吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (6): 1738-1745.doi: 10.13229/j.cnki.jdxbgxb.20220870

• 交通运输工程·土木工程 • 上一篇

蔗渣纤维表面改性及其沥青混合料路用性能

李祖仲1( ),李梦园1,刘卫东2(

),李梦园1,刘卫东2( ),庞萧萧3,唐豪1,张学磊4,马晨杨1

),庞萧萧3,唐豪1,张学磊4,马晨杨1

- 1.长安大学 材料科学与工程学院,西安 710064

2.广西交科集团有限公司 广西道路结构与材料重点实验室,南宁 530007

3.天津大学 材料科学与工程学院,天津 300072

4.中交天津港湾工程研究院有限公司,天津 300222

Surface modification of bagasse fibers and road performances of asphalt mixture

Zu-zhong LI1( ),Meng-yuan LI1,Wei-dong LIU2(

),Meng-yuan LI1,Wei-dong LIU2( ),Xiao-xiao PANG3,Hao Tang1,Xue-lei ZHANG4,Chen-yang MA1

),Xiao-xiao PANG3,Hao Tang1,Xue-lei ZHANG4,Chen-yang MA1

- 1.School of Materials Science and Engineering,Chang′an University,Xi′an 710064

2.Guangxi Transportation Science and Technology Co. ,Ltd. ,Nanning 530007 China

3.School of Materials Science and Engineering,Tianjin University,Tianjin 300072,China

4.Tianjin Port Engineering Institute Company Ltd. of CCCC,Tianjin 300222,China

摘要:

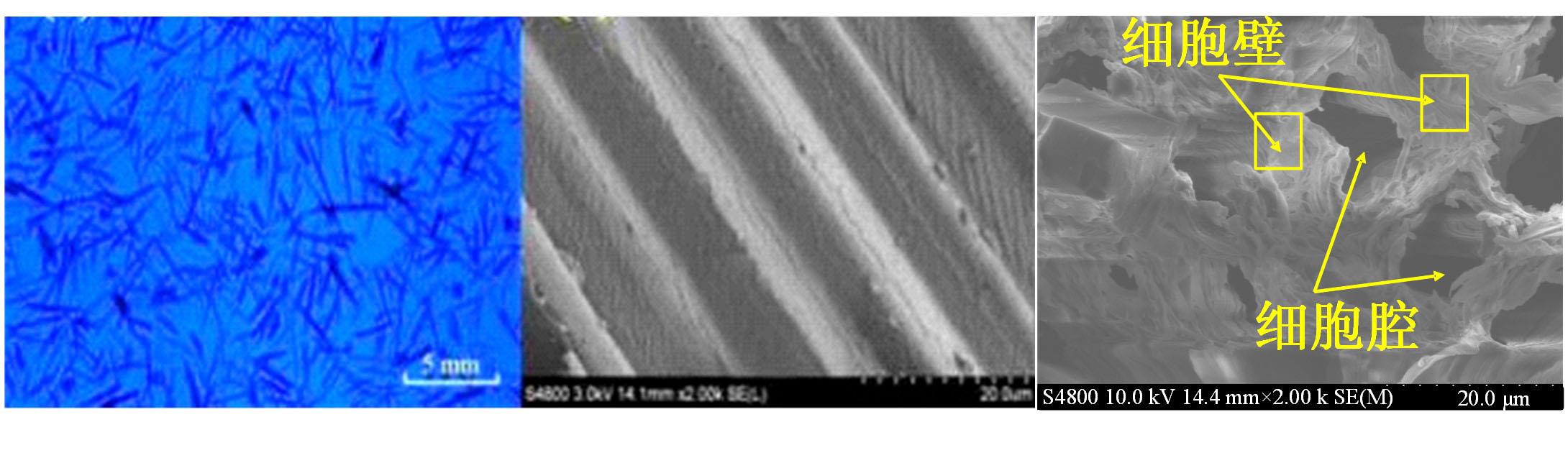

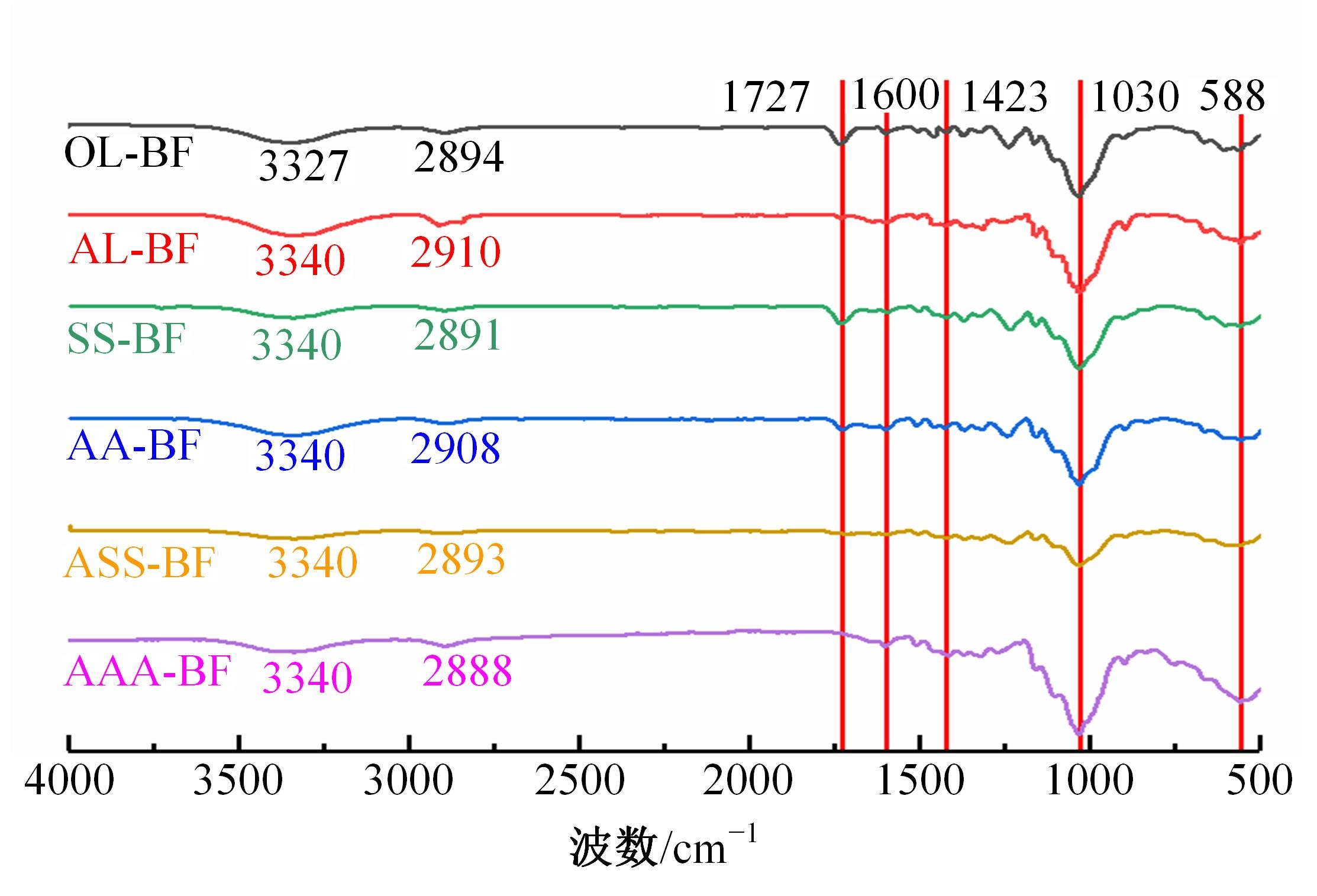

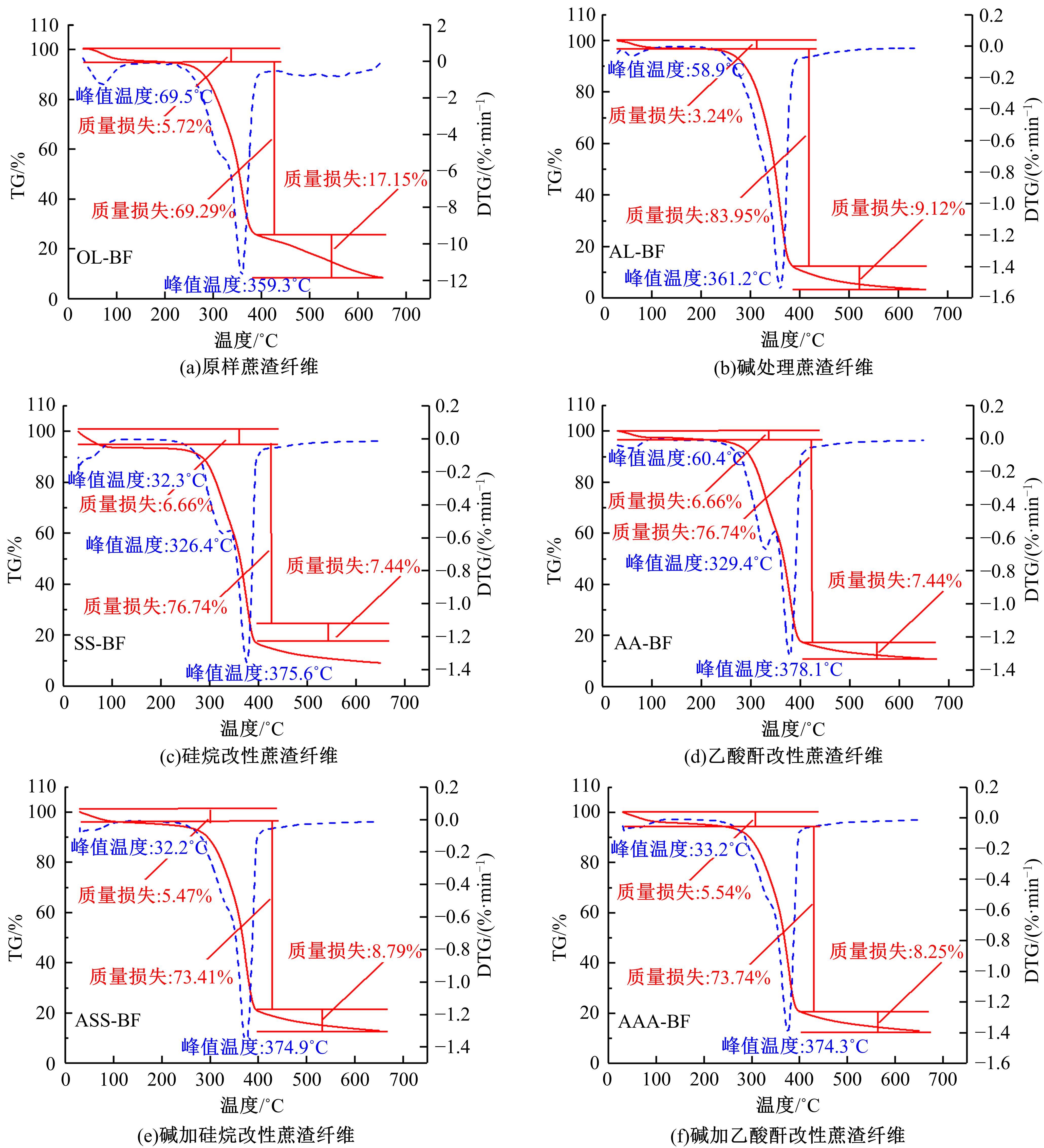

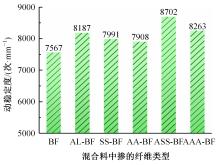

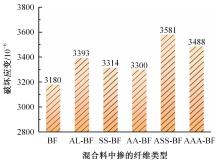

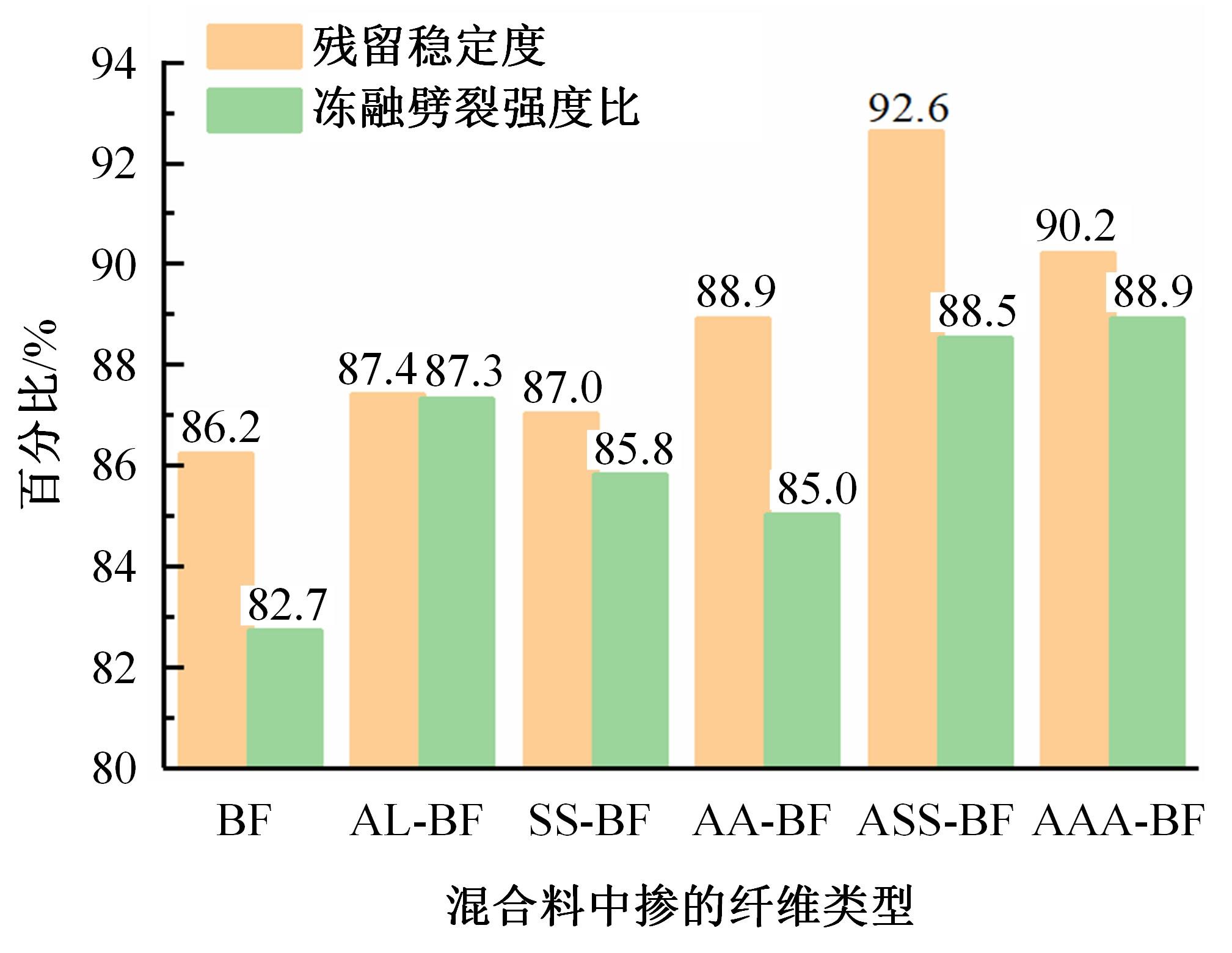

为了提升蔗渣纤维沥青混合料的路用性能,分别采用一步改性法(碱、硅烷、乙酸酐)和二步改性法(碱与硅烷、碱与乙酸酐)对蔗渣纤维进行表面化学处理,并依据规范测试纤维的基本技术性能。分别以红外光谱、扫描电镜及热重法研究其改性前、后结构变化和热降解特性,并以SMA-13沥青混合料为例,分析表面改性对蔗渣纤维沥青混合料路用性能的改善效果。结果表明:与未改性的蔗渣纤维相比较,改性后纤维的吸油率倍数可提高10.9%以上;碱、硅烷、乙酸酐都能降低纤维表面分子的极性,且二步法中碱与硅烷的改性方案能够最有效地去除纤维中的无