吉林大学学报(工学版) ›› 2023, Vol. 53 ›› Issue (9): 2554-2562.doi: 10.13229/j.cnki.jdxbgxb.20211243

剪力钉连接件拉剪共同作用抗剪性能

- 山东大学 土建与水利学院,济南 250061

Shear properties of shear stud connectors under combined tension and shear loading

- School of Civil Engineering,Shandong University,Jinan 250061,China

摘要:

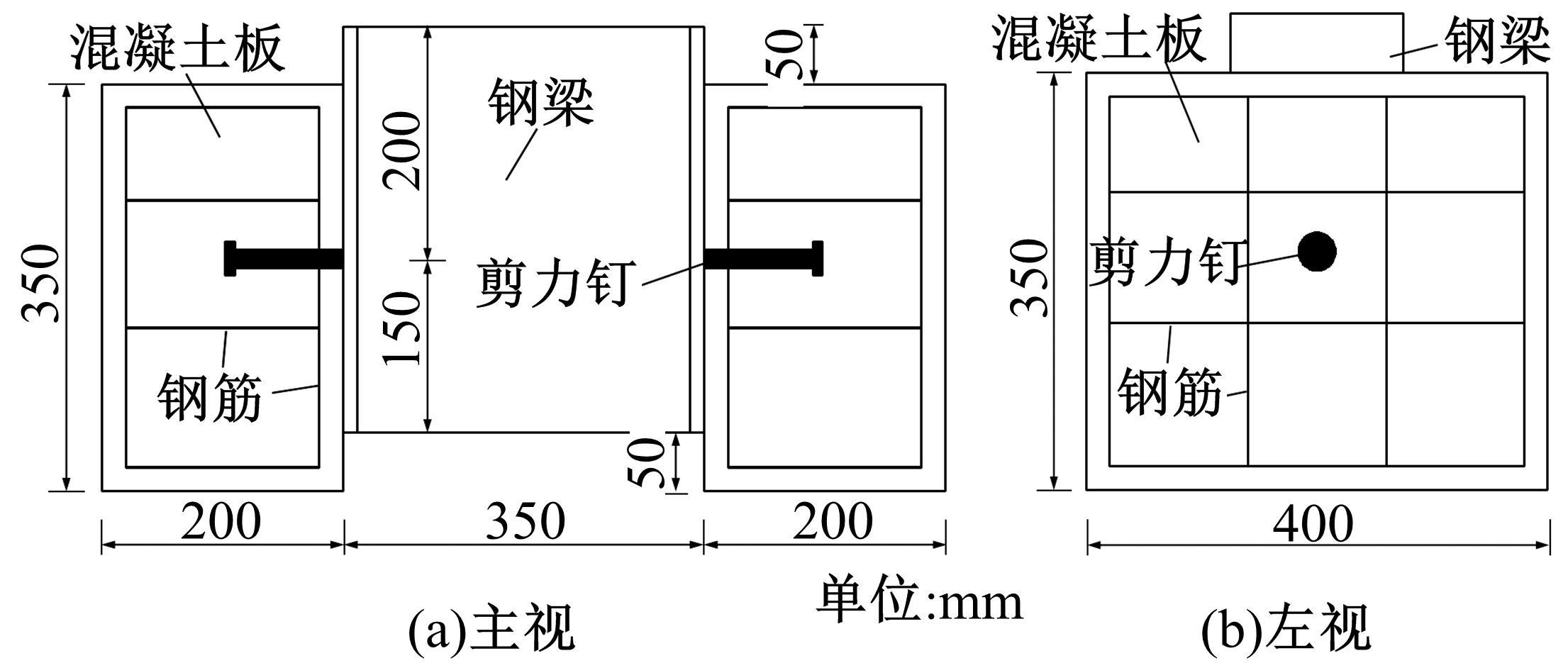

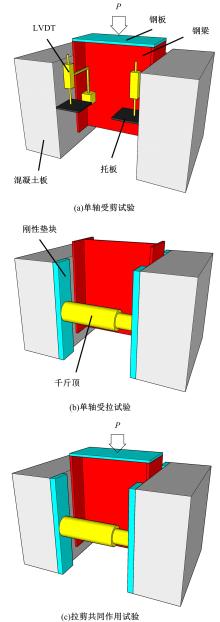

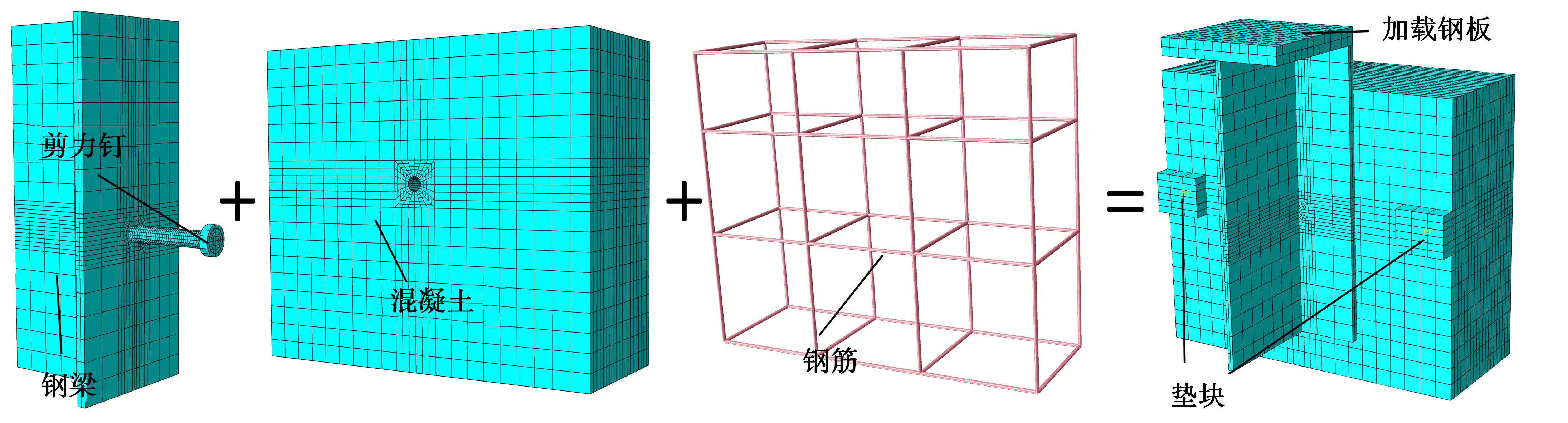

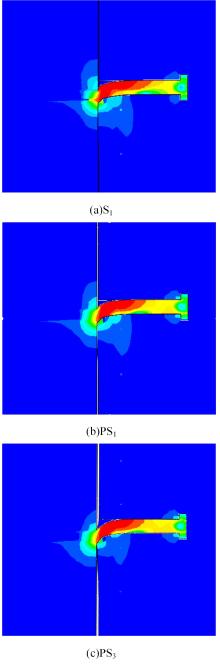

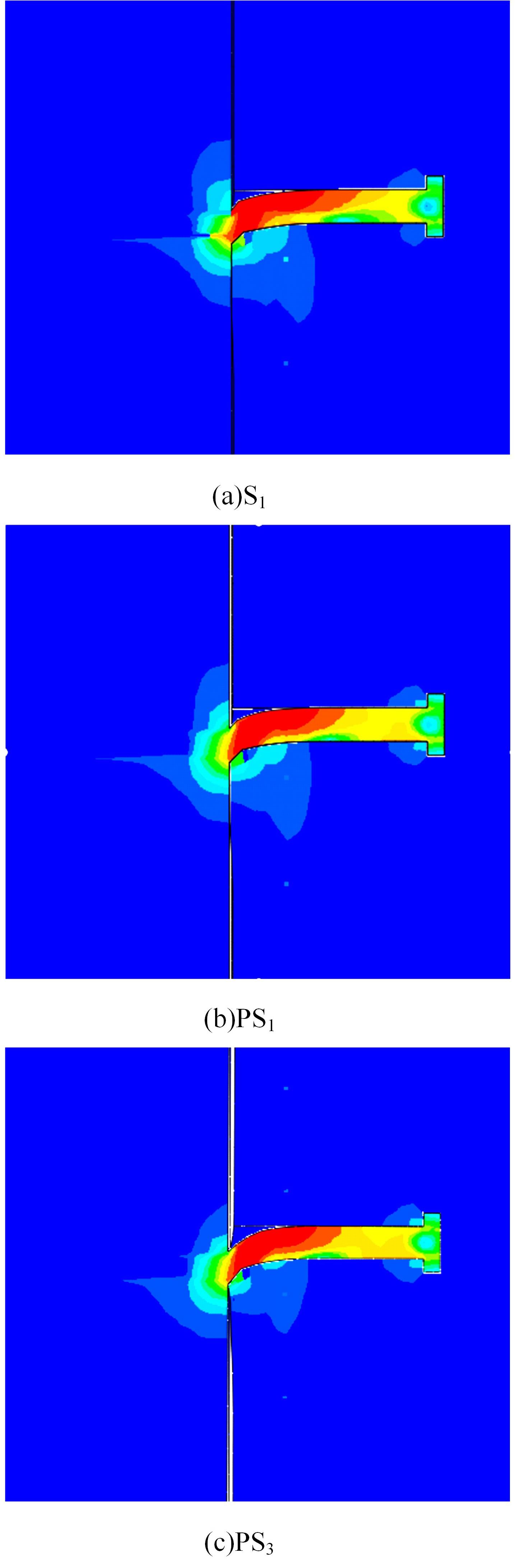

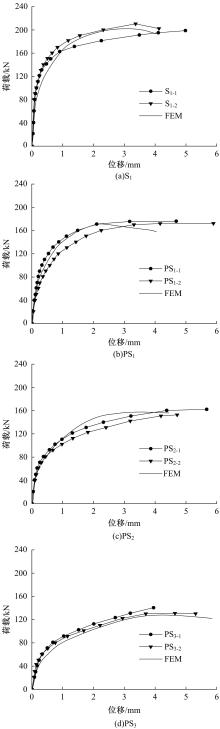

