吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (7): 1958-1965.doi: 10.13229/j.cnki.jdxbgxb.20221195

• 交通运输工程·土木工程 • 上一篇

钢混组合梁栓钉锈胀下混凝土板开裂行为数值分析

- 西南交通大学 土木工程学院,成都 610031

Numerical analysis on cracking behavior of concrete slab due to corrosion expansion of stud connector in steel-concrete composite beam

Lin XIAO( ),Huan-bo WEI,Xing WEI(

),Huan-bo WEI,Xing WEI( ),Zhi-rui KANG

),Zhi-rui KANG

- School of Civil Engineering,Southwest Jiaotong University,Chengdu 610031,China

摘要:

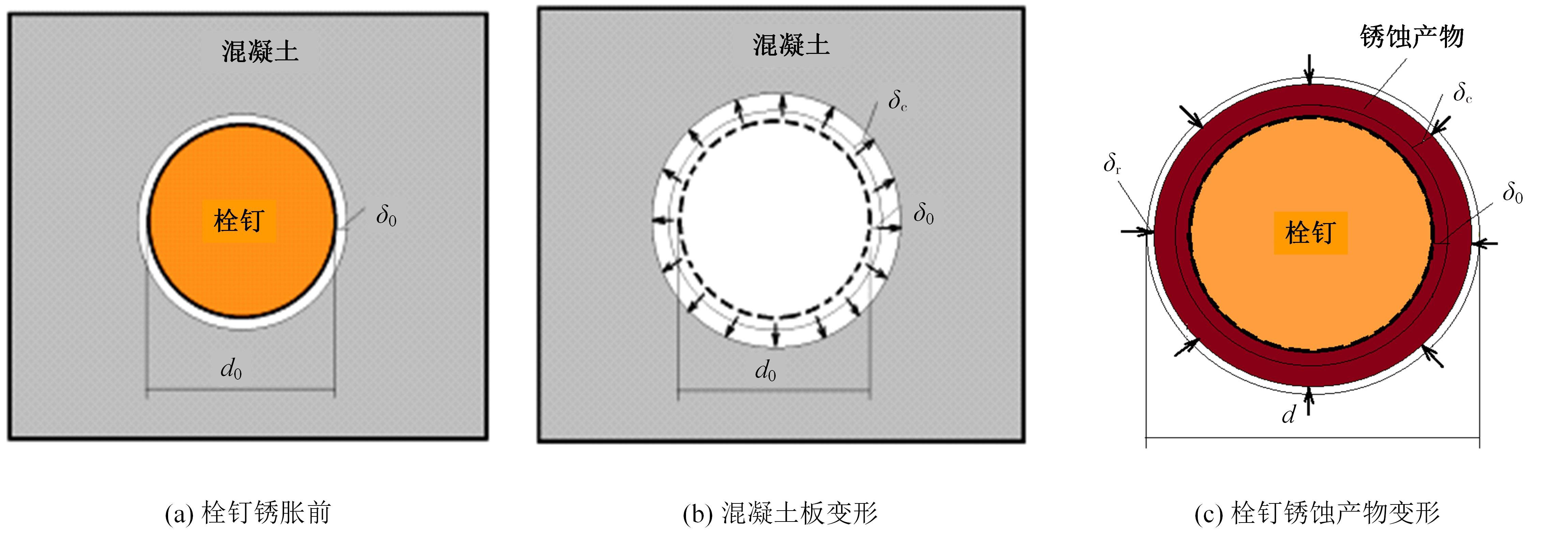

