吉林大学学报(工学版) ›› 2021, Vol. 51 ›› Issue (2): 450-457.doi: 10.13229/j.cnki.jdxbgxb20190998

• 车辆工程·机械工程 • 上一篇

微斜面式重型静压轴承润滑油膜高速特性

- 1.南京工程学院 机械工程学院,南京 211167

2.南京工程学院 燕山大学-南京工程学院联合研究院,南京 211167

3.南京交通职业技术学院,南京 211188

4.哈尔滨理工大学 机械动力工程学院,哈尔滨 150080

High⁃speed characteristics of micro⁃beveled heavy duty hydrostatic bearing lubricant oil film

Yan-qin ZHANG1,2( ),Yi LUO1,Shi-qian NI3(

),Yi LUO1,Shi-qian NI3( ),Ru-kang WU2,Zhi-quan ZHANG4

),Ru-kang WU2,Zhi-quan ZHANG4

- 1.College of Mechanical Engineering,Nanjing Institute of Technology,Nanjing 211167,China

2.Yanshan University & Nanjing Institute of Technology Joint Research Institute,Nanjing Institute of Technology,Nanjing 211167,China

3.Nanjing Vocational Institute of Transport Technology,Nanjing 211188,China

4.School of Mechanical Power Engineering,Harbin University of Science and Technology,Harbin 150080,China

摘要:

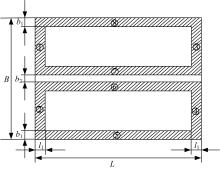

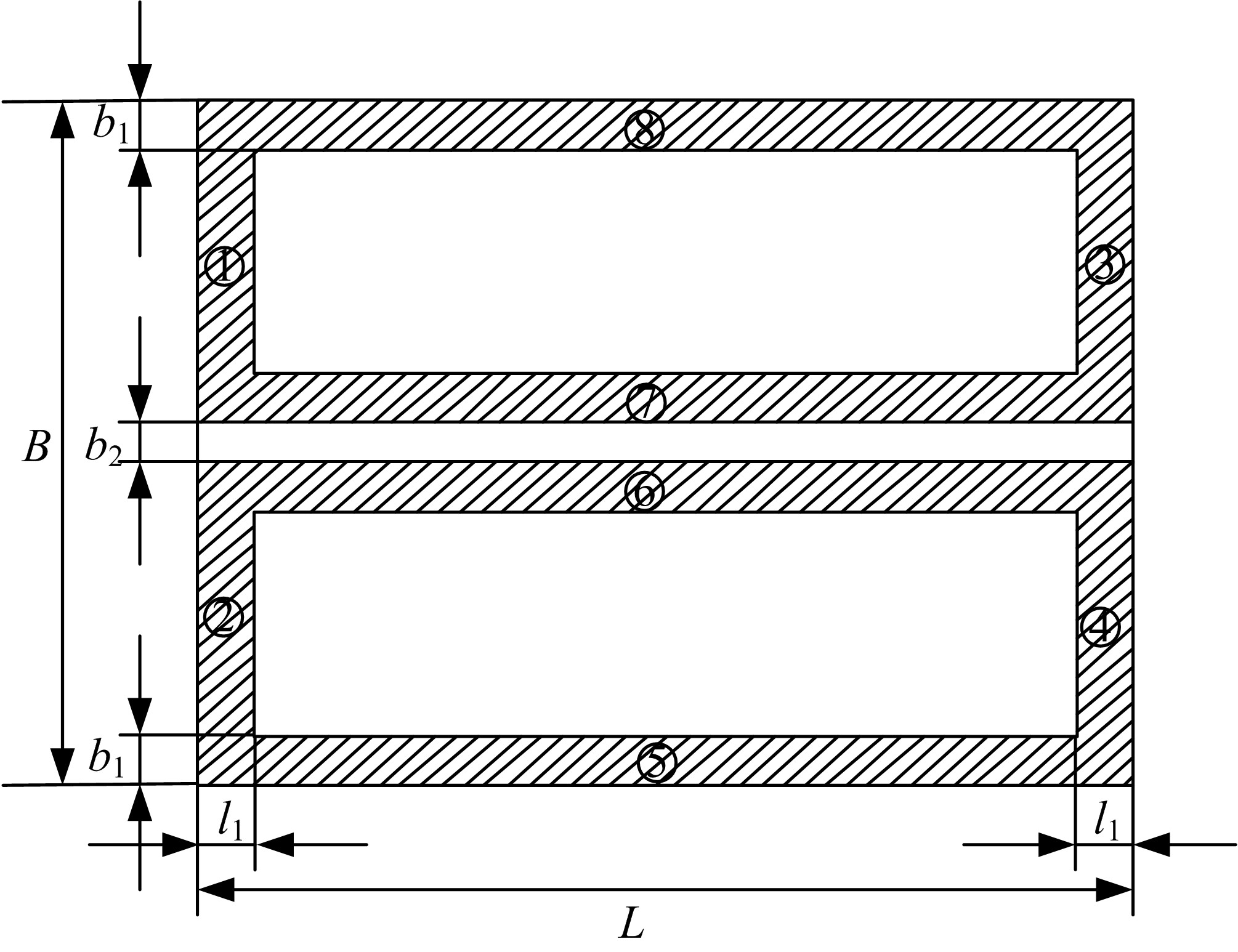

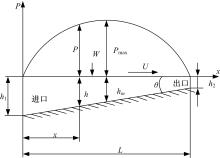

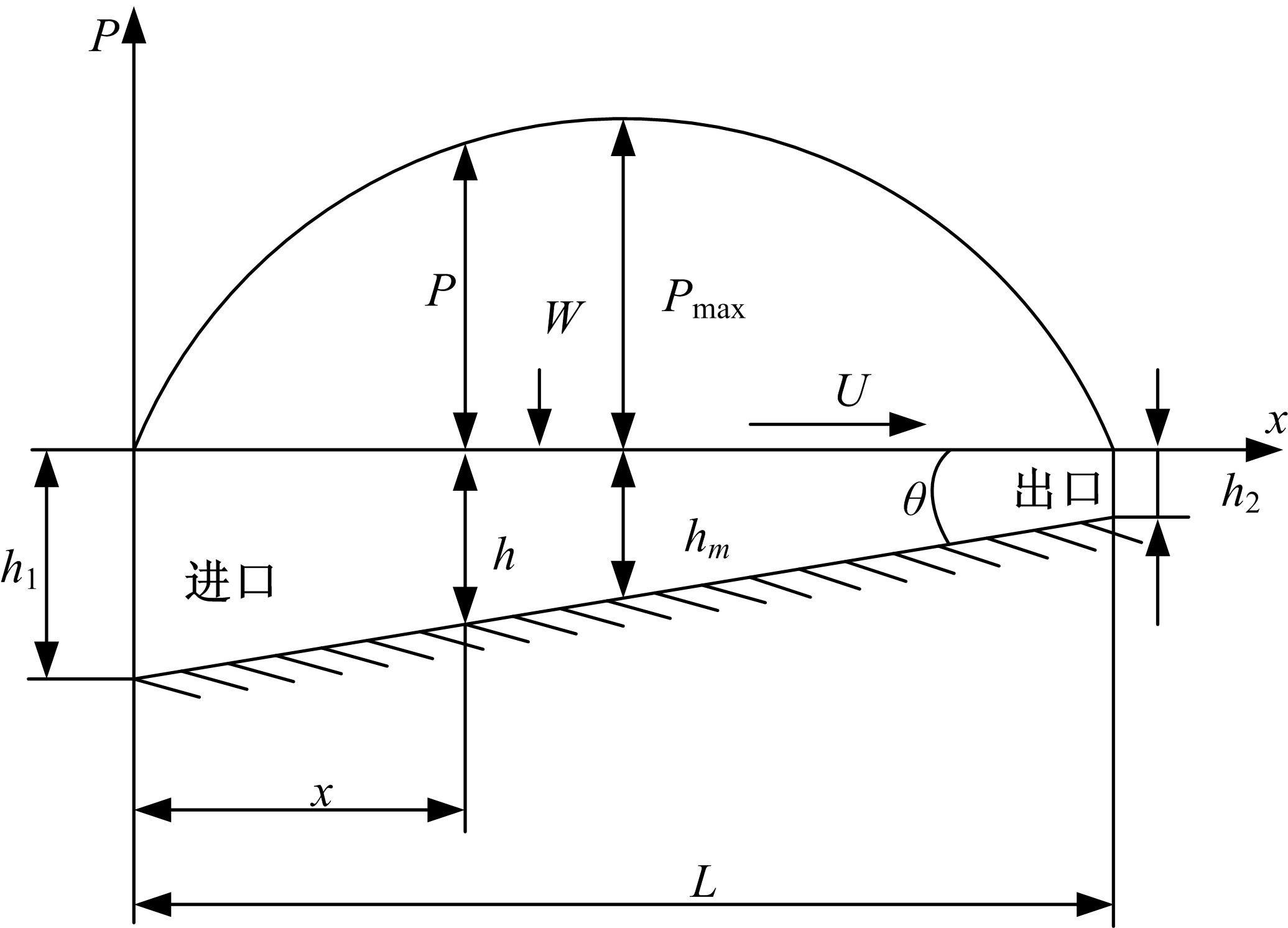

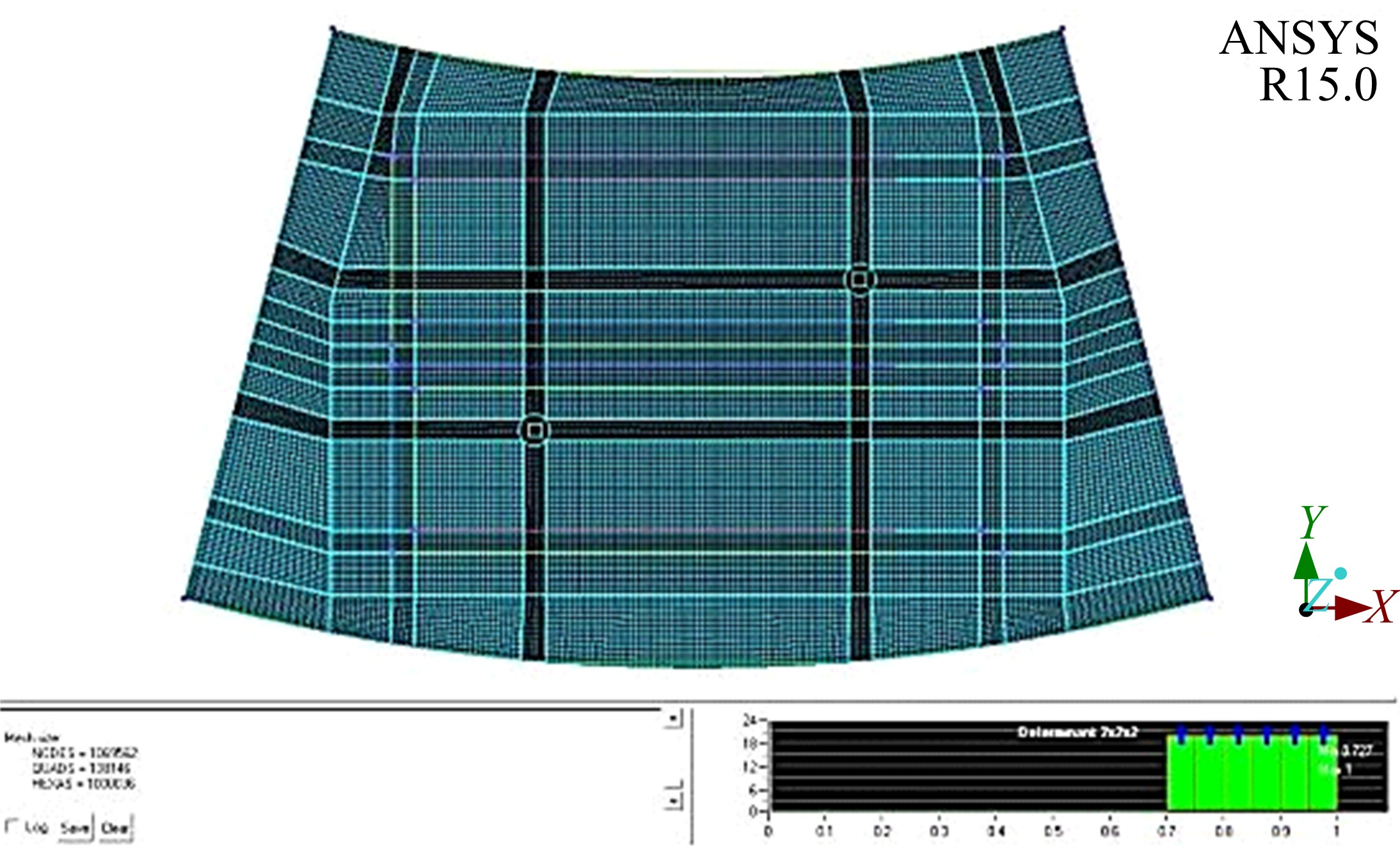

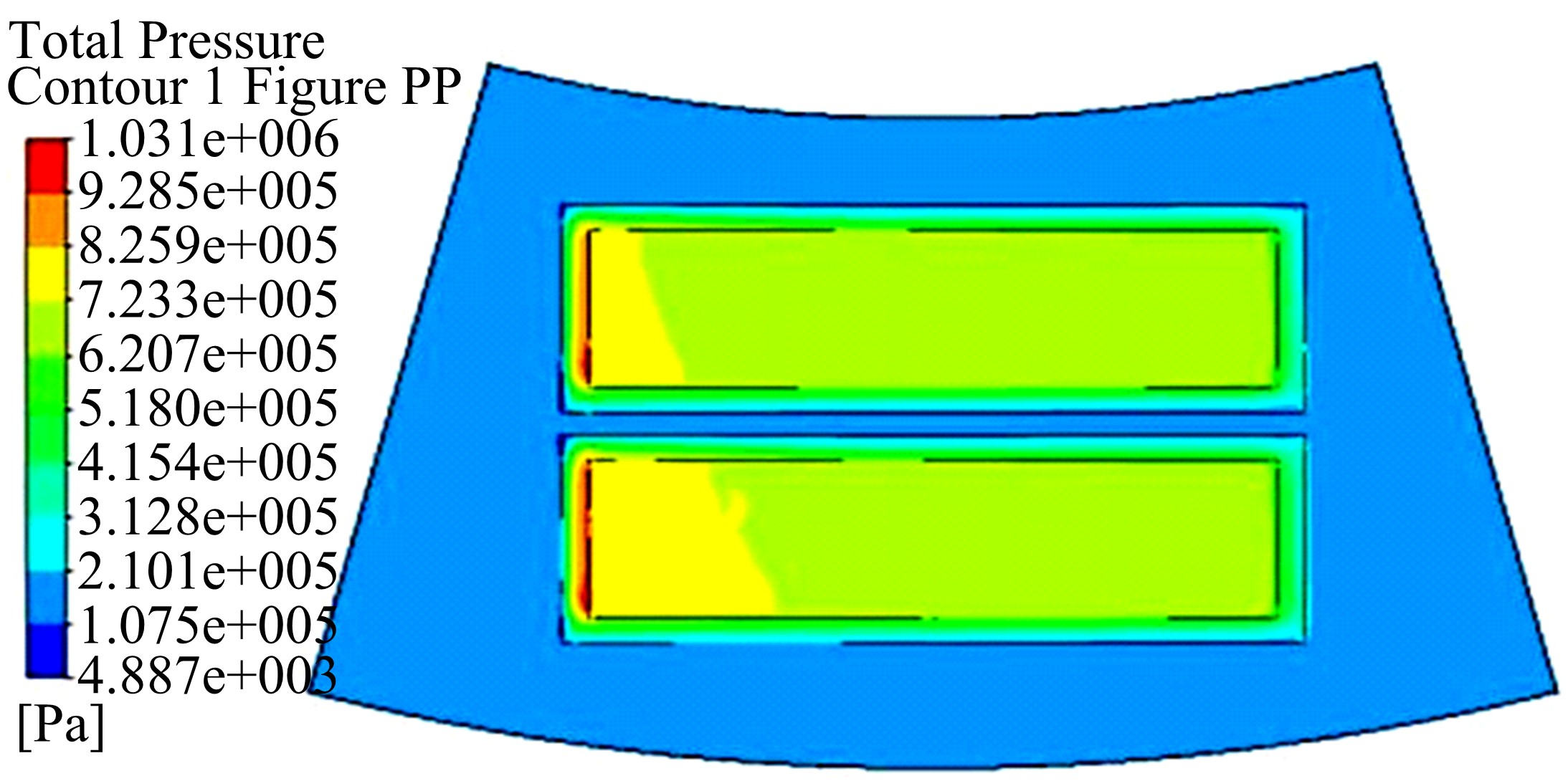

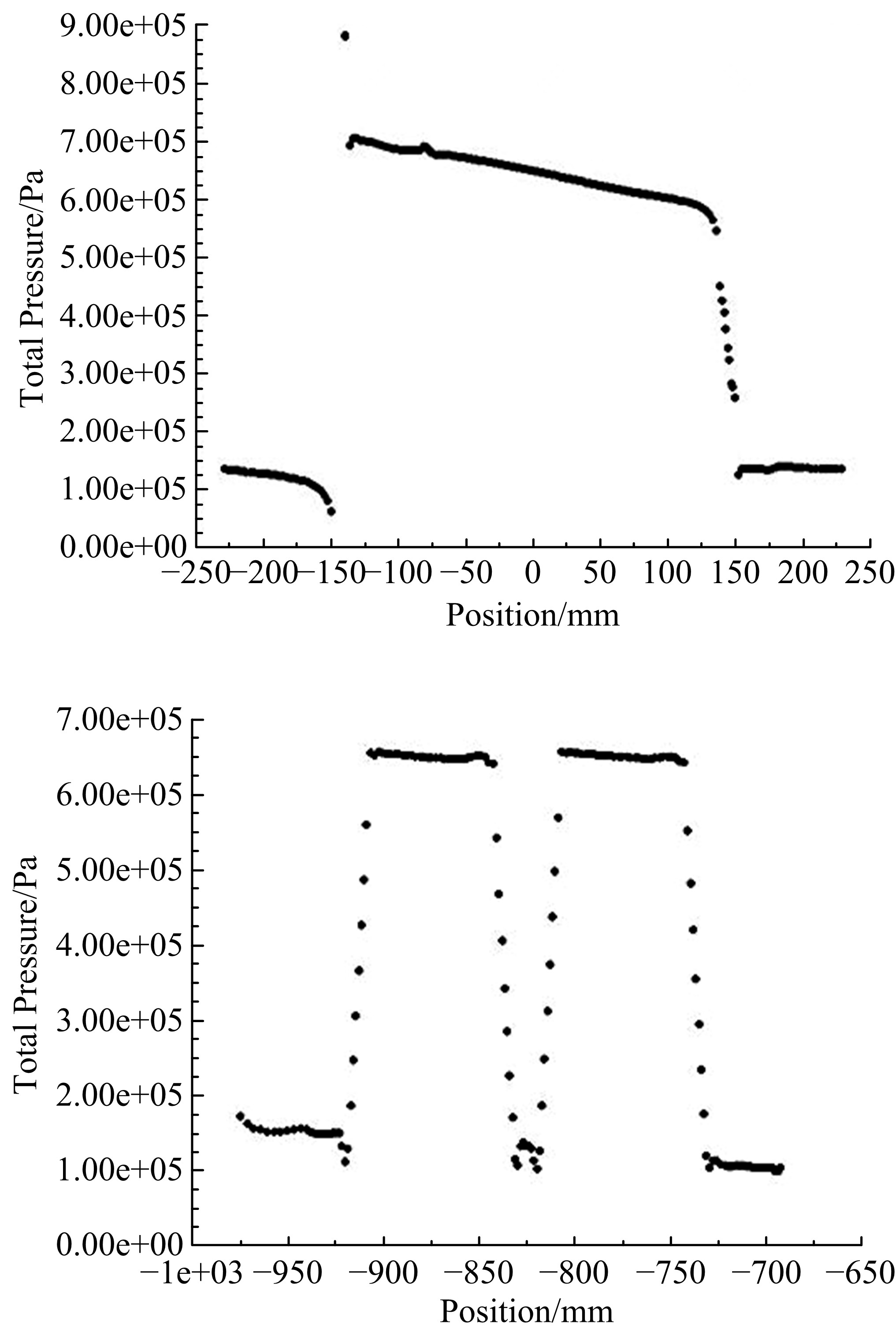

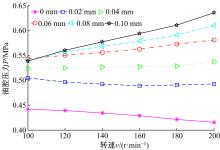

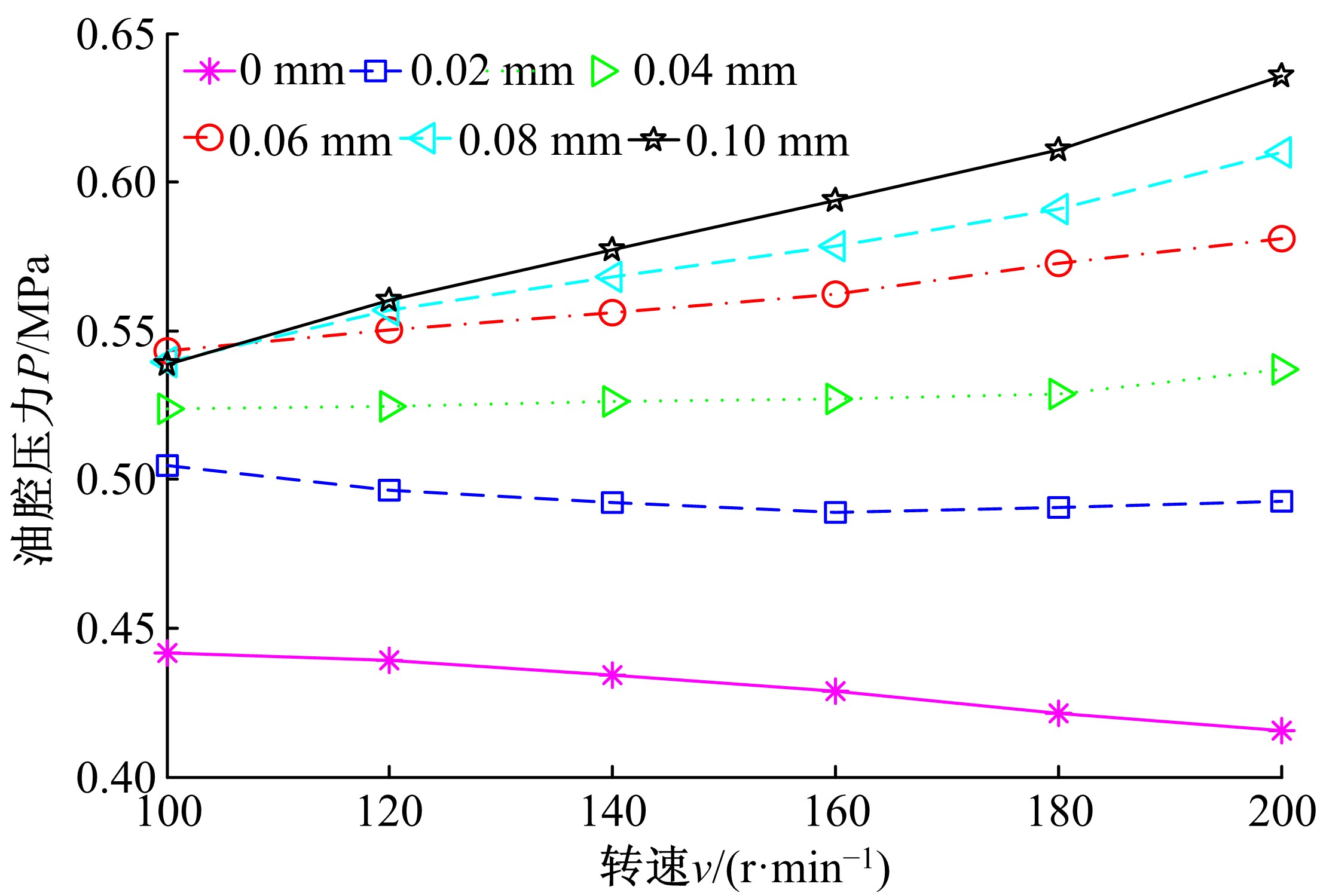

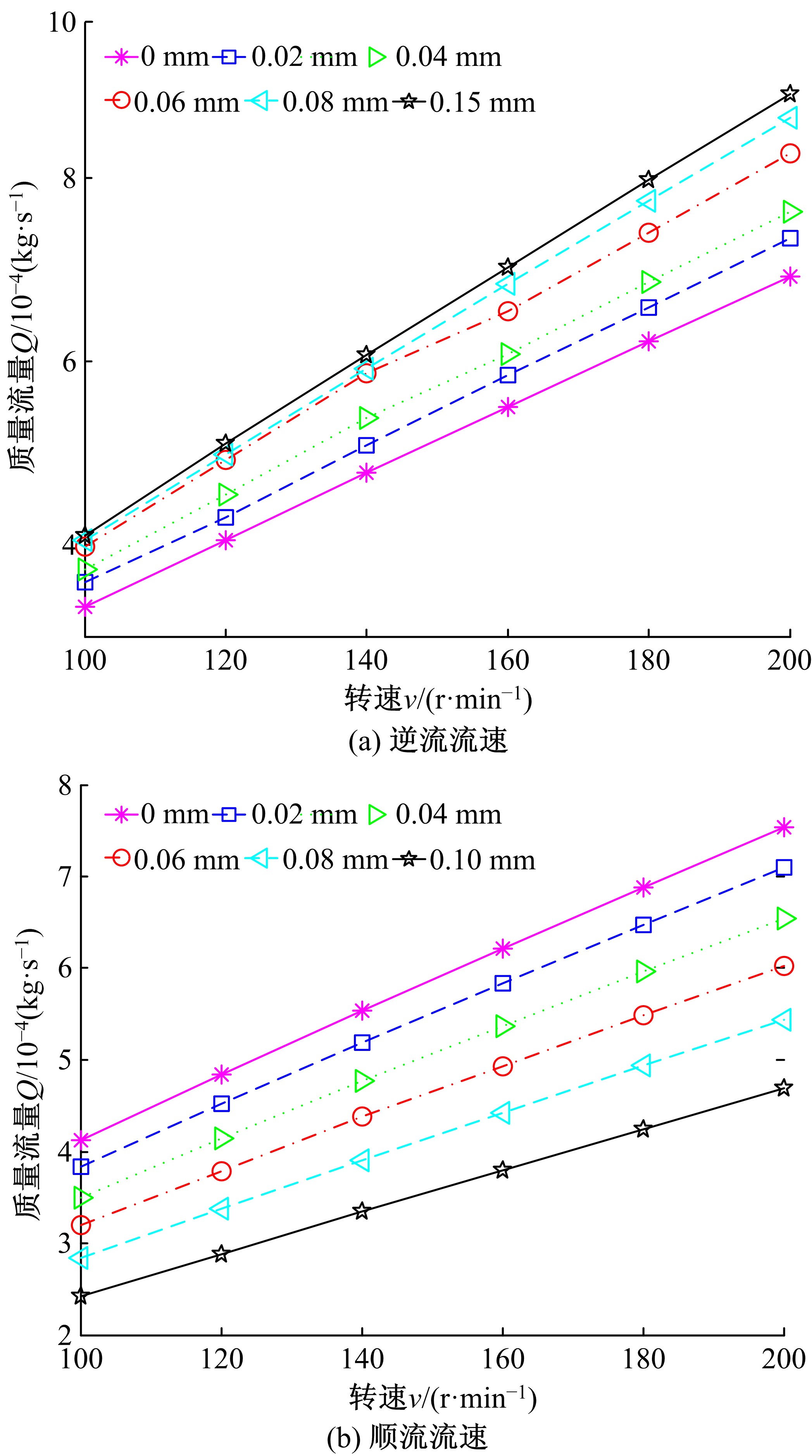

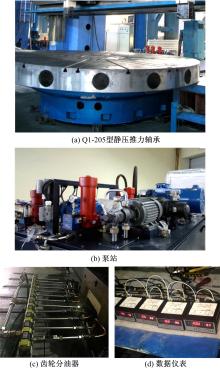

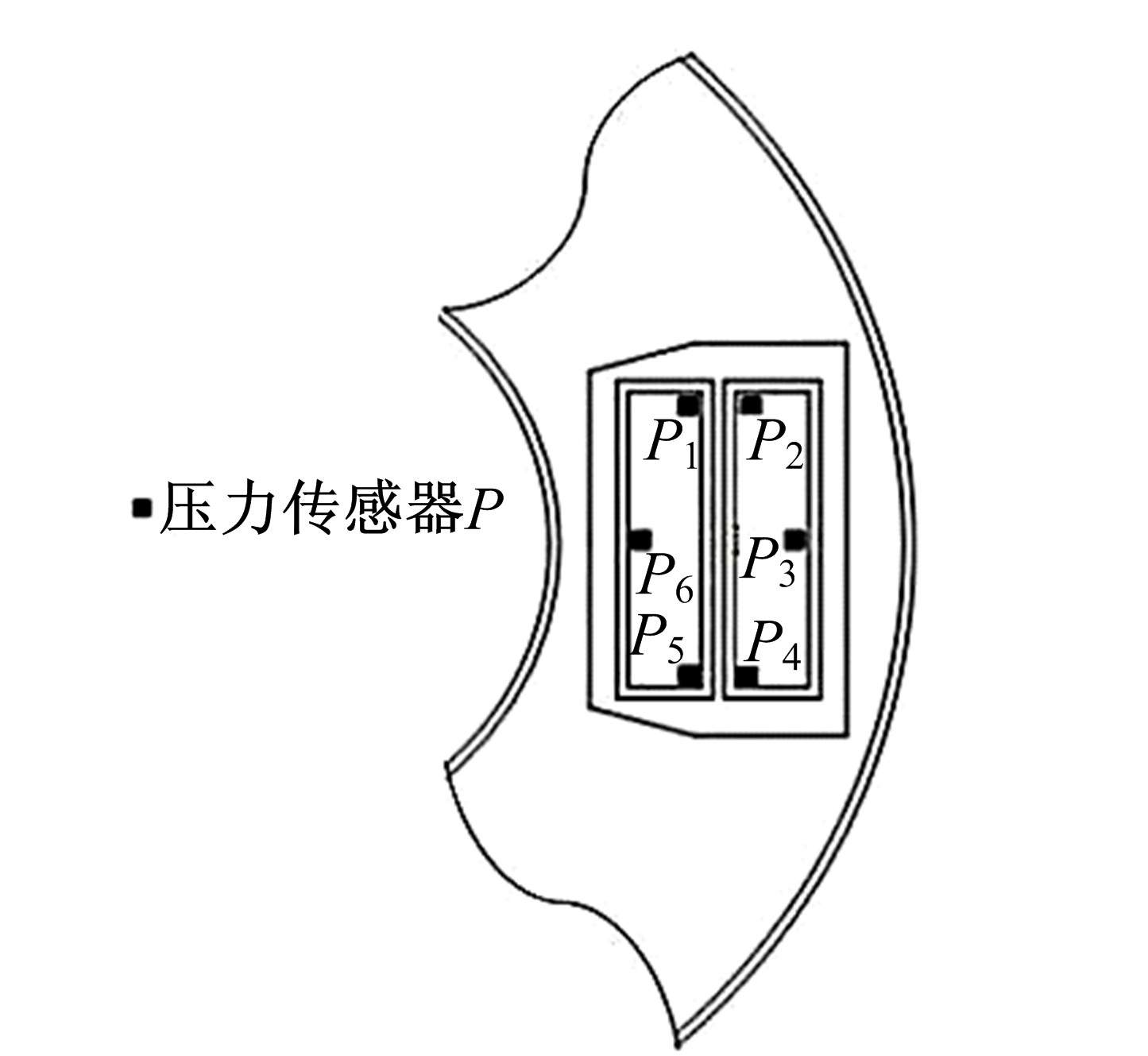

