吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (12): 3460-3467.doi: 10.13229/j.cnki.jdxbgxb.20230177

热变形参数对2.25Cr-lMo-0.25V钢动态再结晶的影响

- 太原科技大学 材料科学与工程学院,太原 030024

Effect of thermo-mechanical processing parameters on dynamic recrystallization of 2.25Cr-lMo-0.25V Steel

- College of Materials Science and Engineering,Taiyuan University of Science and Technology,Taiyuan 030024,China

摘要:

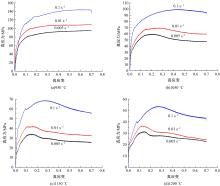

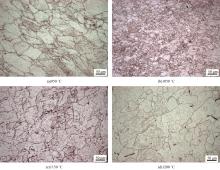

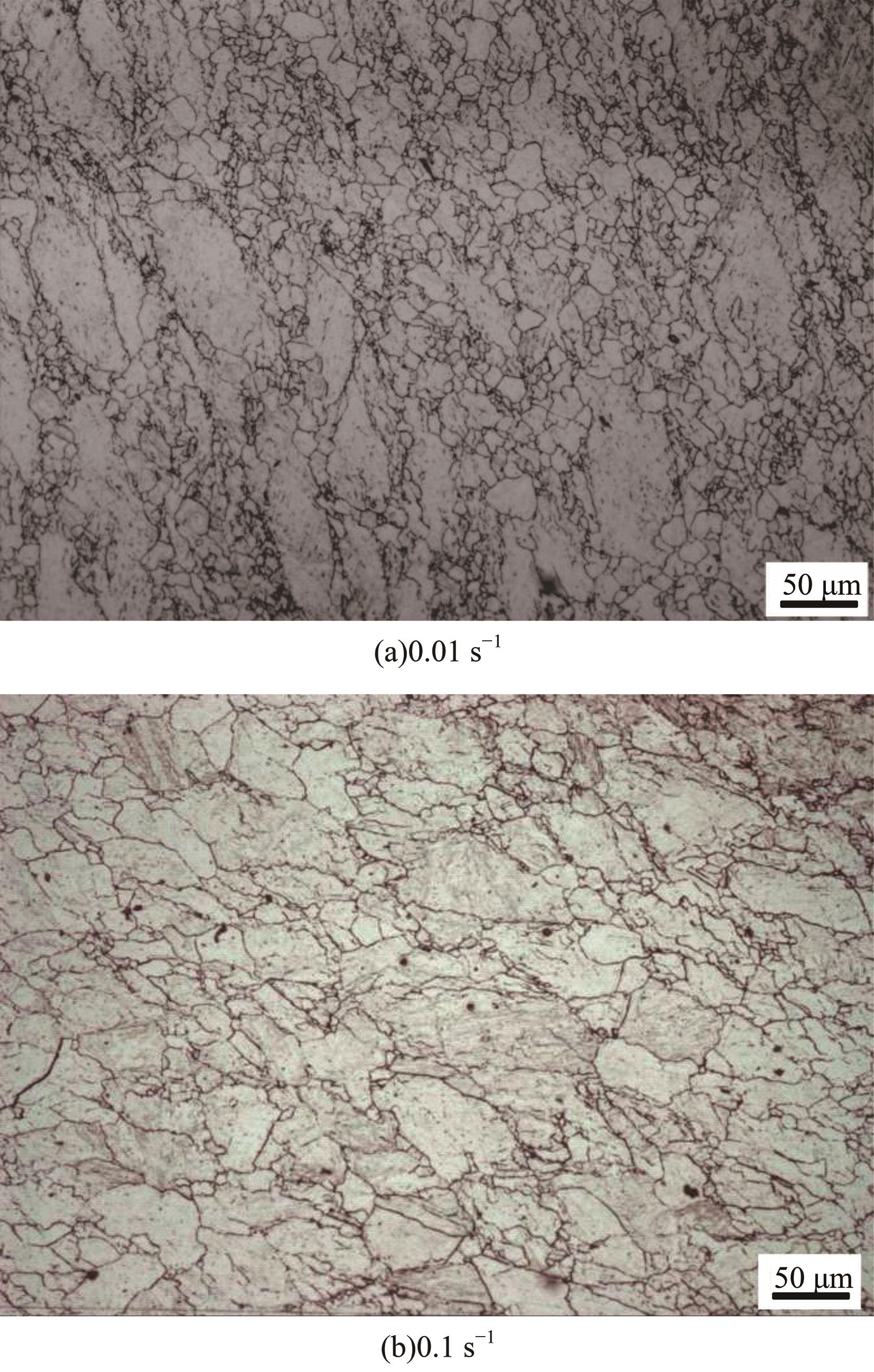

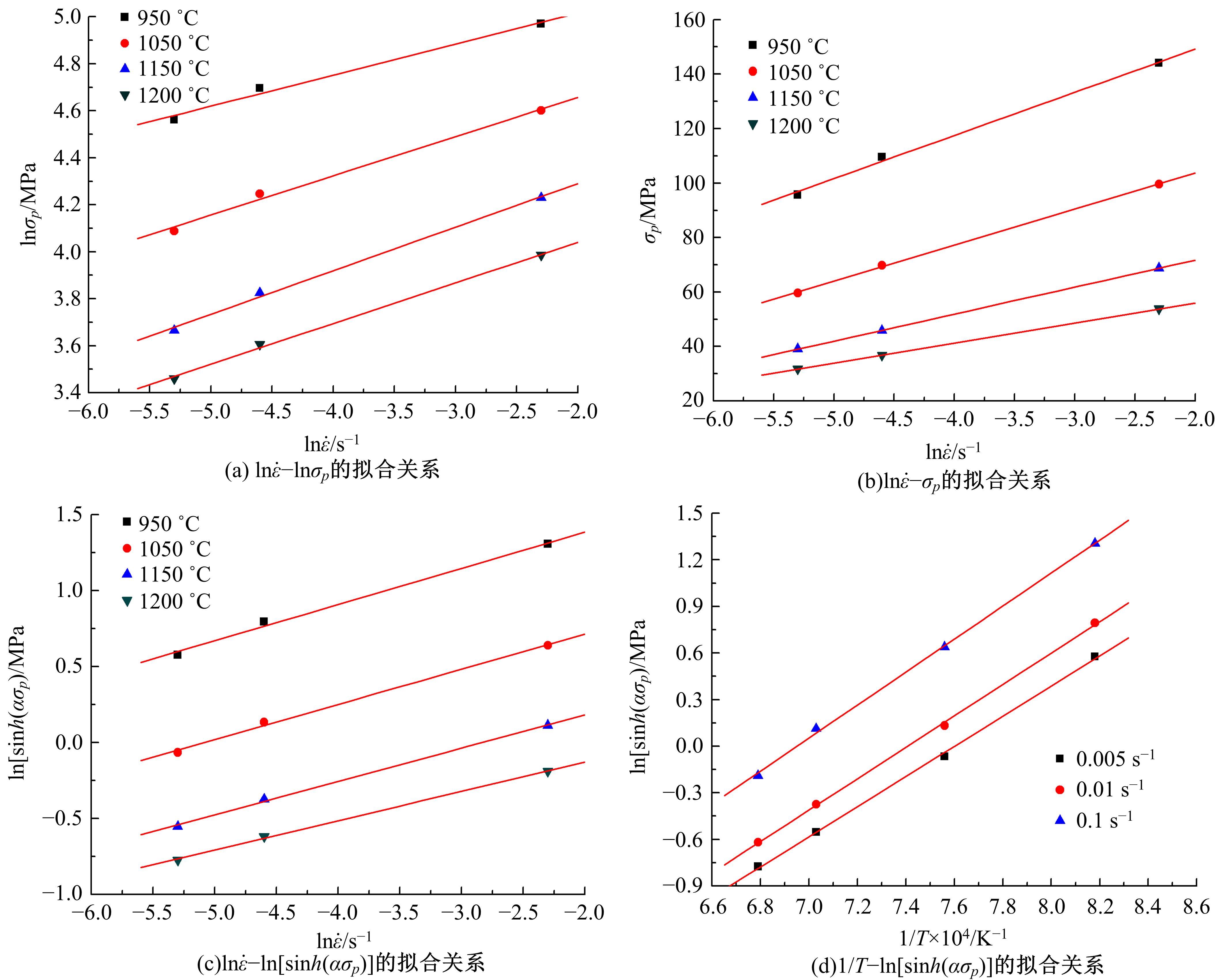

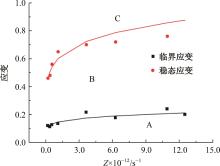

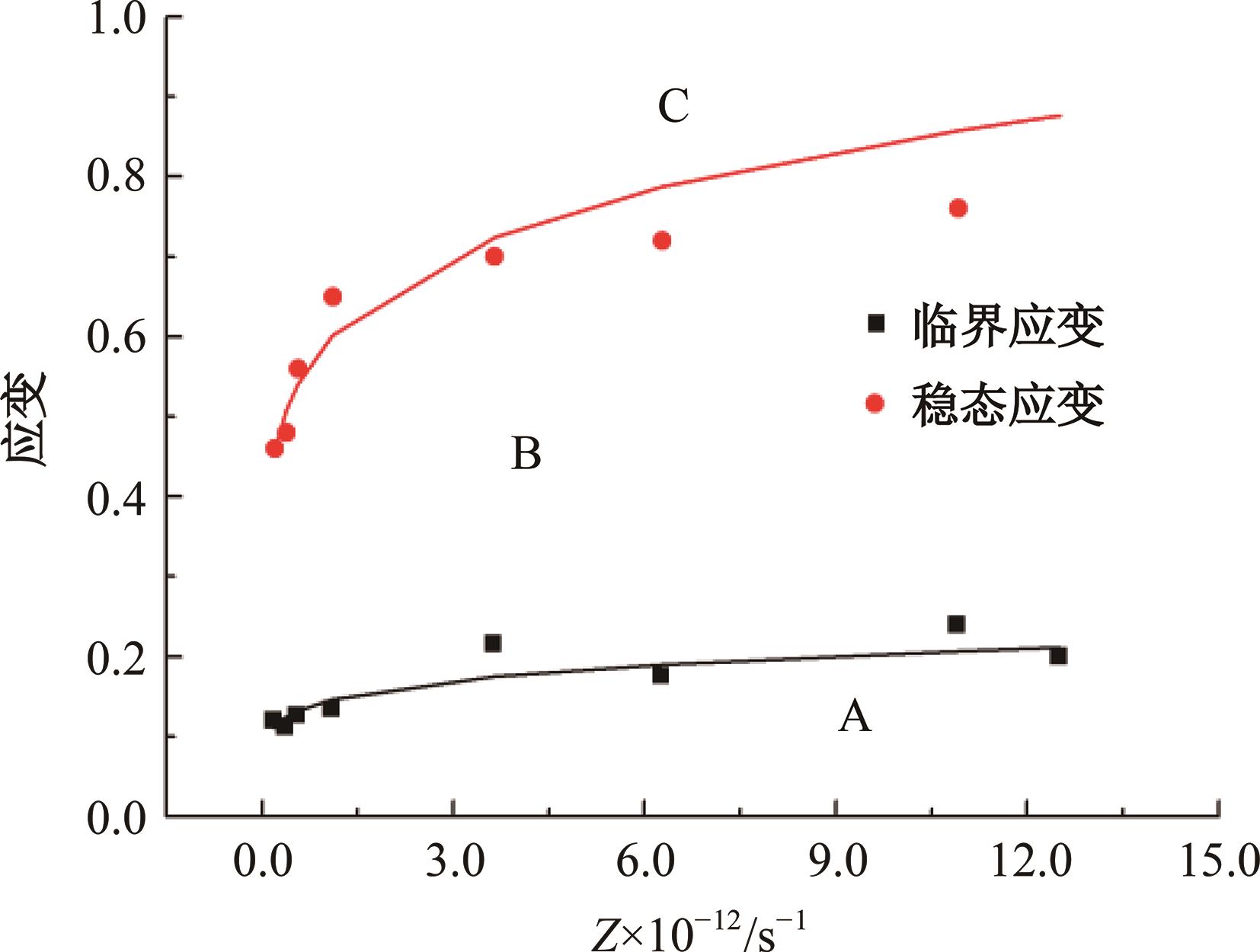

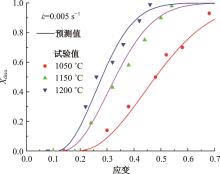

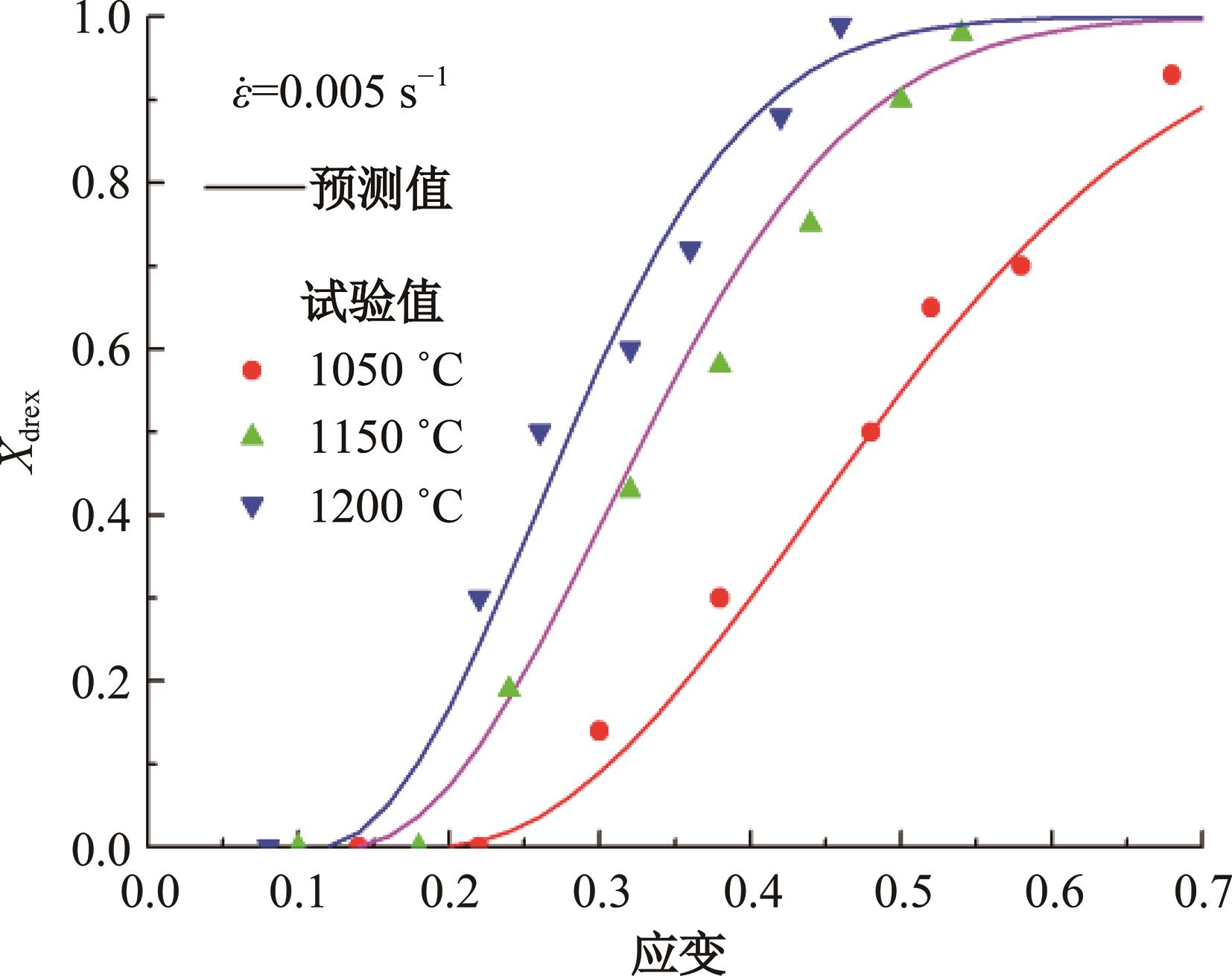

采用Gleeble-1500D热模拟试验机,通过热压缩实验研究了2.25Cr-lMo-0.25V钢在温度为950~1 200 ℃,应变速率为0.005~0.1 s-1时的热变形及动态再结晶行为。结果表明:流动应力及动态再结晶都具有显著的温度、应变速率敏感性。通过回归分析确定了临界应变、稳态应变与Zener-Hollomon参数共同表征的动态再结晶状态图,建立了动态再结晶动力学方程和动态再结晶晶粒尺寸模型。本文研究成果为2.25Cr-lMo-0.25V钢热成形工艺参数的合理制订提供了参考数据。

