Journal of Jilin University(Engineering and Technology Edition) ›› 2025, Vol. 55 ›› Issue (6): 1817-1833.doi: 10.13229/j.cnki.jdxbgxb.20240763

Research progress on the performance changes of lithium⁃ion batteries after aging

Xue-wei SONG1,2( ),Ze-ping YU1,Yang XIAO1,2(

),Ze-ping YU1,Yang XIAO1,2( ),De-ping WANG3,Quan YUAN4,Xin-zhuo LI1,Jia-wen ZHENG1

),De-ping WANG3,Quan YUAN4,Xin-zhuo LI1,Jia-wen ZHENG1

- 1.College of Automotive Engineering,Jilin University,Changchun 130022,China

2.State Key Laboratory of Automotive Simulation and Control,Jilin University,Changchun 130022,China

3.Research and Development Institute,China FAW Group Corporation Limited,Changchun 130022,China

4.Department of Mechanical Engineering,Ningbo University of Technology,Ningbo 315336,China

CLC Number:

- U469.7

| [1] | 孙智鹏, 陈立铎, 卜祥军, 等. 动力电池挤压机械损伤后性能演化研究[J]. 电源技术, 2020, 44(7): 964-966, 1039. |

| Sun Zhi-peng, Chen Li-duo, Bu Xiang-jun, et al. Study on performance evolution of power battery after crushing mechanical damage[J]. Chinese Journal of Power Sources, 2020, 44(7): 964-966, 1039. | |

| [2] | 山彤欣, 王震坡, 洪吉超, 等. 新能源汽车动力电池“机械滥用-热失控”及其安全防控技术综述[J]. 机械工程学报, 2022, 58(14): 252-275. |

| Shan Tong-xin, Wang Zhen-po, Hong Ji-chao. Overview of "mechanical abuse-thermal runaway" of electric vehicle power battery and its safety prevention and control technology[J]. Journal of Mechanical Engineering, 2022, 58(14): 252-275. | |

| [3] | 倪浩, 马晶晶. 一季度: 中国汽车产销开门红[EB/OL]. [2024-04-12]. . |

| [4] | Kalaga K, Rodrigues F M, Trask E S, et al. Calendar-life versus cycle-life aging of lithium-ion cells with silicon-graphite composite electrodes[J]. Electrochimica Acta, 2018, 280: 221-228. |

| [5] | Deng J, Bae C, Denlinger A, et al. Electric vehicles batteries: Requirements and challenges[J]. Joule, 2020, 4(3): 511-515. |

| [6] | Liu S, Winter M, Lewerenz M, et al. Analysis of cyclic aging performance of commercial Li4Ti5O12-based batteries at room temperature[J]. Energy, 2019, 173: 1041-1053. |

| [7] | Zhang Y, Liu Z, Sun X, et al. Experimental study of thermal charge-discharge behaviors of pouch lithium-ion capacitors[J]. Journal of Energy Storage, 2019, 25: No.100902. |

| [8] | 陈泽宇, 熊瑞, 孙逢春. 电动汽车安全事故研究与分析现状[J]. 机械工程学报, 2019, 55(24): 93-104, 116. |

| Chen Ze-yu, Xiong Rui, Sun Feng-chun. Research status and analysis for battery safety accidents in electric vehicles[J]. Journal of Mechanical Engineering, 2019, 55(24): 93-104, 116. | |

| [9] | Jin C. Brief talk about lithium-ion batteries' safety and influencing factors[J]. IOP Conference Series: Materials Science and Engineering, 2017, 274: No.012152. |

| [10] | Feng X, Ouyang M, Liu X, et al. Thermal runaway mechanism of lithium ion battery for electric vehicles: A review[J]. Energy Storage Materials, 2018, 10: 246-267. |

| [11] | Wang K, Ouyang D, Qian X, et al. Early warning method and fire extinguishing technology of lithium-ion battery thermal runaway: a review[J]. Energies, 2023, 16(7): No.2960. |

| [12] | Chen J, Wang G, Song H, et al. Stress and displacement of cylindrical lithium-ion power battery during charging and discharging[J]. Energies, 2022, 15(21): No.8244. |

