吉林大学学报(工学版) ›› 2021, Vol. 51 ›› Issue (6): 1953-1958.doi: 10.13229/j.cnki.jdxbgxb20200596

• 车辆工程·机械工程 • 上一篇

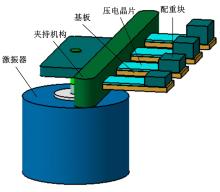

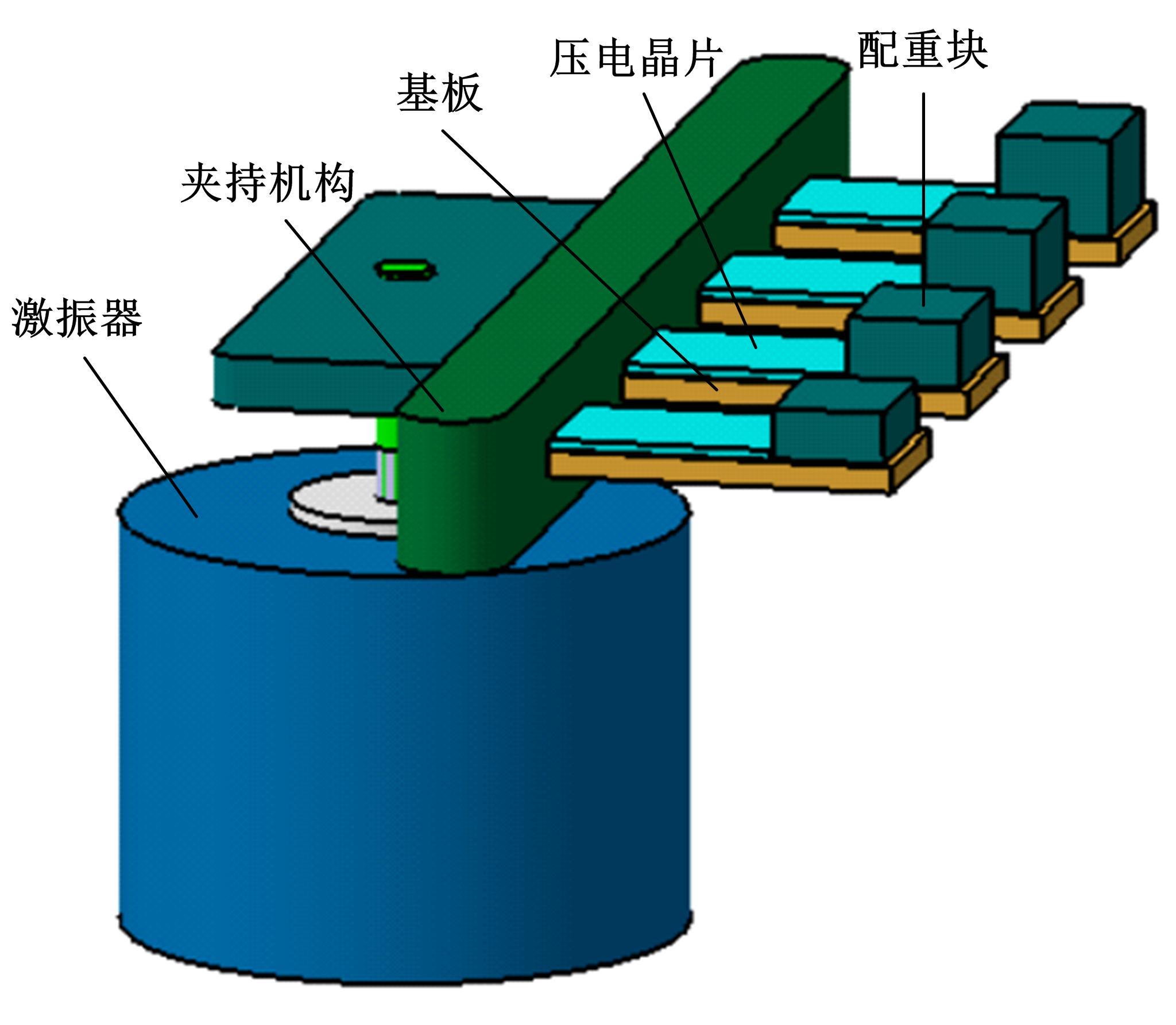

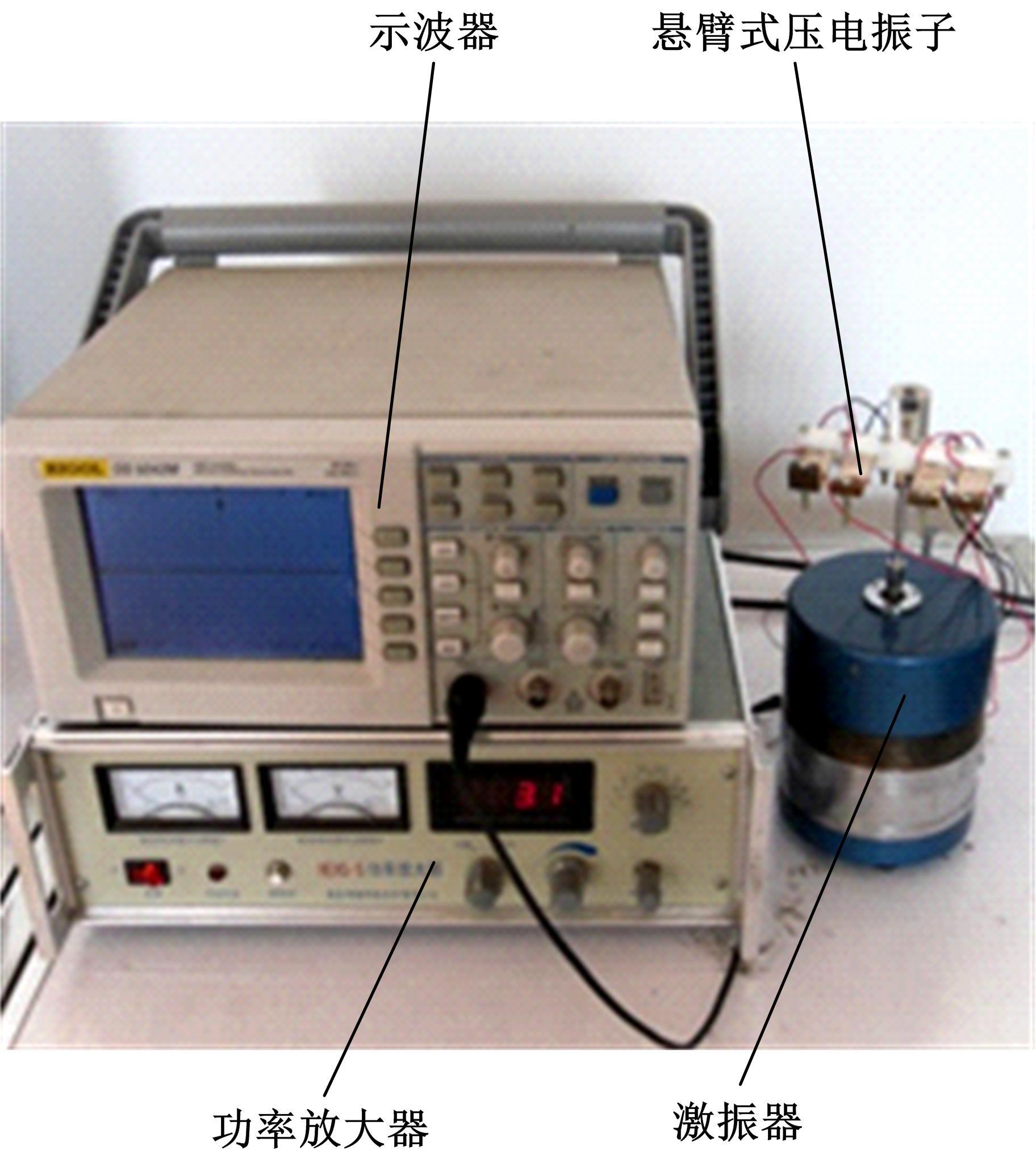

悬臂式压电振子宽频发电装置设计及测试

田晓超1,2( ),王海刚1,2,王虎1,2,王志聪1,2,赵剑2,杨志刚3(

),王海刚1,2,王虎1,2,王志聪1,2,赵剑2,杨志刚3( ),吴越3

),吴越3

- 1.长春大学 机械与车辆工程学院,长春 130022

2.长春大学 吉林省人体健康状态辨识与机能增强重点实验室,长春 130022

3.吉林大学 机械与航空航天工程学院,长春 130022

Design and test of broadband power generation device with cantilever piezoelectric vibrator

Xiao-chao TIAN1,2( ),Hai-gang WANG1,2,Hu WANG1,2,Zhi-cong WANG1,2,Jian ZHAO2,Zhi-gang YANG3(

