吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (4): 1166-1174.doi: 10.13229/j.cnki.jdxbgxb.20221139

• 农业工程·仿生工程 • 上一篇

大方捆打捆机压缩机构优化设计及试验

张伏1,2( ),娄立民1,3,钱丹3,王世强3,冯春凌3,赵一荣3(

),娄立民1,3,钱丹3,王世强3,冯春凌3,赵一荣3( )

)

- 1.河南科技大学 农业装备工程学院,洛阳 471003

2.机械装备先进制造河南省协同创新中心,洛阳 471003

3.洛阳拖拉机研究所有限公司,洛阳 471039

Optimum design and test of compression mechanism of big square baler

Fu ZHANG1,2( ),Li-min LOU1,3,Dan QIAN3,Shi-qiang WANG3,Chun-ling FENG3,Yi-rong ZHAO3(

),Li-min LOU1,3,Dan QIAN3,Shi-qiang WANG3,Chun-ling FENG3,Yi-rong ZHAO3( )

)

- 1.College of Agricultural Equipment Engineering,Henan University of Science and Technology,Luoyang 471003,China

2.Collaborative Innovation Center of Advanced Manufacturing of Machinery and Equipment of Henan Province,Luoyang 471003,China

3.Luoyang Tractor Research Institute Co. ,Ltd. ,Luoyang 471039,China

摘要:

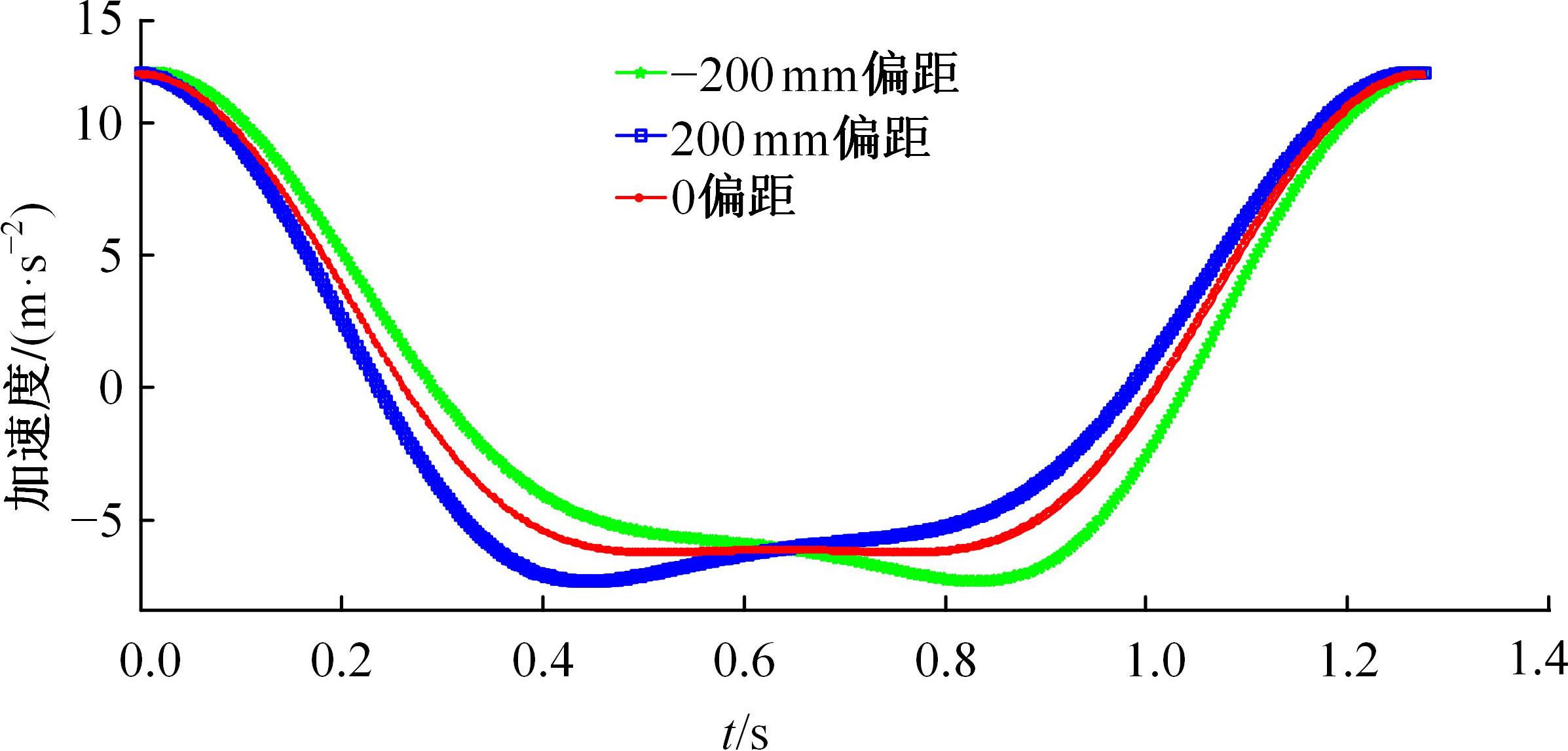

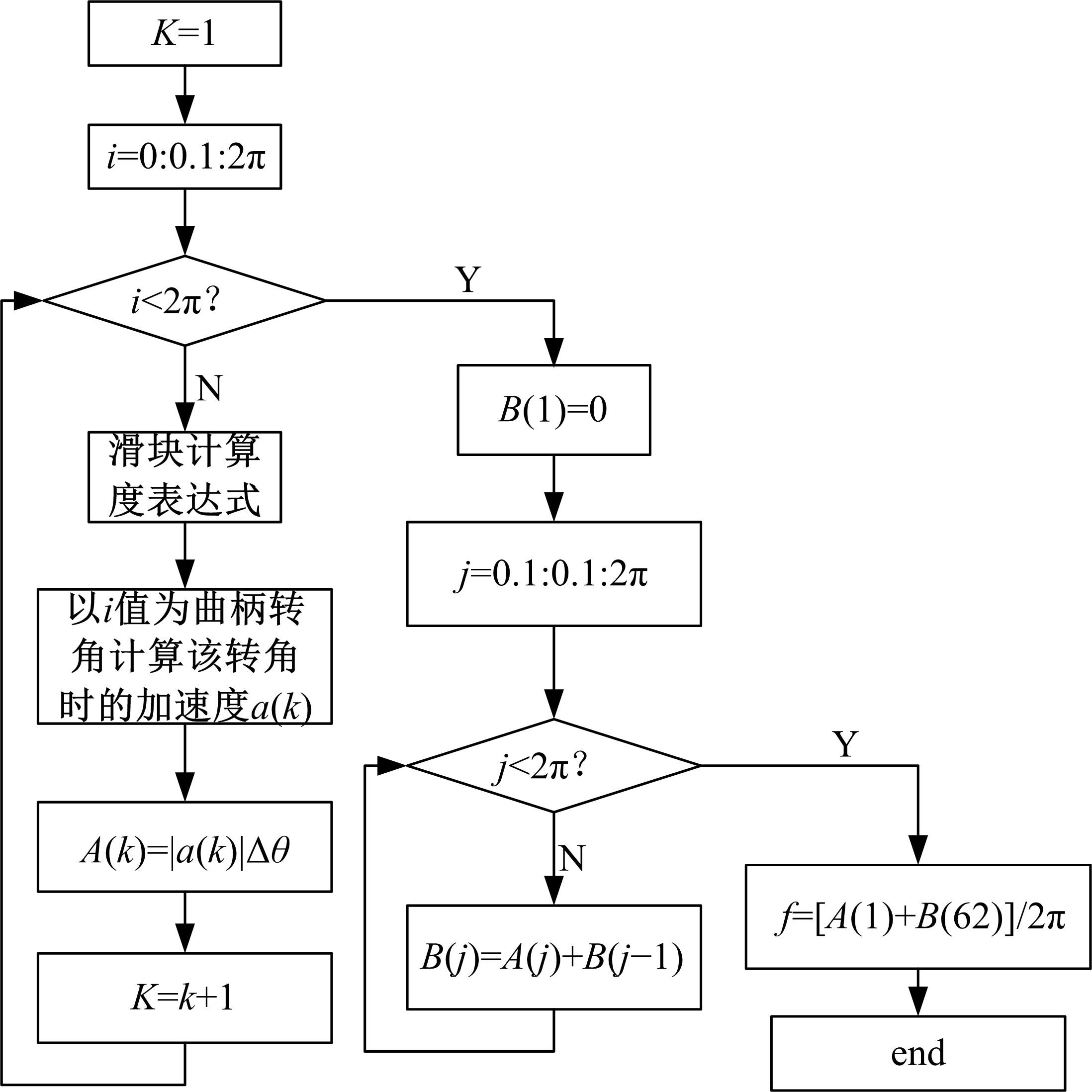

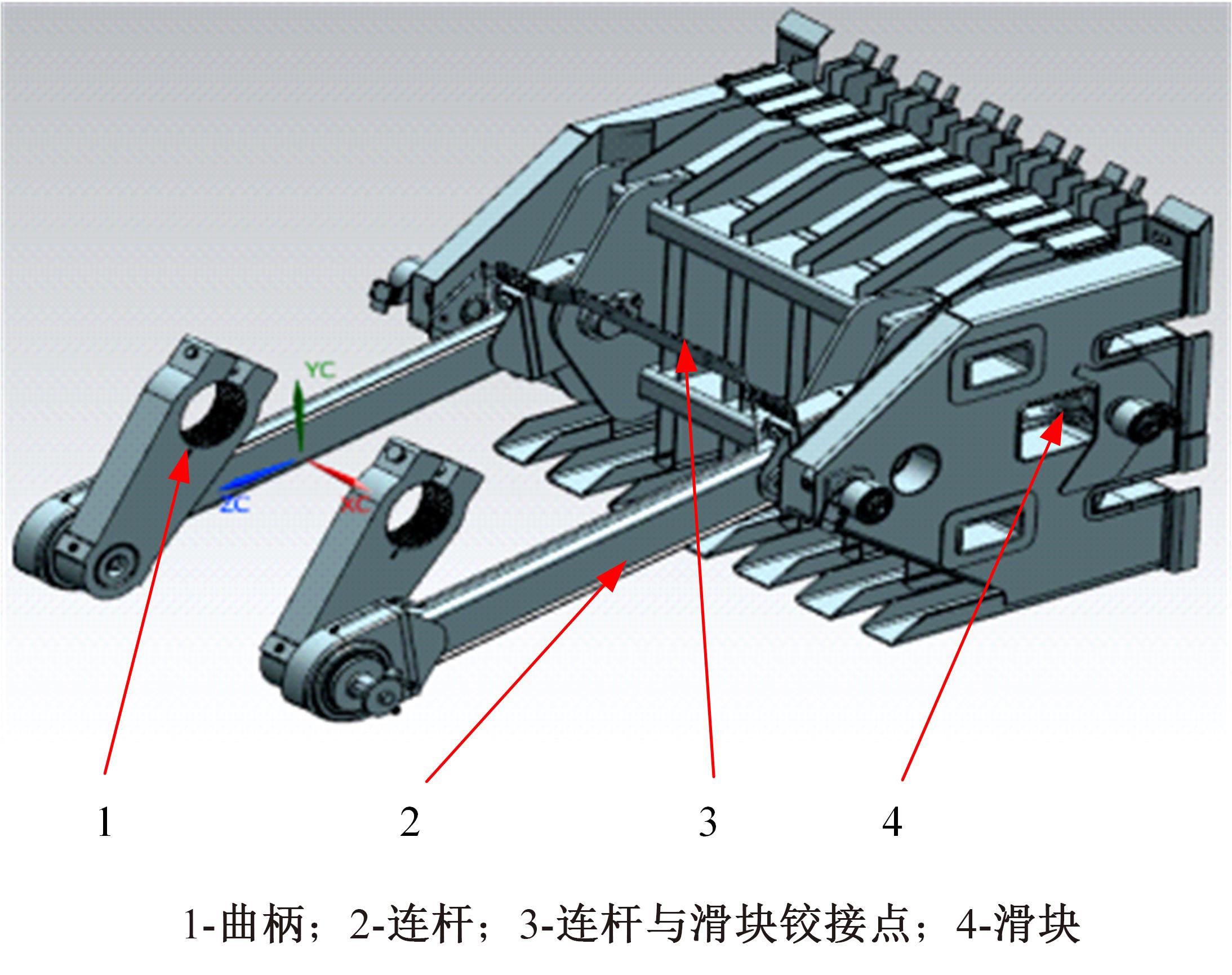

