吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (9): 2401-2413.doi: 10.13229/j.cnki.jdxbgxb.20231068

• 车辆工程·机械工程 •

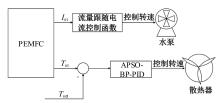

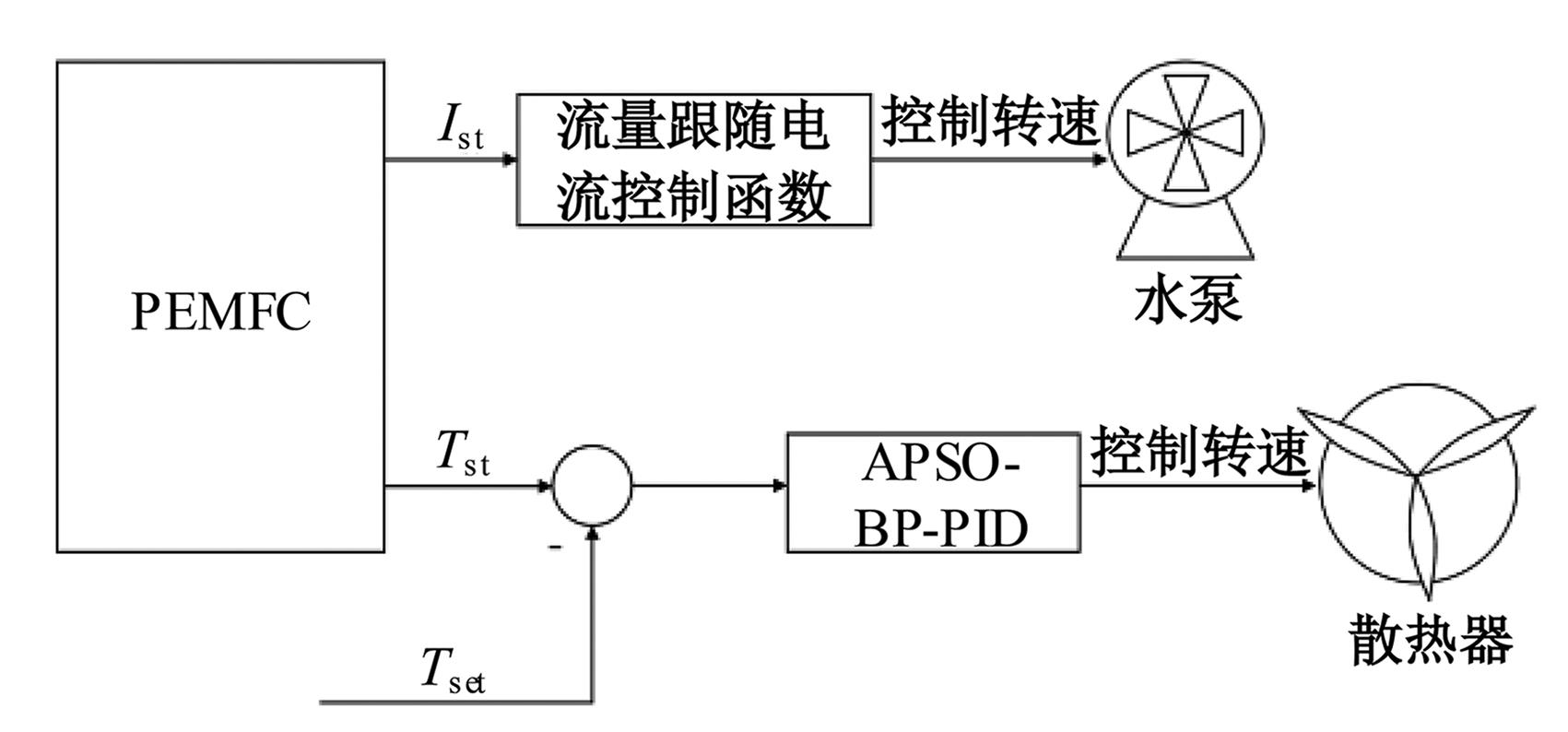

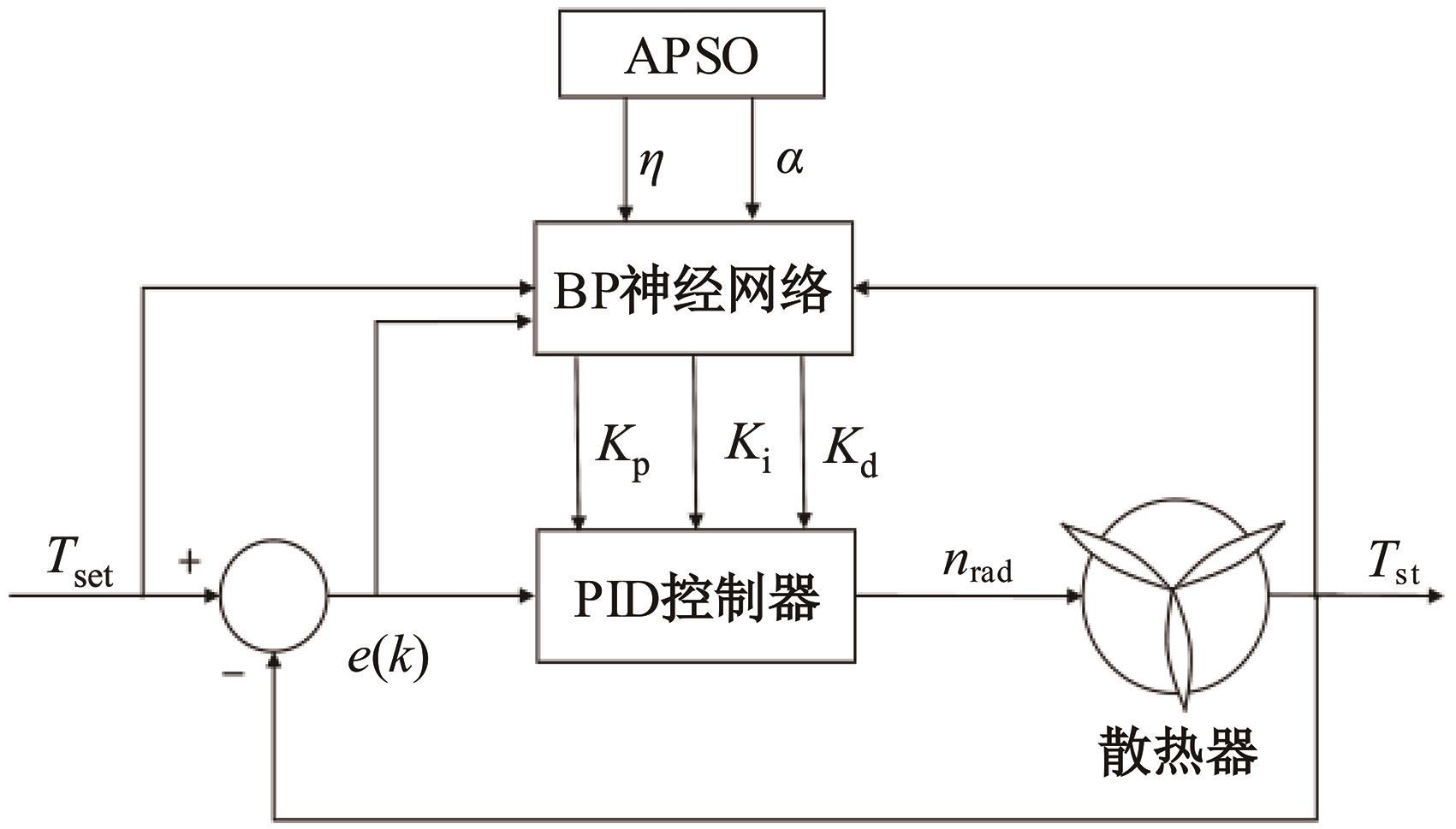

基于APSO-BP-PID控制的质子交换膜燃料电池热管理系统温度控制

商蕾1( ),杨萍2,杨祥国1(

),杨萍2,杨祥国1( ),潘建欣3,杨军3,张梦如1

),潘建欣3,杨军3,张梦如1

- 1.武汉理工大学 船海与能源动力工程学院,武汉 430063

2.武汉理工大学 交通与物流工程学院,武汉 430063

3.武汉氢能与燃料电池产业技术研究院有限公司 技术研发中心,武汉 430064

Temperature control of proton exchange membrane fuel cell thermal management system based on APSO-BP-PID control strategy

Lei SHANG1( ),Ping YANG2,Xiang-guo YANG1(

),Ping YANG2,Xiang-guo YANG1( ),Jian-xin PAN3,Jun YANG3,Meng-ru ZHANG1

),Jian-xin PAN3,Jun YANG3,Meng-ru ZHANG1

- 1.School of Naval Architecture,Ocean and Energy Power Engineering,Wuhan University of Technology,Wuhan 430063,China

2.School of Transportation and Logistics Engineering,Wuhan University of Technology,Wuhan 430063,China

3.Technology R&D Center,Wuhan Institute of Hydrogen and Fuel Cell Industrial Technology Co. ,Ltd. ,Wuhan 430064,China

摘要:

