吉林大学学报(工学版) ›› 2019, Vol. 49 ›› Issue (6): 1936-1944.doi: 10.13229/j.cnki.jdxbgxb20181279

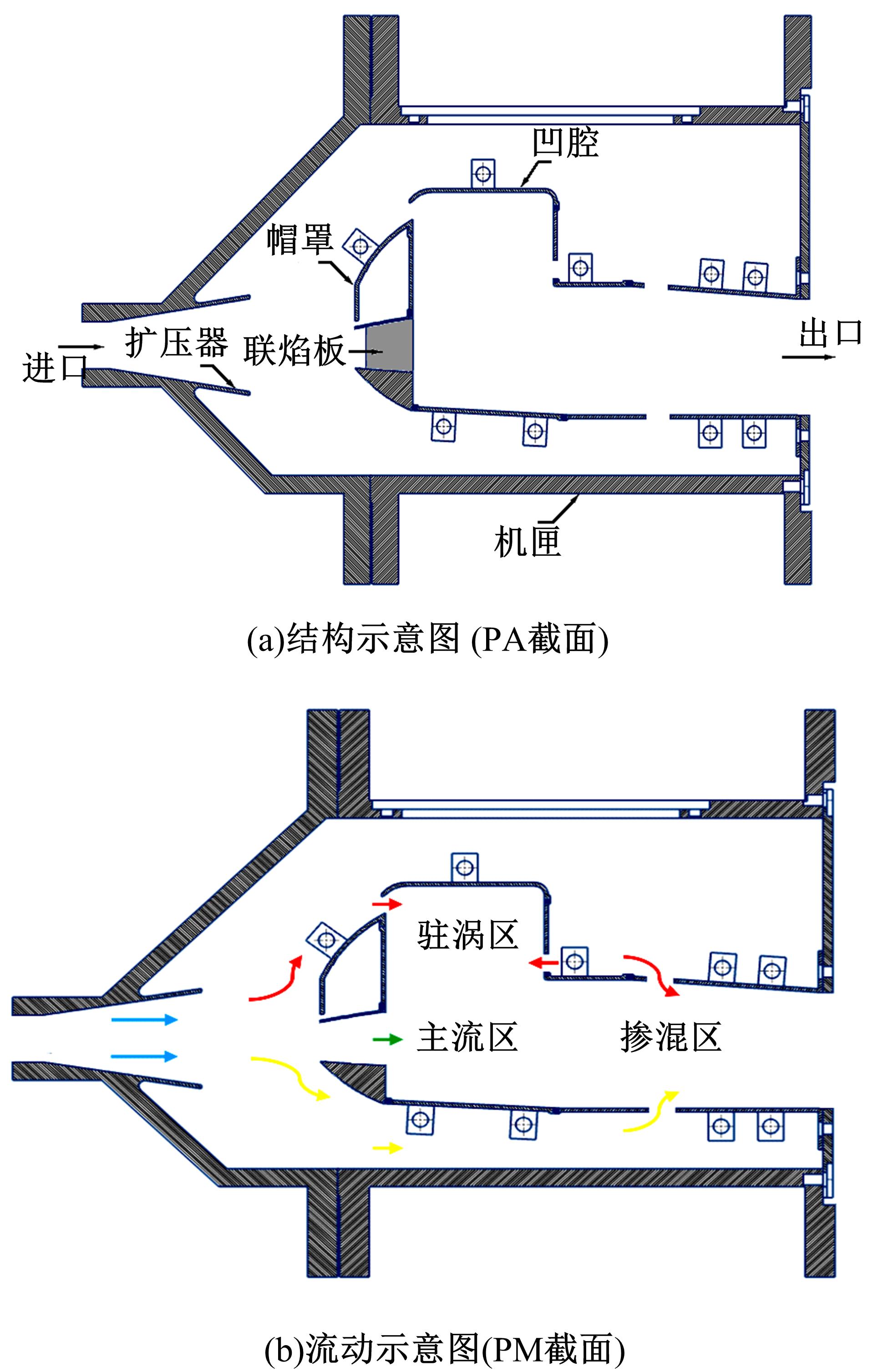

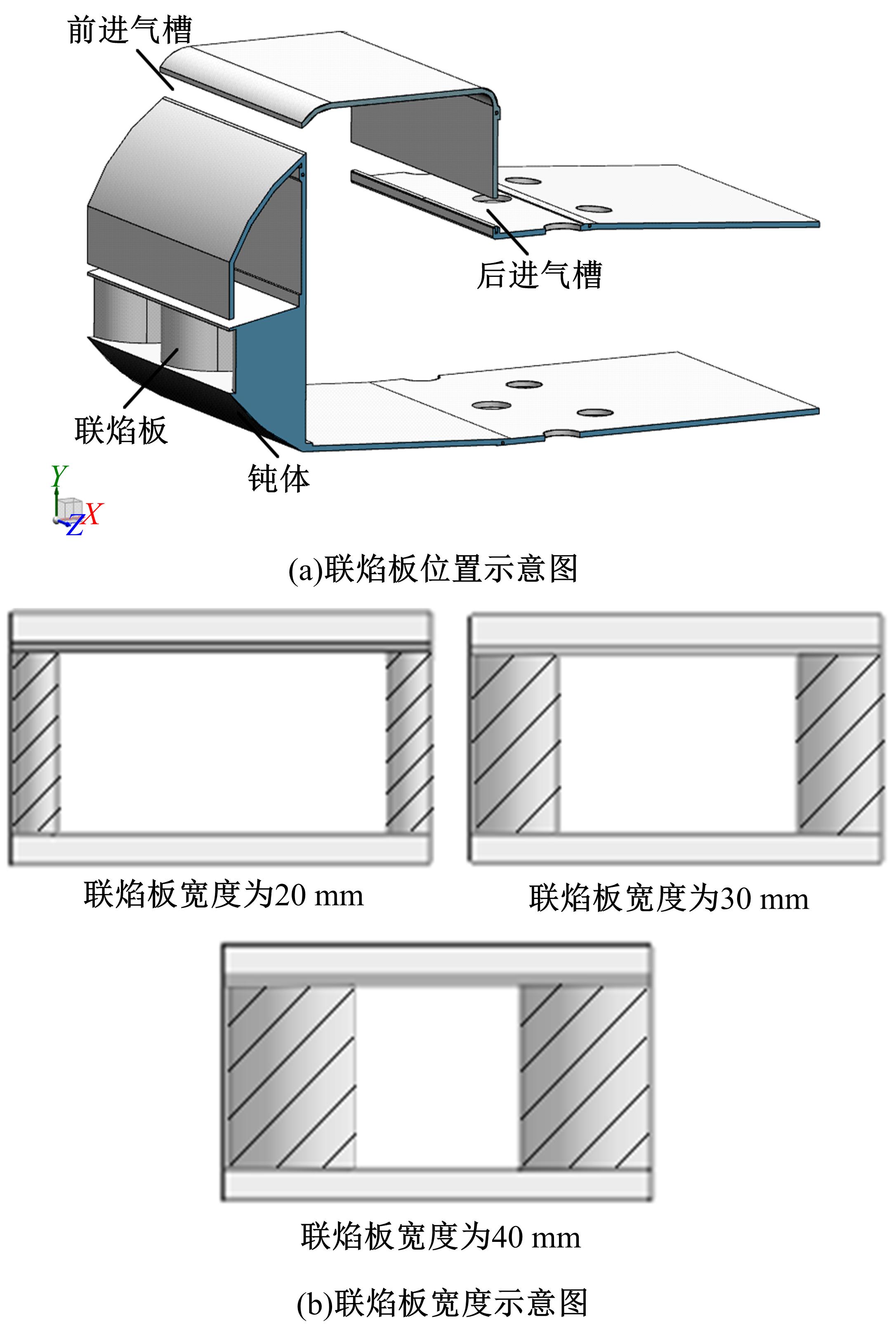

联焰板宽度对单凹腔驻涡燃烧室流线形态的影响

- 1. 南京航空航天大学 能源与动力学院,南京 210016

2. 南京航空航天大学 江苏省航空动力系统重点实验室,南京 210016

Effects of radial strut width on flow structure ofsingle⁃cavity trapped vortex combustor

Yi-xiao ZHU1( ),Xiao-min HE1,2(

),Xiao-min HE1,2( ),Yi JIN1,2

),Yi JIN1,2

- 1. College of Energy and Power Engineering, Nanjing University of Aeronautics and Astronautics, Nanjing 210016,China

