吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (5): 1196-1204.doi: 10.13229/j.cnki.jdxbgxb.20220757

• 车辆工程·机械工程 • 上一篇

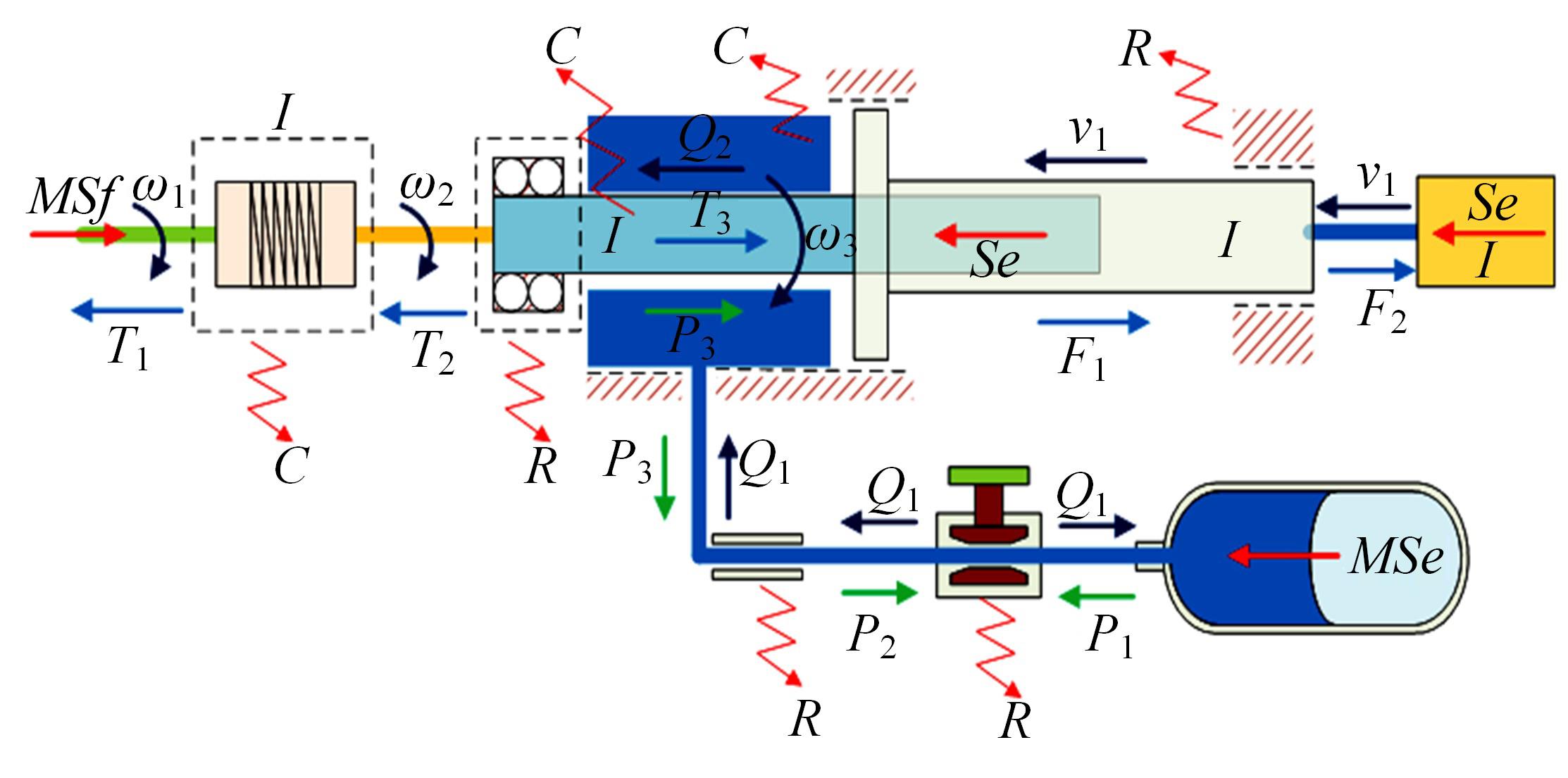

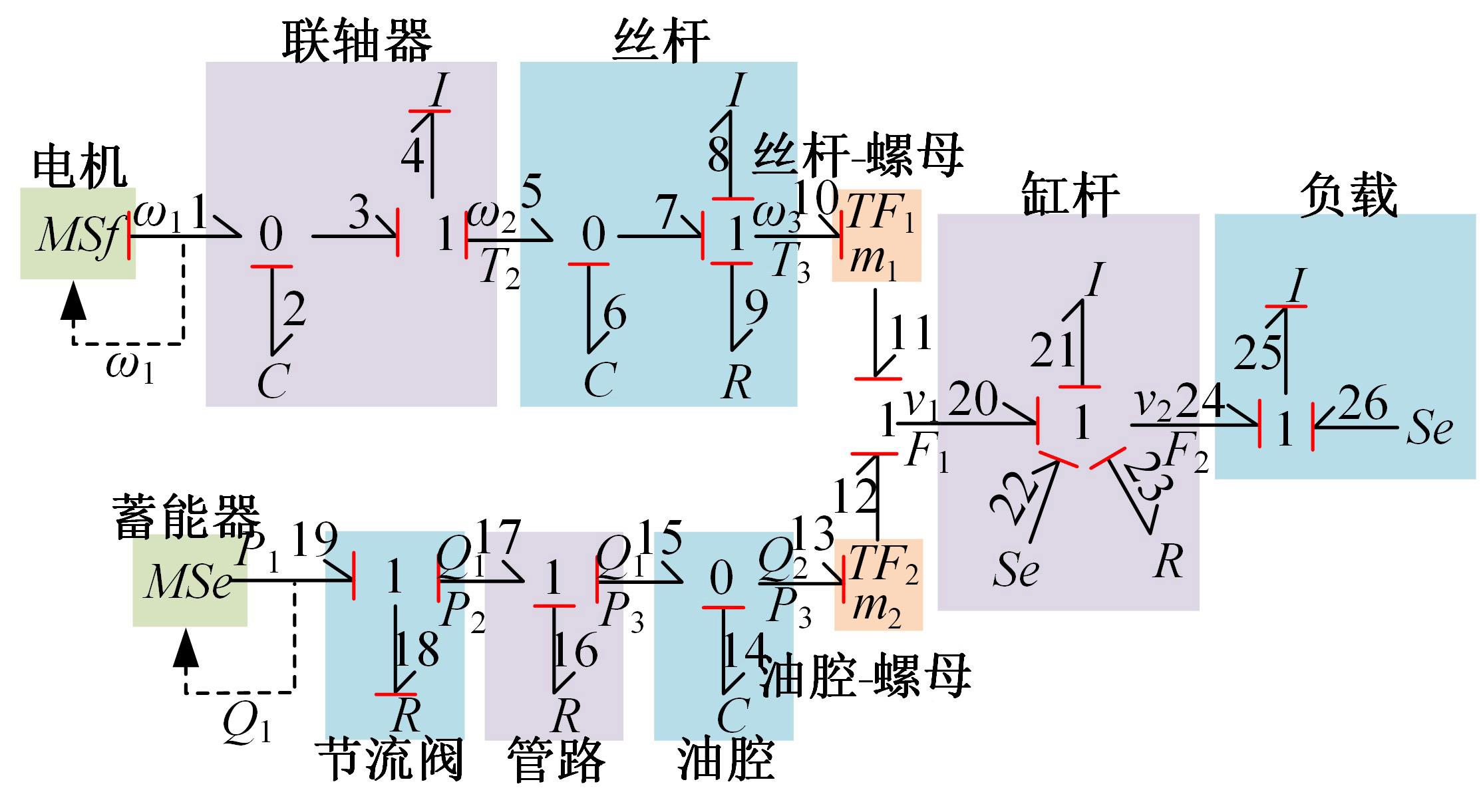

基于能量回收的新型电伺服作动器及其动态能耗分析

- 1.燕山大学 机械工程学院,河北 秦皇岛 066000

2.燕山大学 车辆与能源学院,河北 秦皇岛 066000

3.中国船舶集团有限公司 系统工程研究院,北京 100094

A new electric servo actuator based on energy recovery and its dynamic energy consumption analysis

Qian LIU1( ),Zhu-xin ZHANG2(

),Zhu-xin ZHANG2( ),Ding-xuan ZHAO1,Li-xin WANG1,Ya-fei WANG3

),Ding-xuan ZHAO1,Li-xin WANG1,Ya-fei WANG3

- 1.School of Mechanical Engineering,Yanshan University,Qinhuangdao 066000,China

2.School of Vehicle and Energy,Yanshan University,Qinhuangdao 066000,China

3.Systems Engineering Research Institute,China State Shipbuilding Corporation Limited,Beijing 100094,China

摘要:

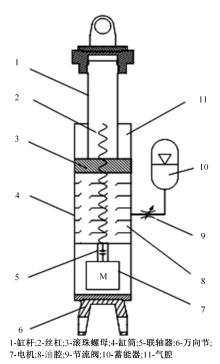

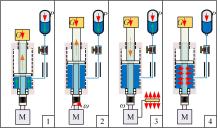

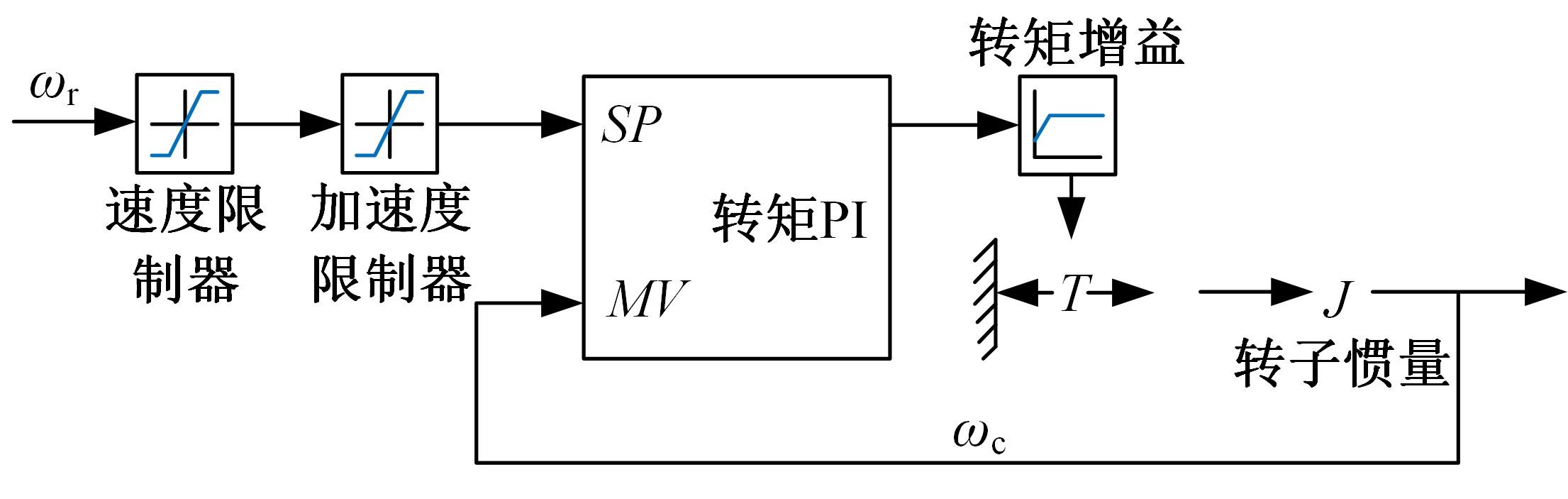

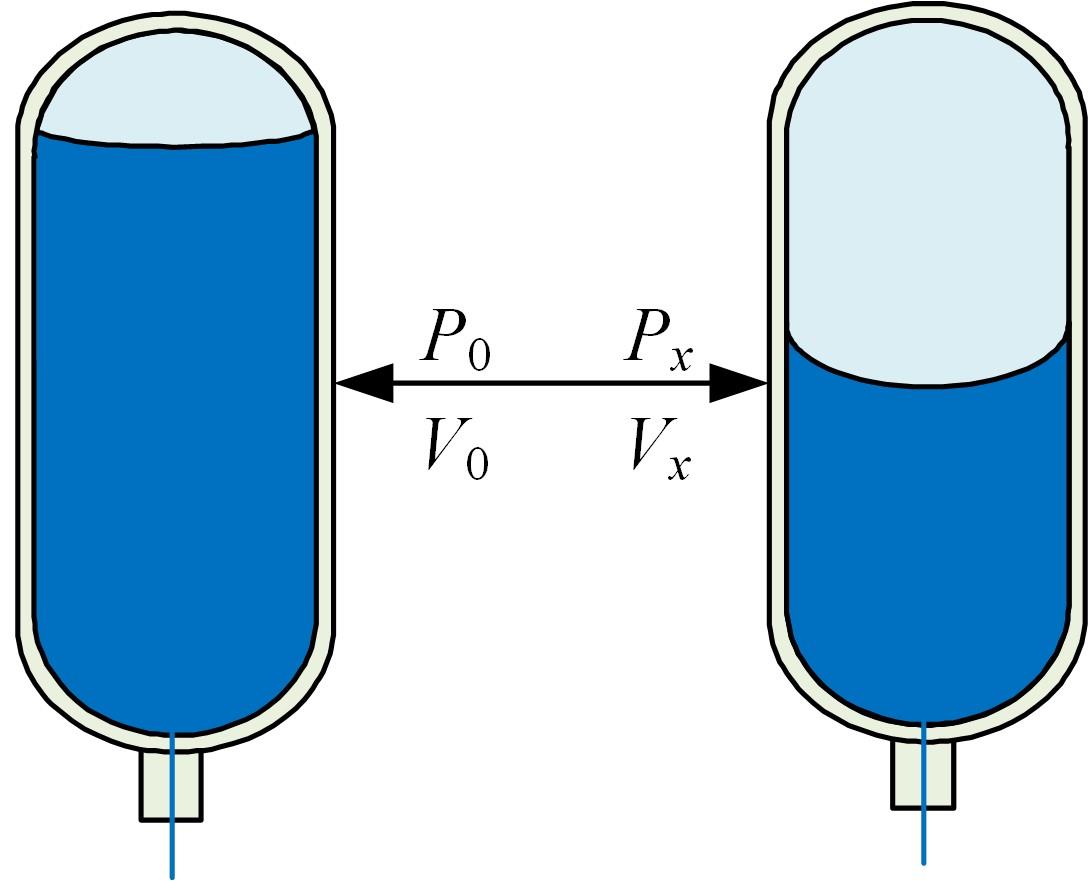

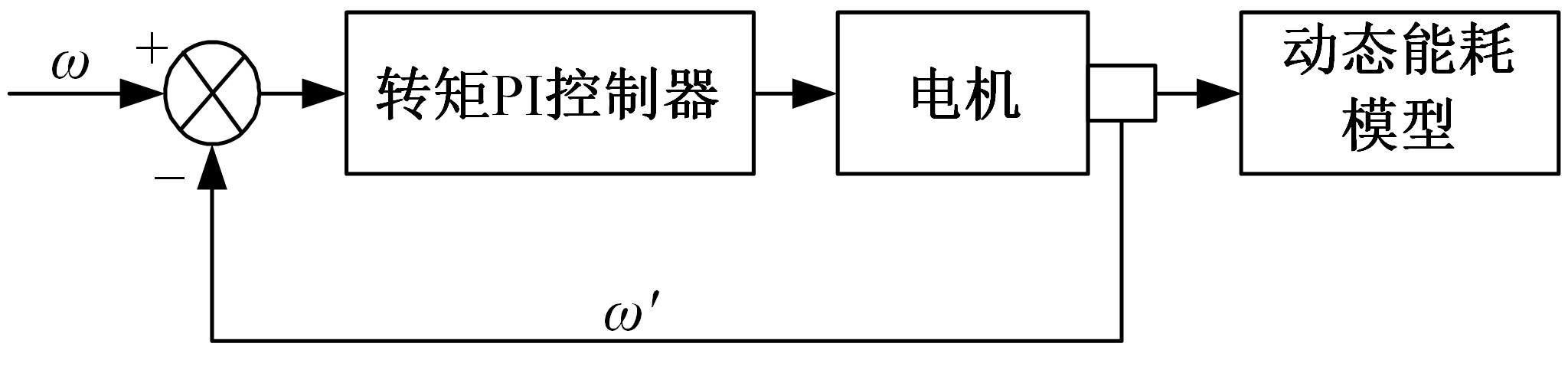

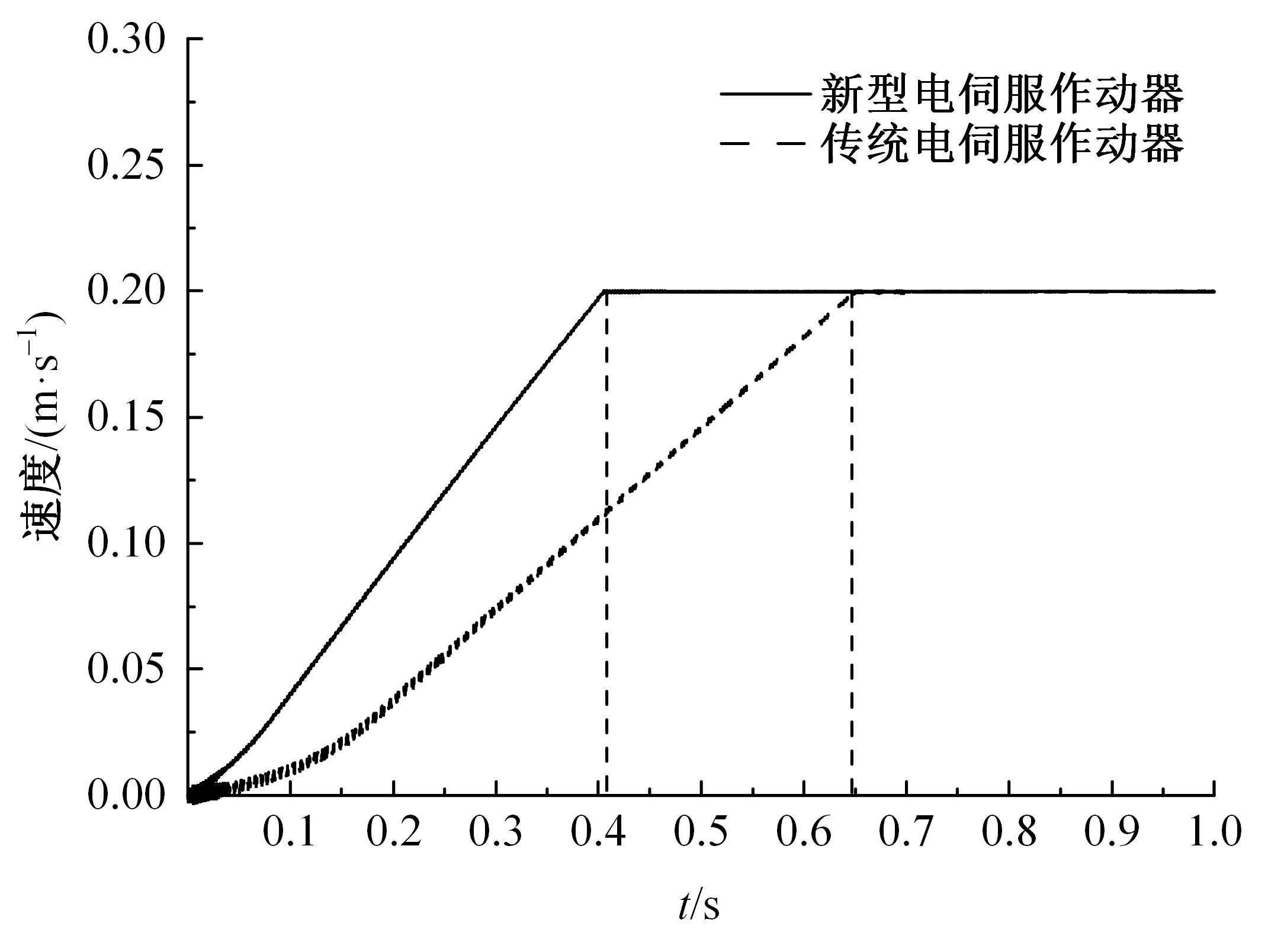

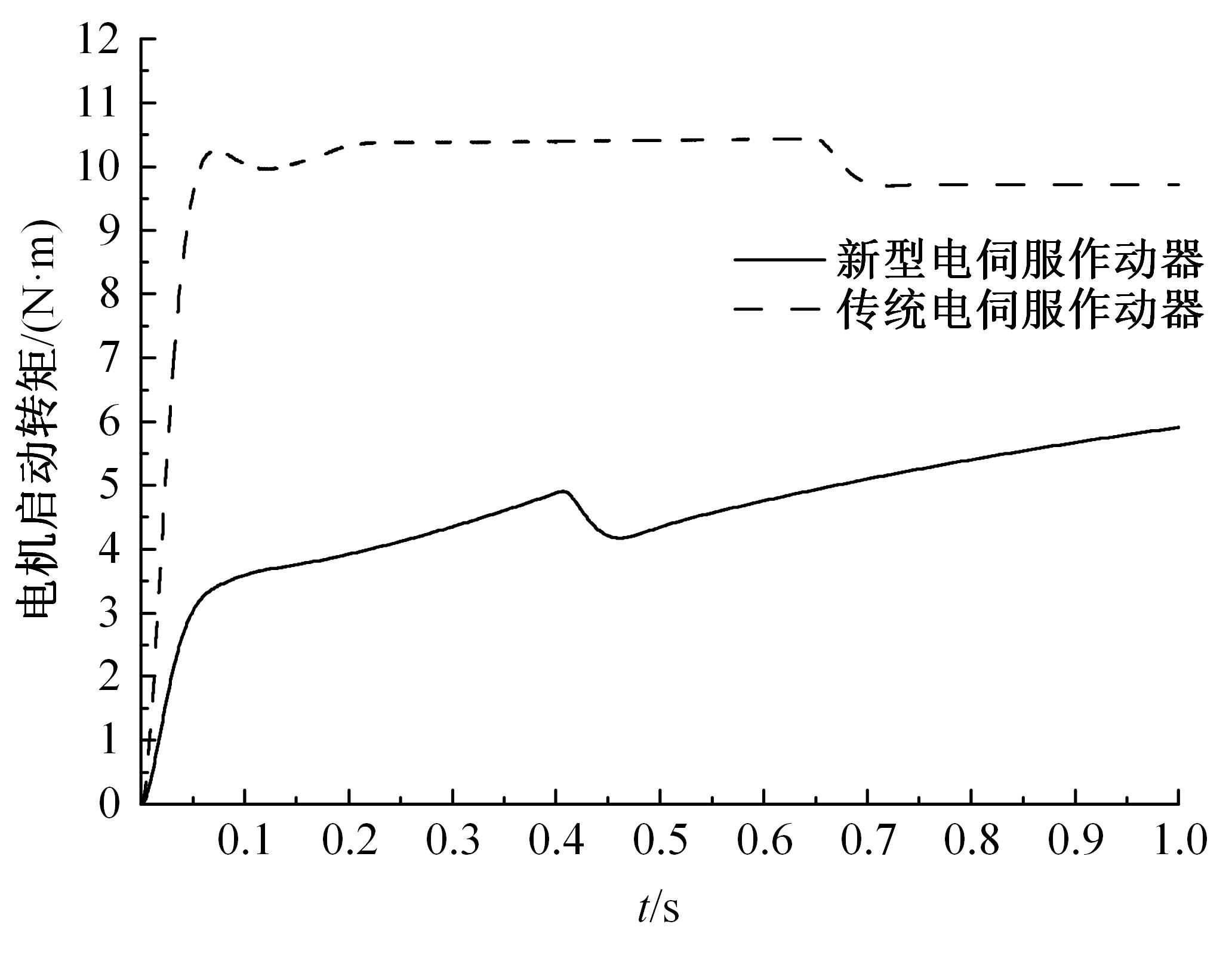

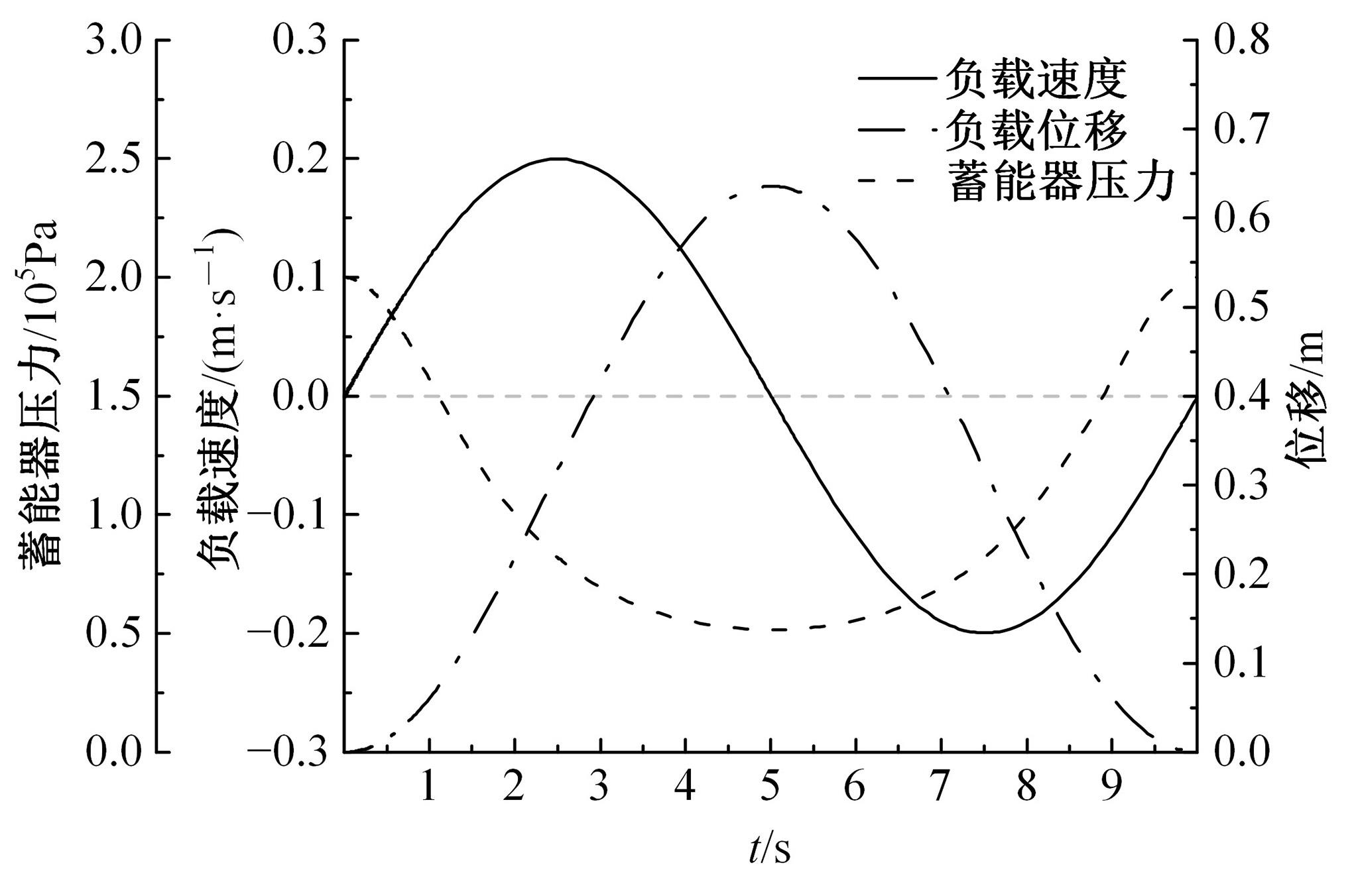

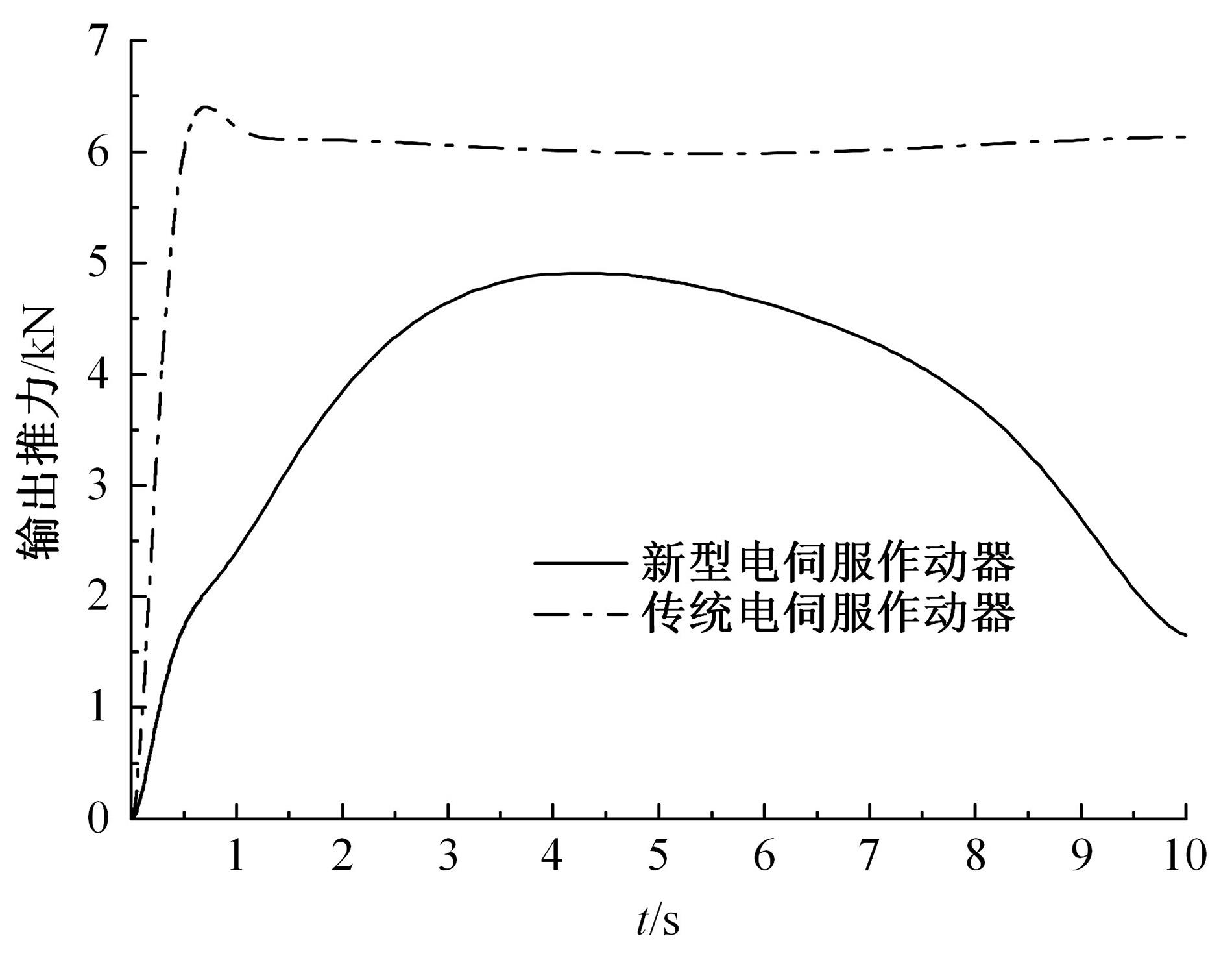

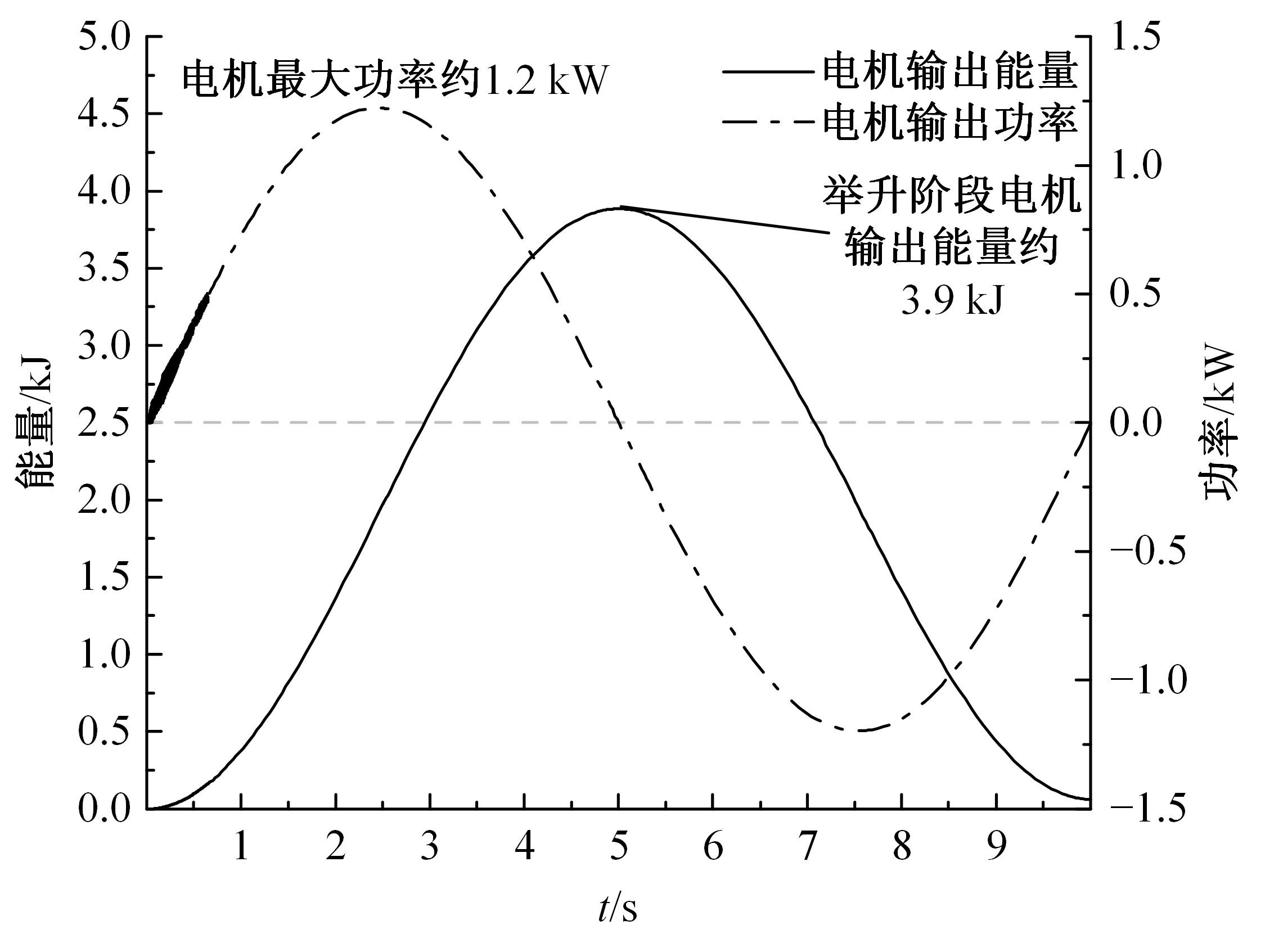

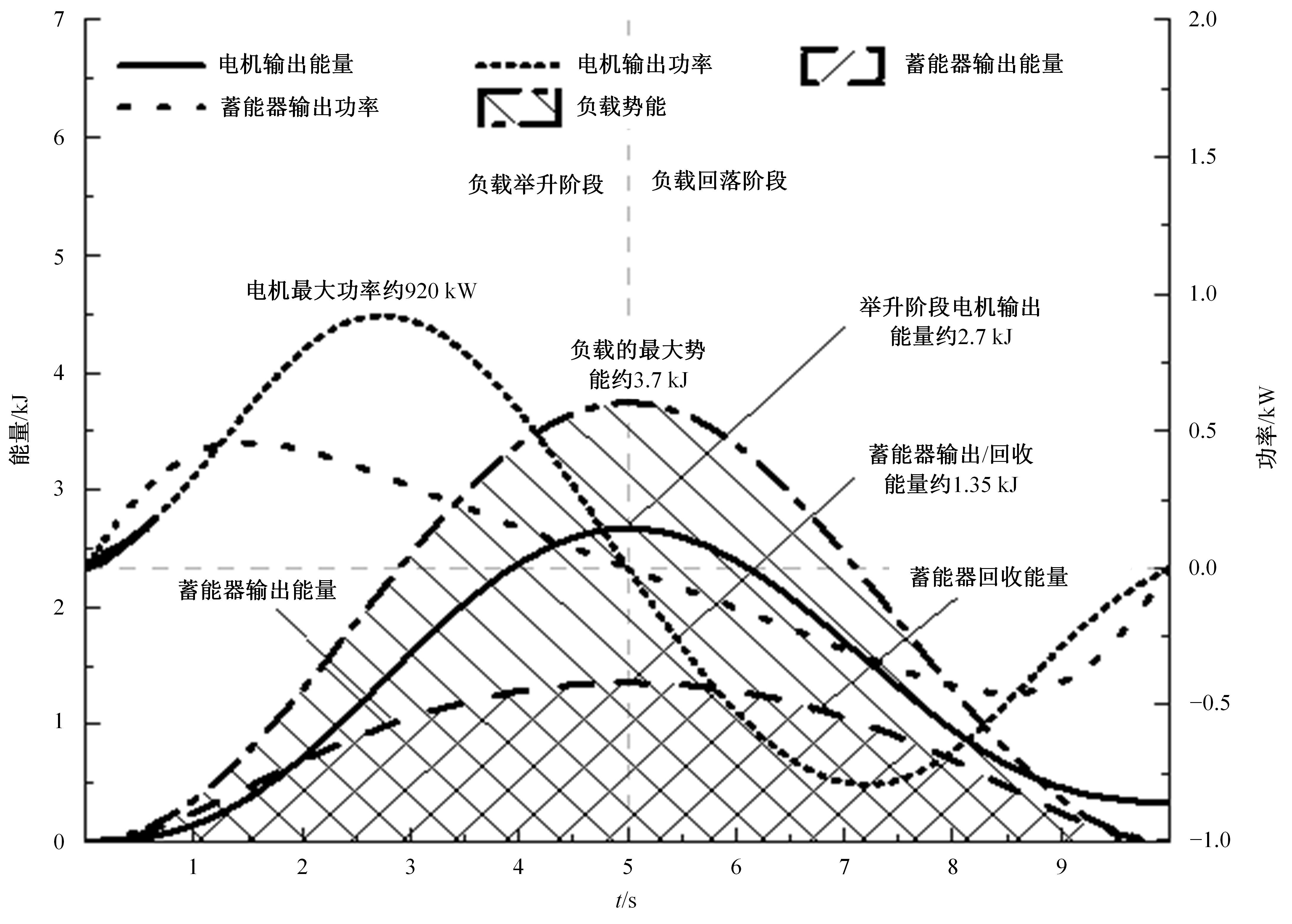

针对现有电伺服作动器在负载回落阶段负载势能被浪费的问题,提出了基于能量回收的新型电伺服作动器的实现方案。该方案通过与传动系统并联的蓄能器来回收负载回落时耗散的势能,在负载举升时将其用于提供辅助推力。结合功率键合图理论引入了一种复杂能域下的机械系统动态能耗分析方法,建立了新型电伺服作动器的动态能耗模型,并进行了对比仿真实验。结果表明,所设计的电伺服作动器使得系统响应时间缩短了约36.9%,所需的电机启动转矩降低了约43.3%;在举升负载时的能耗降低了约31%,在负载回落时能够回收36%的势能;在工作过程中滚珠螺旋副的承载大大降低,有助于减少摩擦热、延长丝杠的使用寿命。

