吉林大学学报(工学版) ›› 2023, Vol. 53 ›› Issue (1): 220-225.doi: 10.13229/j.cnki.jdxbgxb20210541

• 交通运输工程·土木工程 • 上一篇

沥青混合料的搅拌功率试验和黏度模型

- 1.长安大学 运输工程学院,西安 710064

2.长安大学 道路施工技术与装备教育部重点实验室,西安 710064

3.甘肃路桥建设集团有限公司 公路建设与养护技术材料及装备交通运输行业研发中心,兰州 730030

Mixing power test and viscosity model of asphalt mixture

Nie-yang-zi LIU1( ),Xin RONG2,Hong-hai LIU2(

),Xin RONG2,Hong-hai LIU2( ),Qing-hua BIAN3,Hai LAN2

),Qing-hua BIAN3,Hai LAN2

- 1.School of Transportation Engineering,Chang'an University,Xi'an 710064,China

2.Key Laboratory of Road Construction Technology and Equipment,Ministry of Education,Chang'an University,Xi'an 710064,China

3.Research and Development Center of Highway Construction and Maintenance Technology,Materials and Equipment,Transportation Industry,Gansu Road and Bridge Construction Group Co. ,Ltd. ,Lanzhou 730030,China

摘要:

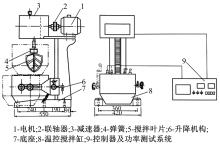

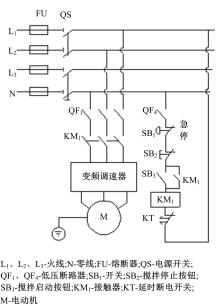

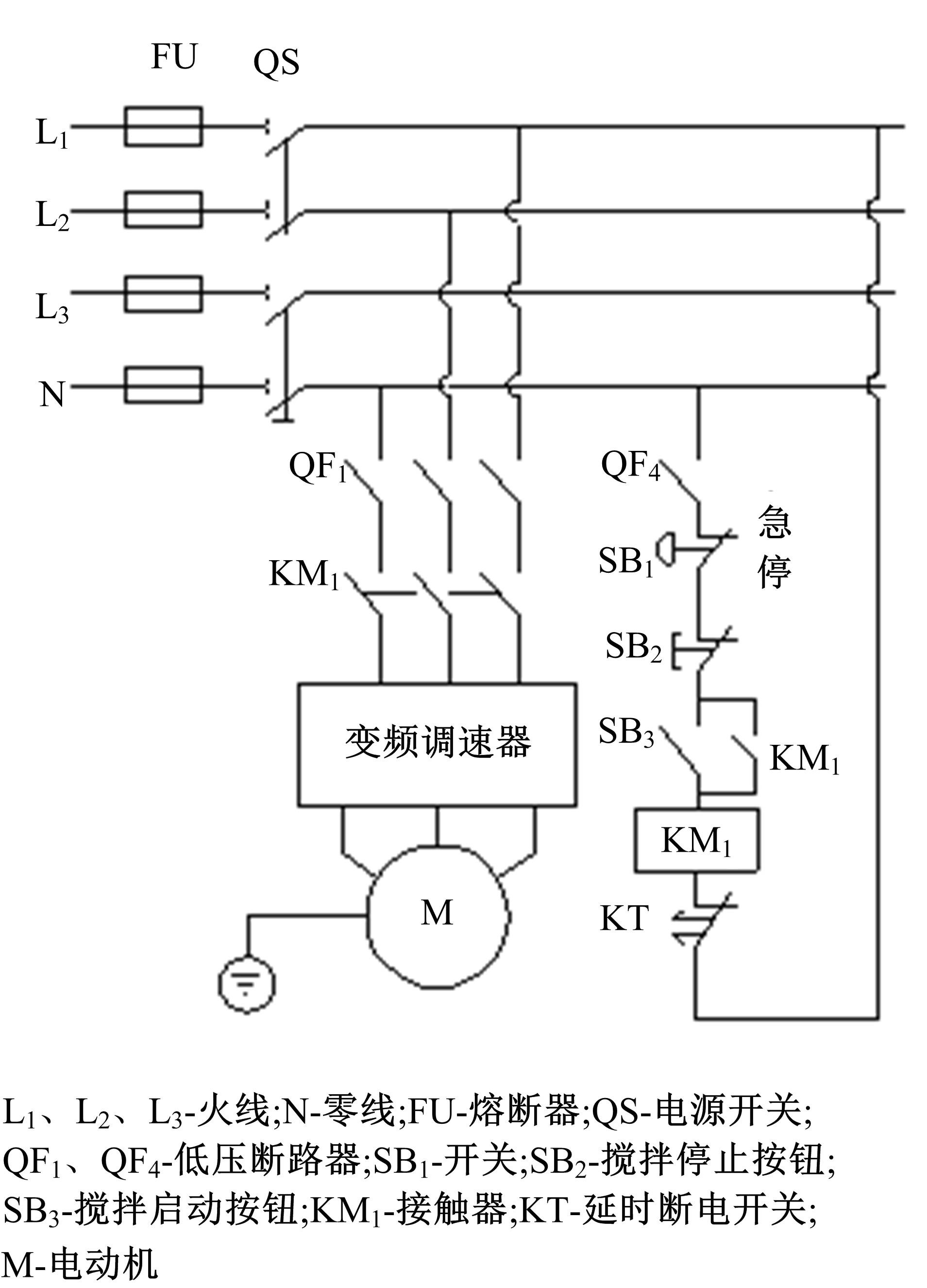

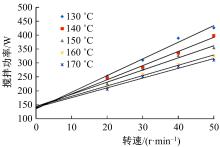

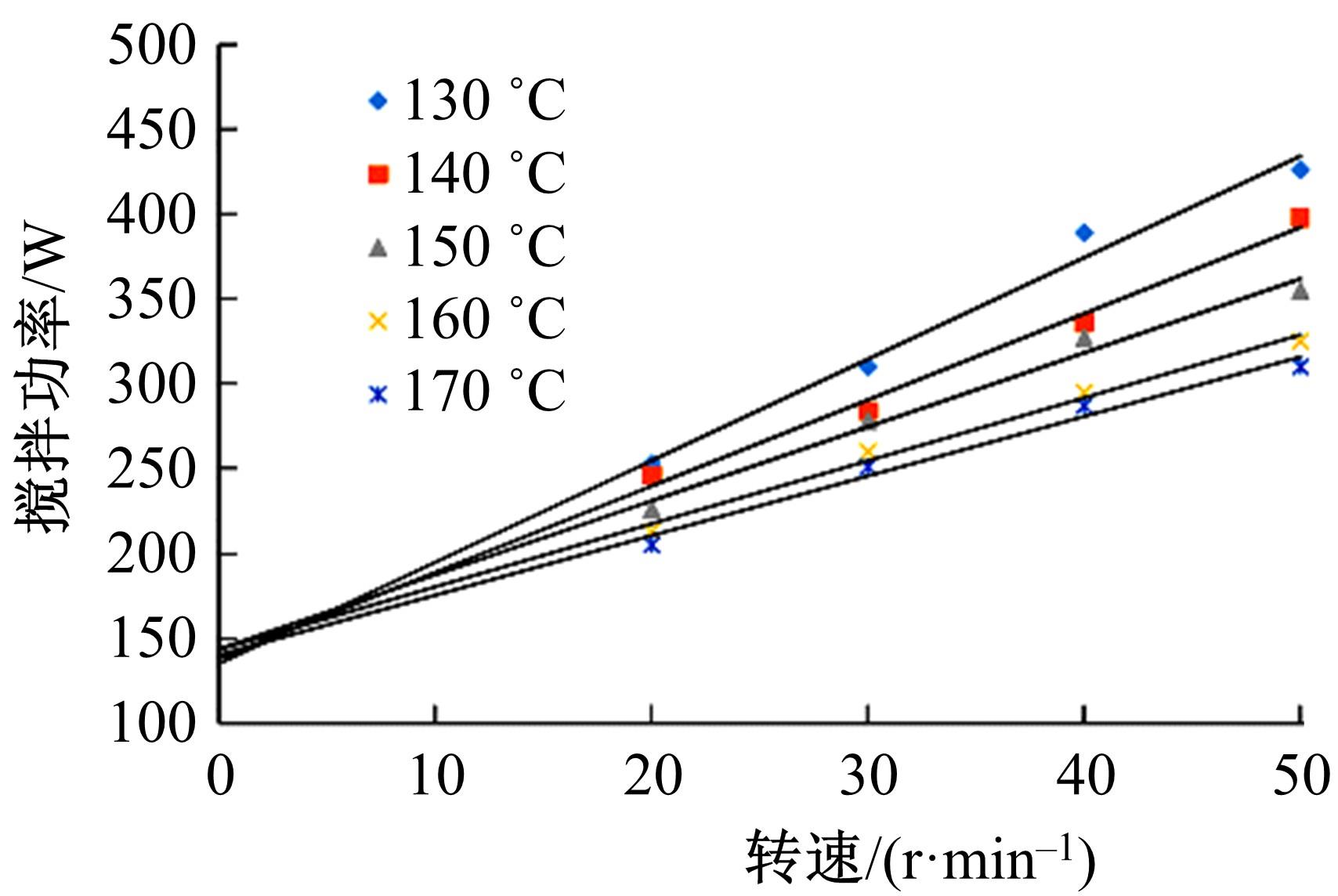

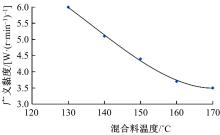

针对由沥青“黏度-温度”试验曲线确定的混合料理论施工温度与工程实际施工温度差距较大问题,通过进行沥青混合料的搅拌功率试验,对其施工温度确定方法进行了理论和试验研究。采用经过改制的搅拌机,测定不同温度与搅拌转速下的混合料搅拌功率,得到三者之间的关系,进而建立了由搅拌功率表征的沥青混合料广义塑性黏度模型。该模型表明:沥青混合料的广义塑性黏度决定于混合料的温度,以及矿料物理性质、级配、沥青类型和用量等材料因素,而与搅拌机的转速无关,代表了沥青混合料的流变特性;通过测定沥青混合料在不同温度下的广义塑性黏度,得到广义塑性黏度随温度的变化曲线,在该曲线中梯度变化明显变缓的温度可作为该种沥青混合料的施工控制温度。

中图分类号:

- U414

| 1 | 李志伟,贺海,董彪,等. 温拌沥青混合料施工工艺研究[J]. 筑路机械与施工机械化, 2013,30(6):52-56. |

| Li Zhi-wei, He Hai, Dong Biao, et al. Research on construction technology of warm mixing asphalt mixture[J]. Road Machinery & Construction Mechanization, 2013, 30(6): 52-56. | |

