吉林大学学报(工学版) ›› 2025, Vol. 55 ›› Issue (3): 820-828.doi: 10.13229/j.cnki.jdxbgxb.20230564

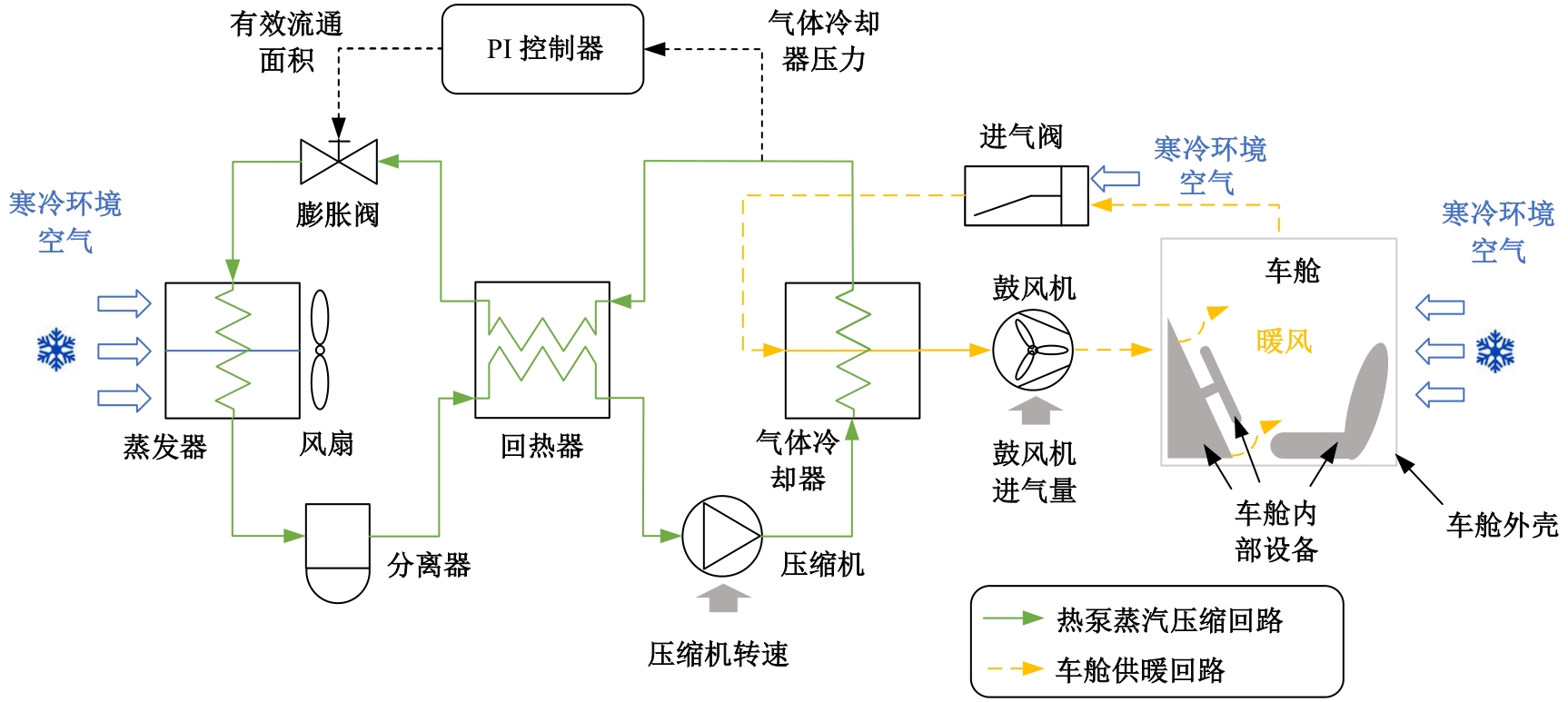

