吉林大学学报(工学版) ›› 2021, Vol. 51 ›› Issue (2): 754-760.doi: 10.13229/j.cnki.jdxbgxb20200030

• 农业工程·仿生工程 • 上一篇

基于虚拟仿真的拖拉机后悬挂检测装置设计与实验

丛茜1,2( ),徐金3,马博帅3,张晓超4,陈廷坤1,3(

),徐金3,马博帅3,张晓超4,陈廷坤1,3( )

)

- 1.吉林大学 工程仿生教育部重点实验室,长春 130022

2.吉林大学 汽车仿真与控制国家重点实验室,130022

3.吉林大学 生物与农业工程学院,长春 130022

4.洛阳拖拉机研究所有限公司,洛阳 471039

Design and test of tractor hydraulic suspension system testing device based on virtual simulation

Qian CONG1,2( ),Jin XU3,Bo-shuai MA3,Xiao-chao ZHANG4,Ting-kun CHEN1,3(

),Jin XU3,Bo-shuai MA3,Xiao-chao ZHANG4,Ting-kun CHEN1,3( )

)

- 1.Key Laboratory of Bionic Engineering,Ministry of Education,Jilin University,Changchun 130022,China

2.State Key Laboratory of Automotive Simulation and Control,Jilin University,Changchun 130022,China

3.College of Biological and Agricultural Engineering,Jilin University,Changchun 130022,China

4.Luoyang Tractor Research Institute Co. ,Ltd. ,Luoyang 471039,China

摘要:

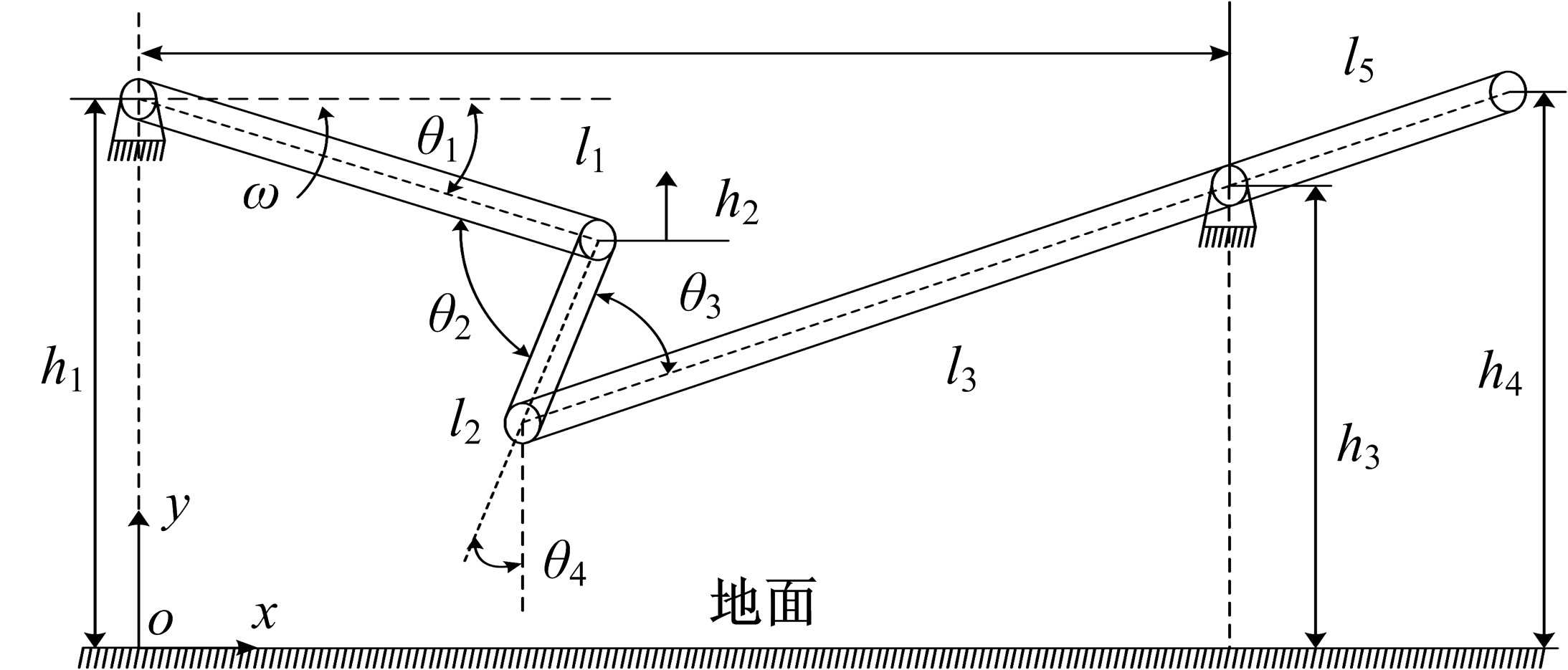

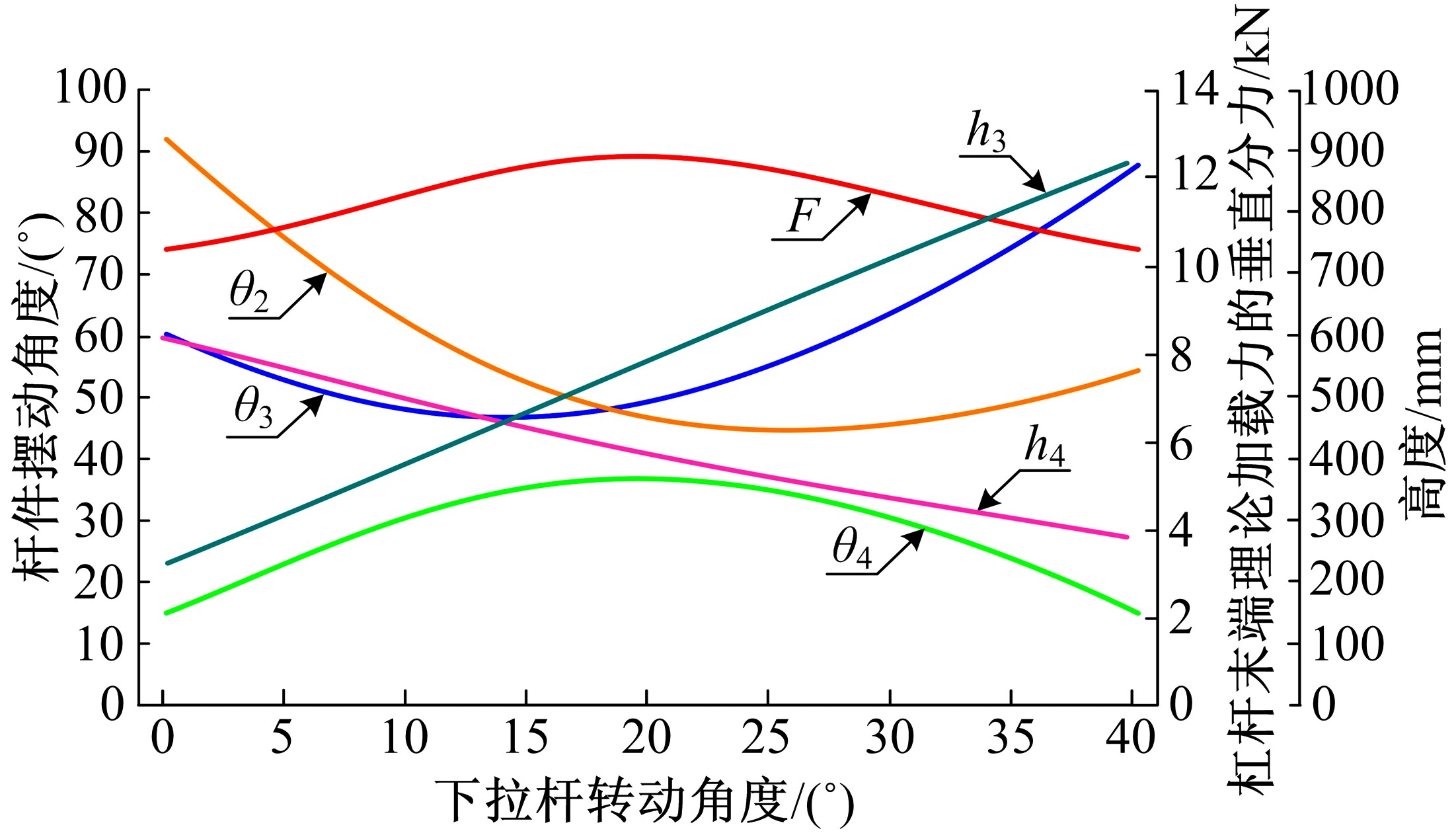

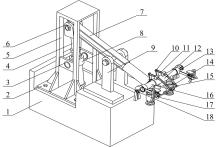

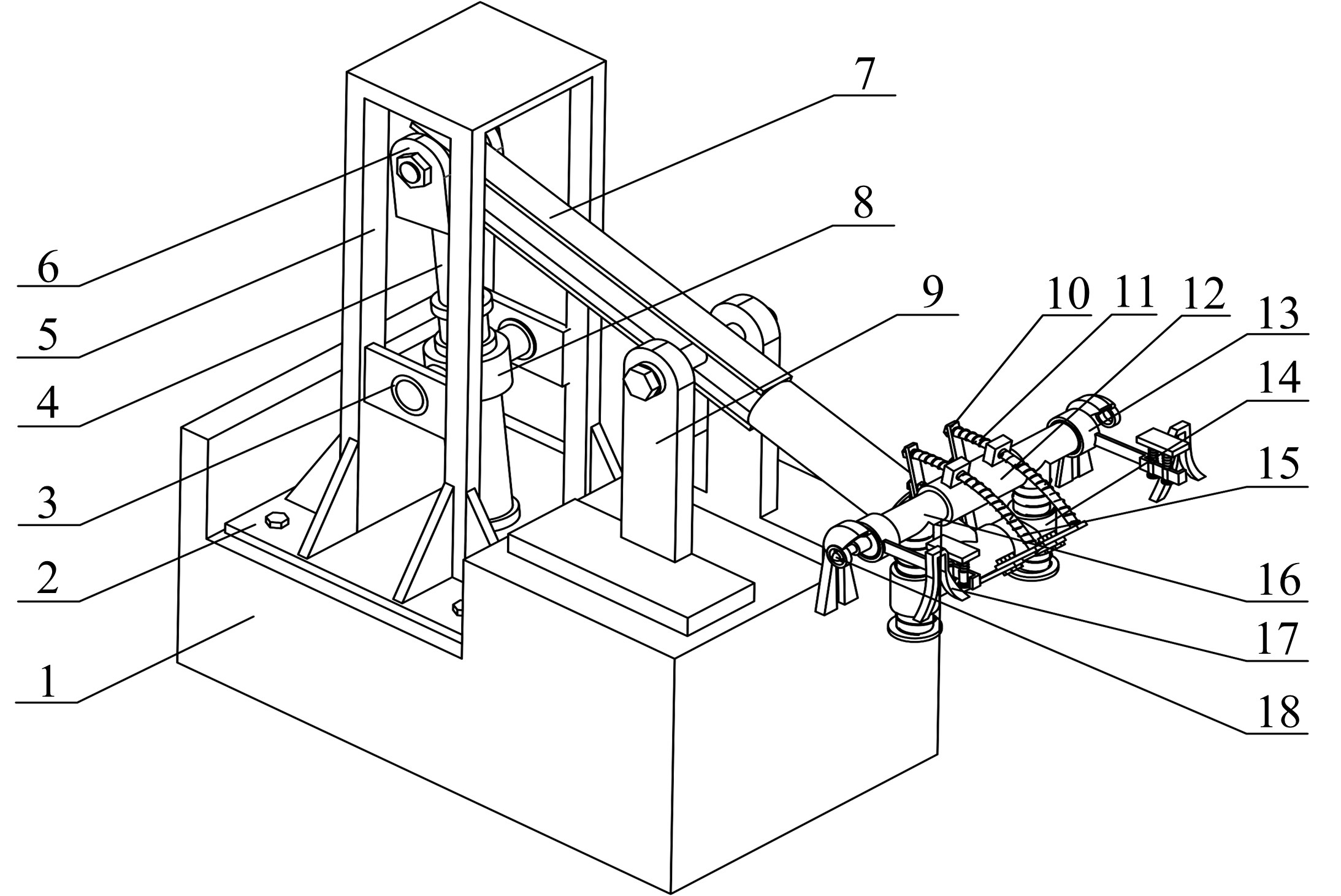

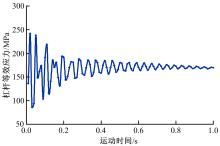

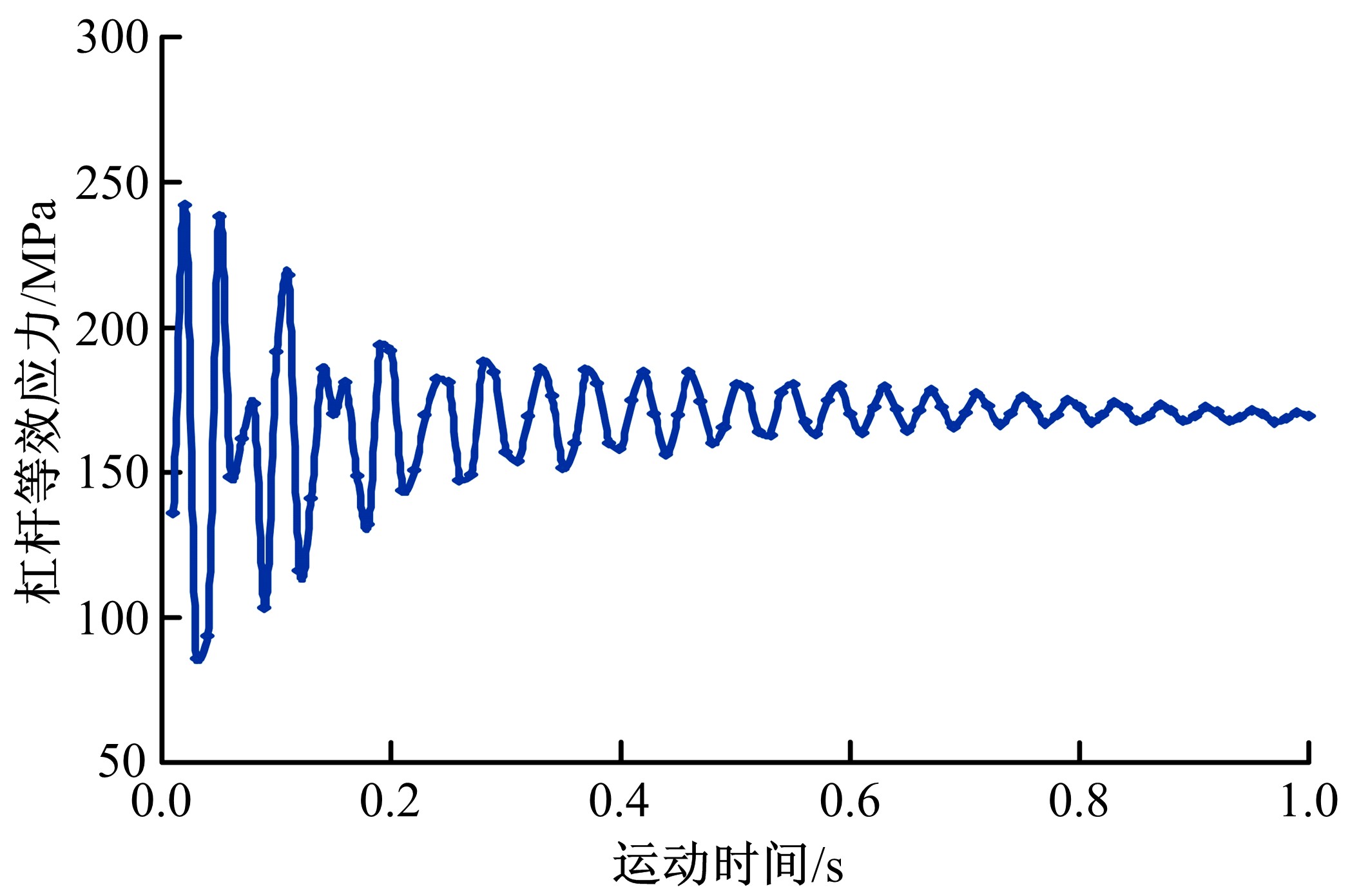

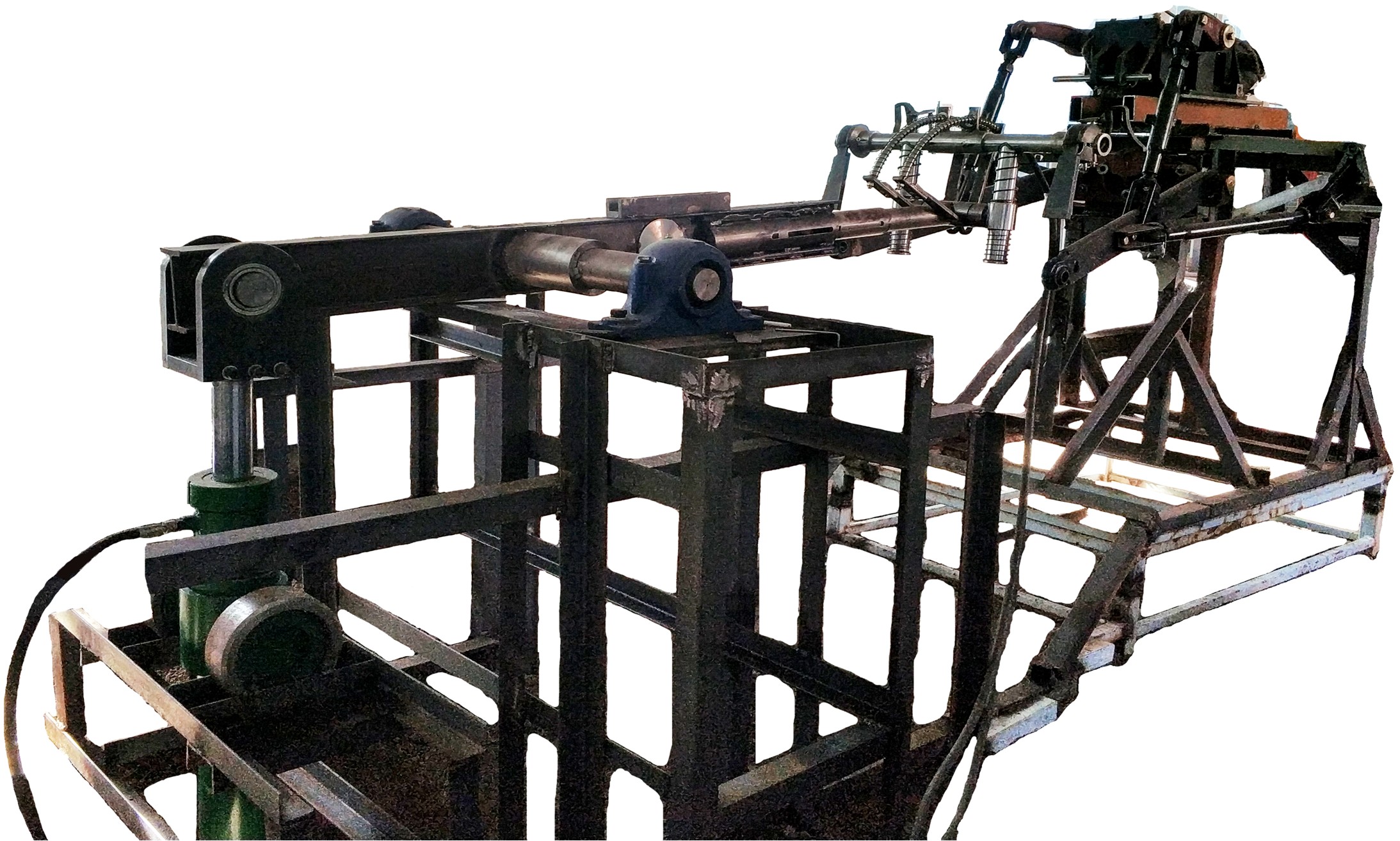

针对目前拖拉机液压悬挂检测效率低、劳动强度大且易造成人身伤害等问题,基于虚拟仿真本文设计了一种用于拖拉机液压悬挂检测的挂接检测装置,该装置由挂接部分和加载部分组成。挂接部分采用液压自动控制的方式完成拖拉机下拉杆的定位和穿销,加载部分通过液压加载油缸和杠杆机构对拖拉机下拉杆进行加载,并且采用杠杆加载方式可减小加载油缸运动位移,避免实验场地开挖地沟。