吉林大学学报(工学版) ›› 2023, Vol. 53 ›› Issue (7): 1943-1950.doi: 10.13229/j.cnki.jdxbgxb.20211021

• 材料科学与工程 • 上一篇

高温水浸对T800/环氧树脂基复合材料性能的影响

- 沈阳航空航天大学 机电工程学院,沈阳 110136

Effect of high temperature immersion on properties of T800 carbon fiber/epoxy resin composites

Liang XU( ),Yu-bo BIAN,Song ZHOU(

),Yu-bo BIAN,Song ZHOU( ),Jing-hou XIAO

),Jing-hou XIAO

- College of Mechatronics Engineering,Shenyang Aerospace University,Shenyang 110136,China

摘要:

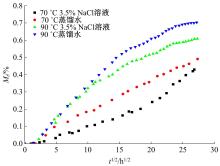

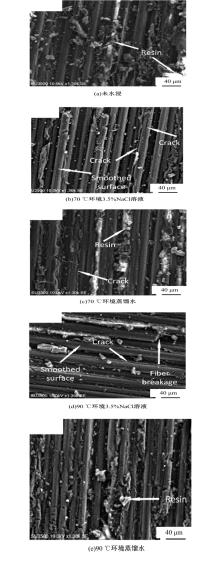

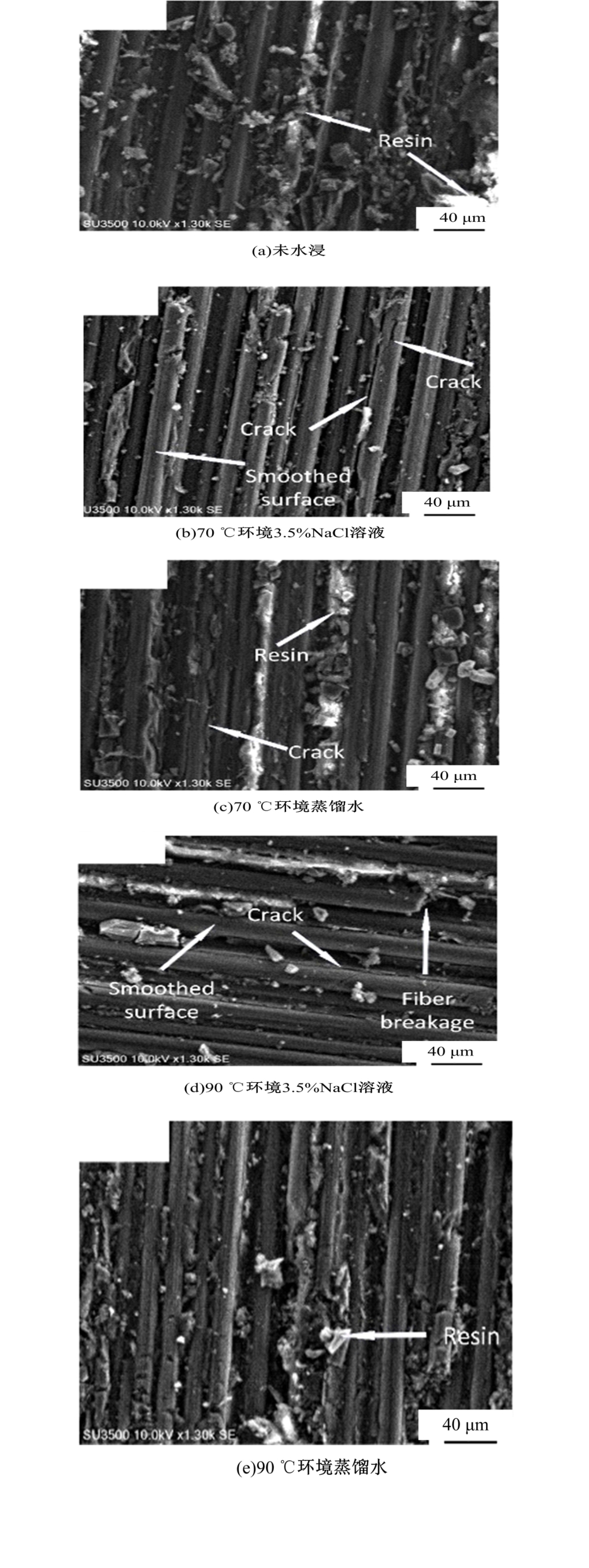

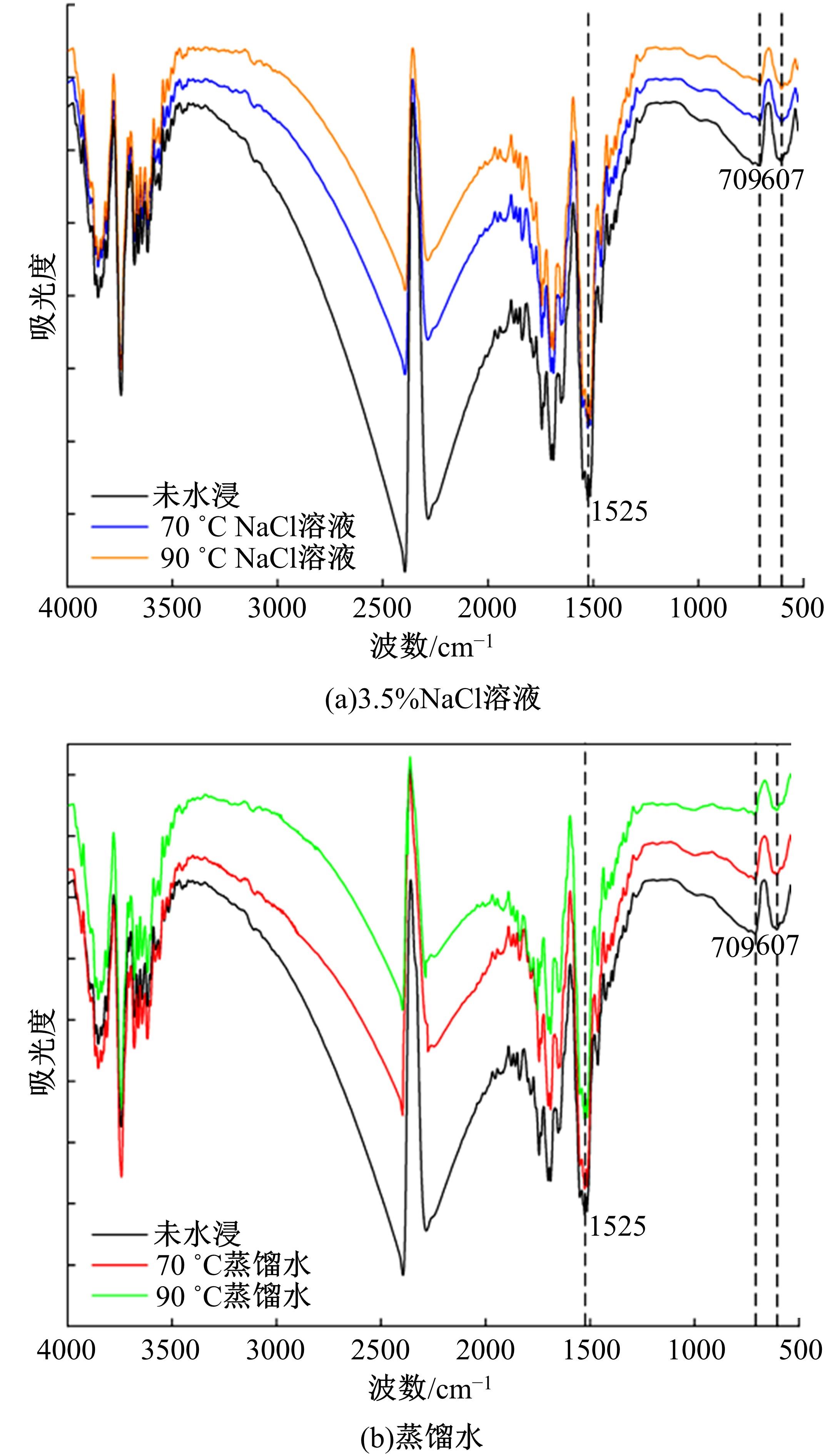

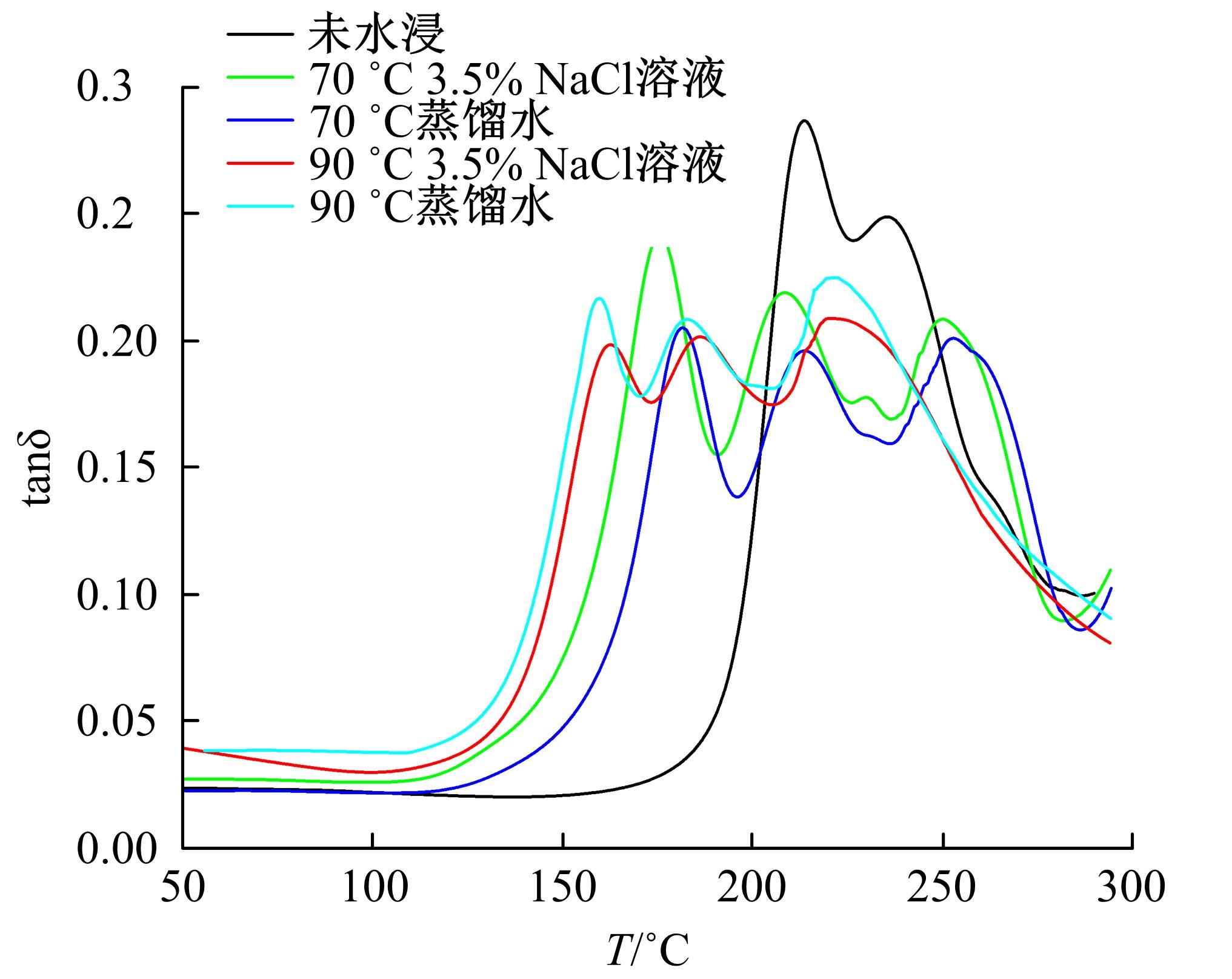

