| 1 | 林学东, 李德刚, 田维 . 高压喷射的高速直喷柴油机混合气形成及燃烧过程[J]. 吉林大学学报:工学版, 2009, 39(6): 1446-1451. | | 1 | Lin Xue-dong , Li De-gang , Tian Wei . Air-fuel mixture formation and combustion process of a high-speed direct-injection diesel engine with high pressure injection[J]. Journal of Jilin University(Engineering and Technology Edition), 2009, 39(6): 1446-1451. | | 2 | 林学东, 顾静静, 李德刚, 等 . 柴油机燃烧室结构对混合气形成及燃烧特性的影响[J]. 吉林大学学报:工学版, 2014, 44(6): 1647-1654. | | 2 | Lin Xue-dong , Gu Jing-jing , Li De-gang , et al . Effects of combustion chamber on the mixture formation and combustion characteristics of diesel engine[J]. Journal of Jilin University(Engineering and Technology Edition), 2014, 44(6): 1647-1654. | | 3 | Guo B , Zhang W , Wang X . Failure analysis of a modern high performance diesel engine cylinder head[J]. Advances in Mechanical Engineering, 2014, 2014(8): 1-7. | | 4 | Steiner H , Brenn G , Ramstorfer F , et al . Increased cooling power with nucleate boiling flow in automotive engine applications[C]∥New Trends and Developments in Automotive System Engineering,Italy,2011: 249-272. | | 5 | Hosny Z , Abou Z . Forced convection and sub-cooled flow boiling heat transfer in asymmetrically heated ducts of T-section[J]. Energy Conversion and Management, 2004, 45(7/8): 1043-1065. | | 6 | Robinson K , Campbell N A F , Hawley J G , et al . A review of precision engine cooling[C]∥SAE Paper, 1999-01-0578. | | 7 | Finlay I C , Boyle R J , Pirault J P , et al . Nucleate and film boiling of engine coolants flowing in an uniformly heated duct of small cross section[C]∥SAE Paper, 870032. | | 8 | Yu W , France D W , Singh D , et al . Subcooled flow boiling of ethylene glycol/water mixtures in a bottom-heated tube[J]. International Journal of Heat and Mass Transfer, 2014, 72(5): 637-645. | | 9 | Robinson K , Hawley J G , Campell N A F . Experimental and modeling aspects of flow boiling heat transfer for application to internal combustion engines[J]. Proceedings of the Institution of Mechanical Engineers, Part D: Journal of Automobile Engineering, 2003, 217(10): 877-889. | | 10 | Steiner H , Breitsch?del B , Brenn G , et al . Nucleate boiling flow—Experimental investigations and wall heat transfer modeling for automotive engine applications[J/OL].[2018-05-28].https:∥. | | 11 | Chen W , Fang X . A note on the Chen correlation of saturated flow boiling heat transfer[J]. International Journal of Refrigeration, 2014, 48: 100-104. | | 12 | Setoodeh H , Keshavarz A , Ghasemian A , et al . Subcooled flow boiling of ethylene–glycol/water mixture in an inclined channel with a hot spot: an experimental study[J]. International Communications in Heat & Mass Transfer, 2016, 78: 285-294. | | 13 | Chen J C . Correlation for boiling heat transfer to saturated fluids in convective flow[J]. Industrial & Engineering Chemistry Process Design and Development, 1966, 5(3): 322-329. | | 14 | Dittus F W , Boelter L M K . Heat transfer in automobile radiator of the tubular type[J]. International Communications in Heat & Mass Transfer, 1985, 12(1): 3-22. | | 15 | Forster H K , Zuber N . Dynamics of vapor bubbles and boiling heat transfer[J]. Aiche Journal, 1955, 1(4): 531-535. | | 16 | Steiner H , Kobor A , Gebhard L . A wall heat transfer model for subcooled boiling flow[J]. International Journal of Heat & Mass Transfer, 2005, 48(19): 4161-4173. | | 17 | Paz M C , Conde M , Suárez E , et al . On the effect of surface roughness and material on the subcooled flow boiling of water: experimental study and global correlation[J]. Experimental Thermal & Fluid Science, 2015, 64: 114-124. | | 18 | Hua S , Huang R , Li Z , et al . Experimental study on the heat transfer characteristics of subcooled flow boiling with cast iron heating surface[J]. Applied Thermal Engineering, 2015, 77: 180-191. | | 19 | Li Y Y , Chen Y J , Liu Z H . A uniform correlation for predicting pool boiling heat transfer on plane surface with surface characteristics effect[J]. International Journal of Heat & Mass Transfer, 2014, 77: 809-817. | | 20 | Soleimani B , Keshavarz A . Heat transfer enhancement of an internal subcooled flow boiling over a hot spot[J]. Applied Thermal Engineering, 2016, 99: 206-213. |

