Journal of Jilin University(Engineering and Technology Edition) ›› 2023, Vol. 53 ›› Issue (9): 2686-2694.doi: 10.13229/j.cnki.jdxbgxb.20211199

Previous Articles Next Articles

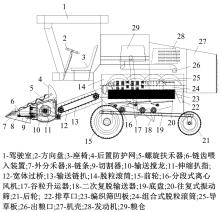

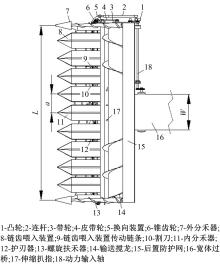

Design and experiments of self⁃propelled quinoa combine harvester

Rui-jie SHI1( ),Fei DAI1,Wu-yun ZHAO1(

),Fei DAI1,Wu-yun ZHAO1( ),Fa-rong YANG2,Feng-wei ZHANG1,Yi-ming ZHAO1,Hao QU1,Tian-fu WANG1,Jun-hai GUO1

),Fa-rong YANG2,Feng-wei ZHANG1,Yi-ming ZHAO1,Hao QU1,Tian-fu WANG1,Jun-hai GUO1

- 1.College of Mechanical and Electrical Engineering,Gansu Agricultural University,Lanzhou 730070,China

2.Livestock Grass and Green Agriculture,Gansu Academy of Agricultural Sciences,Lanzhou 730070,China

CLC Number:

- S225.5

| 1 | Carrasco R R, Espinoza C, Jacobsen S E. Nutritional value and use of the andean crops quinoa (Chenopodium quinoa) and kañiwa (Chenopodium pallidicaule)[J]. Food Reviews International, 2006, 19(1):179-189. |

| 2 | 黄杰, 杨发荣, 李敏权, 等. 13个藜麦材料在甘肃临夏旱作区适应性的初步评价[J]. 草业学报, 2016, 25(3): 191-201. |

| Huang Jie, Yang Fa-rong, Li Min-quan, et al. Preliminary evaluation of adaptability of 13 quinoa varieties in the linxia arid region of gansu province, China[J]. Acta Prataculturae Sinica, 2016, 25(3): 191-201. | |

| 3 | 杨发荣, 黄杰, 魏玉明, 等. 藜麦生物学特性及应用[J]. 草业科学, 2017, 34(3): 607-613. |

| Yang Fa-rong, Huang Jie, Wei Yu-ming, et al. A review of biological characteristics, applications, and culture of chenopodium quinoa [J]. Pratacultural Science, 2017, 34(3): 607-613. | |

| 4 | 袁飞敏, 权有娟, 刘德梅, 等. 藜麦植株形态及花器结构的初步观察[J]. 甘肃农业大学学报, 2018, 53(4): 49-53. |

| Yuan Fei-min, Quan You-juan, Liu De-mei, et al. Primary observation the plant morphologic and floral structure on quiona(Chenopodium quinoa Willd)[J]. Journal of Gansu Agricultural University, 2018, 53(4): 49-53. | |

| 5 | 付丽红, 李晓斌. 基于岭脊分析的藜麦淀粉提取及糊化特性研究[J]. 农业工程学报, 2016, 32(18): 299-306. |

| Fu Li-hong, Li Xiao-bin. Extraction and gelatinization characteristics of chenopodium quinoa willd starch based on ridge analysis[J]. Transactions of the Chinese Society of Agricultural Engineering, 2016, 32(18): 299-306. | |

| 6 | Stikic R, Glamoclija D, Demin M, et al. Agronomical and nutritional evaluation of quinoa seeds (Chenopodium quinoa Willd.) as an ingredient in bread formulations[J]. Journal of Cereal Science, 2012, 55(2): 132-138. |

| 7 | González J A, Konishi Y, Bruno M, et al. Interrelationships among seed yield, total protein and amino acid composition of ten quinoa (Chenopodium quinoa) cultivars from two different agroecological regions[J]. Journal of the Science and Food Agriculture, 2012, 92(6): 1222-1229. |