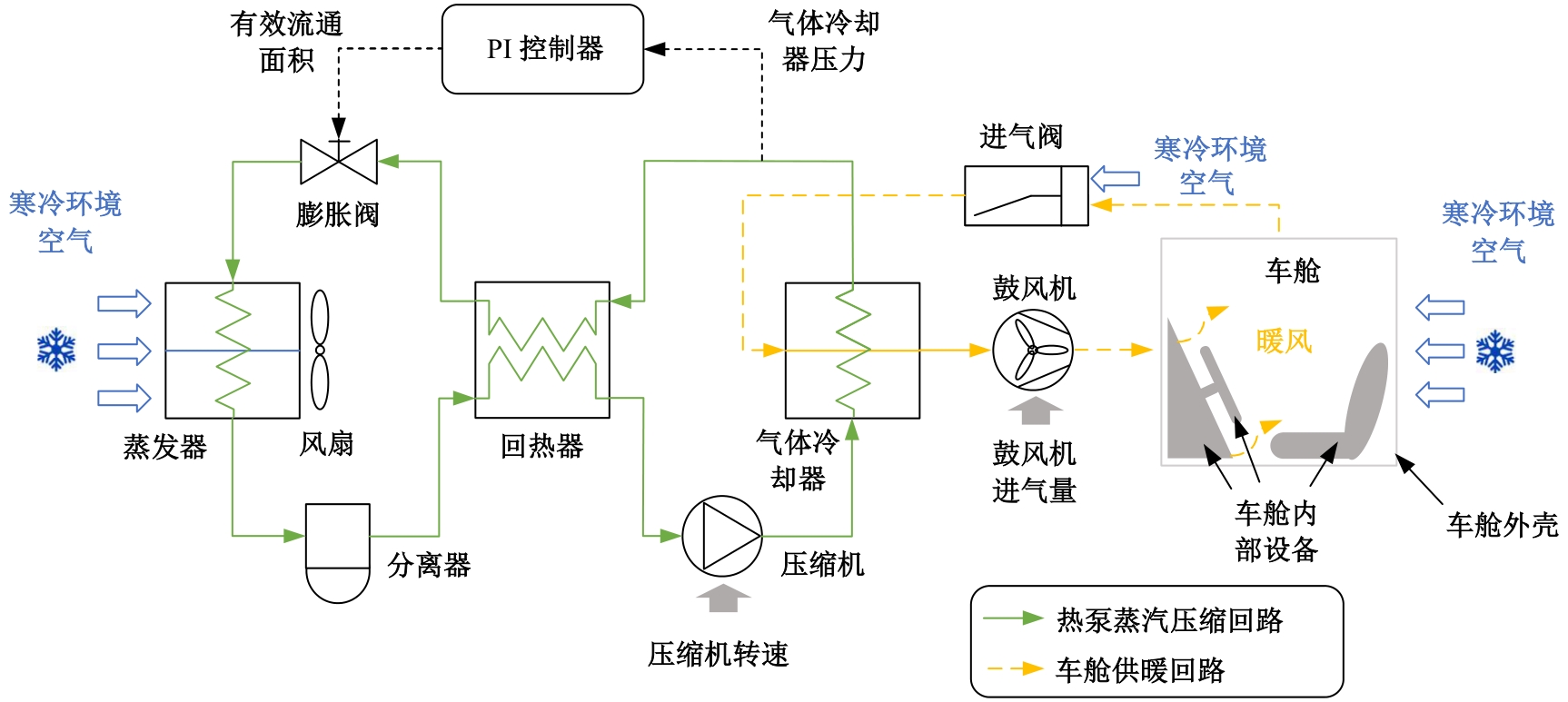

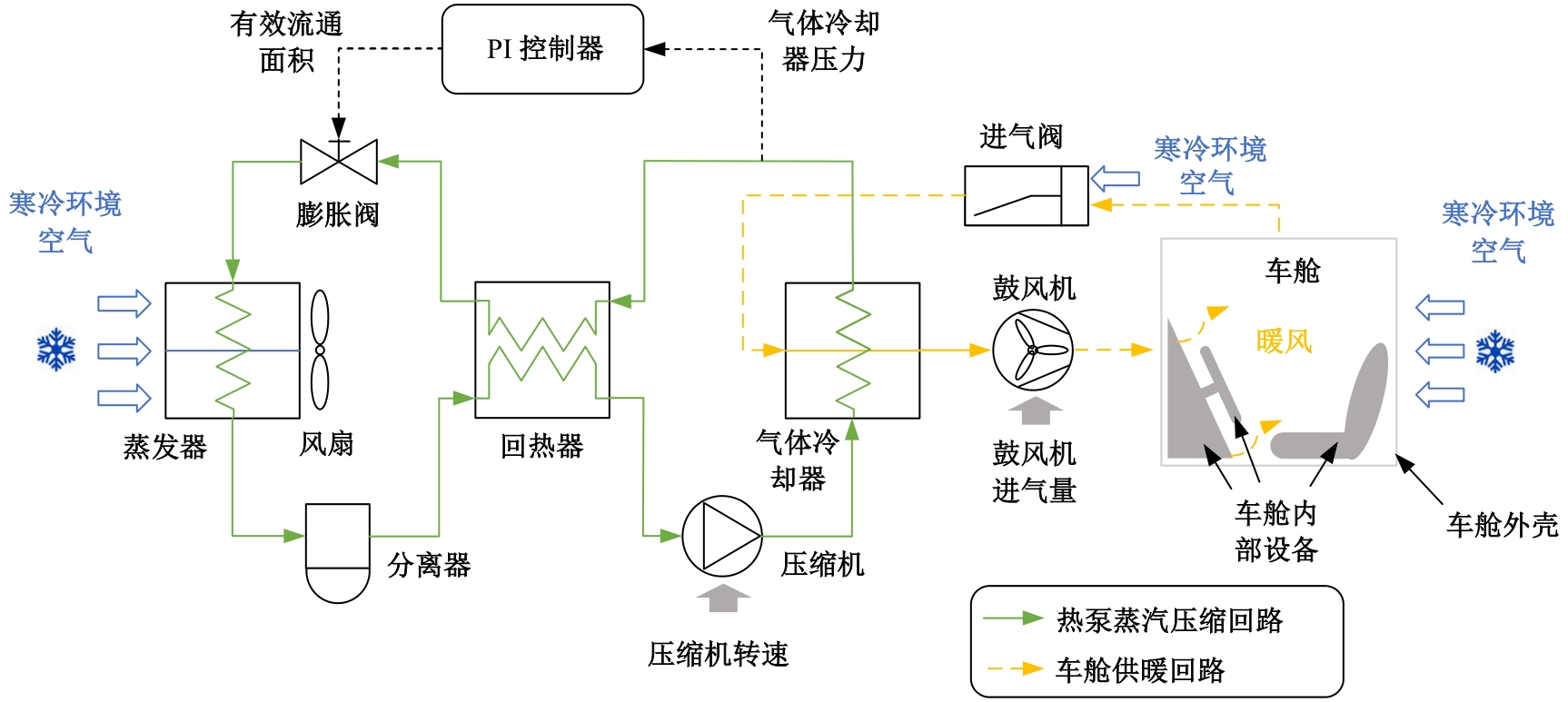