),Hai-gang WANG1,2,Hu WANG1,2,Zhi-cong WANG1,2,Jian ZHAO2,Zhi-gang YANG3( ),Yue WU3

),Yue WU3

- 1.Institute of Mechanical and Vehicle Engineering,Changchun University,Changchun 130022,China

2.Jilin Provincial Key Laboratory of Human Health Status Identification and Function Enhancement,Changchun University,Changchun 130022,China

3.College of Mechanical and Aerospace Engineering,Jilin University,Changchun 130022,China

摘要:

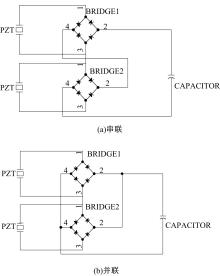

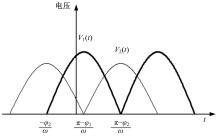

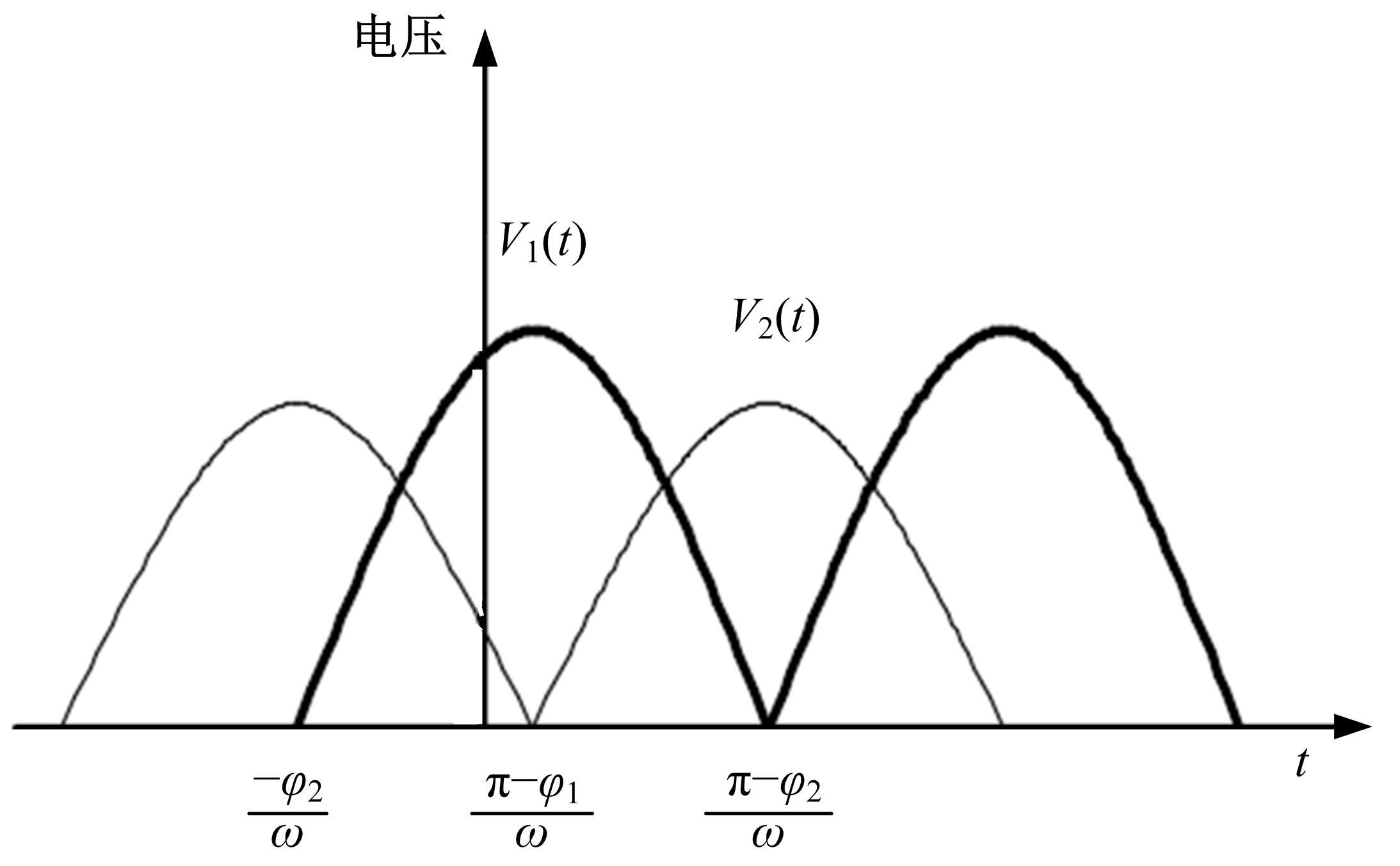

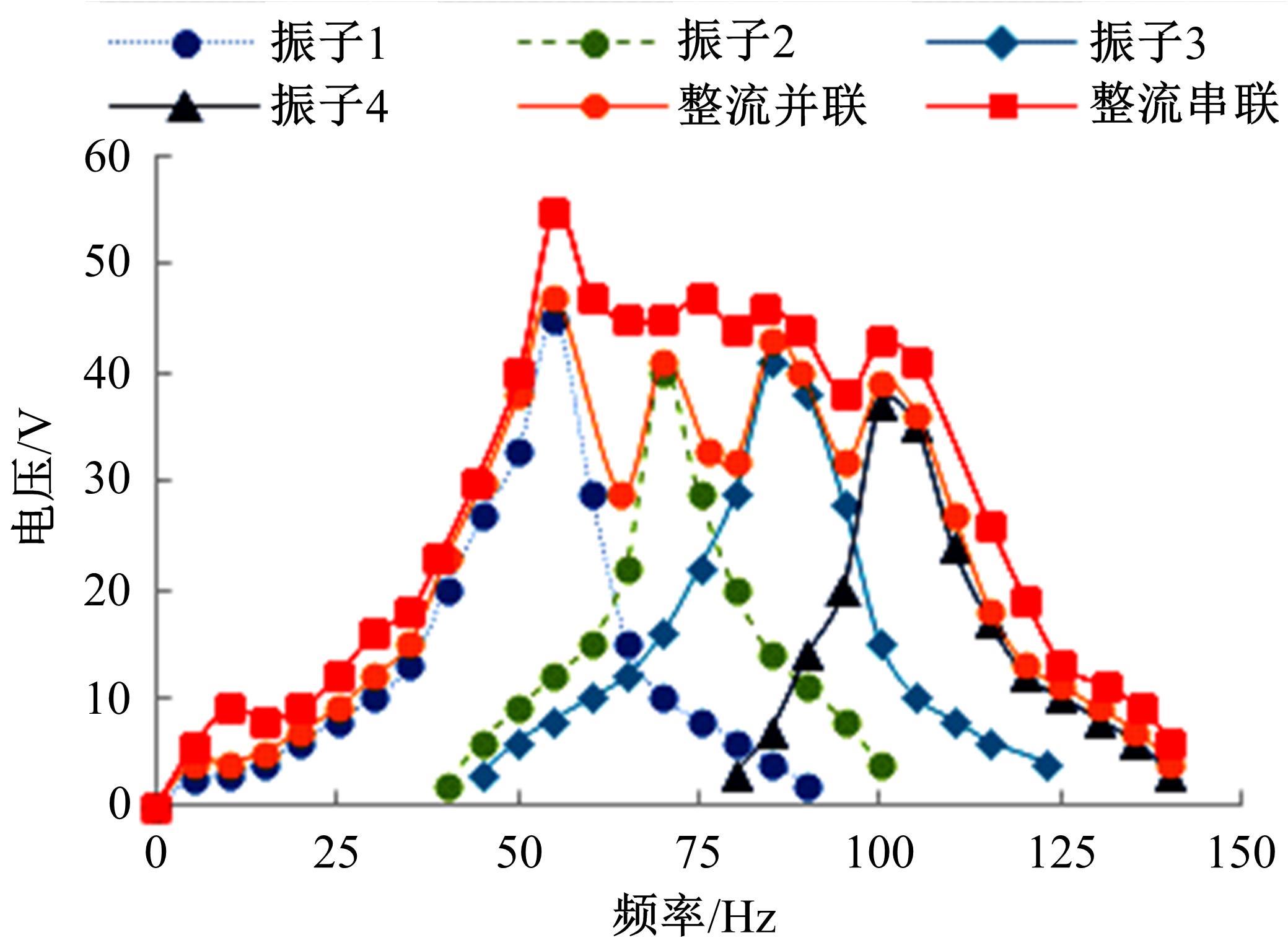

为了提高压电材料的发电量和发电效率,设计了一种悬臂式压电振子宽频发电装置。首先,对单个压电振子进行电压输出和相频特性分析,得出影响电压输出的影响因素。然后,对双压电振子整流后串/并联进行电压输出特性分析,当两压电振子串/并联整流后,输出的电压为两个压电振子输出电压的较大值且频宽增大。最后,对4个压电振子进行发电实验测试。结果表明,当输出电压为30 V时,单个压电振子的有效发电频宽约为10 Hz左右,经整流后串/并联的4个压电振子串联有效发电频率为44.5~121.3 Hz,宽度约为77 Hz,有效提高了发电频宽,该装置可应用在狭窄空间自适应供电。