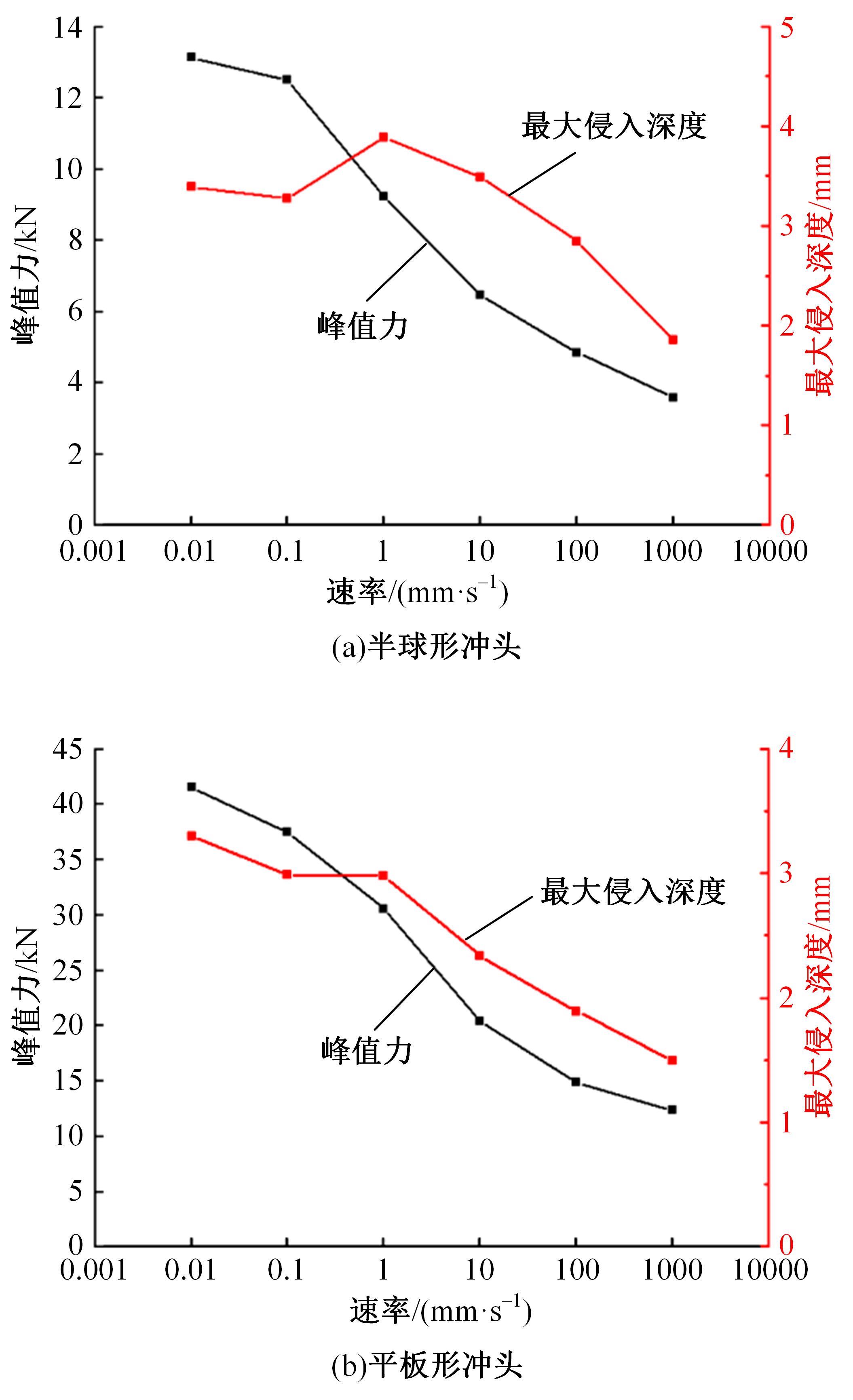

| [13] | Wang G, Zhang S, Li M, et al. Deformation and failure properties of high-ni lithium-ion battery under axial loads[J]. Materials, 2021, 14(24): No.7844. |

| [14] | Mo F, Tian Y, Zhao S, et al. Working temperature effects on mechanical integrity of cylindrical lithium-ion batteries[J]. Engineering Failure Analysis, 2022, 137: No.106399. |

| [15] | Voyiadjis G Z, Akbari E, Łuczak B, et al. Towards determining an engineering stress-strain curve and damage of the cylindrical lithium-ion battery using the cylindrical indentation test[J]. Batteries, 2023, 9(4): No.233. |

| [16] | Cannarella J, Arnold C B. State of health and charge measurements in lithium-ion batteries using mechanical stress[J]. Journal of Power Sources, 2014, 269: 7-14. |

| [17] | Gantenbein S, Schönleber M, Weiss M, et al. Capacity fade in lithium-ion batteries and cyclic aging over various state-of-charge ranges[J]. Sustainability, 2019, 11(23): No.6697. |

| [18] | Zhang J, Kang B, Luo Q, et al. Effects of pressure evolution on the decrease in the capacity of lithium-ion batteries[J]. International Journal of Electrochemical Science, 2020, 15(9): 8422-8436. |

| [19] | Yang Z, Patil D, Fahimi B, et al. Online estimation of capacity fade and impedance of lithium-ion batteries based on impulse response Technique[C]∥2017 IEEE Applied Power Electronics Conference and Exposition (APEC). Tampa: IEEE, 2017: 1229-1235. |

| [20] | Yin S, Liu J, Cong B. Review of thermal runaway monitoring, warning and protection technologies for lithium-ion batteries[J]. Processes, 2023, 11(8): No.2345. |

| [21] | Wang X, Li J, Chen S, et al. Online detection of lithium plating onset for lithium-ion batteries based on impedance changing trend identification during charging processes[J]. IEEE Transactions on Transportation Electrification, 2023, 9(2): 3487-3497. |

| [22] | Menz F, Bauer M, Böse O, et al. Investigating the thermal runaway behaviour of fresh and aged large prismatic lithium-ion cells in overtemperature experiments[J]. Batteries, 2023, 9(3): No.159. |

| [23] | Xu X, Sun X, Zhao L, et al. Research on thermal runaway characteristics of NCM lithium-ion battery under thermal-electrical coupling abuse[J]. Ionics, 2022, 28(12): 5449-5467. |

| [24] | Zhang G, Wei X, Chen S, et al. Research on the impact of high-temperature aging on the thermal safety of lithium-ion batteries[J]. Journal of Energy Chemistry, 2023, 87: 378-389. |

| [25] | Liu Q, Zhu Q, Zhu W, et al. Influence of aerogel felt with different thickness on thermal runaway propagation of 18650 lithium-ion battery[J]. Electrochemistry, 2022, 90(8): No.087003. |

| [26] | Osara J A, Ezekoye O A, Marr K C, et al. A methodology for analyzing aging and performance of lithium-ion batteries: Consistent cycling application[J]. Journal of Energy Storage, 2021, 42: No.103119. |

| [27] | Birkl C R, Roberts M R, McTurk E, et al. Degradation diagnostics for lithium ion cells[J]. Journal of Power Sources, 2017, 341: 373-386. |

| [28] | Wood S M, Fang C, Dufek E J, et al. Predicting calendar aging in lithium metal secondarybatteries: the impacts of solid electrolyte interphase composition and stability[J]. Advanced Energy Materials, 2018, 8(26): No.1801427. |

| [29] | Ruiz V, Kriston A, Adanouj I, et al. Degradation studies on lithium iron phosphate - graphite cells. The effect of dissimilar charging – discharging temperatures[J]. Electrochimica Acta, 2017, 240: 495-505. |