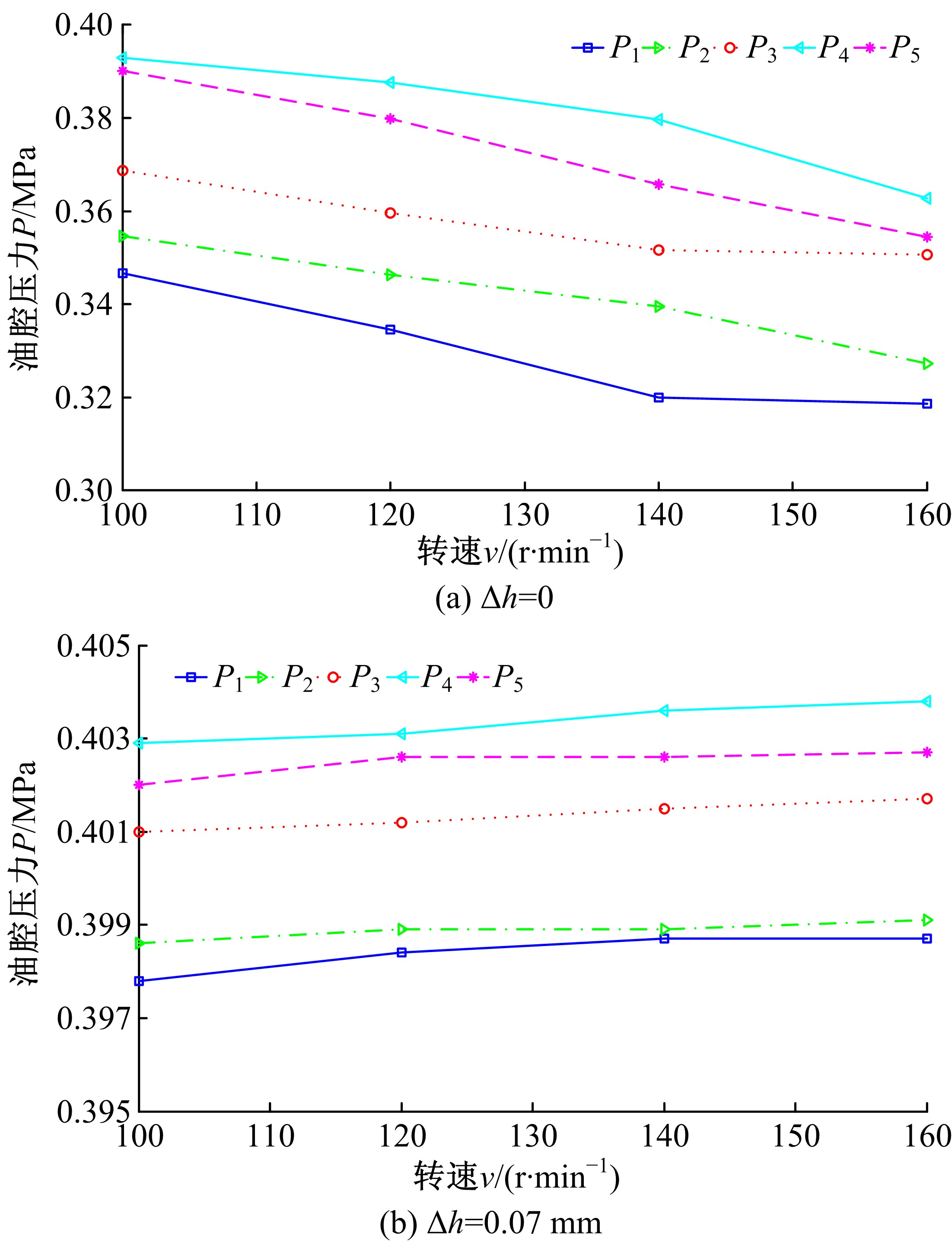

针对重型装备制造业中大尺寸静压轴承高速运行易引起润滑失效问题,进行了变黏度条件下静压轴承高速运行时的楔形油膜润滑性能研究。该研究依据轴承润滑理论,推导出微斜面矩形腔流量方程、静压承载力方程以及不同转速和倾角影响的微斜面动压承载力方程,利用CFD原理和FLUENT软件仿真分析轴承在较高转速100、120、140、160、180、200 r/min下油膜润滑性能,揭示出较高转速工况对油腔压力、流体流速、涡度及流量的影响规律。最后,针对一定楔形高度、较高转速下的油腔压力进行了实验测量,对理论分析和仿真模拟加以验证。研究发现:平面油垫高转速下静压失效现象极其明显,本文微斜面式静压油垫在定载荷下能很好地补偿因轴承高速运行带来的静压损失,其轴承的动压补偿值域为16%~30%,且较高转速下轴承运行实验测量与数值模拟计算结果在规律上有较好的一致性。

中图分类号:

- TH122

| 1 | 陈燕生. 液体静压支承原理和设计[M]. 北京:国防工业出版社, 1980. |

