Journal of Jilin University(Engineering and Technology Edition) ›› 2026, Vol. 56 ›› Issue (1): 109-115.doi: 10.13229/j.cnki.jdxbgxb.20240655

Previous Articles Next Articles

Scaling method of chest mechanical response corridor considering viscosity

Zhi-xin LIU1,2( ),Jun-dong ZHANG1,3,Xiang LI1,2,Qi ZHANG1,4,Zheng-lei YU3,Wei-dong LIU1(

),Jun-dong ZHANG1,3,Xiang LI1,2,Qi ZHANG1,4,Zheng-lei YU3,Wei-dong LIU1( )

)

- 1.China Automotive Technology & Research Center Co. Ltd. ,Tianjin 300300,China

2.School of Mechanical and Aerospace Engineering,Jilin University,Changchun 130022,China

3.Key Laboratory of Bionic Engineering,Ministry of Education,Jilin University,Changchun 130022,China

4.School of Mechanical and Electrical Engineering,Changchun University of Science and Technology,Changchun 130012,China

CLC Number:

- U467.14

| [1] | Xiao S, Qie Y C, Huang J, et al. Influence of restraint load on injury biomechanics in frontal impact based on dummy test[J]. Iranian Journal of Science and Technology, Transactions of Mechanical Engineering, 2020, 44(4): 1065-1075. |

| [2] | Ma W J, Liu W D, Hu J W, et al. Toward future ATDs: anthropometric differences between Chinese and the U.S. Adult populations[C]∥The 13th International Conference on Measuring Technology and Mechatronics Automation(ICMTMA), Beihai, China, 2021:737-742. |

| [3] | 李沛雨. 碰撞载荷下考虑人体差异的胸腔参数化建模及损伤研究[D]. 北京: 清华大学车辆与运载学院, 2019. |

| Li Pei-yu. Parametric modeling and injury analysis of occupant thorax under impact conditions concerning variations among populations[D]. Beijing: School of Vehicle and Mobility, Tsinghua University, 2019. | |

| [4] | 刘欢. 中国体征假人坐姿对正面碰撞中上躯干响应及损伤影响的研究[C]∥长春: 吉林大学机械与航空航天工程学院, 2019. |

| Liu Huan. Research on the influence of Chinese physique dummy sitting on response and injury of upper torso in frontal collision[C]∥Changchun: School of Mechanical and Aerospace Engineering, Jilin University, 2019. | |

| [5] | 黎和俊, 杨震, 周大永, 等. 混Ⅲ假人、GHBMC人体模型以及中国人体模型的正碰损伤差异[J]. 中国机械工程, 2021, 32(15): 1836-1843. |

| Li He-jun, Yang Zhen, Zhou Da-yong, et al. Difference of injury response among Hybrid Ⅲ dummy, GHBMC model and Chinese human body model in frontal crash[J]. China Mechanical Engineering, 2021, 32(15): 1836-1843. | |

| [6] | 陈嘉鑫. 基于中国体征的正碰假人仿真研究与应用[D]. 长春: 吉林大学机械与航空航天工程学院, 2021. |

| Chen Jia-xin. Research on simulation of frontal impact dummy with Chinese physical sign and its application [D]. Changchun: School of Mechanical and Aerospace Engineering, Jilin University, 2021. | |

| [7] | Nahum A M, Gadd C W, Schneider D C, et al. Deflection of the human thorax under sternal impact[C]∥SAE Paper, 1970: No.700400. |

| [8] | Kroell C K, Schneider D C, Nahum A M. Impact tolerance and response of the human thorax[C]∥SAE Paper, 1971: No.710851. |

| [9] | Stalnaker R L, McElhaney J H, Roberts V L, et al. Human torso response to blunt trauma[M]. Human Impact Response: Measurement and Simulation, Boston, USA, 1973: 181-199. |

| [10] | Eppinger R, Marcus J, Morgan R. Development of dummy and injury index for NHTSA’s thoracic side impact protection research program[C]∥SAE Transactions,1984,93:359-387. |

| [11] | Irwin A L, Mertz H J, Elhagediab A M, et al. Guidelines for assessing the biofidelity of side impact dummies of various sizes and ages[J]. Stapp Car Crash Journal, 2002, 46: 297-319. |

| [12] | Kent R. Frontal thoracic response to dynamic loading: the role of superficial tissues, viscera and the rib cage[J]. International Journal of Crashworthiness, 2008, 13(3): 289-300. |

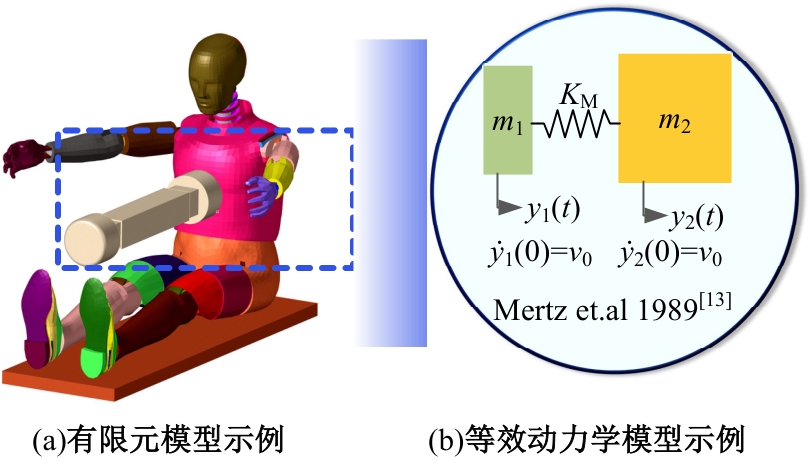

| [13] | Mertz H J, Irwin A L, Melvin J W, et al. Size, weight and biomechanical impact response requirements for adult size small female and large male dummies[C]∥SAE Paper, 1989: No.890756. |

