吉林大学学报(工学版) ›› 2022, Vol. 52 ›› Issue (4): 789-798.doi: 10.13229/j.cnki.jdxbgxb20200881

• 车辆工程·机械工程 • 上一篇

基于圆渐开线建立变截面涡旋齿的方法与理论

- 兰州理工大学 机电工程学院,兰州 730050

Method and theory of establishing variable thickness scrolls based on circle involute

Peng-cheng ZHANG( ),Bin PENG(

),Bin PENG( ),Yu-bo ZHANG

),Yu-bo ZHANG

- School of Mechanical and Electrical Engineering,Lanzhou University of Technology,Lanzhou 730050,China

摘要:

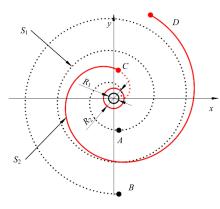

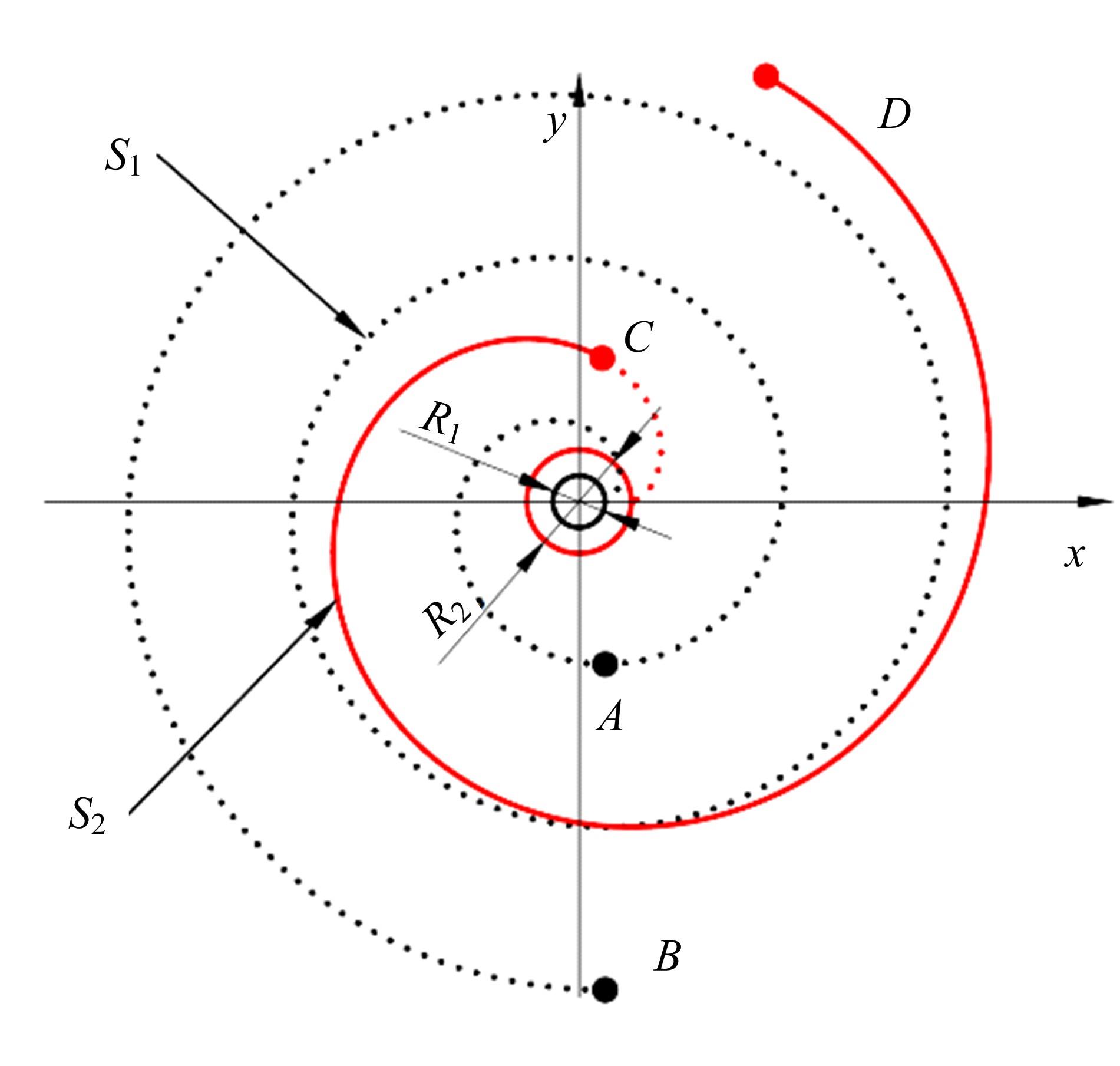

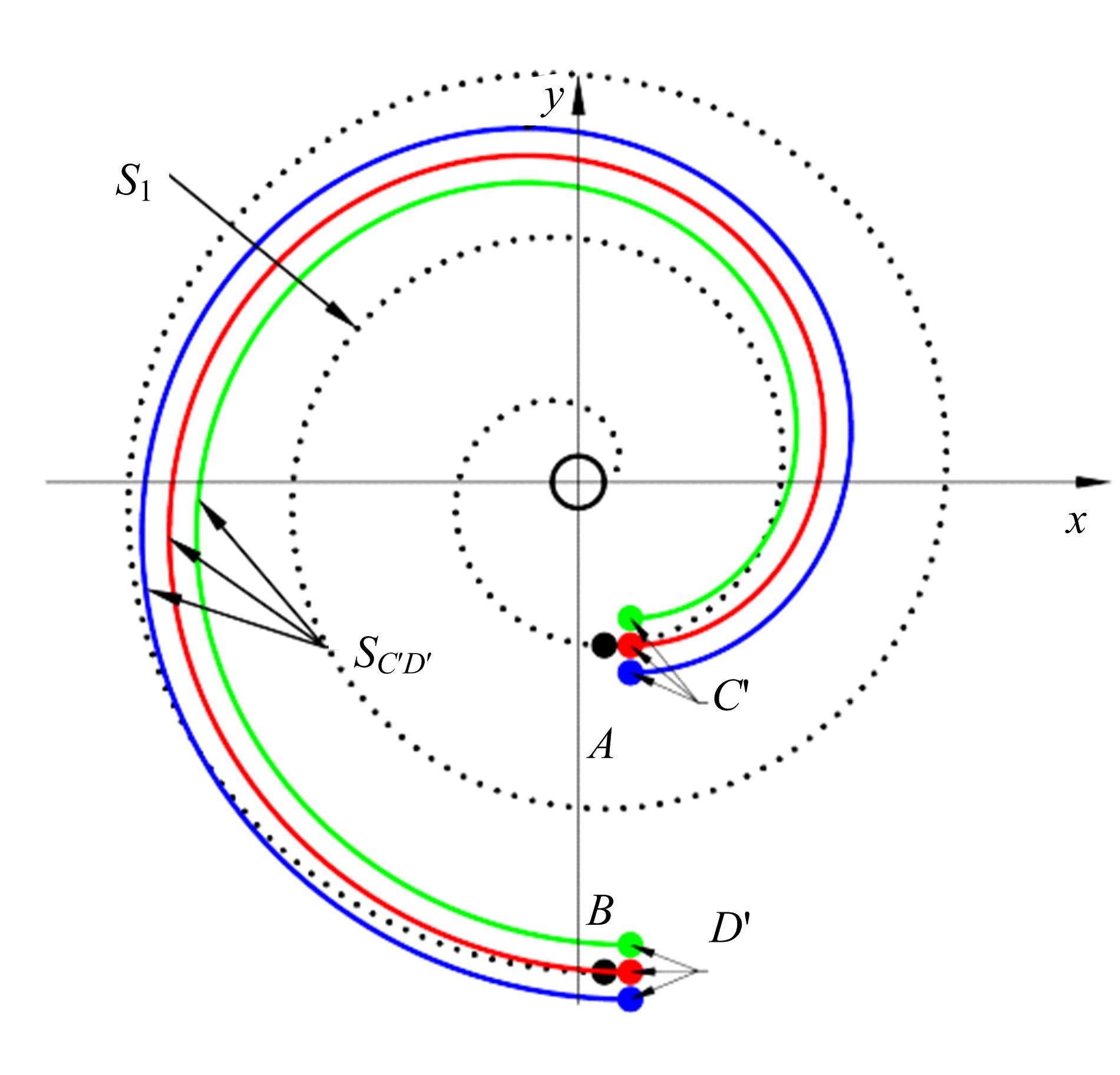

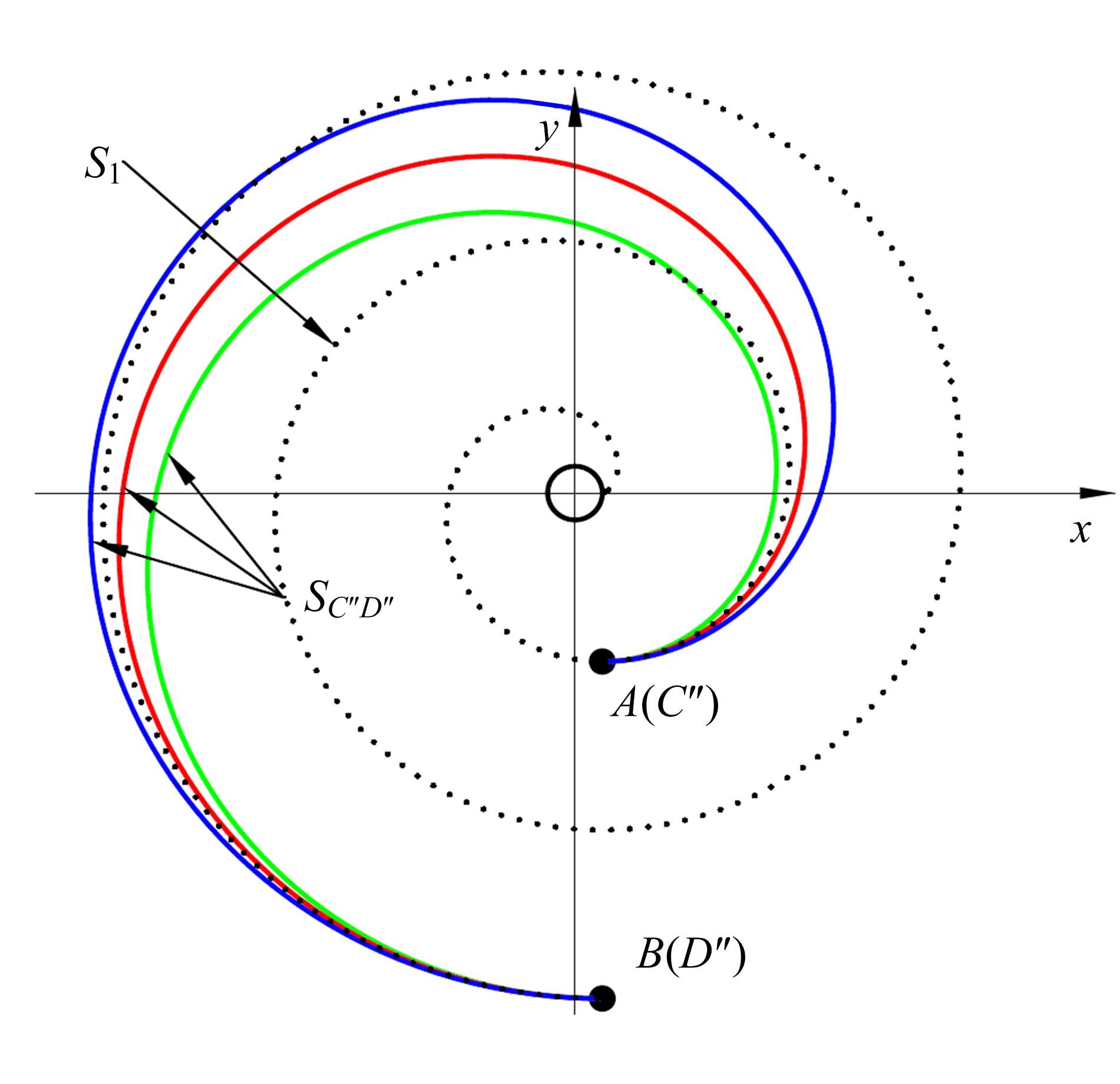

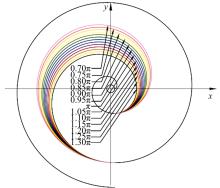