| 2 | 邵俊鹏, 张艳芹, 韩桂华, 等. 重型静压轴承油腔结构优化与流场仿真[J]. 系统仿真学报, 2010, 22(5): 1093-1096. |

| Shao Jun-peng, Zhang Yan-qin, Han Gui-hua, et al. Oil recess structure optimization and flow simulation for heavy hydrostatic bearing[J]. Journal of System Simulation, 2010, 22(5): 1093-1096. | |

| 3 | 张艳芹, 张志全, 冯雅楠, 等. 双矩形腔静压滑动轴承高速时的油膜润滑特性[J]. 摩擦学学报, 2018, 38(5): 609-618. |

| Zhang Yan-qin, Zhang Zhi-quan, Feng Ya-nan, et al. Lubrication characteristics of double rectangular cavity hydrostatic bearing at high speed[J]. Tribology, 2018, 38(5): 609-618. | |

| 4 | 张艳芹, 冯雅楠, 孔鹏睿. 基于热油携带的静压支承油膜温度场及试验[J]. 吉林大学学报: 工学版, 2019, 49(4): 1203-1211. |

| Zhang Yan-qin, Feng Ya-nan,Kong Peng-rui. Temperature field and experiment of hydrostatic bearing oil film based on hot oil carrying[J]. Journal of Jilin University (Engineering and Technology Edition), 2019, 49(4): 1203-1211. | |

| 5 | Yadav S K, Sharma S C. Finite element analysis of tilted thrust pad bearings of various recesses shapes considering thrust