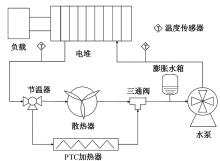

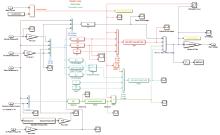

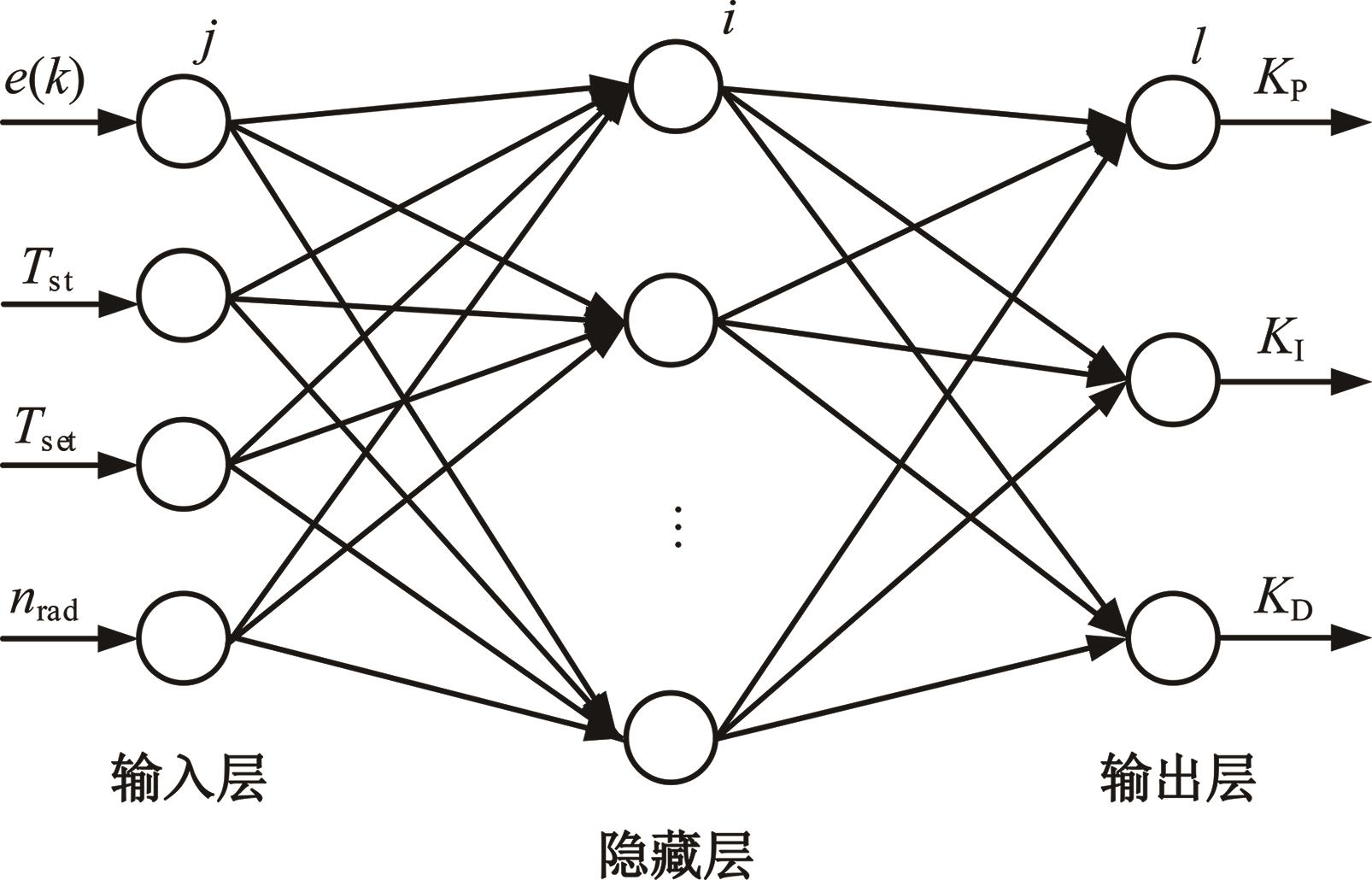

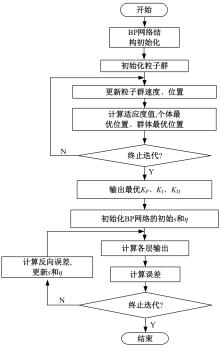

