吉林大学学报(工学版) ›› 2023, Vol. 53 ›› Issue (5): 1338-1344.doi: 10.13229/j.cnki.jdxbgxb.20210937

• 材料科学与工程 • 上一篇

AA6061⁃T6铝薄板无针搅拌摩擦点焊接头结构及性能分析

- 吉林大学 汽车仿真与控制国家重点实验室,长春 130022

Analysis of microstructure and mechanical properties of probeless friction stir spot welding joint in AA6061⁃T6 aluminum thin plate

Gui-shen YU( ),Xin CHEN(

),Xin CHEN( ),Zi-tao WU,Yi-xiong CHEN,Guan-chen ZHANG

),Zi-tao WU,Yi-xiong CHEN,Guan-chen ZHANG

- State Key Laboratory of Automotive Simulation and Control,Jilin University,Changchun 130022,China

摘要:

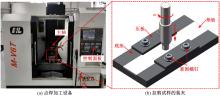

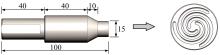

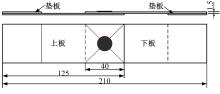

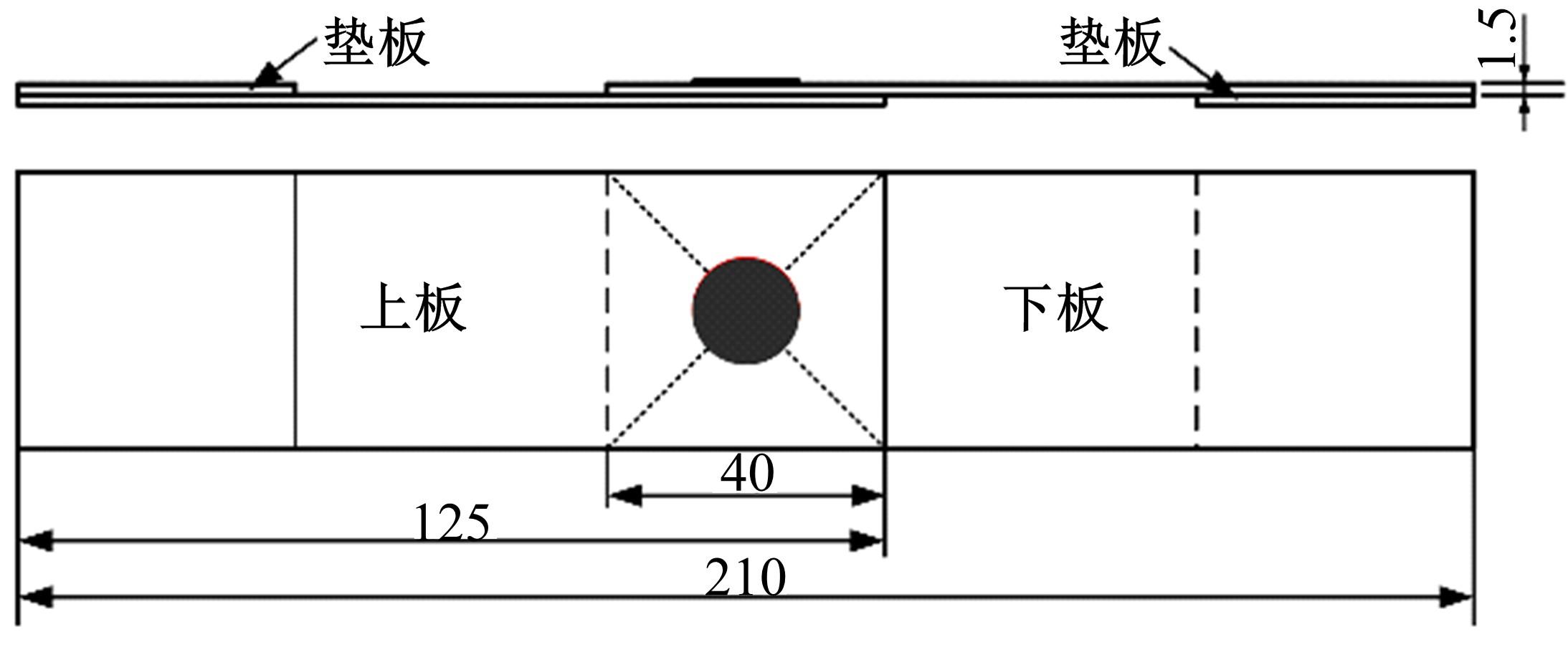

