吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (11): 3358-3371.doi: 10.13229/j.cnki.jdxbgxb.20230043

• 通信与控制工程 • 上一篇

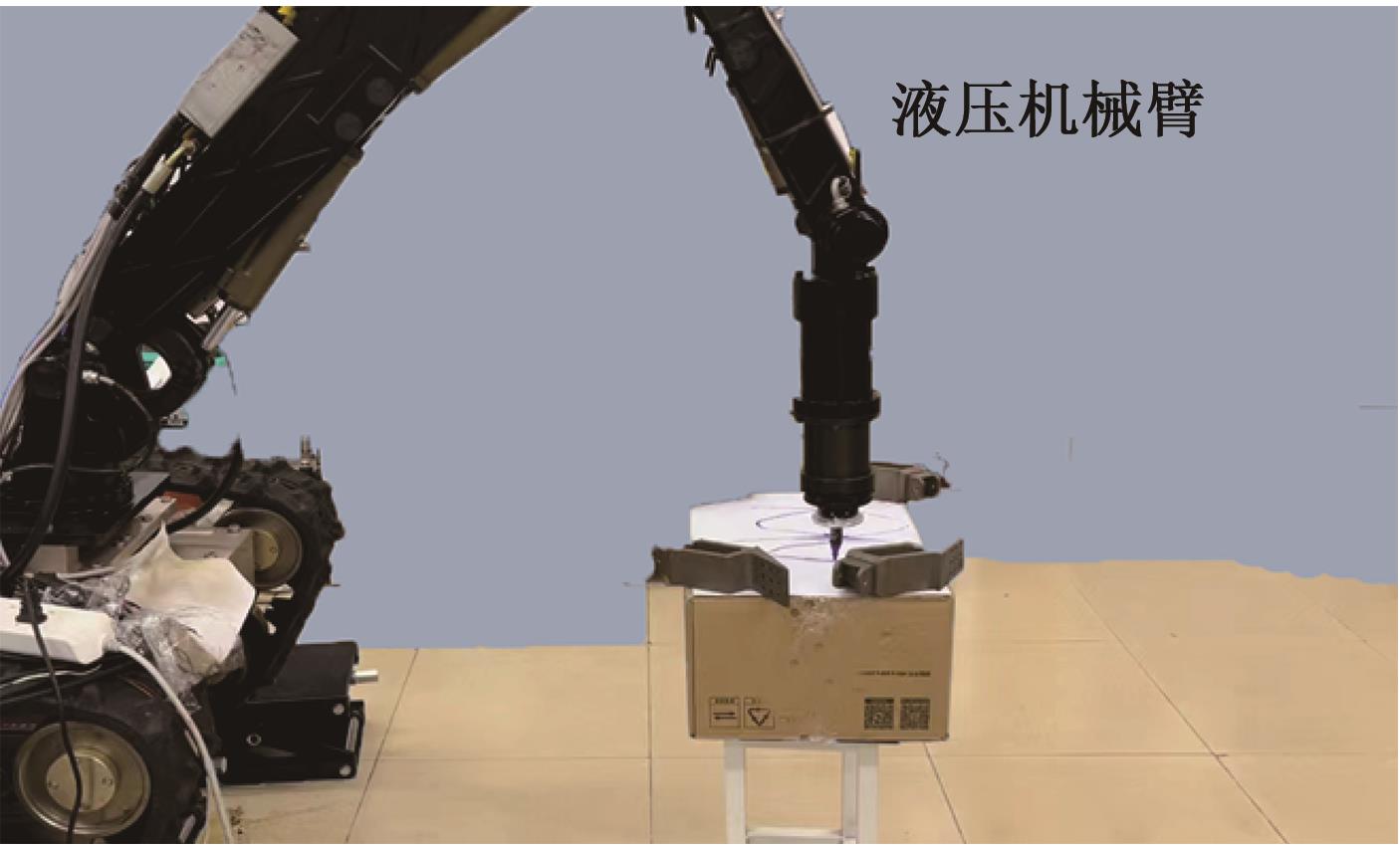

液压机械臂集中式驱控系统研究与应用

郑玉坤1,2( ),孙如月1,2,李凤鸣3,刘义祥1,2,李东广4,宋锐1,2(

),孙如月1,2,李凤鸣3,刘义祥1,2,李东广4,宋锐1,2( )

)

- 1.山东大学 控制科学与工程学院,济南 250061

2.智能无人系统教育部工程研究中心,济南 250061

3.山东建筑大学 信息与电器工程学院,济南 250101

4.中信重工开诚智能装备有限公司,河北 唐山 063020

Research and application of the centralized drive and control system for a hydraulic manipulator

Yu-kun ZHENG1,2( ),Ru-yue SUN1,2,Feng-ming LI3,Yi-xiang LIU1,2,Dong-guang LI4,Rui SONG1,2(

),Ru-yue SUN1,2,Feng-ming LI3,Yi-xiang LIU1,2,Dong-guang LI4,Rui SONG1,2( )

)

- 1.School of Control Science and Engineering,Shandong University,Jinan 250061,China

2.Engineering Research Center of Intelligent Unmanned System,Ministry of Education,Jinan 250061,China

3.School of Information and Electrical Engineering,Shandong Jianzhu University,Jinan 250101,China

4.CITIC HIC KAICHENG Intelligence Equipment Co. ,Ltd. ,Tangshan 063020,China

摘要:

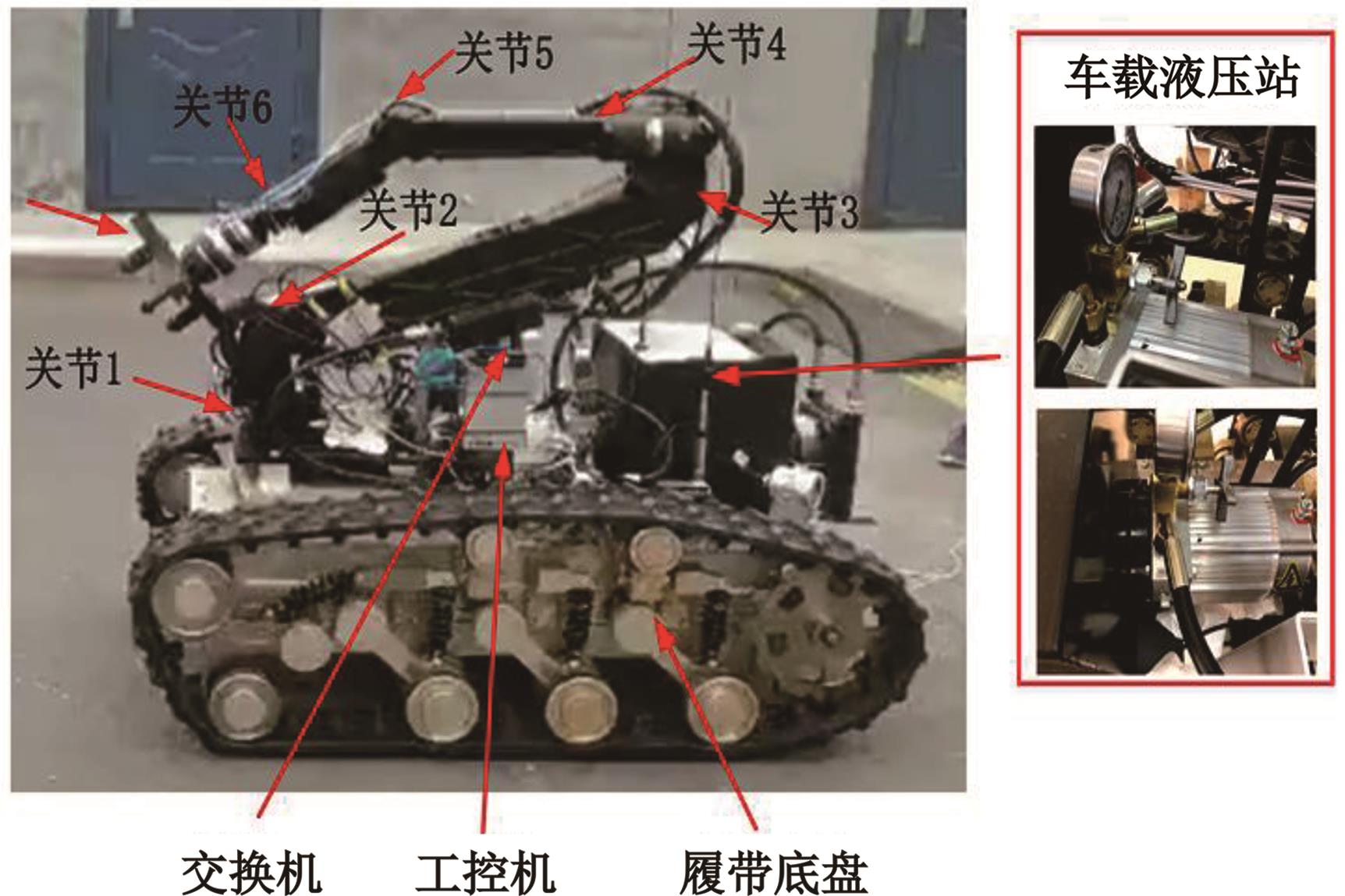

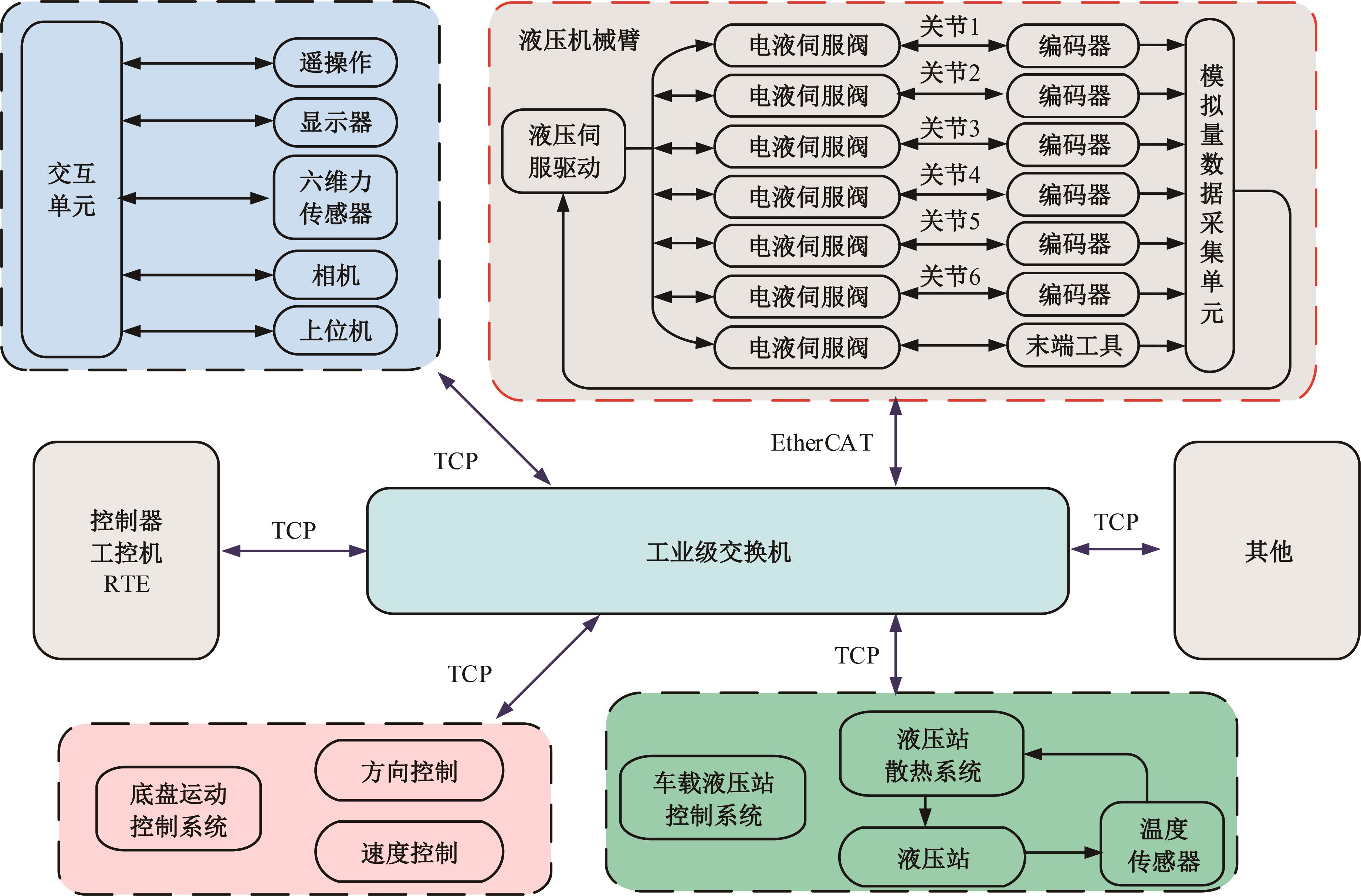

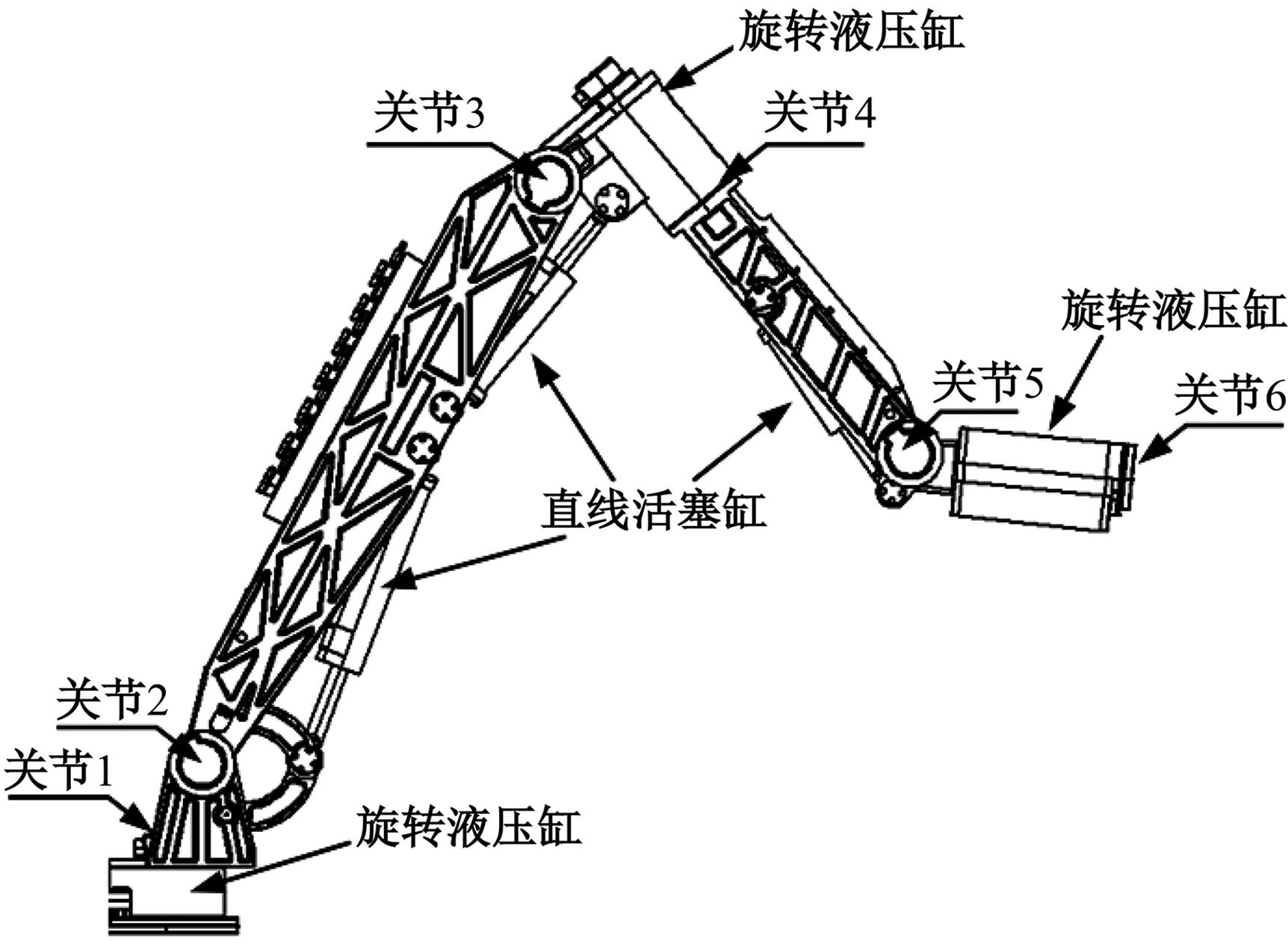

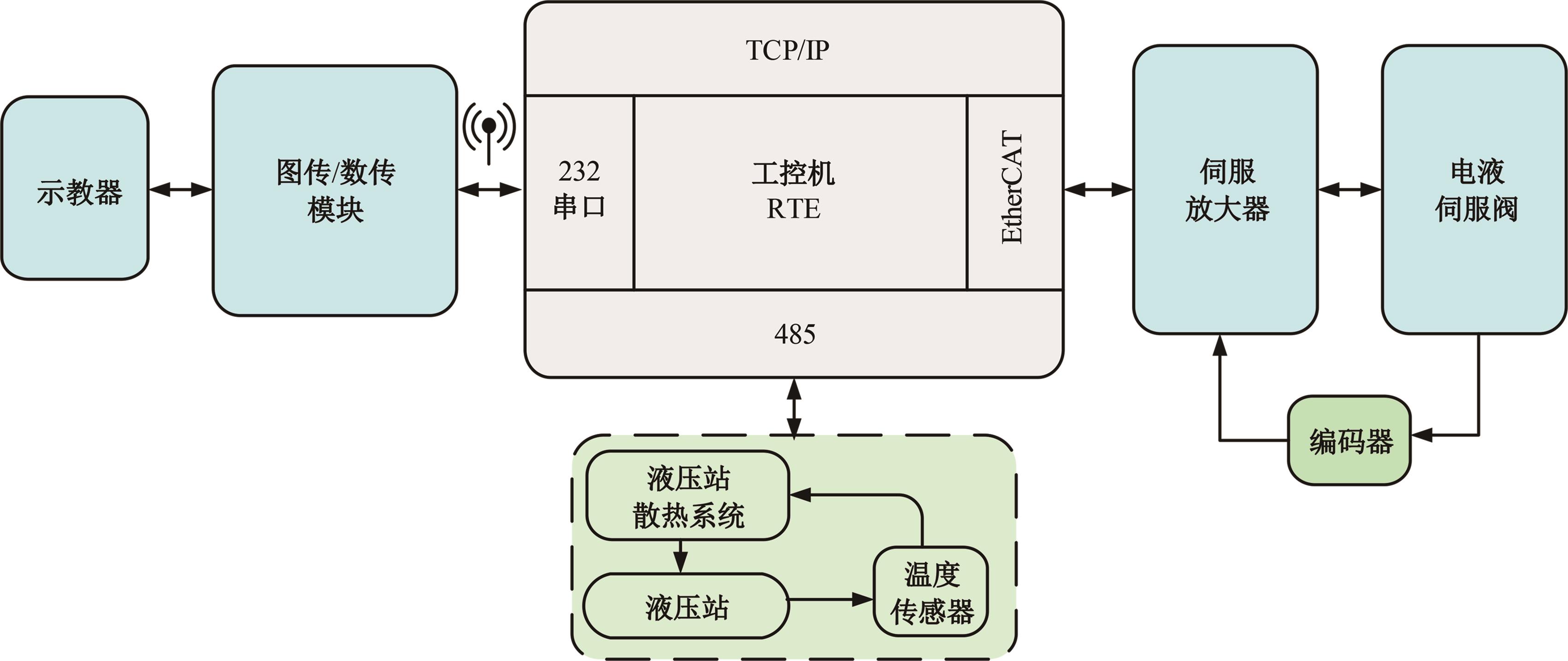

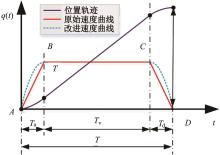