| 8 | 陈庆文, 韩增德, 崔俊伟, 等. 自走式谷物联合收割机发展现状及趋势分析[J]. 中国农业科技导报, 2015, 17(1): 109-114. |

| Cheng Qing-wen, Han Zeng-de, Cui Jun-wei, et al. Development status and trend current situation of self-propelled combine harvester[J]. Journal of Agricultural Science and Technology, 2015, 17(1): 109-114. | |

| 9 | Fu J, Chen Z, Tian L J, et al. Review of grain threshing theory and technology[J]. International Journal of Agricultural and Biological Engineering, 2018, 11(3): 12-20. |

| 10 | 戴飞. 胡麻脱出物分离清选机理与关键技术研究[D]. 兰州:甘肃农业大学机电工程学院,2020. |

| Dai Fei. Study on the separating-cleaning mechanism and key technology of flax threshing material[D]. Lanzhou: College of Mechanical and Electrical Engineering, Gansu Agricultural University, 2020. | |

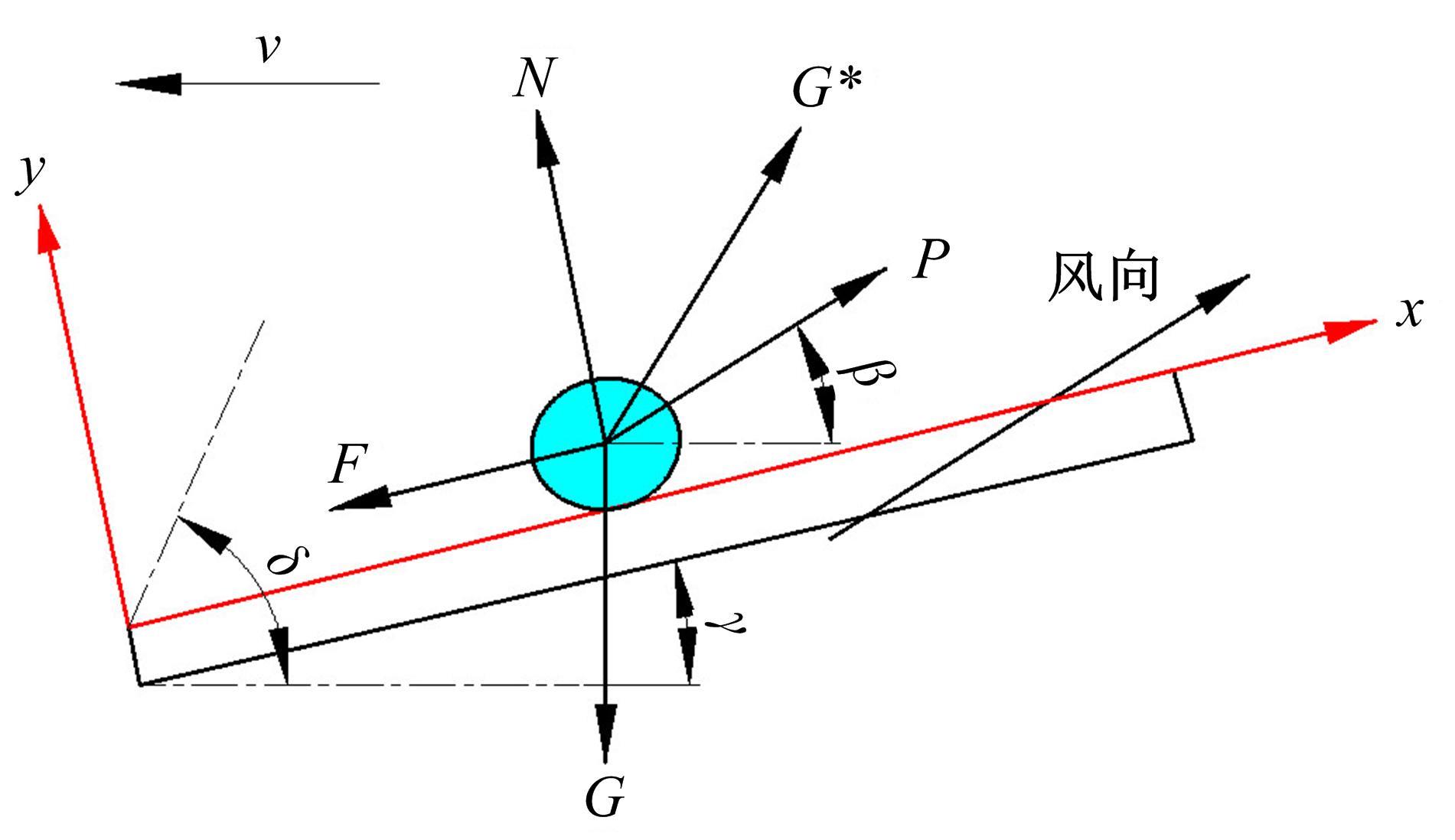

| 11 | 海梅, 杜文亮, 吴英思, 等. 藜麦脱出物空气动力学特性测试与分析[J]. 农机化研究, 2019, 41(2): 192-195, 215. |

| Mei Hai, Du Wen-liang, Wu Yin-si, et al. Test and analysis of aerodynamics on the quinoa threshed mixture[J]. Journal of Agricultural Mechanization Research, 2019, 41(2): 192-195, 215. | |

| 12 | 吴英思, 郭占斌, 杜文亮, 等. 藜麦脱出物的物料特性研究[J]. 农机化研究, 2017, 39(9): 184-189. |

| Wu Ying-si, Guo Zhan-bin, Du Wen-liang, et al. Study of the material properties on the quinoa threshed mixture[J]. Journal of Agricultural Mechanization Research, 2017, 39(9): 184-189. | |