| [14] | Irwin A L, Mertz H J. Biomechanical basis for the CRABI and Hybrid Ⅲ child dummies[C]∥SAE Paper, 1997: No.973317. |

| [15] | Mertz H J, Jarrett K, Moss S, et al. The Hybrid Ⅲ 10-year-old dummy[J]. Stapp Car Crash Journal, 2001, 45: 319-328. |

| [16] | 叶昆, 李黎. 改进的Kelvin碰撞分析模型[J]. 工程力学, 2009, 26(): 245-248. |

| Ye Kun, Li Li. Modified Kelvin pounding analytical model[J]. Engineering Mechanics, 2009, 26(Sup.2): 245-248. | |

| [17] | Liu Z X, Zheng H, Ma W J. Development of a new human thoracic equivalent model during frontal impact[J]. SAE International Journal of Transportation Safety, 2023,11(3):289-306. |

| [18] | Foster K. Analysis of a Slanted-rib Model of the Human Thorax[M]∥Human Impact Response: Measurement and Simulation, Boston: Springer, 1972: 165-177. |

| [1] | Zheng-lei YU,Chao-lei ZHANG,Li-xin CHEN,Ping HU,Tao XU,Bin-kai GUO. Bionic structure design and acoustic and mechanical properties of expressway sound barrier panels [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(9): 3079-3088. |

| [2] | Ying-chun QI,Zhao-hui ZHANG,Li-xin CHEN,Qing-yang WANG,Xue GUO,Zheng-lei YU,Zhi-hui ZHANG. Energy absorption characteristics of bionic helical structures inspired by mantis shrimp [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(4): 1474-1482. |

| [3] | Peng XI,Qian CONG,Shao-bo YE,Hong-bo LI,Yan-qing ZHANG. Bionic design and adsorption performance analysis of vacuum sucker [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(1): 382-391. |

| [4] | Xin YANG,Yang WANG,Jia-feng SONG,Yong ZHU,Bin-bing HUANG,Shu-cai XU. Design and numerical simulation of bionic sandwich panel based on a shrimp chela structure [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(3): 842-851. |

| [5] | Zheng-lei YU,Qing CAO,Jun-dong ZAHNG,Peng-wei SHA,Jing-fu JIN,Wan-zhen WEI,Ping LIANG,Zhi-hui ZHANG. Mechanical properties of a bionic buffer structure of a lander based on additive manufacturing [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(10): 3077-3084. |

| [6] | Han HUANG,Qing-hao YAN,Zhi-xin XIANG,Xin-tao YANG,Jin-bao CHEN,Shu-cai XU. Crashworthiness investigation and optimization of bionic multi⁃cell tube based on shrimp chela [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(3): 716-724. |

| [7] | Zheng-lei YU,Li-xin CHEN,Ze-zhou XU,Ren-long XIN,Long MA,Jing-fu JIN,Zhi-hui ZHANG,Shan JIANG. Analysis of mechanical characteristics and recovery characteristics of bionic protective structures based on additive manufacturing [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(4): 1540-1547. |

| [8] | Zheng-lei YU,Ren-long XIN,Li-xin CHEN,Yi-ning ZHU,Zhi-hui ZHANG,Qing CAO,Jing-fu JIN,Jie-liang ZHAO. Load bearing characteristics of honeycomb protection structure [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(3): 1140-1145. |

| [9] | Chun-bao LIU,Shan-shi CHEN,Chuang SHENG,Zhi-hui QIAN,Lu-quan REN,Lei REN. Bionic hydraulic driving mechanism of spider and its bio⁃inspiration [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(1): 375-381. |

| [10] | Dong⁃liang CHEN,Rui ZANG,Peng DUAN,Wei⁃peng ZHAO,Xu⁃tao WENG,Yang SUN,Yi⁃peng TANG. Biomimetic design of multi⁃link fishbone based on crescent′s fishtail propulsion theory [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1246-1257. |

| [11] | Na WU,Jian ZHUANG,Ke⁃song ZHANG,Hui⁃xin WANG,Yun⁃hai MA. Compression mechanical properties and fracture mechanism of Scapharca Subcrenata shell [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(3): 897-902. |

| [12] | XI Peng,CONG Qian,WANG Qing-bo,GUO Hua-xi. Wear test and anti-friction mechanism analysis of bionic stripe grinding roll [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(6): 1787-1792. |

| [13] | GUO Hao-tian,XU Tao,LIANG Xiao,YU Zheng-lei,LIU Huan,MA Long. Optimization on thermal surface with rib turbulator inspired by turbulence of alopias' gill in simplified gas turbine transition piece [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(6): 1793-1798. |

| [14] | QIAN Zhi-hui, ZHOU Liang, REN Lei, REN Lu-quan. Completely passive walking machine with bionic subtalar joint and matatarsal phalangeal joint [J]. 吉林大学学报(工学版), 2018, 48(1): 205-211. |

| [15] | GE Chang-jiang, YE Hui, HU Xing-jun, YU Zheng-lei. Prediction and control of trailing edge noise on owl wings [J]. 吉林大学学报(工学版), 2016, 46(6): 1981-1986. |

|

||