2. Jiangsu Province Key Laboratory of Aerospace Power Systems, Nanjing University of Aeronautics and Astronautics, Nanjing 210016,China

摘要:

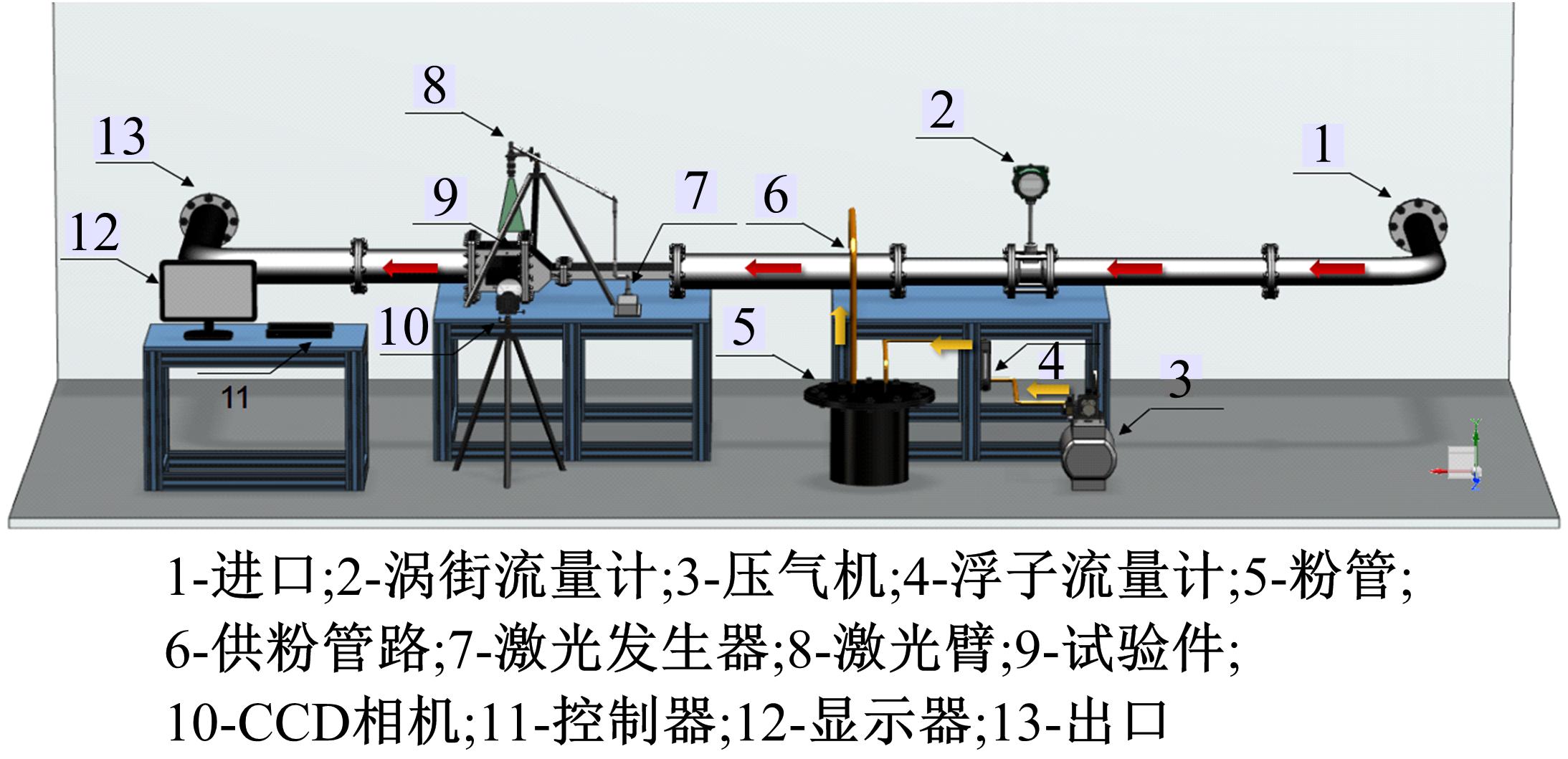

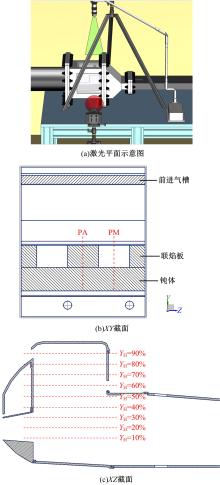

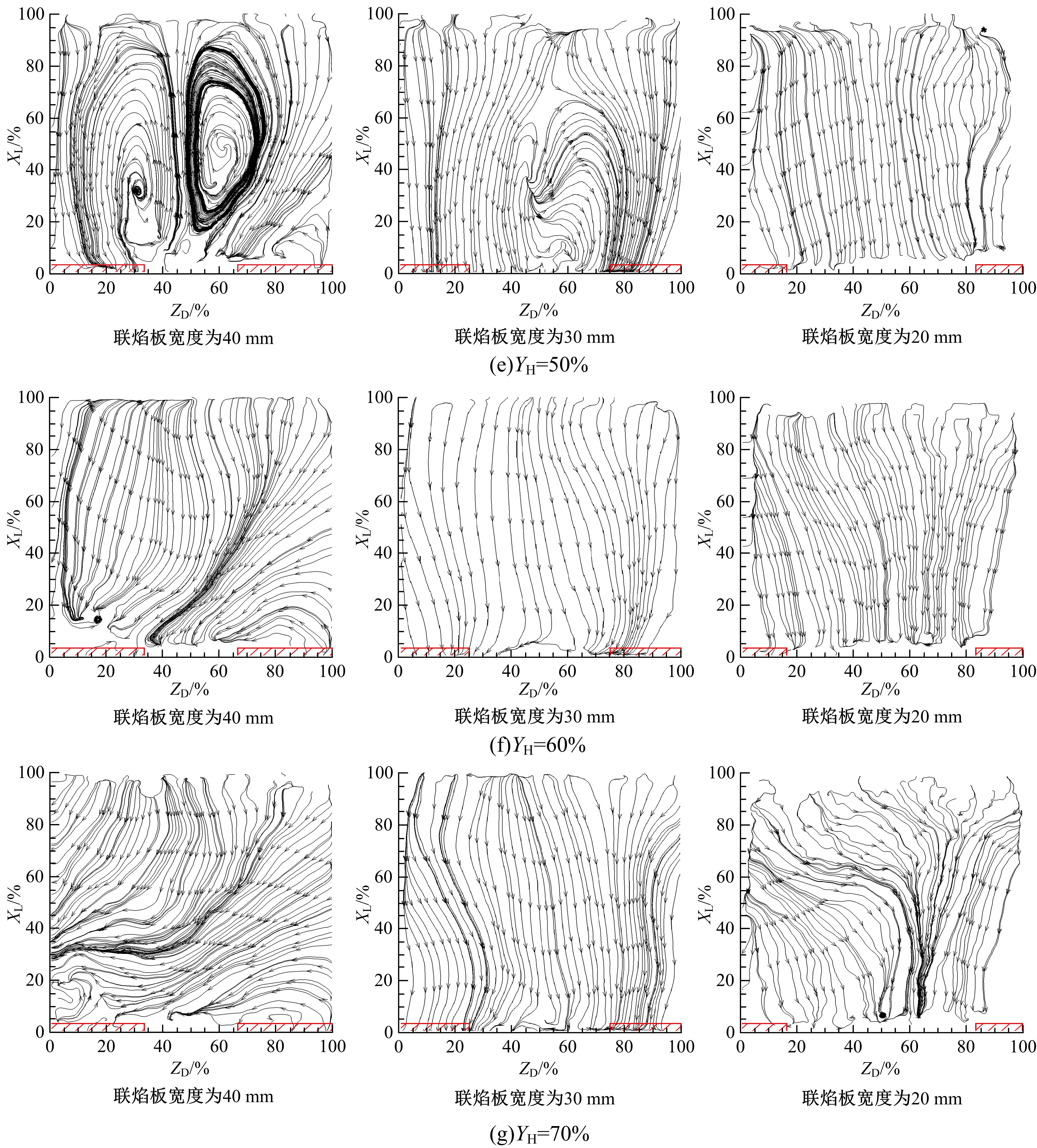

为了研究联焰板宽度对单凹腔驻涡燃烧室流线形态的影响,设计了一个带扩压器和内外机匣的单凹腔驻涡燃烧室,并在此基础上进行了常温、常压状态下的冷态流场试验,试验中设置联焰板宽度分别为40、30、20 mm。研究结果表明:在主流中心截面(PM)上,凹腔内存在双涡流动结构,主涡位于凹腔的中间位置,副涡位于主涡与主流之间;在联焰板中心截面(PA)上,不同的联焰板宽度会形成两种不同的流线形态,当联焰板宽度较宽时,凹腔内为单涡流动结构,仅存在主涡结构,主涡回流气流沿联焰板向火焰筒下壁面流动;当联焰板宽度较窄时,凹腔内为双涡流动结构,主流气流卷入联焰板后方。

中图分类号:

- TK411.12

|

| [1] | 宋昌庆,陈文淼,李君,曲大为,崔昊. 不同当量比下单双点火对天然气燃烧特性的影响[J]. 吉林大学学报(工学版), 2019, 49(6): 1929-1935. |