| 2 | .民用机场沥青道面施工技术规范 [S]. |

| 3 | 张宜洛,董飞龙,赵少宗. TPS高粘沥青施工温度的确定[J]. 筑路机械与施工机械化,2019, 36(5): 35-40. |

| Zhang Yi-luo, Dong Fei-long, Zhao Shao-zong. Determination of construction temperature of TPS high-viscosity asphalt[J]. Road Machinery & Construction Mechanization, 2019, 36(5): 35-40. | |

| 4 | 陈华鑫. 改性沥青的黏度特性和施工温度控制[J]. 石油沥青, 2003, 17(4): 43-46. |

| Chen Hua-xin. Modified asphalt viscosity characteristics and construction temperature control[J]. Petroleum Pitch, 2003, 17(4): 43-46. | |

| 5 | 郑传峰,冯玉鹏,郭学东,等. 粉胶比对沥青胶浆低温黏结强度的影响[J]. 吉林大学学报:工学版, 2016, 46(2): 426-431. |

| Zheng Chuan-feng, Feng Yu-peng, Guo Xue-dong, et al. Effect of filler-to-bitumen ratio on low-temperature cohesive strength of asphalt mortar[J]. Journal of Jilin University (Engineering and Technology Edition), 2016, 46(2): 426-431. | |

