吉林大学学报(工学版) ›› 2022, Vol. 52 ›› Issue (10): 2256-2264.doi: 10.13229/j.cnki.jdxbgxb20210478

• 车辆工程·机械工程 • 上一篇

液压挖掘机动臂势能交互回收利用系统特性

- 1.中南大学 高性能复杂制造国家重点实验室,长沙 410083

2.山河智能装备股份有限公司 技术中心,长沙 410100

Characteristics of boom potential energy alternate recovery and utilization system of hydraulic excavator

Peng HU1( ),Jian-xin ZHU1,2(

),Jian-xin ZHU1,2( ),Chang-sheng LIU2,Da-qing ZHANG2

),Chang-sheng LIU2,Da-qing ZHANG2

- 1.State Key Laboratory of High Performance Complicated,Central South University,Changsha 410083,China

2.R&D Center,Sunward Intelligent Equipment Co. Ltd. ,Changsha 410100,China

摘要:

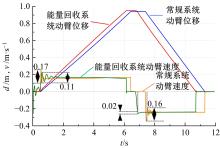

针对传统能量回收系统发热及由此带来的系统可靠性问题,设计了一种基于多液压缸的挖掘机动臂势能交互回收利用系统,并对其特性进行了研究。对动臂势能交互回收利用系统工作原理及能量特性进行分析,针对35 t级挖掘机作业过程中动臂势能的变化特征,进行基于液压缸和蓄能器的系统参数设计。进一步建立了挖掘机能量回收系统虚拟仿真平台,分别对系统运行特性和节能效率进行研究。最后,搭建能量回收系统测试平台,对系统可行性与能效特性进行测试。动臂升降单动作的仿真与试验结果表明,与常规挖掘机相比,该能量回收系统主泵输出的峰值压力降低了57.8%,系统节能效率为51.5%,同时整机操控性保持良好。

中图分类号:

- TH39

| 1 | Wang T, Wang Q F. Modelling and control of a novel hydraulic system with energy regeneration[C]//IEEE/ASME International Conference on Advanced Intelligent Mechatrolics(AIM), Kaohsiung(Taiwan),China, 2012: 922-927. |

| 2 | Kagoshima M, Komiyama M, Nanjo T, et al. Development of new hybrid excavator[J]. Kobelco Technology Review, 2007, 27(27): 39-42. |

| 3 | 龚俊,何清华,张大庆,等. 基于电液能量回收的挖掘机节能系统仿真评价与试验[J]. 吉林大学学报:工学版, 2016, 46(2): 479-486. |

| Gong Jun, He Qing-hua. Zhang Da-qing,et al. Evaluation and testing of electric-hydraulic energy regeneration system of excavator[J]. Journal of Jilin University(Engineering and Technology Edition), 2016, 46(2): 479-486. | |

| 4 | Kwon T, Lee S, Sul S. Power control algorithm for hybrid excavator with supercapacitor [J]. IEEE Transactions on Industry Applications, 2010, 46(4): 1447-1455. |

| 5 | 肖清,王庆丰,张彦廷. 液压挖掘机混合动力系统建模及控制策略研究[J]. 浙江大学学报:工学版, 2007, 41(3): 480-483. |

| Xiao Qing, Wang Qing-feng, Zhang Yan-ting. Study on modeling and control strategy of hybrid system in hydraulic excavator[J]. Journal of Zhejiang University (Engineering Science), 2007, 41(3): 480-483. | |

| 6 | 龚俊. 基于液压马达-泵-电机的挖掘机能量回收系统及控制方法[D]. 长沙: 中南大学机电学院, 2015. |

| Gong Jun. Excavator energy recovery system and control method based on recycling integrated unit of hydraulic motor-pump-electrical motor[D]. Chang sha: College of Mechanical and Electrical Engineering,Central South University, 2015. | |

| 7 | 林贵堃. 液压挖掘机基于液压储能平衡的势能回收系统研究[D]. 长沙: 中南大学机电学院, 2019. |

| Lin Gui-kun. Research on potential energy recovery system of hydraulic excavator based on hydraulic energy storage balance[D]. Changsha: College of Mechanical and Electrical Engineering,Central South University, 2019. | |

| 8 | 李秀磊,吴勇,徐保强,等. 挖掘机动臂液压系统节能研究[J]. 机床与液压, 2015, 43(14): 94-98. |

| Li Xiu-lei, Wu Yong, Xu Bao-qiang, et al. Research on energy saving of excavator boom hydraulic system[J]. Machine Tool & Hydraulics, 2015, 43(14): 94-98. | |

| 9 | Xiao Y, Guan C, Perry Y. Optimal design of a compound hybrid system consisting of torque coupling and energy regeneration for hydraulic hybrid excavator[C]∥Proceedings of IEEE/ASME International Conference on Advanced Intelligent Mechatronics, Busan, Korea, 2015: 73-86. |

| 10 | 肖扬. 油液混合动力挖掘机流量耦合式及扭矩耦合式动力系统研究[D]. 杭州: 浙江大学机械工程学院, 2015. |

| Xiao Yang. Research on flow coupling and toruqe coupling based power-train of hydraulic hybrid excavator[D]. Hangzhou: College of Mechanical Engineering,Zhejiang University, 2015. | |

| 11 | 于安才,姜继海. 液压混合动力挖掘机能量再生控制研究[J]. 哈尔滨工程大学学报, 2012, 33(1): 92-95. |

| Yu An-cai, Jiang Ji-hai. Research on energy regeneration control of hydraulic hybrid excavator[J]. Journal of Harbin Engineering University, 2012, 33(1): 92-95. | |

| 12 | Liang X, Virvalo T. An energy recovery system for a hydraulic crane[J]. Proc IMechE, Part C: Journal of Mechanical Engineerting Science, 2001, 215(6): 737-744. |

