吉林大学学报(工学版) ›› 2022, Vol. 52 ›› Issue (4): 829-836.

• 车辆工程·机械工程 • 上一篇

复合材料板簧迟滞特性线性辨识方法

李伟1( ),宋海生1,陆浩宇1,史文库2,王强1,王晓俊3(

),宋海生1,陆浩宇1,史文库2,王强1,王晓俊3( )

)

- 1.山东交通学院 汽车工程学院, 济南 250357

2.吉林大学 汽车仿真与控制国家重点实验室, 长春 130022

3.山东交通学院 工程机械学院, 济南 250357

Linear identification method of hysteresis characteristic of composite leaf springs

Wei LI1( ),Hai-sheng SONG1,Hao-yu LU1,Wen-ku SHI2,Qiang WANG1,Xiao-jun WANG3(

),Hai-sheng SONG1,Hao-yu LU1,Wen-ku SHI2,Qiang WANG1,Xiao-jun WANG3( )

)

- 1.School of Automotive Engineering,Shandong Jiaotong University,Jinan 250357,China

2.State Key Laboratory of Automotive Simulation and Control,Jilin University,Changchun 130022,China

3.School of Engineering and Machinery,Shandong Jiaotong University,Jinan 250357,China

摘要:

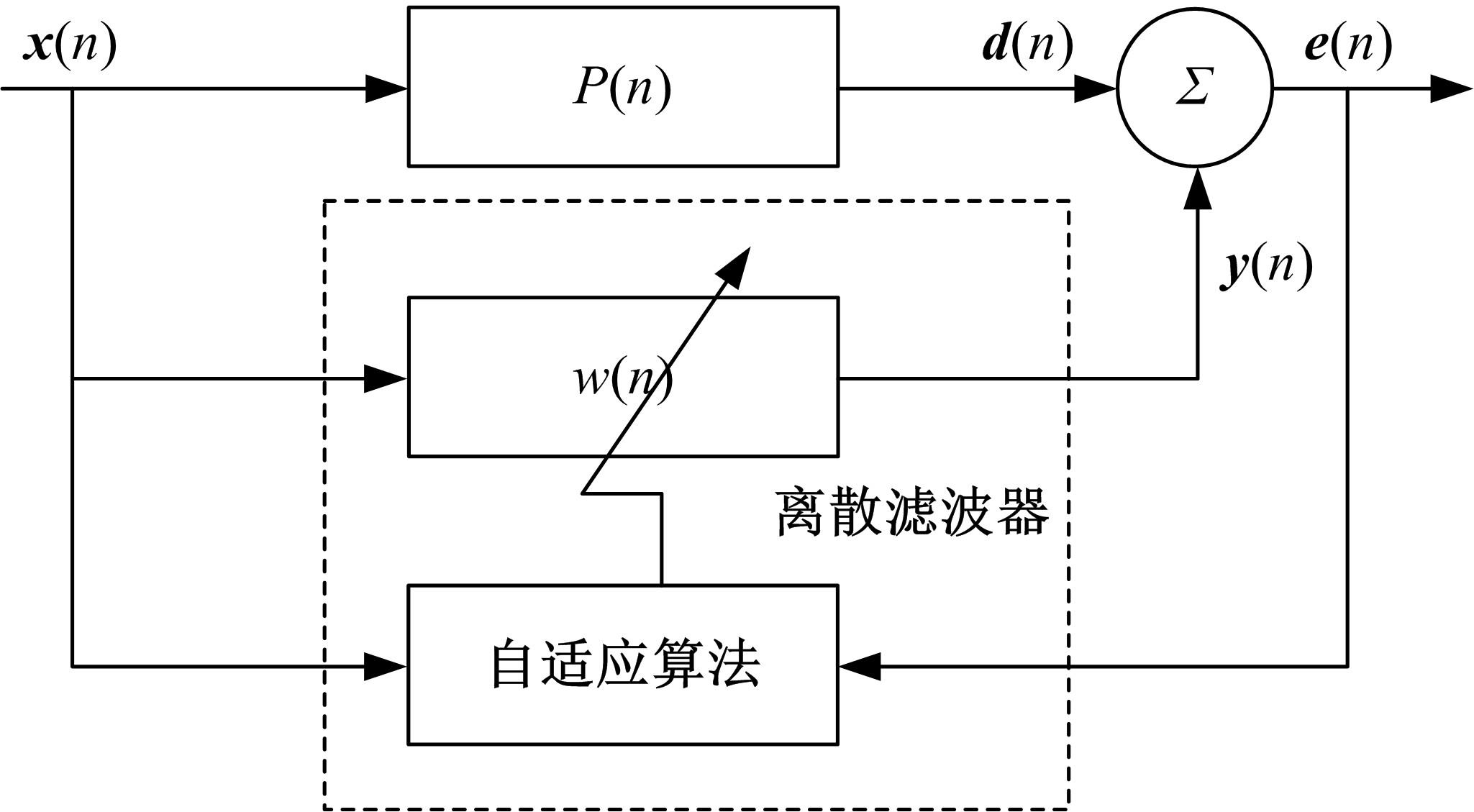

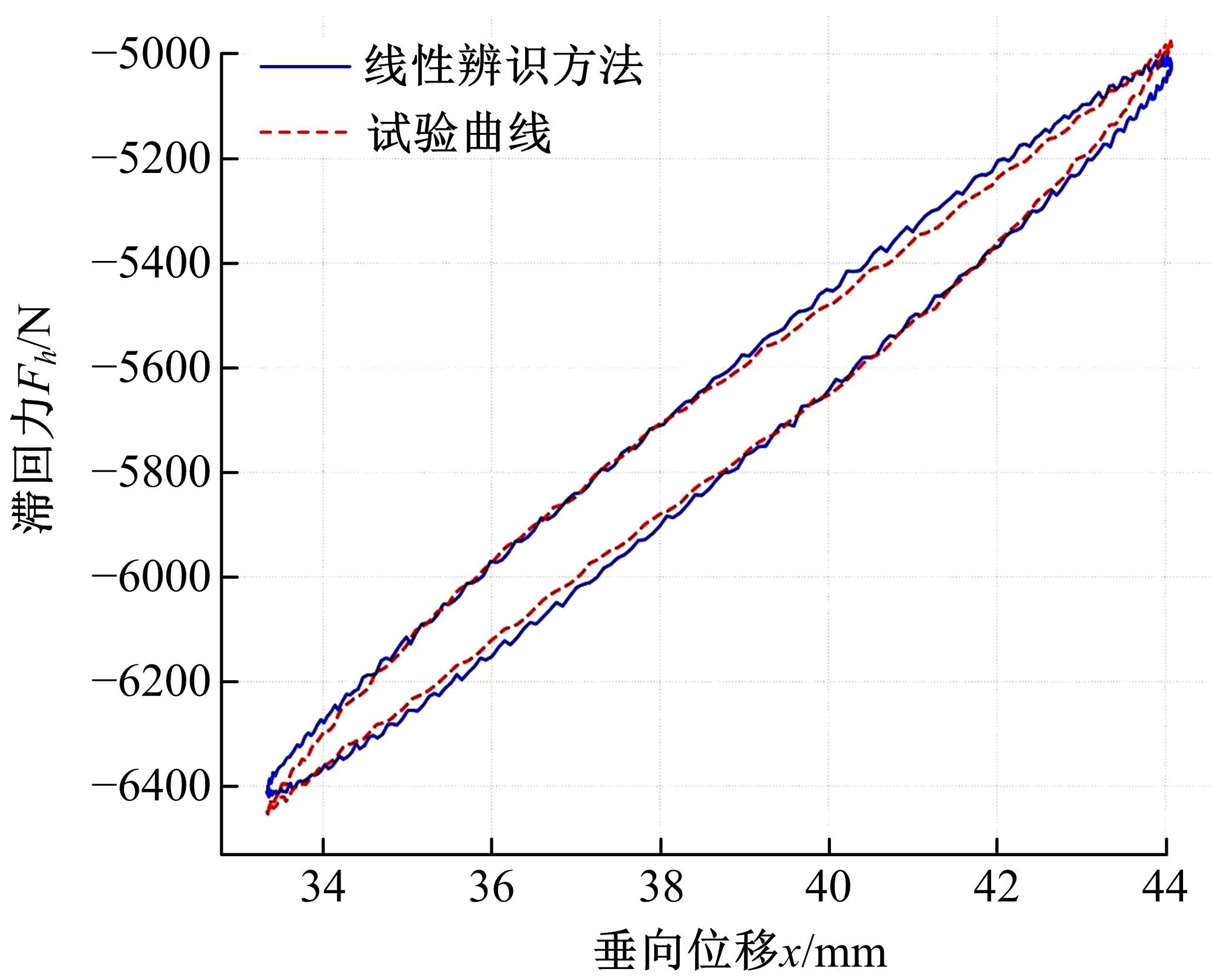

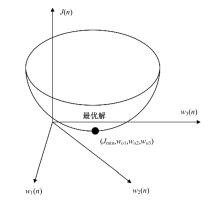

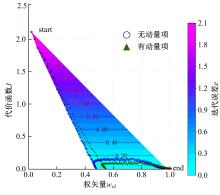

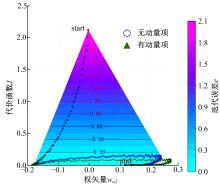

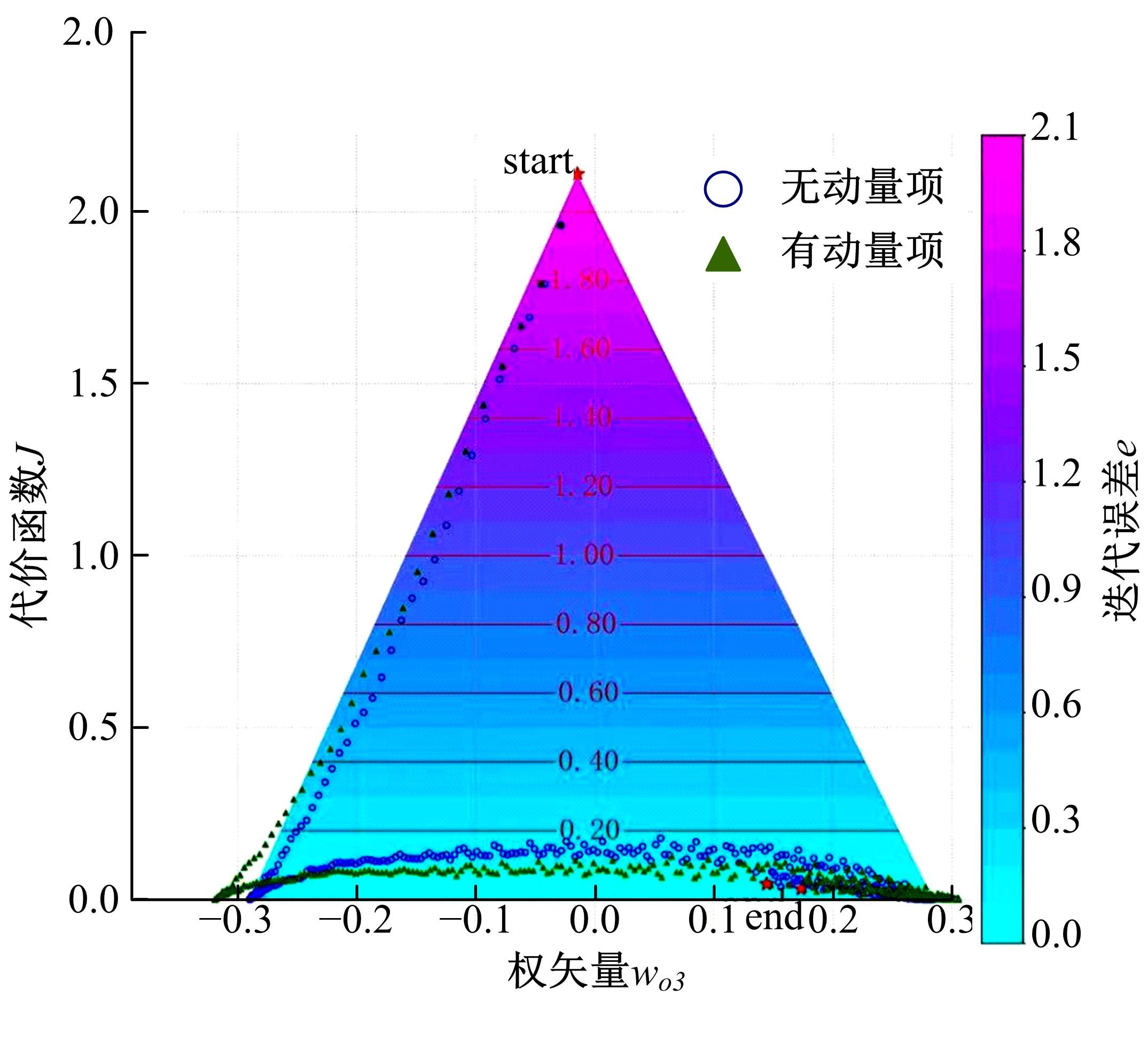

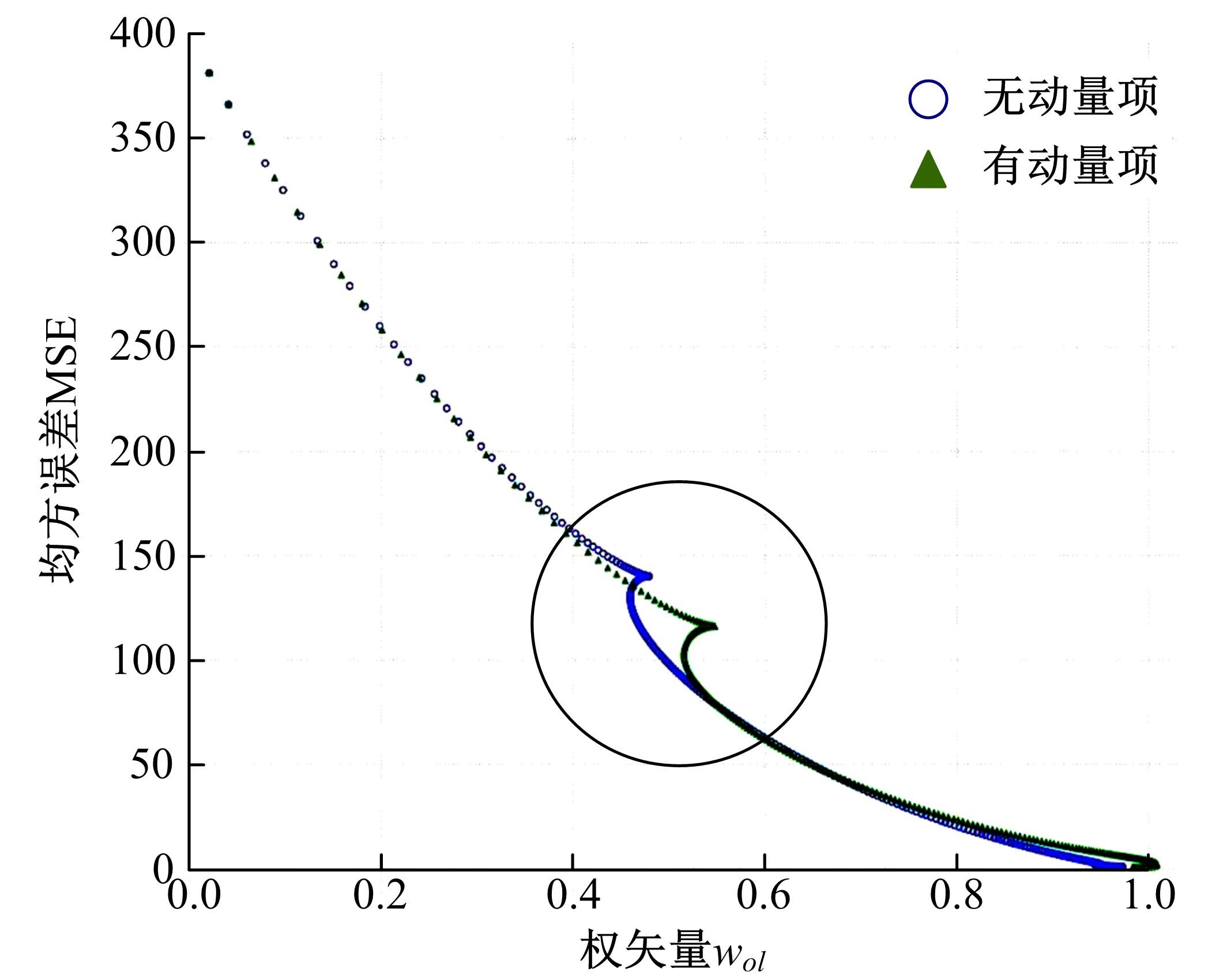

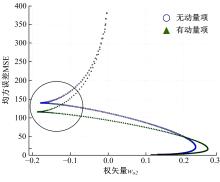

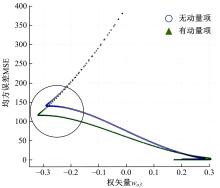

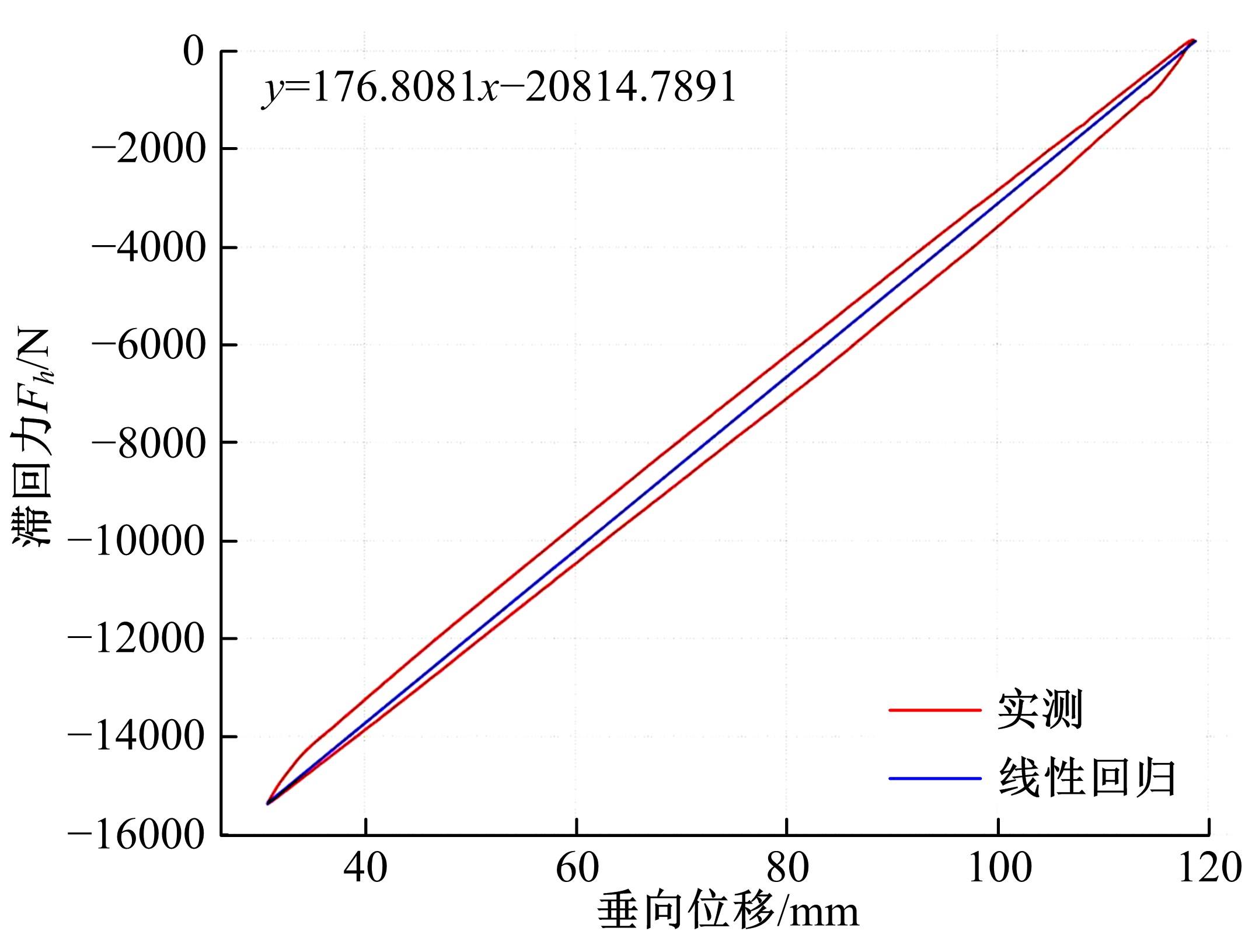

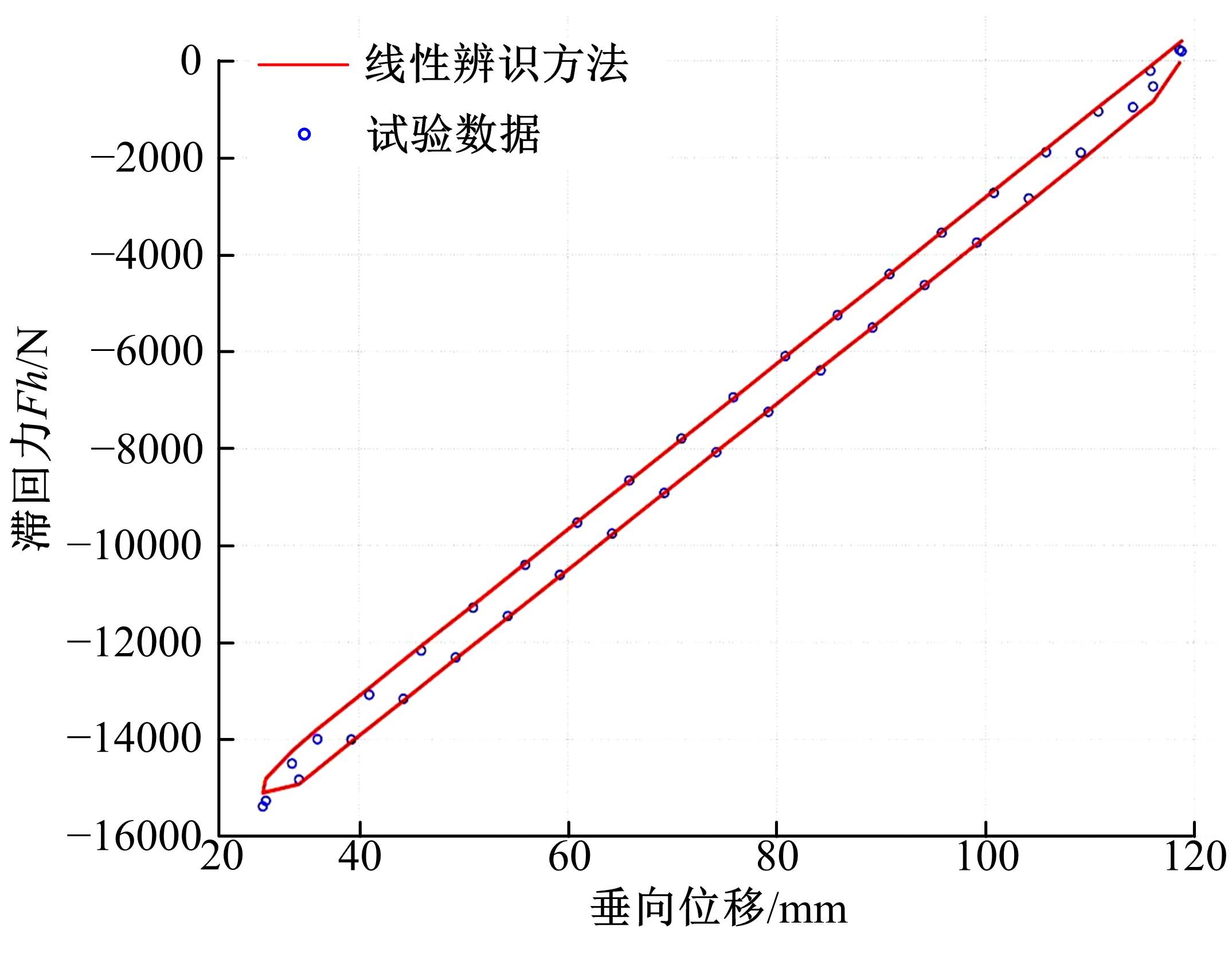

