吉林大学学报(工学版) ›› 2022, Vol. 52 ›› Issue (4): 781-788.doi: 10.13229/j.cnki.jdxbgxb20200919

• 车辆工程·机械工程 • 上一篇

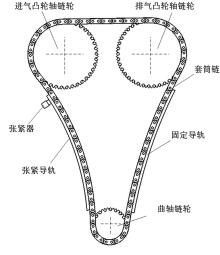

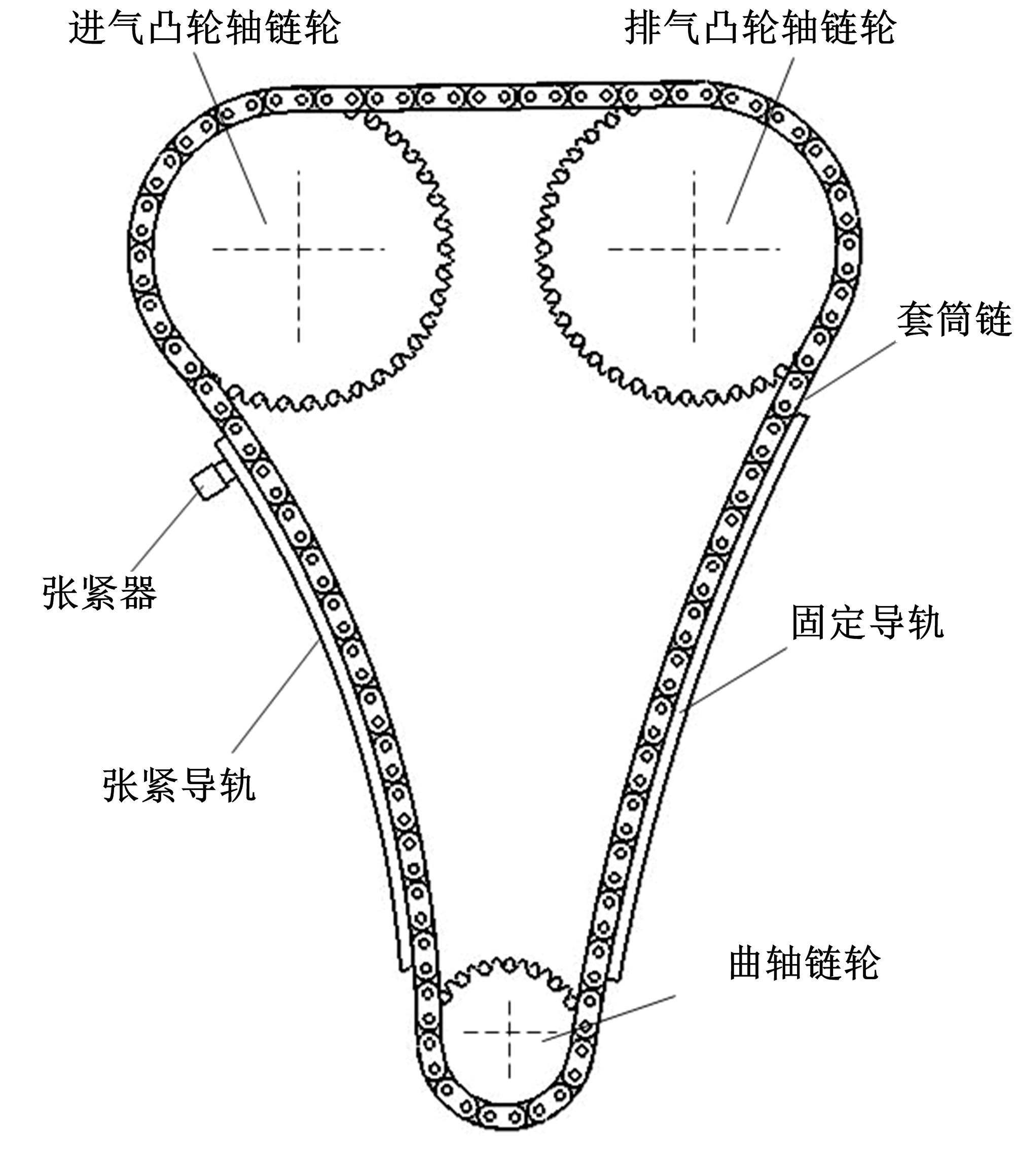

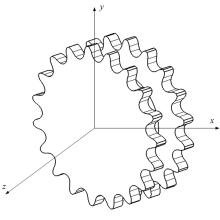

