Journal of Jilin University(Engineering and Technology Edition) ›› 2023, Vol. 53 ›› Issue (9): 2483-2492.doi: 10.13229/j.cnki.jdxbgxb.20211236

Previous Articles Next Articles

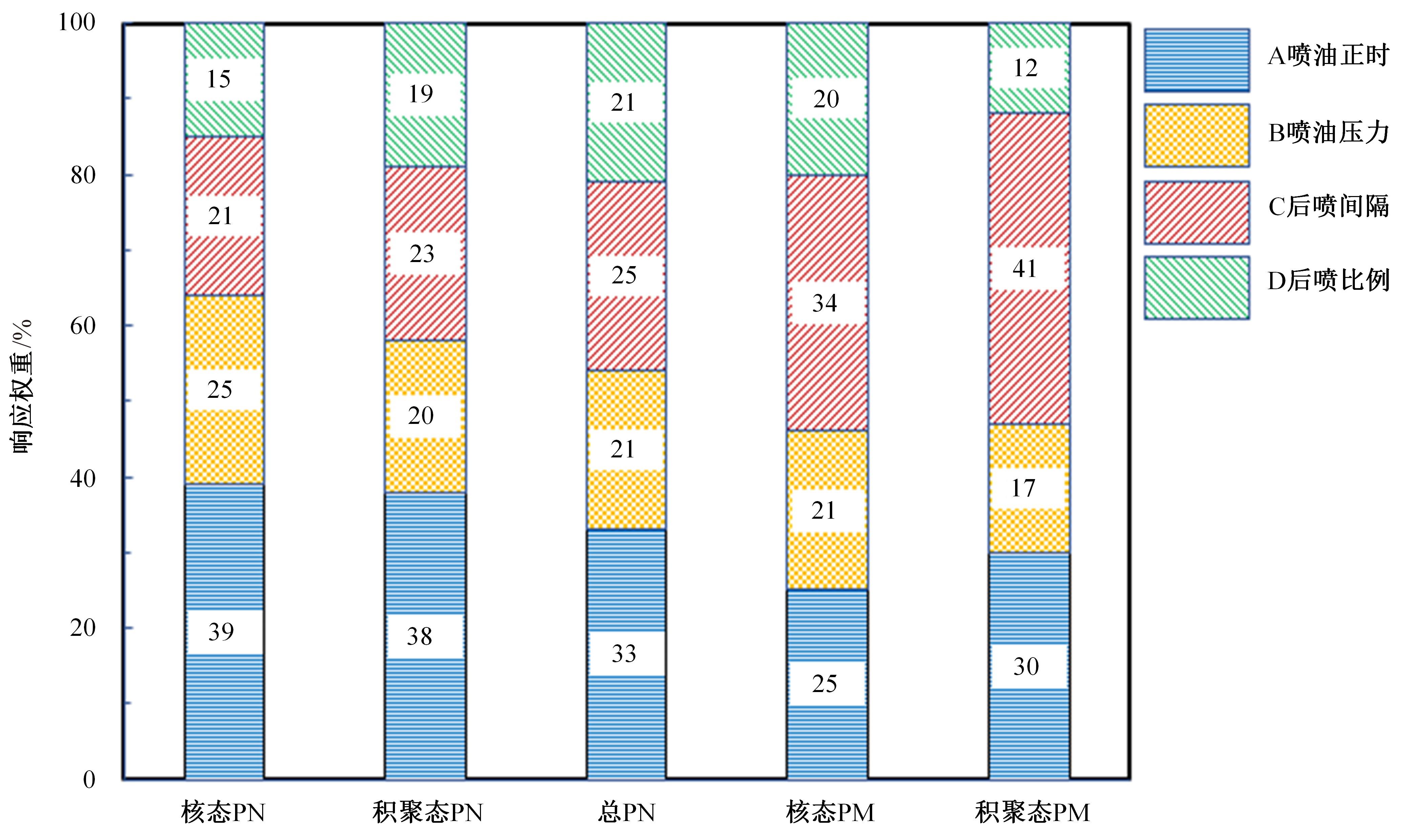

Effects of injection parameters and taguchi method on particulate emissions of diesel engine under transient conditions