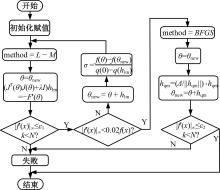

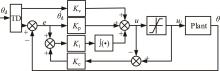

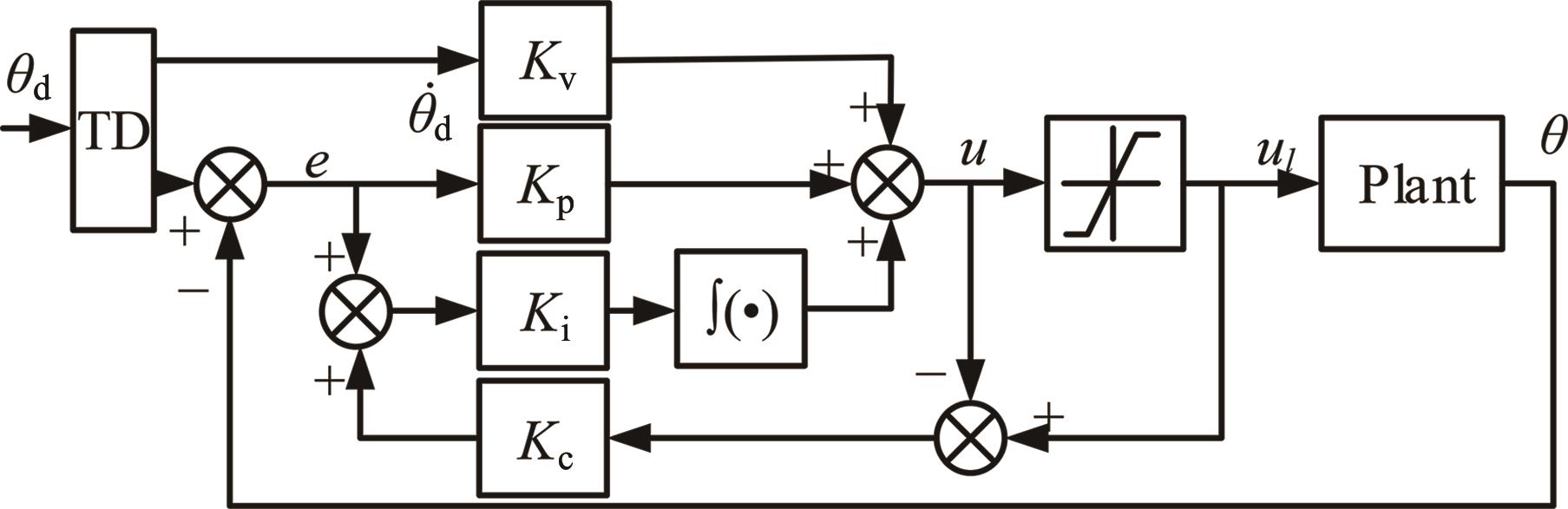

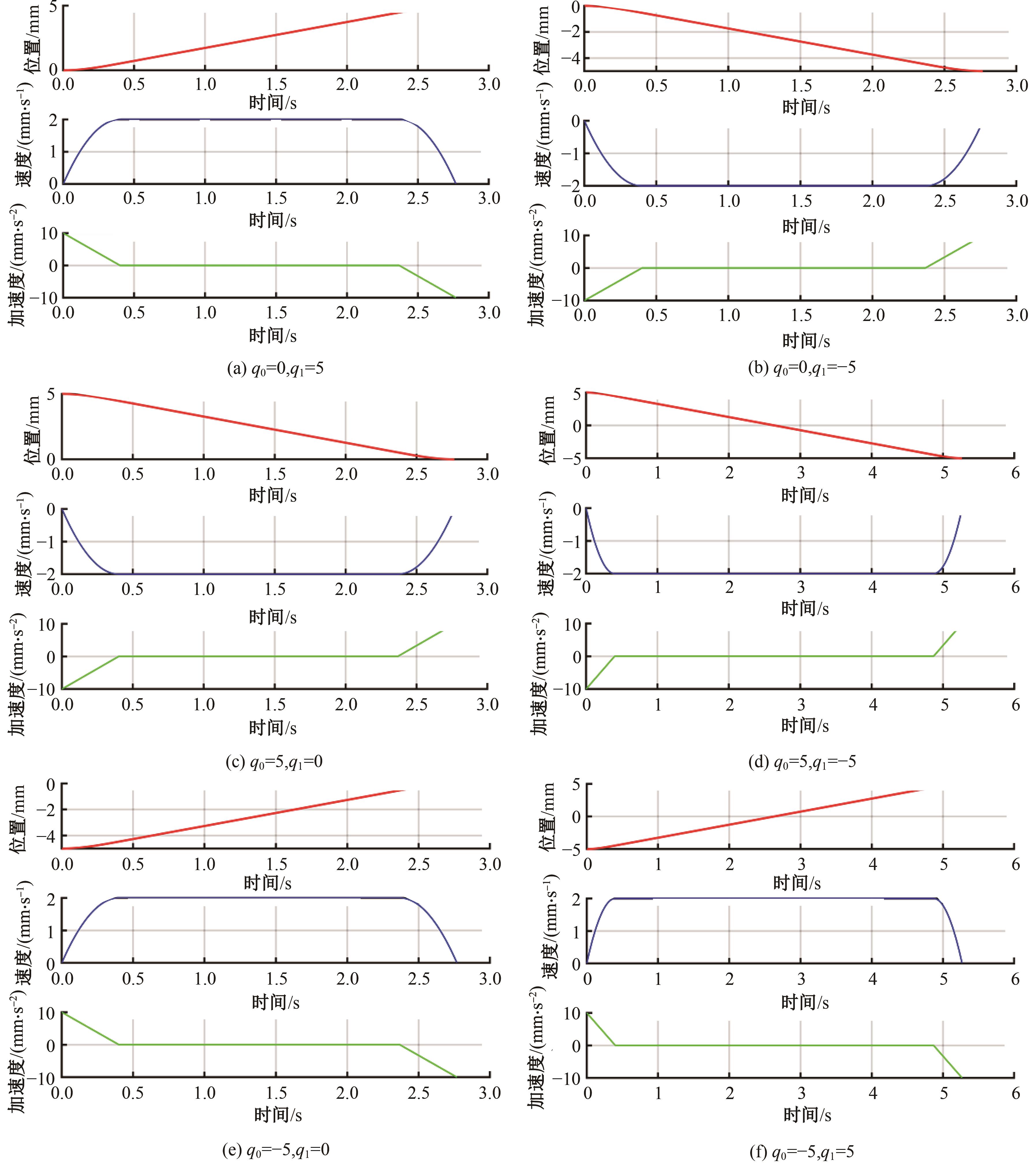

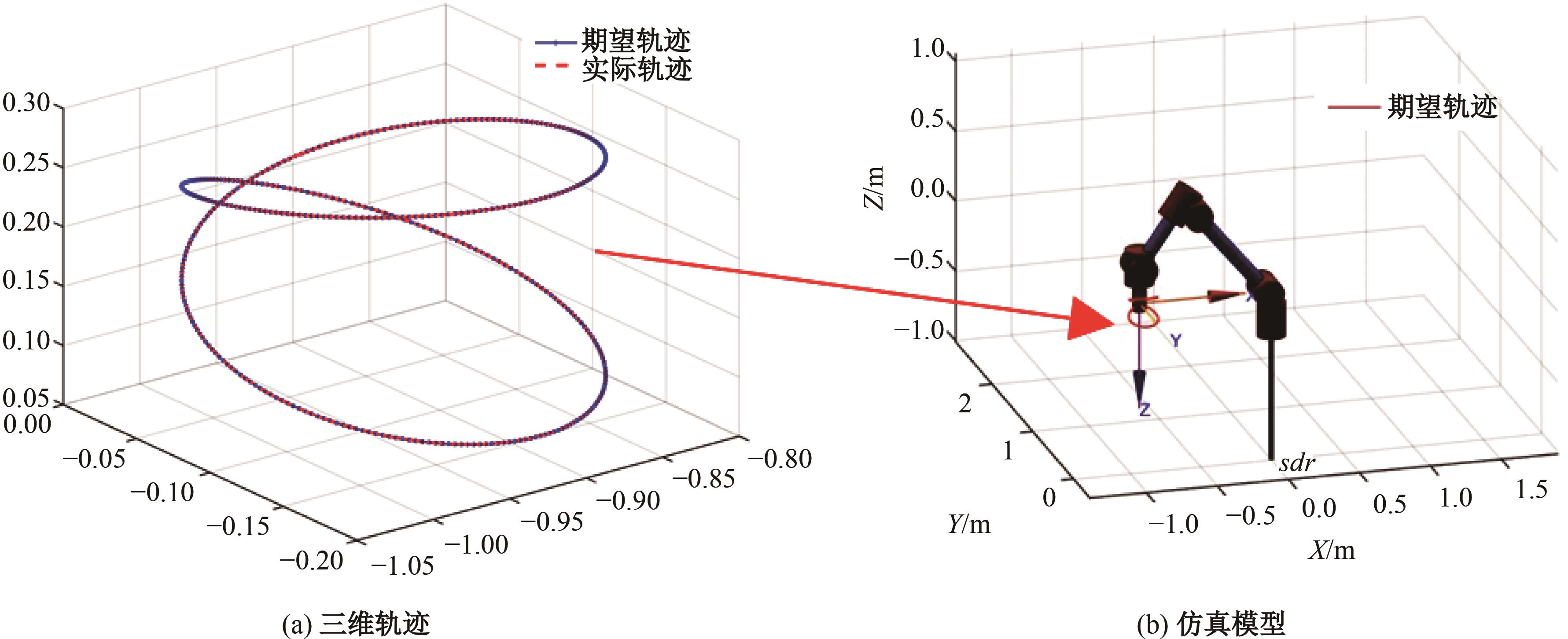