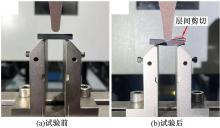

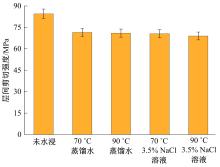

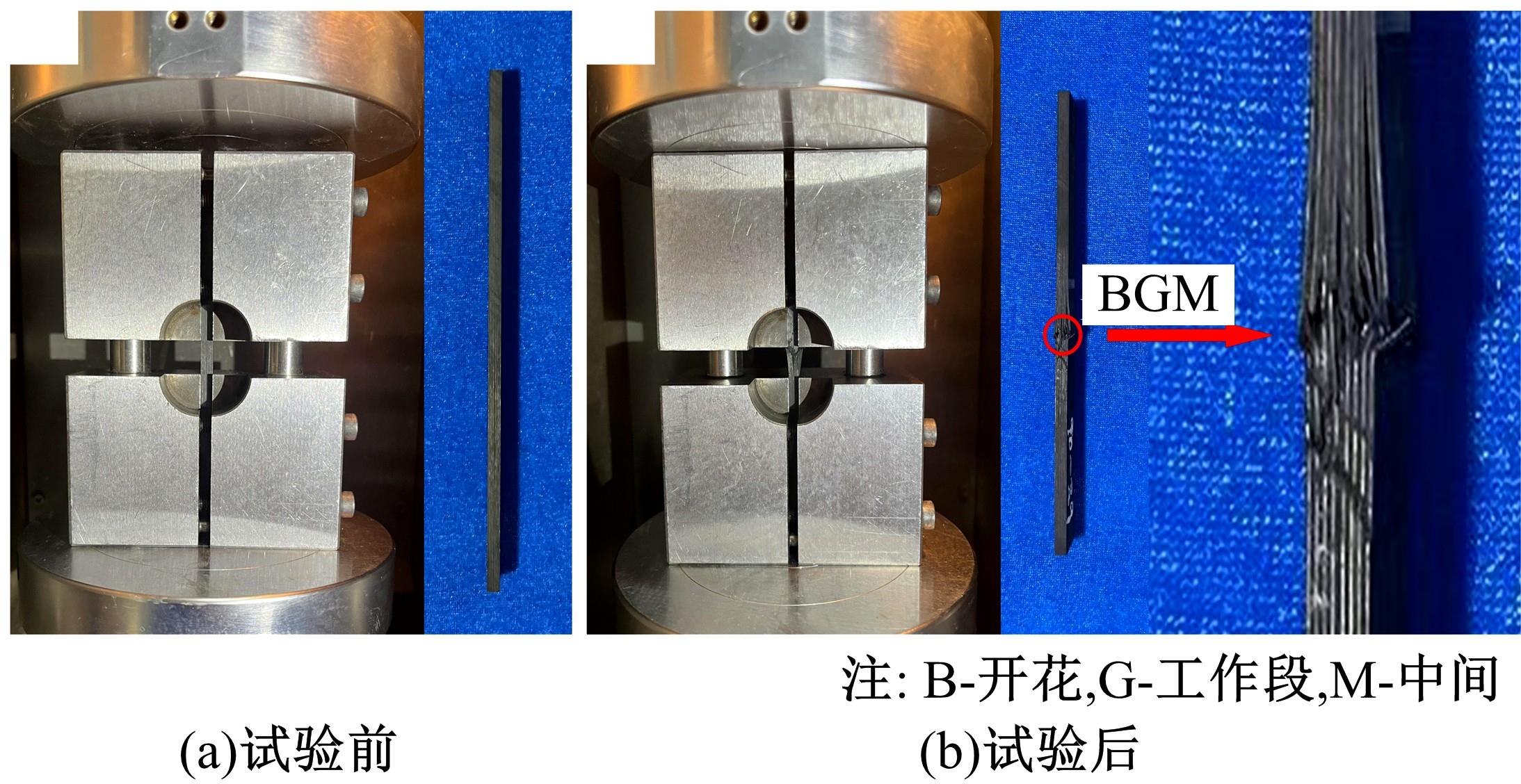

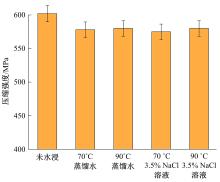

分析了不同温度水浸环境下T800碳纤维/环氧树脂基复合材料的吸湿特性及性能。首先对其进行水浸吸湿试验,再分析其质量变化、吸湿率变化、红外光谱、水浸前后的表面形貌、玻璃化转变温度、压缩强度及层间剪切强度。结果表明,水浸环境温度越高,吸湿速率越快,玻璃化转变温度Tg下降程度越大;经水浸后,试样表面产生裂纹,纤维与树脂基体界面发生破坏,试样的层间剪切强度与压缩强度下降明显。

中图分类号:

- TB332

| 1 | 吕小军,张琦,马兆庆,等.湿热老化对碳纤维/环氧树脂基复合材料力学性能影响研究[J]. 材料工程, 2005(11): 50-53. |

| Xiao-jun Lü, Zhang Qi, Ma Zhao-qing, et al. Effect of hygrothermal aging on mechanical properties of carbon fiber/epoxy resin matrix composites[J]. Materials Engineering, 2005(11): 50-53. | |