| 1 | 曹晨思, 段红玲, 李雪龙. 2.25Cr-1Mo-0.25V 钢大型压力容器封头均质性研究[J]. 大型铸锻件,2022(1): 16-19. |

| Cao Chen-si, Duan Hong-ling, Li Xue-long. Study on the homogeneity of 2.25Cr-1Mo-0.25V hteel large pressure vessel head[J]. Heavy Casting and Forging, 2022(1):16-19. | |

| 2 | 侯敬超, 赵国昌, 庞辉勇, 等. 2.25Cr-1Mo-0.25V 钢148 mm厚板尾部分层缺陷分析及控制工艺[J]. 特殊钢, 2023, 44(2): 43-46. |

| Hou Jing-chao, Zhao Guo-chang, Pang Hui-yong, et al. Analysis on causes of delamination defect at 148 mm heavy thick-ness plate tail of 2.25Cr-1Mo-0.25V steel and control process[J]. Special Steel, 2023, 44(2): 43-46. | |

| 3 | 陈学东, 范志超, 崔军, 等. 我国压力容器高性能制造技术进展[J]. 压力容器, 2021, 38(10): 1-15. |

| Chen Xue-dong, Fan Zhi-chao, Cui Jun, et al. Progress in high-performance manufacturing technology for pressure vessels in China[J]. Pressure Vessel Technology, 2021, 38(10): 1-15. | |

| 4 | 张子平, 吴晓俣, 王常青, 等. 2.25Cr-1Mo-0.25V大型厚壁锻焊加氢反应器制造阶段典型质量问题解析[J]. 石油化工设备技术,2023, 44(1): 45-51. |

| Zhang Zi-ping, Wu Xiao-yu, Wang Chang-qing, et al. On typical quality problems of 2.25Cr-1Mo-0.25V heavy-wall forge welding hydrogenation reactor during manufacturing stage[J]. Petrochemical Equipment Technology, 2023, 44(1): 45-51. | |

| 5 | 邓林涛. 2.25Cr-1Mo-0.25V纯净钢的冶炼及效果[J]. 大型铸锻件, 2005(1): 1-6. |

| Deng Lin-tao.The smelting process and the effects of 2.25Cr-1Mo-0.25V pure steel[J]. Heavy Casting and Forging, 2005(1): 1-6. | |