中图分类号:

- TM619

| 1 | 曾平,刘艳涛,吴博达,等. 一种新型压电式无线发射装置[J]. 吉林大学学报:工学版,2006,36(): 78-82. |

| Zeng Ping, Liu Yan-tao, Wu Bo-da, et al. A novel wireless electropult powered by piezoelectricity[J]. Journal of Jilin University (Engineering and Technology Edition), 2006, 36(Sup.2): 78-82. | |

| 2 | 吴博达,鄂世举,杨志刚,等. 压电驱动与控制技术的发展与应用[J]. 机械工程学报,2003,39(10): 79-85. |

| Wu Bo-da, Shi-ju E, Yang Zhi-gang, et al. Development and application of piezoelectric actuation and control[J]. Journal of Mechanical Engineering, 2003, 39(10): 79-85. | |

| 3 | Lewandowski B E, Kilgore K L, Gustafson K J. Design considerations for an implantable, muscle powered piezoelectric system for generating electrical power[J]. Annals of Biomedical Engineering, 2007, 35(4): 631-641. |

| 4 | Roundy S, Leland E S, Baker J. Improving power output for vibration-based energy scavengers[J]. IEEE Pervasive Computing, 2005, 4(1): 28-36. |

| 5 | Allameh S M, Akogwu O, Collinson M, et al. Piezoelectric generators for biomedical and dental applications: effects of cyclic loading[J]. Journal of Materials Science Materials in Medicine, 2007, 18(1): 39-45. |

| 6 | Ferrari M, Ferrari V, Guizzetti M, et al. Piezoelectric multifrequency energy converter for power harvesting in autonomous microsystems[J]. Sensors and Actuators A Physical, 2008, 142(1): 329-335. |

| 7 | Aktakka E E, Kim H, Najafi K. Energy scavenging from insect flight[J]. Journal of Micromechanics and Microengineering, 2011, 21(9):No.095016. |

| 8 | Kymissis J, Kendall C, Paradiso J A, et al. Parasitic power harvesting in shoes[C]∥Digest of Papers. Second International Symposium on Wearable Computers, Pittsburgh, PA, USA, 1998: 132-139. |

| 9 | Lefeuvre E, Badel A, Richard C, et al. Energy harvesting using piezoelectric materials: case of random vibrations[J]. Journal of Electroceramics, 2007, 19(4): 349-355. |

| 10 | Kim C, Iii D L, Wu C C, et al. Piezoelectric rotary actuator driven devices and applications[J]. Ferroelec trics, 2002, 273(1): 59-64. |

| 11 | Minazara E, Vasic D, Costa F, et al. Piezoelectric diaphragm for vibration energy harvesting[J]. Ultrasonics, 2006, 44(Sup.1): e699-e703. |

| 12 | Roundy S, Leland E S, Baker J. Improving power output for vibration-based energy scavengers[J]. IEEE Pervasive Computing, 2005, 4(1): 28-36. |

| 13 | 闫世伟,杨志刚,菅新乐. 压电式胎压报警器供电装置的发电特性[J]. 吉林大学学报:工学版,2010,40(5): 1268-1272. |

| Yan Shi-wei, Yang Zhi-gang, Jian Xin-le. Power performance of a piezoelectric generator for tire pressure monitoring sensor[J]. Journal of Jilin University (Engineering and Technology Edition), 2010, 40(5): 1268-1272. | |

| 14 | Yayla S, Aya S, Oru M. A case study on piezoelectric energy harvesting with using vortex generator plate modeling for fluids[J]. Renewable Energy, 2020, 157: 1243-1253. |

| 15 | 程光明,庞建志,唐可洪,等. 压电陶瓷发电能力测试系统的研制[J]. 吉林大学学报:工学版,2007,37(2): 367-371. |

| Cheng Guang-ming, Pang Jian-zhi, Tang Ke-hong, et al. Development of measuring system for electricity generating capacity of piezoelectric ceramics[J]. Journal of Jilin University (Engineering and Technology Edition), 2007, 37(2): 367-371. | |

