吉林大学学报(工学版) ›› 2025, Vol. 55 ›› Issue (1): 382-391.doi: 10.13229/j.cnki.jdxbgxb.20230200

• 农业工程·仿生工程 • 上一篇

真空吸盘的仿生设计与吸附性能分析

- 1.山西农业大学 农业工程学院,山西 晋中 032699

2.吉林大学 生物与农业工程学院,长春 130022

Bionic design and adsorption performance analysis of vacuum sucker

Peng XI1( ),Qian CONG2(

),Qian CONG2( ),Shao-bo YE1,Hong-bo LI1,Yan-qing ZHANG1

),Shao-bo YE1,Hong-bo LI1,Yan-qing ZHANG1

- 1.College of Agricultural Engineering,Shanxi Agricultural University,Jinzhong 032699,China

2.College of Biological and Agricultural Engineering,Jilin University,Changchun 130022,China

摘要:

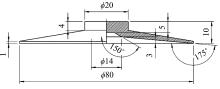

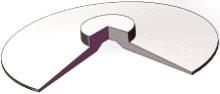

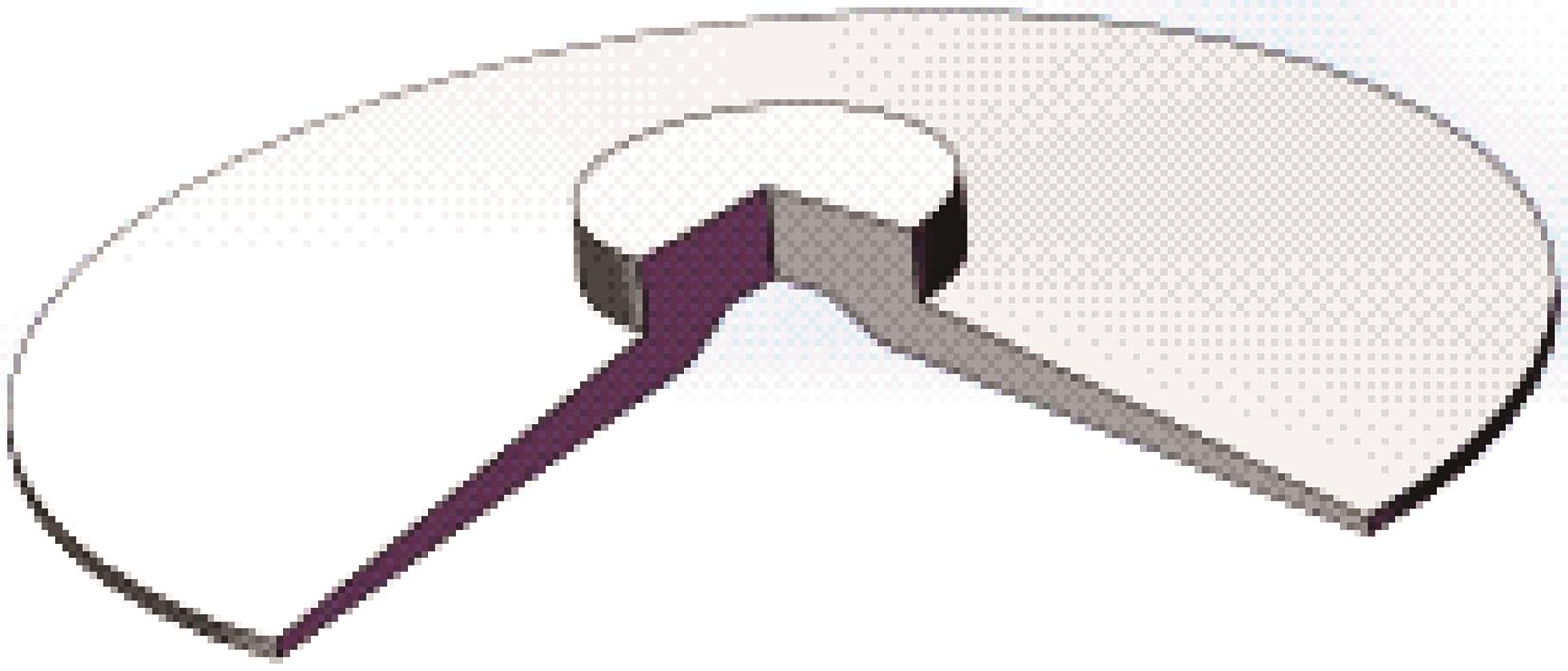

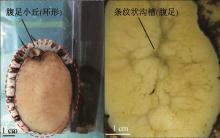

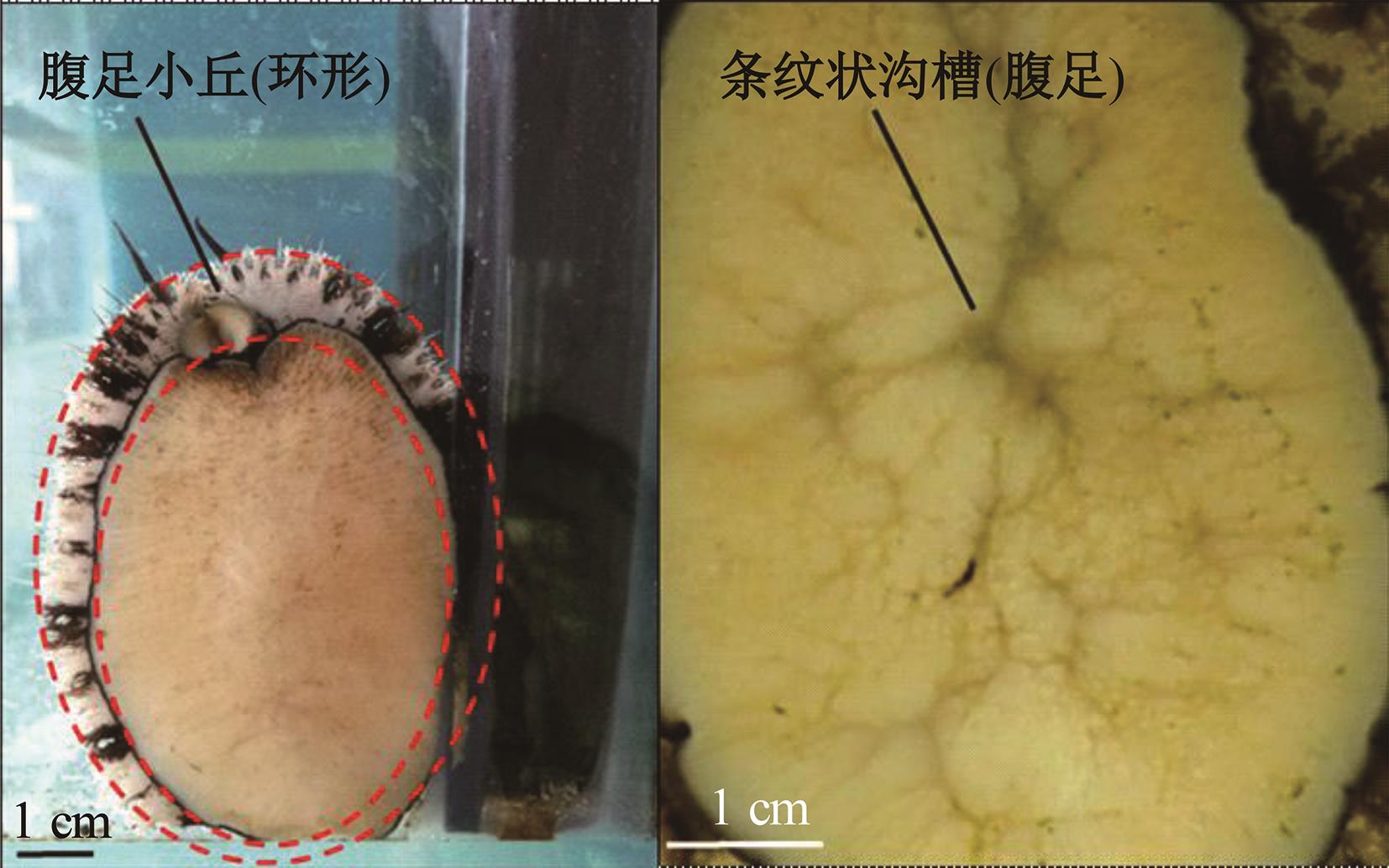

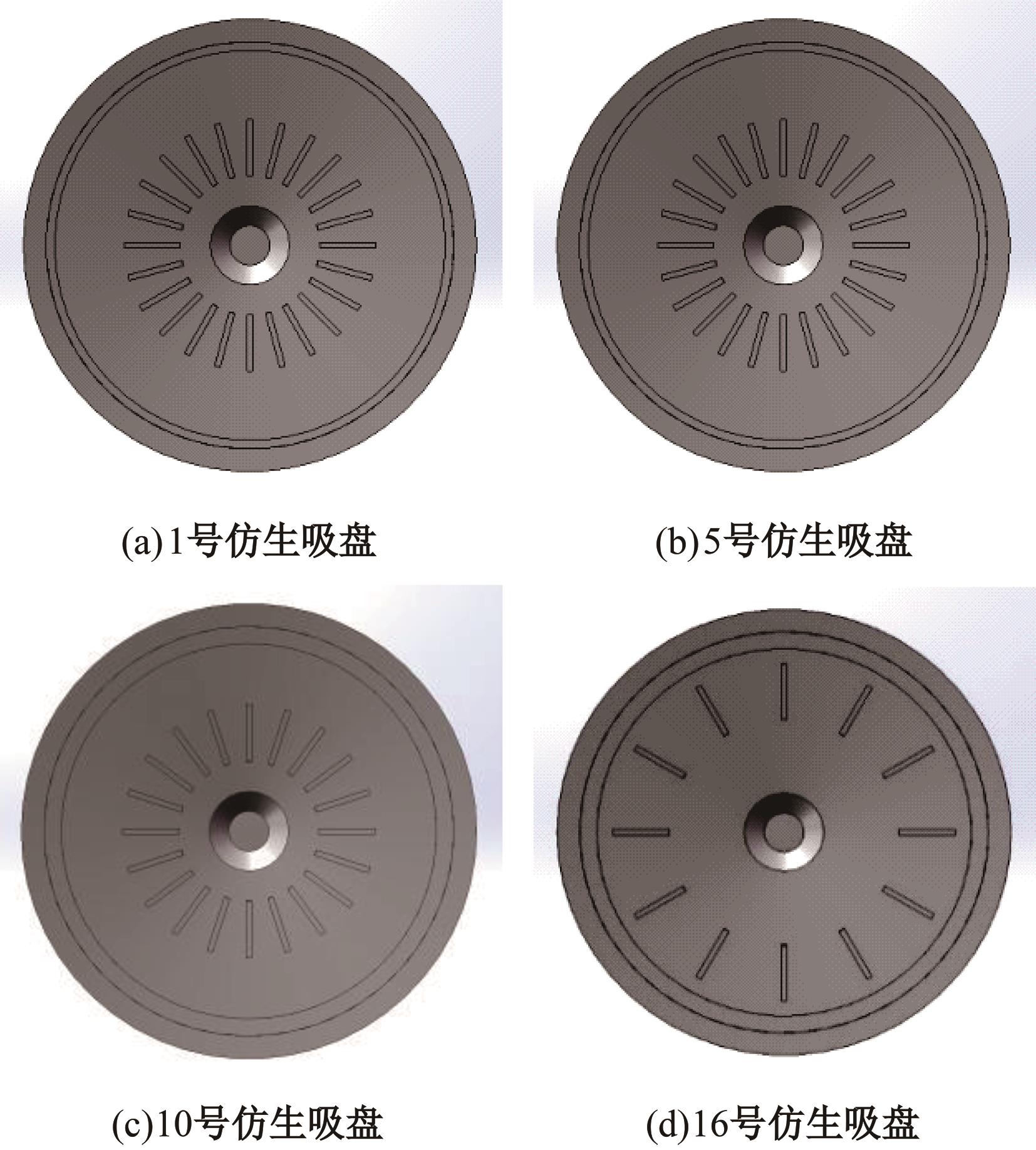

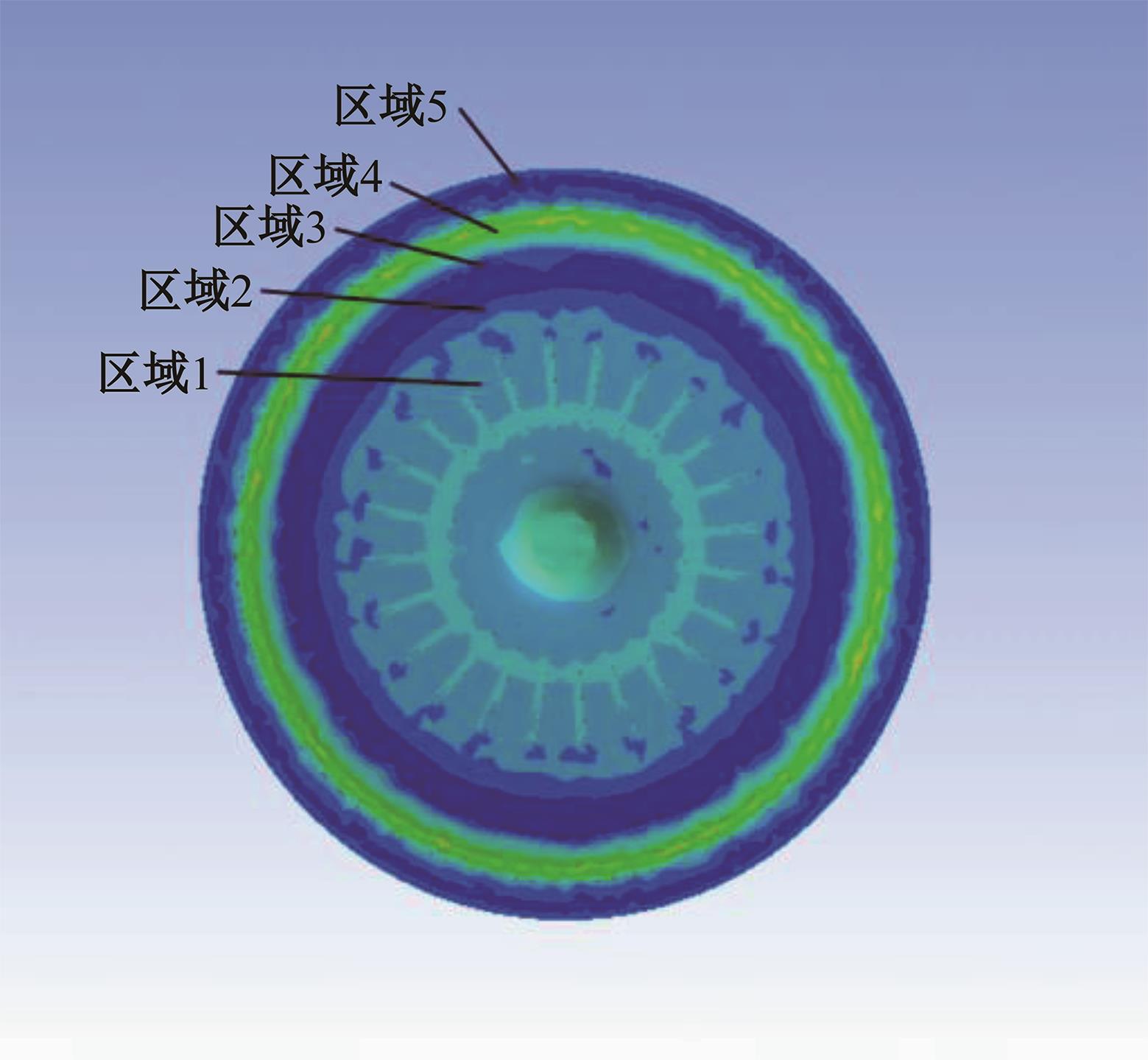

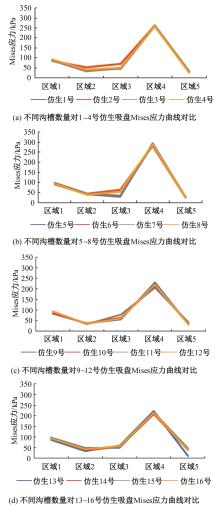

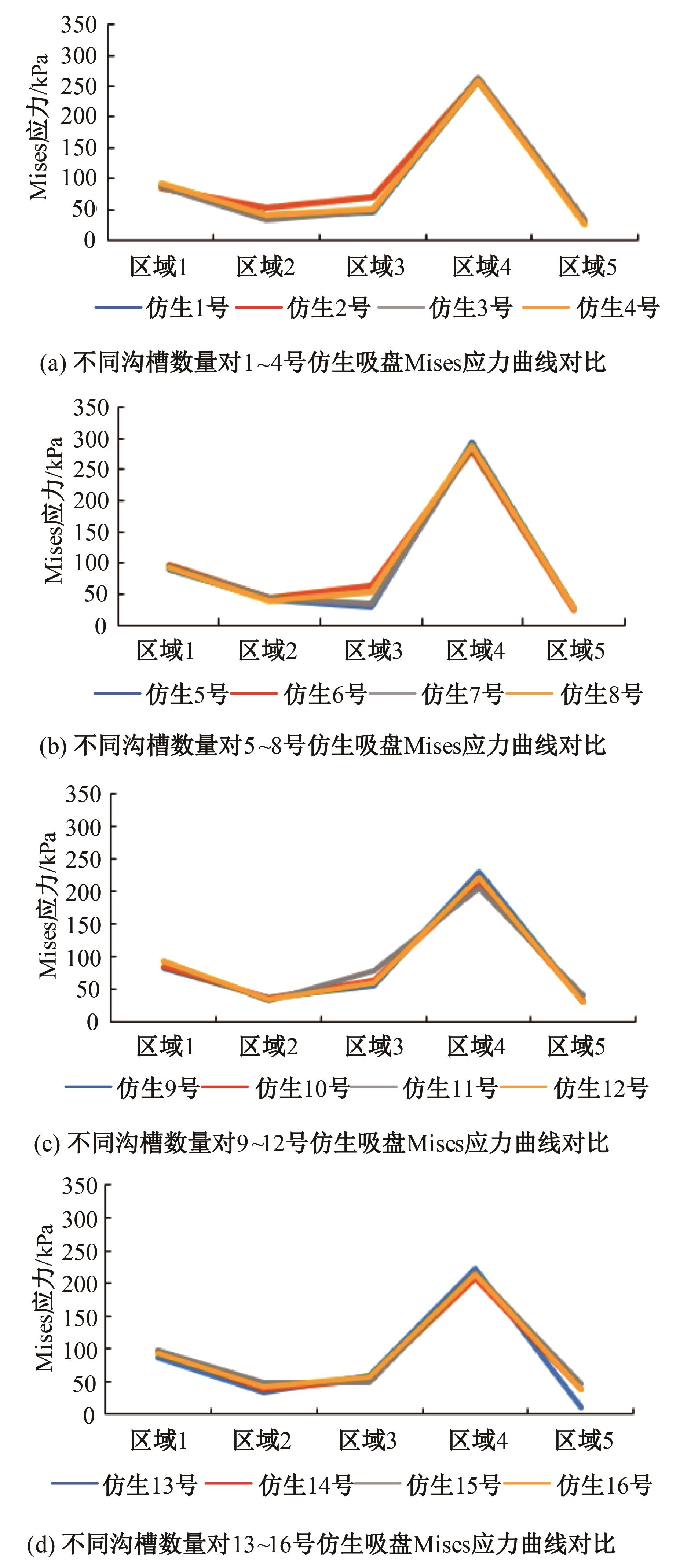

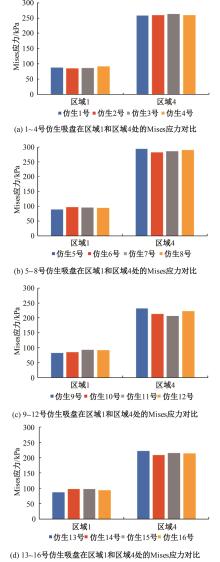

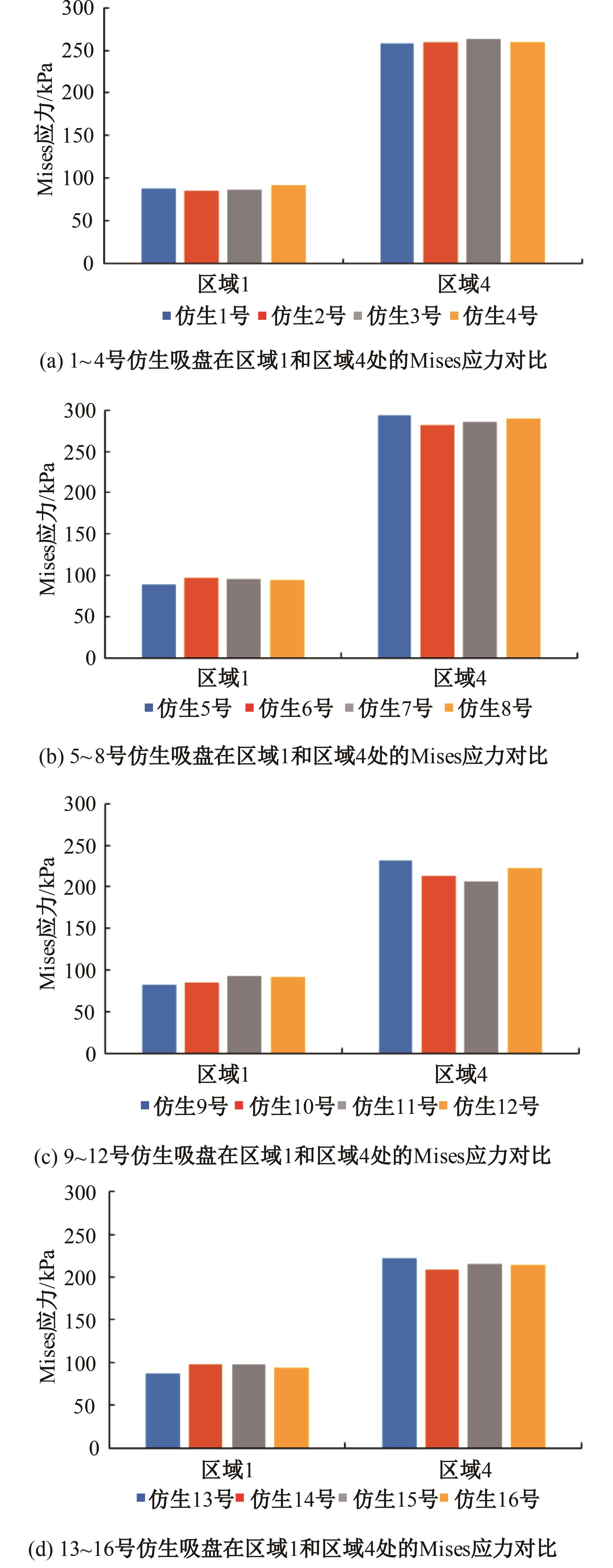

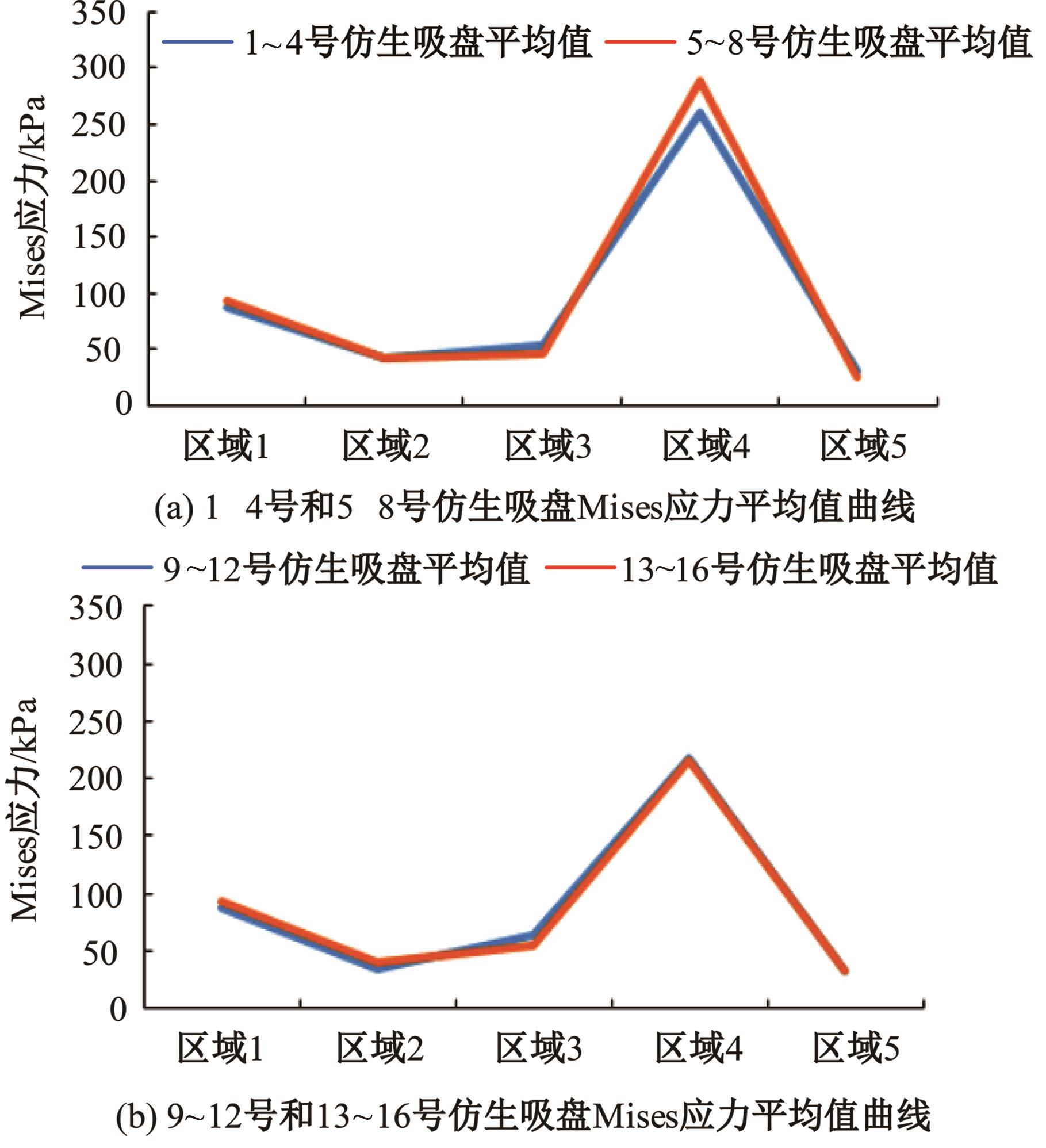

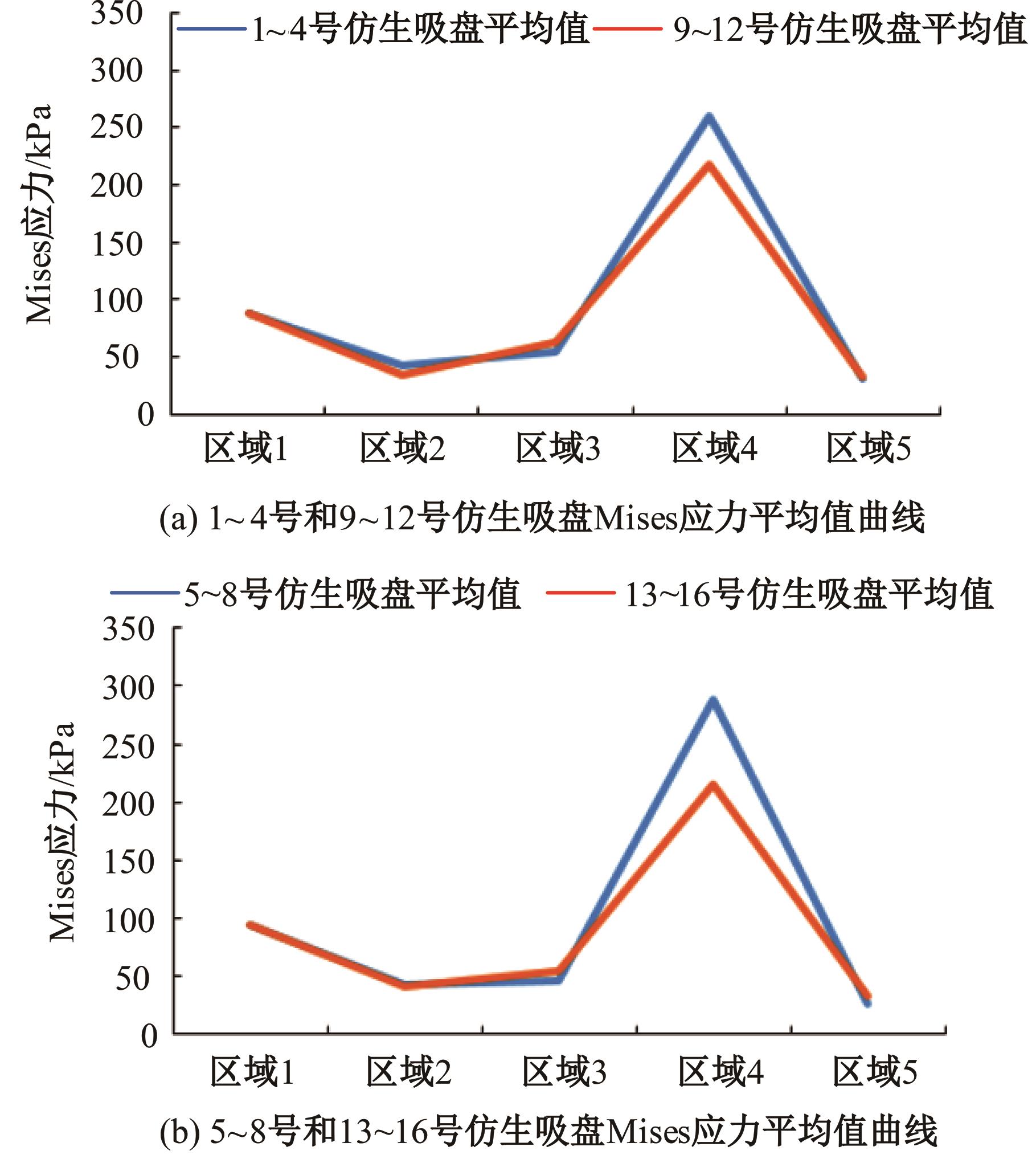