中图分类号:

- TP242.2

| 1 | He X, Xiao G, Hu B, et al. The applications of energy regeneration and conversion technologies based on hydraulic transmission systems: a review[J]. Energy Conversion and Management, 2020, 205:No. 112413. |

| 2 | Quan Z, Quan L, Zhang J. Review of energy efficient direct pump controlled cylinder electro-hydraulic technology[J]. Renewable and Sustainable Energy Reviews, 2014, 35: 336-346. |

| 3 | Liu D, Wang J, Wang S, et al. Active disturbance rejection control for electric cylinders with PD-type event-triggering condition[J]. Control Engineering Practice, 2020, 100: No. 104448. |

| 4 | Asswad E M, Alfayad S, Khalil K. Experimental estimation of friction and friction coefficient of a lightweight hydraulic cylinder intended for robotics applications[J]. International Journal of Applied Mechanics, 2018, 10(8):No. 1850080. |

| 5 | 梁涛, 张晓刚, 葛磊, 等. 泵阀双源协同驱动非对称液压缸系统特性[J]. 液压与气动, 2021, 45(12): 58-64. |

| Liang Tao, Zhang Xiao-gang, Ge Lei, et al. Characteristics of valve control and pump control dual source cooperative drive differential cylinder system[J]. Chinese Hydraulics & Pneumatics, 2021, 45(12): 58-64. | |

| 6 | Qu S, Fassbender D, Vacca A, et al. A high-efficient solution for electro-hydraulic actuators with energy regeneration capability[J]. Energy, 2021, 216: No.119291. |

| 7 | 龚中良, 金可. 电动缸传输效率测试系统的设计与试验研究[J]. 机械设计与制造, 2020, 2020: 300-303. |

| Gong Zhong-liang, Jin Ke. Design and test of transmission efficiency test system for electric cylinder[J]. Machinery Design & Manufacture, 2020, 2020: 300-303. | |