针对复合材料板簧的迟滞特性参数辨识工作,在梯度下降法的基础上提出了一种线性辨识方法,并推导得到递推公式,与已有工作中的改进萤火虫算法进行对比验证,从辨识精度和计算时间两个维度进行了讨论。在此基础上引入了动量项对线性辨识方法进行改进,相较改进前,算法在加速收敛时间的同时,降低了收敛误差。最后,将其用于某款复合材料板簧的迟滞特性辨识。结果表明:相对于智能启发式的非线性算法,线性辨识方法更适合进行复合材料板簧迟滞特性的辨识,其辨识精度与非线性算法相仿,且能将辨识计算时间控制在2.5 ms以内,使得在线参数辨识或数字孪生仿真等对实时性要求较高的工作成为可能。

中图分类号:

- U467.3

| 1 | 钱琛. 某轻型客车复合材料板簧关键特性建模 与性能优化 [D]. 吉林:吉林大学汽车工程学院, 2018. |

| Qian Chen. Key characteristics modeling and performance optimization of composite leaf spring for a light bus [D]. Jilin: College of Automotive Engineering, Jilin University, 2018. | |

| 2 | 王振兴,竺铝涛,沈伟.复合材料汽车板簧的应用研究进展[J].浙江理工大学学报:自然科学版, 2022,47(1):38-43. |

| Wang Zhen-xing, Zhu Lv-tao, Shen Wei. Progress in the application research of composite automobile leaf springs[J]. Journal of Zhejiang Sci-Tech University (Natural Science Edition), 2022, 47(1): 38-43. | |