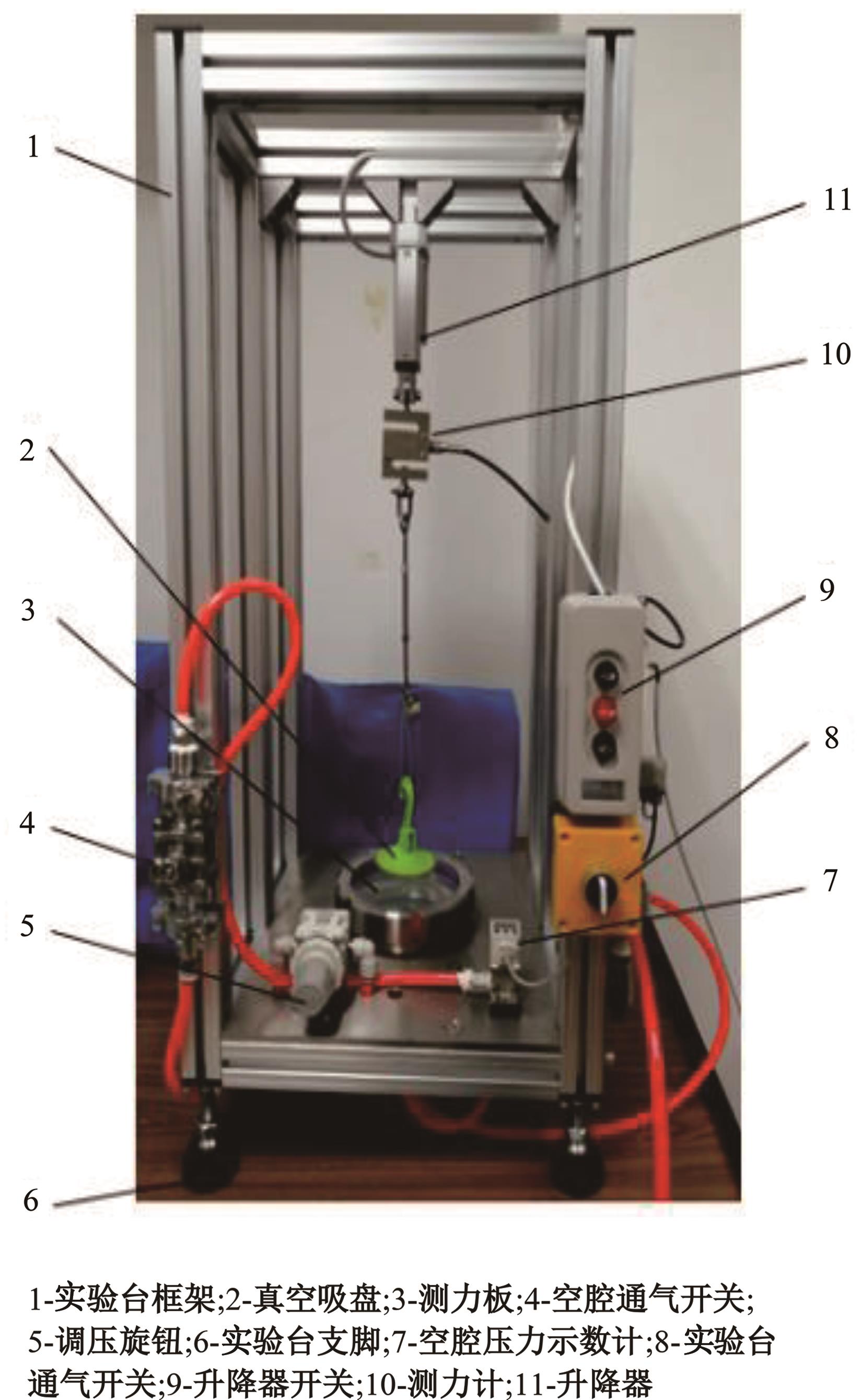

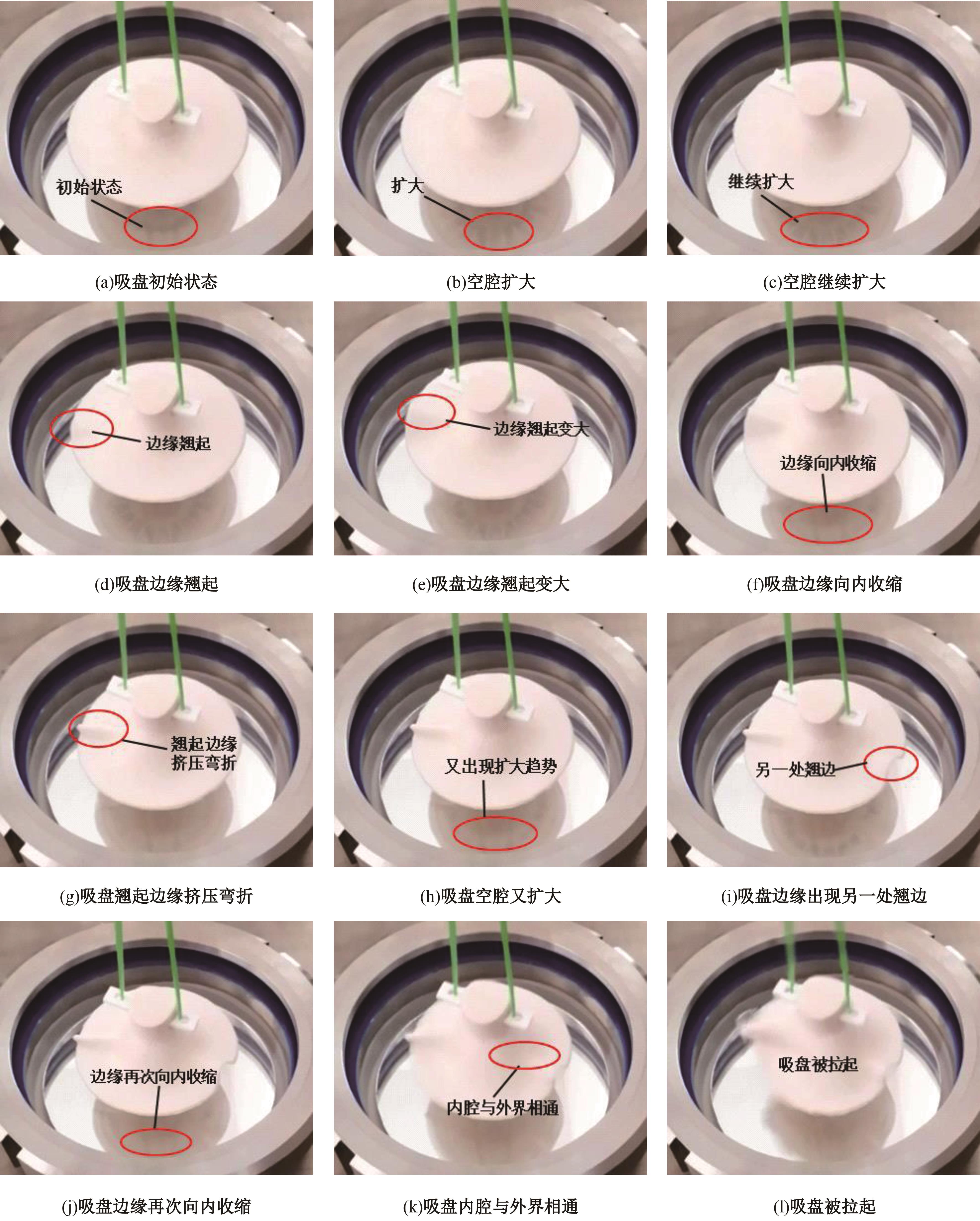

本文从仿生学角度出发,对基于鲍鱼腹足优良吸附性的仿生吸盘吸附性能进行研究。通过提取腹足表面形态设计仿生吸盘,并对吸盘吸附性进行模拟分析,选取模拟结果良好的仿生吸盘进行拉伸实验,根据实验结果探究吸附机理。结果表明,密封环宽度对仿生吸盘Mises应力具有较大影响,而沟槽距吸盘中心距离与沟槽分布数量的影响很小。密封环宽度为1.5 mm的仿生吸盘所受Mises应力要大于宽度为3 mm的仿生吸盘。在40%真空度下,密封环宽度为1.5 mm,沟槽距吸盘中心距离为20 mm,沟槽分布数量为12的仿生吸盘具有最大吸附力,其最大吸附力比标准吸盘提高了5.32%。本研究表明仿生吸盘可以有效提高吸盘的吸附性能。仿生吸盘密封环结构可以有效阻止吸盘边缘向内收缩,同时沟槽结构可以延缓吸盘内腔与外界连通的可能,从而达到提高吸盘吸附性能的目的。

中图分类号:

- TB17

| 1 | 白联强,宋仲康,王鹏.不同泄漏情况下真空吸盘内部流场仿真分析[J].机械工程师, 2018(7): 33-35, 38. |