| 13 | 赵子龙, 郭占斌, 杜文亮, 等. 浸水藜谷的机械特性研究[J]. 农机化研究, 2018, 40(11): 162-165, 170. |

| Zhao Zi-long, Guo Zhan-bin, Du Wen-liang, et al. The study of the mechanical properties of quinoa [J]. Journal of Agricultural Mechanization Research, 2018, 40(11): 162-165, 170. | |

| 14 | 顾建环. 天祝县高原寒旱区藜麦产业全程机械化推广探究[J]. 南方农业, 2020, 14(15):156-157. |

| 15 | 海梅. 藜麦联合收获机脱出物清选试验研究[D]. 呼和浩特: 内蒙古农业大学机电工程学院, 2018. |

| Mei Hai. Experimental study on clearance of quinoa combine harvester[D]. Hohhot: College of Mechanical and Electrical Engineering, Inner Mongolia Agricultural University, 2018. | |

| 16 | 肖正春, 张广伦. 藜麦及其资源开发利用[J]. 中国野生植物资源, 2014, 33(2): 62-66. |

| Xiao Zheng-chun, Zhang Guang-lun. Development and utilization of Chenopodium quinoa willd[J]. Chinese Wild Plant Resources, 2014, 33(2): 62-66. | |

| 17 | 托有德, 朱雪慧. 高原寒旱区藜麦生产机具现状与发展[J]. 农机科技推广, 2020(4):27-29. |

| 18 | 杨科, 刘文瑜, 王旺田, 等. 连作对藜麦生长和生理特性的影响[J]. 江西农业大学学报, 2021, 43(2): 244-252. |

| Yang Ke, Liu Wen-yu, Wang Wang-tian, et al. Effects of continuous cropping on growth and physiological characteristics of quinoa[J]. Acta Agriculturae Universitatis Jiangxiensis, 2021, 43(2):244-252. | |