| 3 | Venkatesan M, Devaraj H. Design and analysis of composite leaf spring in light vehicle[J]. International Journal of Modern Engineering Research, 2012, 2(1): 213-218. |

| 4 | Krishnamurthy K, Ravichandran P. Modeling and structural analysis of leaf spring using composite materials[J]. Materials Today: Proceedings, 2020,33: 4228-4232. |

| 5 | 柯俊,史文库,钱琛,等.复合材料板簧刚度的预测及匹配设计方法[J].浙江大学学报:工学版,2015,11(49):2103-2110. |

| Ke Jun, Shi Wen-ku, Qian Chen, et al. Prediction and matching design method for stiffness of composite leaf spring[J]. Journal of Zhejiang University (Engineering Science), 2015,11(49):2103-2110. | |

| 6 | 周孔亢,陆建辉,侯永涛,等. 基于RecurDyn的钢板弹簧动力学模型的建立与参数辨识[J]. 机械工程学报,2014,50(4):128-134. |

| Zhou Kong-kang, Lu Jian-hui, Hou Yong-tao, et al. Dynamics modeling and parameter identification of leaf spring based on RecurDyn[J]. Journal of Mechanical Engineering,2014,50(4):128-134. | |

| 7 | Rajesh S, Bhaskar B. Response of composite leaf springs to low velocity impact loading[J]. Applied Mechanics and Materials,2014,591:47-50. |

| 8 | Guillaume Puel, Béatrice Bourgeteau, Denis Aubry, et al. Parameter identification of nonlinear time-dependent rubber bushings models towards their integration in multibody simulations of a vehicle chassis [J]. Mechanical Systems and Signal Processing,2013,36(2):354-369. |

| 9 | 周金龙,董凌华,杨卫东. 直升机后缘襟翼驱动器迟滞现象仿真与抑制[J]. 航空学报,2020,41(4):144-154. |

| Zhou Jin-long, Dong Ling-hua, Yang Wei-dong. Hysteresis modeling and suppression of piezoelectric actuator for helicopter trailing edge flaps[J]. Acta Aeronautica et Astronautica Sinica,2020,41(4):144-154. | |

| 10 | 章杰,吴茵,张邦基, 等. 板簧Bouc‐Wen迟滞模型的仿真与试验研究 [J]. 汽车工程,2017,39(12):1402-1408, 1443. |

| Zhang Jie, Wu Yin, Zhang Bang-ji, et al. Simulation and experimental study on Bouc‐Wen hysteresis model of leaf spring [J]. Automotive Engineering,2017,39(12):1402-1408, 1443. | |

