吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (11): 3231-3243.doi: 10.13229/j.cnki.jdxbgxb.20230024

• 交通运输工程·土木工程 • 上一篇

基于可解释机器学习的锈蚀RC构件抗剪承载力预测模型

- 1.长沙理工大学 土木工程学院,长沙 410114

2.长沙理工大学 南方地区桥梁长期性能提升技术国家地方联合工程实验室,长沙 410114

Prediction model for shear capacity of corroded RC beams based on interpretable machine learning

Li-zhao DAI1,2( ),Chong WANG1,Ping YUAN1,Lei WANG1(

),Chong WANG1,Ping YUAN1,Lei WANG1( )

)

- 1.School of Civil Engineering,Changsha University of Science & Technology,Changsha 410114,China

2.National-Local Joint Laboratory of Engineering Technology for Long-term Performance Enhancement of Bridges in Southern District,Changsha University of Science & Technology,Changsha 410114,China

摘要:

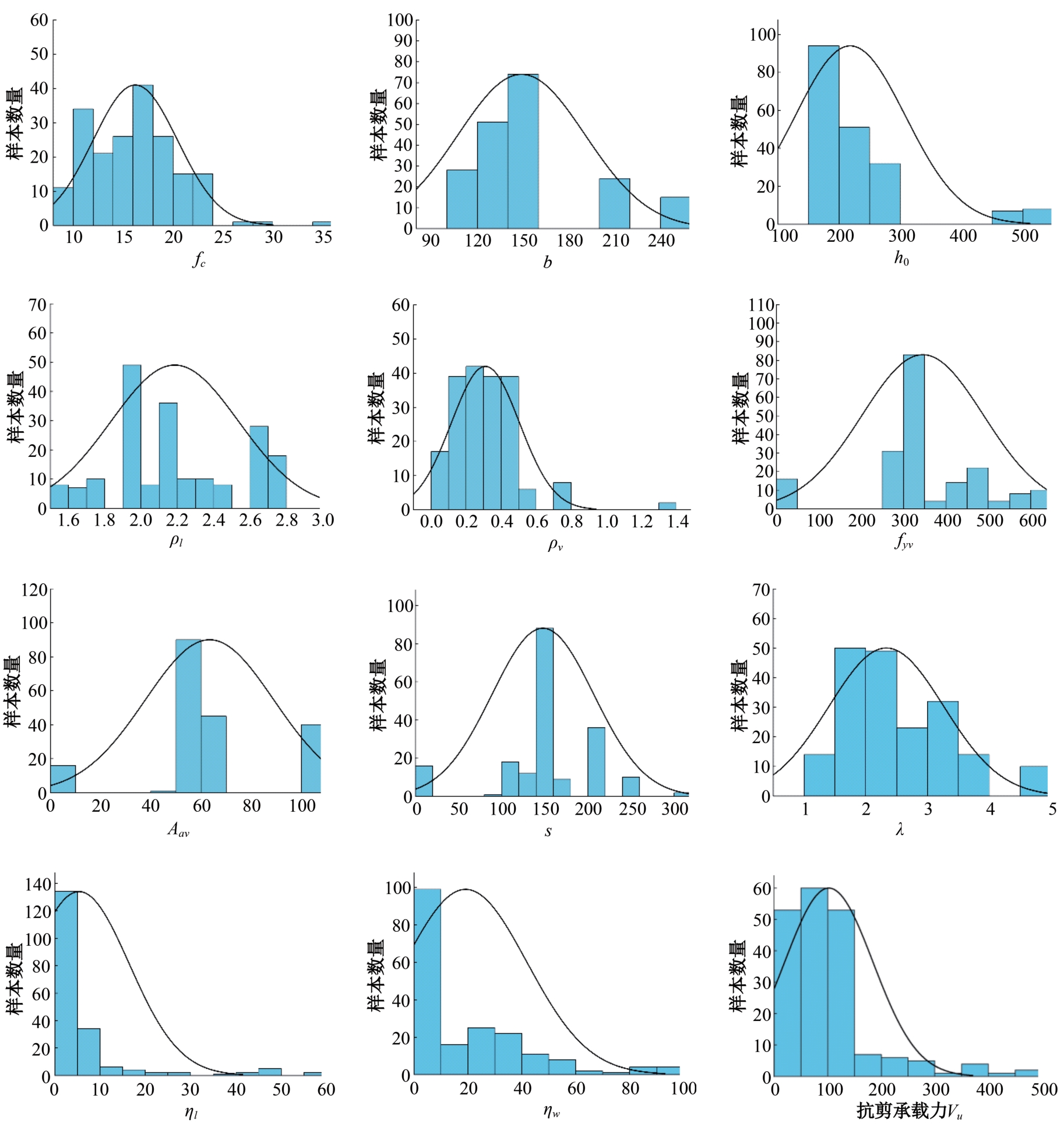