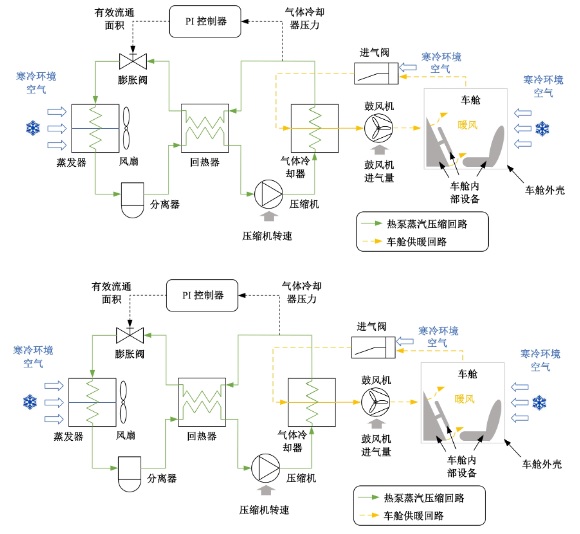

冬季网联纯电动汽车热泵空调生态制热控制方法

宫洵1( ),任航1,张华霖2,汪介瑜1,胡云峰3,4,孙耀3(

),任航1,张华霖2,汪介瑜1,胡云峰3,4,孙耀3( )