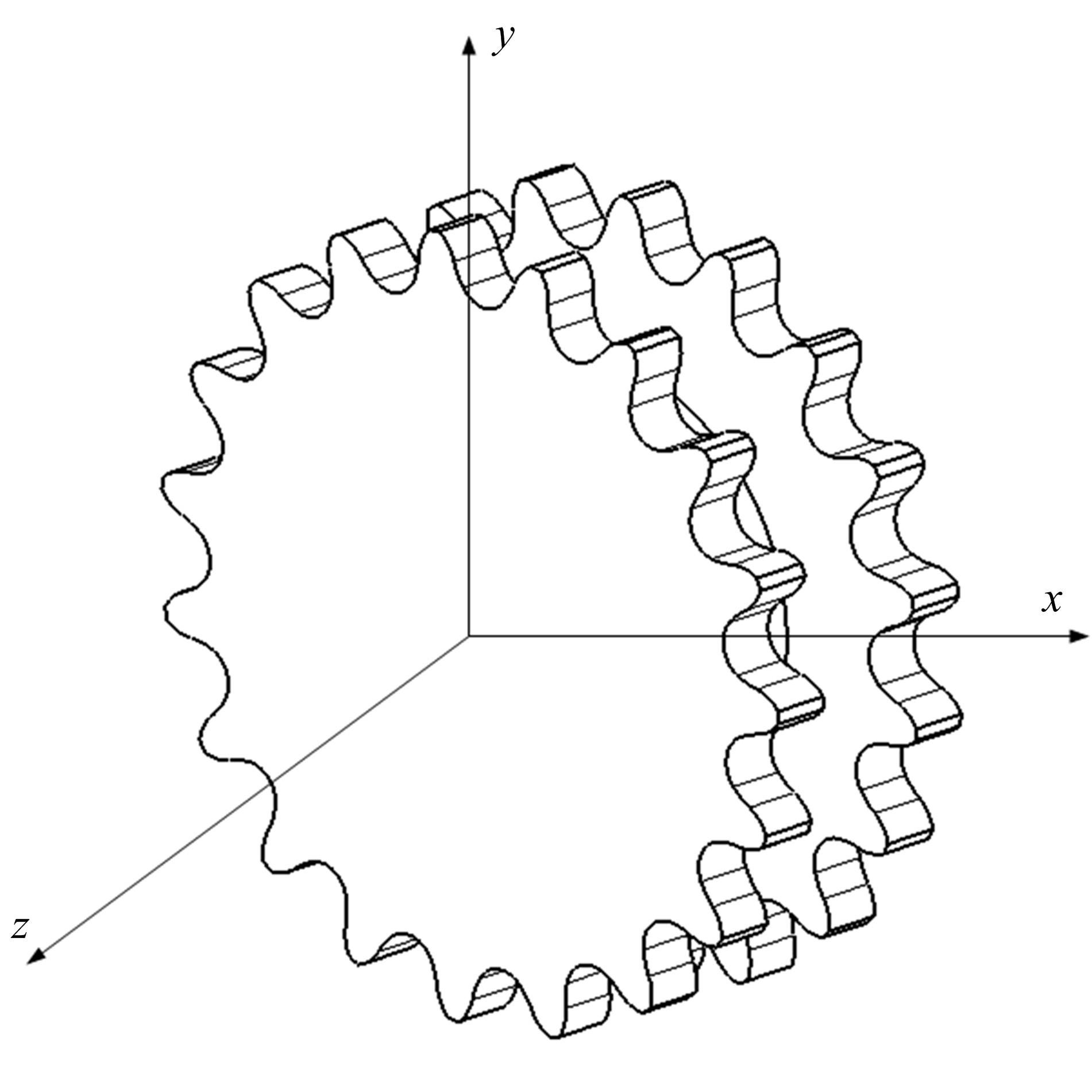

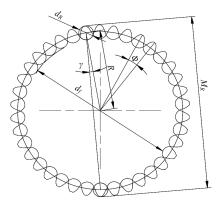

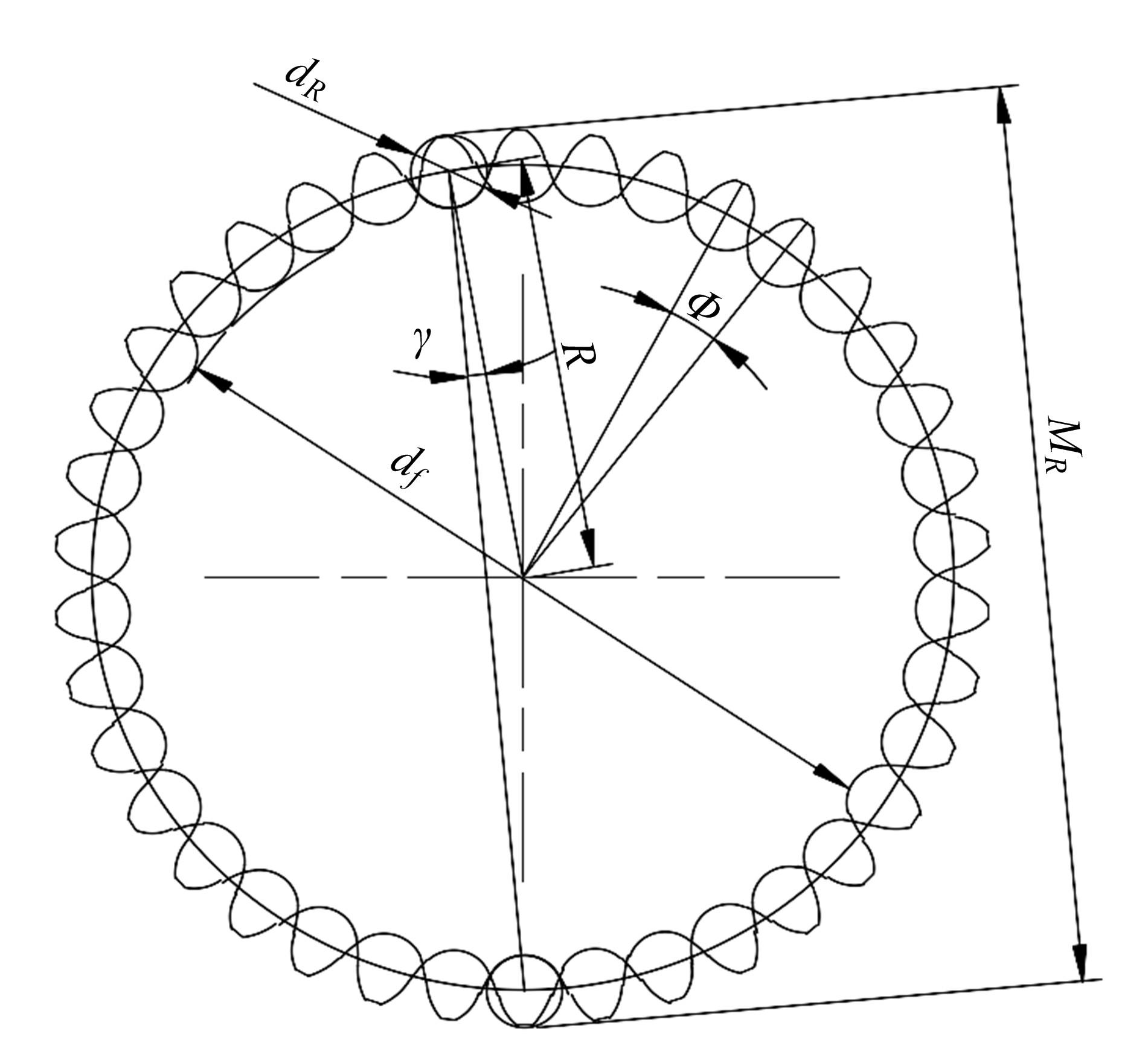

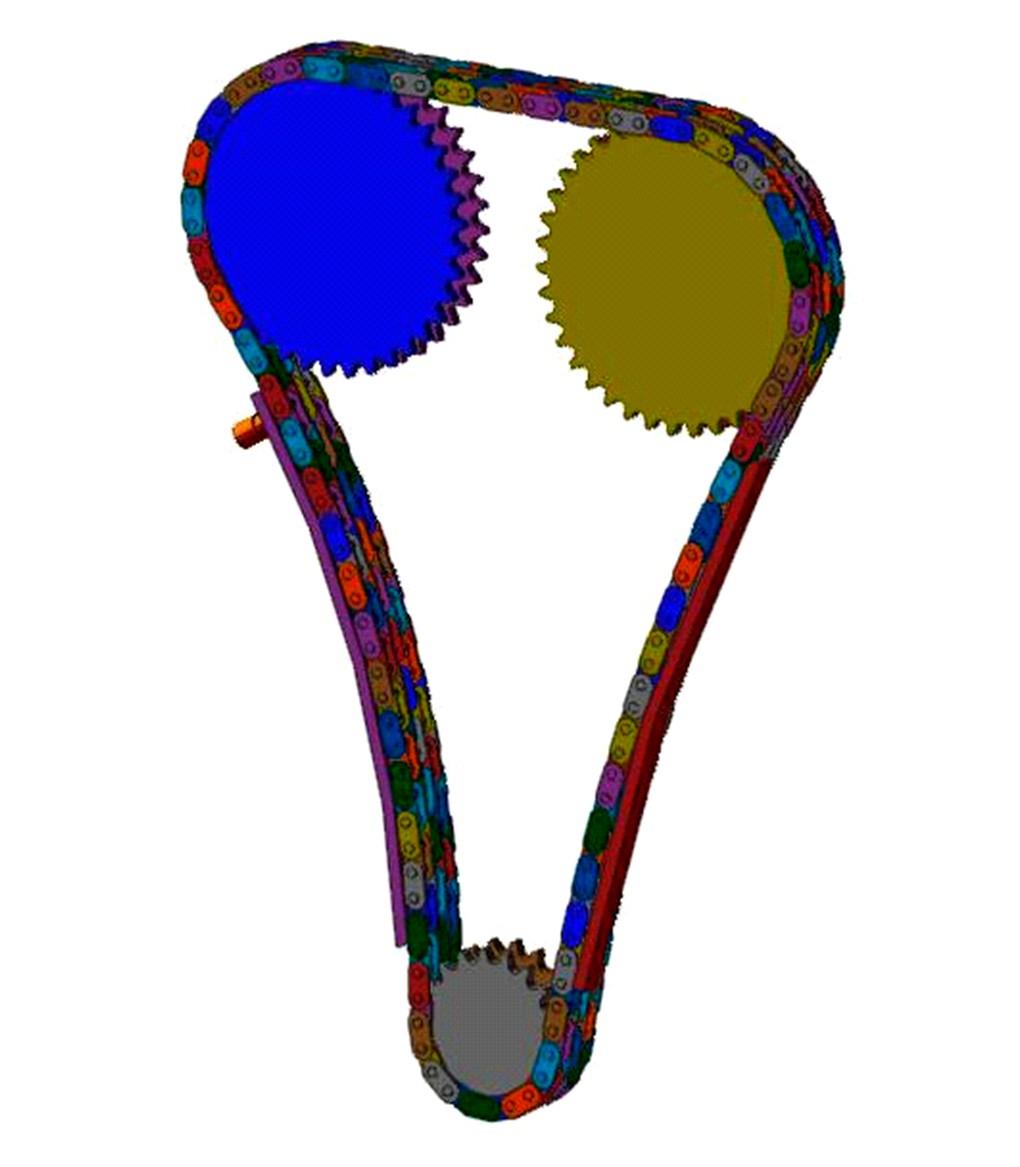

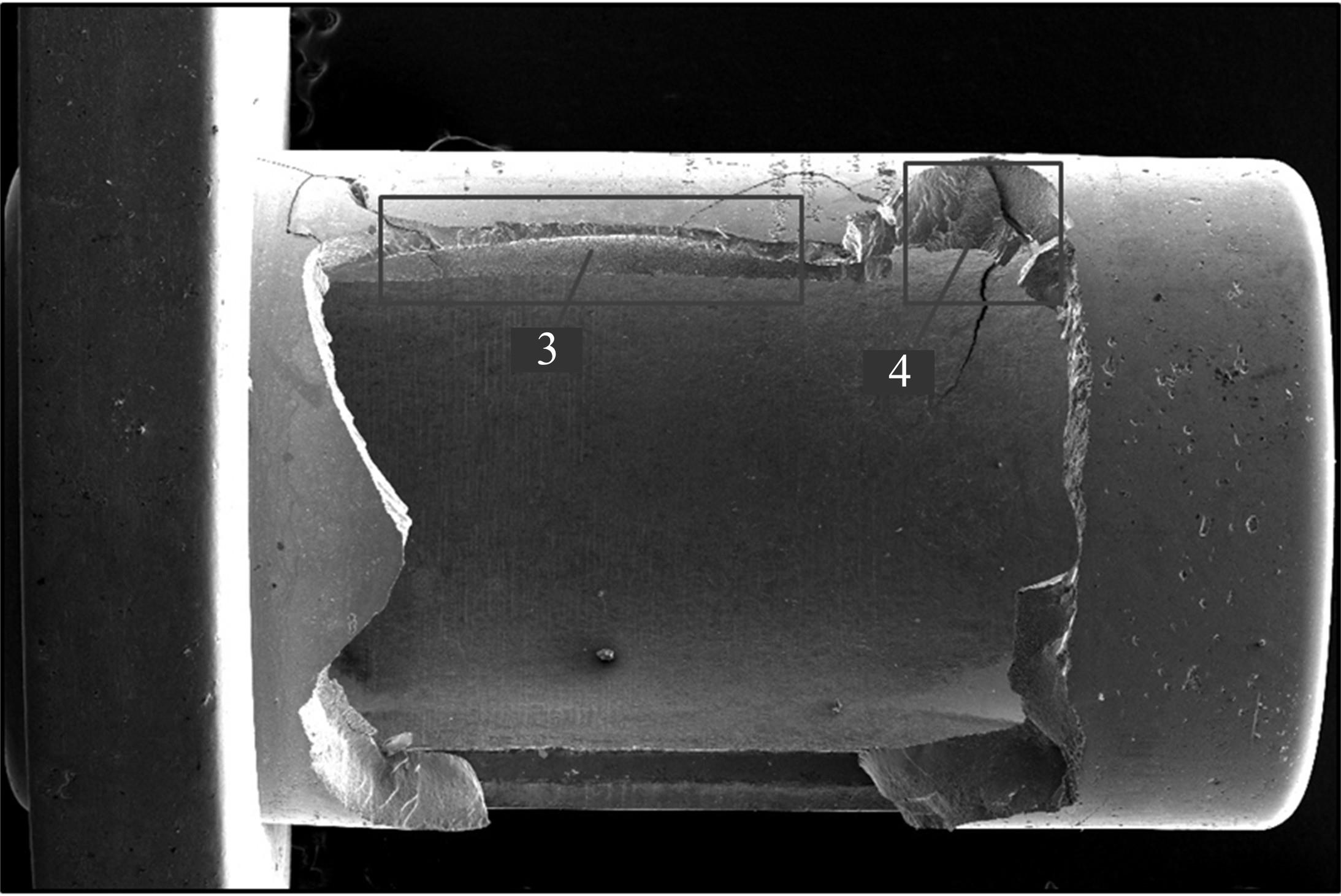