| Bai Lian-qiang, Song Zhong-kang, Wang Peng. Simulation Analysis on Internal Flow Field of a Vacuum Suction Cup under Different Leakage Conditions[J]. Mechanical Engineer, 2018(7): 33-35, 38. | |

| 2 | 秦建华,邓晨韵,王敦球,等.基于有限元的不同布局方式对真空吸附装置的影响[J].桂林理工大学学报, 2017, 37(4): 713-717. |

| Qin Jian-hua, Deng Chen-yun, Wang Dun-qiu, et al. Influence analysis of different layout methods on the vacuum adsorption device based on ANSYS method[J]. Journal of Guilin University of Technology, 2017, 37(4): 713-717. | |

| 3 | 聂俊峰,王涛,许英南,等.柔性吸盘真空吸附性能试验[J].液压与气动,2020(5): 131-137. |

| Nie Jun-feng, Wang Tao, Xu Ying-nan, et al. Vacuum Adsorption Test of Flexible Suction Cup[J]. Chinese Hydraulics&Pneumatics, 2020(5): 131-137. | |

| 4 | 施迈茨.施迈茨——用于包装行业的新型波纹吸盘SPB 4f[EB/OL]. [2023-06-25]. . |

| 5 | AIRBEST.SOP系列圆形海绵吸盘[EB/OL]. [2023-06-25]. . |

| 6 | Peng X Y, Ma C D, Ji J X, et al. Underwater adhesion mechanisms and biomimetic study of marine life[J]. Tribology, 2020, 40(6): 816-830. |

| 7 | Maie T, Blob R W. Adhesive force and endurance of the pelvic sucker across different modes of waterfall-climbing in gobiid fishes: contrasting climbing mechanisms share aspects of ontogenetic change[J]. Zoology, 2021, 149:No. 125969. |

| 8 | Palecek A M, Schoenfuss H L, Blob R W. Sucker shapes, skeletons, and bioinspiration: how hard and soft tissue morphology generates adhesive performance in waterfall climbing goby fishes[J]. Integrative And Comparative Biology, 2022, 62(4):No.094. |

| 9 | Wang S H, Luo H Y, Linghu C H, et al. Elastic energy storage enabled magnetically actuated, octopus‐inspired smart adhesive[J]. Advanced Functional Materials, 2021, 31(9): No.2009217. |

| 10 | Baik S, Hwang G W, Jang S, et al. Bioinspired microsphere-embedded adhesive architectures for an electrothermally actuating transport device of dry/wet pliable surfaces[J]. ACS Applied Materials And Interfaces, 2021, 13(5): 6930-6940. |

| 11 | Huie J M, Summers A P. The effects of soft and rough substrates on suction-based adhesion[J]. The Journal of Experimental Biology, 2022, 225(9): No.243773. |

| 12 | Kazuma T, Yasutaka M, Masatsugu S, et al. A New Concept for an Adhesive Material Inspired by Clingfish Sucker Nanofilaments[J]. Langmuir: The ACS Journal of Surfaces and Colloids, 2022, 38(3): 1215-1222. |