| 6 | Xiang L, Bo L C, Meng J, et al. Influence of short-term aging on anti-cracking performance of warm modified asphalt at intermediate temperature[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2019, 582:No.123877. |

| 7 | 孙培,韩森,高榕,等. 基于评价SBS改性沥青高温性能的修正软化点方法[J]. 铁道科学与工程学报, 2017, 14(2): 250-256. |

| Sun Pei, Han Sen, Gao Rong, et al. A revised softening point method based on evaluation the high temperature property of SBS modified asphalt[J]. Journal of Railway Science and Engineering, 2017, 14(2): 250-256. | |

| 8 | Gudimettla J M, Cooley L A, Brown E R. Workability of hot-mix asphalt[J]. Transportation Research Record, 2004, 1891: 229-237. |

| 9 | 张琛,汪海年,尤占平,等. 橡胶沥青混合料和易性与压实特性的相关性[J]. 东南大学学报:自然科学版, 2016, 46(1): 202-208. |

| Zhang Chen, Wang Hai-nian, You Zhan-ping, et al. Correlation between workability and compaction property of rubber asphalt mixture[J]. Journal of Southeast University (Natural Science Edition), 2016, 46(1): 202-208. | |

| 10 | 侯曙光. 热拌与温拌沥青混合料和易性试验[J].南京工业大学学报, 2011, 33(5): 36-39. |

| Hou Shu-guang. Hot mix and warm mix asphalt mixture workability test[J]. Journal Nanjing Tech University, 2011, 33(5): 36-39. | |

| 11 | 延西利,田辉黎,延喜乐,等. 沥青混合料的变速拌和功率测试与拌和流变模型[J]. 交通运输工程学报, 2016, 16(5): 1-7. |

| Yan Xi-li, Tian Hui-li, Yan Xi-le, et al. Asphalt mixture variable speed mixing power test and mixing rheological model[J]. Journal of Traffic and Transportation Engineering, 2016, 16(5): 1-7. | |

| 12 | 延西利,景宏君,游庆龙,等. 沥青混合料的拌和流动特性及和易性指数[J]. 土木工程学报, 2019, 52(10): 120-128. |

| Yan Xi-li, Jing Hong-jun, You Qing-long, et al. Mixing flow characteristic and workability index of asphalt mixtures[J]. China Civil Engineering Journal, 2019, 52(10): 120-128. | |

| 13 | 李昂.不同性质沥青混合料的变速拌和及和易性指数研究[D]. 西安:长安大学公路学院, 2017. |

| Li Ang. Experiment at different mixing velocities and workability index of asphalt mixture with different bitumen[D]. Xi'an: School of Highway, Chang'an University, 2017. | |

| 14 | 李梦怡. 高黏改性剂对沥青流变性能的影响[J]. 公路交通科技,2018, 35(4): 14-20. |

| Li Meng-yi. Effect of high viscosity modifier on rheological property of asphalt[J]. Journal of Highway and Transportation Research and Development, 2018, 35(4): 14-20. | |

| 15 | 延西利,梁春雨,艾涛. 基于沥青与石料界面剪切的黏塑性流变模型研究[J].土木工程学报, 2014, 47(2): 136-144. |

| Yan Xi-li, Liang Chun-yu, Ai Tao. Research on viscoelastic rheological model based on the interfacial shear of asphalt and stone[J]. China Civil Engineering Journal, 2014, 47(2): 136-144. | |

| 16 | 黄刚,何兆益,黄涛. 沥青混合料动态蠕变黏弹性特性分析[J]. 东南大学学报:自然科学版, 2012, 42(6): 1211-1216. |

| Huang Gang, He Zhao-yi, Huang Tao. Analysis of dynamic creep viscoelastic properties of asphalt mixture[J]. Journal of Southeast University (Natural Science Edition), 2012, 42(6): 1211-1216. | |

| 17 | Behl A, Chandra S, Aggarwal V K, et al. Zero shear viscosity of bitumen-filler mastics of warm-mix binders[J]. Journal of Materials in Civil Engineering, 2014, 27(1): 46-51. |