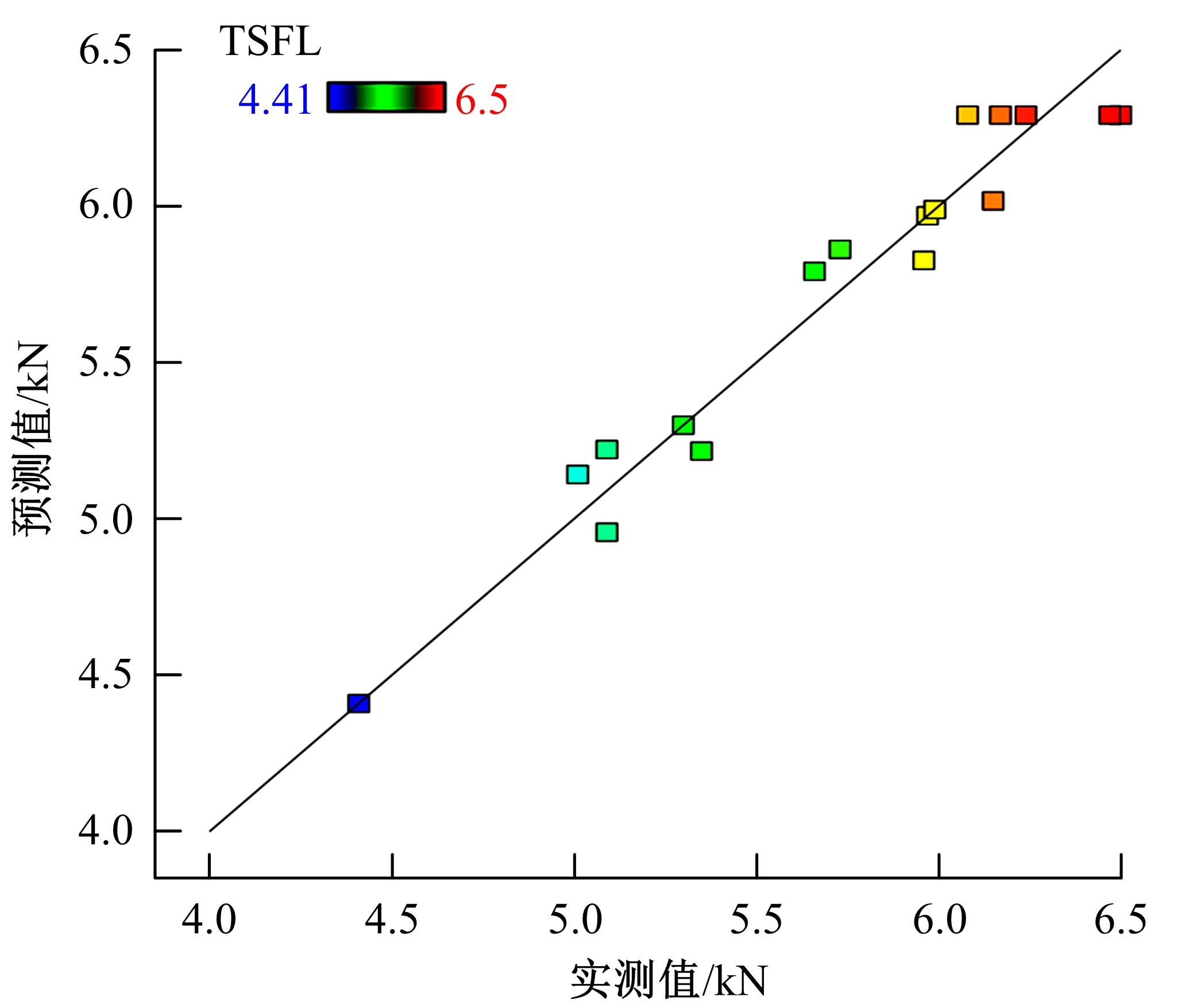

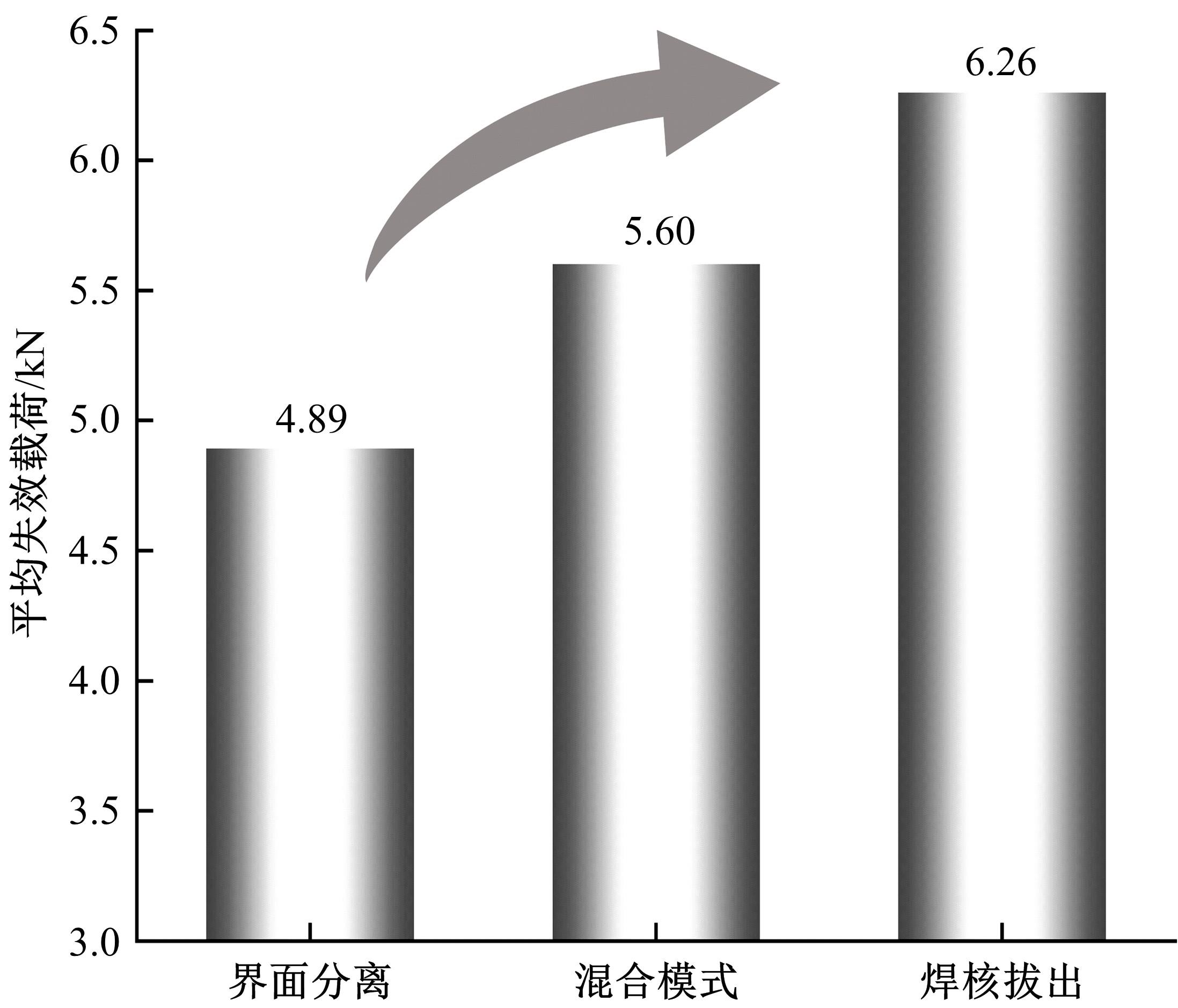

以车身覆盖件用1.5 mm厚AA6061-T6铝薄板为研究对象,采用Box-Behnken试验设计分析了不同焊接参数对无针搅拌摩擦点焊(PFSSW)接头力学性能及断裂模式的影响规律。通过响应面方法(RSM)对PFSSW接头的拉剪性能进行优化。结果表明:焊点的金相呈现“盆形”结构,当搅拌头转速为2950 r/min、下压量为0.6 mm和停留时间为7 s时,接头的最高拉剪失效载荷为6.41 kN。PFSSW焊点断口呈现3种断裂模式。其中,焊核拔出模式下接头的平均失效载荷最高(6.26 kN),界面分离断裂模式最低(4.89 kN),混合断裂模式居中(5.60 kN)。