| 2 | Venkatesha B K, Saravanan R, Babu K A. Effect of moisture absorption on woven bamboo/glass fiber reinforced epoxy hybrid composites[J]. Materials Today: Proceedings, 2021(45): 216-221. |

| 3 | 王国建,孙耀宁,姜宏,等. 湿热-高温循环老化对环氧乙烯基酯树脂/玻璃纤维复合材料性能影响[J]. 工程塑料应用, 2020, 48(9): 121-126. |

| Wang Guo-jian, Sun Yao-ning, Jiang Hong, et al. Influences of cyclic hygrothermal-thermal aging on properties of epoxy vinylester resin/glass fiber composites[J]. Engineering Plastics Application, 2020, 48(9): 121-126. | |

| 4 | Li H L, Zhang K F, Fan X T, et al. Effect of seawater ageing with different temperatures and concentrations on static/dynamic mechanical properties of carbon fiber reinforced polymer composites[J]. Composites Part B, 2019, 173: No. 106910. |

| 5 | 余海燕,吴航宇,石慧茹. 湿热环境中碳纤维复合材料层合板的强度退化及老化寿命预测[J]. 机械工程材料, 2021, 45(4): 40-45. |

| Yu Hai-yan, Wu Hang-yu, Shi Hui-ru. Strength degradation and aging life prediction of carbon fiber composite laminates in hot and humid environment[J]. Materials for Mechanical Engineering, 2021, 45(4): 40-45. | |

| 6 | 王汝敏. 聚合物基复合材料及工艺[M]. 北京: 科学技术出版社, 2004. |

| 7 | John F M, Sandra R. Water absorption dimensional change and radial pressure in resin matrix dental restorative materials [J]. Biomaterials, 2004, 25: 4001-4007. |

| 8 | 包建文,陈祥宝. 5284/T300复合材料湿热性能研究[J]. 宇航材料工艺, 2000(4): 39-42. |

| Bao Jian-wen, Chen Xiang-bao. Study on the moisture and thermal properties of 5284/T300 composites[J]. Aerosp Mater Technol, 2000(4): 39-42. | |

| 9 | 栗晓飞,张琦,谢国君,等. 影响碳纤维增强树脂基复合材料腐蚀重要环境因素的研究[J]. 装备环境工程, 2005, 2(6): 34-40. |

| Li Xiao-fei, Zhang Qi, Xie Guo-jun, et al. Study on important environmental factors affecting corrosion of carbon fiber reinforced resin matrix composites[J]. Equipment Environmental Engineering, 2005, 2(6): 34-40. | |

| 10 | Wolff E G. Polymer Matrix Composites: Moisture Effects and Dimensional Stability, International Encyclopedia of Composites[M]. New York: VCH Publishers, 1991. |