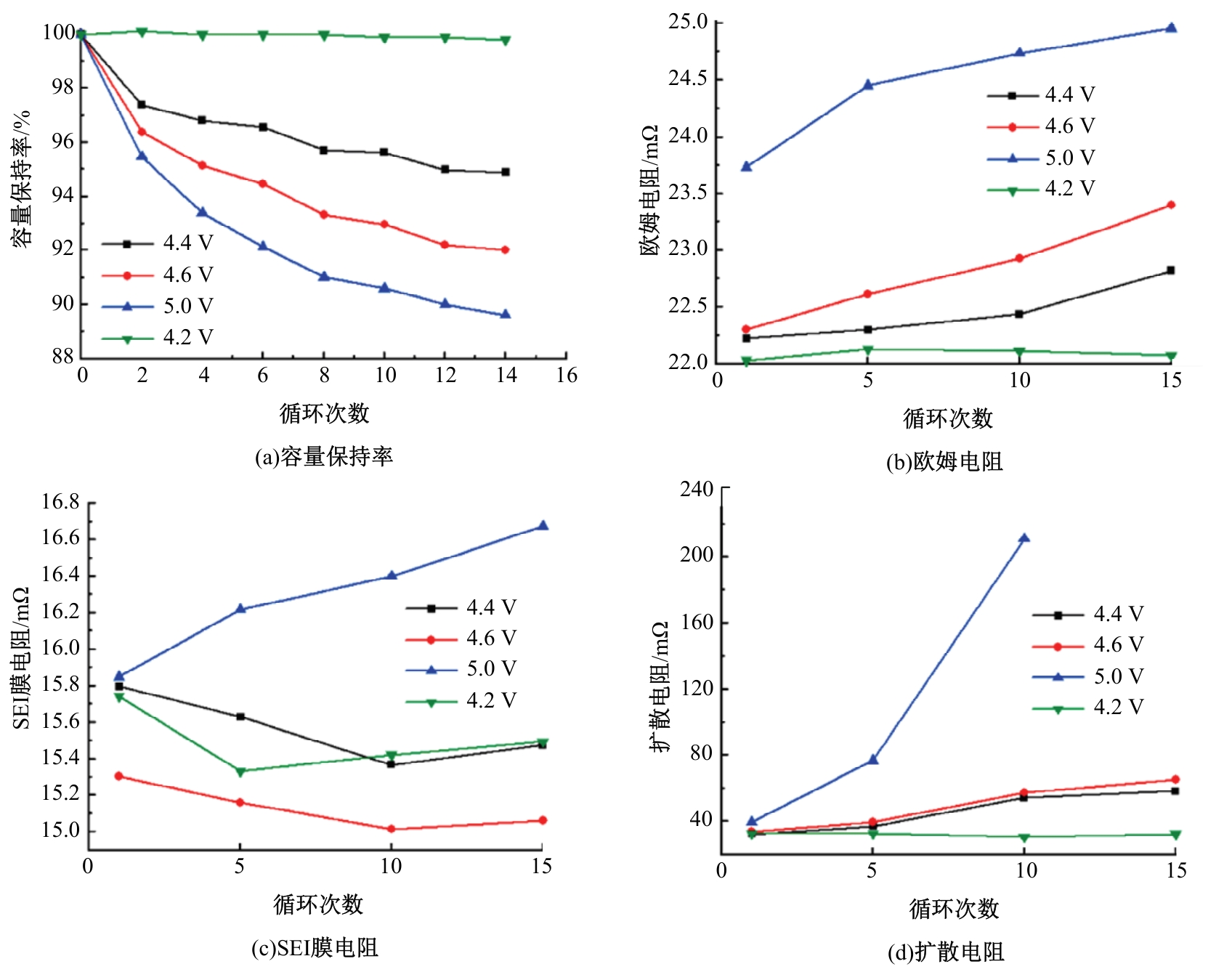

| [30] | Liu J, Wang Z, Bai J. Influences of multi factors on thermal runaway induced by overcharging of lithium-ion battery[J]. Journal of Energy Chemistry, 2022, 70: 531-541. |

| [31] | Lin N, Jia Z, Wang Z, et al. Understanding the crack formation of graphite particles in cycled commercial lithium-ion batteries by focused ion beam-scanning electron microscopy[J]. Journal of Power Sources, 2017, 365: 235-239. |

| [32] | Maures M, Zhang Y, Martin C, et al. Impact of temperature on calendar ageing of lithium-ion battery using incremental capacity analysis[J]. Microelectronics Reliability, 2019, 100: No.113364. |

| [33] | Lei Z, Zhang Y, Lei X. Temperature uniformity of a heated lithium-ion battery cell in cold climate[J]. Applied Thermal Engineering, 2018, 129: 148-154. |

| [34] | Geisbauer C, Wöhrl K, Mittmann C, et al. Review—Review of safety aspects of calendar aged lithium ion batteries[J]. Journal of the Electrochemical Society, 2020, 167(9): No.090523. |