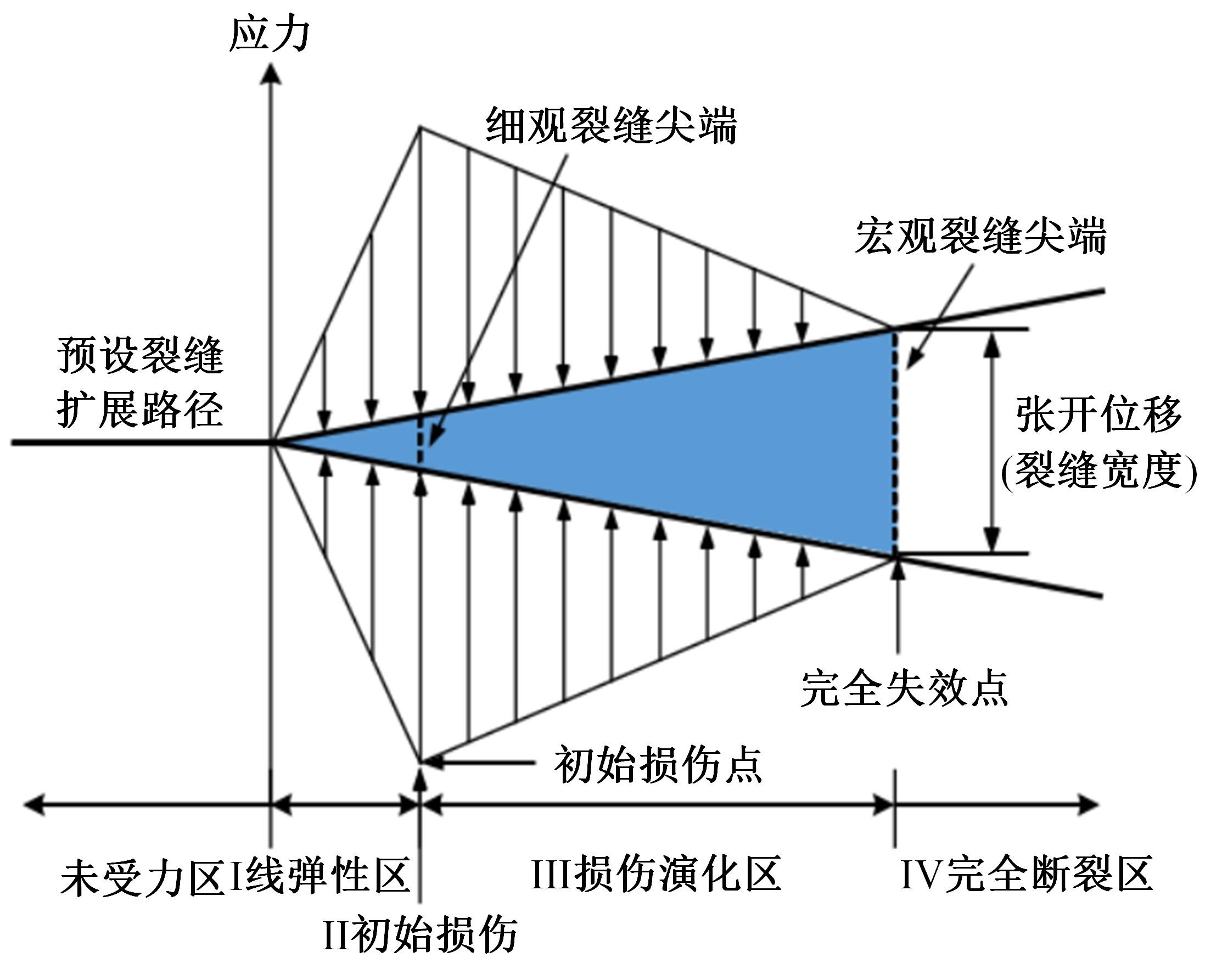

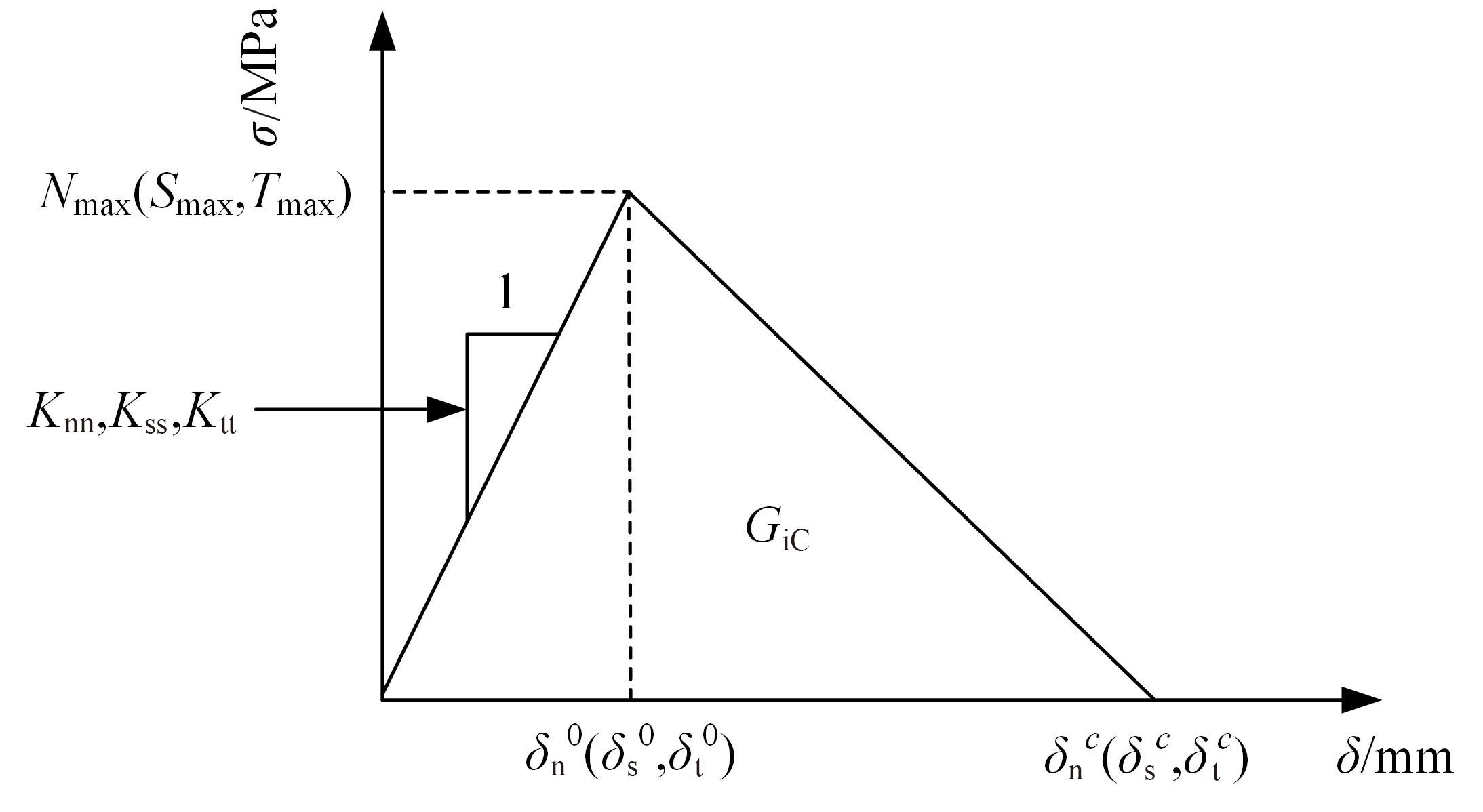

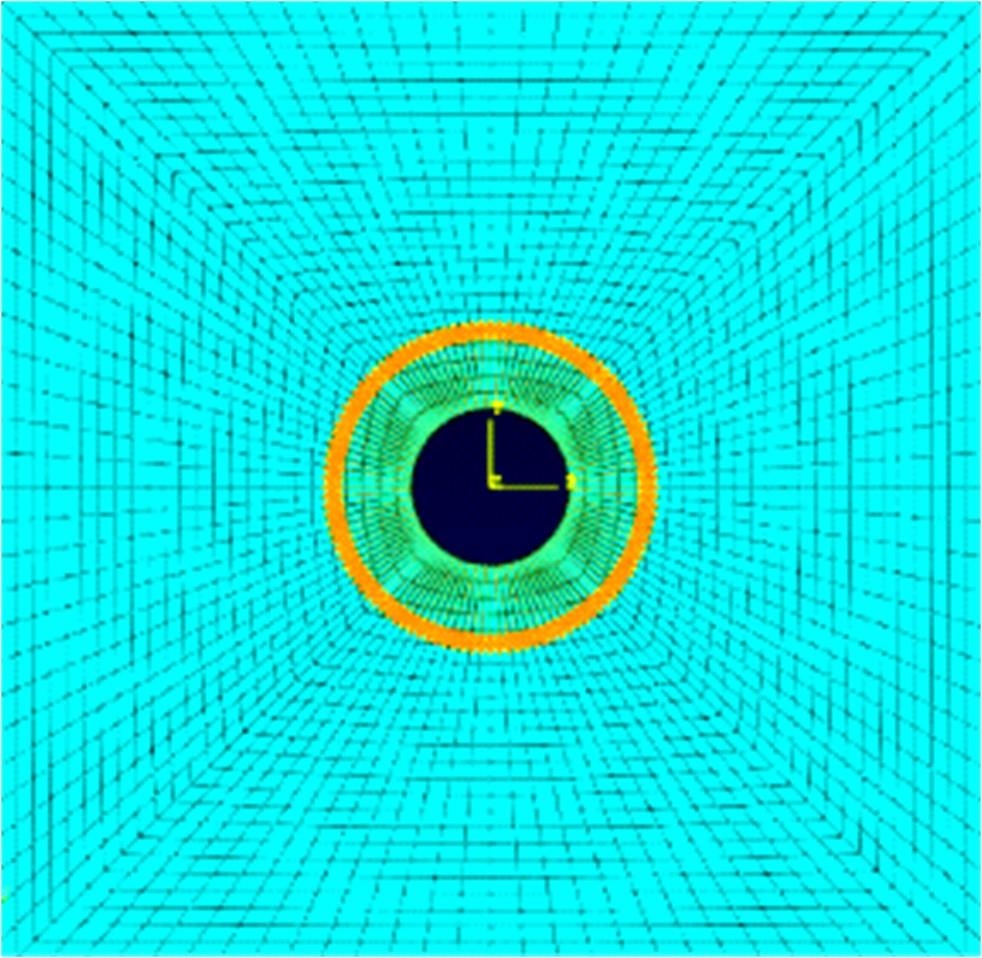

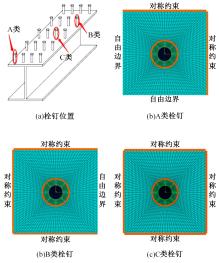

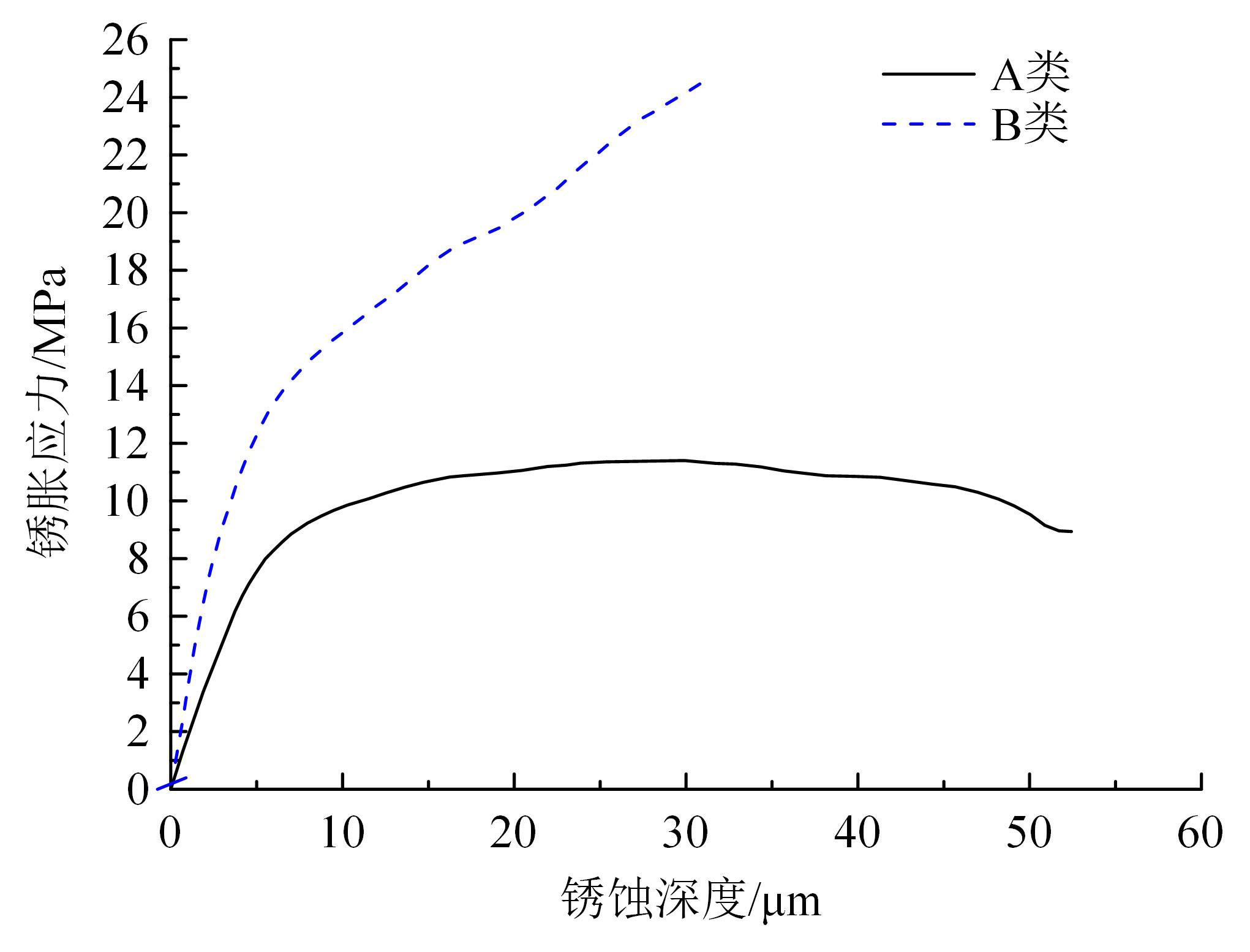

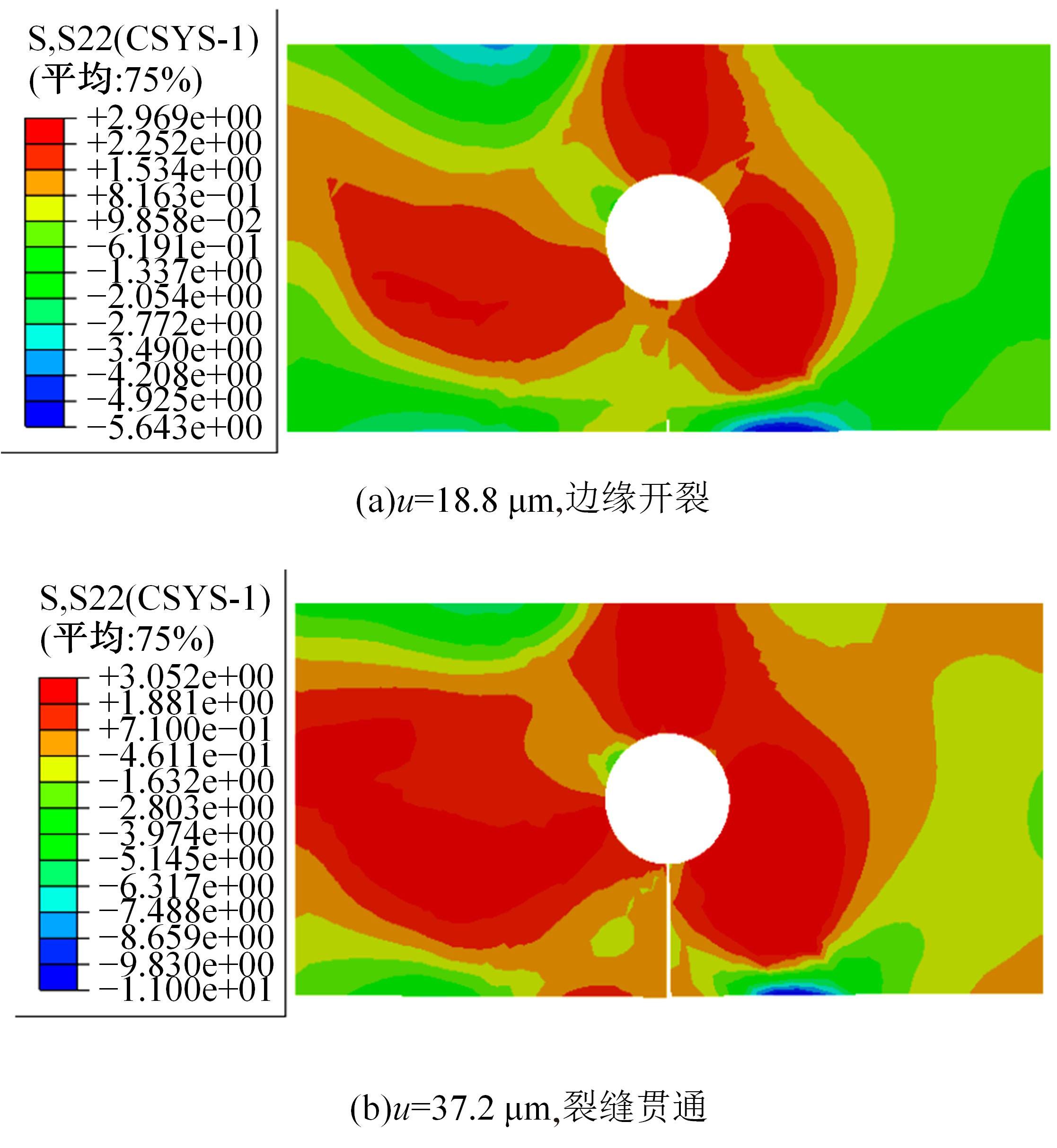

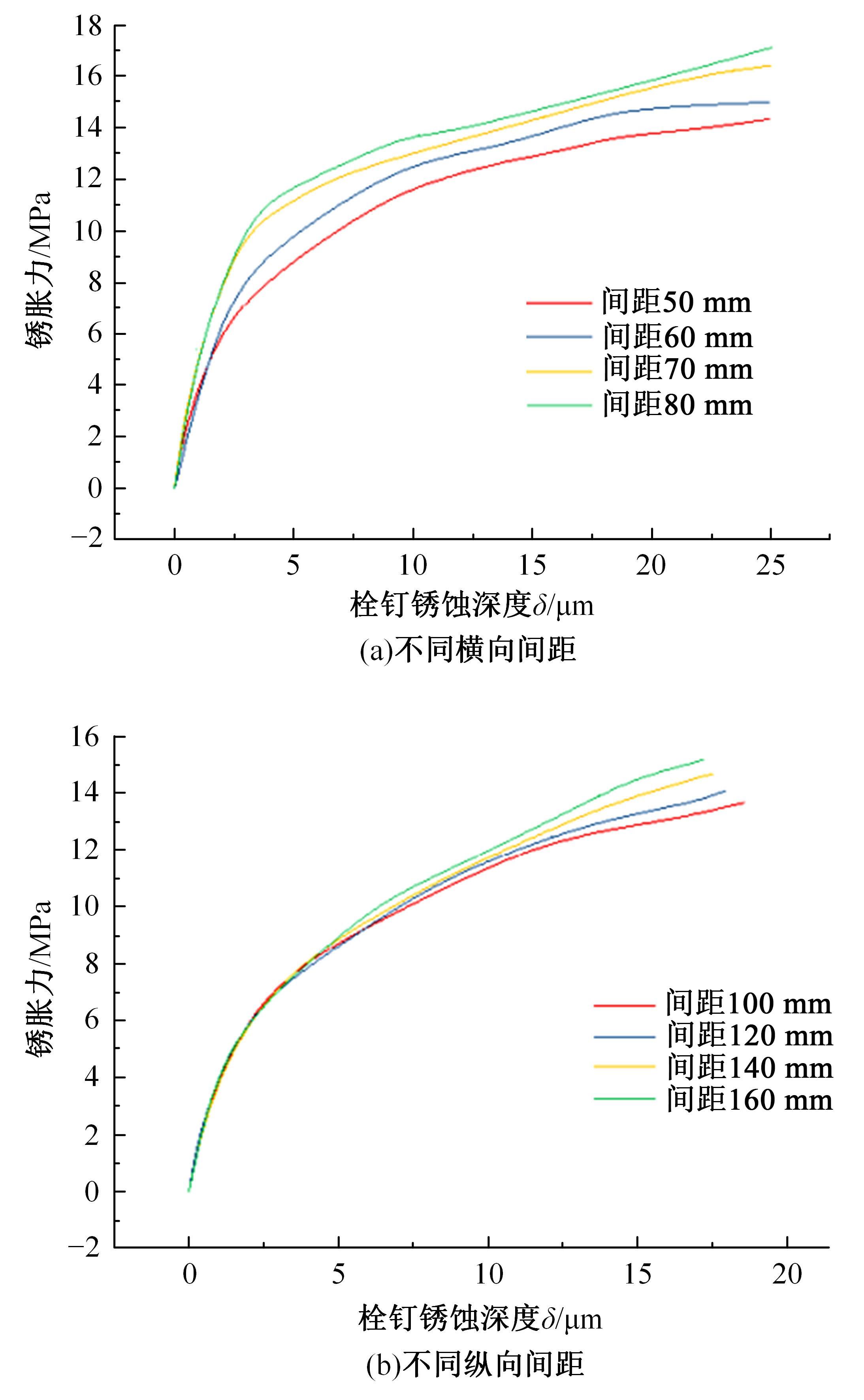

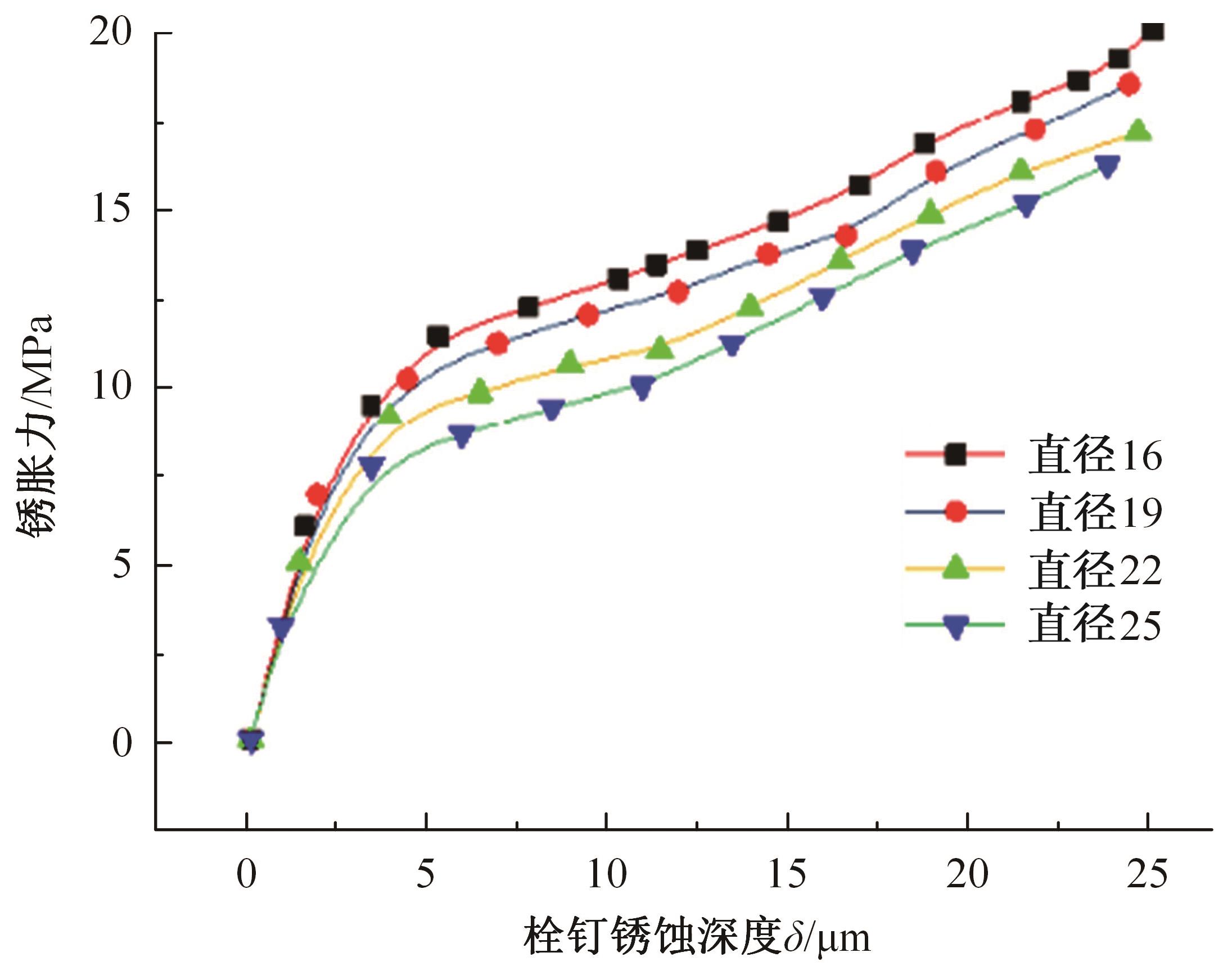

为研究腐蚀环境中钢-混组合梁栓钉锈胀引发的混凝土板开裂行为,本文利用ABAQUS有限元分析软件建立混凝土板塑性损伤模型。采用环向均匀位移模拟栓钉锈胀作用,选用基于牵引力-分离法则(Traction-separation law)的粘聚区模型模拟混凝土开裂,计算分析3种不同约束边界、4种不同栓钉间距及4种栓钉直径条件下,混凝土板锈胀应力分布及开裂行为。研究结果表明:随着边界约束的增加,栓钉需要更大的腐蚀深度才会引起混凝土板开裂。