吉林大学学报(工学版) ›› 2020, Vol. 50 ›› Issue (5): 1669-1676.doi: 10.13229/j.cnki.jdxbgxb20190523

• 材料科学与工程 • 上一篇

焊接能量对铜/钛超声波焊接接头性能的影响

- 吉林大学 材料科学与工程学院,长春 130022

Effect of welding energy on performance of Cu/Ti joints obtained by ultrasonic welding

Xiao-yan GU( ),Cheng-long SUI,Xing DI,Zheng-yu MENG,Kai-xuan ZHU,Chang-chun CHU

),Cheng-long SUI,Xing DI,Zheng-yu MENG,Kai-xuan ZHU,Chang-chun CHU

- College of Materials Science and Engineering,Jilin University,Changchun 130022, China

摘要:

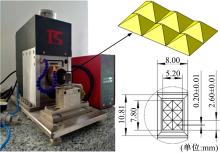

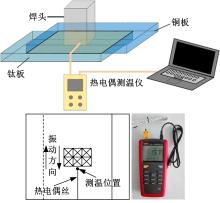

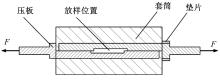

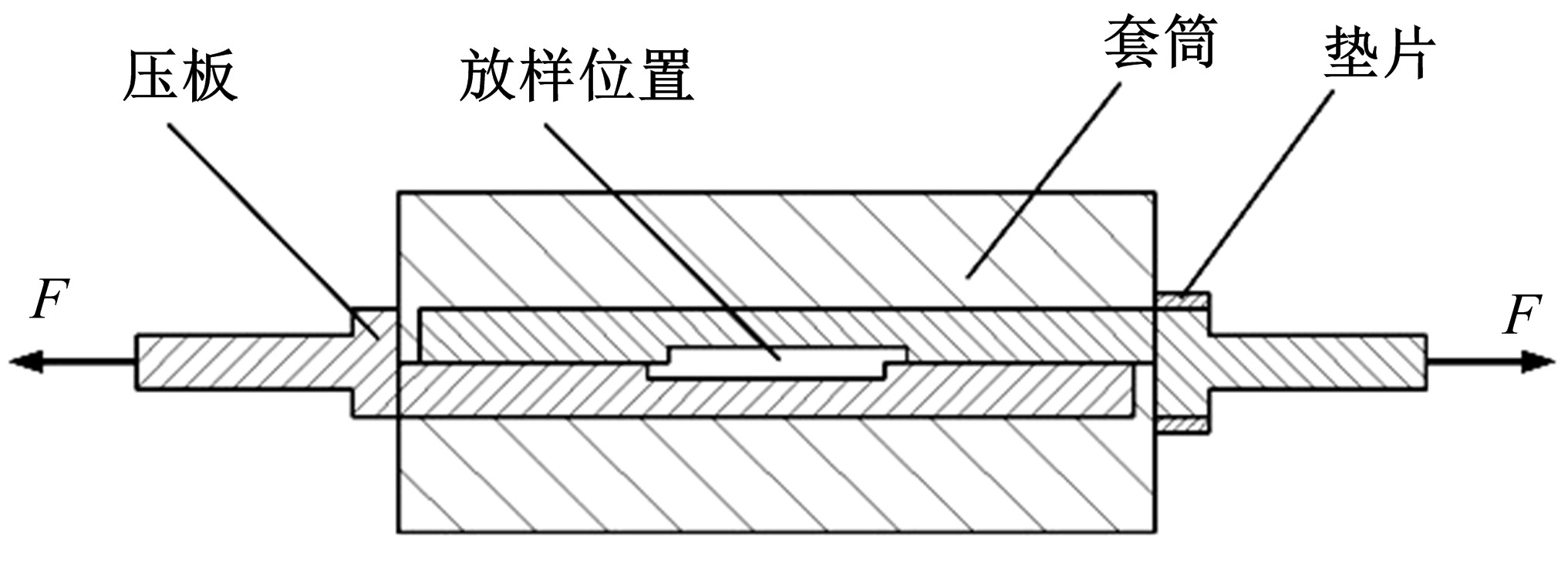