| [2] | 刘长铖,刘忠长,田径,许允,杨泽宇. 重型增压柴油机燃烧过程中的缸内㶲损失[J]. 吉林大学学报(工学版), 2019, 49(6): 1911-1919. |

| [3] | 胡潇宇,李国祥,白书战,孙柯,李思远. 考虑加热面粗糙度和材料的沸腾换热修正模型[J]. 吉林大学学报(工学版), 2019, 49(6): 1945-1950. |

| [4] | 王德军,吕志超,王启明,张建瑞,丁建楠. 基于EKF及调制傅式级数的缸压辨识[J]. 吉林大学学报(工学版), 2019, 49(4): 1174-1185. |

| [5] | 臧鹏飞,王哲,高洋,孙晨乐. 直线电机/发动机系统稳态运行综合控制策略[J]. 吉林大学学报(工学版), 2019, 49(3): 798-804. |

| [6] | 董伟,宋佰达,邱立涛,孙昊天,孙平,蒲超杰. 直喷汽油机暖机过程中两次喷射比例对燃烧和排放的影响[J]. 吉林大学学报(工学版), 2018, 48(6): 1755-1761. |

| [7] | 李志军, 汪昊, 何丽, 曹丽娟, 张玉池, 赵新顺. 催化型微粒捕集器碳烟分布及其影响因素[J]. 吉林大学学报(工学版), 2018, 48(5): 1466-1474. |

| [8] | 秦静, 徐鹤, 裴毅强, 左子农, 卢莉莉. 初始温度和初始压力对甲烷-甲醇裂解气预混层流燃烧特性的影响[J]. 吉林大学学报(工学版), 2018, 48(5): 1475-1482. |