| [35] | Daubinger P, Ebert F, Hartmann S, et al. Impact of electrochemical and mechanical interactions on lithium-ion battery performance investigated by operando dilatometry[J]. Journal of Power Sources, 2021, 488: No.229457. |

| [36] | Jia X, Zhang C, Wang L Y, et al. Early diagnosis of accelerated aging for lithium-ion batteries with an integrated framework of aging mechanisms and data-driven methods[J]. IEEE Transactions on Transportation Electrification, 2022, 8(4): 4722-4742. |

| [37] | Zhu Y, Zhu J, Jiang B, et al. Insights on the degradation mechanism for large format prismatic graphite/LiFePO4 battery cycled under elevated temperature[J]. Journal of Energy Storage, 2023, 60: No.106624. |

| [38] | Grimsmann F, Brauchle F, Gerbert T, et al. Impact of different aging mechanisms on the thickness change and the quick-charge capability of lithium-ion cells[J]. Journal of Energy Storage, 2017, 14: 158-162. |

| [39] | Guo Y, Cai J, Liao Y, et al. Insight into fast charging/discharging aging mechanism and degradation-safety analytics of 18650 lithium-ion batteries[J]. Journal of Energy Storage, 2023, 72: No.108331. |

| [40] | Weber N, Schuhmann S, Tübke J, et al. Chemical thermal runaway modeling of lithium‐ion batteries for prediction of heat and gas generation[J]. Energy Technology, 2023, 11(10): No.2300565. |

| [41] | Wang G, Guo X, Chen J, et al. Safety performance and failure criteria of lithium-ion batteries under mechanical abuse[J]. Energies, 2023, 16(17): No.6346. |

| [42] | Chen X, Wang T, Zhang Y, et al. Dynamic behavior and modeling of prismatic lithium‐ion battery[J]. International Journal of Energy Research, 2020, 44(4): 2984-2997. |

| [43] | Shukla V, Mishra A, Sure J, et al. Size‐dependent failure behavior of commercially available lithium‐iron phosphate battery under mechanical abuse[J]. Process Safety Progress, 2023, 42(4): 674-685. |

| [44] | Spotnitz R, Franklin J. Abuse behavior of high-power, lithium-ion cells[J]. Journal of Power Sources, 2003, 113(1): 81-100. |

| [45] | Qian L, Mishra Y, Zhang Y, et al. Revealing the impact of high current overcharge/overdischarge on the thermal safety of degraded Li-ion batteries[J]. International Journal of Energy Research, 2023, 14: No.8571535 |

| [46] | Erol S, Orazem M E, Muller R P. Influence of overcharge and over-discharge on the impedance response of LiCoO2|C batteries[J]. Journal of Power Sources, 2014, 270: 92-100. |

| [47] | Eom S, Kim M, Kim I, et al. Life prediction and reliability assessment of lithium secondary batteries[J]. Journal of Power Sources, 2007, 174(2): 954-958. |

| [48] | Waldmann T, Wilka M, Kasper M, et al. Temperature dependent ageing mechanisms in lithium-ion batteries—a post-mortem study[J]. Journal of Power Sources, 2014, 262: 129-135. |

| [49] | Peng X, Chen S, Garg A, et al. A review of the estimation and heating methods for lithium‐ion batteries pack at the cold environment[J]. Energy Science & Engineering, 2019, 7(3): 645-662. |

| [50] | Paarmann S, Schuld K, Wetzel T. Inhomogeneous aging in lithium‐ion batteries caused by temperature effects[J]. Energy Technology, 2022, 10(11): No.2200384. |

| [51] | Werner D, Paarmann S, Wiebelt A, et al. Inhomogeneous temperature distribution affecting the cyclic aging of LI-ion cells. Part I: Experimental investigation[J]. Batteries, 2020, 6(1): No.13. |

| [52] | Xiao X, Wu W, Huang X. A multi-scale approach for the stress analysis of polymeric separators in a lithium-ion battery[J]. Journal of Power Sources, 2010, 195(22): 7649-7660. |

| [53] | Xu R, Sun H, Vasconcelos L S, et al. Mechanical and structural degradation of LiNixMnyCozO2 cathode in LI-ion batteries: an experimental study[J]. Journal of the Electrochemical Society, 2017, 164(13): A3333-A3341. |

| [54] | Sprenger M, Dölle N, Schauwecker F, et al. Multiscale analysis and safety assessment of fresh and electrical aged lithium-ion pouch cells focusing on mechanical behavior[J]. Energies, 2022, 15(3): No.847. |

| [55] | Demirocak D E, Bhushan B. Probing the aging effects on nanomechanical properties of a LiFePO4 cathode in a large format prismatic cell[J]. Journal of Power Sources, 2015, 280: 256-262. |

| [56] | Ramdon S, Bhushan B. Nanomechanical characterization and mechanical integrity of unaged and aged Li-ion battery cathodes[J]. Journal of Power Sources, 2014, 246: 219-224. |

| [57] | Blazek P, Westenberger P, Erker S, et al. Axially and radially inhomogeneous swelling in commercial 18650 Li-ion battery cells[J]. Journal of Energy Storage, 2022, 52: No.104563. |

| [58] | Lee S, Park J, Sastry A M, et al. Molecular dynamics simulations of SOC-dependent elasticity of LixMn2O4Spinels in Li-ion batteries[J]. Journal of the Electrochemical Society, 2013, 160(6): A968-A972. |