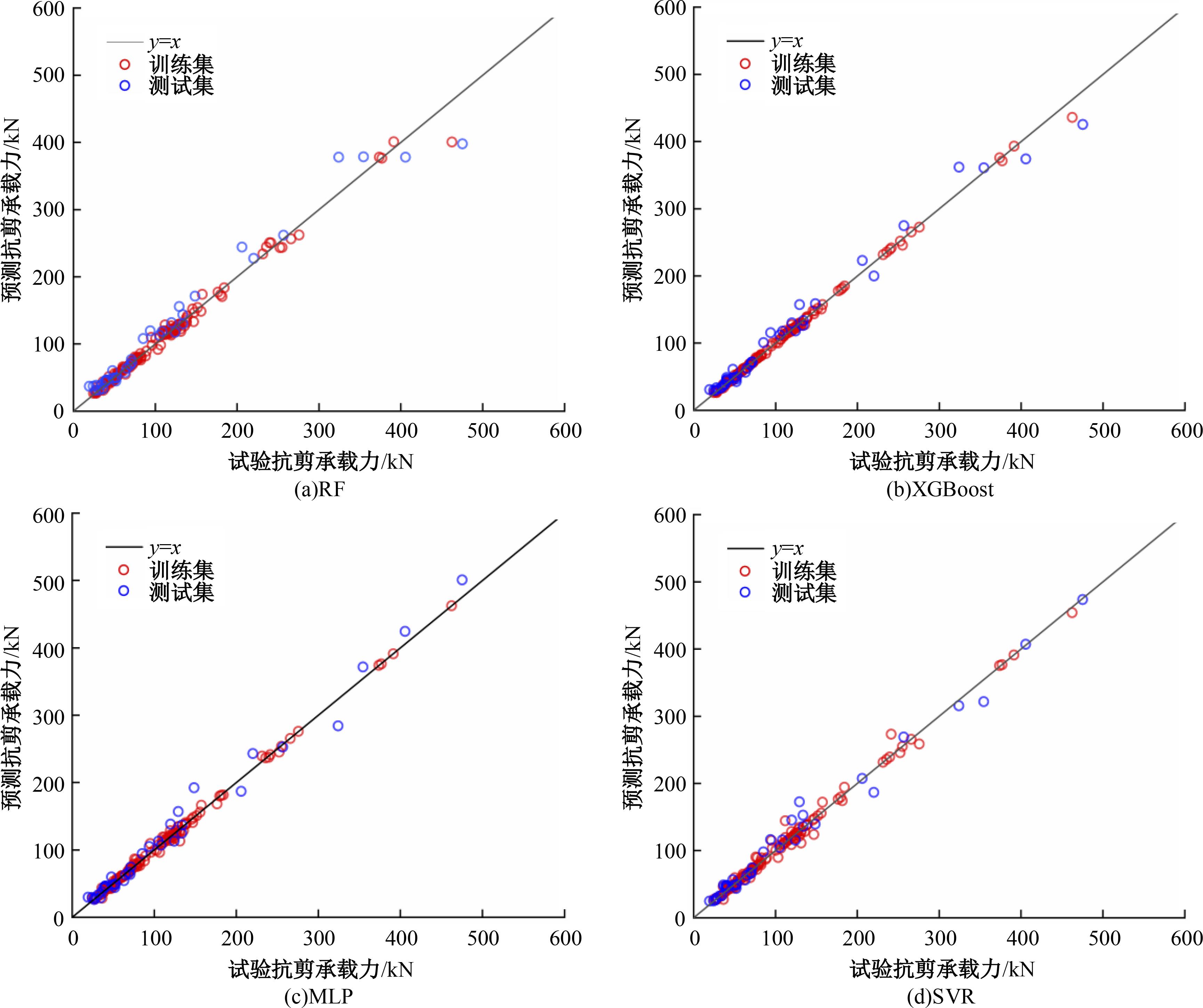

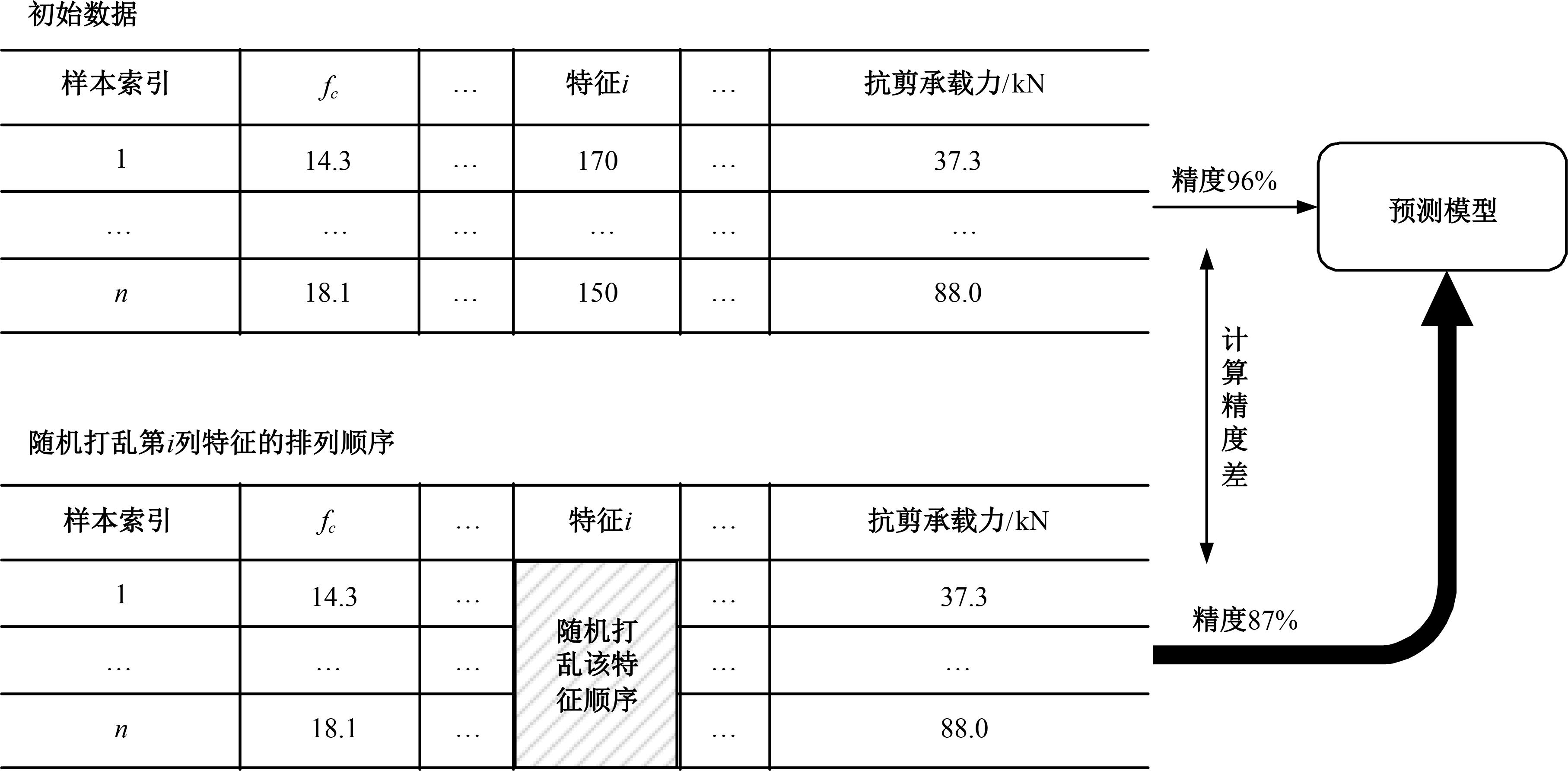

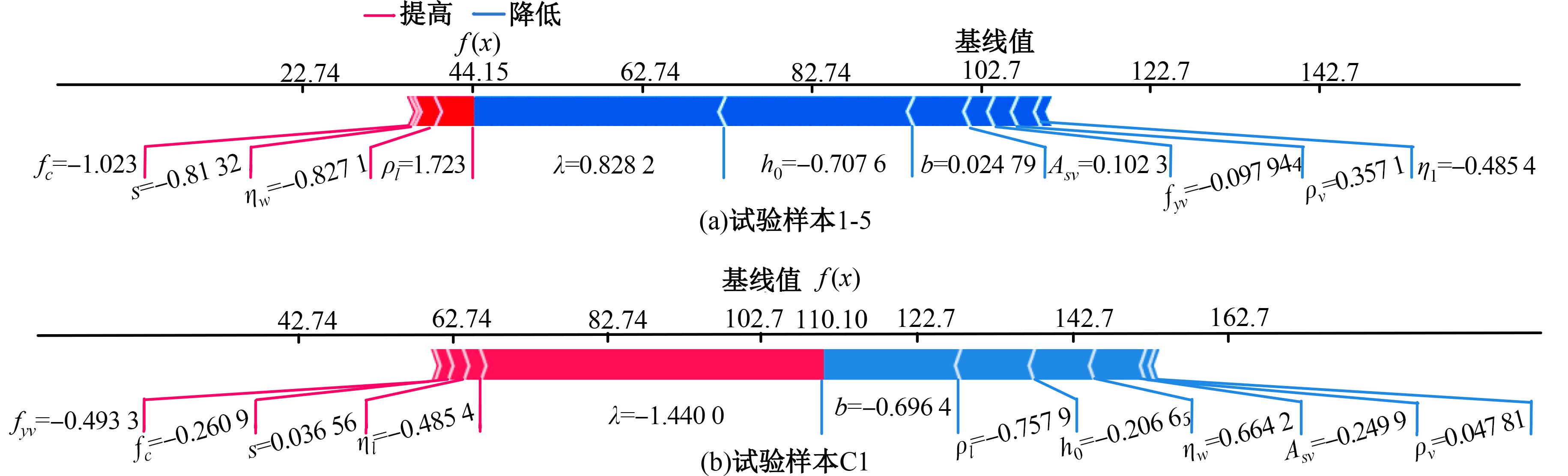

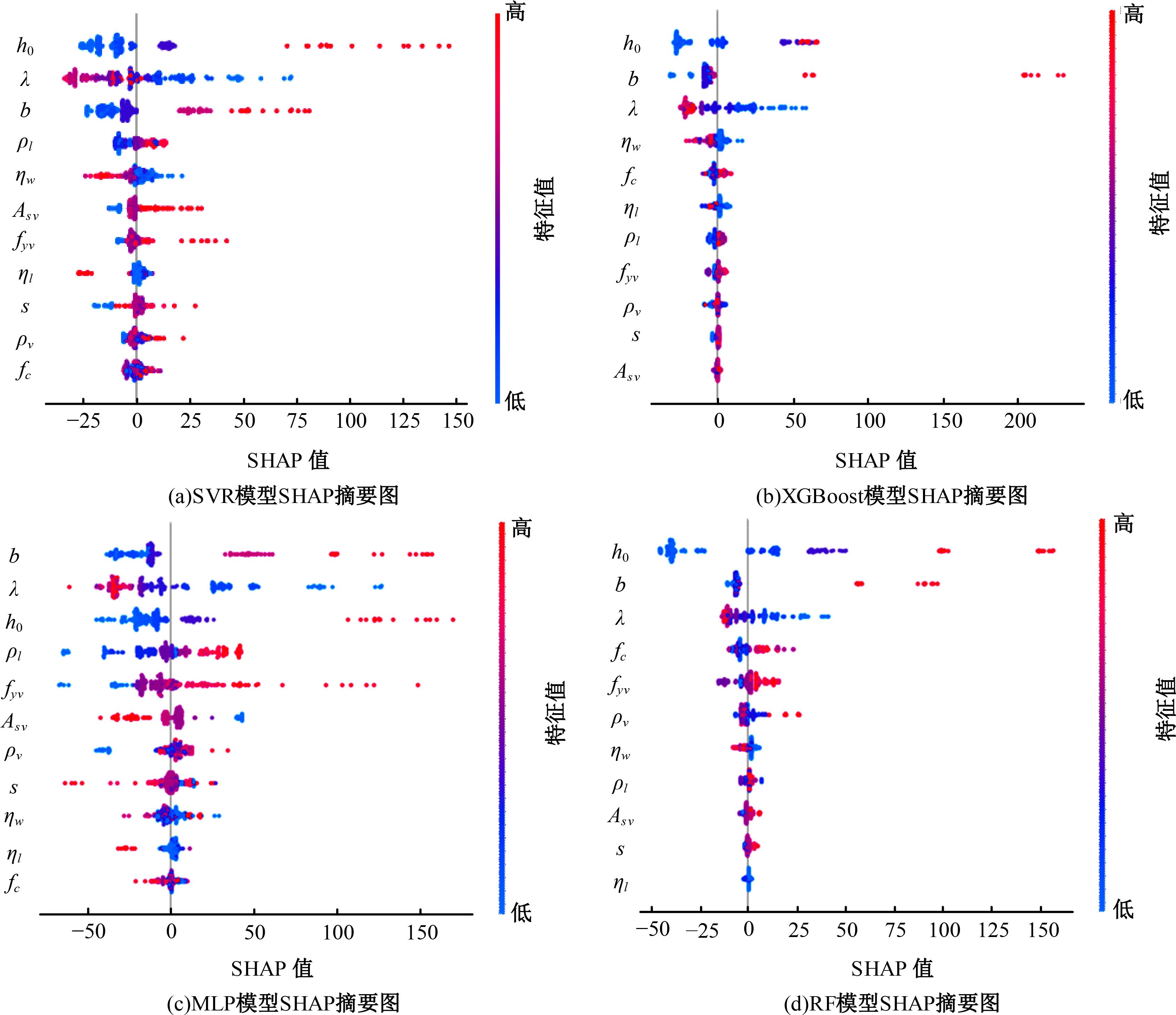

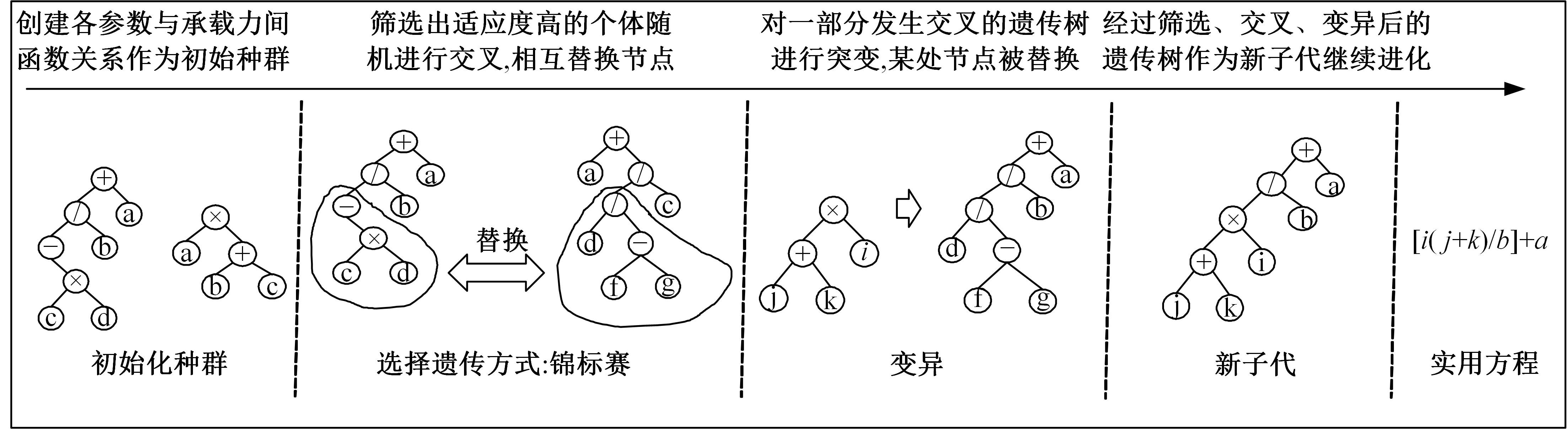

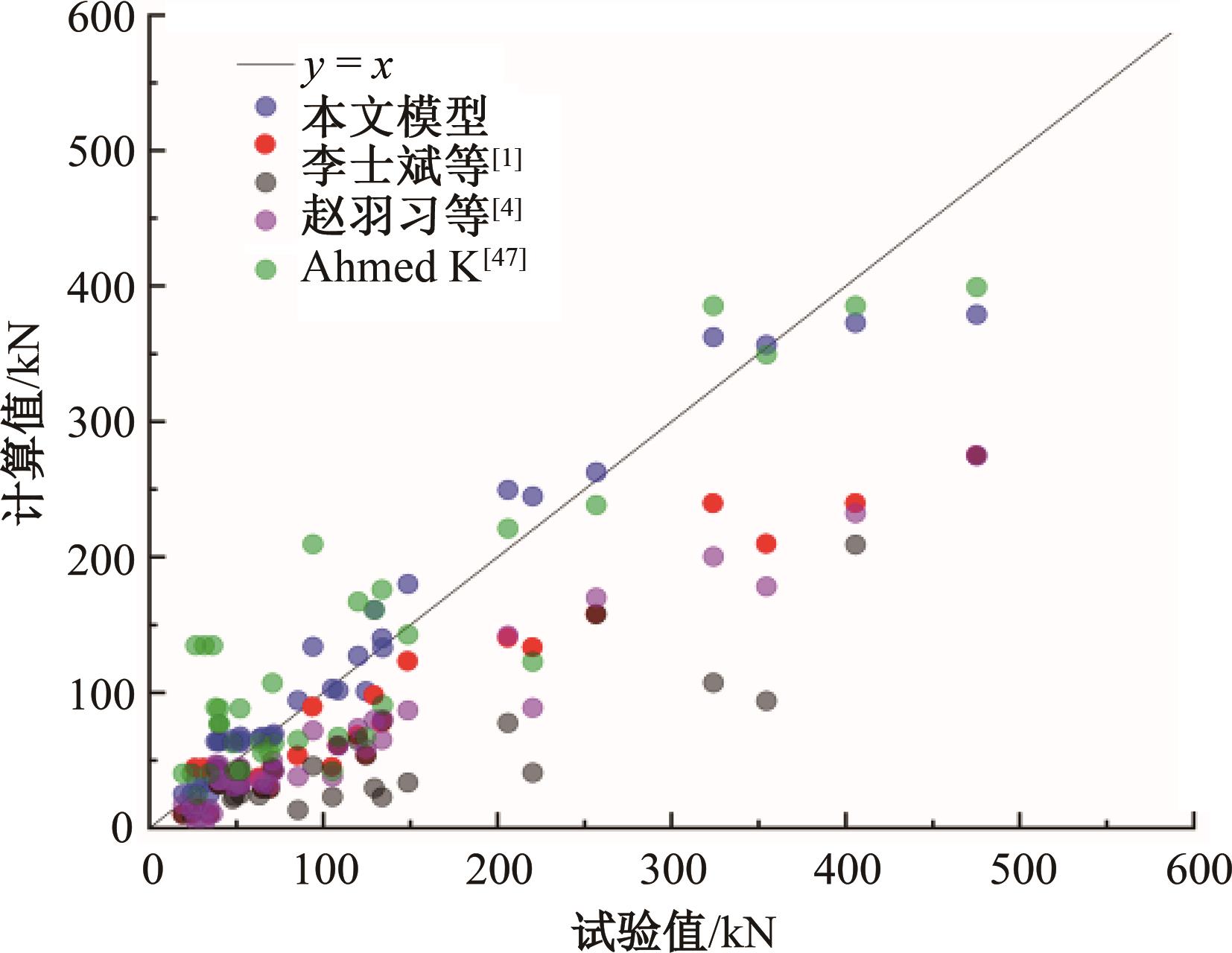

基于机理方法推导的锈蚀钢筋混凝土(RC)构件抗剪承载力模型通常引入一系列假定与修正系数,导致计算结果精度不高和适用性有限。本文基于数据驱动,考虑黑箱模型的可信度与输入特征的合理性,选择锈蚀RC构件的几何尺寸、纵筋配筋率、箍筋屈服强度、箍筋锈蚀率、混凝土强度等关键基本特征,建立了基于可解释机器学习算法的实用模型。结果表明,所有基本特征中锈蚀率、有效高度、剪跨比与梁宽对抗剪承载力较为敏感;本预测模型阐明了锈蚀RC构件关键基本参数与抗剪承载力间显性映射关系,相较于经验模型与黑箱模型,它具有较高的透明度与预测精度。

中图分类号:

- TU375.1

| 1 | 李士彬, 张鑫, 贾留东, 等. 箍筋锈蚀钢筋混凝土梁的抗剪承载力分析[J]. 工程力学, 2011, 28(S1): 60-63. |

| Li Shi-bin, Zhang Xin, Jia Liu-dong, et al. Analysis for shear capacity of reinforced concrete beams with corrosion stirrups[J]. Engineering Mechanics, 2011, 28(S1): 60-63. | |

| 2 | Rodriguez J, Ortega L M, Casal J. Load carrying capacity of concrete structures with corroded reinforcement[J]. Construction and Building Materials, 1997, 11(4): 239-248. |

| 3 | 薛昕, 杨成. 纵向受拉钢筋锈蚀钢筋混凝土梁的抗剪性能[J]. 上海交通大学学报, 2016, 50(11): 1767-1772. |

| Xue Xin, Yang Cheng. Shear performance of reinforced concrete beams containing corroded longitudinal bars[J]. Journal of Shanghai Jiaotong University, 2016, 50(11): 1767-1772. | |

| 4 | 霍艳华. 锈蚀钢筋混凝土简支梁受剪承载力研究[J]. 工业建筑, 2006, 36(z1): 910-912. |

| Huo Yan-hua. Research on shear capacity of simply supported concrete beam with corroded reinforcement[J]. Industrial Construction, 2006, 36(z1): 910-912. | |

| 5 | 梁兴文, 汪萍, 徐明雪, 等. 配筋超高性能混凝土梁受弯性能及承载力研究[J]. 工程力学, 2019, 36(5): 110-119. |

| Liang Xing-wen, Wang Ping, Xu Ming-xue, et al. Investigation on flexural capacity of reinforced ultra high performance concrete beams[J]. Engineering Mechanics, 2019, 36(5): 110-119. | |

| 6 | 何世钦, 贡金鑫. 钢筋混凝土梁中锈蚀钢筋粘结性能的试验研究[J]. 哈尔滨工业大学学报, 2006, 38(12): 2167-2170. |

| He Shi-qin, Gong Jin-xin. Experimental studies on bond characteristics of corroded steel bar in reinforced concrete beams[J]. Journal of Harbin Institute of Technology, 2006, 38(12): 2167-2170. | |

| 7 | 戴理朝, 周亮, 杨晓文, 等. 基于Connector单元的锈蚀RC梁界面粘结性能细观数值模拟[J]. 吉林大学学报: 工学版, 2023, 53(10): 2886-2896. |

| Dai Li-chao, Zhou Liang, Yang Xiao-wen, et al. Microscopic numerical simulation of interface bond performance of corroded RC beam based on connector element[J]. Journal of Jilin University (Engineering and Technology Edition), 2023, 53(10): 2886-2896. | |

| 8 | 徐善华, 牛荻涛. 锈蚀钢筋混凝土简支梁斜截面抗剪性能研究[J]. 建筑结构学报, 2004, 25(5): 98-104. |

| Xu Shan-hua, Niu Di-tao. The shear behavior of corroded simply supported reinforced concrete beam[J]. Journal of Building Structures, 2004, 25(5): 98-104. | |

| 9 | 赵羽习, 金伟良. 锈蚀箍筋混凝土梁的抗剪承载力分析[J]. 浙江大学学报: 工学版, 2008, 42(1): 19-24. |

| Zhao Yu-xi, Jin Wei-liang. Analysis on shearing capacity of concrete beams with corroded stirrups[J]. Journal of Zhejiang University (Engineering Science), 2008, 42(1): 19-24. | |

| 10 | 卢朝辉, 李海, 赵衍刚, 等. 锈蚀钢筋混凝土梁抗剪承载力预测经验模型[J]. 工程力学, 2015, 32(z1): 261-270. |

| Lu Zhao-hui, Li Hai, Zhao Yan-gang, et al. An empirical model for shear strength prediction of corroded RC beams[J]. Engineering Mechanics, 2015, 32(z1): 261-270. | |

| 11 | 金浏, 王涛, 杜修力. 无腹筋RC悬臂梁抗剪强度及尺寸效应理论研究[J]. 计算力学学报, 2020, 37(4): 396-404. |

| Jin Liu, Wang Tao, Du Xiu-li. Size effect theory on shear strength of RC cantilever beams without stirrups[J]. Chinese Journal of Computational Mechanics, 2020, 37(4): 396-404. | |

| 12 | Huang H, Burton H V. Classification of in-plane failure modes for reinforced concrete frames with infills using machine learning[J]. Journal of Building Engineering, 2019, 25: No.100767. |

| 13 | Mangalathu S, Jeon J S. Classification of failure mode and prediction of shear strength for reinforced concrete beam-column joints using machine learning techniques[J]. Engineering Structures, 2018, 160: 85-94. |

| 14 | Mangalathu S, Jeon J S. Machine learning–based failure mode recognition of circular reinforced concrete bridge columns: comparative study[J]. Journal of Structural Engineering, 2019, 145(10): No. 04019104. |

| 15 | Mangalathu S, Jeon J S, DesRoches R. Critical uncertainty parameters influencing seismic performance of bridges using Lasso regression[J]. Earthquake Engineering & Structural Dynamics, 2018, 47(3): 784-801. |

| 16 | Feng D C, Liu Z T, Wang X D, et al. Failure mode classification and bearing capacity prediction for reinforced concrete columns based on ensemble machine learning algorithm[J]. Advanced Engineering Informatics, 2020, 45: No.101126. |

| 17 | Fu B, Feng D C. A machine learning-based time-dependent shear strength model for corroded reinforced concrete beams[J]. Journal of Building Engineering, 2021, 36: No.102118. |

| 18 | Nguyen T H, Nguyen D T, Nguyen D H, et al. Evaluation of residual strength of corroded reinforced concrete beams using machine learning models[J]. Arabian Journal for Science and Engineering, 2022, 47(8): 9985-10002. |