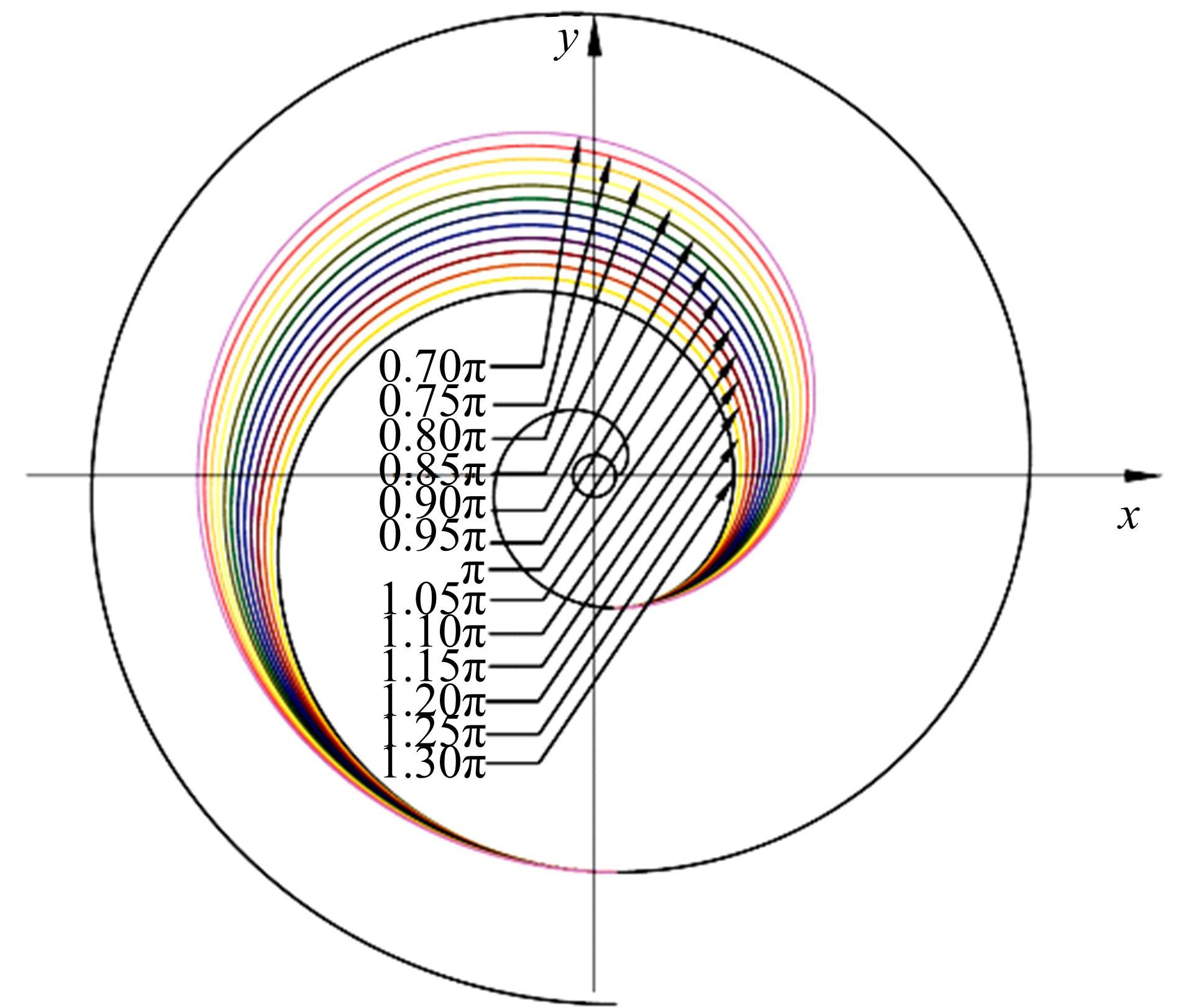

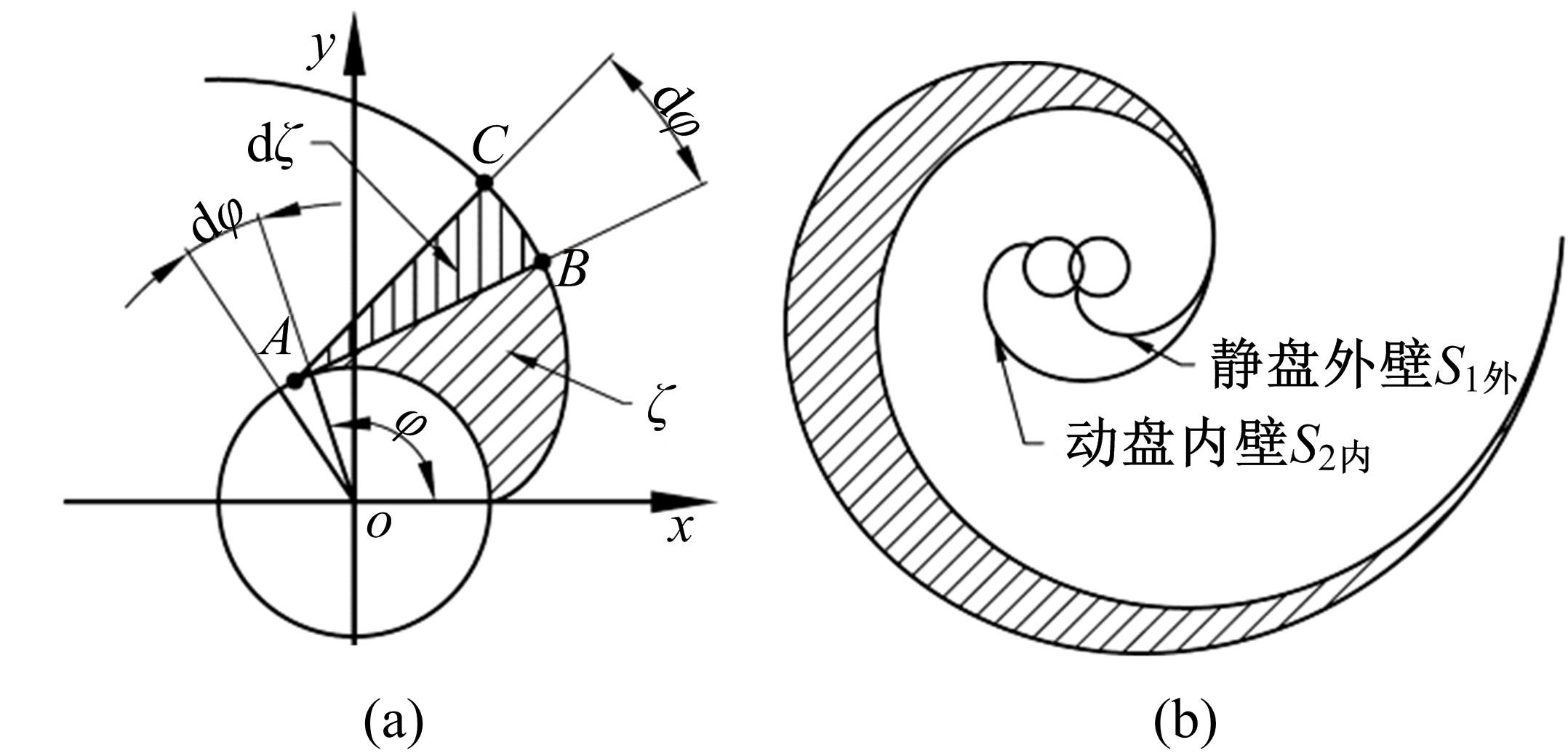

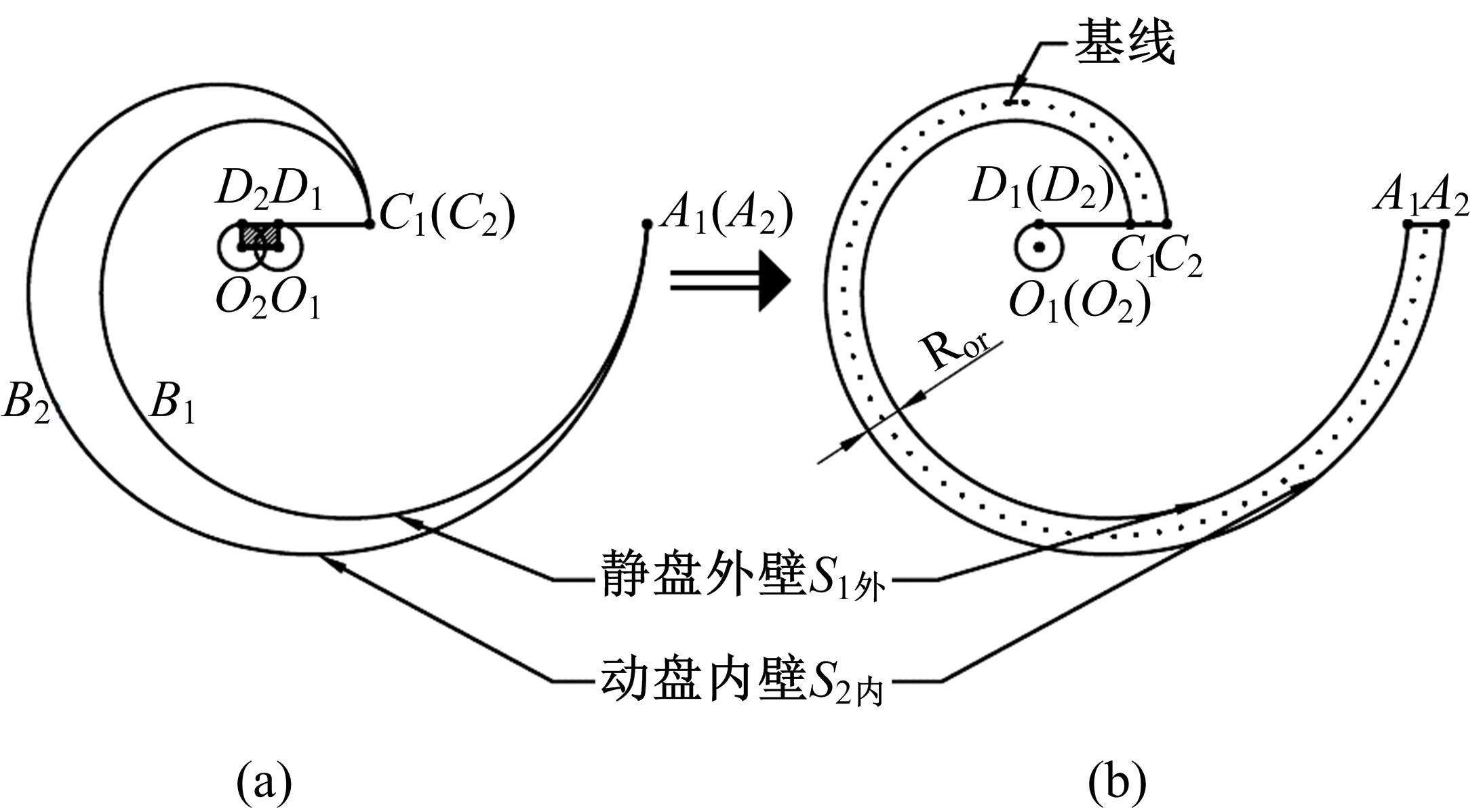

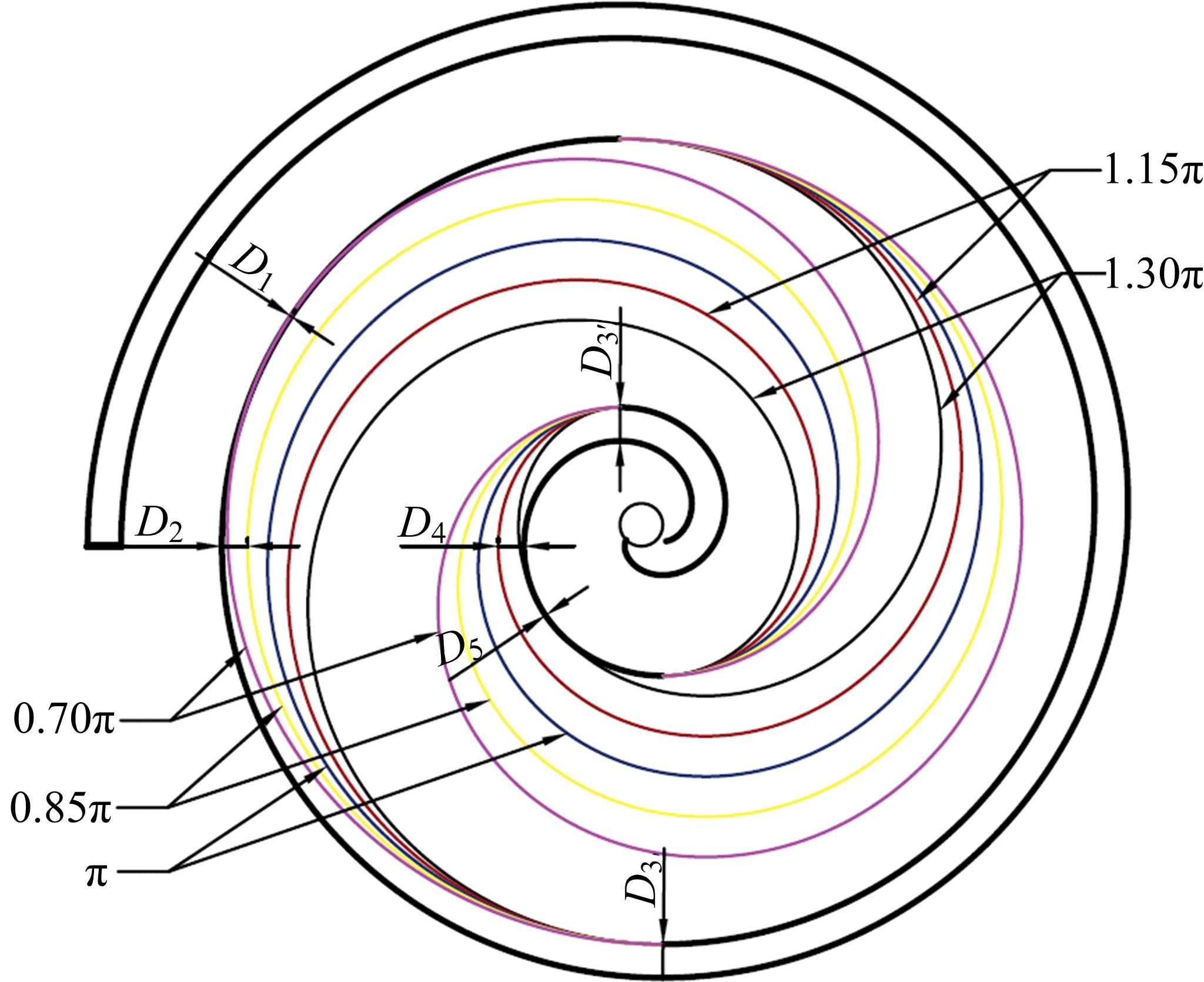

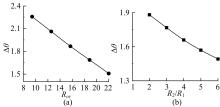

根据圆渐开线的性质,提出一种由不同圆渐开线组合的新型变截面涡旋齿的建立方法。详细论述了型线的生成方法,阐述了建立基线的基本条件,推导出型线的一般方程,给出2种计算容积的方法,讨论正确生成内、外壁型线的控制变量取值范围。