| [59] | Guo Z, Liu C, Lu B, et al. Experimental study on mechanical properties of graphite electrodes[J]. ECS Transactions, 2018, 85(13): 321-329. |

| [60] | Wang W, Yang S, Lin C, et al. Mechanical and electrical response of cylindrical lithium-ion cells at various state of charge[J]. Energy Procedia, 2018, 145: 128-132. |

| [61] | Ma T, Wu S, Wang F, et al. Degradation mechanism study and safety hazard analysis of overdischarge on commercialized lithium-ion batteries[J]. ACS Applied Materials & Interfaces, 2020, 12(50): 56086-56094. |

| [62] | Guo Z, Yang S, Zhao W, et al. Overdischarge-induced evolution of Cu dendrites and degradation of mechanical properties in lithium-ion batteries[J]. Journal of Energy Chemistry, 2023, 78: 497-506. |

| [63] | Zhang G, Wei X, Zhu J, et al. Revealing the failure mechanisms of lithium-ion batteries during dynamic overcharge[J]. Journal of Power Sources, 2022, 543: No.231867. |

| [64] | Yang R, Yu G, Wu Z, et al. Aging of lithium-ion battery separators during battery cycling[J]. Journal of Energy Storage, 2023, 63: No.107107. |

| [65] | Liu X M, Arnold C B. Effects of cycling ranges on stress and capacity fade in lithium-ion pouch cells[J]. Journal of the Electrochemical Society, 2016, 163(13): A2501-A2507. |

| [66] | Budiman B A, Rahardian S, Saputro A, et al. Structural integrity of lithium-ion pouch battery subjected to three-point bending[J]. Engineering Failure Analysis, 2022, 138: No.106307. |

| [67] | Sheikh M, Elmarakbi A, Elkady M. Thermal runaway detection of cylindrical 18650 lithium-ion battery under quasi-static loading conditions[J]. Journal of Power Sources, 2017, 370: 61-70. |

| [68] | Xu Y, Liu F, Guo J, et al. Mechanical properties and thermal runaway study of automotive lithium-ion power batteries[J]. Ionics, 2021, 28(1): 107-116. |

| [69] | Kisters T, Kuder J, Topel A, et al. Strain-rate dependence of the failure behavior of lithium-ion pouch cells under impact loading[J]. Journal of Energy Storage, 2021, 41: No.102901. |

| [70] | Kovachev G, Ellersdorfer C, Gstrein G, et al. Safety assessment of electrically cycled cells at high temperatures under mechanical crush loads[J]. eTransportation, 2020, 6: No.100087. |

| [71] | Wang C, Xia Y. Temperature dependence in responses of lithium-ion pouch cells under mechanical abuse[J]. Journal of the Electrochemical Society, 2023, 170(6): No.060543. |

| [72] | Xie C, Yang R, Liu F, et al. Simulation study on stress-strain and deformation of separator under battery temperature field[J]. Journal of the Electrochemical Society, 2023, 170(10): No.100530. |

| [73] | Makki M, Ayoub G, Lee C W, et al. Effect of battery fast cyclic charging on the mechanical and fracture behavior of the lithium-ion battery separator[J]. Polymer Degradation and Stability, 2023, 216: No.110469. |