| 19 | Hoang N D, Tran X L, Nguyen H. Predicting ultimate bond strength of corroded reinforcement and surrounding concrete using a metaheuristic optimized least squares support vector regression model[J]. Neural Computing and Applications, 2020, 32: 7289-7309. |

| 20 | Lundberg S M, Lee S I. A unified approach to interpreting model predictions[C]∥Advances in Neural Information Processing Systems, Long Beach, USA, 2017: 4765-4774. |

| 21 | Koza J R. Genetic programming as a means for programming computers by natural selection[J]. Statistics and Computing, 1994, 4: 87-112. |

| 22 | Mangalathu S, Hwang S H, Jeon J S. Failure mode and effects analysis of RC members based on machine-learning-based shapley additive explanations(SHAP) approach[J]. Engineering Structures, 2020, 219: No.110927. |

| 23 | 冯德成, 吴刚. 混凝土结构基本性能的可解释机器学习建模方法[J]. 建筑结构学报, 2022, 43(4): 228-238. |

| Feng De-cheng, Wu Gang. Interpretable machine learning-based modeling approach for fundamental properties of concrete structures[J]. Journal of Building Structures, 2022, 43(4): 228-238. | |

| 24 | Chaabene W B, Nehdi M L. Genetic programming based symbolic regression for shear capacity prediction of SFRC beams[J]. Construction and Building Materials, 2021, 280: No.122523. |

| 25 | Gandomi A H, Alavi A H, Mohammadzadeh S D, et al. An empirical model for shear capacity of RC deep beams using genetic-simulated annealing[J]. Archives of Civil and Mechanical Engineering, 2013, 13: 354-369. |

| 26 | Jeong H, Han S J, Choi S H, et al. Genetic programming approach and data generation for transfer lengths in pretensioned concrete members[J]. Engineering Structures, 2021, 231: No.111747. |

| 27 | 柳世涛. 受腐蚀钢筋混凝土梁抗剪性能研究[D]. 长沙: 中南大学土木工程学院, 2013. |

| Liu Shi-tao. Research on shear behavior of corroded RC beams[D]. Changsha: School of Civil Engineering, Central South University, 2013. | |

| 28 | Xia J, Jin W, Li L. Shear performance of reinforced concrete beams with corroded stirrups in chloride environment[J]. Corrosion Science, 2011, 53(5): 1794-1805. |

| 29 | 翟飞格. 箍筋锈蚀配斜筋RC梁抗剪承载力研究[D]. 长沙: 长沙理工大学土木工程学院, 2010. |

| Zhai Fei-ge. The research on shear capacity of corroded stirrups RC beams with diagonal reinforcement[D]. Changsha: School of Civil Engineering, Changsha University of Science and Technology, 2010. | |

| 30 | 赵冰, 曾凡振. 锈蚀箍筋混凝土简支梁抗剪承载力模型及有限元分析[J]. 中国农村水利水电, 2010, 2010(10): 88-91. |

| Zhao Bing, Zeng Fan-zhen. The model and finite element analysis of shear capacity of simply supported concrete beam with corroded stirrup[J]. China Rural Water and Hydropower, 2010, 2010(10): 88-91. | |

| 31 | 杨晓明, 吴桐, 王耀耀. 小剪跨比锈蚀钢筋混凝土梁受剪性能试验研究[J]. 建筑结构学报, 2019, 40(12): 147-154. |

| Yang Xiao-ming, Wu tong, Wang Yao-yao. Experimental study on shear behavior of corroded reinforced concrete beams with low shear span ratio[J]. Journal of Building Structures, 2019, 40(12): 147-154. | |

| 32 | 李冰, 高向华, 王小惠, 等. 局部区段锈蚀的钢筋混凝土梁抗剪承载力试验研究[J]. 混凝土与水泥制品, 2010, 2010(6): 60-65. |

| Li Bing, Gao Xiang-hua, Wang Xiao-hui, et al. Experimental study on shear capacity of reinforced concrete beams with local section corrosion[J]. Concrete and Cement Products, 2010, 2010(6): 60-65. | |

| 33 | 李学田, 殷惠光. 锈蚀钢筋混凝土梁抗剪能力退化机理和预计模型[J]. 徐州工程学院学报: 自然科学版, 2010, 25(4): 58-63. |

| Li Xue-tian, Yin Hui-guang. Degradation mechanism and predicting models of shearing capacity for corroded reinforced concrete beams[J]. Journal of Xuzhou Institute of Technology (Natural Sciences Edition), 2010, 25(4): 58-63. | |

| 34 | 祝建军. 纵筋锈蚀对无腹筋梁斜截面受剪承载力的影响[D]. 南昌: 南昌大学建筑工程学院, 2007. |

| Zhu Jian-jun. Effect of corroded longitutal reinforcements on shear capacity of simple supported concrete beam without stirrups[D]. Nanchang: School of Civil Engineering and Architecture, Nanchang University, 2007. | |

| 35 | Higgins C, Farrow W C. Tests of reinforced concrete beams with corrosion-damaged stirrups[J]. ACI Materials Journal, 2006, 103(1): 133-141. |

| 36 | 王小惠, 刘西拉. 基于粘结强度变化的锈蚀无腹筋梁承载能力的研究[J]. 四川建筑科学研究, 2007, 33(3): 56-61. |

| Wang Xiao-hui, Liu Xi-la. Research on load carrying capacity of corroded RC beam without web reinforcement on the basis of the change of bond strength[J]. Sichuan Building Science, 2007, 33(3): 56-61. | |