)

- 1.吉林大学 人工智能学院,长春 130012

2.西南大学 工程技术学院,重庆 400715

3.吉林大学 汽车底盘集成与仿生全国重点实验室,长春 130022

4.吉林大学 通信工程学院,长春 130012

Eco⁃heating control method for connected electric automotive heat pump system in winter conditions

Xun GONG1( ),Hang REN1,Hua-lin ZHANG2,Jie-yu WANG1,Yun-feng HU3,4,Yao SUN3(

),Hang REN1,Hua-lin ZHANG2,Jie-yu WANG1,Yun-feng HU3,4,Yao SUN3( )

)

- 1.School of Artificial Intelligence,Jilin University,Changchun 130012,China

2.College of Engineering and Technology,Southwest University,Chongqing 400715,China

3.National Key Laboratory of Automotive Chassis Integration and Bionics,Jilin University,Changchun 130022,China

4.College of Communication Engineering,Jilin University,Changchun 130012,China

摘要:

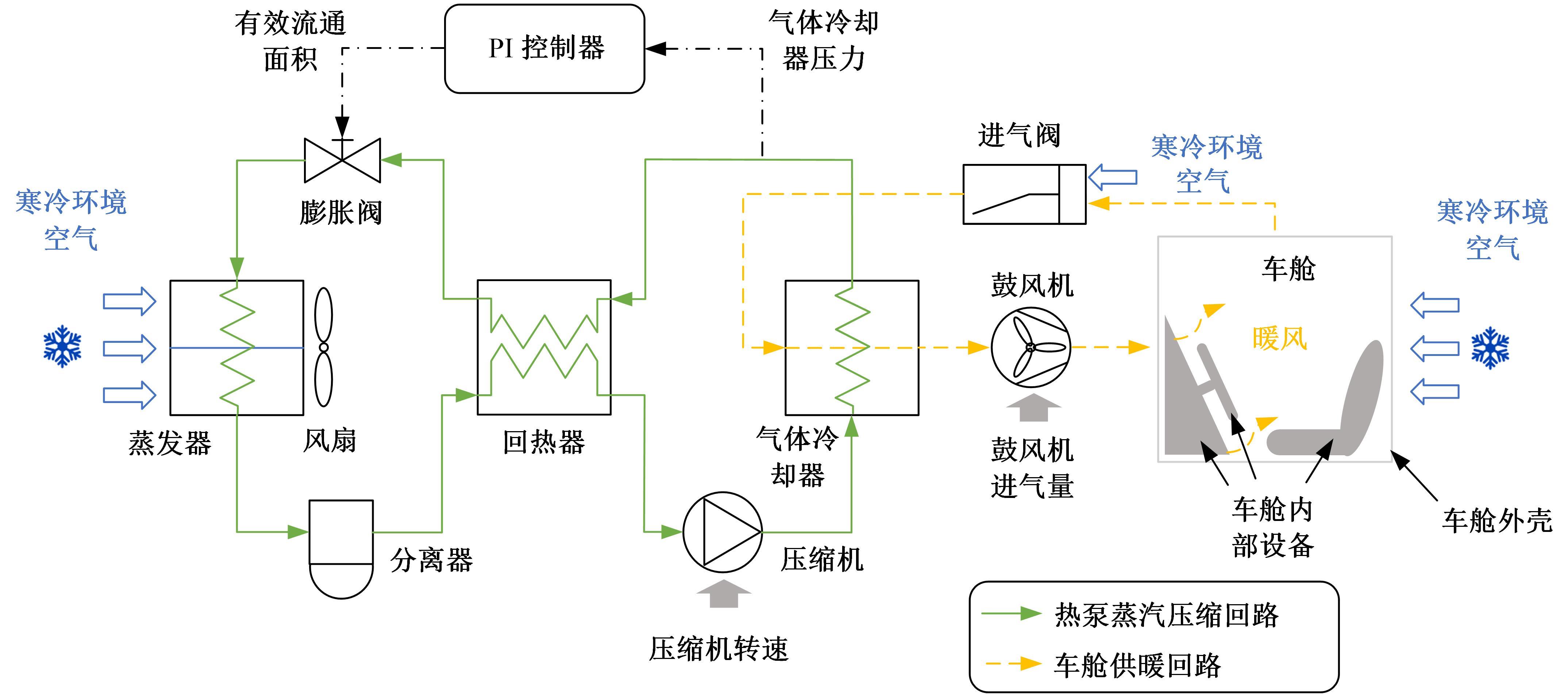

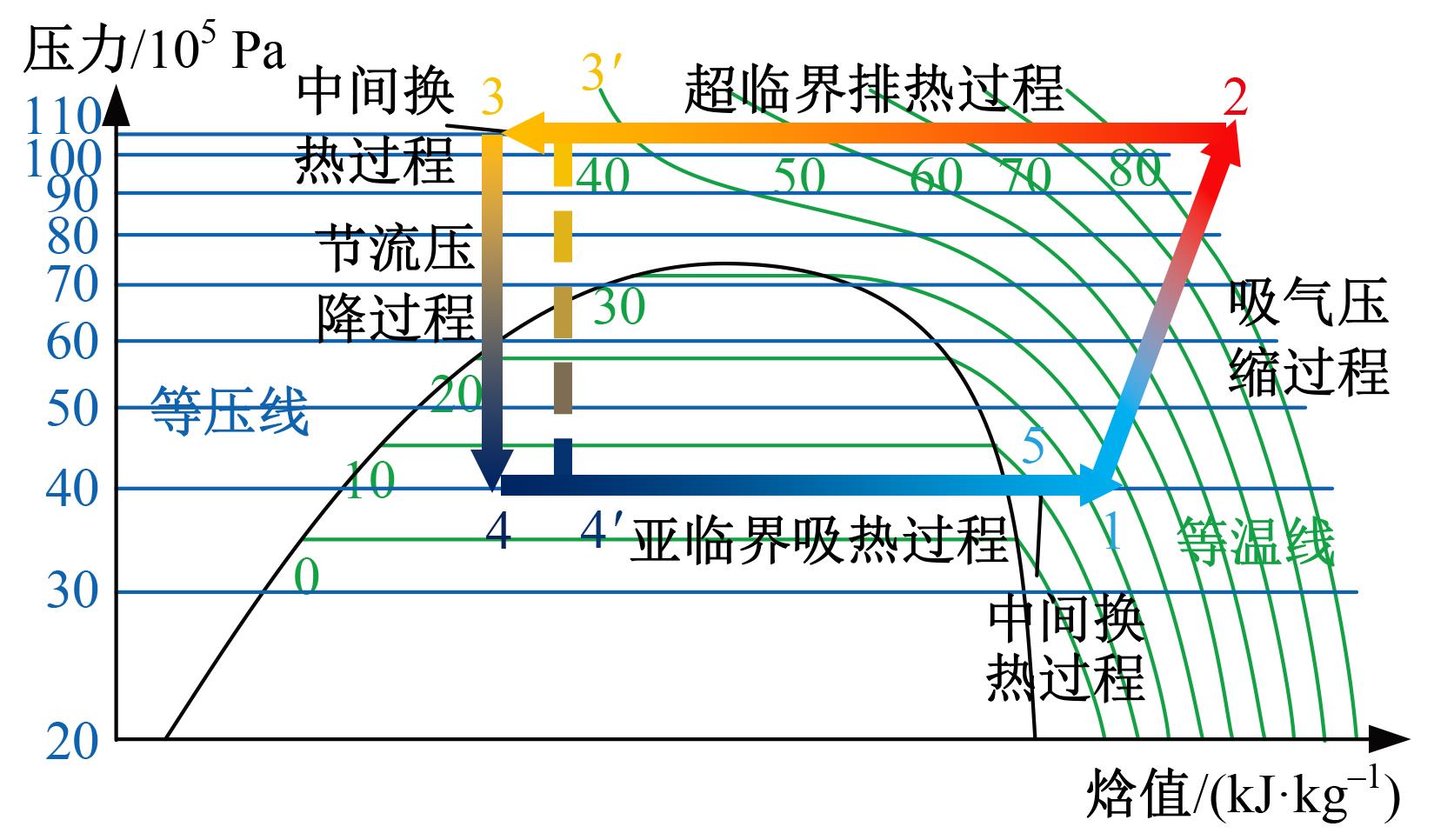

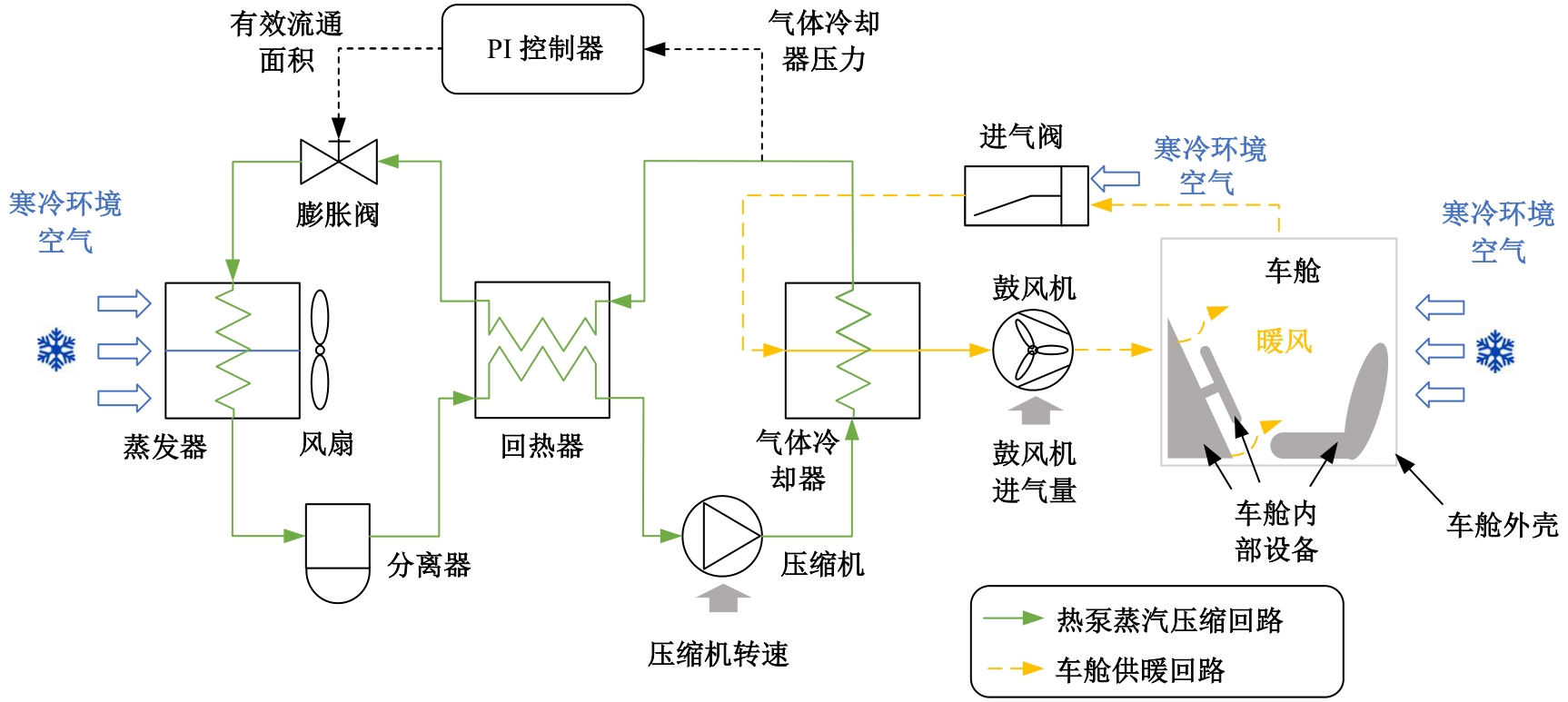

为应对冬季寒冷气候条件下车舱供暖需求带来的纯电动汽车“续航焦虑”问题,发掘了车速与热泵空调系统能耗的灵敏度关系,并发展了一种新型的面向控制的热泵空调系统高精度预测模型范式。然后,以此为基础将网联环境下的车速预瞄信息整合到热管理控制器设计中,形成了一种基于模型预测控制(MPC)的预见性生态制热策略(EHS)。最后,将所提出的EHS在基于Dymola的高保真物理仿真模型进行了验证,结果表明:利用车速预瞄信息可以预见性地优化空调系统运行负荷,在满足热舒适度需求的同时,可以相较基准控制器进一步实现18.46%~20.61%的能效提升。