|

),Guo-xiang LI(

),Guo-xiang LI( ),Shu-zhan BAI,Ke SUN,Si-yuan LI

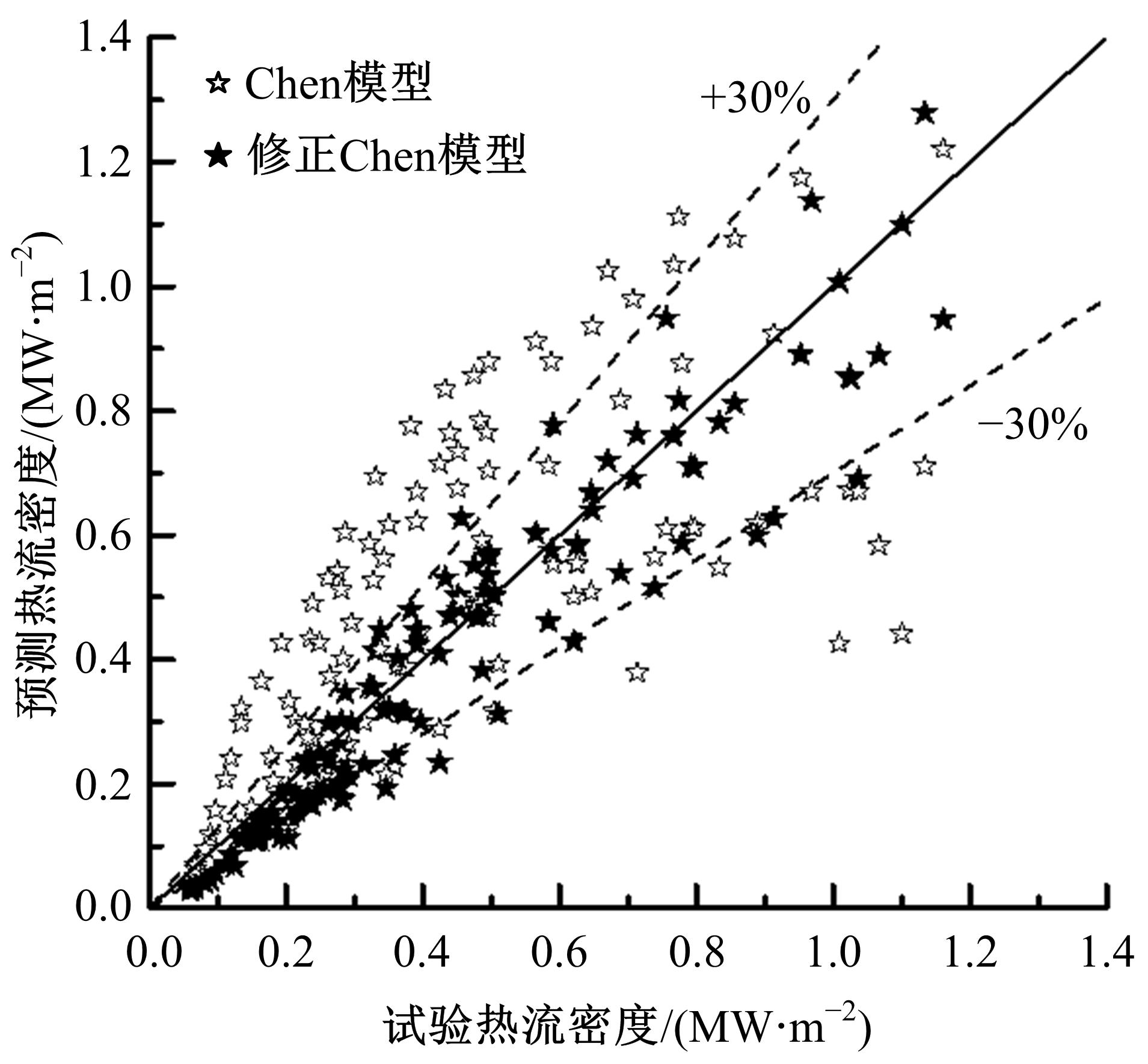

),Shu-zhan BAI,Ke SUN,Si-yuan LI