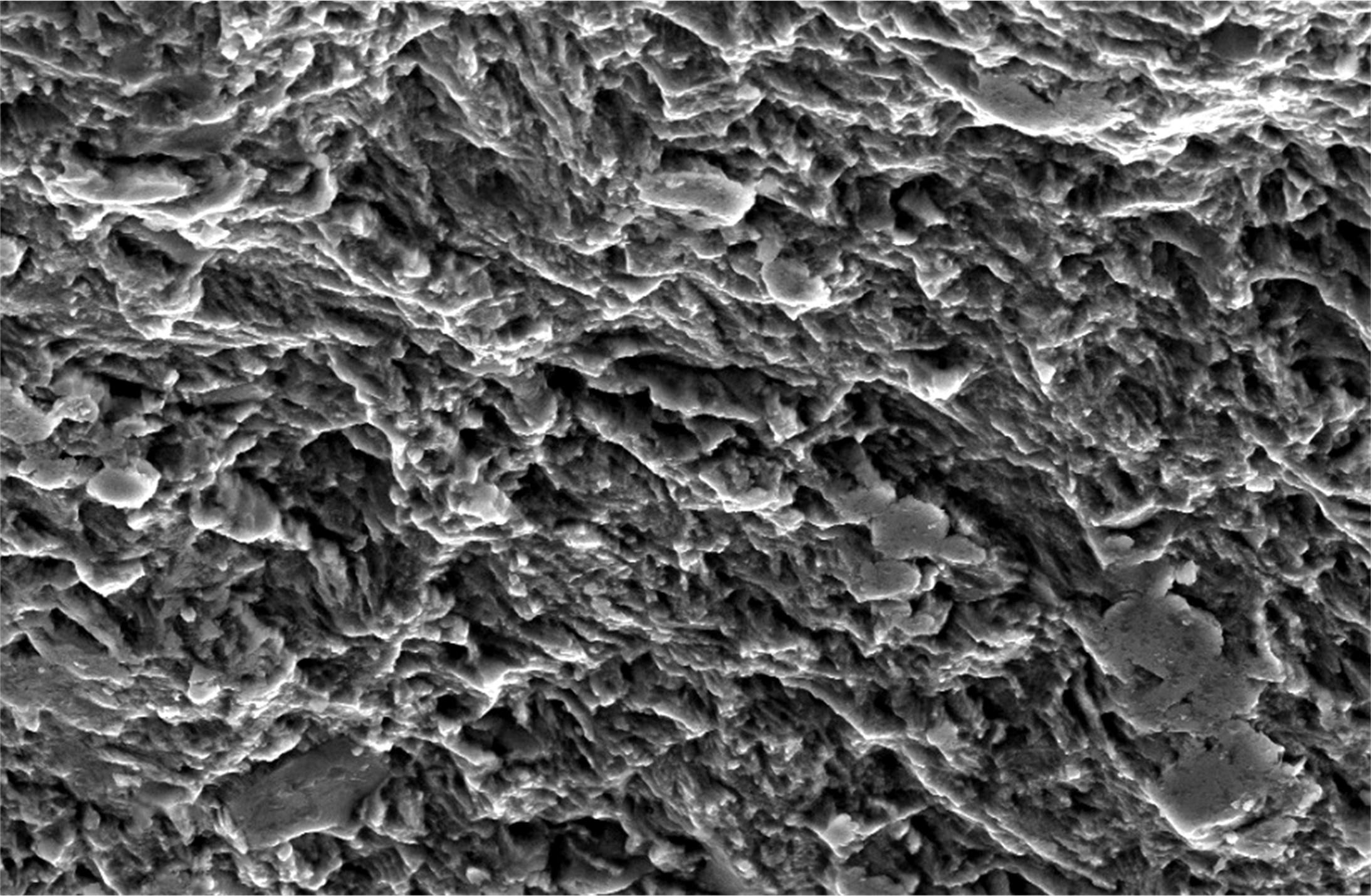

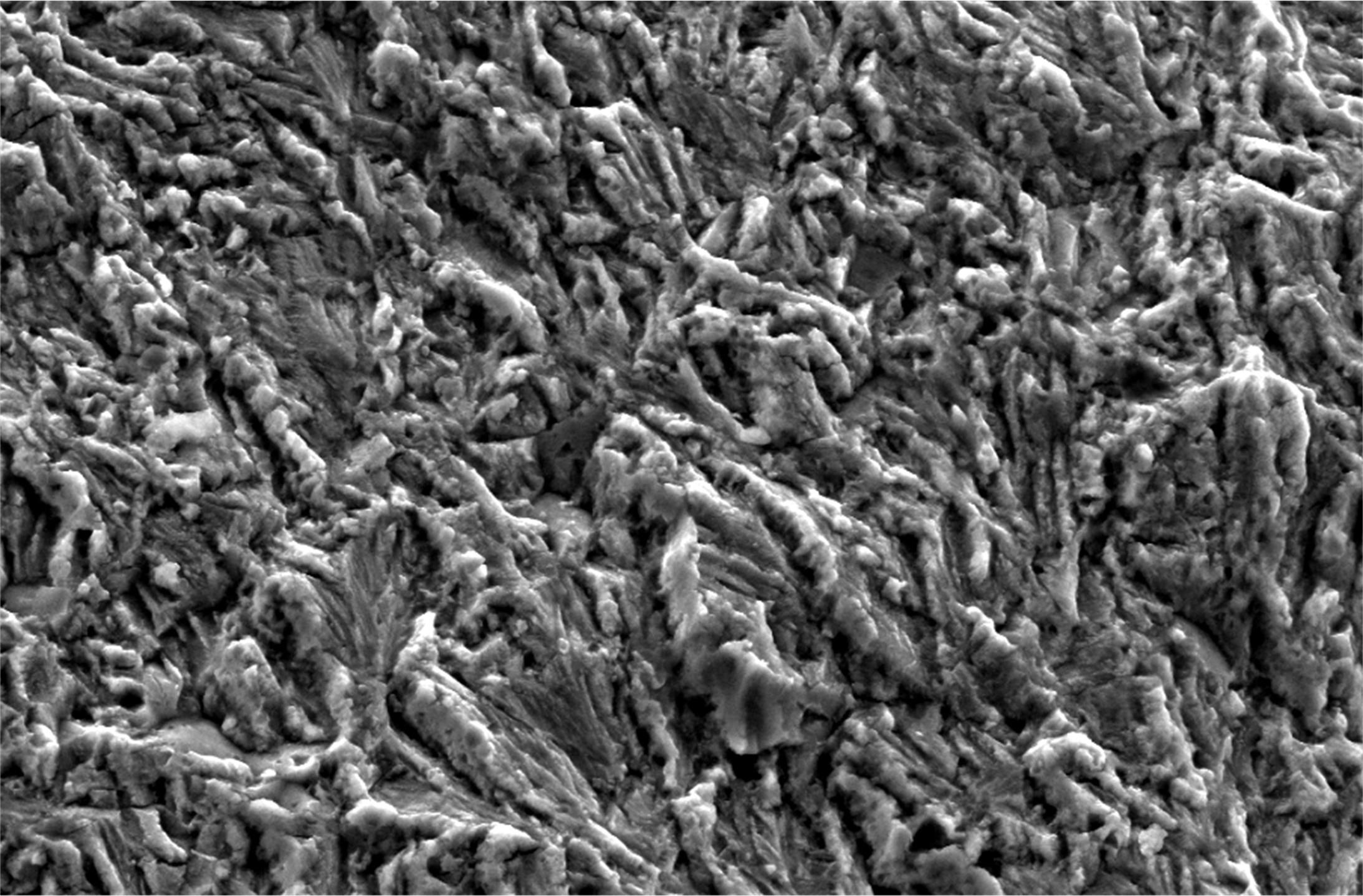

双相正时套筒链的动力学仿真分析及磨损失效

- 吉林大学 机械与航空航天工程学院,长春 130022

Dynamic simulation analysis and wear failure of dual-phase timing bush chain

Ya-bing CHENG( ),Lu-xiang CHEN,Ping-yu GE,Ze-yu YANG,Peng-yu CAO

),Lu-xiang CHEN,Ping-yu GE,Ze-yu YANG,Peng-yu CAO

- College of Mechanical and Aerospace Engineering,Jilin University,Changchun 130022,China

摘要:

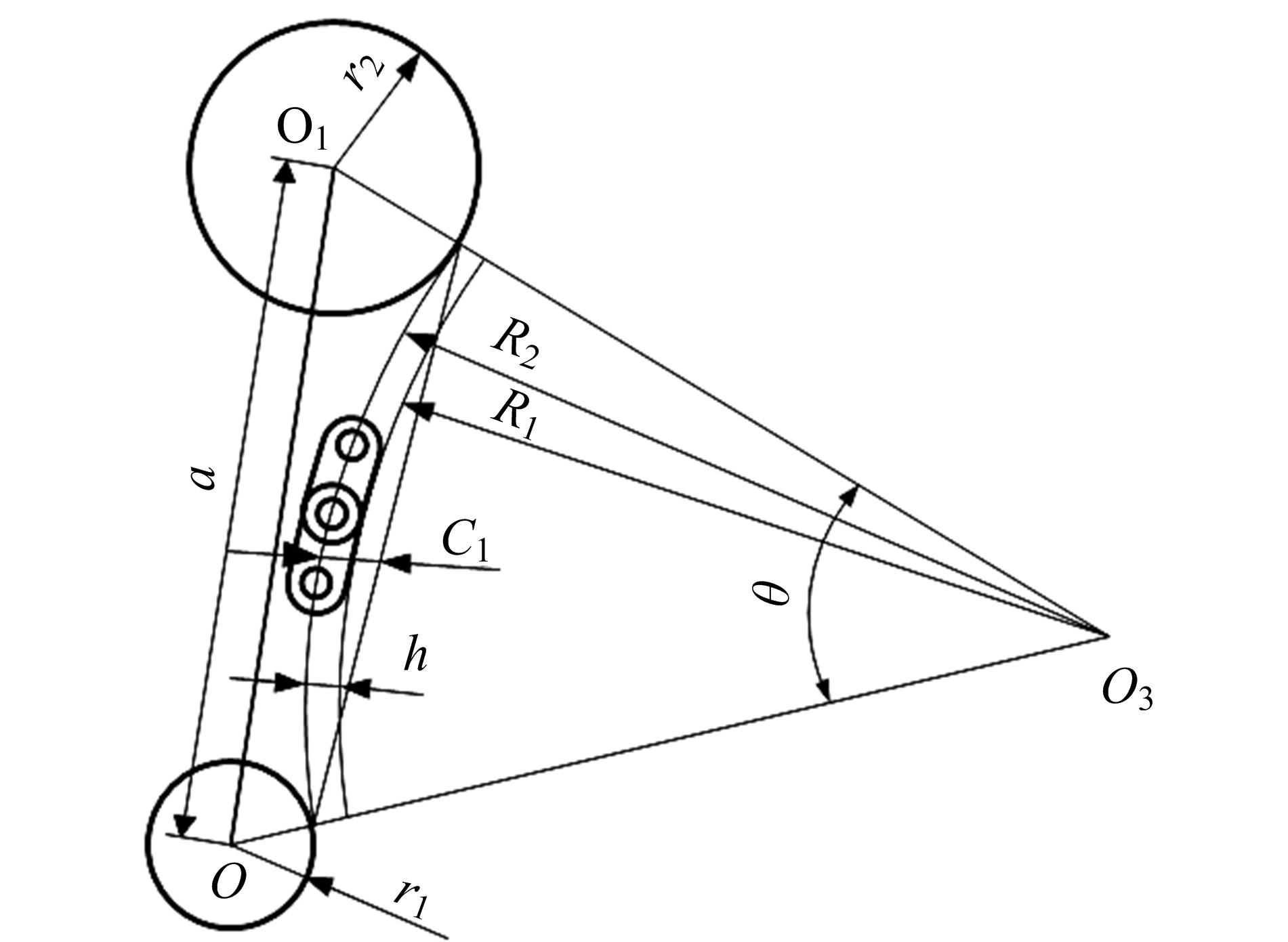

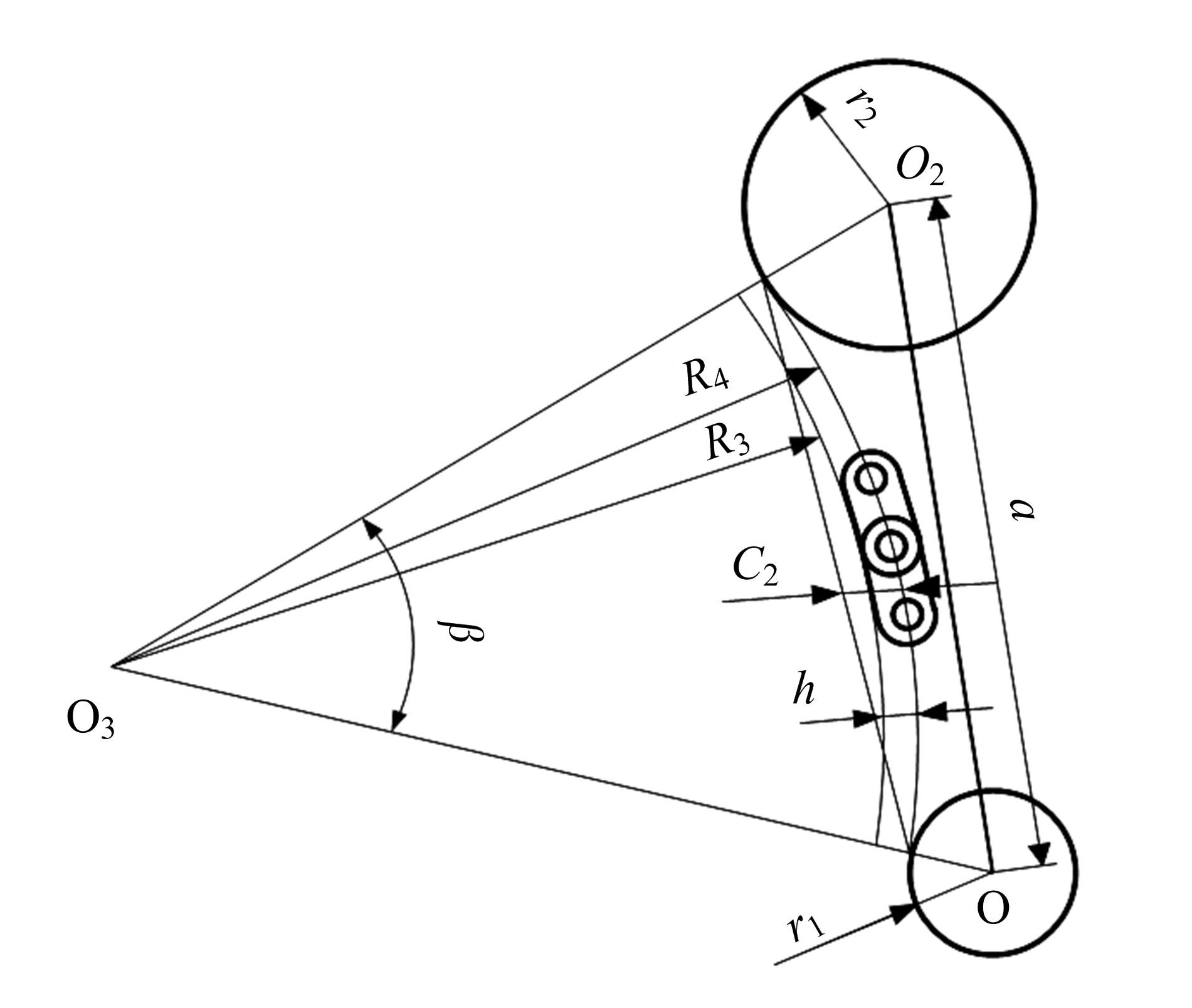

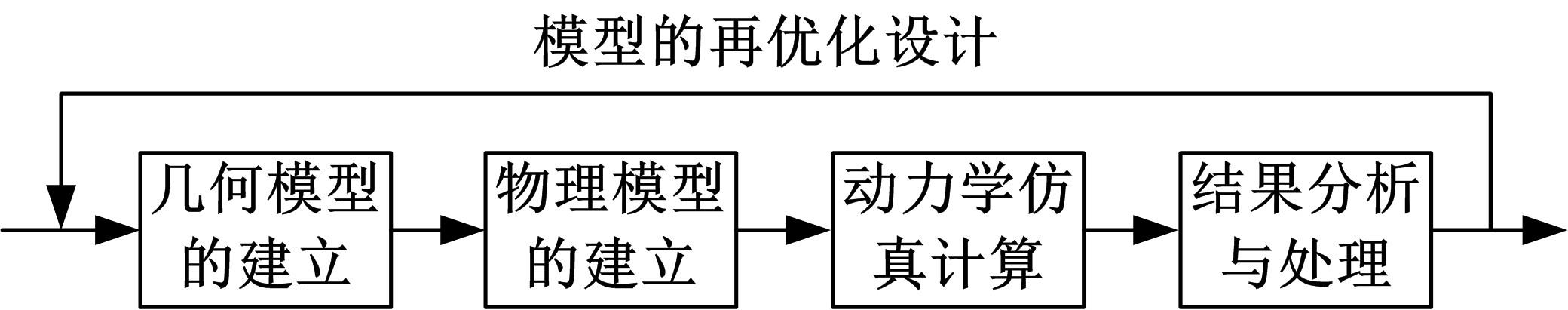

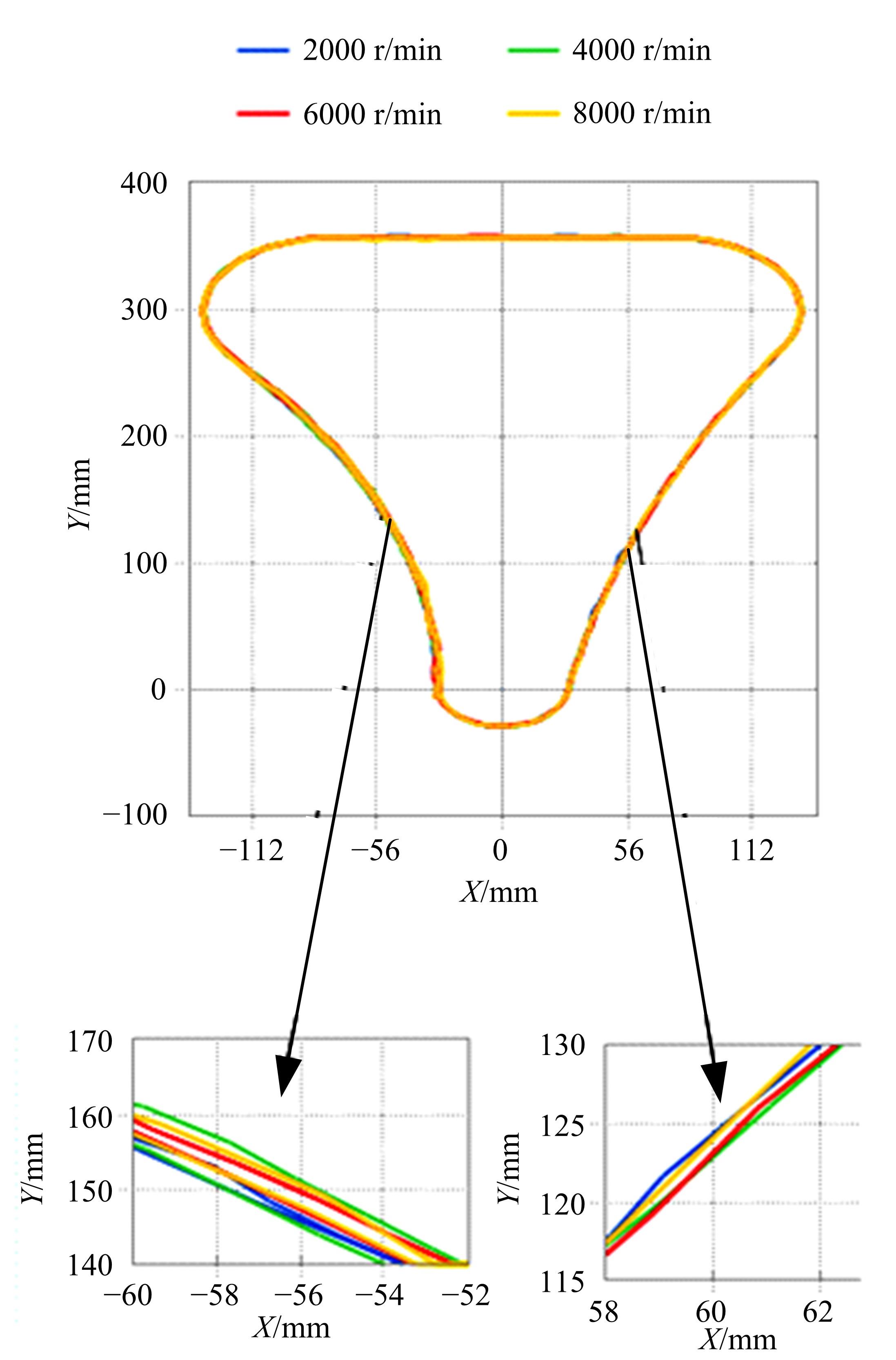

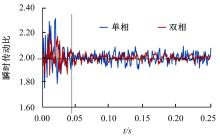

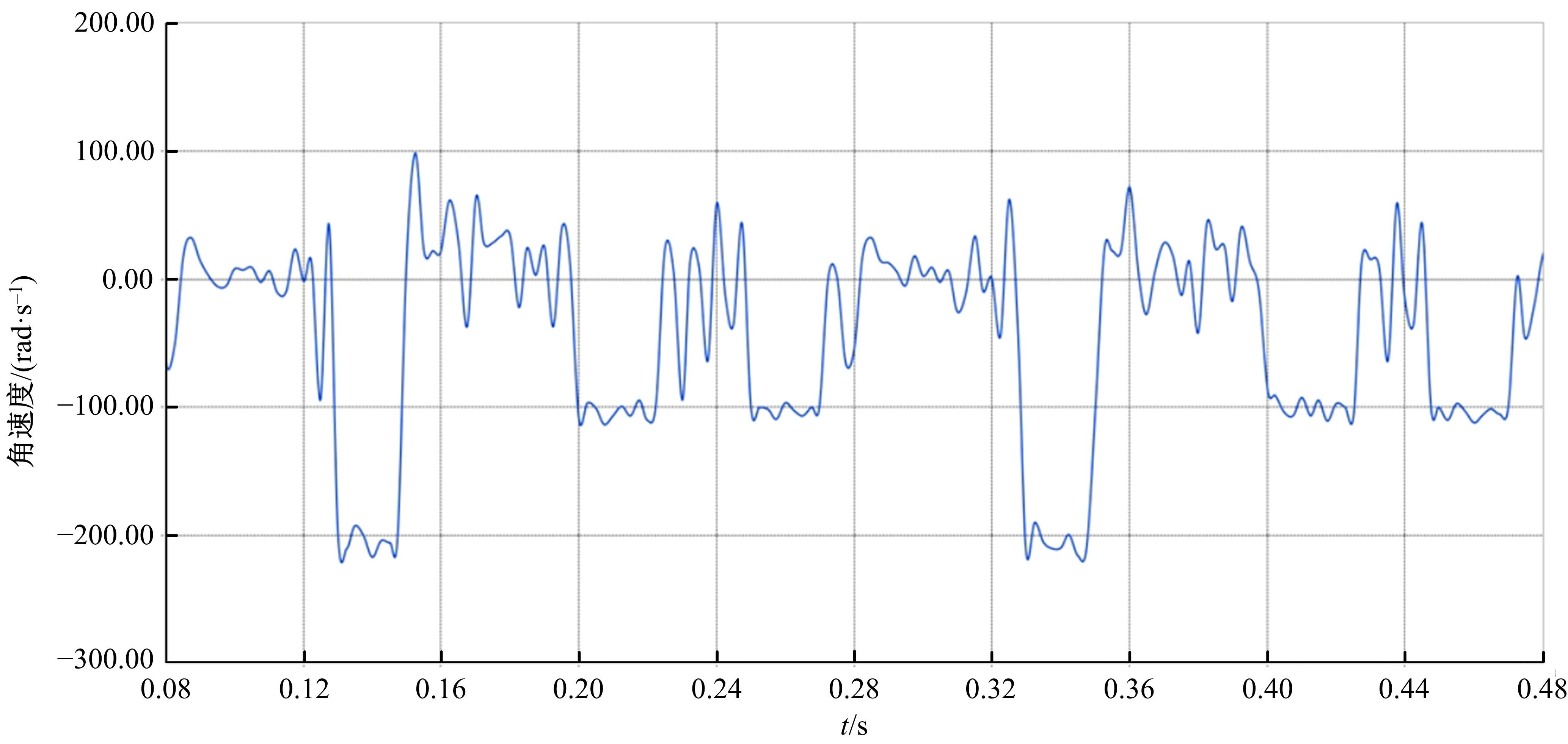

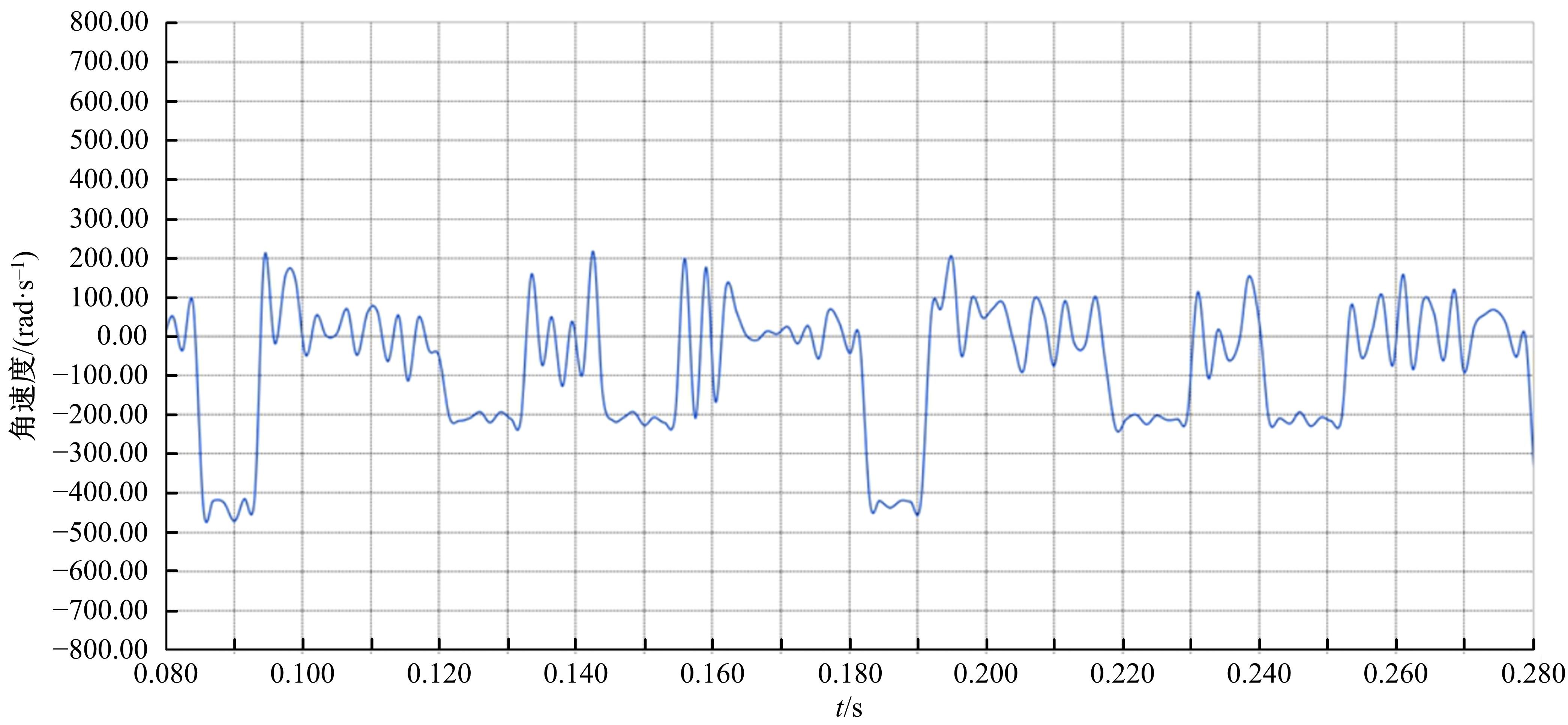

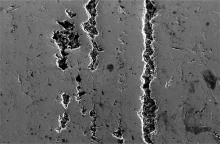

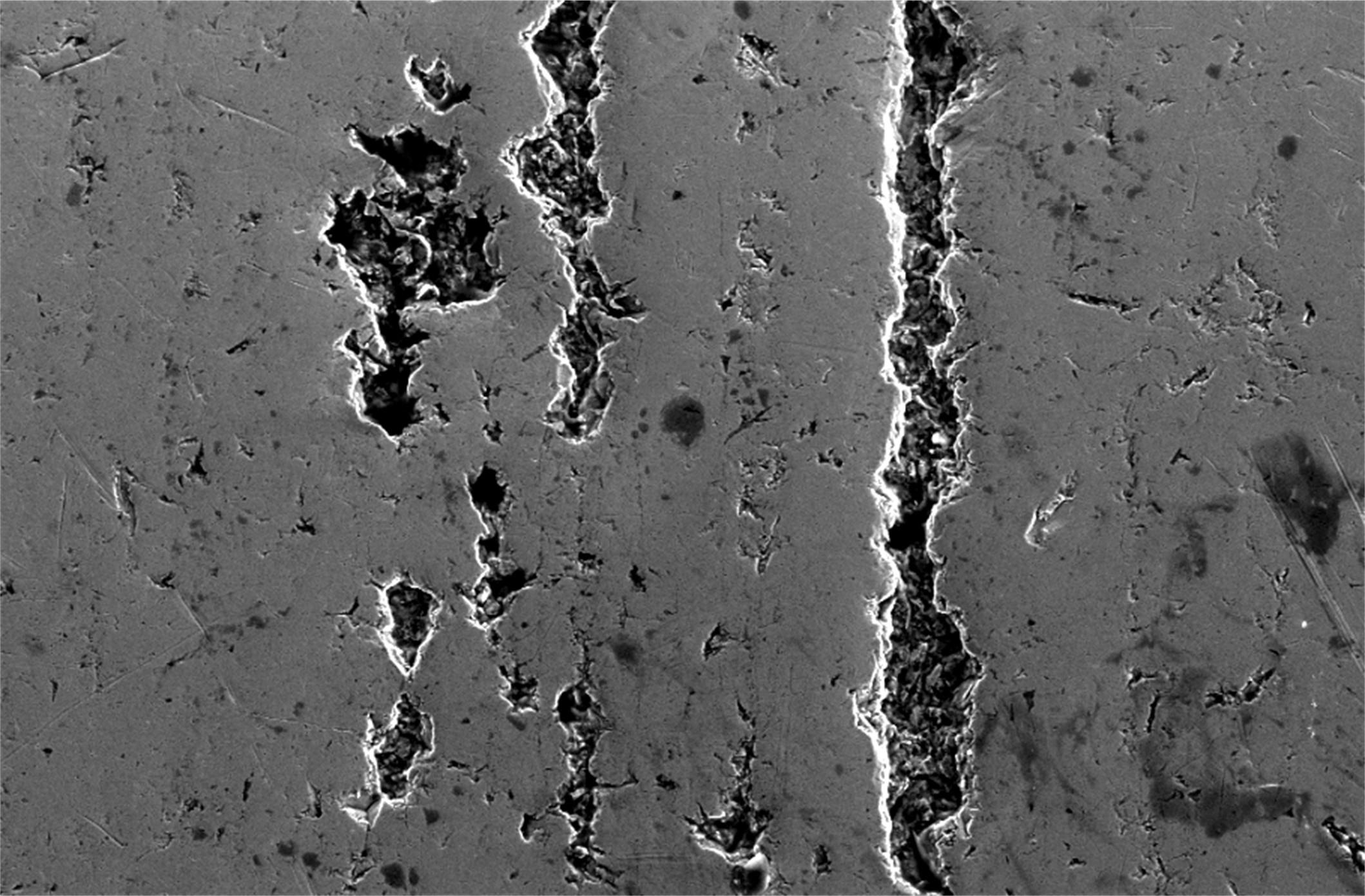

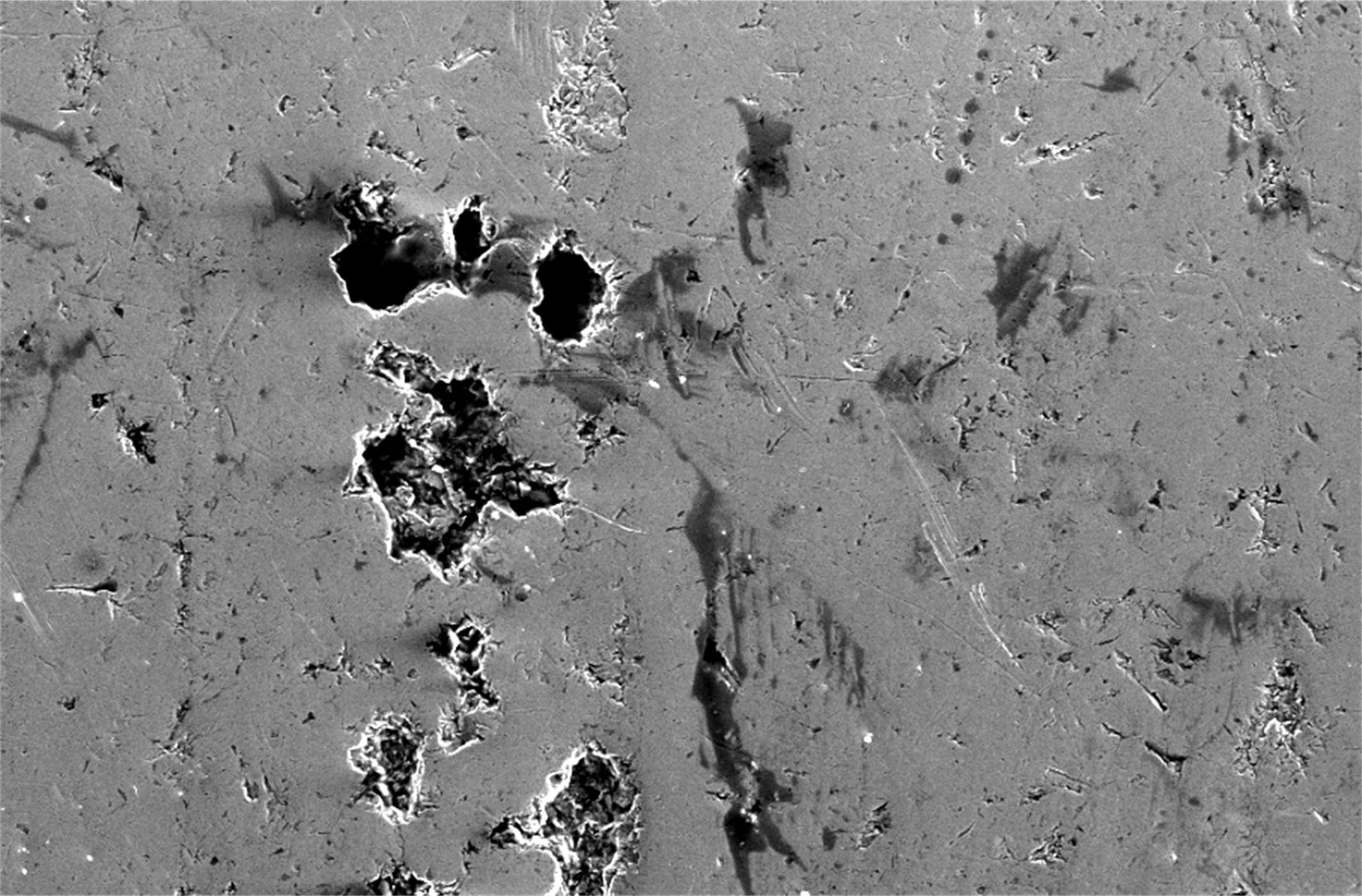

为了减小汽车发动机正时链传动系统的传动误差,提高发动机的传动负载,提出了一种新型双相正时套筒链传动系统。这种新型双相链传动系统通过改变每相链轮的位置,有效地减少了套筒与链轮接触所产生的振动,在一定程度上抑制了传动噪声。通过对所设计的双相正时套筒链传动系统进行动力学仿真分析,选取部分动态特性参数与单相系统进行对比,结果表明该双相正时套筒链传动系统的传动性能优于单相正时系统。磨损失效研究为进一步分析正时套筒链传动系统的使用寿命提供了一定的科学依据。

中图分类号:

- TH132.45

| 1 | 孟繁忠, 李宝林, 吕翔, 等. 汽车发动机正时链系统设计方法[J]. 哈尔滨工业大学学报, 2009, 41(5): 121-124. |

| Meng Fan-zhong, Li Bao-lin, Lv Xiang, et al. Design method of timing chain system for automotive engine[J]. Journal of Harbin Institute of Technology, 2009, 41(5): 121-124. | |

| 2 | Xi J X, Feng Z M, Wang G Q, et al. Vibration and noise source identification methods for a diesel engine[J]. Journal of Mechanical Science and Technology, 2015, 29(1): 181-189. |

| 3 | 王淑坤, 孟繁忠, 程亚兵, 等. 汽车发动机正时链的多冲特性[J]. 哈尔滨工业大学学报, 2005, 37(4): 495-497. |