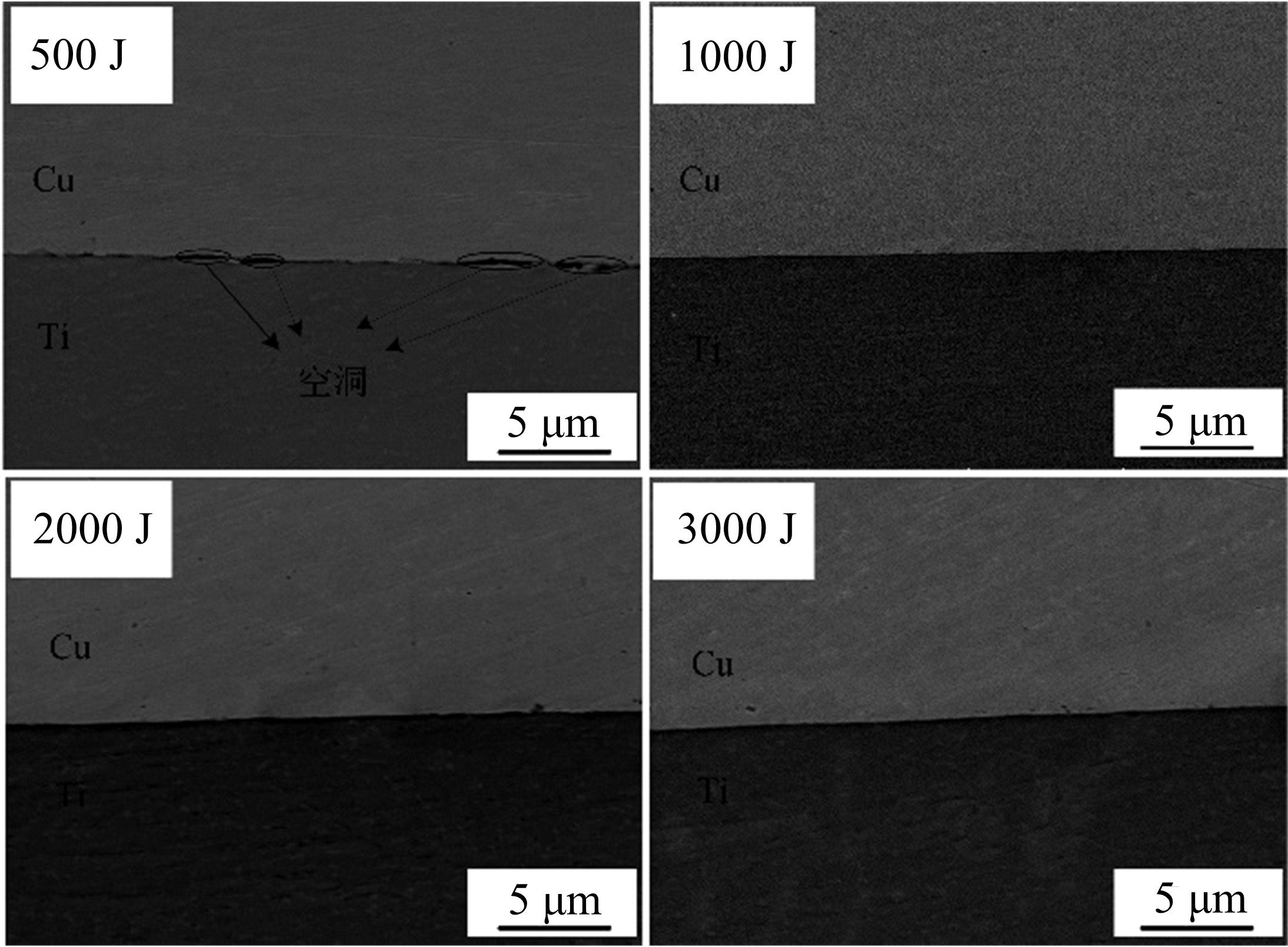

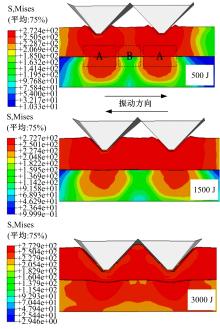

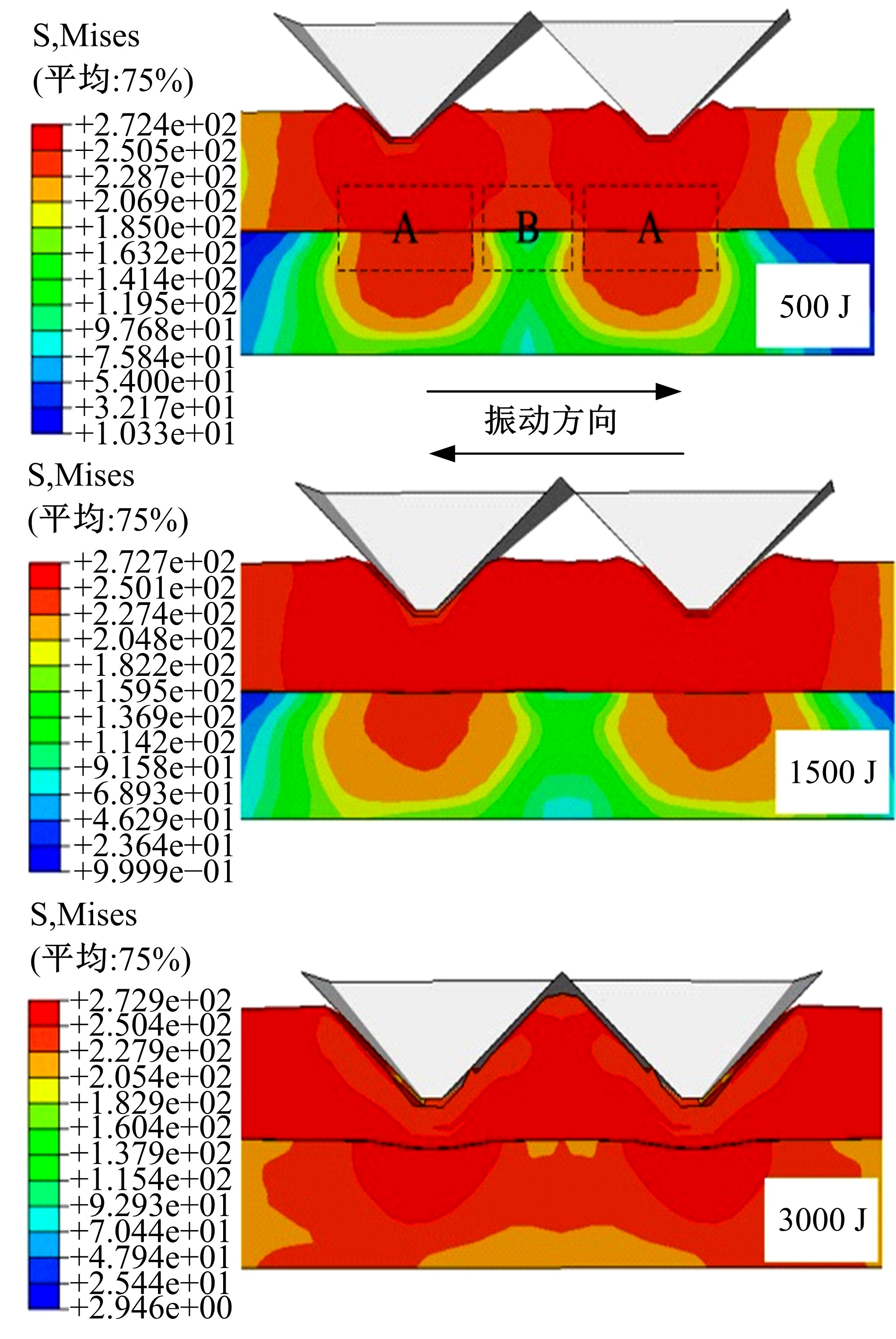

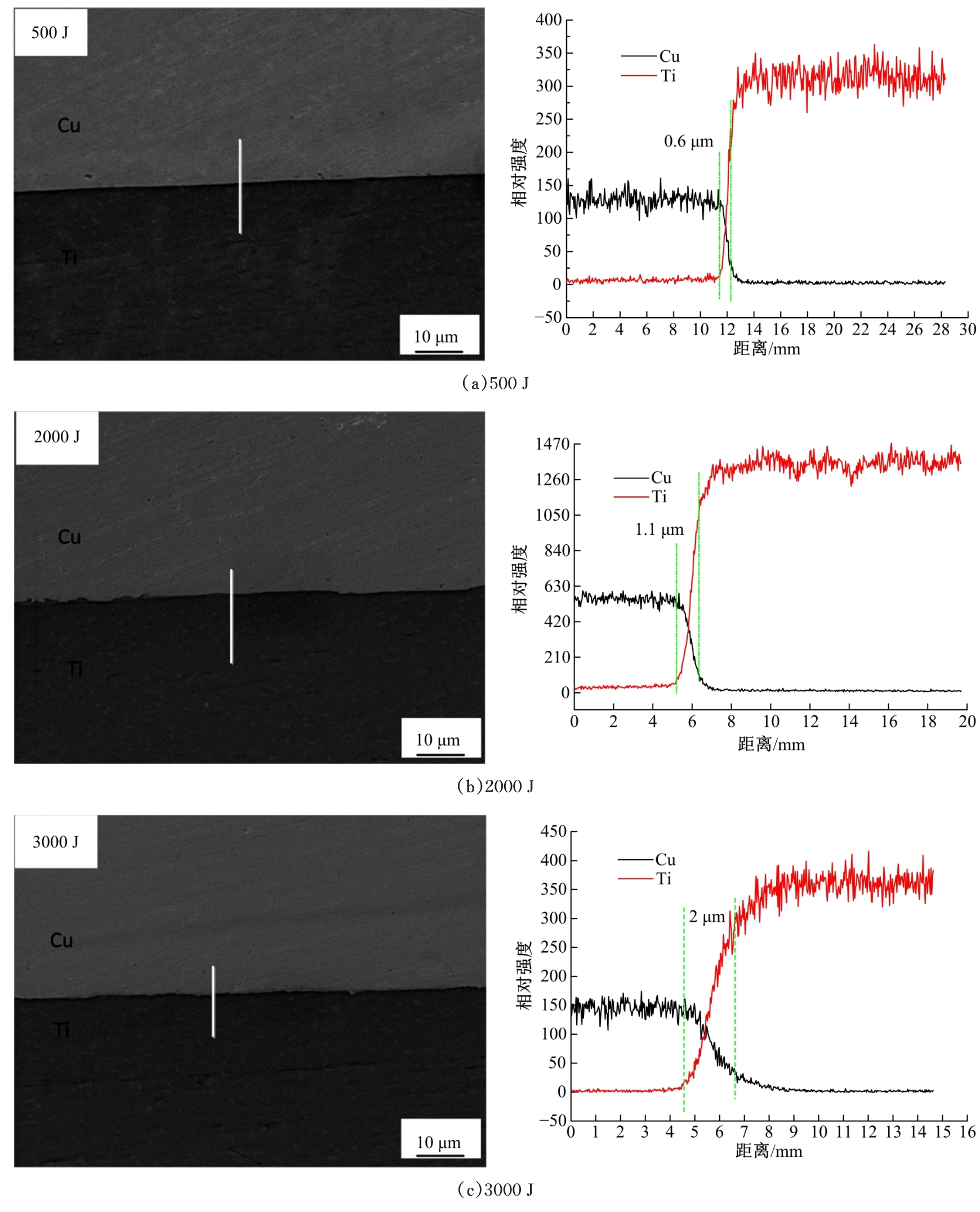

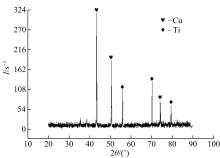