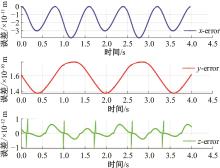

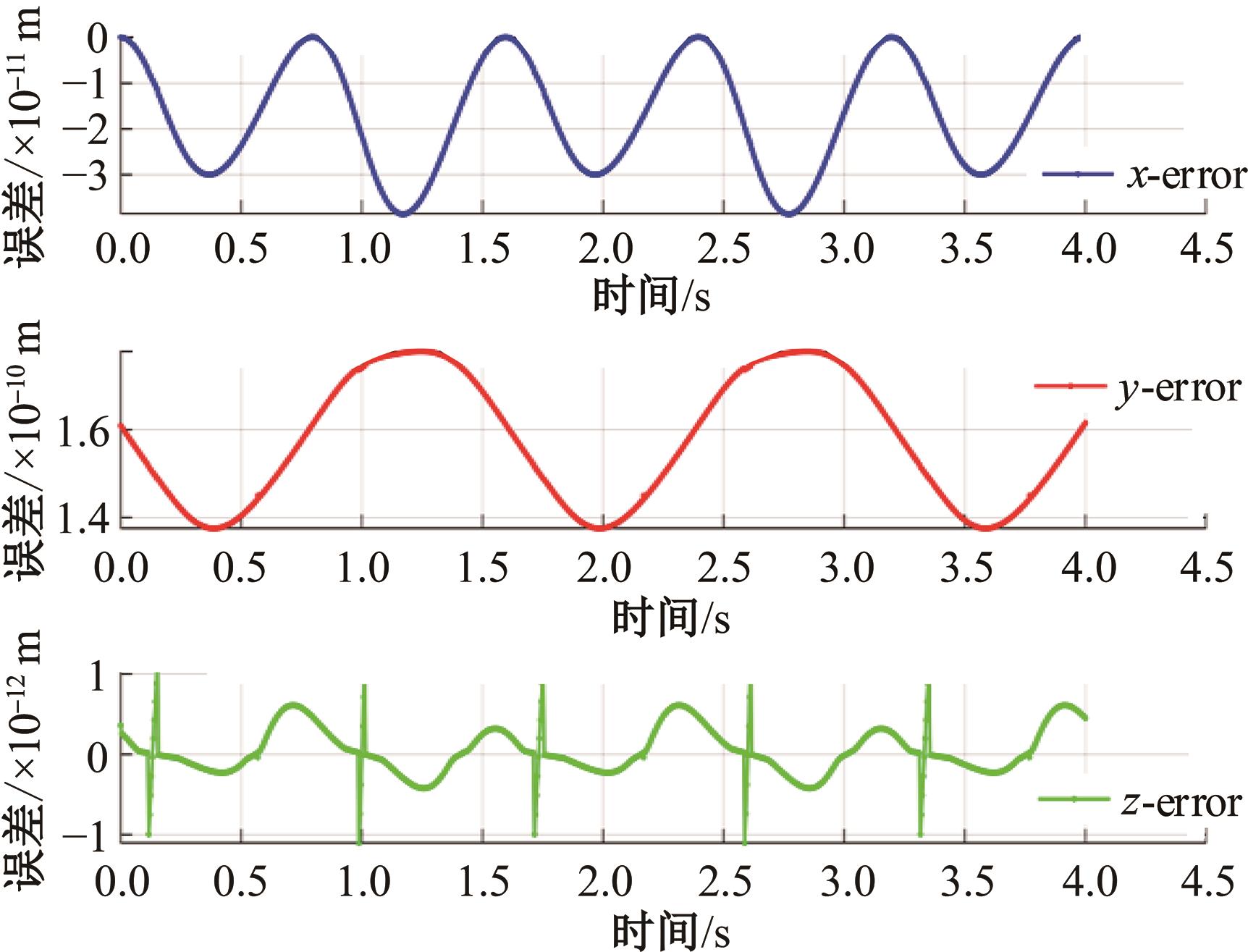

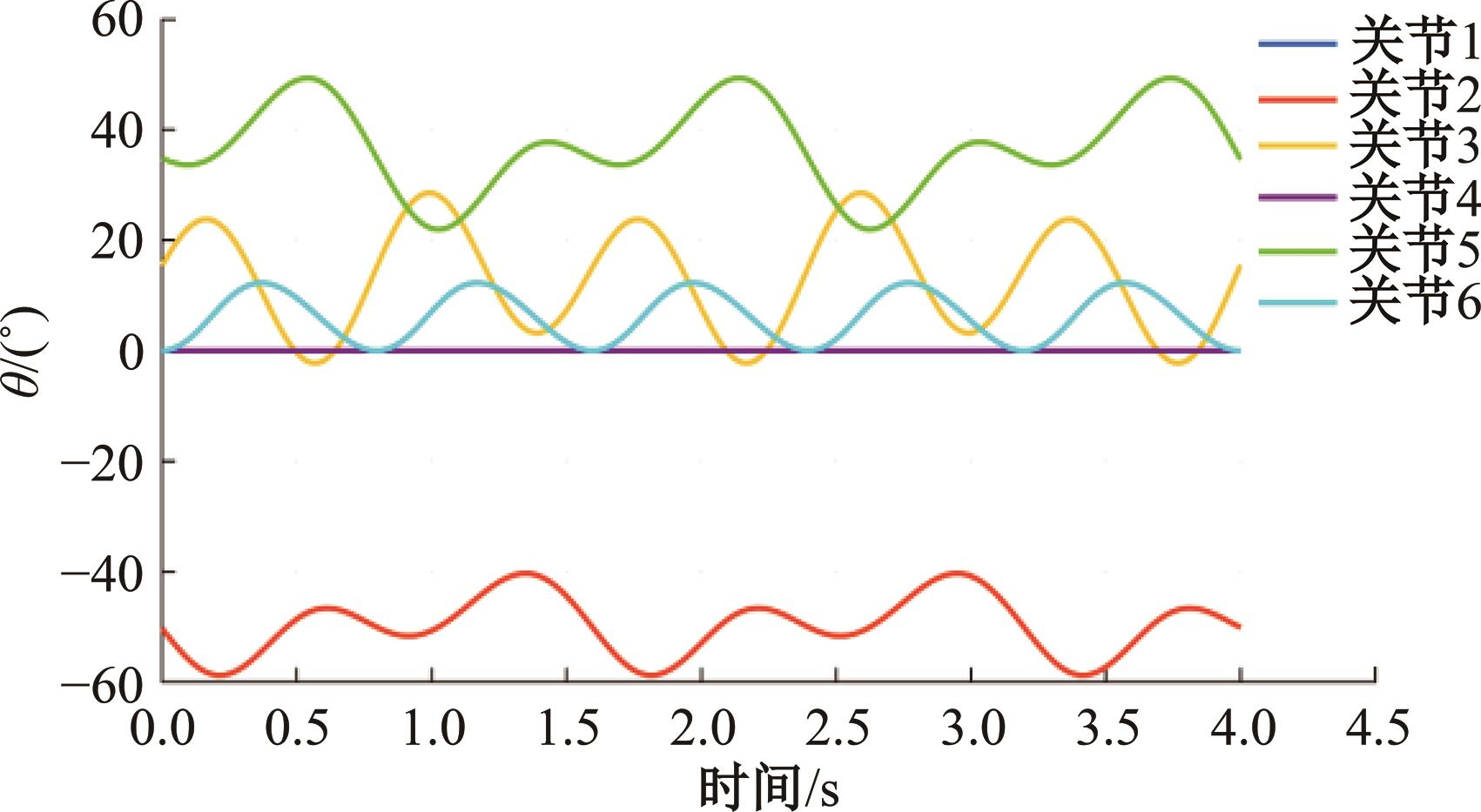

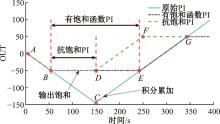

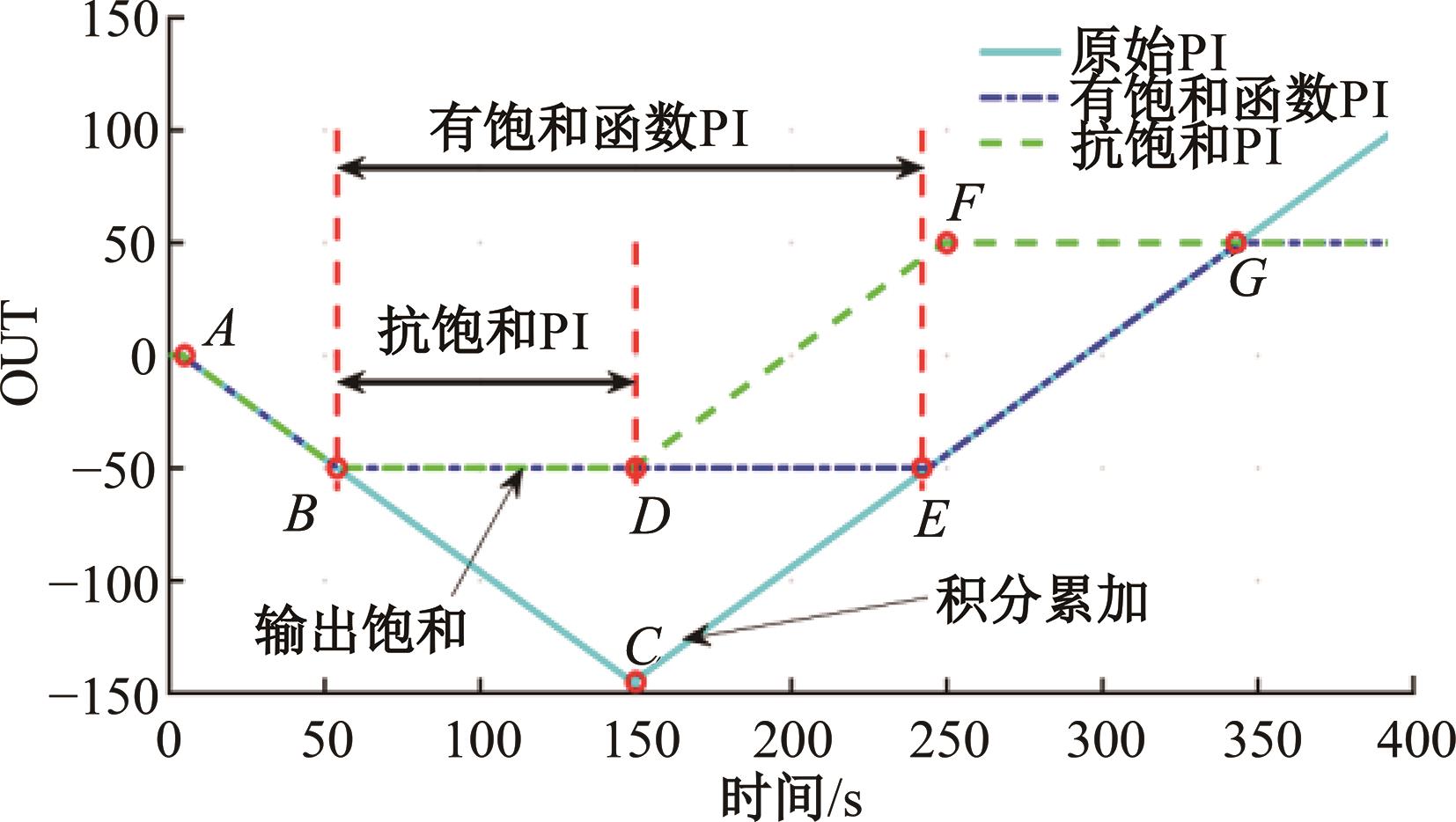