| 19 | 魏玉明, 黄杰, 顾娴, 等. 藜麦规范化栽培技术规程[J]. 甘肃农业科技, 2015(12):77-80. |

| 20 | 沈宝云, 胡静, 郭谋子, 等. 早熟藜麦新品种条藜2号的选育及栽培技术[J]. 种子, 2019, 38(4): 137-140. |

| Shen Bao-yun, Hu Jing, Guo Mou-zi, et al. Breeding and cultivation techniques of new early maturity variety chenopodium quinoa cv. Tiaoli No.2[J]. Seed, 2019, 38(4): 137-140. | |

| 21 | 王丽娜, 任翠梅, 王明泽, 等. 中国藜麦种质资源分布及研究现状[J]. 黑龙江农业科学, 2020(12): 142-145. |

| Wang Li-na, Ren Cui-mei, Wang Ming-ze, et al. Distribution and research status of quinoa germplasm resources in China[J]. Heilongjiang Agricultural Sciences, 2020(12): 142-145. | |

| 22 | Atul B, Deepak O. Origin of genetic variability and improvement of quinoa(Chenopodium quinoa willd.)[J]. Gene Pool Diversity and Crop Improvement, 2016, 10: 241-270. |

| 23 | 郭建芳, 武小平, 丁健, 等. 矮壮素对藜麦抗倒伏的影响[J]. 山西农业科学, 2020, 48(7): 1019-1021, 1025. |

| Guo Jian-fang, Wu Xiao-ping, Ding Jian, et al. Effect of chlormequat chloride on lodging resistance of quinoa [J]. Journal of Shanxi Agricultural Sciences, 2020, 48(7): 1019-1021, 1025. | |