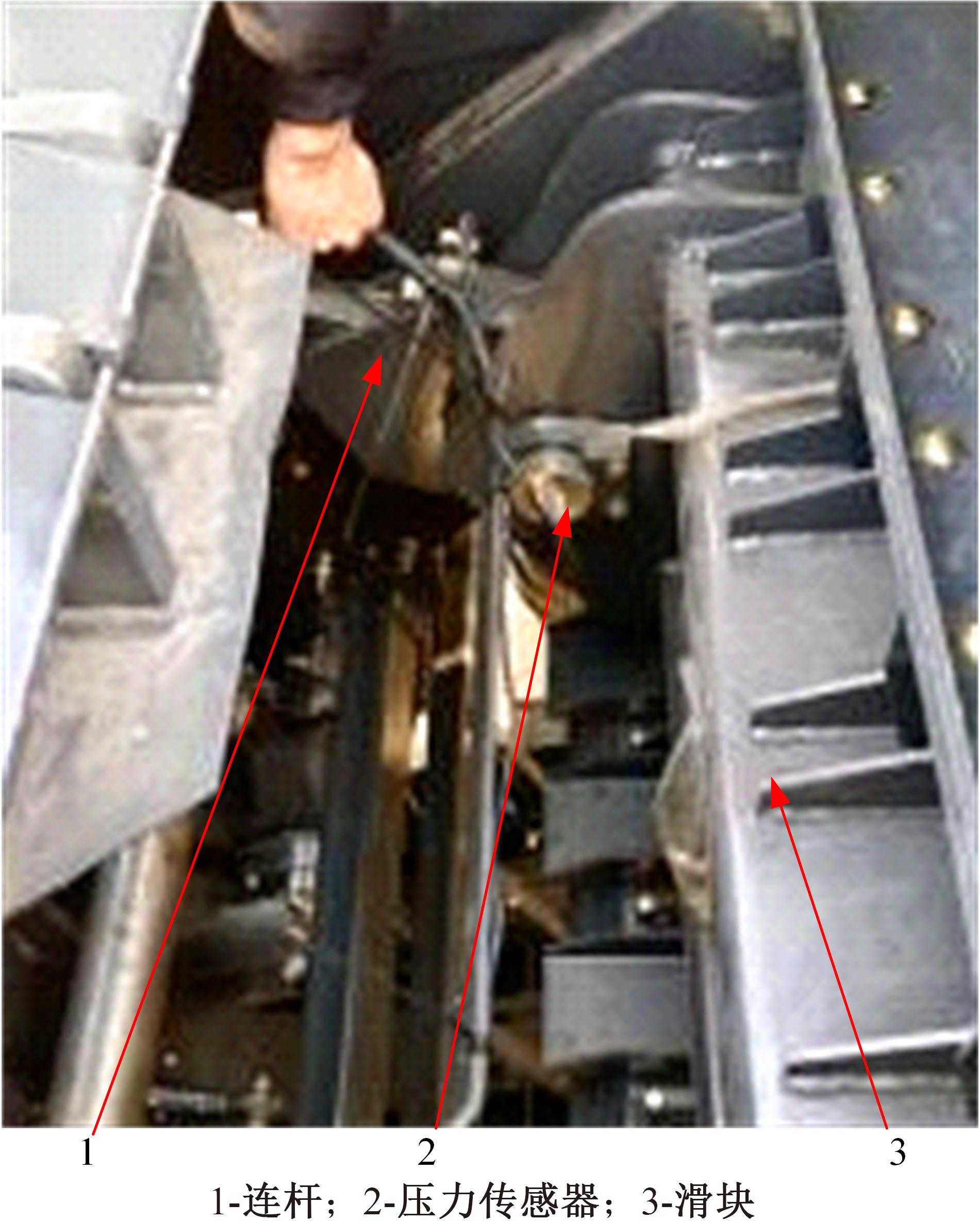

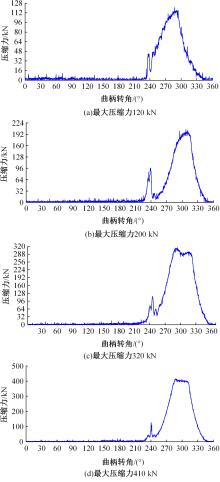