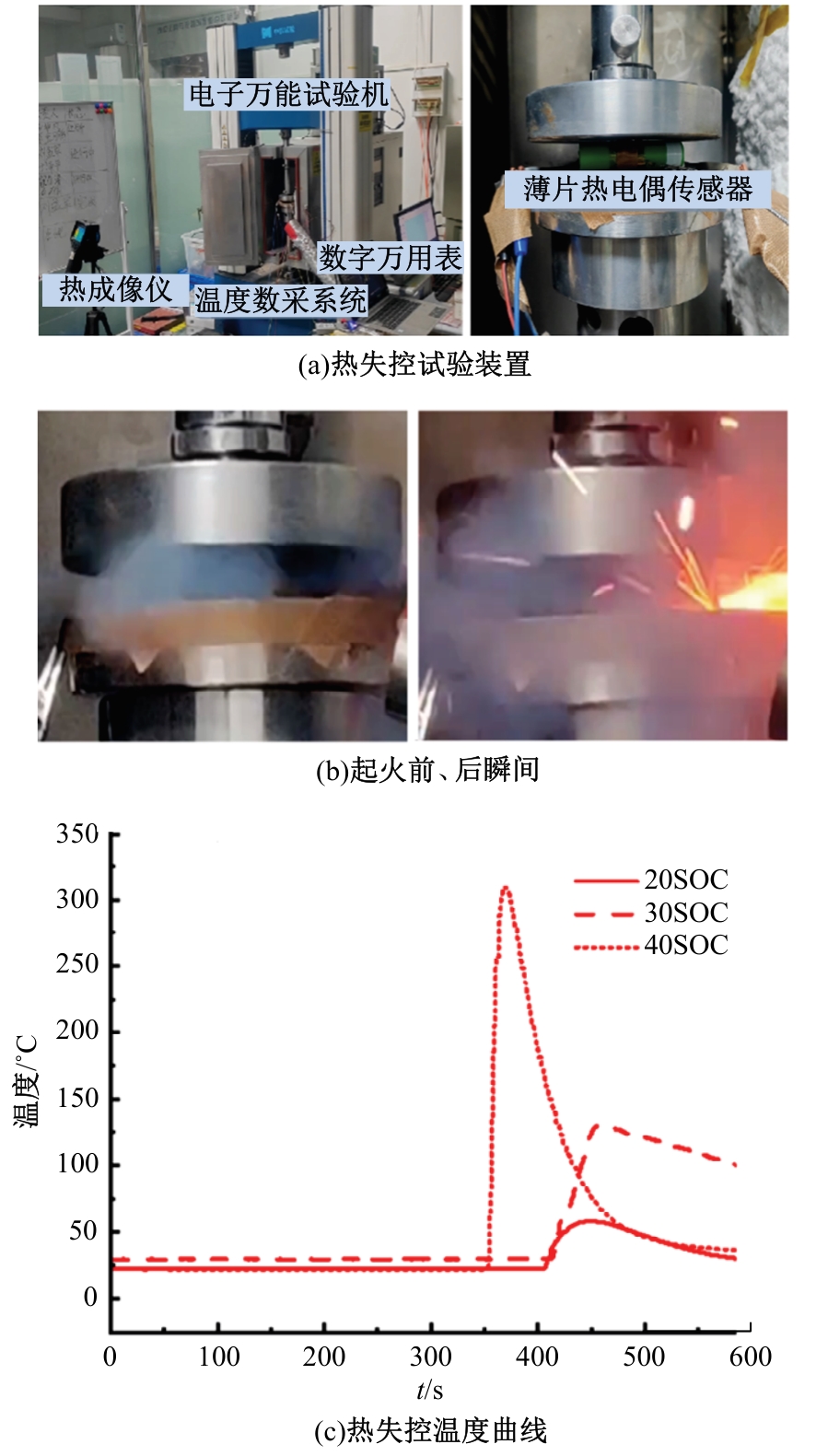

| [74] | 刘孟军. 热损伤积累对圆柱形锂离子电池机械滥用安全性的影响[D]. 长春: 吉林大学汽车工程学院, 2024. |

| Liu Meng-jun. Effect of thermal damage accumulation on mechanical abuse safety of cylindrical lithium-ion batteries[D]. Changchun: College of Automotive Engineering, Jilin University, 2024. | |

| [75] | Feiler S, Daubinger P, Gold L, et al. Interplay between elastic and electrochemical properties during active material transitions and aging of a lithium‐ion battery[J]. Batteries & Supercaps, 2023, 6(4): No.e202200518. |

| [76] | Hong G, Li N, Yang H, et al. Changes of adhesion properties for negative electrode and positive electrode under wet conditions and different states of charge[J]. International Journal of Adhesion and Adhesives, 2021, 108: No.102870. |

| [77] | Zhou Y. External pressure: an overlooked metric in evaluating next-generation battery performance[J]. Current Opinion in Electrochemistry, 2022, 31: No.100916. |

| [78] | 高菲, 肖阳, 张文华, 等. 高温和荷电状态对锂离子电池单体力学响应的耦合影响[J]. 吉林大学学报: 工学版, 2020, 50(5): 1574-1583. |

| Gao Fei, Xiao Yang, Zhang Wen-hua, et al. Influence of coupling of elevated temperature and state of charge on mechanical response of Li-ion battery cells[J]. Journal of Jilin University (Engineering and Technology Edition), 2020, 50(5): 1574-1583. | |

| [79] | Guo R, Lu L, Ouyang M, et al. Mechanism of the entire overdischarge process and overdischarge-induced internal short circuit in lithium-ion batteries[J]. Scientific Reports, 2016, 6(1): No.30248. |

| [80] | Zhu W, Zhou P, Ren D, et al. A mechanistic calendar aging model of lithium‐ion battery considering solid electrolyte interface growth[J]. International Journal of Energy Research, 2022, 46(11): 15521-15534. |

| [81] | Genieser R, Loveridge M, Bhagat R. Practical high temperature (80 ℃) storage study of industrially manufactured Li-ion batteries with varying electrolytes[J]. Journal of Power Sources, 2018, 386: 85-95. |

| [82] | Röder P, Stiaszny B, Ziegler J C, et al. The impact of calendar aging on the thermal stability of a LiMn2O4–Li(Ni1/3Mn1/3Co1/3)O2/graphite lithium-ion cell[J]. Journal of Power Sources, 2014, 268: 315-325. |

| [83] | Naumann M, Schimpe M, Keil P, et al. Analysis and modeling of calendar aging of a commercial LiFePO4/graphite cell[J]. Journal of Energy Storage, 2018, 17: 153-169. |

| [84] | Cloos L, Queisser O, Chahbaz A, et al. Thermal transients to accelerate cyclic aging of lithium‐ion batteries[J]. Batteries & Supercaps, 2023, 7(3): No.e202300445. |

| [85] | Liu Y, Mao G, Yang M, et al. Slight overcharge aging behaviors and thermal runaway characteristics of Li(Ni0.5Co0.2Mn0.3)O2/graphite batteries at different ambient temperatures[J]. ACS Applied Energy Materials, 2023, 6(12): 6760-6772. |

| [86] | Ecker M, Nieto N, Käbitz S, et al. Calendar and cycle life study of Li(NiMnCo)O2-based 18650 lithium-ion batteries[J]. Journal of Power Sources, 2014, 248: 839-851. |

| [87] | Wildfeuer L, Karger A, Aygül D, et al. Experimental degradation study of a commercial lithium-ion battery[J]. Journal of Power Sources, 2023, 560: No.232498. |

| [88] | Xu F, He H, Liu Y, et al. Failure investigation of LiFePO4 cells under overcharge conditions[J]. Journal of the Electrochemical Society, 2012, 159(5): A678-A687. |

| [89] | Zhang L, Huang L, Zhang Z, et al. Degradation characteristics investigation for lithium-ion cells with NCA cathode during overcharging[J]. Applied Energy, 2022, 327: No.120026. |