中图分类号:

- TP273

| 1 | Enthaler A, Weustenfeld T, Gauterin F, et al. Thermal management consumption and its effect on remaining range estimation of electric vehicles[C]∥International Conference on Connected Vehicles and Expo,Shenzhen, China, 2014: 170-177. |

| 2 | Reyes J R M D, Parsons R V, Hoemsen R. Winter happens: the effect of ambient temperature on the travel range of electric vehicles[J]. IEEE Transactions on Vehicular Technology, 2016, 65(6): 4016-4022. |

| 3 | Jeffers M A, Chaney L, Rugh J P. Climate control load reduction strategies for electric drive vehicles in cold weather[J]. SAE International Journal of Passenger Cars-Mechanical Systems, 2016, 9: 75-82. |

| 4 | Noel L, de Rubens G Z, Sovacool B K, et al. Fear and loathing of electric vehicles: the reactionary rhetoric of range anxiety[J]. Energy Research & Social Science, 2019, 48: 96-107. |

| 5 | Jiang L, Wang R Z, Li J B, et al. Performance analysis on a novel sorption air conditioner for electric vehicles[J]. Energy Conversion and Management, 2018, 156: 515-524. |

| 6 | Yu B, Yang J, Wang D, et al. Energy consumption and increased EV range evaluation through heat pump scenarios and low GWP refrigerants in the new test procedure WLTP[J]. International Journal of Refrigeration, 2019, 100: 284-294. |

| 7 | Boewe D E, Bullard C W, Yin J M, et al. Contribution of internal heat exchanger to transcritical R-744 cycle performance[J]. HVAC&R Research, 2001, 7(2): 155-168. |

| 8 | Aprea C, Maiorino A. An experimental evaluation of the transcritical CO2 refrigerator performances using an internal heat exchanger[J]. International Journal of Refrigeration, 2008, 31(6): 1006-1011. |

| 9 | Dong J Q, Wang Y B, Jia S W, et al. Experimental study of R744 heat pump system for electric vehicle application[J]. Applied Thermal Engineering, 2021, 183: No.116191. |

| 10 | Wang Y B, Dong J Q, Jia S W, et al. Experimental comparison of R744 and R134a heat pump systems for electric vehicle application[J]. International Journal of Refrigeration, 2021, 121: 10-22. |

| 11 | Song Y, Cui C, Yin X, et al. Advanced development and application of transcritical CO2 refrigeration and heat pump technology—a review[J]. Energy Reports, 2022, 8: 7840-7869. |

| 12 | Wang Y, Li W, Zhang Z, et al. Performance evaluation and prediction for electric vehicle heat pump using machine learning method[J]. Applied Thermal Engineering, 2019, 159:No. 113901. |

| 13 | Lorentzen G. Revival of carbon dioxide as a refrigerant[J]. International Journal of Refrigeration, 1994, 17(5): 292-301. |

| 14 | Wang H, Kolmanovsky I, Amini M R, et al. Model predictive climate control of connected and automated vehicles for improved energy efficiency[C]∥Annual American Control Conference, Wisconsin, America, 2018: 828-833. |

| 15 | He H, Jia H, Sun C, et al. Stochastic model predictive control of air conditioning system for electric vehicles: Sensitivity study, comparison, and improvement[J]. IEEE Transactions on Industrial Informatics, 2018, 14(9): 4179-4189. |

| 16 | Zhang Q, Meng Y, Greiner C, et al. Air conditioning system performance and vehicle fuel economy trade-offs for a hybrid electric vehicle[C]∥SAE Technical Paper,2017-0171. |