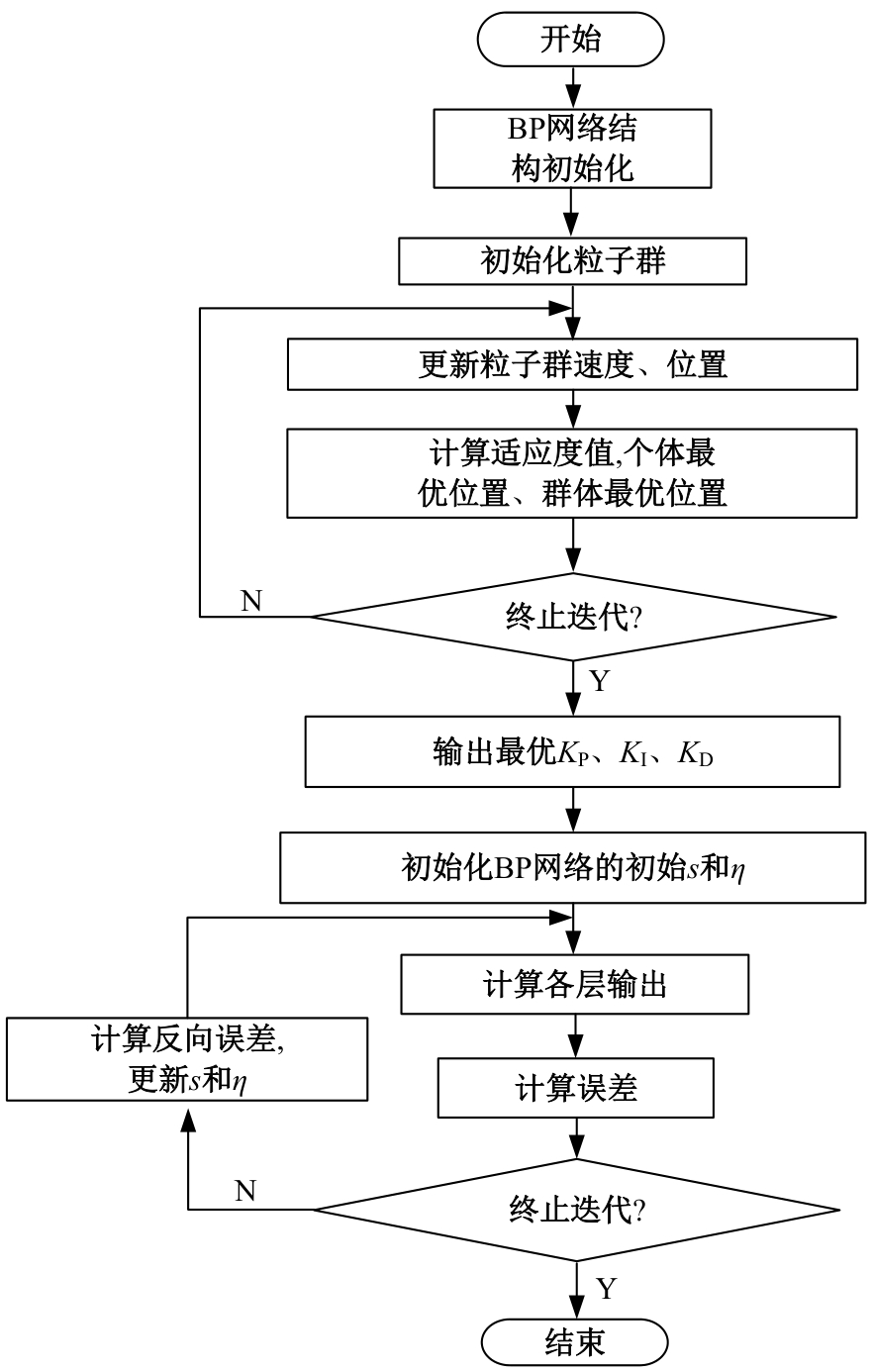

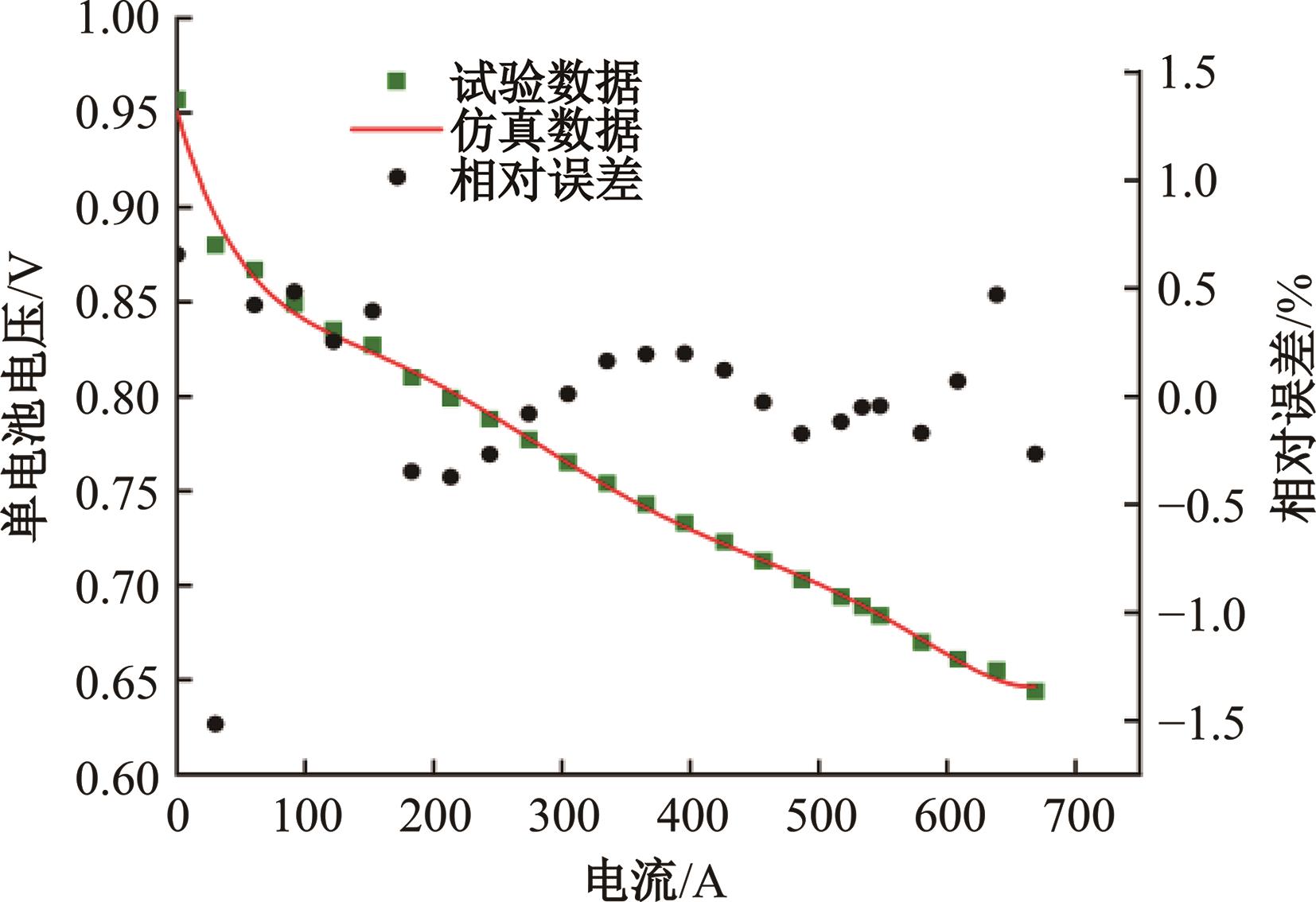

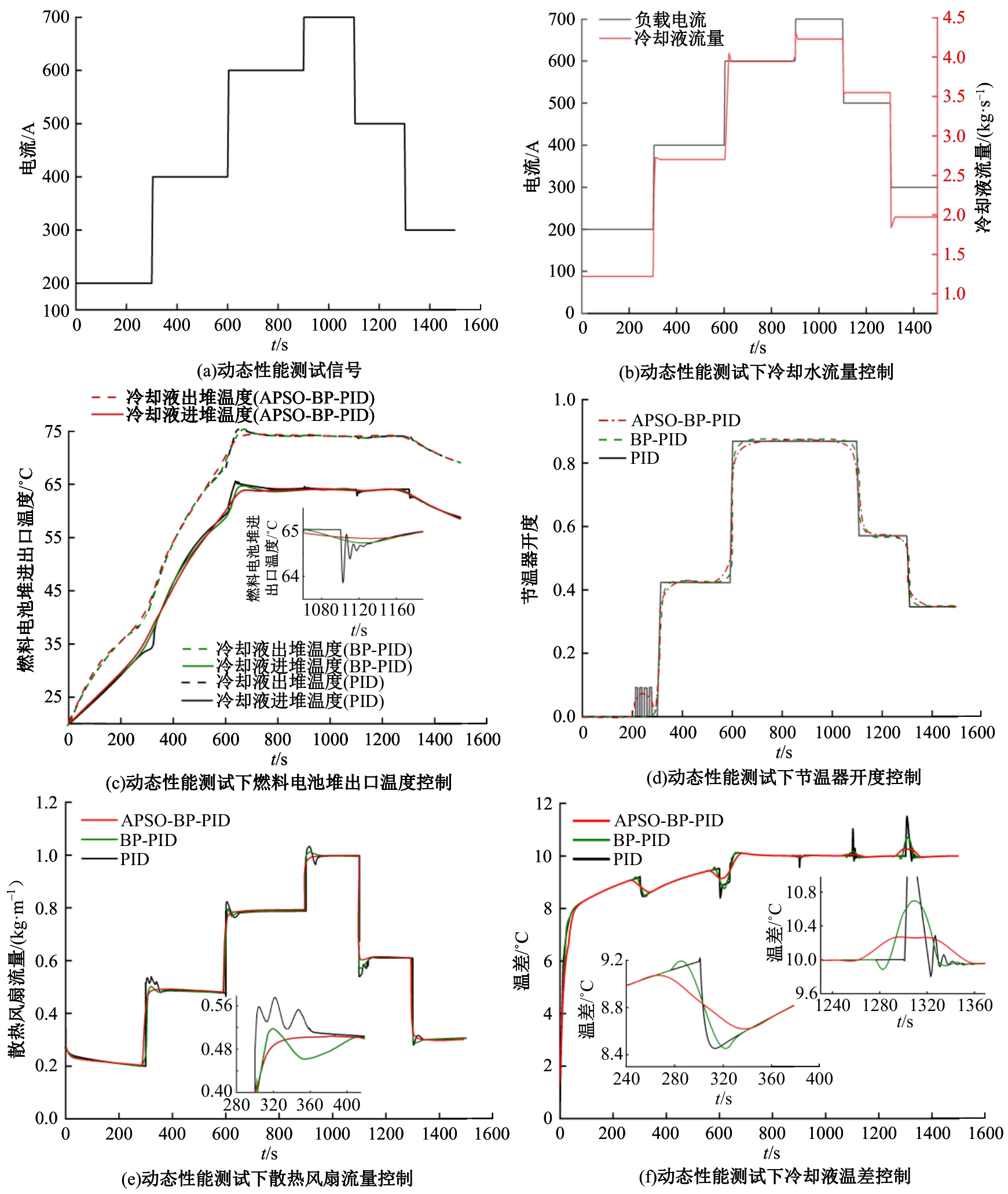

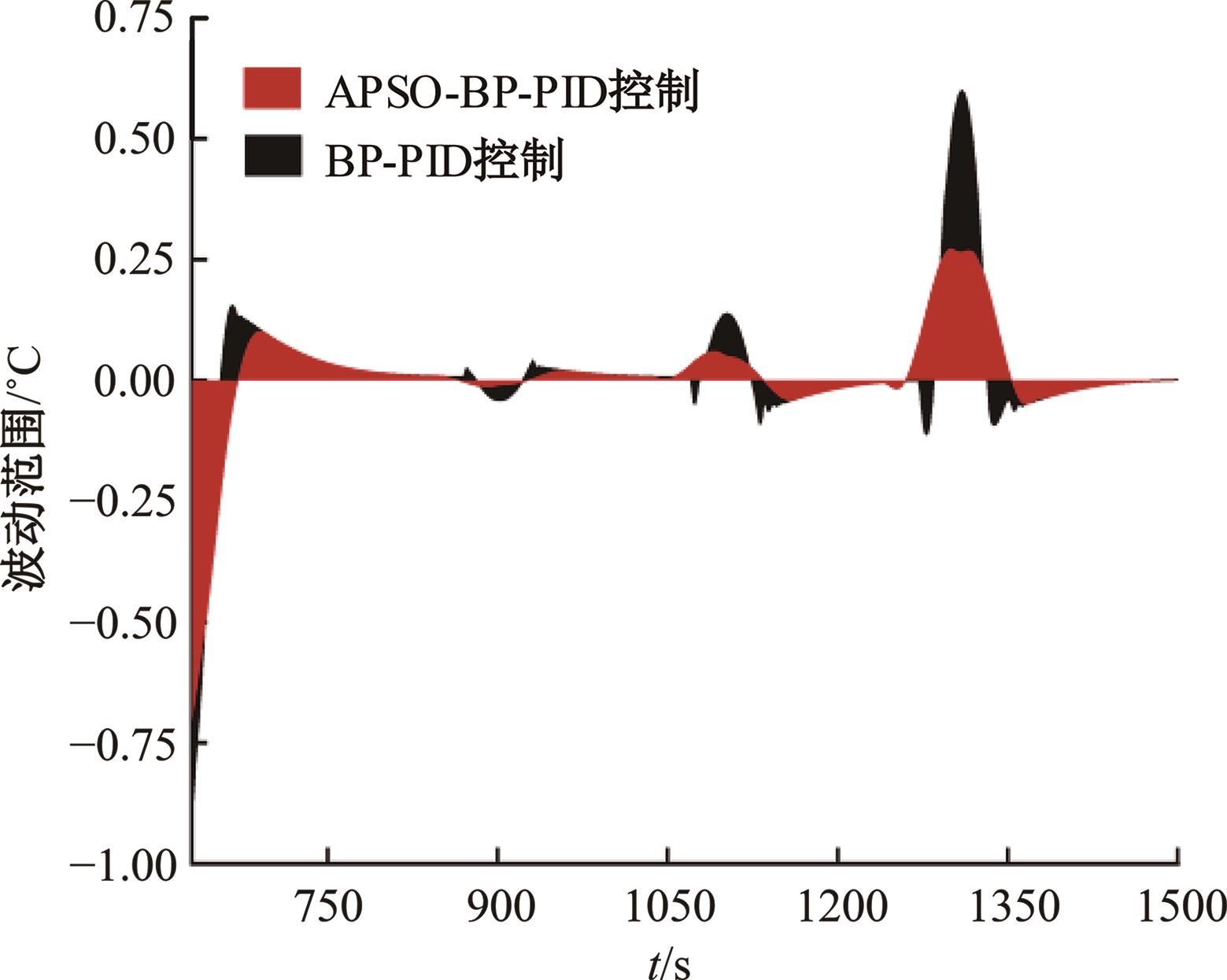

针对质子交换膜燃料电池热管理系统存在响应速度慢、系统振荡、温度波动大及强耦合性等问题,本文提出了一种冷却液流量跟随电流控制,基于自适应粒子群算法优化神经网络的PID控制策略,并在Matlab/Simulink平台搭建燃料电池堆功率为125 kW质子交换膜燃料电池热管理系统,用于分析各零部件之间的流量分配和热量交换,在不同工况下与神经网络优化的PID控制策略和传统PID控制策略进行对比。仿真结果表明:在不同工况下,本文提出的控制策略能实现散热风扇和循环水泵的解耦;在阶跃信号测试下,实现循环水泵流量跟随电流快速响应;在动态性能测试下,实现无超调且在30 s内稳定,减小系统的振荡量,减轻燃料电池堆进出口冷却液温差和燃料电池堆电压的波动程度。结果说明该控制策略具有良好的控制性能。