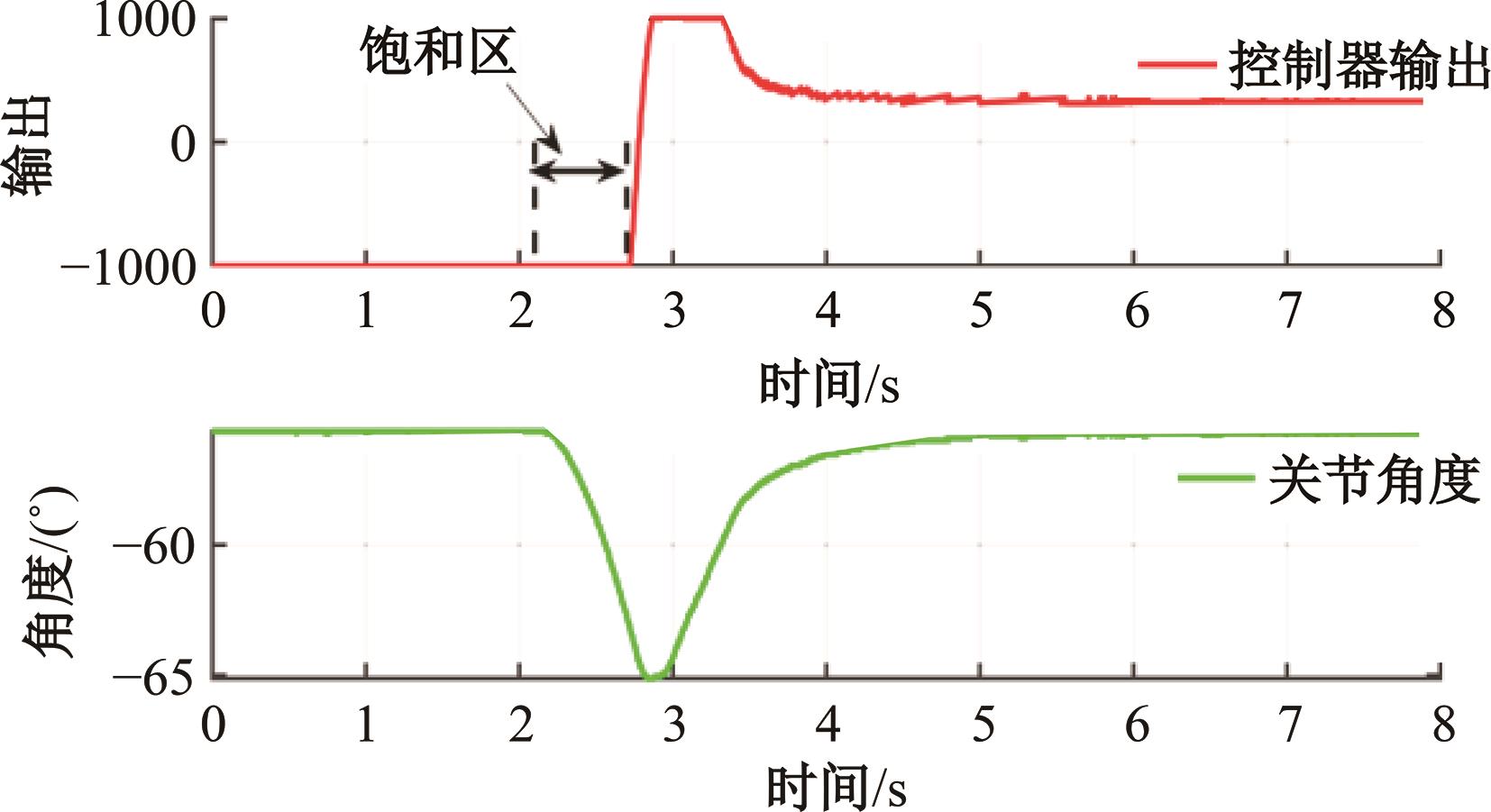

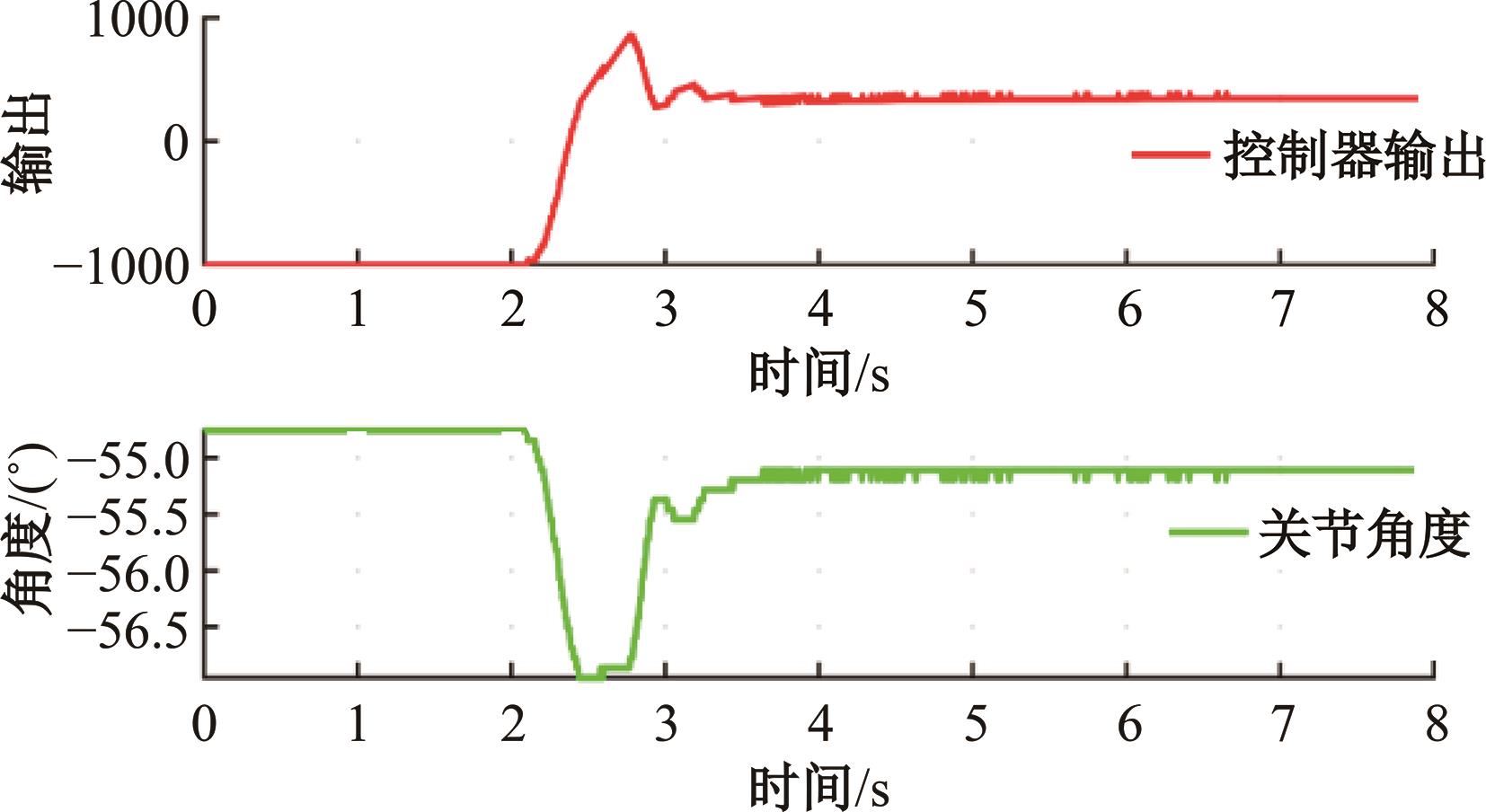

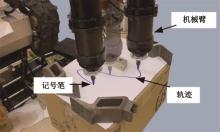

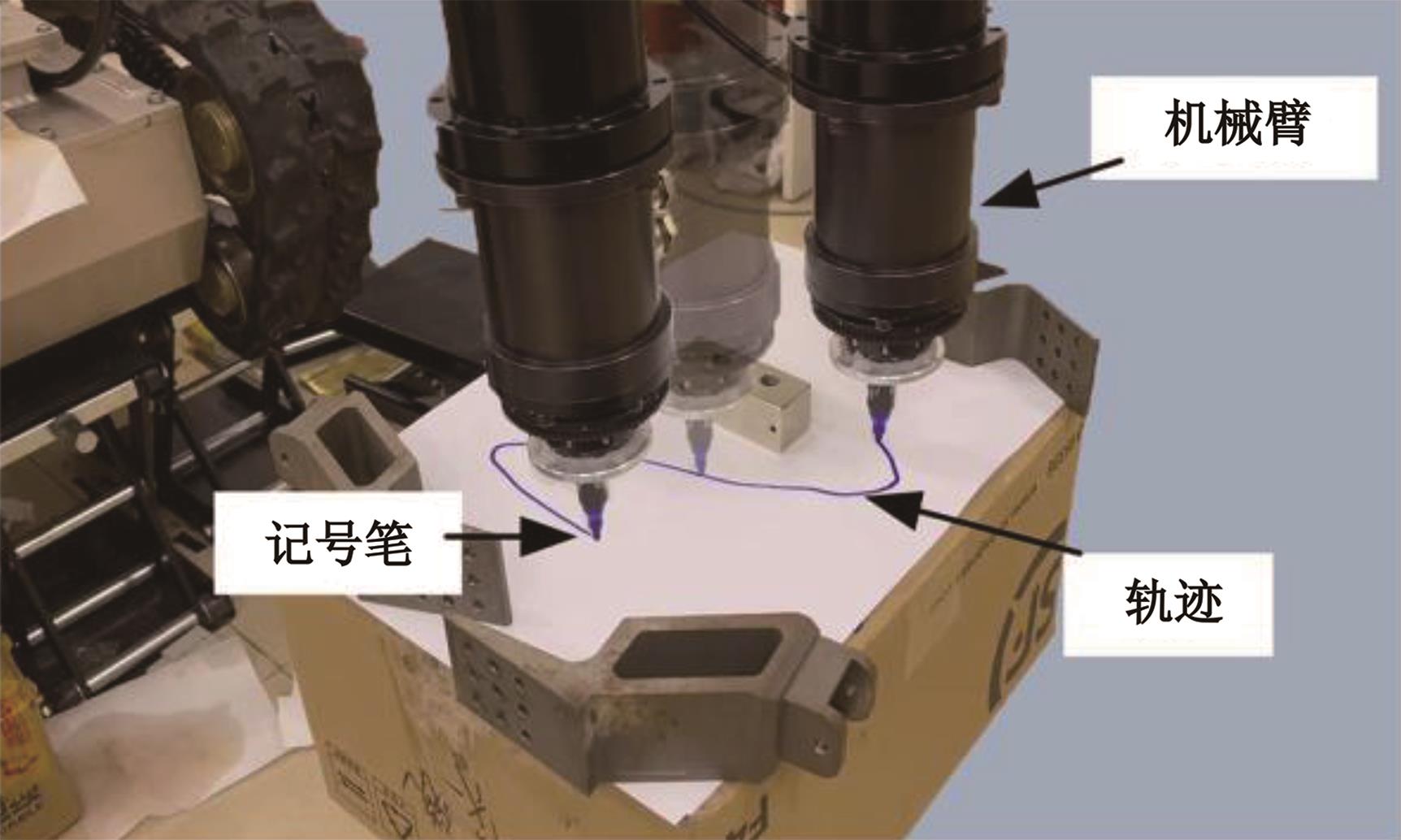

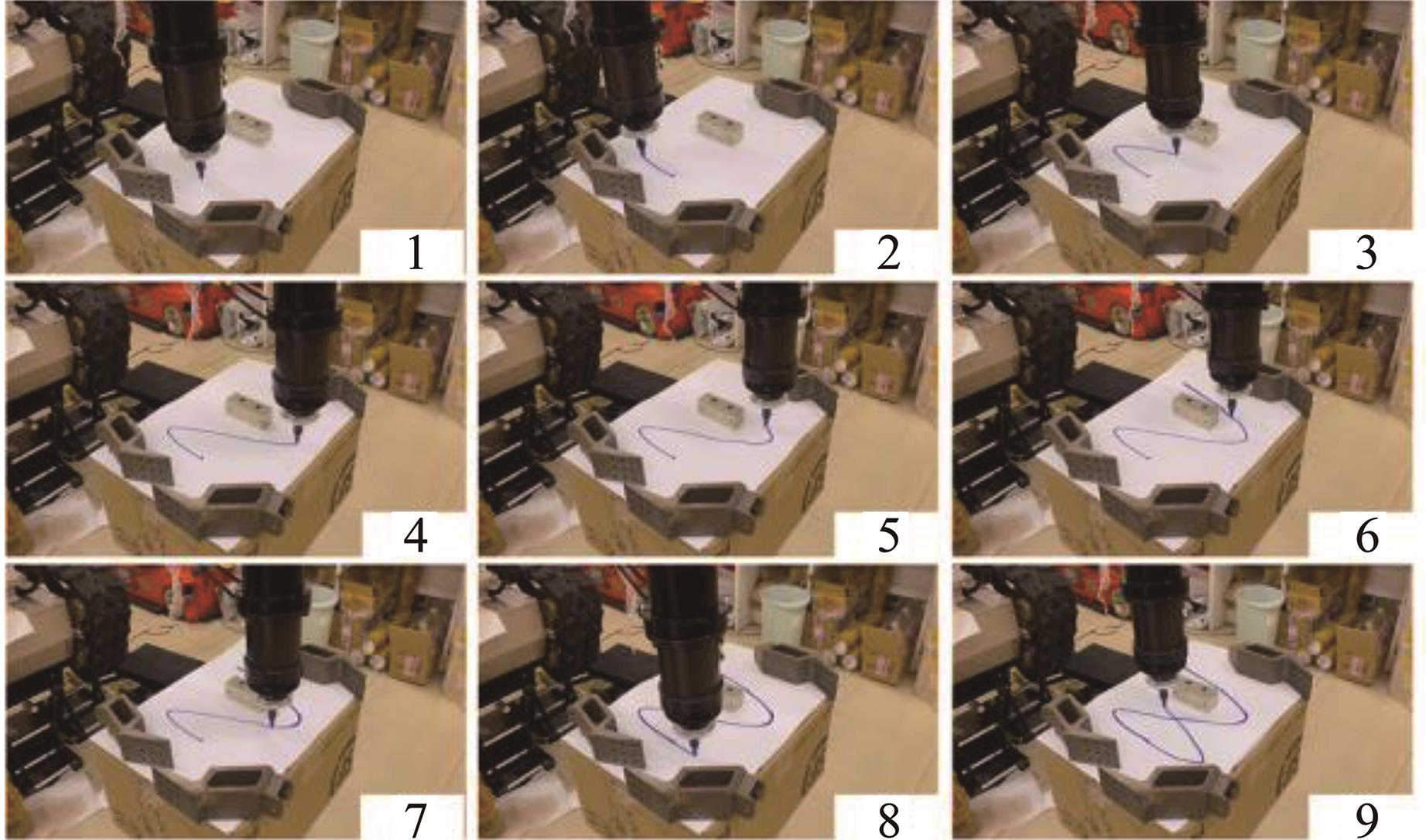