| [9] | 林学东, 江涛, 许涛, 李德刚, 郭亮. 高压共轨柴油机起动工况高压泵控制策略[J]. 吉林大学学报(工学版), 2018, 48(5): 1436-1443. |

| [10] | 宫洵, 蒋冰晶, 胡云峰, 曲婷, 陈虹. 柴油机主-从双微元Urea-SCR系统非线性状态观测器设计与分析[J]. 吉林大学学报(工学版), 2018, 48(4): 1055-1062. |

| [11] | 钟兵, 洪伟, 金兆辉, 苏岩, 解方喜, 张富伟. 进气门早关液压可变气门机构运动特性[J]. 吉林大学学报(工学版), 2018, 48(3): 727-734. |

| [12] | 席雷, 徐亮, 高建民, 赵振, 王明森. 厚壁矩形带肋通道内蒸汽流动及传热特性[J]. 吉林大学学报(工学版), 2018, 48(3): 752-759. |

| [13] | 李龙, 张幽彤, 左正兴. 变负载控制在自由活塞内燃发电机的缸压控制中的应用[J]. 吉林大学学报(工学版), 2018, 48(2): 473-479. |

| [14] | 卫海桥, 裴自刚, 冯登全, 潘家营, 潘明章. 压电喷油器多次喷射对GDI汽油机颗粒物排放的影响[J]. 吉林大学学报(工学版), 2018, 48(1): 166-173. |

| [15] | 田径, 刘忠长, 刘金山, 董春晓, 钟铭, 杜文畅. 基于燃烧边界参数响应曲面设计的柴油机性能优化[J]. 吉林大学学报(工学版), 2018, 48(1): 159-165. |

|