| 11 | 李玲,蔡安江,蔡力钢,等. 基于Bouc-Wen模型辨识结合面动态特性研究[J]. 振动与冲击,2013,32(20):139-144. |

| Li Ling, Cai An-jiang, Cai Li-gang, et al. Dynamic characteristics identification of joint interfaces based on a Bouc‐Wen model[J]. Journal of Vibration and Shock,2013,32(20):139-144. | |

| 12 | Charalampakis E, Dimou K. Identification of Bouc-Wen hysteretic systems using particle swarm optimization [J]. Computers & Structures,2010,88 (21):1197-1205. |

| 13 | 史文库,张曙光,张友坤,等. 基于改进海鸥算法的磁流变减振器模型辨识[J/OL]. [2021-11-29].. |

| 14 | 卢荡,董益量,秦民,等.钢板弹簧动态力建模[J].吉林大学学报:工学版,2011,41():12-16. |

| Lu Dang, Dong Yi-liang, Qin Min, et al. Modeling of dynamic load for leaf spring [J]. Journal of Jilin University (Engineering and Technology Edition), 2011,41(S1):12-16. | |

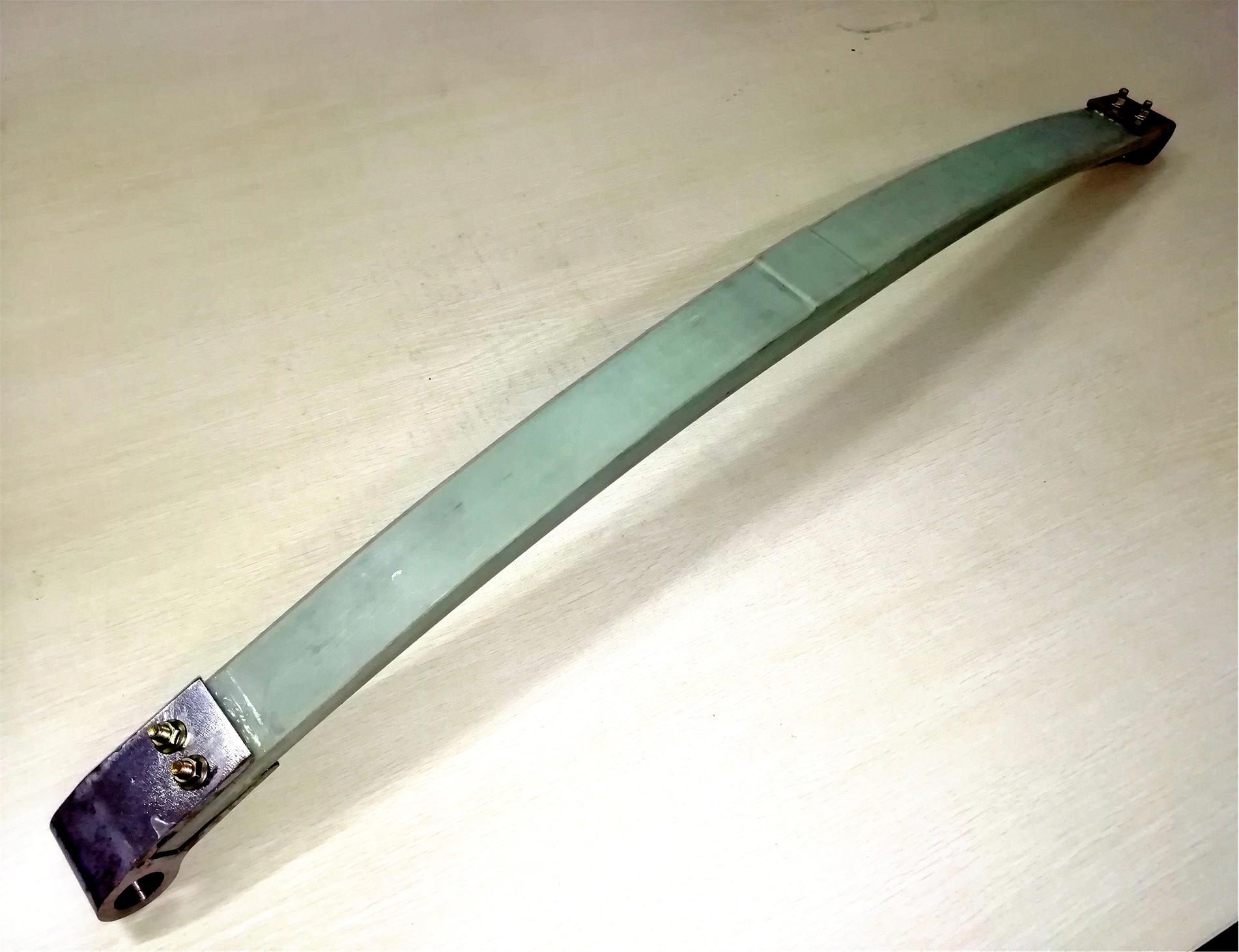

| 15 | 刘鹤龙,史文库,高蕊,等. 复合材料板簧的迟滞特性建模与试验研究[J]. 汽车工程,2021, 43(6):934-942. |

| Liu He-long, Shi Wen-ku, Gao Rui, et al. Modeling and experimental study on hysteresis characteristic of composite leaf springs [J]. Automotive Engineering, 2021, 43(6):934-942. | |