运用Adams和Workbench对拖拉机液压悬挂挂接检测装置分别进行运动学仿真和力学仿真,结果表明,该挂接检测装置设计符合运动学要求,未出现干涉卡死现象,且满足力学要求。试制了拖拉机液压悬挂挂接检测装置,开展挂接与承载提升实验,在装置末端施加5 kN的加载力,同时拖拉机下拉杆提升650 mm。试验表明:研制的挂接检测装置可准确、快速挂接下拉杆,并能完成拖拉机液压悬挂承载提升,满足预期要求。该研究可为拖拉机液压悬挂智能化、高效率检测以及相关检测装置的设计提供参考。

中图分类号:

- S220

| 1 | 白学峰, 常江雪, 纪鸿波, 等. 拖拉机液压悬挂装置发展趋势及技术标准研究[J]. 拖拉机与农用运输车, 2018, 45(6): 19-22. |

| Bai Xue-feng, Chang Jiang-xue, Ji Hong-bo, et al. Research on development trend and technical standards of tractor hydraulic hitch[J]. Tractor & Farm Transporter, 2018, 45(6): 19-22. | |

| 2 | 王智才. 建设现代农业加快推进农业机械化[J]. 农业机械学报, 2004(3): 154-158, 163. |

| Wang Zhi-cai. Construction of a modern agriculture and boosting of farm mechanization[J]. Transactions of the Chinese Society for Agricultural Machinery, 2004(3): 154-158, 163. | |

| 3 | 中华人民共和国统计局. 中国统计年鉴—2018[M]. 北京: 中国统计出版社, 2018. |

| 4 | 罗锡文, 廖娟, 胡炼, 等. 提高农业机械化水平促进农业可持续发展[J]. 农业工程学报, 2016, 32(1): 1-11. |

| Luo Xi-wen, Liao Juan, Hu Lian, et al. Improving agricultural mechanization level to promote agricultural