| 24 | 郭建芳, 武小平, 丁健 [J]. 现代农业科技, 2019(15): 18-19. |

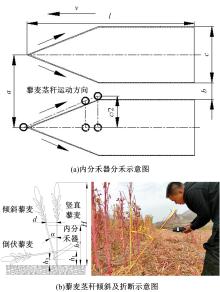

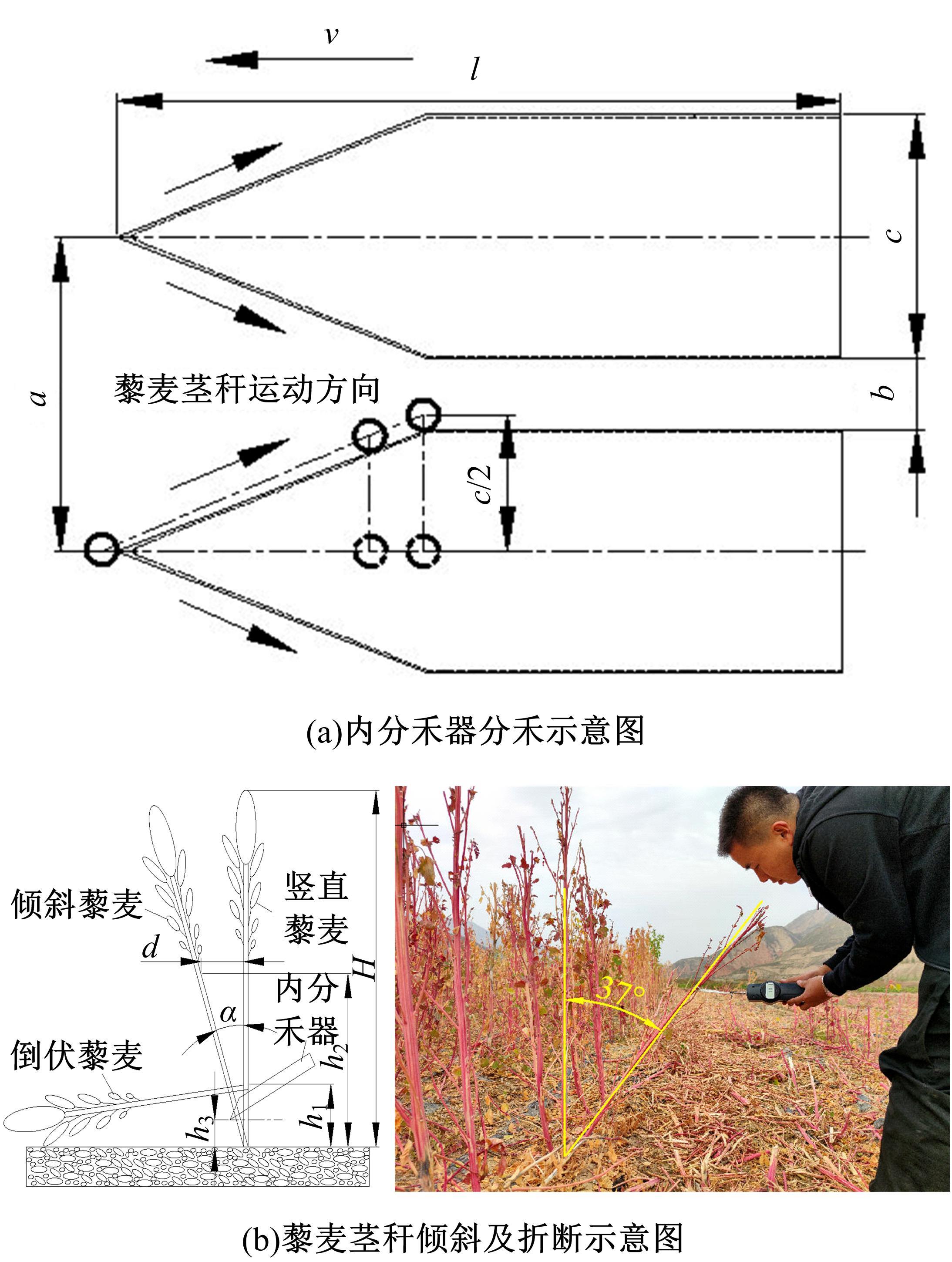

| 25 | 刘巍, 黄小毛, 马丽娜, 等. 油葵联合收获机专用割台设计与试验[J]. 农业机械学报, 2020, 51(8): 83-88, 135. |

| Liu Wei, Huang Xiao-mao, Ma Li-na, et al. Design and experiment of special header of oil sunflower combine harvester[J]. Transactions of the Chinese Society for Agricultural Machinery, 2020, 51(8): 83-88, 135. | |

| 26 | 杜岳峰, 毛恩荣, 朱忠祥, 等. 两行玉米收获机割台设计与试验[J]. 农业机械学报, 2013, 44():22-26. |

| Du Yue-feng, Mao En-rong, Zhu Zhong-xiang, et al. Design and experiment of two-row corn harvester header[J]. Transactions of the Chinese Society for Agricultural Machinery, 2013, 44(Sup.2): 22-26. | |