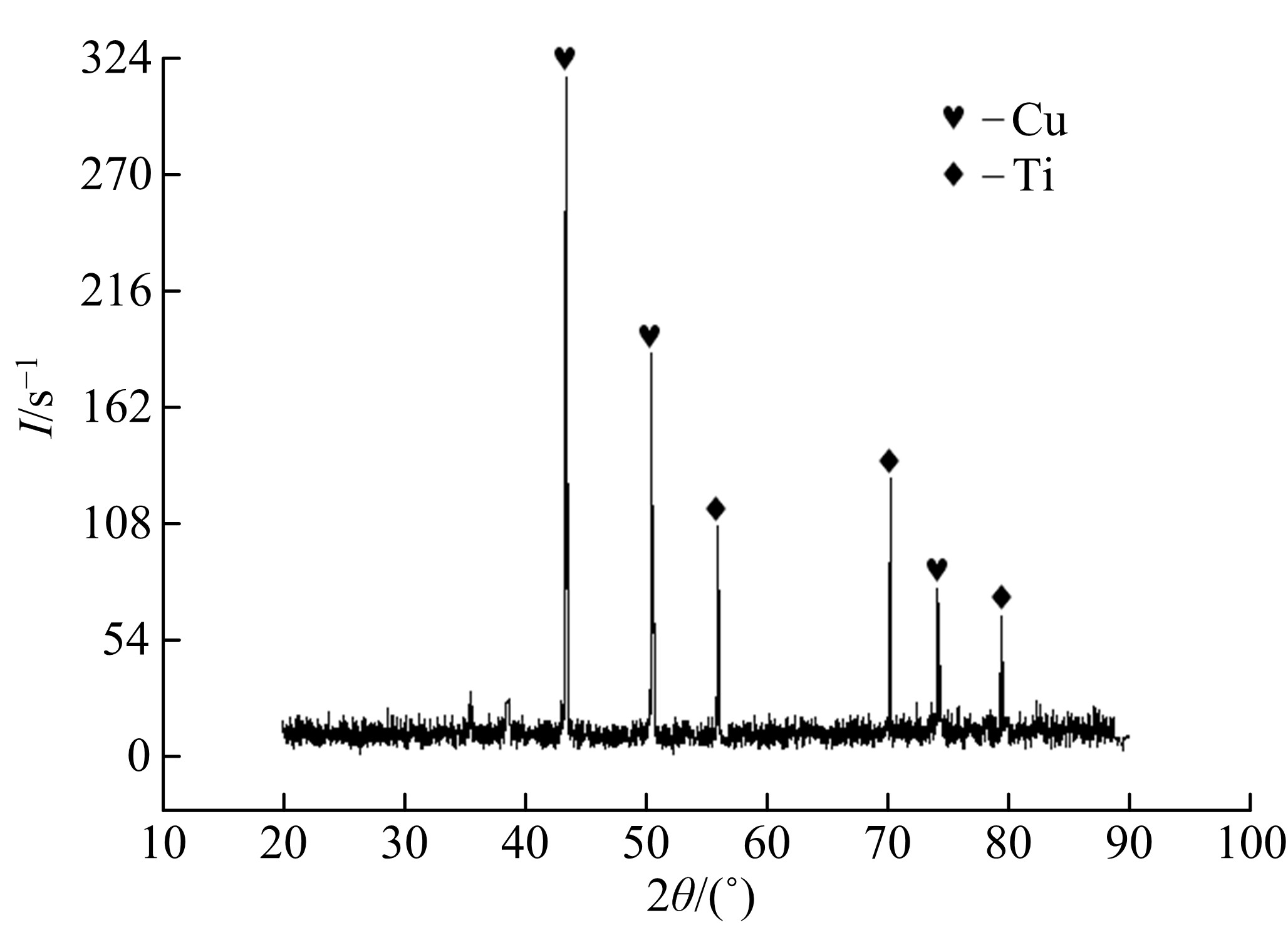

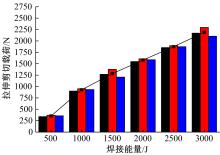

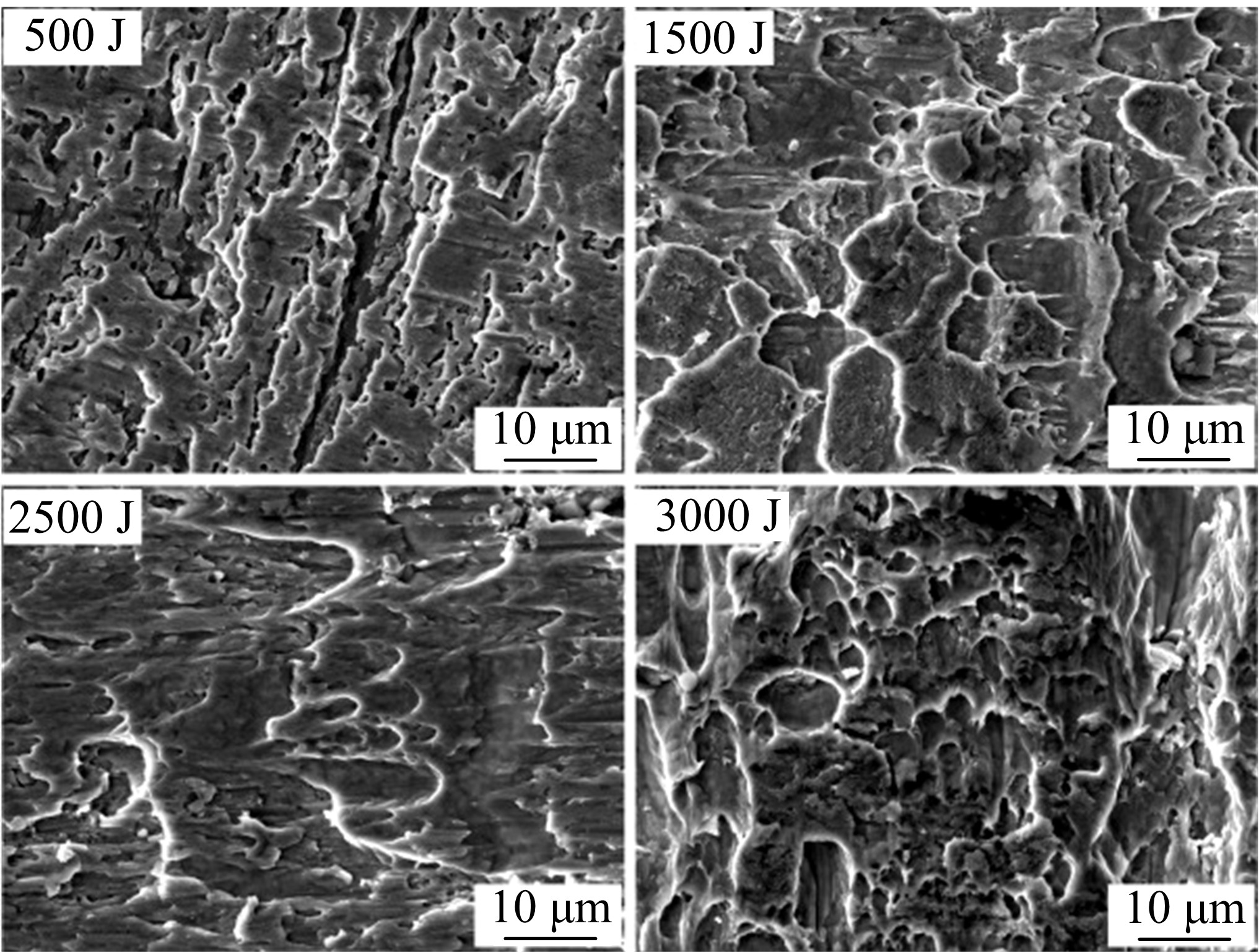

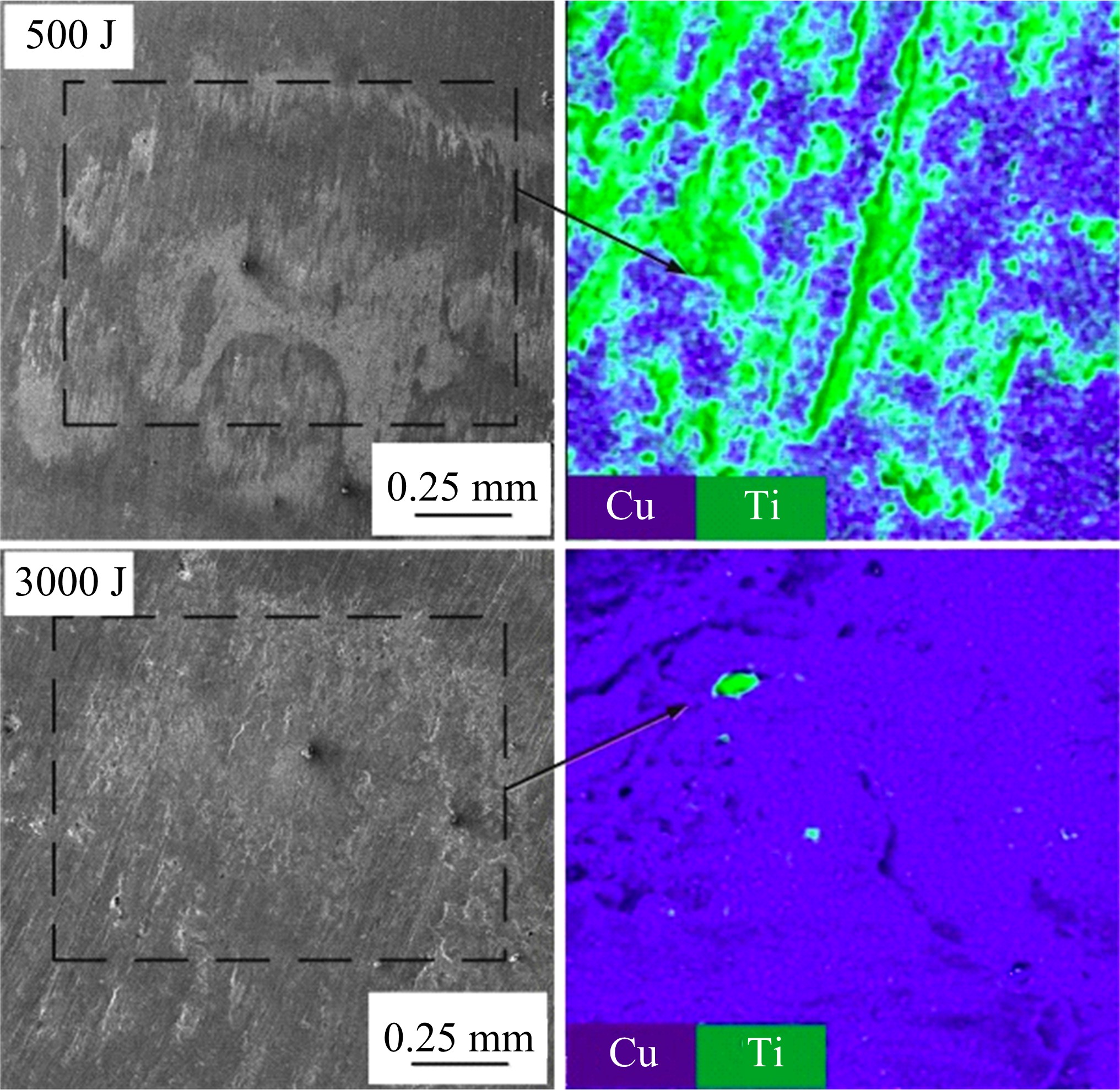

采用高功率超声波点焊机成功焊接T2纯铜和Ti6Al4V钛合金异种金属,分析了不同焊接能量对接头的界面温度、横截面宏观形貌、界面成形和力学性能的影响。研究发现:随着焊接能量的增加,峰值温度和高温停留时间升高,压痕深度逐渐升高,接头界面均较平直,未出现金属间化合物,存在扩散层,最大厚度为2 μm,拉剪力随着接头结合面积的扩大而逐渐增大,最大值为2322 N。接头沿界面靠近铜侧母材断裂,断裂模式由脆性断裂过渡至韧-脆混合断裂。利用ABAQUS有限元数值模拟软件对不同焊接能量下的界面进行应力分析,系统地阐述了铜/钛超声波焊接接头界面成形机理。