定形成分,提高了纤维表面的疏水性和界面相容性;改性后纤维的热解温度升高,热解速率变小;改性后蔗渣纤维沥青混合料的动稳定度、低温弯曲破坏应变、浸水马歇尔试验残留稳定度和冻融劈裂抗拉强度比指标最大可分别提高15.0%、12.6%、7.5%和7.0%。整体而言,在5种改性方案中,碱与硅烷改性方案呈现出最优的改性效果。

中图分类号:

- U414

| 1 | 覃潇, 申爱琴, 郭寅川. 基于关联性的玄武岩纤维沥青胶浆及其混合料性能研究[J]. 材料导报, 2016, 30(12): 124-128, 152. |

| Qin Xiao, Shen Ai-qin, Guo Yin-chuan. Relevance research on road performance of basalt fiber reinforced bitumen mastics and corresponding mixture[J]. Journal of materials engineering, 2016, 30(12): 124-128, 152. | |

| 2 | 朱春凤, 程永春, 梁春雨, 等. 硅藻土-玄武岩纤维复合改性沥青混合料路用性能试验[J]. 吉林大学学报: 工学版, 2020, 50(1): 165-173. |

| Zhu Chun-feng, Cheng Yong-chun, Liang Chun-yu, et al. Road performance experiment of diatomite-basalt fiber composite modified asphalt mixture[J]. Journal of Jilin University (Engineering and Technology Edition), 2020, 50(1): 165-173. | |

| 3 | 宫亚峰, 申杨凡, 谭国金, 等. 不同孔隙率下纤维土无侧限抗压强度[J]. 吉林大学学报: 工学版, 2018, 48(3): 712-719. |

| Gong Ya-feng, Shen Yang-fan, Tan Guo-jin, et al. Uncofined compressive strength of fiber soil with different porosity[J]. Journal of Jilin University (Engineering and Technology Edition), 2018, 48(3): 712-719. | |

| 4 | 王玉林, 卢东, 徐宁. 木质素纤维对再生透水沥青混合料路用性能研究[J]. 公路, 2021, 66(2): 52-56. |

| Wang Yu-lin, Lu Dong, Xu Ning. Effect of lignin fiber on the road performance of recycled pervious asphalt mixtures[J]. Highway, 2021, 66(2): 52-56. | |

| 5 | Karahancer S S, Eriskin E, Sarioglu O, et al. Utilization of arundo donax in hot mix asphalt as a fiber[J]. Construction and Building Materials, 2016, 125: 981-986. |