| 27 | 谢里阳. 可靠性设计[M]. 北京: 高等教育出版社, 2013. |

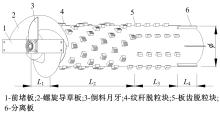

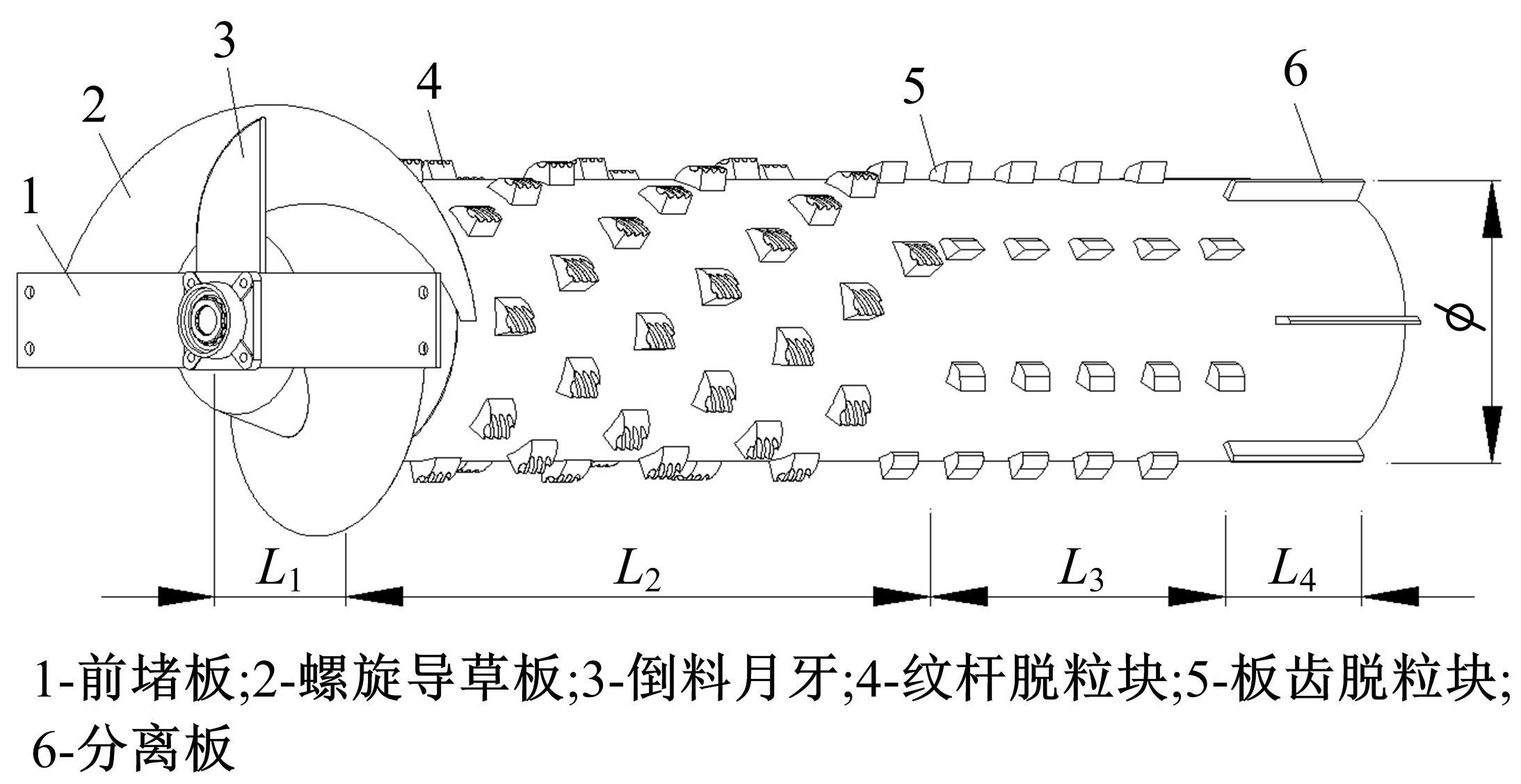

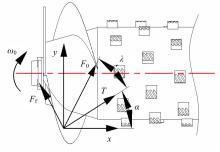

| 28 | 廖庆喜, 徐阳, 袁佳诚, 等. 油菜联合收获机切抛组合式纵轴流脱离装置设计与试验[J]. 农业机械学报, 2019, 50(7):140-150. |

| Liao Qing-xi, Xu Yang, Yuan Jia-cheng, et al. Design and experiment on combined cutting and throwing longitudinal axial flow threshing and separating device of rape combine harvester[J]. Transactions of the Chinese Society for Agricultural Machinery, 2019, 50(7):140-150. | |