| 6 | 方迁, 叶成立, 金杨, 等. 2.25Cr-1Mo-0.25V钢中B含量控制研究[J]. 大型铸锻件, 2021(1): 1-3. |

| Fang Qian, Ye Cheng-li, Jin Yang, et al. Study on content control of boron in 2.25Cr-1Mo-0.25V steel[J]. Heavy Casting and Forging, 2021(1): 1-3. | |

| 7 | Zhang Y T, Han H B, Miao L D, et al. Quantitative carbide analysis using the rietveld method for 2.25Cr-1Mo-0.25V steel[J]. Materials Characterization, 2009, 60(9): 953-956. |

| 8 | 马窦琴, 宋亚虎, 赵学谦, 等. 加氢锻件用2.25Cr-1Mo-0.25V钢的冲击韧性研究[J]. 材料科学与工程学报,2020, 38(4): 625-628. |

| Ma Dou-qin, Song Ya-hu, Zhao Xue-qian, et al. Research on impact toughness of 2.25Cr-1Mo-0.25V steel for hydrogenation forgings[J]. Journal of Materials Science& Engineering, 2020, 38(4): 625-628. | |

| 9 | 张景利, 付瑞东, 王纯宇, 等. 2.25Cr-1Mo-0.25V钢的热变形行为及其形变组织[J]. 塑性工程学报,2010, 17(3): 44-49. |

| Zhang Jing-li, Fu Rui-dong, Wang Chun-yu, et al. Hot deforming behaviors and microstructures of 2.25Cr-1Mo-0.25V steels[J]. Journal of Plasticity Engineering, 2010, 17(3): 44-49. | |

| 10 | 仲杨,秦晓波,郑志镇,等. 石化容器用2.25Cr-1Mo-0.25V钢的CMT电弧熔丝增材制造工艺及组织性能研究[J]. 中国机械工程,2022, 33(10): 1251-1259. |

| Zhong Yang, Qin Xiao-bo, Zheng Zhi-zhen, et al. Study on microstructure and mechanics properties of 2.25Cr-1Mo-0.25V steel fabricated by CMT wire ARC additive manufactureing for petrochemical vessels[J]. China Mechanical Engineering, 2022, 33(10): 1251-1259. | |

| 11 | Humphreys F J, Hatherly M. Recrystallization and Related Annealing Phenomena[M]. Oxford:ELSEVIER Ltd., 2004. |

| 12 | 杨觉先. 金属塑性变形物理基础[M]. 北京:冶金工业出版社, 1988. |

| 13 | Faulkner R, Martin J. Dislocation theory for engineers: worked examples[M]. Oxford: The Alden Press, 2000. |

| 14 | 崔忠圻.金属学与热处理[M]. 北京: 机械工业出版社, 1995. |

| 15 | Saadatkia S, Mirzadeh H, Cabrera J M. Hot deformation behavior, dynamic recrystallization, and physically-based constitutive modeling of plain carbon steels[J]. Materals Science and Engineering A, 2015, 636: 196-202. |

| 16 | Eiwahabi M, Cabrera J M, Prado J M. Hot working of two AISI 304 steels: a comparative study[J]. Materals Science and Engineering A, 2003, 343(1/2): 116-125. |

| 17 | Mcqueen H J, Yue S, Ryan N D, et al. Hot working characteristics of steels in austenitic state[J]. Journal of Materials Processing Technology, 1995, 53(1): 293-310. |

| 18 | Ebrahimi G R, Keshmiri H, Maldar A R, et al. Dynamic recrystallization behavior of 13%Cr martensitic stainless steel under hot working condition[J]. Journal of Materials Science and Technology, 2012, 28(5): 467-473. |

| 19 | Chen F, Cui Z S, Chen S J. Recrystallization of 30Cr2Ni4MoV ultra-super-critical rotor steel during hot deformation, part I: dynamic recrystallization[J]. Materals. Science and Engineering A, 2011, 528(15): 5073-5080. |