中图分类号:

- TG453

| 1 | 李亚江, 王娟, 刘鹏. 异种难焊接材料的焊接及应用[M]. 北京: 化学工业出版社, 2004. |

| 2 | 赵宇光, 周伟, 彭新. 钛合金表面低氧压熔结Al-Cr涂层及其高温抗氧化性[J]. 吉林大学学报: 工学版, 2004, 34(4): 521-526. |

| Zhao Yu-guang, Zhou Wei, Peng Xin. Low oxygen pressure self-fused Al-Cr coatings formed on surface of Ti alloy and their oxidation resistance[J]. Journal of Jilin University(Engineering and Technology Edition), 2004, 34(4): 521-526. | |

| 3 | Jackson M J, Kopac J, Balazic M, et al. Titanium and titanium alloy applications in medicine[J]. International Journal of Nano and Biomaterials, 2007, 1(1): 3-34. |

| 4 | Jiang Z Q, Yang H, Zhen M, et al. State-of-the-arts and prospectives of manufacturing and application of titanium alloy tube in aviation industry[J]. Journal of Plasticity Engineering, 2009, 16(4): 44-50, 84. |

| 5 | Wang B Z, Li X M, Li Z, et al. Application and prospect of titanium and titanium alloy in automobile industry[J]. Titanium Industry Progress, 2006(5): 38-41. |

| 6 | 季杰, 马学智. 铜及铜合金的焊接[J]. 焊接技术, 1999(2): 13-15. |

| Ji Jie, Ma Xue-zhi. Welding of copper and copper alloys[J]. Welding Technology, 1999(2): 13-15. | |

| 7 | 刘伟, 陈国庆, 张秉刚, 等. 铜/钛合金电子束焊接工艺优化[J]. 焊接学报, 2008, 29(5): 89-92. |

| Liu Wei, Chen Guo-qing, Zhang Bing-gang, et al. Investigation on process optimization of Cu/Ti electron beam welding[J]. Transactions of the China Welding Institution, 2008, 29(5): 89-92. | |

| 8 | 宋敏霞, 赵熹华, 郭伟, 等. Ti-6Al-4V/Ni/ZQSn10-10的扩散连接[J]. 吉林大学学报: 工学版, 2006, 36(1): 42-45. |

| Song Min-xia, Zhao Xi-hua, Guo Wei, et al. Diffusion bonding of Ti-6Al-4V to ZQSn10-10 with nickel interlayer[J]. Journal of Jilin University(Engineering and Technology Edition), 2006, 36(1): 42-45. | |

| 9 | Luo Y, Xie X J, Wan R, et al. Influence of thermal effect on micro-hardness of magnesium alloy weld of vacuum electron beam welding[J]. Rare Metal Materials & Engineering, 2017(2): 496-502. |

| 10 | Zhao Y, Wang W, Yan K, et al. Microstructure and properties of Cu/Ti laser welded joints[J]. Journal of Materials Processing Technology, 2018, 257: 244-249. |

| 11 | Wei L, Zhang B, He J, et al. Microstructure and performance of dissimilar joint QCr0.8/TC4 welded by uncentered electron beam[J]. Rare Metals, 2007(Sup.1): 344-348. |

| 12 | 刘红, 任连保, 马余选, 等. TA2与T2异种金属焊接的工艺研究[J]. 钛工业进展, 2005, 22(4): 30-32. |

| Liu Hong, Ren Lian-bao, Ma Yu-xuan, et al. Dissimilar metal welding of TA2 and T2[J]. Titanium Industry Progress, 2005, 22(4): 30-32. | |

| 13 | Shiue R K, Wu S K, Chan C H. Infrared brazing Cu and Ti using a 95Ag-5Al braze alloy[J]. Metallurgical and Materials Transactions A, 2004, 35(10): 3177-3186. |

| 14 | Shiue R K, Wu S K, Chan C H. The interfacial reactions of infrared brazing Cu and Ti with two silver-based braze alloys[J]. Journal of Alloys & Compounds, 2004, 372(1/2): 148-157. |

| 15 | Kim S Y, Jung S B, Shur C C, et al. Mechanical properties of copper to titanium joined by friction welding[J]. Journal of Materials Science, 2003, 38(6): 1281-1287. |