栓钉横向间距从50 cm增加到80 cm,使混凝土边缘开裂需要锈蚀深度增加到1.59倍。栓钉直径从16 mm增加到25 mm,使混凝土边缘开裂需要锈蚀深度减小到0.87倍。

中图分类号:

- TU398.9

| 1 | 卫星,肖林,温宗意,等.钢-混组合结构桥梁2020年度研究进展[J]. 土木与环境工程学报, 2021,43():107-119. |

| Wei Xing, Xiao Lin, Wen Zong-yi,et al. Research progress of steel-concrete composite bridges in 2020 [J]. Journal of Civil and Environmental Engineering, 2021,43(Sup.1): 107-119. | |

| 2 | 魏欢博. 腐蚀环境下钢-混结合梁栓钉连接件服役性能退化规律研究[D].成都:西南交通大学土木工程学院, 2021. |

| Wei Huan-bo. Degradation law of service performance of steel-concrete beam stud connectors in corrosive environment[D]. Chengdu: School of Civil Engineering,Southwest Jiaotong University, 2021. | |

| 3 | Bhargava K, Ghosh A K, Mori Y, et al. Modeling of time to corrosion-induced cover cracking in reinforced concrete structures[J]. Cement and Concrete Research, 2005, 35(11):2203-2218. |

| 4 | 王海龙,金伟良,孙晓燕.基于断裂力学的钢筋混凝土保护层锈胀开裂模型[J].水利学报,2008, 39(7) : 863-869. |

| Wang Hai-long, Jin Wei-liang, Sun Xiao-yan. Fracture model for protective layer cracking of reinforced concrete structure due to rebar corrosion[J]. Journal of Hydraulic Engineering, 2008, 39(7):863-869. | |