根据不同要求可快速建立一系列圆渐开线变截面涡旋齿的几何模型,为变截面涡旋齿型线的研究拓宽了思路。研究结果表明:相比传统的变截面涡旋齿几何模型的建立方法,提出的新型变截面涡旋齿的建立方法不但具有传统变截面涡旋齿的优点,而且减少了建立变截面涡旋齿的计算量,在一定程度上降低了变截面涡旋齿的加工难度,扩大了变截面涡旋压缩机或膨胀机的实际应用。

中图分类号:

- TH45

| 1 | Peng B, Zhu B G, Vincent L. Theoretical and experimental analysis of scroll expander[C]∥The 23rd International Compressor Engineering Conference at Purdue, West Lafayette, Indiana, USA, 2016: 1-12. |

| 2 | 王怀信, 王大彪, 张圣君. 低温有机朗肯循环系统参数的理论与实验优化[J]. 天津大学学报, 2014, 47(5): 408-413. |

| Wang Huai-xin, Wang Da-biao, Zhang Sheng-jun. Theoretical and experimental optimization of low-temperature organic rankine cycle system parameters[J]. Journal of Tianjin University, 2014, 47(5): 408-413. | |

| 3 | 陈进, 王立存, 李世六. 通用涡旋型线理论研究与深入分析[J]. 机械工程学报, 2006, 42(5): 11-15. |

| Chen Jin, Wang Lin-cun, Li Shi-liu. Study and profound analysis on general profile theory of scrolls[J]. Journal of Mechanical Engineering, 2006, 42(5): 11-15. | |