| 18 | Wang H P, Liu X Y, Apostolidis P, et al. Rheological behavior and its chemical interpretation of crumb rubber modified asphalt containing warm-mix additives[J]. Transportation Research Record, 2018, 2672(28): 337-348. |

| 19 | Zhang Feng, Hu Chang-bin, Zhuang Wei-long. The research for low-temperature rheological properties and structural characteristics of high-viscosity modified asphalt[J]. Journal of Thermal Analysis & Calorimetry, 2018, 131(2): 1025-1034. |

| [1] | 杨柳,王创业,王梦言,程阳. 设置自动驾驶小客车专用车道的六车道高速公路交通流特性[J]. 吉林大学学报(工学版), 2023, 53(7): 2043-2052. |

| [2] | 周正峰,于晓涛,陶雅乐,郑茂,颜川奇. 基于灰色关联分析的树脂与弹性体高黏沥青高温性能评价[J]. 吉林大学学报(工学版), 2023, 53(7): 2078-2088. |

| [3] | 马涛,马源,黄晓明. 基于多元非线性回归的智能压实关键参数最优解[J]. 吉林大学学报(工学版), 2023, 53(7): 2067-2077. |

| [4] | 魏海斌,韩栓业,毕海鹏,刘琼辉,马子鹏. 智能感知道路主动除冰雪系统及实验技术[J]. 吉林大学学报(工学版), 2023, 53(5): 1411-1417. |

| [5] | 郑睢宁,何锐,路天宇,徐紫祎,陈华鑫. RET/胶粉复合改性沥青制备及其混合料性能评价[J]. 吉林大学学报(工学版), 2023, 53(5): 1381-1389. |

| [6] | 关博文,邸文锦,王发平,吴佳育,张硕文,贾治勋. 干湿循环与交变荷载作用下混凝土硫酸盐侵蚀损伤[J]. 吉林大学学报(工学版), 2023, 53(4): 1112-1121. |

| [7] | 杨帆,李琛琛,李盛,刘海伦. 温缩作用下双层连续配筋混凝土路面配筋率设计参数对比分析[J]. 吉林大学学报(工学版), 2023, 53(4): 1122-1132. |

| [8] | 魏海斌,马子鹏,毕海鹏,刘汉涛,韩栓业. 基于力学响应分析方法的导电橡胶复合路面铺装技术[J]. 吉林大学学报(工学版), 2023, 53(2): 531-537. |

| [9] | 刘状壮,张有为,季鹏宇,Abshir Ismail Yusuf,李林,郝亚真. 电热型融雪沥青路面传热特性研究[J]. 吉林大学学报(工学版), 2023, 53(2): 523-530. |

| [10] | 时爽,林岚钦,马涛,顾临皓,张燕宁. 基于分子动力学的生物质透层油稳定性[J]. 吉林大学学报(工学版), 2023, 53(1): 197-209. |

| [11] | 陈栩,曹超飞,尚静,黄明星,艾长发,任东亚. 动静水环境作用下级配离析对沥青混合料水损害的影响评价[J]. 吉林大学学报(工学版), 2023, 53(1): 210-219. |

| [12] | 彭勇,章秀芳,郭泽宇,陆学元,李彦伟. 离散元法分析集料接触特性对沥青混合料剪切疲劳寿命的影响[J]. 吉林大学学报(工学版), 2023, 53(1): 178-187. |

| [13] | 孙雅珍,郑直,黄伟明,王金昌. 基于状态空间法的含裂缝水泥路面结构分析[J]. 吉林大学学报(工学版), 2023, 53(1): 188-196. |

| [14] | 时成林,王勇,吴春利,宋文祝. 路堤挡土墙主动土压力计算方法修正[J]. 吉林大学学报(工学版), 2022, 52(6): 1394-1403. |

| [15] | 何兆益,李金凤,周文,官志桃. 多孔沥青混合料的动态模量及其预估模型[J]. 吉林大学学报(工学版), 2022, 52(6): 1375-1385. |

|

||