| Wang Shu-kun, Meng Fan-zhong, Cheng Ya-bing, et al. Multicycle impact property of automotive engine timing chain[J]. Journal of Harbin Institute of Technology, 2005, 37(4): 495-497. | |

| 4 | Cheng Y, Yin S, Wang X, et al. Design and analysis of double-side meshing and dual-phase driving timing silent chain system[J]. Journal of Mechanical Engineering, 2016, 62(2): 127-136. |

| 5 | Cheng Y B, Yin S B, Meng C H, et al. Design and analysis of engine timing silent chain system[J]. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 2015, 230(13): 2225-2234. |

| 6 | Cheng Y B, Wang X P, Liu H, et al. Research on multi-variation coupling effect of heart-shaped dual phase Hy-Vo silent chain system[J]. Advances in Engineering Software, 2017, 107: 1-6. |

| 7 | Cheng Y, Wang Y, Li L, et al. Design method of dual phase Hy-Vo silent chain transmission system[J]. Journal of Mechanical Engineering, 2015, 61(4): 237-246. |

| 8 | 白永新. 回转疲劳试验台齿形链传动系统设计与动力学分析[D]. 长春: 吉林大学机械与航空航天学院, 2019. |

| Bai Yong-xin. Design and dynamic analysis of toothed chain drive system on rotary fatigue test bench[D]. Changchun: College of Mechanical Engineering and Aeronautics and Astronautics, Jilin University, 2019. | |