pad flexibility[J]. Journal of Engineering Tribology, 2016, 230(1): 872-893. |

| 6 | 尹文锋, 赵三星. 轴颈倾斜对稳态滑动轴承性能的影响[J]. 机械设计与制造, 2017(5): 26-29. |

| Yin Wen-feng,Zhao San-xing. Effect of misaligned journal on the performance of steady state bearing[J]. Mechanical Design and Manufacturing, 2017(5): 26-29. | |

| 7 | 江桂云, 王勇勤, 严兴春. 油膜轴承动静压混合效应的分析[J]. 机械设计, 2010, 27(7): 86-89. |

| Jiang Gui-yun, Wang Yong-qin, Yan Xing-chun. Analysis on hybrid hydrodynamic-static effect of oil film bearings[J]. Journal of Machine Design, 2010, 27(7): 86-89. | |

| 8 | Sharma S C, Jain S, Bharuka D. Influence of recess shape on the performance of a capillary compensated circular thrust pad hydrostatic bearing[J]. Tribology International, 2002, 35(6): 347-356. |

| 9 | Rajasekhar N E, Sharma S C. Orifice compensated multirecess hydrostatic/hybrid journal bearing system of various geometric shapes of recess operating with micro polar lubricant[J]. Tribology International, 2011, 44(3): 284-296. |