sustainable development[J]. Transactions of the Chinese Society of Agricultural Engineering, 2016, 32(1): 1-11. | |

| 5 | 周济. 智能制造——“中国制造2025”的主攻方向[J]. 中国机械工程, 2015, 26(17): 2273-2284. |

| Zhou Ji. Intelligent manufacturing: the main attack direction of "Made in China 2025"[J]. China Mechanical Engineering, 2015, 26(17): 2273-2284. | |

| 6 | 李金华. 德国“工业4.0”与“中国制造2025”的比较及启示[J]. 中国地质大学学报: 社会科学版, 2015, 15(5): 71-79. |

| Li Jin-hua. Comparison and enlightenment between "Industrial 4.0 in Germany" and "Made in China 2025"[J]. Journal of China University of Geosciences (Social Sciences Edition), 2015, 15(5): 71-79. | |

| 7 | 王川, 孙坦. 大数据驱动下的农业信息科技创新与服务——中国农业科学院农业信息研究所“十三五”发展规划[J]. 数字图书馆论坛, 2016(11): 34-39. |

| Wang Chuan, Sun Tan. The innovation and service of agricultural information technology driven by big data: development plan in 13th five-year of agricultural information institute of Chinese academy of agricultural sciences[J]. Digital Library Forum, 2016(11): 34-39. | |