| 37 | . 混凝土结构设计规范 [S]. |

| 38 | Liaw A, Wiener M. Classification and regression by random forest[J]. R News, 2002, 2(3): 18-22. |

| 39 | Safavian S R, Landgrebe D. A survey of decision tree classifier methodology[J]. IEEE Transactions on Systems, Man, and Cybernetics, 1991, 21(3): 660-674. |

| 40 | Freund Y, Schapire R E. A decision-theoretic generalization of on-line learning and an application to boosting[J]. Journal of Computer and System Sciences, 1997, 55(1): 119-139. |

| 41 | Chen T, Guestrin C. Xgboost: a scalable tree boosting system[C]∥Proceedings of the 22nd ACM Sigkdd International Conference on Knowledge Discovery and Data Mining, San Francisco, USA, 2016: 785-794. |

| 42 | Rumelhart D E, Hinton G E, Williams R J. Learning representations by back-propagating errors[J]. Nature, 1986, 323(6088): 533-536. |

| 43 | Hearst M A, Dumais S T, Osuna E, et al. Support vector machines[J]. IEEE Intelligent Systems and Their Applications, 1998, 13(4): 18-28. |

| 44 | Friedman J H. On bias, variance, 0/1—loss, and the curse-of-dimensionality[J]. Data Mining and Knowledge Discovery, 1997, 1: 55-77. |

| 45 | Kuhn M, Johnson K. Feature Engineering and Selection: A Practical Approach for Predictive Models[M]. Boca Raton: Chapman & Hall/CRC Press, 2019. |

| 46 | Breiman L. Random forests[J]. Machine Learning, 2001, 45: 5-32. |

| 47 | Elsayed A K. Shear capacity assessment of reinforced concrete beams with corroded stirrups[J]. Construction and Building Materials, 2017, 134: 176-184. |

| [1] | 王福成,赵欣荣,田家冰,解国梁,周立明. 水稻秸秆灰对混凝土抗压性能及微观结构的影响[J]. 吉林大学学报(工学版), 2024, 54(9): 2620-2630. |

| [2] | 刘一凡,缪志伟,申晨,耿祥东. 基于蒙特卡罗法的不均匀锈蚀钢筋力学性能评估[J]. 吉林大学学报(工学版), 2024, 54(4): 1007-1015. |

| [3] | 冯琼,田浩正,乔宏霞,念腾飞,韩文文. 自然暴露与盐雾加速环境下钢筋混凝土劣化规律及等效关系[J]. 吉林大学学报(工学版), 2024, 54(2): 494-505. |

| [4] | 范博松,邵春福. 城市轨道交通突发事件风险等级判别方法[J]. 吉林大学学报(工学版), 2024, 54(2): 427-435. |

| [5] | 孙敏,朱远恒,高鹏真,李振东,方有珍. 多降雨环境下锈蚀钢筋混凝土柱装配节点抗震性监测[J]. 吉林大学学报(工学版), 2024, 54(12): 3545-3551. |

| [6] | 周丰丰,于涛,范雨思. 基于质谱数据的生成对抗自编码器整合投票算法[J]. 吉林大学学报(工学版), 2024, 54(10): 2969-2977. |

| [7] | 陈文杰,苏振兴,孙先涛,刘远远,胡祥涛,智亚丽. 噪声环境下外骨骼设备语音信号的特征提取[J]. 吉林大学学报(工学版), 2024, 54(10): 3050-3057. |

| [8] | 安然,王有志. 剪力钉连接件拉剪共同作用抗剪性能[J]. 吉林大学学报(工学版), 2023, 53(9): 2554-2562. |

| [9] | 匡亚川,陈立斌,李超举,贺宇豪. 栓钉剪力连接件力学性能分析[J]. 吉林大学学报(工学版), 2023, 53(2): 538-546. |

| [10] | 闫清峰,张纪刚,王涛,陈德刚,郁有升,杨迎春. 预制预装修模块化建筑连接节点抗震性能[J]. 吉林大学学报(工学版), 2023, 53(2): 505-514. |

| [11] | 周丰丰,颜振炜. 基于混合特征的特征选择神经肽预测模型[J]. 吉林大学学报(工学版), 2023, 53(11): 3238-3245. |

| [12] | 戴理朝,周亮,杨晓文,王磊. 基于Connector单元的锈蚀RC梁界面粘结性能细观数值模拟[J]. 吉林大学学报(工学版), 2023, 53(10): 2886-2896. |

| [13] | 郭辉,付接递,李振东,严岩,李虓. 基于改进鲸鱼算法优化SVM参数和特征选择[J]. 吉林大学学报(工学版), 2023, 53(10): 2952-2963. |

| [14] | 李佩泽,赵世舜,翁小辉,蒋鑫妹,崔洪博,乔建磊,常志勇. 基于多传感器优化的农药残留快速检测新方法[J]. 吉林大学学报(工学版), 2022, 52(8): 1951-1956. |

| [15] | 周丰丰,朱海洋. 基于三段式特征选择策略的脑电情感识别算法SEE[J]. 吉林大学学报(工学版), 2022, 52(8): 1834-1841. |

|

||