中图分类号:

- TM911.4

| 1 | 徐东, 刘岩, 李志勇, 等. 氢能开发利用经济性研究综述[J]. 油气与新能源, 2021,33(2): 50-56. |

| Xu Dong, Liu Yan, Li Zhi-yong, et al. Review of economic research on hydrogen energy development and utilization[J]. Oil & Gas & New Energy, 2021,33(2): 50-56. | |

| 2 | Zhou M G, Hu T T. Analysis of carbon emission status under the carbon neutral target in China for earth's atmospheric balance[J]. IOP Conference Series: Earth and Environmental Science, 2021, 804(4): No. 042082. |

| 3 | Kang J N, Wei Y M, Liu L C, et al. Observing technology reserves of carbon capture and storage via patent data: paving the way for carbon neutral[J]. Technological Forecasting & Social Change, 2021, 171(6): No. 120933. |

| 4 | 刘镇宁, 江柯, 赵韬韬,等. 大功率质子交换膜燃料电池测试系统的开发及试验[J]. 吉林大学学报:工学版, 2022, 52(9): 2025-2033. |

| Liu Zhen-ning, Jiang Ke, Zhao Tao-tao, et al. Development and test of high-power proton exchange membrane fuel cell test system[J]. Journal of Jilin University(Engineering and Technology Edition, 2022, 52(9): 2025-2033. | |

| 5 | 李洁. 燃料电池温度控制研究[D]. 武汉: 武汉理工大学自动化学院, 2015. |

| Li Jie. Research on temperature control of fuel cell[D]. Wuhan: School of Automation, Wuhan University of Technology, 2015. | |

| 6 | Zhao X, Li Y, Liu Z, et al. Thermal management system modeling of a water-cooled proton exchange membrane fuel cell[J]. International Journal of Hydrogen Energy, 2015, 40(7): 3048-3056. |

| 7 | 李春华, 朱新坚. 基于递归模糊神经网络的PEMFC温度控制研究[J]. 热能动力工程, 2012, 27(6): 721-725,741-742. |

| Li Chun-hua, Zhu Xin-jian. Research on PEMFC temperature control based on recurrent fuzzy neural Network[J]. Journal of Engineering for Thermal Energy and Power, 2012, 27(6): 721-725,741-742. | |

| 8 | Han J, Yu S, Yi S. Advanced thermal management of automotive fuel cells using a model reference adaptive control algorithm[J]. International Journal of Hydrogen Energy, 2017, 42(7): 4328-4341. |

| 9 | Chen F, Jiao J, Yu Y, et al. Active control of stack inlet and outlet coolant temperature for the PEM fuel cell system[C]∥2017 International Conference on Fuel Cell Science, Engineering and Technology, Tianjin, China, 2017: No. V001T01A001. |

| 10 | Carton J G, Lawlor V, Olabi A G, et al. Water droplet accumulation and motion in PEM (proton exchange membrane) fuel cell mini-channels[J]. Energy, 2012, 39(1): 63-73. |

| 11 | Rojas J D, Ocampo-Martinez C, Kunusch C. Thermal modelling approach and model predictive control of a water-cooled PEM fuel cell system[C]∥39th Annual Conference of the IEEE Industrial Electronics Society, Vienna, Austria, 2013: 3806-3811. |

| 12 | Zhao D, Gao F, Massonnat P, et al. Parameter sensitivity analysis and local temperature distribution effect for a PEMFC system[J]. IEEE Transactions on Energy Conversion, 2015, 30(3): 1008- 1018. |

| 13 | 牛茁. 水冷型质子交换膜燃料电池热管理系统控制研究[D]. 成都: 西南交通大学电气工程学院,2018. |

| Niu Zhuo. Research on control of thermal management system of water-cooled proton exchange membrane fuel cell[D]. Chengdu: School of Electrical Engineering, Southwest Jiaotong University, 2018. | |

| 14 | 赵洪波, 刘杰, 马彪,等. 水冷PEMFC热管理系统控制策略及仿真研究[J]. 化工学报, 2020, 71(5): 2139-2150. |

| Zhao Hong-bo, Liu Jie, Ma Biao, et al. Control strategy and simulation research of water-cooled PEMFC thermal management system[J]. CIESC Journal, 2020, 71(5): 2139-2150. | |

| 15 | 裴尧旺, 陈凤祥, 胡哲,等. 基于自适应LQR控制的质子交换膜燃料电池热管理系统温度控制[J]. 吉林大学学报:工学版, 2022, 52(9): 2014-2024. |