中图分类号:

- U465.2

| 1 | Paidar M, Ramalingam V V, Moharrami A, et al. Development and characterization of dissimilar joint between AA2024-T3 and AA6061-T6 by modified friction stir clinching process[J]. Vacuum, 2020, 176: 109298. |

| 2 | 聂昕, 朱伟强, 蔡洪丰, 等.基于焊点载荷的焊接工艺参数优化[J].焊接学报,2018,39(5):114-120, 134. |

| Nie Xin, Zhu Wei-qiang, Cai Hong-feng, et al. Optimization of resistance spot welding parameters based on load of welding spot[J]. Transactions of the China Welding Institution, 2018, 39(5): 114-120, 134. | |

| 3 | Zhang B, Chen X, Pan K, et al. J-integral based correlation evaluation between microstructure and mechanical strength for FSSW joints made of automotive aluminum alloys[J]. Journal of Manufacturing Processes, 2019, 44: 62-71. |

| 4 | Zhang B, Chen X, Pan K, et al. Thermo-mechanical simulation using microstructure-based modeling of friction stir spot welded AA 6061-T6[J]. Journal of Manufacturing Processes, 2019, 37: 71-81. |

| 5 | 陈鑫, 潘凯旋, 张彪, 等. 搅拌摩擦点焊瞬态输入组合热源模型[J]. 吉林大学学报: 工学版, 2020, 50(4): 1316-1323. |

| Chen Xin, Pan Kai-xuan, Zhang Biao, et al. Transient input combined heat source model of friction stir spot welding[J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(4): 1316-1323. | |

| 6 | Ikumapayi O M, Akinlabi E T. Recent advances in keyhole defects repairs via refilling friction stir spot welding[J]. Materials Today-Proceedings, 2019, 18: 2201-2208. |

| 7 | Suryanarayanan R, Sridhar V. Effect of process parameters in pinless friction stir spot welding of Al 5754-Al 6061 alloys[J]. Metallography, Microstructure, Analysis, 2020, 9(2): 261-272. |

| 8 | Li W Y, Chu Q, Yang X W, et al. Microstructure and morphology evolution of probeless friction stir spot welded joints of aluminum alloy[J]. Journal of Materials Processing Technology, 2018, 252: 69-80. |

| 9 | Chu Q, Yang X W, Li W Y, et al. Impact of surface state in probeless friction stir spot welding of an Al-Li alloy[J]. Science and Technology of Welding and Joining, 2019, 24(3): 200-208. |

| 10 | Chu X, Yin M, Gao J, et al. Effects of shoulder geometry on microstructures and mechanical properties of probeless friction stir spot welded aluminum 7075-T651 sheets[J]. Metals, 2020, 10(12): 10121605. |

| 11 | Atak A. Impact of pinless stirring tools with different shoulder profile designs on friction stir spot welded joints[J]. Journal of Mechanical Science and Technology, 2020, 34(9): 3735-3743. |

| 12 | Yazdi S R, Beidokhti B, Haddad-Sabzevar M. Pinless tool for FSSW of AA 6061-T6 aluminum alloy[J]. Journal of Materials Processing Technology, 2019, 267: 44-51. |

| 13 | Zhang Z, Yu Y, Zhao H, et al. Interface behavior and impact properties of dissimilar Al/Steel keyhole-free FSSW joints[J]. Metals, 2019, 9(6): 9060691. |

| 14 | 宫文彪, 朱芮, 郄新哲, 等. 6082铝合金超厚板搅拌摩擦焊接头组织与性能[J]. 吉林大学学报: 工学版, 2020, 50(2): 512-519. |

| Gong Wen-biao, Zhu Rui, Xin-zhe Qie, et al. Microstructure and properties of 6082 aluminum alloy ultra-thick plate preparated by friction stir weld[J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 512-519. | |