| [90] | Lai X, Zheng Y, Zhou L, et al. Electrical behavior of overdischarge-induced internal short circuit in lithium-ion cells[J]. Electrochimica Acta, 2018, 278: 245-254. |

| [91] | Ouyang D, Weng J, Chen M, et al. Experimental analysis on the degradation behavior of overdischarged lithium‐ion battery combined with the effect of high‐temperature environment[J]. International Journal of Energy Research, 2019, 44(1): 229-241. |

| [92] | Zou L, Zhao W, Liu Z, et al. Revealing cycling rate-dependent structure evolution in Ni-rich layered cathode materials[J]. ACS Energy Letters, 2018, 3(10): 2433-2440. |

| [93] | Dhanabalan A, Song B F, Biswal S L. Extreme rate capability cycling of porous silicon composite anodes for lithium‐ion batteries[J]. Chemelectrochem, 2021, 8(17): 3318-3325. |

| [94] | Liu Y, Liao Y G, Lai M C. Aging experiments on the 20 Ah lithium‐ion polymer battery cells[J]. Energy Storage, 2021, 4(2): No.e312. |

| [95] | Spielbauer M, Soellner J, Berg P, et al. Experimental investigation of the impact of mechanical deformation on aging, safety and electrical behavior of 18650 lithium-ion battery cells[J]. Journal of Energy Storage, 2022, 55: No.105564. |

| [96] | 朱瑞卿, 胡玲玲, 周名哲. 锂电池多次冲击下的失效模式及损伤机制[J]. 固体力学学报, 2023, 44(6): 795-804. |

| Zhu Rui-qing, Hu Ling-ling, Zhou Ming-zhe. Failure modes and damage mechanisms of lithium batteries under multiple impacts[J]. Chinese Journal of Solid Mechanics, 2023, 44(6): 795-804. | |

| [97] | Lewerenz M, Fuchs G, Becker L, et al. Irreversible calendar aging and quantification of the reversible capacity loss caused by anode overhang[J]. Journal of Energy Storage, 2018, 18: 149-159. |

| [98] | Kim S, Barnes P, Zhang H, et al. Calendar life of lithium metal batteries: accelerated aging and failure analysis[J]. Energy Storage Materials, 2024, 65: No.103147. |

| [99] | Barcellona S, Codecasa L, Colnago S, et al. Cycle aging effect on the open circuit voltage of lithium-ion battery[C]∥2023 IEEE International Conference on Electrical Systems for Aircraft, Railway, Ship Propulsion and Road Vehicles & International Transportation Electrification Conference (ESARS-ITEC). Venice: IEEE, 2023: 1-6. |

| [100] | Huo W W, He H W, Sun F C. Electrochemical-thermal modeling for a ternary lithium ion battery during discharging and driving cycle testing[J]. RSC Advances, 2015, 5: 57599-57607. |

| [101] | Abe Y, Kumagai S. Effect of negative/positive capacity ratio on the rate and cycling performances of LiFePO4/graphite lithium-ion batteries[J]. Journal of Energy Storage, 2018, 19: 96-102. |

| [102] | 韩雪冰, 欧阳明高, 卢兰光, 等. 电动车磷酸铁锂电池衰减后开路电压特性分析[J]. 电源技术, 2015, 39(9): 1876-1878. |

| Han Xue-bing, Ouyang Ming-gao, Lu Lan-guang, et al. Characteristics analysis of open circuit voltage of aged LiFePO4 battery for electric vehicle[J]. Chinese Journal of Power Sources, 2015, 39(9): 1876-1878. | |

| [103] | Liu Y, Liao Y G, Lai M. Effects of depth-of-discharge, ambient temperature, and aging on the internal resistance of lithium-ion battery cell[C]∥2021 International Conference on Electrical, Computer and Energy Technologies (ICECET), Cape Town, South Africa, 2021: 1-5. |

| [104] | Terborg L, Weber S, Blaske F, et al. Investigation of thermal aging and hydrolysis mechanisms in commercial lithium ion battery electrolyte[J]. Journal of Power Sources, 2013, 242: 832-837. |

| [105] | Boerger E M, Gottschalk F, Drescher L, et al. Shaking lithium‐ion cells on a rocker—temperature‐dependent influence of mechanical movement on lithium‐ion battery lifetime[J]. Chemie Ingenieur Technik, 2021, 94(4): 603-606. |

| [106] | Kim J, Kim J, Kim Y, et al. Influence of mechanical fatigue at different states of charge on pouch-type Li-ion batteries[J]. Materials, 2022, 15(16): No.5557. |

| [107] | 陈兵, 郑莉莉, 李希超, 等. 老化电池的放电性能与充放电产热特性[J]. 储能科学与技术, 2022, 11(2): 679-689. |

| Chen Bing, Zheng Li-li, Li Xi-chao, et al. Discharge performance and charge-discharge heat generation characteristics of aging batteries[J]. Energy Storage Science and Technology, 2022, 11(2): 679-689. | |

| [108] | Feng X, Ren D, Zhang S, et al. Influence of aging paths on the thermal runaway features of lithium-ion batteries in accelerating rate calorimetry tests[J]. International Journal of Electrochemical Science, 2019, 14(1): 44-58. |

| [109] | Zhang N, Mei W, Li Y, et al. Investigation on mechanical bending caused thermal runaway of lithium-ion cell[J]. Journal of Energy Storage, 2023, 68: No.107688. |

| [110] | Ren D, Feng X, Lu L, et al. Overcharge behaviors and failure mechanism of lithium-ion batteries under different test conditions[J]. Applied Energy, 2019, 250: 323-332. |