| 6 | 李振霞, 陈渊召, 周建彬, 等. 玉米秸秆纤维沥青混合料路用性能及机理分析[J]. 中国公路学报, 2019, 32(2): 47-58. |

| Li Zhen-xia, Chen Yuan-zhao, Zhou Jian-bin, et al. Analysis of road performance and fiber mechanism for corn stalk fiber asphalt mixture[J]. China Journal of Highway and Transport, 2019, 32(2): 47-58. | |

| 7 | Zhang Z, Zhang H, Gao Y, et al. Laboratory evaluation of the effect of kapok fibers on the rheological and fatigue properties of bitumen[J]. Construction and Building Materials, 2021, 272: No.121819. |

| 8 | 程培峰, 王聪, 张开元, 等. 水稻秸秆纤维沥青胶浆流变性能影响因素研究[J]. 功能材料, 2021, 52(12): 12116-12123. |

| Cheng Pei-feng, Wang Cong, Zhang Kai-yuan, et al. Study on influencing factors of high and low temperature and rheological properties of rice straw fiber asphalt mortar[J]. Journal of Functional Materials, 2021, 52(12): 12116-12123. | |

| 9 | Li Z, Zhang X, Fa C, et al. Investigation on characteristics and properties of bagasse fibers: performances of asphalt mixtures with bagasse fibers[J]. Construction and Building Materials, 2020, 248: No. 118648. |

| 10 | Mansor S, Zainuddin N I, Aziz N A, et al. Sugarcane bagasse fiber-An eco-friendly pavement of SMA[C]∥Advances in Civil Engineering and Science Technology, Penang, Malaysia, 2020: No.020032. |

| 11 | Meneses J P C, Lutif Teixeira J E S, Alvarez A E, et al. Exploratory study on the addition of sugarcane bagasse fibers to permeable friction course mixtures[J]. Journal of Materials in Civil Engineering, 2021, 33(9): No.04021241. |

| 12 | 张鹏. 掺蔗渣纤维再生沥青混合料在市政路面工程中的应用研究[D]. 西安: 长安大学材料学院, 2021. |

| Zhang Peng. Study on the application of recycling asphalt mixture with bagasse fibers in municipal pavement engineering[D]. Xi´an: School of Materials Science and Engineering of Chang'an University, 2021. | |

| 13 | Väisänen T, Das O, Tomppo L. A review on new bio-based constituents for natural fiber-polymer Composites[J]. Journal of Cleaner Production, 2017, 149(15): 582-596. |

| 14 | Al Arni S. Extraction and isolation methods for lignin separation from sugarcane bagasse: a review[J]. Industrial Crops and Products, 2018, 115: 330-339. |

| 15 | Mukesh, Godara S S. Effect of chemical modification of fiber surface on natural fiber composites: a review[J]. Materials Today: Proceedings, 2019, 18(7): 3428-3434. |

| 16 | Azwa Z N, Yousif B F, Manalo A C, et al. A review on the degradability of polymeric composites based on natural fibres[J]. Materials & Design, 2013, 47: 424-442. |

| 17 | Ranganagowda R P G, Kamath S S, Bennehalli B, et al. Spectral studies on chemically modified single areca fibre[J]. Materials Today: Proceedings, 2018, 5(14): 28018-28025. |

| 18 | 张亚云. 蔗渣纤维表面改性及其沥青胶浆性能研究[D]. 西安: 长安大学材料学院, 2020. |

| Zhang Ya-yun. Study on surface modification of bagasse fibers and properties of asphalt mortar with bagasse fibers[D]. Xi´an: School of Materials Science and Engineering of Chang´an University, 2020. | |

| 19 | Jiang D, An P, Cui S, et al. Effect of leaf fiber modification methods on mechanical and heat-insulating properties of leaf fiber cement-based composite materials[J]. Journal of Building Engineering, 2018, 19: 573-583. |

| 20 | Mazzanti V, Pariante R, Bonanno A, et al. Reinforcing mechanisms of natural fibers in green composites: role of fibers morphology in a PLA/hemp model system[J]. Composites science and technology, 2019, 180: 51-59. |