| 9 | 韩炜. 正时齿形链磨损与回转疲劳特性试验研究[D]. 长春: 吉林大学物理学院, 2018. |

| Han Wei. Experimental study on the wear and swing fatigue characteristics of timing toothed chains[D]. Changchun: School of Physics, Jilin University, 2018. | |

| 10 | 范成岩, 许树新, 王洪军, 等. 三轴正时链系统的磨损及其限定条件[J]. 吉林大学学报:工学版, 2017, 47(1): 122-128. |

| Fan Cheng-yan, Xu Shu-xin, Wang Hong-jun, et al. Wear and conditioning of the three-axis timing chain system[J]. Journal of Jilin University (Engineering and Technology Edition), 2017, 47(1): 122-128. | |

| 11 | Yu Z, Shao L T, Zhang C, et al. Numerical and experimental investigation on dynamic performance of bump foil journal bearing based on journal orbit[J]. Chinese Journal of Aeronautics, 2021, 34(2): 586-600. |

| 12 | Zhou Y, Xing T, Song Y, et al. Digital-twin-driven geometric optimization of centrifugal impeller with free-form blades for five-axis flank milling[J]. Journal of Manufacturing Systems, 2021, 58(B): 22-35. |

| [1] | 张龙,徐天鹏,王朝兵,易剑昱,甄灿壮. 基于卷积门控循环网络的齿轮箱故障诊断[J]. 吉林大学学报(工学版), 2022, 52(2): 368-376. |

| [2] | 郑伟,孙见君,马晨波,於秋萍,张玉言,牛韬. 汽车轮毂加工夹具的研究现状及展望[J]. 吉林大学学报(工学版), 2022, 52(1): 25-36. |