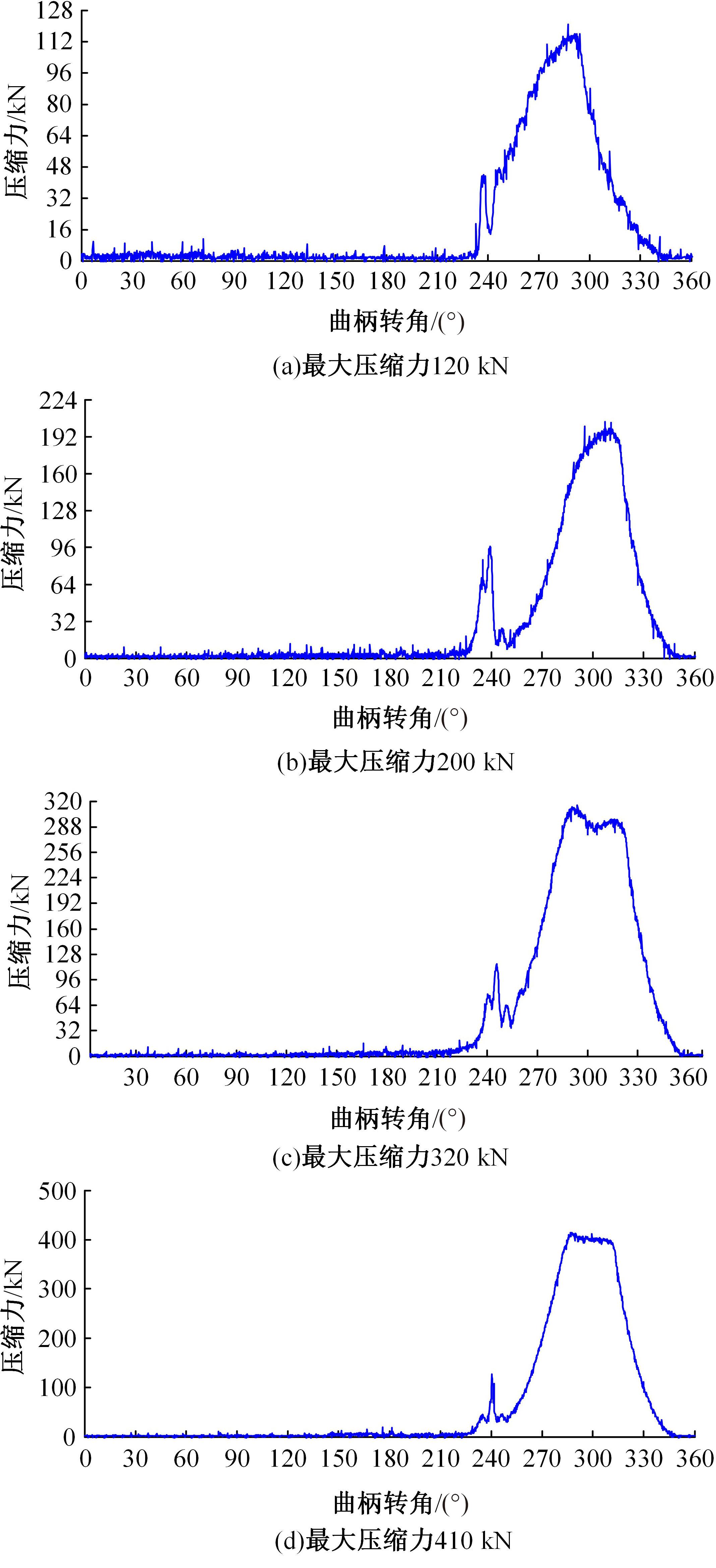

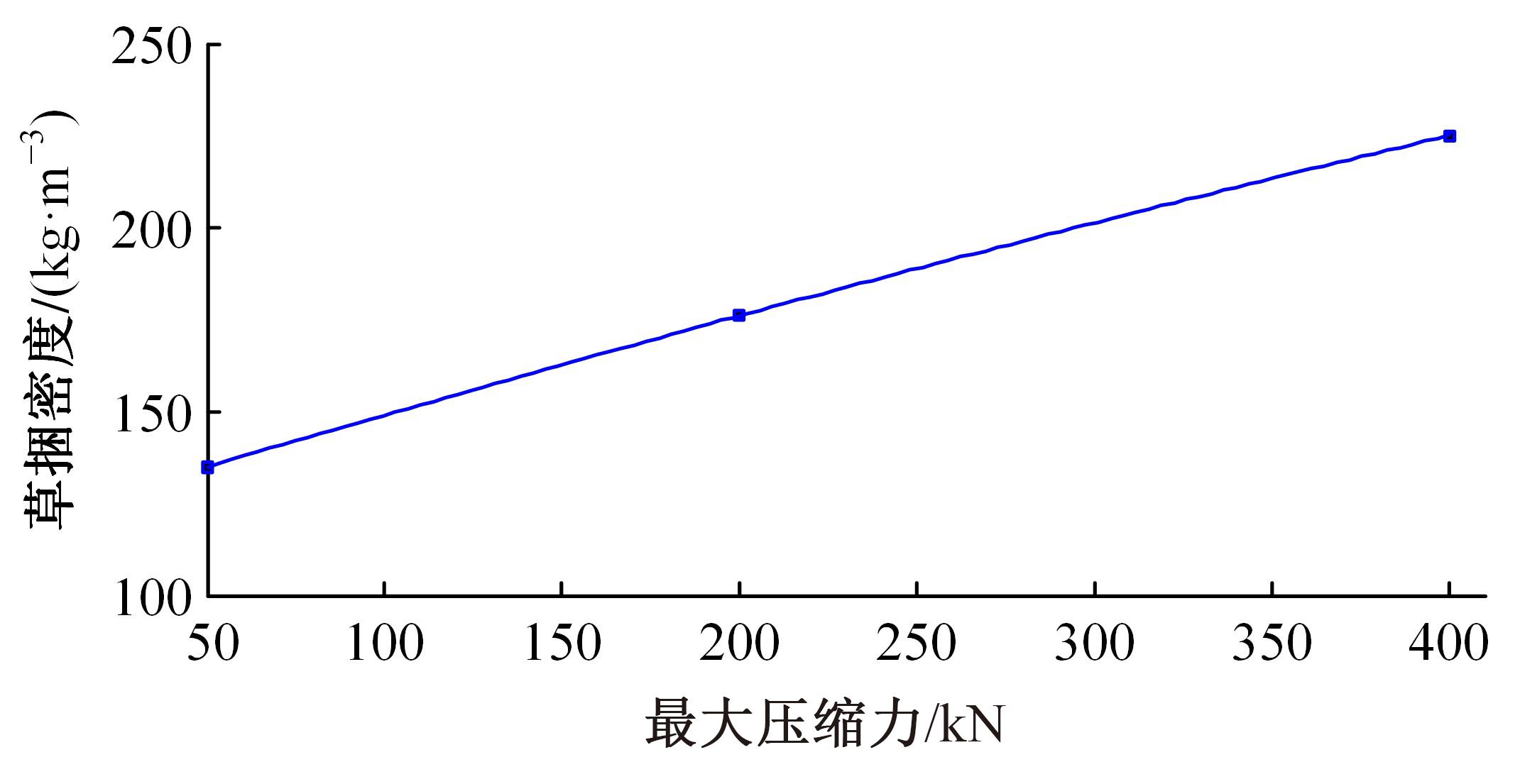

针对大方捆打捆机存在压缩机构往复运动惯性力大而产生振动难以解决的问题,采用模型优化设计方法对压缩机构进行了研究。在分析打捆机压缩机构惯性力、草捆密度影响因素的基础上,以最小传动角、速度不均匀系数等约束构建压缩机构惯性力优化模型,采用内点惩罚函数算法解算模型,根据优化方案设计压缩机构并完成田间试验。研究结果表明:在满足草捆密度的条件下,所设计的压缩机构相对原机构平均惯性力降低10.2%,草捆密度达到230 kg/m3,峰值压缩力为410 kN。所研究的压缩机构对打捆机研发具有重要的工程应用价值。

中图分类号:

- S220.1

| 1 | 凯斯纽荷兰.纽荷兰助力高质苜蓿收获[J]. 农业机械, 2021(8): 28-29. |

| 2 | 知谷客. 麦赛福格森助力中国草都牧草全程机械化收获[J]. 农业机械, 2018(7): 49-51. |

| 3 | 王德成, 贺长彬, 武红剑, 等. 苜蓿生产全程机械化技术研究现状与发展分析[J]. 农业机械学报, 2017, 48(8): 1-25. |

| Wang De-cheng, He Chang-bin, Wu Hong-jian, et al. Review of alfalfa full-mechanized production technology[J]. Transactions of the Chinese Society for Agricultural Machinery, 2017, 48(8): 1-25. | |

| 4 | 王锋德, 陈志, 王俊友, 等. 4YF-1300型大方捆打捆机设计与试验[J]. 农业机械学报, 2009, 40(11): 36-41. |

| Wang Feng-de, Chen Zhi, Wang Jun-you, et al. Design and experiment of 4YF-1300 large rectangular baler[J]. Transactions of the Chinese Society for Agricultural Machinery, 2009, 40(11): 36-41. | |

| 5 | 陈锋, 杨军太, 燕晓辉, 等. 9YDF-90型大方捆打捆机性能试验[J]. 农业工程, 2011, 1(1): 20-22. |

| Chen Feng, Yang Jun-tai, Yan Xiao-hui, et al. Perfomace experiment of model 9YDF-90 big baler[J]. Agricultural Engineering, 2011, 1(1): 20-22. | |

| 6 | 陈锋. 大方捆打捆机压缩机构设计及压缩试验研究 [D]. 北京: 中国农业机械化科学研究院, 2007. |

| Chen Feng. Compressing mechanism design of large rectangular baler and experimental study on compression research[D]. Beijing: Chinese Academy of Agricultural Mechanization Sciences, 2007. | |

| 7 | 魏凤雄. 大方捆打捆机压缩机构结构设计与研究[D]. 北京: 北京林业大学工学院, 2020. |

| Wei Feng-xiong. Structure design and research of compression mechanism of the big baling machine[D]. Beijing: College of Engineering,Beijing Forestry University, 2020. | |

| 8 | 李春燕. 大方捆打捆机压缩室的缩比模型及其电液控制系统研究[D]. 长春: 吉林大学机械与航空航天工程学院, 2020. |

| Li Chun-yan. Study on ratio model and hydraulic control system of Large bundle baler chamber[D]. Changchun: School of Mechanical and Aerospace Engineering, Jilin University, 2020. | |

| 9 | 王春光, 杨明韶, 童淑敏, 等. 高密度压捆时牧草在压缩室内的受力和变形研究[J]. 农业工程学报, 1999, 5(4): 55-59. |

| Wang Chun-guang, Yang Ming-shao, Tong Shu-min, et al. Study on compressing process of hay in the compressing chamber of high density bales[J]. Transactions of the Chinese Society of Agricultural Engineering(Transactions of the CSAE), 1999, 5(4): 55-59. | |

| 10 | Flick D E, Nigon C M, Shinners K J, et al. Control system for a continuous compaction large square baler[J]. Computers and Electronics in Agriculture, 2019, 165: 104969 |

| 11 | McAfee J R, Shinners K J, Friede J C. Twine tension in high-density large square bales[J]. Applied Engineering in Agriculture, 2018, 34(3): 515-525. |

| 12 | Tang Z, Li Y, Zhou Y P, et al. Inertial vibration characteristics of track chassis caused by reciprocating motion of crank slider[J]. Shock and Vibration, 2019, 2019:1-18. |

| 13 | 周跃鹏, 陈树人, 唐忠, 等. 曲柄滑块秸秆压缩机构振动研究: 基于惯性力平衡法[J]. 农机化研究, 2019, 41(4): 37-41. |

| Zhou Yue-peng, Chen Shu-ren, Tang Zhong, et al. Vibration research of franck slider mechanism of straw compression[J]. Agricultural Mechanization Research, 2019, 41(4): 37-41. | |

| 14 | 王艳红, 赵弢. 2019汉诺威国际农机展创新奖: 迪尔获唯一金奖, 39项银奖各具特色[J]. 农业机械, 2019(12): 27-33. |

| 15 | 李慧, 何进, 李洪文, 等. 基于逆向数据的强制脱扣型方草压捆机打结器[J]. 吉林大学学报:工学版, 2011, 41(6): 1652-1658. |