| 4 | 王立存, 李世六, 明勇, 等. 涡旋压缩机型线耦合机理动态性研究[J]. 哈尔滨工业大学学报, 2009, 41(7):187-189. |

| Wang Li-cun, Li Shi-liu, Ming Yong, et al. Dynamics of joggling principle for scroll profiles of scroll compressor[J]. Journal of Harbin Institute of Technology, 2009, 41(7): 187-189. | |

| 5 | 彭斌, 李要红, 赵生显. 涡旋膨胀机的性能模拟[J].中国机械工程, 2018, 29(8):965-970, 978. |

| Peng Bin, Li Yao-hong, Zhao Sheng-xian. Performance simulation for scroll expanders[J]. China Mechanical Engineering, 2018, 29(8): 965-970, 978. | |

| 6 | Shaffer B R, Groll E A. Variable wall thickness scroll geometry modeling with use of a control volume approach[J]. International Journal of Refrigeration, 2013, 36(7): 1809-1820. |

| 7 | Bell I. Theoretical and experimental analysis of liquid flooded compression in scroll compressors[D]. West Lafayette: Purdue University, 2011. |

| 8 | Morishita E, Sugihara M, Inabat T, et al. Scroll compressor analytical model[C]∥Proceedings of International Compressor Engineering Conference 1984. Purdue University, West Lafayette, Indiana, USA, 1984:487-495. |

| 9 | 李连生. 线段渐开线涡旋压缩机的几何理论[J] .流体机械, 1994, 22(12): 22-28. |

| Li Lian-sheng. Geometric theory of line involute scroll compressor[J]. Fluid Machinery, 1994, 22(12): 22-28. | |

| 10 | 李雪琴, 王君. 一种涡旋压缩机的圆弧线段等壁厚组合型线[J] .流体机械, 2010, 38(8): 27-30. |

| Li Xue-qin, Wang Jun. A novel combined profile of arc and line segment for scroll compressor[J]. Fluid Machinery, 2010, 38(8): 27-30. | |

| 11 | 王君, 官华, 戴克文. 多涡旋齿圆渐开线和圆弧组合型线构建[J] .流体机械, 2008, 36(5): 14-17, 29. |

| Wang Jun, Guan Hua, Dai Ke-wen. Construction of involute and arc combination profile for multi-wrap scroll compressor[J]. Fluid Machinery, 2008, 36(5): 14-17, 29. | |

| 12 | 彭斌, 孙迎. 变截面涡旋压缩机数学模型及试验研究[J].机械工程学报, 2015, 51(14): 185-191. |

| Peng Bin, Sun Ying. Investigation of mathematical modeling and experiment for variable thickness scroll compressor [J]. Journal of Mechanical Engineering, 2015, 51(14): 185-191. | |

| 13 | 彭斌, 张朋成. 一种变截面涡旋膨胀机的几何模型及容积变化[J].机械设计与制造, 2019, 56(6): 5-8. |

| Peng Bin, Zhang Peng-cheng. Geometric model and volume change of a variable cross section scroll expander[J]. Machinery Design&Manufacture, 2019, 56(6): 5-8. | |

| 14 | 孙永吉, 刘涛. 涡旋压缩机复杂变截面涡旋型线高速加工研究[J].现代制造工程, 2017, 39(7): 25-30. |

| Sun Yong-ji, Liu Tao. Research on high speed machining complex scroll profiles of scroll compressor[J]. Modern Manufacturing Engineering, 2017, 39(7): 25-30. | |

| 15 | 李新, 何传江. 矩阵理论及其应用[M]. 重庆: 重庆大学出版社, 2005. |

| 16 | 刘涛, 邬再新, 刘振全. 法向等距线法生成涡旋压缩机型线的研究[J]. 机械工程学报, 2004, 40(6): 55-58. |

| Liu Tao, Wu Zai-xin, Liu Zhen-quan. Study on generating profile with nomal-equidistant-curve method for scroll compressor[J]. Journal of Mechanical Engineering, 2004, 40(6): 55-58. | |

| 17 | 孙迎. 变截面涡旋压缩机数学模型的研究[D]. 兰州: 兰州理工大学温州泵阀工程研究院, 2012. |

| Sun Ying. Research on the mathematical modeling of variable thickness scroll compressor[D]. Lanzhou: Wenzhou Pump and Valve Engineering Research Institute, Lanzhou University of Technology, 2012. | |

| 18 | 王君, 刘振全. 涡旋压缩机渐开线类型线的双圆弧修正[J]. 机械工程学报, 2005, 41(9): 202-206. |

| Wang Jun, Liu Zhen-quan. Double circle arc of involute type wrape of scroll compressor[J]. Journal of Mechanical Engineering, 2005, 41(9): 202-206. | |