| 29 | 中国农业机械化科学研究院. 农业机械设计手册(下册)[M]. 北京: 中国农业科学技术出版社, 2007. |

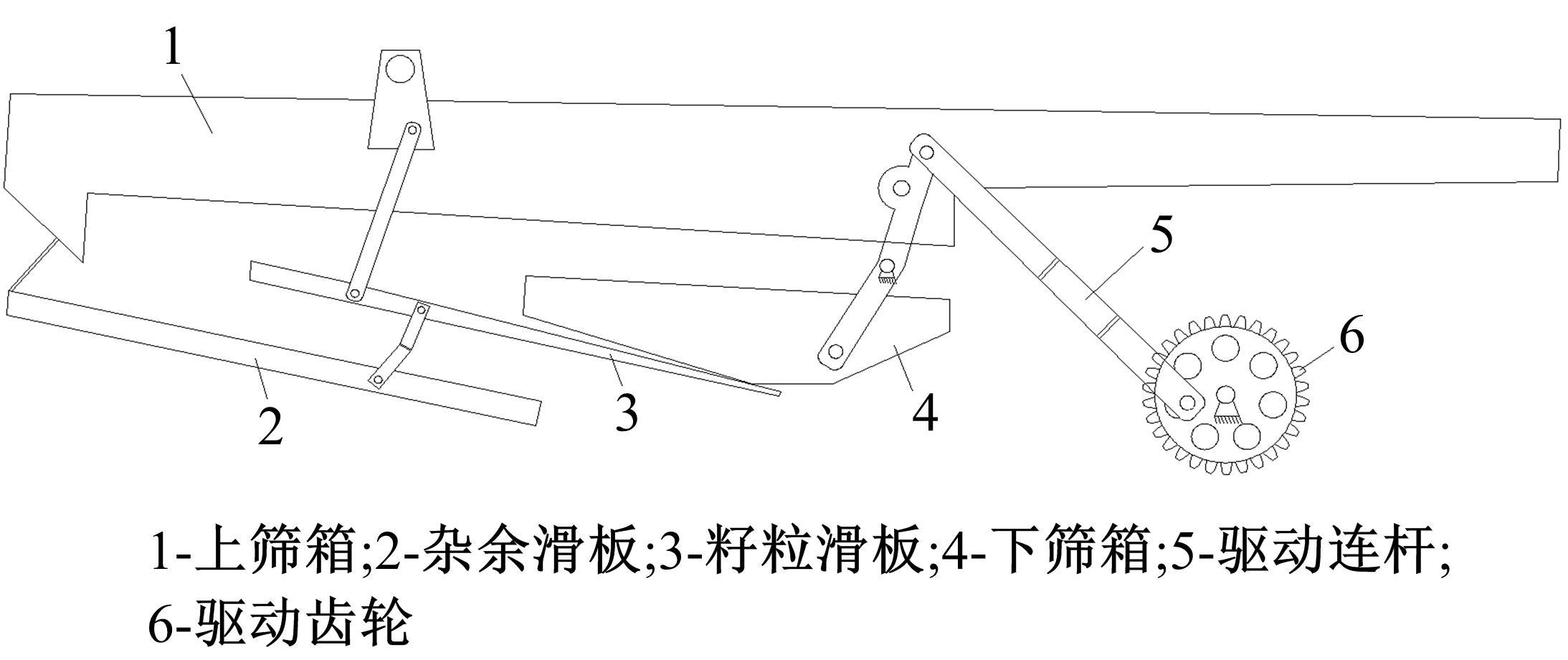

| 30 | 戴飞, 付秋峰, 赵武云, 等. 双风道风筛式胡麻脱出物分离清选机设计与试验[J]. 农业机械学报, 2021, 52(4): 117-125, 247. |

| Dai Fei, Fu Qiu-feng, Zhao Wu-yun, et al. Design and test of double duct system of air-screen separating and cleaning machine for flax threshing material[J]. Transactions of the Chinese Society for Agricultural Machinery, 2021, 52(4): 117-125, 247. | |

| 31 | 李耀明. 谷物联合收割机的设计与分析[M]. 北京: 机械工业出版社, 2014. |

| 32 | 耿端阳, 牟孝栋, 张国栋, 等. 小麦联合收获机清选机理分析与优化试验[J]. 吉林大学学报:工学版, 2022, 52(1):219-230. |

| Geng Duan-yang, Mu Xiao-dong, Zhang Guo-dong, et al. Analysis and optimization of cleaning mechanism of wheat combine harvester[J]. Journal of Jilin University (Engineering and Technology Edition), 2022, 52(1): 219-230. | |