| 17 | Zhang Q, Canova M. Lumped-parameter modeling of an automotive air conditioning system for energy optimization and management[C]∥Dynamic Systems and Control Conference,Palo Alto, California, USA, 2013: No.V001T04A003. |

| 18 | 田镇. 基于热泵的纯电动汽车热管理系统的实验研究与仿真分析[D]. 上海: 上海交通大学机械与动力工程学院, 2016. |

| Tian Zhen. Experimental study and simulation analysis of electric vehicle thermal management system based on heat pump[D]. Shanghai: School of Mechanical Engineering, Shanghai Jiao Tong University, 2016. | |

| 19 | Fayazbakhsh M A, Bahrami M. Comprehensive modeling of vehicle air conditioning loads using heat balance method[C]∥SAE Technical Paper, 2013-1507. |

| [1] | 李寿涛,杨路,屈如意,孙鹏鹏,于丁力. 基于模型预测控制的滑移率控制方法[J]. 吉林大学学报(工学版), 2024, 54(9): 2687-2696. |

| [2] | 鲜斌,王光怡,蔡佳明. 多无人机吊挂负载运输系统的非线性鲁棒控制设计[J]. 吉林大学学报(工学版), 2024, 54(6): 1788-1795. |

| [3] | 王宏志,王婷婷,兰淼淼,徐硕. 基于位置跟踪的机械臂多电机新型滑模控制策略[J]. 吉林大学学报(工学版), 2024, 54(5): 1443-1458. |

| [4] | 赵军,赵子亮,朱庆林,郭斌. 不依赖观测器的不确定性系统输出反馈鲁棒控制[J]. 吉林大学学报(工学版), 2024, 54(3): 828-835. |

| [5] | 李文航,倪涛,赵丁选,邓英杰,师小波. 基于模型预测反馈技术的救援车辆液压悬挂系统控制方法[J]. 吉林大学学报(工学版), 2024, 54(3): 610-619. |

| [6] | 赵靖华,张雨彤,曹派,王忠恕,李小平,孙亚南,解方喜. 压缩天然气发动机增程式电动汽车能量管理优化[J]. 吉林大学学报(工学版), 2024, 54(3): 600-609. |

| [7] | 江和耀,王永海,吴幼冬,王萍. 四轮毂驱动电动车辆横向稳定与侧倾预防协同控制策略[J]. 吉林大学学报(工学版), 2024, 54(2): 540-549. |

| [8] | 刘果,熊坚,杨秀建,何扬帆. 基于曲率增广的智能车辆轨迹跟踪控制[J]. 吉林大学学报(工学版), 2024, 54(12): 3717-3728. |

| [9] | 刘刚,范群,杨旭,任宏斌. 无人驾驶汽车变速换道轨迹跟踪动态控制[J]. 吉林大学学报(工学版), 2024, 54(12): 3729-3739. |

| [10] | 宋秀兰,柴伟豪,何德峰,应颂翔. DoS攻击下网联车队安全协同自适应预测巡航控制[J]. 吉林大学学报(工学版), 2024, 54(11): 3406-3416. |

| [11] | 蒋渊德,欧阳铭,赵祥模,秦孔建,郑兵兵. 车辆纵侧向辅助驾驶集成优化控制策略[J]. 吉林大学学报(工学版), 2024, 54(10): 2741-2753. |

| [12] | 徐卓君,王耀祥,黄兴,彭程. 多无人机地面移动目标搜寻和定位[J]. 吉林大学学报(工学版), 2023, 53(3): 832-840. |

| [13] | 何德峰,周丹,罗捷. 跟随式车辆队列高效协同弦稳定预测控制[J]. 吉林大学学报(工学版), 2023, 53(3): 726-734. |

| [14] | 申富媛,李炜,蒋栋年. 四旋翼无人机寿命预测和自主维护方法[J]. 吉林大学学报(工学版), 2023, 53(3): 841-852. |

| [15] | 谢波,高榕,许富强,田彦涛. 低附着路况条件下人车共享转向系统稳定控制[J]. 吉林大学学报(工学版), 2023, 53(3): 713-725. |

|

||