| 5 | 周锡武,卫军,徐港.钢筋混凝土保护层锈胀开裂的临界锈蚀量模型[J].武汉理工大学学报,2009,31(12):99-102. |

| Zhou Xi-wu, Wei Jun, Xu Gang. Bar critical corrosion ratio model of reinforcement concrete cover corrosion expanding crack[J]. Journal of Wuhan University of Technology, 2009,31(12): 99-102. | |

| 6 | 陈海忠,曹龙飞,张华,等.混凝土锈胀开裂的断裂过程分析[J].华中科技大学学报:自然科学版,2010,38(9):101-103. |

| Chen Hai-zhong, Cao Long-fei, Zhang Hua, et al. Analysis of breaking-down process of rebars corrosion expansion cracking in reinforce concrete[J]. Journal of Huazhong University of Science and Technology, 2010,38(9):101-103. | |

| 7 | 林刚,向志海,刘应华.钢筋混凝土保护层锈胀开裂时间预测模型[J].清华大学学报:自然科学版,2010,50(7): 1125-1129. |

| Lin Gang, Xiang Zhi-hai, Liu Ying-hua. Modeling of time to corrosion cracking in reinforced concrete structures[J]. Journal of Tsinghua University, 2010, 50(7): 1125-1129. | |

| 8 | Bossio A, Monetta T, Bellucci F, et al. Modeling of concrete cracking due to corrosion process of reinforcement bars [J]. Cement and Concrete Research, 2015, 71:78-92. |

| 9 | Lu C H, Yuan S Q, Liu R G. Experimental and probabilistic analysis of time to corrosion-induced cover cracking for marine reinforced concrete structures[J]. Corrosion Engineering, Science and Technology, 2017, 52(2):124-133. |

| 10 | Zhang X G, Li M H, Tang L P, et al. Corrosion induced stress field and cracking time of reinforced concrete with initial defects: analytical modeling and experimental investigation[J]. Corrosion Science, 2017, 120:158-170. |

| 11 | 伦培元, 张小刚, 张强,等. 基于初始缺陷形状的混凝土结构锈胀开裂理论模型[J]. 东北大学学报:自然科学版, 2020, 41(7):1020-1026. |