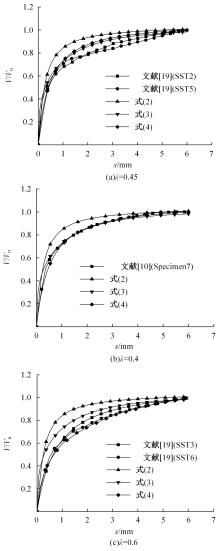

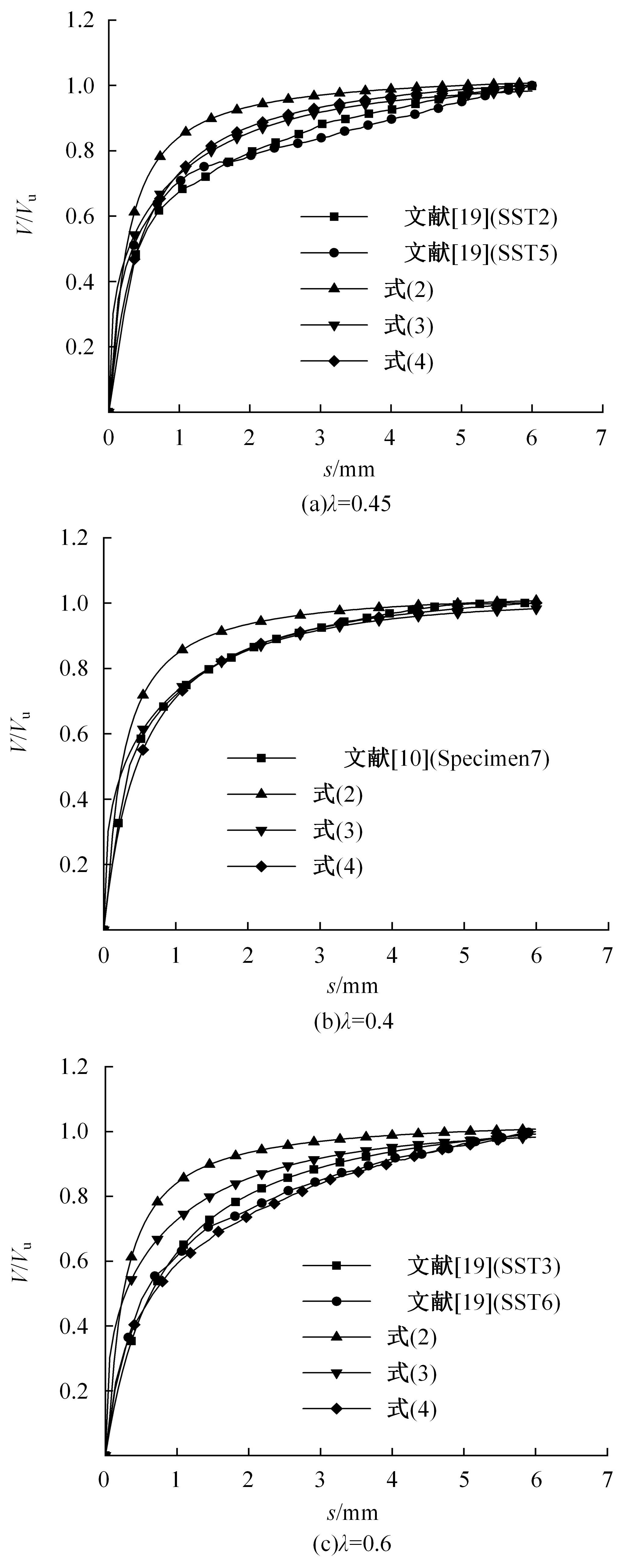

为明确剪力钉连接件在拉剪荷载作用下的力学性能,开展了5组受拉、受剪和拉剪共同作用模型试验,结合有限元模型,探讨了混凝土强度和剪力钉尺寸对抗剪承载力的影响,提出了拉剪共同作用剪力钉连接件荷载-滑移关系式和抗剪承载力计算公式。结果表明:当拉力施力比从0增到0.6时,剪切刚度下降69%,弹性极限荷载与抗剪承载力的比值从0.55下降至0.24,抗剪承载力下降31%;混凝土强度和拉力施力比对剪力钉抗剪承载力的影响具有相关性。本文提出的拉剪共同作用剪力钉连接件荷载-滑移关系式和抗剪承载力计算公式可应用于工程设计和计算。

中图分类号:

- U443.3

| 1 | 王倩, 刘玉擎. 焊钉连接件抗剪承载力试验研究[J]. 同济大学学报: 自然科学版, 2013, 41(5): 659-663. |

| Wang Qian, Liu Yu-qing. Experimental study of shear stud connectors[J]. Journal of Tongji University (Natural Science Edition), 2013, 41(5): 659-663. | |