| 19 | Peng B, Lemort V, Legros A, et al. Variable thickness scroll compressor performance analysis-Part I: geometric and thermodynamic modelling[J]. Proceedings of the Institution of Mechanical Engineering, 2016, 231 (4): 633-640. |

| 20 | 王国梁. 基于对称圆弧修正的单元组合型线涡旋压缩机特性研究[J]. 机械工程学报, 2011, 47(16): 139-142. |

| Wang Guo-liang. Investigation of wrap profile modification based on symmetric arc shaped curves for the scroll compressor with unit combined profile[J]. Journal of Mechanical Engineering, 2011, 47(16): 139-142. | |

| 21 | 王珺. 等距曲线的有理逼近新方法[D]. 合肥: 合肥工业大学巢湖学院数学系, 2009. |

| Wang Jun. New algorithms for rational approximation of offset curves[D]. Hefei: Department of Mathematics, Chaohu College, Hefei University of Technology, 2009. | |

| 22 | 李国龙, 任唯贤, 谢天明, 等. 求解共轭齿形的轮转曲线等距偏移法[J].重庆大学学报, 2019, 42(5): 10-18. |

| Li Guo-long, Ren Wei-xian, Xie Tian-ming, et al. An equidistant offset algorithm of rotation curve to solve conjugate gear profile[J]. Journal of Chongqing University, 2019, 42(5): 10-18. | |

| 23 | 梁栋. 共轭曲线齿轮啮合理论研究[D]. 重庆: 重庆大学机械传动国家重点实验室, 2015. |

| Liang Dong. Research on meshing theory of conjugate-curve gear transmission[D]. Chongqing: State Key Laboratory of Mechanical Transmission, Chongqing University, 2015. |

| [1] | 程亚兵,陈璐翔,葛平玉,杨泽宇,曹鹏宇. 双相正时套筒链的动力学仿真分析及磨损失效[J]. 吉林大学学报(工学版), 2022, 52(4): 781-788. |

| [2] | 张龙,徐天鹏,王朝兵,易剑昱,甄灿壮. 基于卷积门控循环网络的齿轮箱故障诊断[J]. 吉林大学学报(工学版), 2022, 52(2): 368-376. |

| [3] | 郑伟,孙见君,马晨波,於秋萍,张玉言,牛韬. 汽车轮毂加工夹具的研究现状及展望[J]. 吉林大学学报(工学版), 2022, 52(1): 25-36. |

| [4] | 田晓超,王海刚,王虎,王志聪,赵剑,杨志刚,吴越. 悬臂式压电振子宽频发电装置设计及测试[J]. 吉林大学学报(工学版), 2021, 51(6): 1953-1958. |

| [5] | 陈魏,雷雨龙,李兴忠,付尧,扈建龙,侯利国. 低速工况下渐开线圆柱直齿轮齿面粘着磨损计算[J]. 吉林大学学报(工学版), 2021, 51(5): 1628-1634. |

| [6] | 胡晶,李聪,张邦成,乔晓利,张心明,周笑平. 考虑离心膨胀的双级串联轴承油膜刚度和阻尼[J]. 吉林大学学报(工学版), 2021, 51(5): 1601-1611. |

| [7] | 姚宗伟,高旭东,刘刚,毕秋实. 基于数值仿真的大型塔式磨机工作特性分析[J]. 吉林大学学报(工学版), 2021, 51(5): 1642-1650. |

| [8] | 李晓韬,任金鹏,李晓旭,杨航. 双压电振子反相模态驱动的直线驱动器机理[J]. 吉林大学学报(工学版), 2021, 51(2): 468-471. |

| [9] | 侯才生,刘涛,郭李先. 一种新型变壁厚涡旋型线的构建理论[J]. 吉林大学学报(工学版), 2020, 50(5): 1627-1634. |

| [10] | 程功,肖科,王家序,蒲伟,韩彦峰. 混合润滑状态下齿轮接触刚度[J]. 吉林大学学报(工学版), 2020, 50(2): 494-503. |

| [11] | 毛艳,成凯. 基于Hopfield神经网络的单缸插销式伸缩臂伸缩路径优化[J]. 吉林大学学报(工学版), 2020, 50(1): 53-65. |

| [12] | 郭震,于红英,滑忠鑫,赵娣. 刚性折纸机构运动分析及折叠过程仿真[J]. 吉林大学学报(工学版), 2020, 50(1): 66-76. |

| [13] | 贾富淳,孟宪皆,雷雨龙. 基于多目标遗传算法的二自由度动力吸振器优化设计[J]. 吉林大学学报(工学版), 2019, 49(6): 1969-1976. |

| [14] | 谢志江,王昆,皮阳军,吴小勇,郭映位. 新的6⁃PSS型并联机构正向运动学求解方法[J]. 吉林大学学报(工学版), 2019, 49(6): 1977-1985. |

| [15] | 曹恩国,刘坤,吉硕,孙震源,徐洪伟,骆星吉. 减重站起康复训练系统机械结构设计与优化[J]. 吉林大学学报(工学版), 2019, 49(5): 1558-1566. |

|

||