| Pei Yao-wang, Chen Feng-xiang, Hu Zhe, et al. Temperature control of proton exchange membrane fuel cell thermal management system based on adaptive LQR control[J]. Journal of Jilin University (Engineering and Technology Edition), 2022, 52(9): 2014-2024. | |

| 16 | Huang L H, Chen J, Liu Z Y, et al. Adaptive thermal control for PEMFC systems with guaranteed performance[J]. International Journal of Hydrogen Energy, 2018, 43(25): 11550-11558. |

| 17 | Chen F X, Jiao J R, Hou Z J, et al. Robust polymer electrolyte membrane fuel cell temperature tracking control based on cascade internal model control[J]. Journal of Power Sources, 2020, 479: No. 229008. |

| 18 | Pukrushpan J T. Modeling and control of fuel cell systems and fuel processors[D]. Michigan: The University of Michigan, 2003. |

| 19 | Saygili Y, Eroglu I, Kincal S. Model based temperature controller development for water cooled PEM fuel cell systems[J]. International Journal of Hydrogen Energy, 2015, 40(1): 615-622. |

| 20 | 刘岩, 丁天威, 王宇鹏,等. 基于自适应控制的燃料电池发动机热管理策略[J].吉林大学学报:工学版, 2022, 52(9): 2168-2174. |

| Liu Yan, Ding Tian-wei, Wang Yu-peng, et al. Thermal management strategy of fuel cell engine based on adaptive control strategy[J]. Journal of Jilin University (Engineering and Technology Edition), 2022, 52(9): 2168-2174. |

| [1] | 特木尔朝鲁朝鲁,张亚萍. 基于卷积神经网络的无线传感器网络链路异常检测算法[J]. 吉林大学学报(工学版), 2024, 54(8): 2295-2300. |

| [2] | 朱圣杰,王宣,徐芳,彭佳琦,王远超. 机载广域遥感图像的尺度归一化目标检测方法[J]. 吉林大学学报(工学版), 2024, 54(8): 2329-2337. |

| [3] | 赵宏伟,武鸿,马克,李海. 基于知识蒸馏的图像分类框架[J]. 吉林大学学报(工学版), 2024, 54(8): 2307-2312. |

| [4] | 张锦洲,姬世青,谭创. 融合卷积神经网络和双边滤波的相贯线焊缝提取算法[J]. 吉林大学学报(工学版), 2024, 54(8): 2313-2318. |

| [5] | 孙铭会,薛浩,金玉波,曲卫东,秦贵和. 联合时空注意力的视频显著性预测[J]. 吉林大学学报(工学版), 2024, 54(6): 1767-1776. |

| [6] | 魏晓辉,王晨洋,吴旗,郑新阳,于洪梅,岳恒山. 面向脉动阵列神经网络加速器的软错误近似容错设计[J]. 吉林大学学报(工学版), 2024, 54(6): 1746-1755. |

| [7] | 张玺君,余光杰,崔勇,尚继洋. 基于聚类算法和图神经网络的短时交通流预测[J]. 吉林大学学报(工学版), 2024, 54(6): 1593-1600. |

| [8] | 李光保,高栋,路勇,平昊,周愿愿. 基于改进神经网络和Fluent的气液固技术的内表面处理[J]. 吉林大学学报(工学版), 2024, 54(6): 1537-1547. |

| [9] | 黄玲,崔躜,游峰,洪佩鑫,钟浩川,曾译萱. 适用于多车交互场景的车辆轨迹预测模型[J]. 吉林大学学报(工学版), 2024, 54(5): 1188-1195. |

| [10] | 张西广,张龙飞,马钰锡,樊银亭. 基于密度峰值的海量云数据模糊聚类算法设计[J]. 吉林大学学报(工学版), 2024, 54(5): 1401-1406. |

| [11] | 都雪静,王宁,张杰,裴玉龙. 寒区危险路段半挂汽车列车横向稳定性控制策略[J]. 吉林大学学报(工学版), 2024, 54(4): 996-1006. |

| [12] | 夏超,王梦佳,朱剑月,杨志刚. 基于分层卷积自编码器的钝体湍流流场降阶分析[J]. 吉林大学学报(工学版), 2024, 54(4): 874-882. |

| [13] | 杨国俊,齐亚辉,石秀名. 基于数字图像技术的桥梁裂缝检测综述[J]. 吉林大学学报(工学版), 2024, 54(2): 313-332. |

| [14] | 周遊,洪伟,解方喜,刘宇,宫洵,李小平. 气门控制策略对无节气门发动机性能的影响[J]. 吉林大学学报(工学版), 2024, 54(1): 55-65. |

| [15] | 高海龙,徐一博,刘坤,李春阳,卢晓煜. 基于多源数据融合的高速公路路网短时交通流参数实时预测[J]. 吉林大学学报(工学版), 2024, 54(1): 155-161. |

|

||