| 8 | 娄开成, 徐志鹏. 液压动态加载的伺服电动缸综合性能测试系统设计[J]. 中国计量大学学报, 2017, 28(4): 467-471. |

| Lou Kai-cheng, Xu Zhi-peng. Design of servo electric cylinders comprehensive performance test systems of based on hydraulic dynamic loading[J]. Journal of China University of Metrology, 2017, 28(4):467-471. | |

| 9 | 权龙, 夏连鹏, 赵斌, 等. 液压驱动机械臂势能回收利用研究工作进展[J]. 机械工程学报, 2018, 54(20): 4-13. |

| Quan Long, Xia Lian-peng, Zhao Bin, et al. Innovation progress in research on gravitational potential energy recovery and utilization of hydraulic driven mechanical arm[J]. J Mech Eng, 2018, 54(20): 4-13. | |

| 10 | 李泽鹏, 权龙, 葛磊, 等. 液电混合驱动液压挖掘机动臂特性及能效研究[J]. 机械工程学报, 2018, 54(20): 213-219. |

| Li Ze-peng, Quan Long, Ge Lei, et al. Research on characteristics and energy efficiency of hydraulic-electric combined driving hydraulic excavator boom[J]. J Mech Eng, 2018, 54(20): 213-219. | |

| 11 | 刘昌盛, 何清华, 张大庆, 等. 混合动力挖掘机势能回收系统参数优化与试验[J].吉林大学学报: 工学版, 2014, 44(2): 379-386. |

| Liu Chang-sheng, He Qing-hua, Zhang Da-qing, et al. Parameter optimization and experiment of potential energy recovery system of hybrid excavator[J]. Journal of Jilin University (Engineering and Technology Edition), 2014, 44(2): 379-386. | |

| 12 | 朱建新, 刘复平, 朱俊霖, 等. 电动叉车势能回收液压系统工作效率分析与实验[J]. 机械设计与研究, 2011, 27(6): 101-104. |

| Zhu Jian-xin, Liu Fu-ping, Zhu Jun-lin, et al. Analysisand experimental study on hydraulic system work efficiency for recovering the potential energy of electric forklift[J]. Machine Design and Research, 2011, 27(6): 101-104. | |

| 13 | 赵丁选, 陈明东, 戴群亮, 等. 油液混合动力液压挖掘机动臂势能回收系统[J].吉林大学学报: 工学版, 2011, 41(): 150-154. |

| Zhao Ding-xuan, Chen Ming-dong, Dai Qun-liang, et al. System of arm potential energy recovery in hybrid hydraulic excavators[J]. Journal of Jiin University(Engineering and Technology Edition), 2011, 41(Sup.1): 150-154. | |

| 14 | Lin T, Huang W, Ren H, et al. New compound energy regeneration system and control strategy for hybrid hydraulic excavators[J]. Automation in Construction, 2016, 68: 11-20. |

| 15 | Lin T, Wang Q, Hu B, et al. Research on the energy regeneration systems for hybrid hydraulic excavators[J]. Automation in Construction, 2010, 19(8): 1016-1026. |