| 10 | Guo L. Different geometric configurations research of high speed hybrid bearings[J]. Journal of Hunan University of Arts and Science (Natural Science Edition), 2013, 15(3): 40-43. |

| 11 | 王禹, 王连吉, 王续跃. 液体静压推力轴承设计与FLUENT仿真分析[J]. 机械设计与制造, 2017, 9(58): 220-224. |

| Wang Yu, Wang Lian-ji, Wang Xu-yue. Design of hydrostatic thrust bearing and simulation analysis by fluent[J]. Machinery Design & Manufacture, 2017, 9(58): 220-224. | |

| 12 | 张耀满, 殷鑫贤. 数控车床的液体动静压轴承油膜压力特性[J]. 东北大学学报: 自然科学版, 2017, 38(5): 695-699. |

| Zhang Yao-man, Yin Xin-xian. Oil film pressure characteristics of liquid hybrid bearings in the CNC lathe[J]. Journal of Northeastern University (Natural Science), 2017, 38(5): 695-699. | |

| 13 | Ettles C M, López G D, Borgna H. Optimized design of a large reversible thrust bearing[J]. Journal of Tribology, 2016, 138(4): 1701-1709. |

| 14 | Yu X D, Meng X L, Jiang H, et al. Research on lubrication performance of super heavy constant flow hydrostatic thrust bearing[J]. Advanced Science Letters, 2011, 4(8): 2738-2741. |

| 15 | Yu M, Yu X D. Influence of recess shape on comprehensive lubrication performance of high speed and heavy load hydrostatic thrust bearing[J]. Industrial Lubrication and Tribology, 2019, 71(2): 301-308. |

| 16 | 于晓东, 付旭, 刘丹, 等. 环形腔多油垫静压推力轴承热变形[J]. 吉林大学学报: 工学版, 2015, 45(2): 460-465. |

| Yu Xiao-dong, Fu Xu, Liu Dan, et al. Thermal deformation of annular recess multi-pad hydrostatic thrust bearing[J]. Journal of Jilin University (Engineering and Technology Edition), 2015,45(2):460-465. | |

| 17 | Su J C T, Lie K N. Rotation effects on hybrid hydrostatic/hydrodynamic journal bearings[J]. Industrial Lubrication and Tribology, 2014, 53(6): 261-269. |

| 18 | Korneev A, Li S B. Computation of pressure and temperature fields in lubricating layer of tapered hydrostatic dynamic bearings[J]. Bulletin of Bryansk State Technical University, 2017, 3(1): 12-24. |

| [1] | 王洪雁,邱贺磊,郑佳,裴炳南. 光照变化下基于低秩稀疏表示的视觉跟踪方法[J]. 吉林大学学报(工学版), 2020, 50(1): 268-277. |

| [2] | 何仁,涂琨. 基于温度补偿气隙宽度的电磁制动器[J]. 吉林大学学报(工学版), 2019, 49(6): 1777-1785. |

| [3] | 刘祥勇, 李万莉. 包含蓄能器的电液比例控制模型[J]. 吉林大学学报(工学版), 2018, 48(4): 1072-1084. |

| [4] | 晋超琼, 张葆, 李贤涛, 申帅, 朱枫. 基于扰动观测器的光电稳定平台摩擦补偿策略[J]. 吉林大学学报(工学版), 2017, 47(6): 1876-1885. |

| [5] | 付文智, 刘晓东, 王洪波, 闫德俊, 刘晓莉, 李明哲, 董玉其, 曾振华, 刘桂彬. 关于1561铝合金曲面件的多点成形工艺[J]. 吉林大学学报(工学版), 2017, 47(6): 1822-1828. |

| [6] | 王辉, 周杰, 熊煜, 陶亚平, 向荣. 基于逆向工程的复杂曲面冲压件回弹补偿[J]. 吉林大学学报(工学版), 2017, 47(6): 1842-1847. |

| [7] | 朱冰, 冯瑶, 赵健, 吴坚, 王鹏飞, 汪昶. 商用半挂车制动迟滞补偿系统设计与分析[J]. 吉林大学学报(工学版), 2017, 47(5): 1352-1357. |

| [8] | 谢志江, 吴小勇, 范乃吉, 郭宗环, 袁岳军, 王康. 神光-III精密装校平台运动学分析[J]. 吉林大学学报(工学版), 2017, 47(5): 1504-1511. |

| [9] | 鄢永耀, 刘伟, 付锦江. 高定位精度转台检测系统调整误差补偿[J]. 吉林大学学报(工学版), 2017, 47(3): 855-860. |

| [10] | 管欣, 洪峰, 贾鑫, 田磊, 段春光. 汽车驾驶模拟器视觉系统传输延迟补偿[J]. 吉林大学学报(工学版), 2017, 47(1): 28-34. |

| [11] | 李义, 梁继才, 滕菲, 梁策, 于佳奇. 型材多点拉弯成形模具型面的分段补偿迭代方法[J]. 吉林大学学报(工学版), 2016, 46(6): 1961-1966. |

| [12] | 吉淑娇, 雷艳敏, 朱明. 基于背景特征点匹配的视频稳像[J]. 吉林大学学报(工学版), 2016, 46(6): 2116-2122. |

| [13] | 沈伟, 张迪嘉, 孙毅, 姜继海. 前向补偿结合滑模控制的液压泵/马达斜盘角度控制器[J]. 吉林大学学报(工学版), 2016, 46(5): 1513-1519. |

| [14] | 吕朝辉, 沈萦华, 李精华. 基于Kinect的深度图像修复方法[J]. 吉林大学学报(工学版), 2016, 46(5): 1697-1703. |

| [15] | 宗长富, 万滢, 赵伟强, 张不扬, 韩正铁. 气压电控制动系统仿真平台及补偿控制策略开发[J]. 吉林大学学报(工学版), 2016, 46(3): 711-717. |

|

||