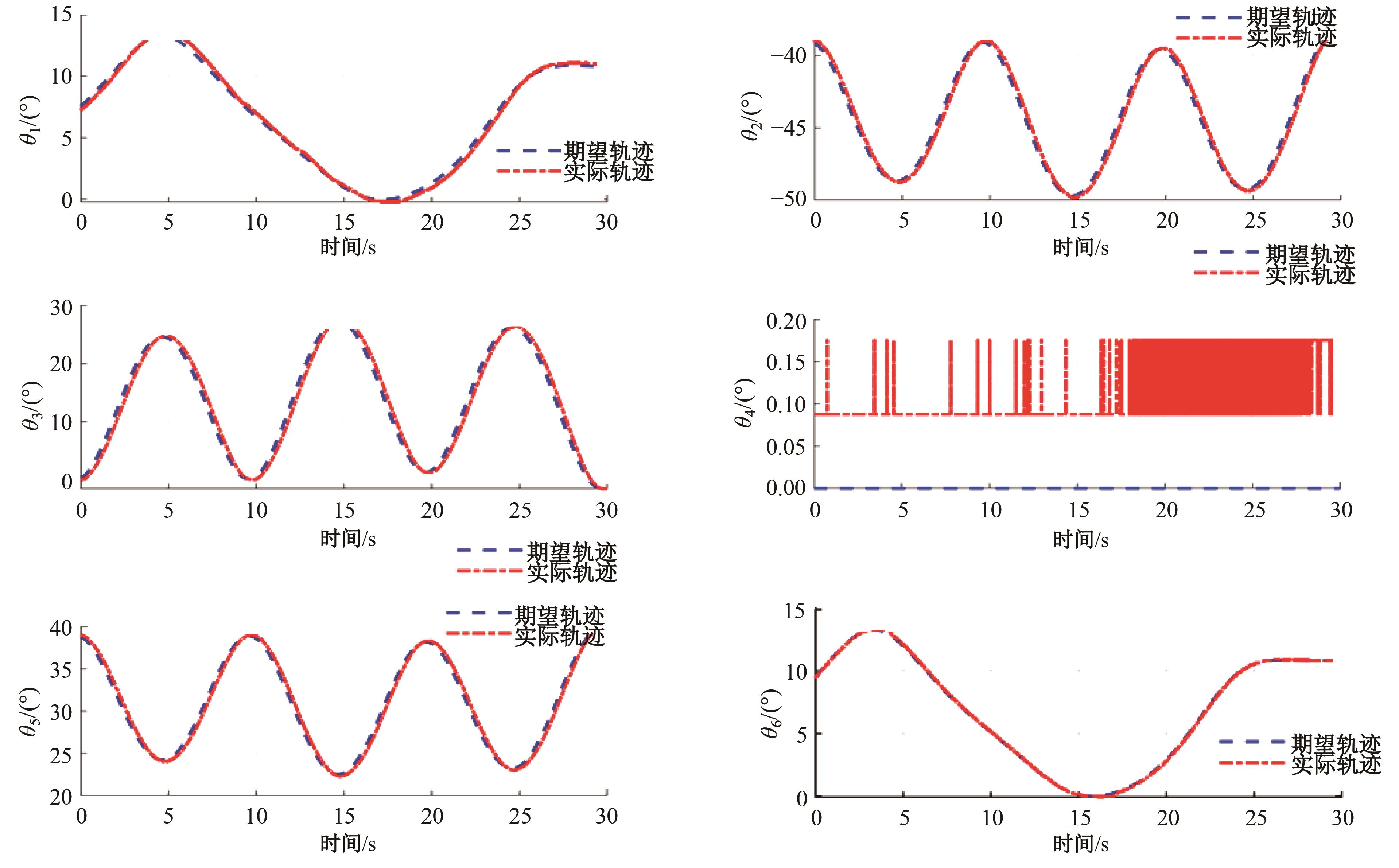

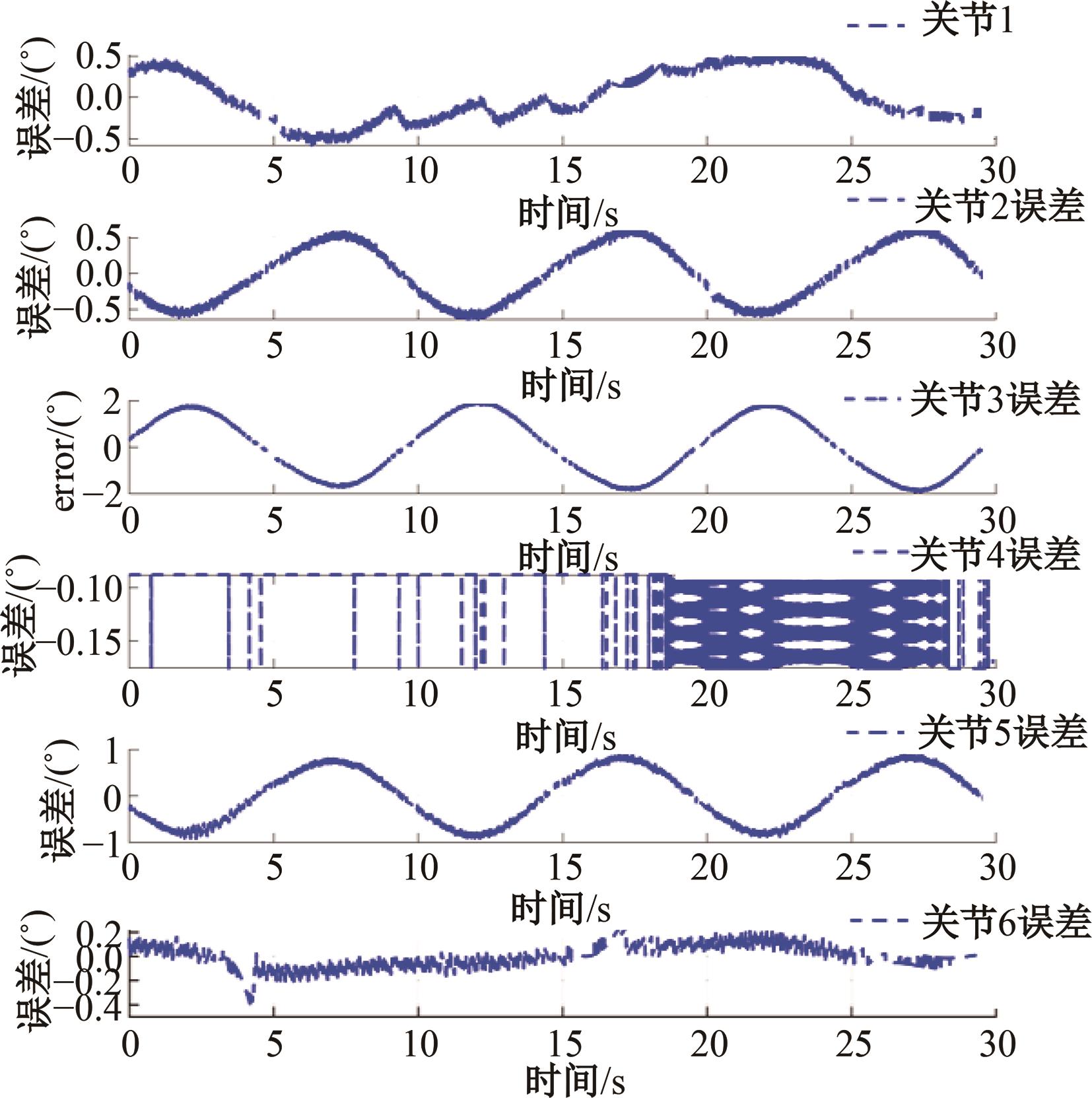

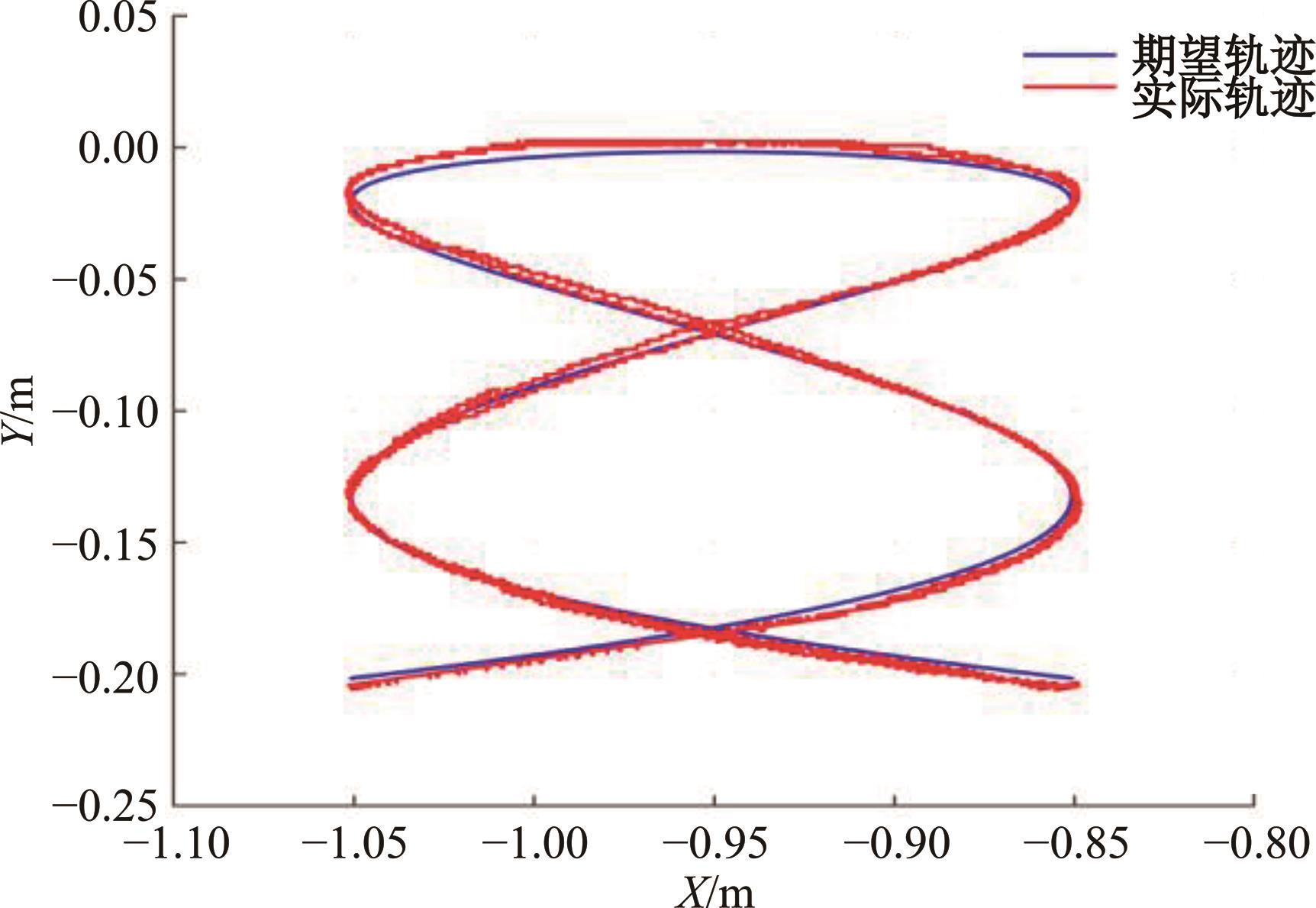

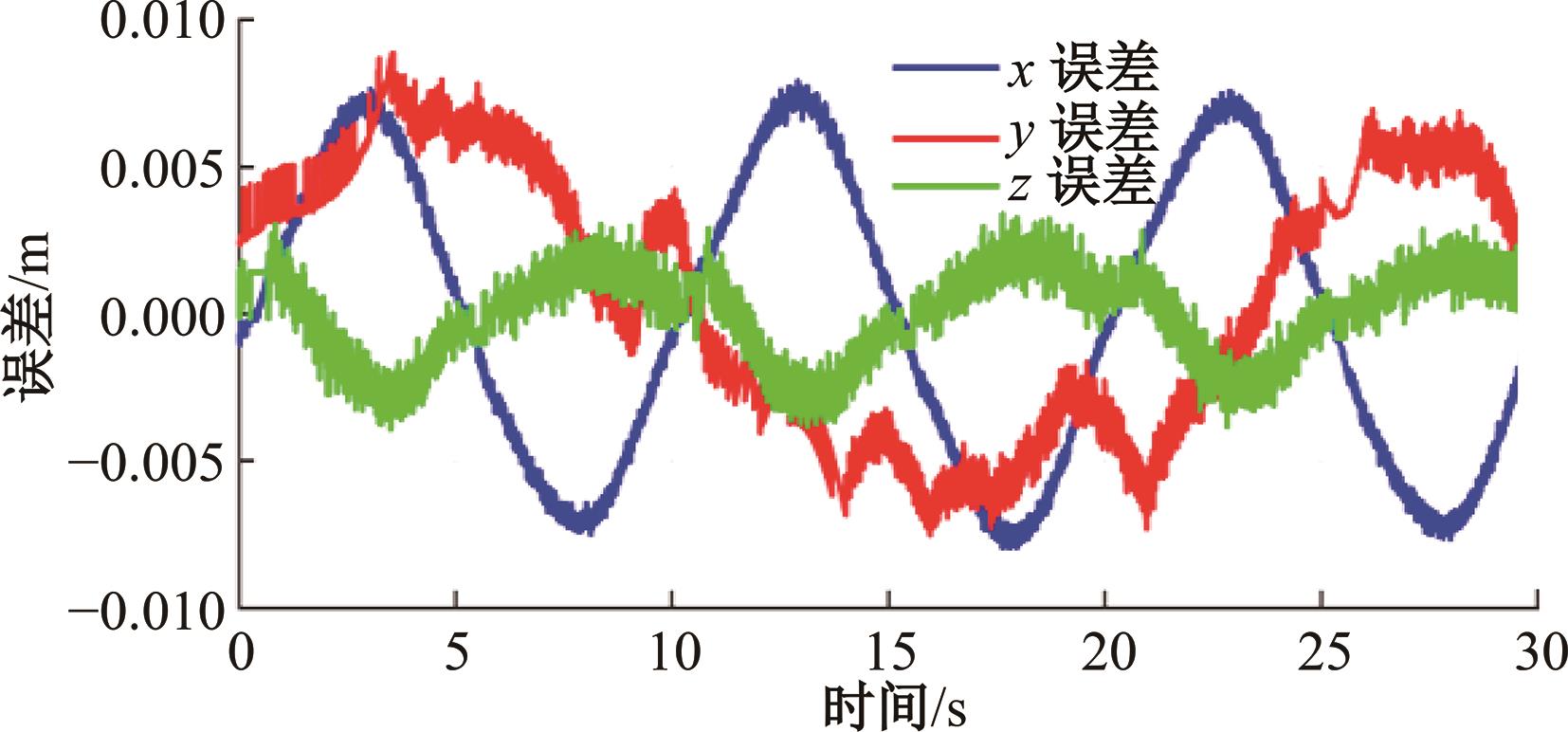

针对大负载作业需求,设计了一种基于液压驱动的六自由度机械臂实时控制系统。采用单一工控机构建液压机械臂实时控制系统,即上层任务调度和底层电液伺服驱动通过单一控制器完成。设计了基于抛物线的改进梯形速度曲线优化策略;提出了融合Levenberg-marquardt (LM)与拟牛顿(Quasi-Newton methods)的逆运动学迭代求解方法;引入了具有抗积分饱和PI控制器,抑制积分饱和影响;通过仿真和物理样机完成了机械臂在笛卡尔空间中的连续轨迹跟踪性能测试和控制系统综合性能测试。实验结果表明:该控制系统稳定可靠,实时性强,满足工程控制要求。