| 16 | 樊延都, 张博航, 陈凯. 滚珠丝杠副高密封性组合油封[P]中国: CN2021I2532349.8, 2022-04-12. |

| 17 | 谷玉念, 林新忠. 滚珠丝杠副及密封结构[P].中国:CN202121293380.4,2021-11-26. |

| 18 | Liu W, Li L, Cai W, et al. Dynamic characteristics and energy consumption modelling of machine tools based on bond graph theory[J]. Energy, 2020, 212: No.118767. |

| 19 | Chen Y, Sun Q, Guo Q, et al. Dynamic modeling and experimental validation of a water hydraulic soft manipulator based on an improved Newton-Euler iterative method[J]. Micromachines, 2022, 13(1):No. 13010130. |

| 20 | Ungureanu L M, Petrescu F I T. Dynamics of mechanisms with superior couplings[J]. Applied Sciences, 2021, 11(17): No.11178207. |

| 21 | Tu T W. Dynamic modelling of a railway wheelset based on Kane's method[J]. International Journal of Heavy Vehicle Systems, 2020, 27(1/2): 202-226. |

| 22 | Somu N, Mr G R, Ramamritham K. A hybrid model for building energy consumption forecasting using long short term memory networks[J]. Applied Energy, 2020, 261: No.114131. |

| 23 | Saeedi M, Moradi M, Hosseini M, et al. Robust optimization based optimal chiller loading under cooling demand uncertainty[J]. Applied Thermal Engineering, 2019, 148: 1081-1091. |

| 24 | Su S, Wang X, Cao Y, et al. An energy-efficient train operation approach by integrating the metro timetabling and eco-driving[J]. IEEE Trasactions on Intelligent Transportation Systems, 2019, 21(10): 4252-4268. |

| 25 | KomuZ G, Geitner G H. Systems featuring chain structures⁃a generalized bond graph modelling[J]. International Journal of General Systems, 2019, 48(8): 861-889. |

| 26 | Geinter G H, Komurgoz G. Generic power split modelling for compound epicyclic four-speed gears[J]. Mechanism and Machine Theory, 2017, 116: 50-68. |

| 27 | Zhang Z, Liu Q, Zhao D, et al. Electrical aircraft ship integrated secure and traverse system design and key characteristics analysis[J]. Applied Sciences, 2022, 12(5): No.12052603. |

| 28 | Zhang Z, Liu Q, Zhao D, et al. Research on shipborne helicopter electric rapid secure device: system design, modeling, and simulation[J]. Sensors, 2022, 22(4): No.22041514. |

| 29 | Wang Y, Zhao D, Wang L, et al. Dynamic simulation and analysis of the elevating mechanism of a forklift based on a power bond graph[J]. Journal of Mechanical Science and Technology, 2016, 30(9): 4043-4048. |

| 30 | Kato S, Sasaki S. Effects of hydraulic oil and lubricant additives on dynamic friction properties under various reciprocating sliding conditions[J]. Friction, 2020, 8(2): 471-480. |

| 31 | Yi T, Ma F, Jin C, et al. Investigation on thermal characteristics of the oil-circulating hydraulic energy storage system for hybrid mining trucks[J]. Frontiers in Energy Research, 2021, 9:No. 733919. |

| [1] | 赵慧,朱发强,蒋林,王诗虎. 双叶片液压关节主被动联合柔顺控制分析[J]. 吉林大学学报(工学版), 2024, 54(1): 86-98. |

| [2] | 陈淑江,徐春望,路长厚,王康. 嵌入控制油腔的静压主轴轴心运动主动控制分析与试验[J]. 吉林大学学报(工学版), 2023, 53(4): 973-981. |

| [3] | 蒋林,杨立,张文俊,张琼玉,吴艳霞. 在障碍物检测时对斜坡点云的检测处理算法[J]. 吉林大学学报(工学版), 2023, 53(11): 3221-3228. |

| [4] | 王骏骋,吕林峰,李剑敏,任洁雨. 分布驱动电动汽车电液复合制动最优滑模ABS控制[J]. 吉林大学学报(工学版), 2022, 52(8): 1751-1758. |

| [5] | 蒋林,周玲,赵慧. 液压伺服柔驱机构设计及其刚度连续可调分析[J]. 吉林大学学报(工学版), 2022, 52(7): 1499-1508. |

| [6] | 杨志军,高忠义,王丽君,黄观新,危宇泰. 面向刚柔耦合定位平台的模型预测控制算法[J]. 吉林大学学报(工学版), 2022, 52(12): 2806-2815. |

| [7] | 胡鹏,朱建新,刘昌盛,张大庆. 液压挖掘机动臂势能交互回收利用系统特性[J]. 吉林大学学报(工学版), 2022, 52(10): 2256-2264. |

| [8] | 李学勇,赵仲秋,张春松,路长厚. 基于有限元的人体⁃机械手交互力计算方法[J]. 吉林大学学报(工学版), 2021, 51(5): 1612-1619. |

| [9] | 施昕昕,黄家才,高芳征. 基于分数阶BICO滤波器的运动控制测量噪声抑制[J]. 吉林大学学报(工学版), 2021, 51(5): 1873-1878. |

| [10] | 于萍,穆特,朱黎辉,周子业,宋杰. 钻具输送装置非线性动力学分析及稳定性控制[J]. 吉林大学学报(工学版), 2021, 51(3): 820-830. |

| [11] | 姜继海,赵存然,张冠隆,车明阳. 航空煤油柱塞泵摩擦副涂层材料摩擦性能[J]. 吉林大学学报(工学版), 2021, 51(1): 147-153. |

| [12] | 胡明伟,王洪光,潘新安. 基于正交设计的协作机器人全域结构优化设计[J]. 吉林大学学报(工学版), 2021, 51(1): 370-378. |

| [13] | 贺继林, 陈毅龙, 吴钪, 赵喻明, 汪志杰, 陈志伟. 起重机卷扬系统能量流动分析及势能回收系统实验[J]. 吉林大学学报(工学版), 2018, 48(4): 1106-1113. |

| [14] | 仇艳凯, 李宝仁, 杨钢, 曹博, 刘真. 新型液压消声器吸收液压系统压力脉动的机理和特性[J]. 吉林大学学报(工学版), 2018, 48(4): 1085-1091. |

| [15] | 刘祥勇, 李万莉. 包含蓄能器的电液比例控制模型[J]. 吉林大学学报(工学版), 2018, 48(4): 1072-1084. |

|

||