| [111] | Zhang G, Wei X, Chen S, et al. Comprehensive investigation of a slight overcharge on degradation and thermal runaway behavior of lithium-ion batteries[J]. ACS Applied Materials & Interfaces, 2021, 13(29): 35054-35068. |

| [112] | Wang D, Zheng L, Li X, et al. Effects of overdischarge rate on thermal runaway of NCM811 Li-ion batteries[J]. Energies, 2020, 13(15): No.3885. |

| [113] | Ohneseit S, Finster P, Floras C, et al. Thermal and mechanical safety assessment of type 21700 lithium-ion batteries with NMC, NCA and LFP cathodes-investigation of cell abuse by means of accelerating rate calorimetry (ARC)[J]. Batteries, 2023, 9(5): No.237. |

| [114] | Wei G, Huang R, Zhang G, et al. A comprehensive insight into the thermal runaway issues in the view of lithium-ion battery intrinsic safety performance and venting gas explosion hazards[J]. Applied Energy, 2023, 349: No.121651. |

| [115] | Zhao L, Zheng M, Zhang J, et al. Numerical modeling of thermal runaway for low temperature cycling lithium-ion batteries[J]. Journal of Energy Storage, 2023, 63: No.107053. |

| [116] | Yuan Q, Xu X, Zhu L, et al. Effects of local thermal accumulation conditions on the thermal characteristics of lithium-ion batteries under high-rate charging[J]. Journal of Energy Engineering, 2020, 146(6): No.04020072. |

| [117] | Zhai Q, Xu X, Kong J, et al. 3D simulation study on thermal behavior and thermal stress of lithium‐ion battery[J]. Energy Technology, 2022, 11(2): No.2200795. |

| [118] | 杨发庆. 基于力热电耦合模型的锂离子电池安全分析[D]. 长春: 吉林大学汽车工程学院, 2024. |

| Yang Fa-qing. Safety analysis of lithium-ion battery based on mechanical-thermal-electric coupled model[D]. Changchun: College of Automotive Engineering, Jilin University, 2024. | |

| [119] | Zhao R, Liu J, Gu J. Simulation and experimental study on lithium ion battery short circuit[J]. Applied Energy, 2016, 173: 29-39. |

| [1] | Chun XIAO,Zi-chun YI,Bing-yin ZHOU,Shao-rui ZHANG. Fuzzy energy management strategy of fuel cell electric vehicle based on improved pigeon⁃inspired optimization [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(6): 1873-1882. |

| [2] | Mei-xia JIA,Jian-jun HU,Feng XIAO. Multi⁃physics simulation method of vehicle motor under varying working conditions based on multi⁃software combination [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(6): 1862-1872. |

| [3] | Wei-dong LI,Cao-yuan MA,Hao SHI,Heng CAO. An automatic driving decision control algorithm based on hierarchical reinforcement learning [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(5): 1798-1805. |

| [4] | Dang LU,Yan-ru SUO,Yu-hang SUN,Hai-dong WU. Estimation of tire camber and sideslip combined mechanical characteristics based on dimensionless expression [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(5): 1516-1524. |

| [5] | Tao ZHANG,Huang-da LIN,Zhong-jun YU. Real-time rolling optimization control method for gearshift of hybrid electric vehicles [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(4): 1215-1224. |

| [6] | Zhen-hai GAO,Cheng-yuan ZHENG,Rui ZHAO. Review of active safety verification and validation for autonomous vehicles in real and virtual scenarios [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(4): 1142-1162. |

| [7] | Dang LU,Xiao-fan WANG,Hai-dong WU. Analysis of uniform distribution characteristics of contact pressure of TWEEL tires [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(3): 811-819. |

| [8] | Jun-long QU,Wen-ku SHI,Sheng-yi XUAN,Zhi-yong CHEN. Parameter design method of multiple dynamic vibration absorbers for suppressing multi-frequency resonance of automotive powertrain [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(2): 444-455. |

| [9] | Xin CHEN,Xiang-yuan ZHANG,Zi-tao WU,Gui-shen YU,Li-fei YANG. Effect of process sequence on tensile shear properties of PFSSW joints for automotive aluminum sheets [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(2): 468-475. |

| [10] | Hong-yu HU,Zheng-guang ZHANG,You QU,Mu-yu CAI,Fei GAO,Zhen-hai GAO. Driver behavior recognition method based on dual-branch and deformable convolutional neural networks [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(1): 93-104. |

| [11] | Jun-nian WANG,Yu-jing CAO,Zhi-ren LUO,Kai-xuan LI,Wen-bo ZHAO,Ying-yi MENG. Online detection algorithm of road water depth based on binocular vision [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(1): 175-184. |

| [12] | Cao TAN,Hao-xin REN,Wen-qing GE,Ya-dong SONG,Jia-yu LU. Improved active disturbance rejection control for hydraulic vibration stages based on the direct-drive valve [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(1): 84-92. |

| [13] | Shou-tao LI,Lu YANG,Ru-yi QU,Peng-peng SUN,Ding-li YU. Slip rate control method based on model predictive control [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(9): 2687-2696. |

| [14] | Liang WU,Yi-fan GU,Biao XING,Fang-wu MA,Li-wei NI,Wei-wei JIA. Steering four-wheel distributed integrated control method based on LQR [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(9): 2414-2422. |

| [15] | Yu-hai WANG,Xiao-zhi LI,Xing-kun LI. Predictive energy saving algorithm for hybrid electric truck under high-speed condition [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(8): 2121-2129. |

|