| 2 | 匡亚川, 陈立斌, 李超举, 等. 栓钉剪力连接件力学性能分析[J]. 吉林大学学报:工学版, 2023, 53(2): 538-546. |

| Kuang Ya-chuan, Chen Li-bin, Li Chao-ju, et al. Analysis of mechanical properties of stud shear connectors[J]. Journal of Jilin University (Engineering and Technology Edition), 2023, 53(2): 538-546. | |

| 3 | 鞠晓臣, 赵欣欣, 刘晓光, 等. 火灾作用下剪力钉抗拔性能研究[J]. 桥梁建设, 2018, 48(2): 55-60. |

| Ju Xiao-chen, Zhao Xin-xin, Liu Xiao-guang, et al. Study of pullout performance of shear stud under fire[J]. Bridge Construction, 2018, 48(2): 55-60. | |

| 4 | 蔺钊飞, 刘玉擎. 焊钉连接件抗拉承载力试验[J]. 同济大学学报: 自然科学版, 2015, 43(9): 1313-1319, 1331. |

| Lin Zhao-fei, Liu Yu-qing. Experimental study on static behavior of headed studs under tension force[J]. Journal of Tongji University (Natural Science Edition), 2015, 43(9): 1313-1319, 1331. | |

| 5 | Luis P, Jerome F. Headed steel stud anchors in composite structures,part II: tension and interaction[J]. Journal of Constructional Steel Research, 2010, 66(2): 213-228. |

| 6 | 薛东焱, 宛青云, 潘志宏, 等. 剪力与拉拔力共同作用下焊钉受力性能分析[J]. 江苏科技大学学报:自然科学版, 2020, 34(2): 97-102. |