| 21 | . 沥青路面用纤维 [S]. |

| 22 | . 公路沥青路面施工技术规范 [S]. |

| 23 | . 公路工程沥青及沥青混合料试验规程 [S]. |

| 24 | Li Z, Fa C, Zhao H, et al. Investigation on evolution of bitumen composition and micro-structure during aging[J]. Construction and Building Materials, 2020, 244: No. 118322. |

| [1] | 孙雅珍,薛博欣,孙岩,王志臣,潘嘉伟. 考虑非均匀性的沥青混合料开裂行为细观模拟[J]. 吉林大学学报(工学版), 2024, 54(6): 1708-1718. |

| [2] | 朱先勇,谢良稳,樊跃香,姜城,孙炜佳,王鹏,肖雄. 搅拌摩擦加工参数对镁合金表面改性层的影响[J]. 吉林大学学报(工学版), 2023, 53(8): 2263-2271. |

| [3] | 朱俊清,赵学儒,马涛,黄晓明,朱洪洲. 基于卫星遥感的路域地质灾害监测方法[J]. 吉林大学学报(工学版), 2023, 53(6): 1861-1872. |

| [4] | 金辰,曾孟源,吴荻非. 基于振动传递的水泥混凝土路面接缝损伤感知[J]. 吉林大学学报(工学版), 2023, 53(6): 1736-1745. |

| [5] | 张阳,王傲鹏,张靖霖,马涛,陈思宇. 水泥稳定碎石材料干燥收缩研究综述[J]. 吉林大学学报(工学版), 2023, 53(2): 297-311. |

| [6] | 刘聂玚子,荣鑫,刘洪海,边庆华,兰海. 沥青混合料的搅拌功率试验和黏度模型[J]. 吉林大学学报(工学版), 2023, 53(1): 220-225. |

| [7] | 彭勇,章秀芳,郭泽宇,陆学元,李彦伟. 离散元法分析集料接触特性对沥青混合料剪切疲劳寿命的影响[J]. 吉林大学学报(工学版), 2023, 53(1): 178-187. |

| [8] | 何兆益,李金凤,周文,官志桃. 多孔沥青混合料的动态模量及其预估模型[J]. 吉林大学学报(工学版), 2022, 52(6): 1375-1385. |

| [9] | 郭庆林,刘强,吴春利,李黎丽,李懿明,刘富春. 导电沥青及混合料裂缝局部温度场及愈合效果[J]. 吉林大学学报(工学版), 2022, 52(6): 1386-1393. |

| [10] | 姚玉权,仰建岗,高杰,宋亮. 基于性能-费用模型的厂拌再生沥青混合料优化设计[J]. 吉林大学学报(工学版), 2022, 52(3): 585-595. |

| [11] | 董伟智,张爽,朱福. 基于可拓层次分析法的沥青混合料路用性能评价[J]. 吉林大学学报(工学版), 2021, 51(6): 2137-2143. |

| [12] | 商拥辉,徐林荣,刘维正,蔡雨. 重载铁路改良土和A组填料过渡段的动力特性[J]. 吉林大学学报(工学版), 2021, 51(6): 2128-2136. |

| [13] | 魏海斌,王相焱,王富玉,张勇. 基于振动成型AC-25沥青混合料力学性能及细观分析[J]. 吉林大学学报(工学版), 2021, 51(4): 1269-1276. |

| [14] | 任敏达,丛林,孙思林,冯汉卿. 多次孔隙水压作用下沥青混合料性能演化试验[J]. 吉林大学学报(工学版), 2021, 51(4): 1277-1286. |

| [15] | 程永春,李赫,李立顶,王海涛,白云硕,柴潮. 基于灰色关联度的矿料对沥青混合料力学性能的影响分析[J]. 吉林大学学报(工学版), 2021, 51(3): 925-935. |

|

||