| 16 | 单小彪,袁江波,谢涛,等. Cymbal压电发电机系统[J]. 吉林大学学报:工学版,2011,41(5): 1331-1334. |

| Shan Xiao-biao, Yuan Jiang-bo, Xie Tao, et al. Cymbal piezoelectric generator system[J]. Journal of Jilin University (Engineering and Technology Edition), 2011, 41(5): 1331-1334. | |

| 17 | 唐可洪,阚君武,任玉,等. 压电发电装置的功率分析与试验[J]. 吉林大学学报:工学版,2009,39(6): 1550-1553. |

| Tang Ke-hong, Kan Jun-wu, Ren Yu, et al. Power analysis and test of piezoelectric generator[J]. Journal of Jilin University (Engineering and Technology Edition), 2009, 39(6): 1550-1553. | |

| 18 | 刘行尚. 用于胎压报警器多晶片压电自供电装置的设计与试验[D]. 长春:吉林大学机械与航空航天工程学院,2015. |

| Liu Xing-shang. Design and experiment of multi-chip piezoelectric self-powered device in tire pressure monitoring system[D]. Changchun: School of Mechanical and Aerospace Engineering, Jilin University, 2015. |

| [1] | 胡晶,李聪,张邦成,乔晓利,张心明,周笑平. 考虑离心膨胀的双级串联轴承油膜刚度和阻尼[J]. 吉林大学学报(工学版), 2021, 51(5): 1601-1611. |

| [2] | 姚宗伟,高旭东,刘刚,毕秋实. 基于数值仿真的大型塔式磨机工作特性分析[J]. 吉林大学学报(工学版), 2021, 51(5): 1642-1650. |

| [3] | 陈魏,雷雨龙,李兴忠,付尧,扈建龙,侯利国. 低速工况下渐开线圆柱直齿轮齿面粘着磨损计算[J]. 吉林大学学报(工学版), 2021, 51(5): 1628-1634. |

| [4] | 刁延松,郭荡,屠康,焦圣伦,刘芸,刘秀丽. 新型异形钢管混凝土柱⁃钢梁节点抗震性能试验[J]. 吉林大学学报(工学版), 2021, 51(5): 1724-1733. |

| [5] | 李晓韬,任金鹏,李晓旭,杨航. 双压电振子反相模态驱动的直线驱动器机理[J]. 吉林大学学报(工学版), 2021, 51(2): 468-471. |

| [6] | 侯才生,刘涛,郭李先. 一种新型变壁厚涡旋型线的构建理论[J]. 吉林大学学报(工学版), 2020, 50(5): 1627-1634. |

| [7] | 程功,肖科,王家序,蒲伟,韩彦峰. 混合润滑状态下齿轮接触刚度[J]. 吉林大学学报(工学版), 2020, 50(2): 494-503. |

| [8] | 毛艳,成凯. 基于Hopfield神经网络的单缸插销式伸缩臂伸缩路径优化[J]. 吉林大学学报(工学版), 2020, 50(1): 53-65. |

| [9] | 郭震,于红英,滑忠鑫,赵娣. 刚性折纸机构运动分析及折叠过程仿真[J]. 吉林大学学报(工学版), 2020, 50(1): 66-76. |

| [10] | 贾富淳,孟宪皆,雷雨龙. 基于多目标遗传算法的二自由度动力吸振器优化设计[J]. 吉林大学学报(工学版), 2019, 49(6): 1969-1976. |

| [11] | 谢志江,王昆,皮阳军,吴小勇,郭映位. 新的6⁃PSS型并联机构正向运动学求解方法[J]. 吉林大学学报(工学版), 2019, 49(6): 1977-1985. |

| [12] | 曹恩国,刘坤,吉硕,孙震源,徐洪伟,骆星吉. 减重站起康复训练系统机械结构设计与优化[J]. 吉林大学学报(工学版), 2019, 49(5): 1558-1566. |

| [13] | 李俊烨,刘洋,卢慧,孟文卿,杨兆军,张心明. 基于分子动力学的磨粒微切削单晶铁数值分析[J]. 吉林大学学报(工学版), 2019, 49(5): 1567-1574. |

| [14] | 张艳芹,冯雅楠,孔鹏睿,于晓东,孔祥滨. 基于热油携带的静压支承油膜温度场及试验[J]. 吉林大学学报(工学版), 2019, 49(4): 1203-1211. |

| [15] | 杨成,赵永胜,刘志峰,蔡力钢. 基于多尺度理论的栓接结合部动力学建模[J]. 吉林大学学报(工学版), 2019, 49(4): 1212-1220. |

|

||