| [3] | 田晓超,王海刚,王虎,王志聪,赵剑,杨志刚,吴越. 悬臂式压电振子宽频发电装置设计及测试[J]. 吉林大学学报(工学版), 2021, 51(6): 1953-1958. |

| [4] | 陈魏,雷雨龙,李兴忠,付尧,扈建龙,侯利国. 低速工况下渐开线圆柱直齿轮齿面粘着磨损计算[J]. 吉林大学学报(工学版), 2021, 51(5): 1628-1634. |

| [5] | 胡晶,李聪,张邦成,乔晓利,张心明,周笑平. 考虑离心膨胀的双级串联轴承油膜刚度和阻尼[J]. 吉林大学学报(工学版), 2021, 51(5): 1601-1611. |

| [6] | 姚宗伟,高旭东,刘刚,毕秋实. 基于数值仿真的大型塔式磨机工作特性分析[J]. 吉林大学学报(工学版), 2021, 51(5): 1642-1650. |

| [7] | 李晓韬,任金鹏,李晓旭,杨航. 双压电振子反相模态驱动的直线驱动器机理[J]. 吉林大学学报(工学版), 2021, 51(2): 468-471. |

| [8] | 侯才生,刘涛,郭李先. 一种新型变壁厚涡旋型线的构建理论[J]. 吉林大学学报(工学版), 2020, 50(5): 1627-1634. |

| [9] | 程功,肖科,王家序,蒲伟,韩彦峰. 混合润滑状态下齿轮接触刚度[J]. 吉林大学学报(工学版), 2020, 50(2): 494-503. |

| [10] | 毛艳,成凯. 基于Hopfield神经网络的单缸插销式伸缩臂伸缩路径优化[J]. 吉林大学学报(工学版), 2020, 50(1): 53-65. |

| [11] | 郭震,于红英,滑忠鑫,赵娣. 刚性折纸机构运动分析及折叠过程仿真[J]. 吉林大学学报(工学版), 2020, 50(1): 66-76. |

| [12] | 贾富淳,孟宪皆,雷雨龙. 基于多目标遗传算法的二自由度动力吸振器优化设计[J]. 吉林大学学报(工学版), 2019, 49(6): 1969-1976. |

| [13] | 谢志江,王昆,皮阳军,吴小勇,郭映位. 新的6⁃PSS型并联机构正向运动学求解方法[J]. 吉林大学学报(工学版), 2019, 49(6): 1977-1985. |

| [14] | 曹恩国,刘坤,吉硕,孙震源,徐洪伟,骆星吉. 减重站起康复训练系统机械结构设计与优化[J]. 吉林大学学报(工学版), 2019, 49(5): 1558-1566. |

| [15] | 李俊烨,刘洋,卢慧,孟文卿,杨兆军,张心明. 基于分子动力学的磨粒微切削单晶铁数值分析[J]. 吉林大学学报(工学版), 2019, 49(5): 1567-1574. |

|

||