| 13 | 丛茜,徐金,史孝杰,等.仿生凹坑型吸盘设计与试验[J].吉林大学学报:工学版: 2024,54(4):1144-1152. |

| Cong Qian, Xu Jin, Shi Xiao-jie, et al. Bionic pit design and experiment of the sucker[J]. Journal of Jilin University(Engineering and Technology Edition), 2024,54(4):1144-1152. | |

| 14 | Popov V L, Filippov A E, Gorb S N. Biological microstructures with high adhesion and friction: numerical approach[J]. Physics-Uspekhi, 2016, 59(9): 829-845. |

| 15 | Ditsche P, Wainwright D K, Summers A P. Attachment to challenging substrates-fouling, roughness and limits of adhesion in the northern clingfish(Gobiesox maeandricus)[J]. Journal of Experimental Biology, 2014, 217(14): 2548-2554. |

| 16 | Ditsche P, Summers A P. Learning from Northern clingfish (Gobiesox maeandricus): bioinspired suction cups attach to rough surfaces[J]. Philosophical Transactions of the Royal Society B: Biological Sciences, 2019, 374(1784): No.20190204. |

| 17 | Chuang Y C, Chang H K, Liu G L, et al. Climbing upstream: Multi-scale structural characterization and underwater adhesion of the Pulin river loach (Sinogastromyzon puliensis)[J]. Journal of the Mechanical Behavior of Biomedical Materials, 2017, 73:76-85. |

| 18 | Zhang Y, Li S, Zuo P, et al. Adhesion behaviors of abalone under the action of water flow[J]. Frontiers in Mechanical Engineering, 2021(7): No.659468. |

| 19 | Zhang Y, Li S, Zuo P, et al. A mechanics study on the self-righting of abalone from the substrate[J]. Applied Bionics and Biomechanics, 2020(1): No.8825451. |

| 20 | Li J, Ma C, Liu J, et al. The co-effect of microstructures and mucus on the adhesion of abalone from a mechanical perspective[J]. Biosurface and Biotribology, 2021, 7(4): 180-186. |

| 21 | Lin A Y M, Brunner R, Chen P Y, et al. Underwater adhesion of abalone: the role of van der Waals and capillary forces[J]. Acta Materialia, 2009, 57(14): 4178-4185. |

| 22 | Li J, Zhang Y, Liu S, et al. Insights into adhesion of abalone: a mechanical approach[J]. Journal of the Mechanical Behavior of Biomedical Materials, 2018, (77): 331-336. |

| [1] | 丛茜,徐金,史孝杰,金敬福,陈廷坤. 仿生凹坑型吸盘设计与试验[J]. 吉林大学学报(工学版), 2024, 54(4): 1144-1152. |

| [2] | 杨欣,王阳,宋家锋,朱勇,黄彬兵,许述财. 基于虾螯结构的仿生夹层板设计及数值模拟[J]. 吉林大学学报(工学版), 2024, 54(3): 842-851. |

| [3] | 于征磊,曹青,张钧栋,沙鹏威,金敬福,魏万祯,梁平,张志辉. 基于增材制造的着陆器仿生缓冲结构的力学特性[J]. 吉林大学学报(工学版), 2024, 54(10): 3077-3084. |

| [4] | 黄晗,闫庆昊,向枳昕,杨鑫涛,陈金宝,许述财. 基于虾螯的仿生多胞薄壁管耐撞性分析及优化[J]. 吉林大学学报(工学版), 2022, 52(3): 716-724. |

| [5] | 陈奕颖,金敬福,丛茜,陈廷坤,任露泉. 不同冰点介质对冰黏附强度的影响[J]. 吉林大学学报(工学版), 2021, 51(5): 1926-1932. |

| [6] | 于征磊,陈立新,徐泽洲,信仁龙,马龙,金敬福,张志辉,江山. 基于增材制造的仿生防护结构力学及回复特性分析[J]. 吉林大学学报(工学版), 2021, 51(4): 1540-1547. |

| [7] | 于征磊,信仁龙,陈立新,朱奕凝,张志辉,曹青,金敬福,赵杰亮. 仿蜂窝防护结构的承载特性[J]. 吉林大学学报(工学版), 2021, 51(3): 1140-1145. |

| [8] | 刘春宝,陈山石,盛闯,钱志辉,任露泉,任雷. 蜘蛛生物液压驱动原理及其功能仿生探索[J]. 吉林大学学报(工学版), 2020, 50(1): 375-381. |

| [9] | 陈东良,臧睿,段鹏,赵伟鹏,翁旭涛,孙杨,唐艺鹏. 基于新月鱼尾推进理论的多连杆鱼骨仿生设计[J]. 吉林大学学报(工学版), 2019, 49(4): 1246-1257. |

| [10] | 吴娜,庄健,张克松,王慧鑫,马云海. 毛蚶贝壳曲面承压力学特性及断裂机理[J]. 吉林大学学报(工学版), 2019, 49(3): 897-902. |

| [11] | 郭昊添,徐涛,梁逍,于征磊,刘欢,马龙. 仿鲨鳃扰流结构的过渡段换热表面优化设计[J]. 吉林大学学报(工学版), 2018, 48(6): 1793-1798. |

| [12] | 熙鹏,丛茜,王庆波,郭华曦. 仿生条纹形磨辊磨损试验及耐磨机理分析[J]. 吉林大学学报(工学版), 2018, 48(6): 1787-1792. |

| [13] | 田为军, 王骥月, 李明, 张兴旺, 张勇, 丛茜. 面向水上机器人的水黾运动观测[J]. 吉林大学学报(工学版), 2018, 48(3): 812-820. |

| [14] | 钱志辉, 周亮, 任雷, 任露泉. 具有仿生距下关节和跖趾关节的完全被动步行机[J]. 吉林大学学报(工学版), 2018, 48(1): 205-211. |

| [15] | 陈东辉, 刘伟, 吕建华, 常志勇, 吴婷, 慕海锋. 基于虾夷扇贝体表结构的玉米茬根捡拾器仿生设计[J]. 吉林大学学报(工学版), 2017, 47(4): 1185-1193. |

|

||