| Li Hui, He Jin, Li Hong-wen, et al. Mandatory strip type knotter for square baler based on reversed data[J]. Journal of Jilin University (Engineering and Technology Edition), 2011, 41(6): 1652-1658. | |

| 16 | 平忠源. 方捆机压缩室切刀对玉米秸秆的切割过程分析及试验研究[D]. 哈尔滨: 东北农业大学工程学院, 2017. |

| Ping Zhong-yuan. Mechanism analysis and experimental research of cutting corn stalk by chamber knife of rectangular baler[D]. Harbin: College of Engineering, Northeast Agricultural University, 2017. | |

| 17 | 中国农业机械化科学研究院. 农业机械设计手册[M]. 北京: 中国农业科学技术出版社, 2007. |

| 18 | MF 2200 大型方形打捆机操作员手册[Z]. 爱科公司, 2017. |

| 19 | . 方草捆打捆机 [S]. |

| [1] | 周鹏飞,陈学庚,蒙贺伟,梁荣庆,张炳成,坎杂. 滚筒式机收膜杂除土装置设计及试验[J]. 吉林大学学报(工学版), 2023, 53(9): 2718-2731. |

| [2] | 刘伟健,罗锡文,曾山,文智强,曾力. 履带式再生稻收获机田间转弯机理和性能试验[J]. 吉林大学学报(工学版), 2023, 53(9): 2695-2705. |

| [3] | 张茂健,金敬福,陈奕颖,陈廷坤. 轮式拖拉机对称结构的振动特性[J]. 吉林大学学报(工学版), 2023, 53(7): 2136-2142. |

| [4] | 朱光强,李天宇,周福君,王文明. 鲜食玉米仿生摘穗装置设计与试验[J]. 吉林大学学报(工学版), 2023, 53(4): 1231-1244. |

| [5] | 朱劲松,秦亚婷,刘周强. 预应力UHPC-NC组合梁截面优化设计[J]. 吉林大学学报(工学版), 2023, 53(11): 3151-3159. |

| [6] | 顿国强,刘文辉,毛宁,吴星澎,纪文义,马洪岩. 交替换岗式大豆小区育种排种器优化设计与试验[J]. 吉林大学学报(工学版), 2023, 53(1): 285-296. |

| [7] | 曾山,黄登攀,杨文武,刘伟健,文智强,曾力. 三角履带式再生稻收割机底盘的设计与试验[J]. 吉林大学学报(工学版), 2022, 52(8): 1943-1950. |

| [8] | 杨红波,史文库,陈志勇,郭年程,赵燕燕. 基于某二级减速齿轮系统的齿面修形优化[J]. 吉林大学学报(工学版), 2022, 52(7): 1541-1551. |

| [9] | 魏国粱,张青松,王彪,何坤,廖庆喜. 油菜直播机扣垡犁体参数分析与试验[J]. 吉林大学学报(工学版), 2022, 52(7): 1709-1718. |

| [10] | 张英朝,李昀航,郭子瑜,王国华,张喆,苏畅. 长头重型卡车气动减阻优化[J]. 吉林大学学报(工学版), 2022, 52(4): 745-753. |

| [11] | 姚玉权,仰建岗,高杰,宋亮. 基于性能-费用模型的厂拌再生沥青混合料优化设计[J]. 吉林大学学报(工学版), 2022, 52(3): 585-595. |

| [12] | 张立杰,阿喜塔,田笑,李稳. 基于Gamma过程的加速退化试验多目标优化设计[J]. 吉林大学学报(工学版), 2022, 52(2): 361-367. |

| [13] | 赵泓荀,杨兆军,陈传海,田海龙,王立平. 考虑参数权重的数控机床电主轴加速试验优化设计[J]. 吉林大学学报(工学版), 2022, 52(2): 409-416. |

| [14] | 刘佳杰,马兰,向伟,颜波,文庆华,吕江南. 4QM-4.0型麻类青饲料联合收获机研制[J]. 吉林大学学报(工学版), 2022, 52(12): 3039-3048. |

| [15] | 曾百功,黎奎良,叶进,任丽丽,Rashidov Jaloliddin,张明. 工厂化上海青流水线收割装置的设计与试验[J]. 吉林大学学报(工学版), 2022, 52(11): 2756-2764. |

|

||