| 8 | 谢斌, 武仲斌, 毛恩荣. 农业拖拉机关键技术发展现状与展望[J]. 农业机械学报, 2018, 49(8): 1-17. |

| Xie Bin, Wu Zhong-bin, Mao En-rong. Development and prospect of key technologies on agricultural tractor[J]. Transactions of the Chinese Society for Agricultural Machinery, 2018, 49(8): 1-17. | |

| 9 | 刘长年. 拖拉机液压提升器的分析与设计[J]. 农业机械学报, 1983(4): 44-54. |

| Liu Chang-nian. Analysis and design of hydraulic lifter for a tractor[J]. Transactions of the Chinese Society for Agricultural Machinery, 1983(4): 44-54. | |

| 10 | Borghi M, Zardin B, Pintore F, et al. Energy savings in the hydraulic circuit of agricultural tractors[J]. Energy Procedia,2014, 45: 352-361. |

| 11 | Borodani P, Colombo D, Forestello M, et al.Robust control of a new electro-hydraulic pump for agricultural tractors[J].IFAC Proceedings Volumes, 2011, 44(1): 2266-2271. |

| 12 | Du Q L, Chen X H. Design on control system for electro-hydraulic hitch equipment of tractor[J]. Advanced Material Research, 2014, 945-949: 1513-1516. |

| 13 | Kumar R, Raheman H. Design and development of a variable hitching system for improving stability of tractor trailer combination[J].Engineering in Agriculture, Environment and Food, 2015, 8(3): 187-194. |

| 14 | 李文明. 拖拉机悬挂试验台电液加载系统的设计与研究[D]. 南京: 南京农业大学工学院, 2014. |

| Li Wen-ming. Design and study on electro-hydraulic loading system of tractor's hitch test-bed[D]. Nanjing: College of Engineering, Nanjing Agricultural University, 2014. | |

| 15 | 栾圣罡, 米伯林. 拖拉机液压提升能力试验加载方案的对比研究[J]. 农机化研究, 2002(4): 68-69. |

| Luan Sheng-gang, Mi Bo-lin. Comparable study on the solutions in test of lift capability of tractor hydraulic system[J]. Journal of Agricultural Mechanization Research, 2002(4): 68-69. | |

| 16 | 徐强. 拖拉机机具液压悬挂系统的研究及其加载试验台的研制[D]. 杭州: 浙江大学机械工程学院, 2013. |

| Xu Qiang. The research about the hydraulic hitch system in tractor equipment and the development about loading system of tractor[D]. Hangzhou: School of Mechanical Engineering, Zhejiang University, 2013. | |

| 17 | 吕栗樵, 张兰义, 周云山, 等. 新型拖拉机液压悬挂系统试验台[J]. 农业机械学报, 1992, 23(3): 19-24. |

| Lv Li-qiao, Zhang Lan-yi, Zhou Yun-shan, et al. A new type of testing bench for tractor hydraulic lifting system[J]. Transactions of the Chinese Society for Agricultural Machinery, 1992, 23(3): 19-24. | |

| 18 | 李明生, 宋正河, 迟瑞娟, 等. 大功率拖拉机电液提升器比例下降阀仿真与优化[J]. 农业机械学报, 2012, 43(): 1-5. |

| Li Ming-sheng, Song Zheng-he, Chi Rui-juan, et al. Simulation analysis on proportional lowering value for high-power tractor[J]. Transactions of the Chinese Society for Agricultural Machinery, 2012, 43(sSup.1): 1-5. | |

| 19 | . 农业拖拉机试验规程第4部分:后置三点悬挂装置提升能力[S]. |

| 20 | 孙桓, 陈作模. 机械原理(第八版)[M]. 北京: 高等教育出版社, 2013. |

| 21 | 毕秋实, 王国强, 陈立军, 等. 基于离散元-多体动力学联合仿真的机械式挖掘机挖掘阻力仿真与试验[J]. 吉林大学学报: 工学版, 2019, 49(1): 106-116. |

| Bi Qiu-shi, Wang Guo-qiang, Chen Li-jun, et al. Numerical simulation and experiment on excavation resistance of mechanical excavator based on DEM-MBD co-simulation[J]. Journal of Jilin University (Engineering and Technology Edition), 2019, 49(1): 106-116. | |