| Xue Dong-yan, Wan Qing-yun, Pan Zhi-hong, et al. Mechanical behavior analysis of headed studs under shear and tension loads[J]. Journal of Jiangsu University of Science and Technology (Natural Science Edition), 2020, 34(2): 97-102. | |

| 7 | 刘沐宇, 赖苑林, 邓晓光, 等. 集束式长短剪力钉抗剪承载力计算方法[J]. 中国公路学报, 2018, 31(12): 97-105. |

| Liu Mu-yu, Lai Yuan-lin, Deng Xiao-guang, et al. Calculation method of shear capacity of clustered stud connectors with different lengths and diameters[J]. China Journal of Highway and Transport, 2018, 31(12): 97-105. | |

| 8 | 张阳, 吴洁, 邵旭东, 等. 超高性能混凝土-普通混凝土界面抗剪性能试验研究[J]. 土木工程学报, 2021, 54(7): 81-89. |

| Zhang Yang, Wu Jie, Shao Xu-dong, et al. Experiment on interfacial shear properties between ultra-high performance concrete and normal strength concrete[J]. China Civil Engineering Journal, 2021, 54(7): 81-89. | |

| 9 | Shen M H, Chung K F. An investigation into shear resistances of headed shear studs in solid concrete slabs with local aggregates in Hong Kong[J]. Procedia Engineering, 2011: 1098-1105. |

| 10 | Saari W K, Hajjar J F, Schultz A E, et al. Behavior of shear studs in steel frames with reinforced concrete infill walls[J]. Journal of Constructional Steel Research, 2004, 60(10): 1453-1480. |

| 11 | 蔺钊飞, 刘玉擎. 焊钉连接件拉剪相关关系模型试验[J]. 中国公路学报, 2015, 28(1): 80-86. |

| Lin Zhao-fei, Liu Yu-qing. Model experiment on shear-tension interaction relationship of headed studs[J]. China Journal of Highway and Transport, 2015, 28(1): 80-86. | |

| 12 | Shen M H, Chung K F. Experimental investigation into stud shear connections under combined shear and tension forces[J]. Journal of Constructional Steel Research, 2017, 133(6): 434-447. |

| 13 | Mirza O, Uy B. Effects of the combination of axial and shear loading on the behavior of headed stud steel anchors[J]. Engineering Structures, 2010, 32(1): 93-105. |

| 14 | Mcmackin P J, Slutter R G, Fisher J W. Headed steel anchor under combined loading[J]. AISC Engineering Journal, 1973, 2: 43-52. |

| 15 | 蒲黔辉, 谢宏伟, 樊书文, 等. 拔出破坏的钢混组合结构栓钉连接件承载力的分析方法[J]. 工程科学与技术, 2019, 51(1): 89-95. |

| Pu Qian-hui, Xie Hong-wei, Fan Shu-wen, et al. Analysis method of bearing capacity of stud connector in steel concrete composite structures under push-out failure[J]. Advanced Engineering Sciences, 2019, 51(1): 89-95. | |

| 16 | Luis P, Jerome F. Headed steel stud anchors in composite structures, part I: shear[J]. Journal of Constructional Steel Research, 2010, 66(2): 198-212. |

| 17 | EN 1994-1-1 :2004. Eurocode4: design of composite structures, part 1-1: general rules and rules for buildings [S]. |

| 18 | Han Q H, Wang Y H, Xu J, et al. Static behavior of stud shear connectors in elastic concrete-steel composite beams[J]. Journal of Constructional Steel Research, 2015, 113: 115-126. |

| 19 | Lin Z F, Liu Y Q, He J. Behavior of stud connectors under combined shear and tension loads[J]. Engineering Structures, 2014, 81: 362-376. |

| 20 | Xue D Y, Liu Y Q, Yu Z, et al. Static behavior of multi-stud shear connectors for steel-concrete composite bridge[J]. Steel Construction, 2012, 74(8): 1-7. |

| 21 | 苏庆田, 韩旭, 任飞. 多排焊钉推出试验试件力学性能[J]. 同济大学学报: 自然科学版, 2014, 42(7): 1011-1016. |

| Su Qing-tian, Han Xu, Ren Fei. Static behavior of push-out specimen with multi-row stud connectors[J]. Journal of Tongji University (Natural Science Edition), 2014, 42(7): 1011-1016. | |