| 20 | 陈学文, 王继业, 杨喜晴, 等. Cr8合金钢热变形行为及位错密度演变规律[J].吉林大学学报: 工学版, 2020, 50(1): 91-99. |

| Chen Xue-wen, Wang Ji-ye, Yang Xi-qing, et al. Hot deformation behavior and dislocation density evolution regularity of Cr8 alloy[J]. Journal of Jilin University (Engineering and Technology Edition), 2020, 50(1): 91-99. |

| [1] | 李义,吕晨阳,梁继才,梁策. 不规则Y形铝型材多点拉弯成形截面变形分析[J]. 吉林大学学报(工学版), 2024, 54(1): 105-113. |

| [2] | 吴迪,耿文华,李洪梅,孙大千. 铝/钢等离子弧熔⁃钎焊接头界面电子背散射衍射分析[J]. 吉林大学学报(工学版), 2023, 53(5): 1331-1337. |

| [3] | 卢晓红,乔金辉,周宇,马冲,隋国川,孙卓. 搅拌摩擦焊温度场研究进展[J]. 吉林大学学报(工学版), 2023, 53(1): 1-17. |

| [4] | 庄蔚敏,王恩铭. 随机壁厚三维实体泡沫铝建模及压缩仿真[J]. 吉林大学学报(工学版), 2022, 52(8): 1777-1785. |

| [5] | 王金国,黄恺,闫瑞芳,任帅,王志强,郭劲. 元胞自动机-有限元法模拟碳当量元素对亚共晶球墨铸铁流动性的影响[J]. 吉林大学学报(工学版), 2021, 51(3): 855-865. |

| [6] | 田银宝,申俊琦,胡绳荪,勾健. EP/EN模数对铝合金VP-CMT焊熔滴过渡及焊道成形的影响[J]. 吉林大学学报(工学版), 2020, 50(5): 1663-1668. |

| [7] | 王金国,王志强,任帅,闫瑞芳,黄恺,郭劲. Ti添加量对球墨铸铁组织及力学性能的影响[J]. 吉林大学学报(工学版), 2020, 50(5): 1653-1662. |

| [8] | 修文翠,吴化,韩英,刘云旭. 等温热处理温度对超级贝氏体组织与性能的影响[J]. 吉林大学学报(工学版), 2020, 50(2): 520-525. |

| [9] | 宫文彪,朱芮,郄新哲,崔恒,宫明月. 6082铝合金超厚板搅拌摩擦焊接头组织与性能[J]. 吉林大学学报(工学版), 2020, 50(2): 512-519. |

| [10] | 陈学文,王继业,杨喜晴,皇涛,宋克兴. Cr8合金钢热变形行为及位错密度演变规律[J]. 吉林大学学报(工学版), 2020, 50(1): 91-99. |

| [11] | 王金国,任帅,闫瑞芳,黄恺,王志强. TiC颗粒对铸态球墨铸铁组织和力学性能的影响[J]. 吉林大学学报(工学版), 2019, 49(6): 2010-2018. |

| [12] | 徐戊矫,刘承尚,鲁鑫垚. 喷丸处理后6061铝合金工件表面粗糙度的模拟计算及预测[J]. 吉林大学学报(工学版), 2019, 49(4): 1280-1287. |

| [13] | 李于朋,孙大千,宫文彪. 6082⁃T6铝合金薄板双轴肩搅拌摩擦焊温度场[J]. 吉林大学学报(工学版), 2019, 49(3): 836-841. |

| [14] | 关庆丰,张福涛,彭韬,吕鹏,李姚君,许亮,丁佐军. 含硼、钴9%Cr耐热钢的热变形行为[J]. 吉林大学学报(工学版), 2018, 48(6): 1799-1805. |

| [15] | 关庆丰, 董书恒, 郑欢欢, 李晨, 张从林, 吕鹏. 强流脉冲电子束作用下45#钢表面Cr合金化[J]. 吉林大学学报(工学版), 2018, 48(4): 1161-1168. |

|