| Pei-yuan Lun, Zhang Xiao-gang, Zhang Qiang, et al. Theoretical model of rust expansion cracking of concrete structure based on the initial defect shape[J]. Journal of Northeastern University, 2020, 41(7):1020-1026. | |

| 12 | 方建柯,徐亦冬,徐立锋,等.环境-荷载耦合作用下钢筋锈蚀产物的分子动力学模拟及其锈胀力分析[J].硅酸盐通报,2018,37(10):3275-3280. |

| Fang Jian-ke, Xu Yi-dong, Xu Li-feng, et al. Molecular dynamics simulation and corrosion expansion analysis of reinforcement corrosion products under coupled effect of chloride and loading[J]. Bulletin of the Chinese Ceramic Society, 2018,37(10):3275-3280. | |

| 13 | 胡志坚,夏雷雷,程晨,等.钢筋混凝土构件锈蚀开裂与锈胀力分析[J].哈尔滨工业大学学报,2020, 52(3): 99-105. |

| Hu Zhi-jian, Xia Lei-lei, Cheng Chen. Investigation on corrosion-induced cracking and corrosion expansive pressure in reinforced concrete members[J]. Journal of Harbin Institute of Technology, 2020, 52(3): 99-105. | |

| 14 | 金波,孙楠,方棋洪,等.混凝土构件中钢筋非均匀锈胀力研究[J].固体力学学报,2022,43(4): 456-466. |

| Jin Bo, Sun Nan, Fang Qi-hong, et al. Research on non-uniform corrosion expansion stress of reinforcing bars in concrete members[J]. Chinese Journal of Solid Mechanics, 2022,43(4): 456-466. |

| [1] | 张春雷,邵长宇,苏庆田,戴昌源. 球扁钢肋钢纤维混凝土组合桥面板正弯矩受力性能试验[J]. 吉林大学学报(工学版), 2024, 54(6): 1634-1642. |

| [2] | 孙雅珍,薛博欣,孙岩,王志臣,潘嘉伟. 考虑非均匀性的沥青混合料开裂行为细观模拟[J]. 吉林大学学报(工学版), 2024, 54(6): 1708-1718. |

| [3] | 张彦玲,贾云飞,贾晓远,郑旺,李运生. 装配式小箱梁桥内力横向分布系数建议公式[J]. 吉林大学学报(工学版), 2024, 54(6): 1688-1700. |

| [4] | 黄汉辉,陈康明,吴庆雄. 钢管混凝土桁式弦杆组合连续梁抗弯性能[J]. 吉林大学学报(工学版), 2024, 54(6): 1665-1676. |

| [5] | 邵长江,崔皓蒙,漆启明,庄卫林. 近断层大跨RC轻柔拱桥纵向阻尼器减震研究[J]. 吉林大学学报(工学版), 2024, 54(5): 1355-1367. |

| [6] | 万铜铜,汪海年,郑文华,冯珀楠,陈玉,张琛. 级配碎石层协调沥青混合料层温度收缩变形行为[J]. 吉林大学学报(工学版), 2024, 54(4): 1045-1057. |

| [7] | 赵秋,陈鹏,赵煜炜,余澳. 台后设置拱形结构的无缝桥梁整体受力性能[J]. 吉林大学学报(工学版), 2024, 54(4): 1016-1027. |

| [8] | 张洪,朱志伟,胡天宇,龚燕峰,周建庭. 基于改进YOLOv5s的桥梁螺栓缺陷识别方法[J]. 吉林大学学报(工学版), 2024, 54(3): 749-760. |

| [9] | 韩智强,谢刚,卓亚娟,骆佐龙,李华腾. 基于车轮-桥面相干激励的大跨连续梁桥振动响应[J]. 吉林大学学报(工学版), 2024, 54(2): 436-444. |

| [10] | 杨国俊,齐亚辉,石秀名. 基于数字图像技术的桥梁裂缝检测综述[J]. 吉林大学学报(工学版), 2024, 54(2): 313-332. |

| [11] | 谭国金,欧吉,艾永明,杨润超. 基于改进DeepLabv3+模型的桥梁裂缝图像分割方法[J]. 吉林大学学报(工学版), 2024, 54(1): 173-179. |

| [12] | 龙关旭,张修石,辛公锋,王涛,杨干. 融合机器视觉的桥梁动态称重方法[J]. 吉林大学学报(工学版), 2024, 54(1): 188-197. |

| [13] | 卫星,高亚杰,康志锐,刘宇辰,赵骏铭,肖林. 低温环境下栓钉环焊缝焊接残余应力场数值模拟[J]. 吉林大学学报(工学版), 2024, 54(1): 198-208. |

| [14] | 安然,王有志. 剪力钉连接件拉剪共同作用抗剪性能[J]. 吉林大学学报(工学版), 2023, 53(9): 2554-2562. |

| [15] | 左新黛,张劲泉,赵尚传. 在役混凝土T梁疲劳刚度退化及寿命预测方法[J]. 吉林大学学报(工学版), 2023, 53(9): 2563-2572. |

|

||