Shuang FENG1,2( ),Wei HONG1,2,Xiao-ping LI1,2(

),Wei HONG1,2,Xiao-ping LI1,2( ),Fang-xi XIE1,2

),Fang-xi XIE1,2

- 1.National Key Laboratory of Automotive Chassis Integration and Bionics,Jilin University,Changchun 130022,China

2.College of Automotive Engineering,Jilin University,Changchun 130022,China

CLC Number:

- TK421.5

| 1 | Nilsson T, Froberg A, Aslund J. Optimal operation of a turbocharged diesel engine during transients[J] SAE International Journal of Engines, 2012,5(2): 571-578. |

| 2 | 隋菱歌. 增压柴油机瞬态工况性能仿真及优化[D].长春:吉林大学汽车工程学院,2012. |

| Sui Ling-ge. Simulation and optimization of turbo charged diesel engine performance under transient operations[D]. Changchun; College of Automotive Engineering, Jilin University, 2012. | |

| 3 | Rakopoulos C D, Michos C N, Giakoumis E G. Study of the transient behavior of turbocharged diesel engines including compressor surging using a linearized quasi-steady analysis[C]∥SAE Paper, 2005-01-0225. |

| 4 | Rakopoulos C D, GiakoumisE G, Rakopoulos D C. The effect of friction modelling on the prediction of turbocharged diesel engine transient operation[C]∥SAE Paper, 2004-01-0925. |

| 5 | Grahn M, Johansson K, McKelvey T. Model-based diesel engine management system optimization for transient engine operation[J]. Control Engineering Practice, 2014, 29: 103-114. |

| 6 | Atkinson C, Allain M, Zhang H. Using model-based rapid transient calibration to reduce fuel consumption and emissions in diesel engines[C]∥SAE Paper, 2008-01-1365. |

| 7 | Atkinson C, Mott G. Dynamic model-based calibration optimization: an introduction and application to diesel engines[C]∥SAE Paper, 2005-01-0026, 2005. |

| 8 | Liu S, Cui Y, Wang Y, et al. An evaluation method for transient response performance of turbocharged diesel engines[J]. Energy, 2019, 182:852-863. |

| 9 | 付建勤. 车用发动机瞬变工况运行与性能参数连续检测及热功转换过程研究[D]. 长沙:湖南大学机械与运载工程学院, 2014. |

| Fu Jian-qin. Continuous detecting on the operating and performance parameters of automotive engine under transient conditions and study of the heat-work conversion process[D]. Changsha; College of Mechanical and Vehicle Engineering, Hunan University, 2014. | |

| 10 | 张龙平. 车用柴油机瞬变工况性能劣变及其控制策略研究[D]. 长春:吉林大学汽车工程学院,2015. |

| Zhang Long-ping. Investigation of performance deterioration and control strategy of automotive diesel engine under transient operation conditions[D]. Changchun: College of Automotive Engineering, Jilin University, 2015. | |

| 11 | 刘长铖. 车用增压柴油机瞬变过程能量流及㶲流分析[D]. 长春:吉林大学汽车工程学院, 2020. |

| Liu Chang-cheng. Analysis of energy flow, exergy flow and optimization of energy efficiency in an automotive turbocharged diesel engine[D]. Changchun; College of Automotive Engineering, Jilin University, 2020. | |

| 12 | Tan Pi-qiang, Ruan Shuai-shuai, Hu Zhi-yuan, et al. Particle number emissions from a light-duty diesel engine with biodiesel fuels under transient-state operating conditions[J]. Applied Energy, 2014, 113: 22-31. |

| 13 | 谭丕强, 胡志远, 楼狄明, 等. 车用柴油机瞬变工况的排气颗粒数量[J]. 机械工程学报, 2012, 48(14): 134-140. |

| Tan Pi-qiang, Hu Zhi-yuan, Lou Di-ming. Quantity of exhaust particles in vehicle diesel engine under transient conditions[J]. Chinese Journal of Mechanical Engineering, 2012, 48(14): 134-140. | |

| 14 | Sun Wan-chen, Wang Qiao, Guo Liang, et al. Influence of biodiesel/diesel blends on particle size distribution of CI engine under steady/transient conditions[J]. Fuel, 2019, 245: 336-344. |

| 15 | Zhang X B, Wang Z X, Xiao B, et al. A neural network learning-based global optimization approach for aero-engine transient control schedule[J]. Neurocomputing, 2021, 469: 180-188. |

