, 52(10): 175-185, 232. |

| Liao Qing-xi, Wang Chang, He Kun, et al. Design and experiment on re-cleaning machine for rapeseed after combine harvesting[J]. Transactions of the Chinese Society for Agricultural Machinery, 2021, 52(10): 175-185, 232. | |

| 27 | 黄炎,赵满全. 基于数值模拟与风洞试验的旋风分离式集沙仪优化设计[J].农业工程学报,2015,31(16):50-56. |

| Huang Yan, Zhao Man-quan. Optimization design of performance test of cyclone separator sand sampler based on numerical simulation and wind erosion tunnel experiment[J]. Transactions of the Chinese Society of Agricultural Engineering, 2015, 31(16): 50-56. | |

| 28 | 周韬. 旋风分离器的气固两相特性研究与数值模拟[D].上海:上海交通大学机械与动力工程学院,2007. |

| Zhou Tao. Study and numerical simulation on gas-solid two-phase characteristic of cyclone separator[D]. Shanghai:School of Mechanical Echanical Engineering, Shanghai Jiao Tong University, 2007. | |

| 29 | 董玉平,董磊,强宁,等. 旋风分离器内生物质焦油湍流特性的数值模拟[J]. 农业工程学报, 2010, 26(9): 171-175. |

| Dong Yu-ping, Dong Lei, Qiang Ning, et al. Numerical simulation of biomass gas and tar torrential flow characteristics in cyclone separator[J]. Transactions of the Chinese Society of Agricultural Engineering, 2010, 26(9): 171-175. | |

| 30 | 王国伟,夏晓蒙,朱庆辉,等.基于DEM-CFD耦合的辅助充种气吸式大豆高速精密排种器设计与试验[J].吉林大学学报: 工学版, 2022, 52(5): 1208-1221. |

| Wang Guo-wei, Xia Xiao-meng, Zhu Qing-hui, et al. Design and experiment of soybean high⁃speed precision vacuumseed metering with auxiliary filling structure based on DEM⁃CFD[J]. Journal of Jilin University (Engineering and Technology Edition), 2022, 52(5): 1208-1221. | |

| 31 | 刘立意,郝世杨,张萌,等. 基于CFD-DEM的稻谷通风阻力数值模拟与试验[J].农业机械学报, 2015, 46(8): 27-32. |

| Liu Li-yi, Hao Shi-yang, Zhang Meng, et al. Numerical simulation and experiment on paddy ventilation resistance based on CFD-DEM[J]. Transactions of the Chinese Society for Agricultural Machinery, 2015, 46(8): 27-32. | |

| 32 | 袁竹林, 朱立平, 耿凡. 气固两相流动与数值模拟[M].南京:东南大学出版社, 2013. |

| 33 | 心男.基于 EDEM-Fluent 耦合的气吹式排种器工作过程仿真分析[D].长春:吉林大学生物与农业工程学院, 2013. |

| Xin Nan. Simulation analysis of working process of air-blowing seed-metering device based on coupled EDEM-Fluent[D]. Changchun: College of Biological and Agricultural Engineering, Jilin University,2013. | |

| 34 | 邢浩男,马少春,王风磊,等. 切段式甘蔗收割机排杂风机结构优化与试验[J]. 农业工程学报,2020,36(20): 67-75. |

| Xing Hao-nan, Ma Shao-chun, Wang Feng-lei, et al. Structure optimization and experiment of sugarcane chopper harvester extractor[J]. Transactions of the Chinese Society of Agricultural Engineering, 2020, 36(20): 67-75. | |

| 35 | 袁佳诚,王昌,何坤,等. 油菜联合收获机筛下物组分质量比对清选性能的影响[J]. 吉林大学学报: 工学版, 2021, 51(5): 1897-1907. |

| Yuan Jia-cheng, Wang Chang, He Kun, et al. Effect of components mass ratio under sieve on cleaning system performance for rape combine harvester[J]. Journal of Jilin University (Engineering and Technology Edition), 2021, 51(5): 1897-1907. | |

| 36 | 中国农业机械化科学研究院. 农业机械设计手册(下册)[M]. 北京:中国农业科学技术出版社, 2007. |

| [1] | 张国忠,丁凯权,李正博,陈龙,唐楠锐,刘婉茹,黄海东,周勇,王洪昌. 基于泥鳅体表的水稻直播机仿生滑板设计与试验[J]. 吉林大学学报(工学版), 2024, 54(5): 1482-1492. |

| [2] | 张伏,娄立民,钱丹,王世强,冯春凌,赵一荣. 大方捆打捆机压缩机构优化设计及试验[J]. 吉林大学学报(工学版), 2024, 54(4): 1166-1174. |

| [3] | 周鹏飞,陈学庚,蒙贺伟,梁荣庆,张炳成,坎杂. 滚筒式机收膜杂除土装置设计及试验[J]. 吉林大学学报(工学版), 2023, 53(9): 2718-2731. |

| [4] | 刘伟健,罗锡文,曾山,文智强,曾力. 履带式再生稻收获机田间转弯机理和性能试验[J]. 吉林大学学报(工学版), 2023, 53(9): 2695-2705. |

| [5] | 张茂健,金敬福,陈奕颖,陈廷坤. 轮式拖拉机对称结构的振动特性[J]. 吉林大学学报(工学版), 2023, 53(7): 2136-2142. |

| [6] | 朱光强,李天宇,周福君,王文明. 鲜食玉米仿生摘穗装置设计与试验[J]. 吉林大学学报(工学版), 2023, 53(4): 1231-1244. |

| [7] | 顿国强,刘文辉,毛宁,吴星澎,纪文义,马洪岩. 交替换岗式大豆小区育种排种器优化设计与试验[J]. 吉林大学学报(工学版), 2023, 53(1): 285-296. |

| [8] | 曾山,黄登攀,杨文武,刘伟健,文智强,曾力. 三角履带式再生稻收割机底盘的设计与试验[J]. 吉林大学学报(工学版), 2022, 52(8): 1943-1950. |

| [9] | 魏国粱,张青松,王彪,何坤,廖庆喜. 油菜直播机扣垡犁体参数分析与试验[J]. 吉林大学学报(工学版), 2022, 52(7): 1709-1718. |

| [10] | 刘佳杰,马兰,向伟,颜波,文庆华,吕江南. 4QM-4.0型麻类青饲料联合收获机研制[J]. 吉林大学学报(工学版), 2022, 52(12): 3039-3048. |

| [11] | 曾百功,黎奎良,叶进,任丽丽,Rashidov Jaloliddin,张明. 工厂化上海青流水线收割装置的设计与试验[J]. 吉林大学学报(工学版), 2022, 52(11): 2756-2764. |

| [12] | 万星宇,廖庆喜,蒋亚军,单伊尹,周宇,廖宜涛. 饲用油菜机械化收获切碎过程离散元仿真与试验[J]. 吉林大学学报(工学版), 2022, 52(11): 2735-2745. |

| [13] | 朱光强,李天宇,周福君. 鲜食玉米仿生摘穗柔性夹持输送装置设计与试验[J]. 吉林大学学报(工学版), 2022, 52(10): 2486-2500. |

| [14] | 梁荣庆,钟波,蒙贺伟,孙志民,坎杂. 4QJ⁃3型青贮燕麦捡拾割台的研制[J]. 吉林大学学报(工学版), 2021, 51(5): 1887-1896. |

| [15] | 袁佳诚,王昌,何坤,万星宇,廖庆喜. 油菜联合收获机筛下物组分质量比对清选性能的影响[J]. 吉林大学学报(工学版), 2021, 51(5): 1897-1907. |

|

||