| 22 | 袁锐, 马旭, 马成林, 等. 精密播种机单体的虚拟制造和运动仿真[J]. 吉林大学学报: 工学版, 2006, 36(4): 523-528. |

| Yuan Rui, Ma Xu, Ma Cheng-lin, et al. Virtual manufacturing and motion simulation of precision planter unit[J]. Journal of Jilin University (Engineering and Technology Edition), 2006, 36(4): 523-528. | |

| 23 | 秦大同, 谢里阳. 现代机械设计手册——第1卷[M]. 北京: 化学工业出版社, 2011. |

| 24 | . 农业轮式拖拉机后置式三点悬挂装置0、1N、1、2N、2、3N、3、4N和4类[S]. |

| [1] | 李健,刘孔宇,任宪盛,熊琦,窦雪峰. 基于自适应阈值的Canny算法在MRI边缘检测中的应用[J]. 吉林大学学报(工学版), 2021, 51(2): 712-719. |

| [2] | 许骞艺,秦贵和,孙铭会,孟诚训. 基于改进的ResNeSt驾驶员头部状态分类算法[J]. 吉林大学学报(工学版), 2021, 51(2): 704-711. |

| [3] | 熊璐,魏琰超,高乐天. 基于惯性测量单元/轮速融合的车辆零速检测方法[J]. 吉林大学学报(工学版), 2021, 51(1): 134-138. |

| [4] | 徐涛,马克,刘才华. 基于深度学习的行人多目标跟踪方法[J]. 吉林大学学报(工学版), 2021, 51(1): 27-38. |

| [5] | 陈学深,黄柱健,马旭,齐龙,方贵进. 水稻机械除草避苗控制系统设计与试验[J]. 吉林大学学报(工学版), 2021, 51(1): 386-396. |

| [6] | 耿端阳,谭德蕾,于兴瑞,苏国粱,王骞,鹿秀凤,金诚谦. 玉米柔性脱粒滚筒脱粒元件设计与试验[J]. 吉林大学学报(工学版), 2020, 50(5): 1923-1933. |

| [7] | 陈红松,陈京九. 基于统计的物联网分布式拒绝服务攻击检测[J]. 吉林大学学报(工学版), 2020, 50(5): 1894-1904. |

| [8] | 方伟,黄羿,马新强. 基于机器学习的虚拟网络感知数据缺陷自动检测[J]. 吉林大学学报(工学版), 2020, 50(5): 1844-1849. |

| [9] | 胡钊政,李招康,陶倩文. 基于分布式二维激光测距仪的室内行人检测与跟踪[J]. 吉林大学学报(工学版), 2020, 50(2): 719-729. |

| [10] | 刘洲洲,尹文晓,张倩昀,彭寒. 基于离散优化算法和机器学习的传感云入侵检测[J]. 吉林大学学报(工学版), 2020, 50(2): 692-702. |

| [11] | 武立群,张亮亮. 基于数据挖掘技术的桥梁结构健康状态检测[J]. 吉林大学学报(工学版), 2020, 50(2): 565-571. |

| [12] | 高锐涛,单建,杨洲,文晟,兰玉彬,张泉勇,汪洋. 植保无人机变量喷雾处方图实时解译系统的设计与试验[J]. 吉林大学学报(工学版), 2020, 50(1): 361-374. |

| [13] | 宗长富,文龙,何磊. 基于欧几里得聚类算法的三维激光雷达障碍物检测技术[J]. 吉林大学学报(工学版), 2020, 50(1): 107-113. |

| [14] | 翁小辉,孙友宏,张书军,谢军,常志勇. 基于仿生鼻腔优化的油气检测方法与实验新技术[J]. 吉林大学学报(工学版), 2020, 50(1): 382-388. |

| [15] | 车翔玖,刘华罗,邵庆彬. 基于Fast RCNN改进的布匹瑕疵识别算法[J]. 吉林大学学报(工学版), 2019, 49(6): 2038-2044. |

|

||