| 22 | Katsuhiko T, Katsuyuki N, Sumio H. Shear strength of headed stud shear connector subjected to tensile load[J]. Journal of Constructional Steel, 1999, 7: 233-240. |

| 23 | Bode H, Hanenkamp W. Capacity of headed studs under tension load[J]. Bauingenieur, 1985, 60: 361-367. |

| 24 | 安然, 王有志, 周磊, 等. 剪力钉连接件拉剪复合作用试验及计算模型[J]. 长安大学学报: 自然科学版, 2020, 40(3): 42-52. |

| An Ran, Wang You-zhi, Zhou Lei, et al. Experiment and mechanical model of sheer stud connectors under combined tension and shear force[J]. Journal of chang'an University (Natural Science Edition), 2020, 40(3): 42-52. |

| [1] | 左新黛,张劲泉,赵尚传. 在役混凝土T梁疲劳刚度退化及寿命预测方法[J]. 吉林大学学报(工学版), 2023, 53(9): 2563-2572. |

| [2] | 顾正伟,张攀,吕东冶,吴春利,杨忠,谭国金,黄晓明. 基于数值仿真的简支梁桥震致残余位移分析[J]. 吉林大学学报(工学版), 2023, 53(6): 1711-1718. |

| [3] | 吴春利,黄诗茗,李魁,顾正伟,黄晓明,张炳涛,杨润超. 基于数值仿真和统计分析的洪水作用下桥墩作用效应分析[J]. 吉林大学学报(工学版), 2023, 53(6): 1612-1620. |

| [4] | 谭国金,孔庆雯,何昕,张攀,杨润超,朝阳军,杨忠. 基于动力特性和改进粒子群优化算法的桥梁冲刷深度识别[J]. 吉林大学学报(工学版), 2023, 53(6): 1592-1600. |

| [5] | 江辉,李新,白晓宇. 桥梁抗震结构体系发展述评:从延性到韧性[J]. 吉林大学学报(工学版), 2023, 53(6): 1550-1565. |

| [6] | 王华,王龙林,张子墨,何昕. 基于裂缝宽度变化的连续刚构桥安全性预警技术[J]. 吉林大学学报(工学版), 2023, 53(6): 1650-1657. |

| [7] | 冯宇,郝键铭,王峰,张久鹏,黄晓明. 非平稳极端风作用下大跨桥梁瞬态风致效应分析[J]. 吉林大学学报(工学版), 2023, 53(6): 1638-1649. |

| [8] | 卜建清,郭至博,张吉仁,荀敬川,黄晓明. 多损伤钢-混组合梁桥力学性能有限元分析方法[J]. 吉林大学学报(工学版), 2023, 53(6): 1621-1637. |

| [9] | 王峰,刘双瑞,王佳盈,宋佳玲,王俊,张久鹏,黄晓明. 尺寸和形状效应对多孔结构风阻系数的影响[J]. 吉林大学学报(工学版), 2023, 53(6): 1677-1685. |

| [10] | 王俊,李加武,王峰,张久鹏,黄晓明. 简化U形峡谷风速分布及其对悬索桥抖振响应的影响[J]. 吉林大学学报(工学版), 2023, 53(6): 1658-1668. |

| [11] | 袁野. 温度和车辆作用下梁式桥梁结构固有频率分析方法[J]. 吉林大学学报(工学版), 2023, 53(6): 1702-1710. |

| [12] | 刘子玉,陈士通,支墨墨,黄晓明,陈哲心. 可“临-永”转换抢修钢墩应急使用极限承载力[J]. 吉林大学学报(工学版), 2023, 53(6): 1601-1611. |

| [13] | 张玥,刘传森,宋飞. 桥台背墙对连续梁桥地震易损性的影响[J]. 吉林大学学报(工学版), 2023, 53(5): 1372-1380. |

| [14] | 兰树伟,周东华,陈旭,莫南明. 双柱式高墩桥梁整体稳定性的实用算法[J]. 吉林大学学报(工学版), 2023, 53(4): 1105-1111. |

| [15] | 匡亚川,陈立斌,李超举,贺宇豪. 栓钉剪力连接件力学性能分析[J]. 吉林大学学报(工学版), 2023, 53(2): 538-546. |

|