| 16 | Zhang Miao-miao, Hong Wei, Xie Fang-xi, et al. Combustion, performance and particulate matter emissions analysis of operating parameters on a GDI engine by traditional experimental investigation and Taguchi method[J]. Energy Conversion and Management, 2018, 164: 344-352. |

| 17 | Uslu S, Yaman H, Yesilyurt M K. Optimization of parameters affecting the performance and emissions of a spark ignition engine fueled with n-pentanol/gasoline blends using taguchi method[J]. Arabian Journal for Science and Engineering, 2021, 46(12): 11711-11724. |

| [1] | Yu-ling JIAO,Xue DENG,Lin LI,Wen-jia LIU,Tian-ze ZHANG,Nan CAO. Balancing and collaborative optimization of two⁃sided U⁃type assembly line with multi⁃constraint [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(7): 2053-2060. |

| [2] | Gui-sheng CHEN,Guo-yan LUO,Liang-xue LI,Zhen HUANG,Yi LI. Analysis of diesel particulate filter channel flow field and its noise characteristics in plateau environment [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(7): 1892-1901. |

| [3] | Yan ZHANG,Wei LIU,Shu-yong ZHANG,Yi-qiang PEI,Meng-meng DONG,Jing QIN. Optimization on thermal load of combustion chamber on two/four⁃stroke switchable diesel engine [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(3): 504-514. |

| [4] | Wen-zhi GAO,Yan-jun WANG,Xin-wei WANG,Pan ZHANG,Yong LI,Yang DONG. Real⁃time diagnosis for misfire fault of diesel engine based on convolutional neural network [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(2): 417-424. |

| [5] | Yan SU,Bo WANG,Yu LIU,Fang-xi XIE,Yun-feng HU,Jia-quan DUAN. Effect of diesel injection timing and gasoline ratio on the emissions of homogeneous charge induced ignition [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(1): 37-45. |

| [6] | Yun-feng HU,Yi-tong DING,Zhi-xin ZHAO,Bing-jing JIANG,Jin-wu GAO. Data-driven modeling and receding optimization control of diesel engine combustion process [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(1): 49-62. |

| [7] | Zhong WANG,You LI,Mei-juan ZHANG,Shuai LIU,Rui-na LI,Huai-bei ZHAO. Analysis on particle collision dynamics parameters in diesel exhaust stage [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(1): 39-48. |

| [8] | Jian WANG,Xin XU,Han GU,Duo-jun ZHANG,Sheng-ji LIU. Heating characteristics of DOC based on exhaust thermal management of diesel engine [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 408-416. |

| [9] | Qiao WANG,Wan-chen SUN,Liang GUO,Peng CHENG,Lu-yan FAN,Guo-liang LI. Effects of butanol/diesel blends on combustion and particulate emission characteristics of compression ignition engine [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1920-1928. |

| [10] | Chang-cheng LIU,Zhong-chang LIU,Jing TIAN,Yun XU,Ze-yu YANG. In⁃cylinder exergy destruction during combustion process ofheavy⁃duty turbocharged diesel engine [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1911-1919. |

| [11] | Xiang⁃huan ZU,Chuan⁃lei YANG,He⁃chun WANG,Yin⁃yan WANG. Exhaust gas recirculation performance evaluation of marine diesel engine and its application [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(3): 805-815. |

| [12] | YANG Shuai, FENG Zhi-wei, ZHAO Zhi-guo, ZHOU Yi. 1-Dimensional simulation analysis about the influence of different Miller cycle strategies on diesel engine operating process [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(5): 1444-1454. |

| [13] | LIN Xue-dong, JIANG Tao, XU Tao, LI De-gang, GUO Liang. Control strategy of high pressure pump in starting condition of high pressure common rail diesel engine [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(5): 1436-1443. |

| [14] | GONG Xun, JIANG Bing-jing, HU Yun-feng, QU Ting, CHEN Hong. Design and analysis of nonlinear state observer for master-slave two cell Urea-SCR system of diesel engine [J]. 吉林大学学报(工学版), 2018, 48(4): 1055-1062. |

| [15] | TIAN Jing, LIU Zhong-chang, LIU Jin-shan, DONG Chun-xiao, ZHONG Ming, DU Wen-chang. Performance optimization of diesel engine based on response surface methodology of multi-boundary combustion conditions [J]. 吉林大学学报(工学版), 2018, 48(1): 159-165. |

|