中图分类号:

- TP242.3

| 1 | Yao J, Deng W. Active disturbance rejection adaptive control of hydraulic servo systems[J]. IEEE Transactions on Industrial Electronics,2017, 64(10): 8023-8032. |

| 2 | Zhang L, Zhao J, Long P, et al. An autonomous excavator system for material loading tasks[J]. Sci Robot, 2021, 6(55): eabc3164. |

| 3 | Zhang J, Li W, Yu J, et al. Development of a virtual platform for telepresence control of an underwater manipulator mounted on a submersible vehicle[J]. IEEE Transactions on Industrial Electronics, 2017, 64(2): 1716-1727. |

| 4 | Li Z, Ma X, Li Y, et al. ADRC-ESMPC active heave compensation control strategy for offshore cranes[J]. Ships and Offshore Structures, 2020, 15(10): 1098-1106. |

| 5 | 张旭飞, 邵焱, 付玉琴, 等. 起重机变幅系统Simcenter 3D机液联合仿真分析[J].机械工程学报, 2022, 58(24): 334-341. |

| Zhang Xu-fei, Shao Yan, Fu Yu-qin, et al. Mechanical and hydraulic co-simulation analysis for crane luffing system based on simcenter 3D[J]. Journal of Mechanical Engineering, 2022, 58(24): 334-341. | |

| 6 | Koivumaki J, Mattila J. Stability-guaranteed impedance control of hydraulic robotic manipulators[J]. IEEE/ASME Transactions on Mechatronics, 2017, 22(2): 601-612. |

| 7 | Pi Y, Wang X. Trajectory tracking control of a 6-DOF hydraulic parallel robot manipulator with uncertain load disturbances[J]. Control Engineering Practice, 2011, 19(2): 185-193. |

| 8 | 陈鹰. 海底热液科学考察中的机电装备技术[J]. 机械工程学报, 2002(): 207-211. |

| Chen Ying. Mechatronic devices in the scientific expedition of deep-ser vents[J]. Journal of Mechanical Engineering, 2002(Sup.1): 207-211. | |

| 9 | Sivčev S, Coleman J, Omerdić E, et al. Underwater manipulators: a review[J]. Ocean Engineering, 2018, 163: 431-450. |

| 10 | 陶军. 大洋深处强国梦——我国首台4 500米级无人遥控潜水器“海马号”[J]. 国土资源科普与文化, 2016, 2016(1): 13-19. |

| Tao Jun. Deep ocean power dream— China's first 4 500 meters unmanned remote control submersible "Haima"[J]. Scientific and Cultural Popularization of Natural Resources, 2016, 2016(1): 13-19. | |

| 11 | 王清梅, 王秀莲, 孙斌, 等. 水下主从伺服液压机械手控制系统设计[J]. 液压与气动, 2013, 2013(11): 33-37. |

| Wang Qing-mei, Wang Xiu-lian, Sun Bin, et al. Design of underwater master-slave hydraulic servo manipulator control system[J]. Chinese Hydraulics & Pneumatics, 2013, 2013(11): 33-37. | |

| 12 | Cortés J, Egerstedt M. Coordinated control of multi-robot systems: a survey[J]. SICE Journal of Control, Measurement, and System Integration, 2017, 10(6): 495-503. |

| 13 | Guo Q, Chen Z, Shi Y, et al. Synchronous control for multiple electrohydraulic actuators with feed-back linearization[J]. Mechanical Systems and Signal Processing, 2022, 178: No.109280. |

| 14 | Hoang Q D, Park J, Lee S G. Combined feedback linearization and sliding mode control for vibration suppression of a robotic excavator on an elastic foundation[J]. Journal of Vibration and Control, 2021, 27(3/4): 251-263. |

| 15 | Lin Y, Shi Y, Burton R. Modeling and robust discrete-time sliding-mode control design for a fluid power electrohydraulic actuator (EHA) system[J]. IEEE/ASME Transactions on Mechatronics, 2013, 18(1): 1-10. |

| 16 | Yao J, Deng W. Active disturbance rejection adaptive control of hydraulic servo systems[J]. IEEE Transactions on Industrial Electronics, 2017, 64(10): 8023-8032. |

| 17 | 李元春, 王蒙, 盛立辉, 等. 液压机械臂基于反演的自适应二阶滑模控制[J]. 吉林大学学报: 工学版, 2015, 45(1): 193-201. |

| Li Yuan-chun, Wang Meng, Sheng Li-hui, et al. Adaptive second order sliding mode control for hydraulic manipulator based on backstepping[J]. Journal of Jilin University (Engineering and Technology Edition), 2015, 45(1): 193-201. | |

| 18 | Won D, Kim W, Shin D, et al. High-gain disturbance observer-based backstepping control with output tracking error constraint for electro-hydraulic systems[J]. IEEE Transactions on Control Systems Technology, 2015, 23(2): 787-795. |

| 19 | Guo K, Wei J, Tian Q. Nonlinear adaptive position tracking of an electro-hydraulic actuator[J]. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 2015, 229(17): 3252-3265. |

| 20 | Guo K, Wei J, Fang J, et al. Position tracking control of electro-hydraulic single-rod actuator based on an extended disturbance observer[J]. Mechatronics, 2015, 27: 47-56. |

| 21 | 方一鸣,焦宗夏,王文宾,等. 轧机液压伺服位置系统的自适应反步滑模控制[J]. 电机与控制学报, 2011, 15(10): 95-100. |

| Fang Yi-ming, Jiao Zong-xia, Wang Wen-bin, et al. Adaptive backstepping sliding mode control for rolling mill hydraulic servo position system[J]. Electrical Machine and Control, 2011, 15(10): 95-100. | |

| 22 | Powel M J D. Updating conjugate directions by the BFGS formula[J]. Mathematical Programming, 1987, 38(1): 29-46. |

| [1] | 沈鹏,李小华,刘辉. 具有输入缓冲的机械臂预设定有限时间跟踪控制[J]. 吉林大学学报(工学版), 2025, 55(1): 63-73. |

| [2] | 朱广贺,朱智强,袁逸萍. 连续生产流水线深度强化学习优化调度算法[J]. 吉林大学学报(工学版), 2024, 54(7): 2086-2092. |

| [3] | 鲜斌,王光怡,蔡佳明. 多无人机吊挂负载运输系统的非线性鲁棒控制设计[J]. 吉林大学学报(工学版), 2024, 54(6): 1788-1795. |

| [4] | 王宏志,王婷婷,兰淼淼,徐硕. 基于位置跟踪的机械臂多电机新型滑模控制策略[J]. 吉林大学学报(工学版), 2024, 54(5): 1443-1458. |

| [5] | 赵军,赵子亮,朱庆林,郭斌. 不依赖观测器的不确定性系统输出反馈鲁棒控制[J]. 吉林大学学报(工学版), 2024, 54(3): 828-835. |

| [6] | 常玉林,王逸杰,王建,孙超,张鹏,徐文倩. 考虑定制公交及公交专用道的混合逐日均衡模型[J]. 吉林大学学报(工学版), 2024, 54(11): 3209-3219. |

| [7] | 岳昊,张琦悦,杨子玉,任孟杰,张旭. 拥堵空间排队的静态交通流分配迭代加权算法[J]. 吉林大学学报(工学版), 2024, 54(1): 136-145. |

| [8] | 王艳敏,张伟琦,段广鑫,葛杨. 电子节气门的连续非奇异终端滑模控制[J]. 吉林大学学报(工学版), 2023, 53(7): 2127-2135. |

| [9] | 孙超,尹浩为,汤文蕴,褚昭明. 交通需求估计下的检测器布局和手机数据扩样推断[J]. 吉林大学学报(工学版), 2023, 53(4): 1070-1077. |

| [10] | 齐国元,李阔,王琨. 基于补偿函数观测器的四旋翼无人机姿态受限控制[J]. 吉林大学学报(工学版), 2023, 53(3): 853-862. |

| [11] | 郭洪艳,于文雅,刘俊,戴启坤. 复杂场景智能车辆车道与速度一体化滚动优化决策[J]. 吉林大学学报(工学版), 2023, 53(3): 693-703. |

| [12] | 王德军,张凯然,徐鹏,顾添骠,于文雅. 基于车辆执行驱动能力的复杂路况速度规划及控制[J]. 吉林大学学报(工学版), 2023, 53(3): 643-652. |

| [13] | 徐卓君,王耀祥,黄兴,彭程. 多无人机地面移动目标搜寻和定位[J]. 吉林大学学报(工学版), 2023, 53(3): 832-840. |

| [14] | 何德峰,周丹,罗捷. 跟随式车辆队列高效协同弦稳定预测控制[J]. 吉林大学学报(工学版), 2023, 53(3): 726-734. |

| [15] | 齐国元,陈浩. 基于观测器的四旋翼控制-抗扰-避障一体化[J]. 吉林大学学报(工学版), 2023, 53(3): 810-822. |

|

||