| 16 | Kahraman N, Gülen B. Microstructural and mechanical properties of Cu-Ti plates bonded through explosive welding process[J]. Journal of Materials Processing Technology, 2005, 169(1): 67-71. |

| 17 | Aydin K, Kaya Y, Kahraman N. Experimental study of diffusion welding/bonding of titanium to copper[J]. Materials & Design, 2012, 37: 356-368. |

| 18 | Zhou L, Min J, He W X, et al. Effect of welding time on microstructure and mechanical properties of Al-Ti ultrasonic spot welds[J]. Journal of Manufacturing Processes, 2018, 33: 64-73. |

| 19 | 徐勇, 杨湘杰, 何毅, 等. TC4钛合金流动软化行为及本构模型研究[J]. 稀有金属材料与工程, 2017, 45(5): 1321-1326. |

| Xu Yong, Yang Xiang-jie, He Yi, et al. Flow softening behavior and constitutive equation of TC4 titanium alloy during hot deformation[J]. Rare Metal Materials and Engineering, 2017, 45(5): 1321-1326. | |

| 20 | 宗跃, 吴玉程, 汪峰涛, 等. SiC和SiO2纳米颗粒弥散强化铜基复合材料的制备和性能研究[C]∥中国功能材料及其应用学术会议, 武汉, 2007: 511-513. |

| [1] | 向红亮,陈盛涛,邓丽萍,张伟,詹土生. 微合金化2205双相不锈钢组织及性能[J]. 吉林大学学报(工学版), 2020, 50(5): 1645-1652. |

| [2] | 庄蔚敏,施宏达,解东旋,杨冠男. 钢铝异质无铆钉粘铆复合连接胶层厚度分布[J]. 吉林大学学报(工学版), 2020, 50(1): 100-106. |

| [3] | 蔡中义,孟凡响,陈庆敏,赵轩. 复杂钩舌锻件近净成形的预锻形状优化设计[J]. 吉林大学学报(工学版), 2020, 50(1): 84-90. |

| [4] | 石舟,寇淑清. 36MnVS4裂解连杆性能分析及轻量化设计[J]. 吉林大学学报(工学版), 2019, 49(6): 1992-2001. |

| [5] | 关庆丰,姚欣雯,杨洋,张凌燕,刘迪,李晨,吕鹏. 强流脉冲电子束作用下TC4钛合金表面Cr合金层制备及性能[J]. 吉林大学学报(工学版), 2019, 49(6): 2002-2009. |

| [6] | 依卓,付文智,李明哲. 双层剖分式超高压模具数值模拟及实验[J]. 吉林大学学报(工学版), 2019, 49(5): 1593-1599. |

| [7] | 谷晓燕,刘东锋,刘婧,孙大千,马会峰. 焊接能量对Cu/Al超声波焊接接头组织与性能的影响[J]. 吉林大学学报(工学版), 2019, 49(5): 1600-1607. |

| [8] | 李欣,孙延朋,王丹,陈军绪,谷诤巍,徐虹. 汽车前地板成形有限元数值模拟[J]. 吉林大学学报(工学版), 2019, 49(5): 1608-1614. |

| [9] | 李欣,王丹,陈军绪,孙延朋,谷诤巍,徐虹. 手刹固定板冲压成形数值模拟[J]. 吉林大学学报(工学版), 2019, 49(4): 1258-1265. |

| [10] | 刘文权,盈亮,荣海,胡平. 基于损伤修正M⁃K模型的高强度钢成形极限预测[J]. 吉林大学学报(工学版), 2019, 49(4): 1266-1271. |

| [11] | 张学广,贾明萌,刘纯国,何广忠. 基于增量控制的型材拉弯轨迹设计及有限元仿真[J]. 吉林大学学报(工学版), 2019, 49(4): 1272-1279. |

| [12] | 姜秋月,杨海峰,檀财旺. 22MnB5超高强钢焊接接头强化性能[J]. 吉林大学学报(工学版), 2018, 48(6): 1806-1810. |

| [13] | 胡志清, 颜庭旭, 李洪杰, 吕振华, 廖伟, 刘庚. 深冷处理对铝合金薄板冲剪成形性能的影响[J]. 吉林大学学报(工学版), 2018, 48(5): 1524-1530. |

| [14] | 邱小明, 王银雪, 姚汉伟, 房雪晴, 邢飞. 基于灰色关联的DP1180/DP590异质点焊接头工艺参数优化[J]. 吉林大学学报(工学版), 2018, 48(4): 1147-1152. |

| [15] | 陈俊甫, 管志平, 杨昌海, 牛晓玲, 姜振涛, 宋玉泉. 金属棒试样拉伸和扭转试验应变范围和力学特性对比[J]. 吉林大学学报(工学版), 2018, 48(4): 1153-1160. |

|

||