| 33 | . 收获机械联合收割机试验方法 [S]. |

| 34 | . 计数抽样检测程序 [S]. |

| 35 | . 农业机械试验条件 [S]. |

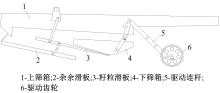

| 36 | 史瑞杰, 戴飞, 刘小龙, 等. 履带式丘陵山地胡麻联合收割机设计与试验[J]. 农业工程学报, 2021, 37(5):59-67. |

| Shi Rui-jie, Dai Fei, Liu Xiao-long, et al. Design and experiments of crawler-type hilly and mountaineous flax combine harvester[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2021, 37(5): 59-67. | |

| 37 | 史瑞杰, 戴飞, 赵武云, 等. 丘陵山地胡麻联合收割机作业参数优化与试验[J]. 吉林大学学报:工学版, 2022, 52(11):2746-2755. |

| Shi Rui-jie, Dai Fei, Zhao Wu-yun, et al. Optimization and experiment of operation parameters of hilly area flax combine harvester[J]. Journal of Jilin University (Engineering and Technology Edition), 2022, 52(11): 2746-2755. |

| [1] | Duan-yang GENG,Xiao-qi JI,Xiao-dong MOU,Hua-biao LI,Hao-lin YANG,Yan-chun YAO,Ji-da WU. Design and experiment of harvesting and cutting table of Broussonetia papyrifera [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(7): 2152-2164. |

| [2] | Si-lin CAO,Jian-hua XIE,Yu-xin YANG,Yong-rui LIU,Yong-tao LU,Bo SUN. Design and experiment of side row cotton straw returning and residual film recovery combined machine [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(5): 1514-1528. |

| [3] | Xue-jun ZHANG,Shuang HUANG,Zeng-lu SHI,Yong-liang YU,Xin-cheng ZHOU,Wei JIN,Yong CHEN,Jia HONG. Design and test of the remaining film picking and baling machine [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(4): 1220-1230. |

| [4] | Jia-jie LIU,Lan MA,Wei XIANG,Bo YAN,Qing-hua WEN,Jiang-nan LYU. Design of 4QM⁃4.0 fibre crops green fodder combine harvester [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(12): 3039-3048. |

| [5] | Rui-jie SHI,Fei DAI,Wu-yun ZHAO,Xiao-long LIU,Jiang-fei QU,Feng-wei ZHANG. Optimization and experiment of operation parameters of hilly area flax combine harvester [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(11): 2746-2755. |

| [6] | Rong-qing LIANG,Bo ZHONG,He-wei MENG,Zhi-min SUN,Za KAN. Design of 4QJ⁃3 type pickup header of silage oat [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(5): 1887-1896. |

| [7] | Jia-cheng YUAN,Chang WANG,Kun HE,Xing-yu WAN,Qing-xi LIAO. Effect of components mass ratio under sieve on cleaning system performance for rape combine harvester [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(5): 1897-1907. |

| [8] | Ji-cheng HUANG,Cheng SHEN,Ai-min JI,Xian-wang LI,Bin ZHANG,Kun-peng TIAN,Hao-lu LIU. Optimization of cutting⁃conveying key working parameters of hemp harvester [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(2): 772-780. |

| [9] | Xue-shen CHEN,Tao CHEN,Tao WU,Xu MA,Ling-chao ZENG,Lin-tao CHEN. Design and experiment on harvester for winter planting potato of straw coverage [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 749-757. |

| [10] | HAN Bao,WU Wen-fu,QUAN Long-zhe. Multi-objective optimization design and simulation on horizontal disk type weeding unit between seedlings [J]. 吉林大学学报(工学版), 2011, 41(03): 692-696. |

| [11] |

Li Jie,Yan Chu-liang,Yang Fang-fei .

Dynamic simulation and parameter optimization of the combine harvester vibration sieve [J]. 吉林大学学报(工学版), 2006, 36(05): 701-0704. |

|