| 15 | Zhou L, Luo L Y, Zhang T P, et al. Effect of rotation speed on microstructure and mechanical properties of refill friction stir spot welded 6061-T6 aluminum alloy[J]. International Journal of Advanced Manufacturing Technology, 2017, 92(9-12): 3425-3433. |

| 16 | 邹阳帆, 王非凡, 李文亚, 等. 不等厚2219铝合金板回填式搅拌摩擦点焊接头组织及性能研究[J]. 机械工程学报, 2020, 56(6): 176-183. |

| Zou Yang-fan, Wang Fei-fan, Li Wen-ya, et al. Study on microstructure and properties of refill friction stir spot welding joints of 2219 aluminum alloy with different thickness[J]. Journal of Mechanical Engineering, 2020, 56(6): 176-183. |

| [1] | 陈磊,王杨,董志圣,宋亚奇. 一种基于转向意图的车辆敏捷性控制策略[J]. 吉林大学学报(工学版), 2023, 53(5): 1257-1263. |

| [2] | 陈鑫,张冠宸,赵康明,王佳宁,杨立飞,司徒德蓉. 搭接焊缝对铝合金焊接结构轻量化设计的影响[J]. 吉林大学学报(工学版), 2023, 53(5): 1282-1288. |

| [3] | 张勇,毛凤朝,刘水长,王青妤,潘神功,曾广胜. 基于Laplacian算法的汽车外流场畸变网格优化[J]. 吉林大学学报(工学版), 2023, 53(5): 1289-1296. |

| [4] | 汪少华,储堃,施德华,殷春芳,李春. 基于有限时间扩张状态观测的HEV鲁棒复合协调控制[J]. 吉林大学学报(工学版), 2023, 53(5): 1272-1281. |

| [5] | 谢超,王起才,于本田,李盛,林晓旭,鲁志铭. 聚氨酯涂膜弹性模量的AFM测定及微观结构分析[J]. 吉林大学学报(工学版), 2023, 53(5): 1322-1330. |

| [6] | 陈小波,陈玲. 定位噪声统计特性未知的变分贝叶斯协同目标跟踪[J]. 吉林大学学报(工学版), 2023, 53(4): 1030-1039. |

| [7] | 赵睿,李云,胡宏宇,高镇海. 基于V2I通信的交叉口车辆碰撞预警方法[J]. 吉林大学学报(工学版), 2023, 53(4): 1019-1029. |

| [8] | 杨红波,史文库,陈志勇,郭年程,赵燕燕. 基于NSGA⁃II的斜齿轮宏观参数多目标优化[J]. 吉林大学学报(工学版), 2023, 53(4): 1007-1018. |

| [9] | 何科,丁海涛,许男,郭孔辉. 基于摄像头和车道线的增强定位系统[J]. 吉林大学学报(工学版), 2023, 53(3): 663-673. |

| [10] | 朱冰,范天昕,赵健,张培兴,孙宇航. 基于危险边界搜索的自动驾驶系统加速测试方法[J]. 吉林大学学报(工学版), 2023, 53(3): 704-712. |

| [11] | 田彦涛,季言实,唱寰,谢波. 深度强化学习智能驾驶汽车增广决策模型[J]. 吉林大学学报(工学版), 2023, 53(3): 682-692. |

| [12] | 张建,刘金波,高原,刘梦可,高振海,杨彬. 基于多模交互的车载传感器定位算法[J]. 吉林大学学报(工学版), 2023, 53(3): 772-780. |

| [13] | 何科,丁海涛,赖宣淇,许男,郭孔辉. 基于Transformer的轮式里程计误差预测模型[J]. 吉林大学学报(工学版), 2023, 53(3): 653-662. |

| [14] | 刘嫣然,孟庆瑜,郭洪艳,李嘉霖. 图注意力模式下融合高精地图的周车轨迹预测[J]. 吉林大学学报(工学版), 2023, 53(3): 792-801. |

| [15] | 谢波,高榕,许富强,田彦涛. 低附着路况条件下人车共享转向系统稳定控制[J]. 吉林大学学报(工学版), 2023, 53(3): 713-725. |

|

||