| 16 | 何荣,郭睿,管欣, 等. 钢板弹簧Fancher模型物理机理及参数辨识[J].吉林大学学报:工学版,2013,43(1):12-16. |

| He Rong, Guo Rui, Guan Xin, et al. Physical mechanism and parameter identification of Fancher leaf spring model [J]. Journal of Jilin University (Engineering and Technology Edition), 2013,43(1):12-16. | |

| 17 | 史文库,刘鹤龙,刘巧斌, 等.复合材料板簧非线性迟滞建模和参数识别[J].振动工程学报,2019,32(6):1050-1059. |

| Shi Wen-ku, Liu He-long, Liu Qiao-bin, et, al. Hysteresis characteristic modelling and parameter identification for composite leaf spring [J]. Journal of Vibration Engineering, 2019,32(6):1050-1059. | |

| 18 | 沈福民. 自适应信号处理 [M]. 西安:西安电子科技大学出版社,2001. |

| 19 | 陈克安. 有源噪声控制[M]. 2版.北京:国防工业出版社,2014. |

| 20 | 李士勇. 智能优化算法与涌现计算[M]. 北京:清华大学出版社,2019. |

| [1] | 李杰,陈涛,郭文翠,赵旗. 汽车非平稳随机振动空间域虚拟激励法及应用[J]. 吉林大学学报(工学版), 2022, 52(4): 738-744. |

| [2] | 庄蔚敏,陈沈,吴迪. 碳纤维增强复合材料包裹强化形式对钢管横向冲击性能的影响[J]. 吉林大学学报(工学版), 2022, 52(4): 819-828. |

| [3] | 史文库,张曙光,张友坤,陈志勇,江逸飞,林彬斌. 基于改进海鸥算法的磁流变减振器模型辨识[J]. 吉林大学学报(工学版), 2022, 52(4): 764-772. |

| [4] | 张英朝,李昀航,郭子瑜,王国华,张喆,苏畅. 长头重型卡车气动减阻优化[J]. 吉林大学学报(工学版), 2022, 52(4): 745-753. |

| [5] | 庄蔚敏,陈沈,王楠. 温度对车身钢铝胶铆连接结构热应力变化的影响[J]. 吉林大学学报(工学版), 2022, 52(1): 70-78. |

| [6] | 段亮,宋春元,刘超,魏苇,吕成吉. 基于机器学习的高速列车轴承温度状态识别[J]. 吉林大学学报(工学版), 2022, 52(1): 53-62. |

| [7] | 卫宇璇,张明,刘佳,刘硕,路明雨,王洪雨. 基于模态缺陷的变刚度复合材料圆柱壳屈曲特性[J]. 吉林大学学报(工学版), 2022, 52(1): 91-100. |

| [8] | 胡兴军,张靖龙,罗雨霏,辛俐,李胜,胡金蕊,兰巍. 冷却管结构及进气方向对空冷中冷器性能的影响[J]. 吉林大学学报(工学版), 2021, 51(6): 1933-1942. |

| [9] | 陈剑斌,周宋泽,费峰永,陈永龙,凌国平. 过盈量及滚花方式对装配式凸轮轴压装失效的影响[J]. 吉林大学学报(工学版), 2021, 51(6): 1959-1966. |

| [10] | 谷拴成,聂红宾. 极温冻融-荷载作用下碳纤维复合材料修复试件损伤分析[J]. 吉林大学学报(工学版), 2021, 51(6): 2108-2120. |

| [11] | 马超,高云凯,刘哲,段月星,田林雳. 骨架式车身多材料及梁截面形状和尺寸优化[J]. 吉林大学学报(工学版), 2021, 51(5): 1583-1592. |

| [12] | 罗勇,韦永恒,黄欢,肖人杰,任淋,崔环宇. 驾驶员意图识别的P2.5插混构型双离合器起步控制[J]. 吉林大学学报(工学版), 2021, 51(5): 1575-1582. |

| [13] | 曾小华,宋美洁,宋大凤,王越. 基于车联网信息的公交客车行驶工况数据处理方法[J]. 吉林大学学报(工学版), 2021, 51(5): 1692-1699. |

| [14] | 杨建,夏琦,周海超,王国林. 修正胎体弦轮廓载重子午线轮胎的降噪机理[J]. 吉林大学学报(工学版), 2021, 51(4): 1198-1203. |

| [15] | 龙江启,向锦涛,俞平,王骏骋. 适用于非线性主动悬架滑模控制的线性干扰观测器[J]. 吉林大学学报(工学版), 2021, 51(4): 1230-1240. |

|

||