| 13 | Virvalo T, Sun W. Improving energy utilization in hydraulic booms-what it all about[C]∥Proceedings of the Sixth International Conference on Fluid Power Transmisson and Control, Hangzhou, China, 2005: 55-65. |

| 14 | 任好玲,林添良,叶月影,等. 基于平衡油缸的动臂势能回收系统参数设计与试验[J]. 中国公路学报, 2017, 30(2): 153-158. |

| Ren Hao-ling, Lin Tian-liang, Ye Yue-ying, et al. Parameters design and experiment of boom potential energy recovery system based on balance cylinder[J]. China Journal of Highway and Transpor, 2017, 30(2): 153-158. | |

| 15 | 叶月影,林添良,任好玲. 基于平衡油缸的势能液压式存储和再利用研究[J]. 液压与气动, 2018(1): 71-77. |

| Ye Yue-ying, Lin Tian-liang, Ren Hao-ling. Research on hydraulic storage and reuse of potential energy based on balance cylinder[J]. Chinese Hydraulics & Pneumatics, 2018(1): 71-77. | |

| 16 | Xia L, Quan L, Ge L, et al. Energy efficiency analysis of integrated drive and energy recuperation system for hydraulic excavator boom[J]. Energy Conversion and Management, 2018, 156: 680-687. |

| 17 | Hao Y, Quan L, Cheng H, et al. Potential energy directly conversion and utilization methods used for heavy duty lifting machinery[J]. Energy, 2018, 155: 242-251. |

| 18 | 王伟平. 大型液压挖掘机气液平衡动臂势能回收系统研究[D]. 徐州: 中国矿业大学机电工程学院, 2018. |

| Wang Wei-ping. Research on boom potential energy recovery system of large hydraulic excavator based on gas-hydraulic balance unit[D]. Xuzhou: College of Mechanical and Electrical Engineering,China Mining University, 2018. | |

| 19 | 胡鹏,朱建新,刘昌盛,等. 基于状态规则的液压挖掘机虚拟驾驶员建模与仿真研究[J]. 中南大学学报:自然科学版, 2021, 52(4): 1118-1128. |

| Hu Peng, Zhu Jian-xin, Liu Chang-sheng, et al. Research on modeling and simulation of virtual driver of hydraulic excavator based on state rules[J]. Journal of Central South University (Science and Technology), 2021, 52(4): 1118-1128. |

| [1] | 隗海林,王泽钊,张家祯,刘洋. 基于Avl-Cruise的燃料电池汽车传动比及能量管理策略[J]. 吉林大学学报(工学版), 2022, 52(9): 2119-2129. |

| [2] | 王骏骋,吕林峰,李剑敏,任洁雨. 分布驱动电动汽车电液复合制动最优滑模ABS控制[J]. 吉林大学学报(工学版), 2022, 52(8): 1751-1758. |

| [3] | 蒋林,周玲,赵慧. 液压伺服柔驱机构设计及其刚度连续可调分析[J]. 吉林大学学报(工学版), 2022, 52(7): 1499-1508. |

| [4] | 王同建,杨书伟,谭晓丹,陈晋市,刘同文,职振领. 基于DEM⁃MBD联合仿真的液压挖掘机作业性能分析[J]. 吉林大学学报(工学版), 2022, 52(4): 811-818. |

| [5] | 施昕昕,黄家才,高芳征. 基于分数阶BICO滤波器的运动控制测量噪声抑制[J]. 吉林大学学报(工学版), 2021, 51(5): 1873-1878. |

| [6] | 李学勇,赵仲秋,张春松,路长厚. 基于有限元的人体⁃机械手交互力计算方法[J]. 吉林大学学报(工学版), 2021, 51(5): 1612-1619. |

| [7] | 于萍,穆特,朱黎辉,周子业,宋杰. 钻具输送装置非线性动力学分析及稳定性控制[J]. 吉林大学学报(工学版), 2021, 51(3): 820-830. |

| [8] | 李洪雪,李世武,孙文财,王琳虹,杨志发. 考虑垂向⁃侧向运动的半挂列车动力学建模及分析[J]. 吉林大学学报(工学版), 2021, 51(2): 549-556. |

| [9] | 姜继海,赵存然,张冠隆,车明阳. 航空煤油柱塞泵摩擦副涂层材料摩擦性能[J]. 吉林大学学报(工学版), 2021, 51(1): 147-153. |

| [10] | 胡明伟,王洪光,潘新安. 基于正交设计的协作机器人全域结构优化设计[J]. 吉林大学学报(工学版), 2021, 51(1): 370-378. |

| [11] | 贺继林, 陈毅龙, 吴钪, 赵喻明, 汪志杰, 陈志伟. 起重机卷扬系统能量流动分析及势能回收系统实验[J]. 吉林大学学报(工学版), 2018, 48(4): 1106-1113. |

| [12] | 李因武, 吴庆文, 常志勇, 杨成. 基于仿生斗齿的反铲液压挖掘机动臂仿真优化设计[J]. 吉林大学学报(工学版), 2018, 48(3): 821-827. |

| [13] | 刘汉光, 王国强, 孟东阁, 赵寰宇. 液压挖掘机履带行走装置的合理预张紧力[J]. 吉林大学学报(工学版), 2018, 48(2): 486-491. |

| [14] | 初亮, 孙成伟, 郭建华, 赵迪, 李文惠. 基于轮缸压力的制动能量回收评价方法[J]. 吉林大学学报(工学版), 2018, 48(2): 349-354. |

| [15] | 彭贝, 高宇, 冯培恩, 邱清盈. 液压挖掘机回转启动过程节能技术[J]. 吉林大学学报(工学版), 2016, 46(6): 1912-1921. |

|

||