| 11 | Xu Z R, Ashbee K. Photo-elastic study of the durability of interfacial bonding of carbon fiber epoxy resin composites[J]. Journal of Materials Science, 1994, 29(2): 394-403. |

| 12 | Xu L, He Y, Ma S H, et al. Effects of hygrothermaland thermal-oxidative ageing on the open-hole properties of T800/high-temperature epoxy resin composites with different hole shapes[J]. High Perform Polym, 2019, 32(5): 494-505. |

| 13 | 周松,贾耀雄,许良,等. 湿热环境对T800碳纤维/环氧树脂基复合材料力学性能的影响[J]. 材料工程, 2021, 46(10): 138-143. |

| Zhou Song, Jia Yao-xiong, Xu Liang, et al. Effect of hygrothermal environmenton mechanical properties of T800 carbon fiber/epoxy resin composites[J]. Journal of Materials Engineering, 2021, 46(10): 138-143. | |

| 14 | 李玉玲,万里强,黄发荣,等. 碳纤维/聚三唑树脂复合材料的湿热老化行为[J]. 玻璃钢/复合材料, 2014(11): 36-41. |

| Li Yu-ling, Wan Li-qiang, Huang Fa-rong, et al. Wet-heat aging behavior of carbon fiber/polytriazole resin composites[J]. Fiber-glass reinforced Plastics/composites, 2014(11):36-41. | |

| 15 | Ma S H, He Y, Hui L, et al. Effects of hygrothermal and thermal aging on the low-velocity impact properties of carbon fiber composites[J]. Adv Compos Mater, 2019, 29(9): 1-18. |

| 16 | 王莉莉,杨小平,于运花,等. 湿热环境对抽油杆CF/VE拉挤复合材料的影响[J]. 复合材料学报, 2004, 21(3): 131-136. |

| Wang Li-li, Yang Xiao-ping, Yu Yun-hua, et al. Effect of hot and humid environment on sucker rod CF/VE pultrusion composites[J]. Acta Materiae Compositae Sinica, 2004, 21(3): 131-136. | |

| 17 | 高建业,洪彬,高振东,等. 碳纤维增强用环氧树脂的湿热老化规律研究[J]. 热固性树脂, 2018, 33(5): 56-59. |

| Gao Jian-ye, Hong Bin, Gao Zhen-dong, et al. Study on damp heat aging law of epoxy resin for carbon fiber reinforcement[J]. Thermosetting Resin, 2018, 33(5): 56-59. | |

| 18 | 高坤,史汉桥,孙宝岗,等. 湿热老化对玻璃纤维/环氧树脂复合材料性能的影响[J]. 复合材料学报, 2016(6): 1147-1152. |

| Gao Kun, Shi Han-qiao, Sun Bao-gang, et al. Effect of hygrothermal aging on properties of glass fiber/epoxy resin composites[J]. Acta Composite Materials, 2016(6): 1147-1152. | |

| 19 | 马少华,王勇刚,回丽,等. 湿热环境下复合材料孔板压缩性能的研究[J]. 宇航材料工艺, 2015, 45(6): 66-70. |

| Ma Shao-hua, Wang Yong-gang, Hui Li, et al. Study on compression properties of composite orifice plates under hot and humid environment[J]. Aerospace Materials Technology, 2015, 45(6): 66-70. | |

| 20 | 余治国,杨胜春,宋笔锋. T700和T300碳纤维增强环氧树脂基复合材料耐湿热老化性能的对比[J]. 机械工程材料, 2009(6): 48-51. |

| Yu Zhi-guo, Yang Sheng-chun, Song Bi-feng. Comparison of hygrothermal aging resistance of T700 and T300 carbon fiber reinforced epoxy resin matrix composites[J]. Mechanical Engineering Materials, 2009(6): 48-51. |

| [1] | 匡亚川,宋哲轩,刘胤虎,莫小飞,伏亮明,罗时权. 新型装配式双舱综合管廊力学性能试验[J]. 吉林大学学报(工学版), 2022, 52(3): 596-603. |

| [2] | 魏海斌,王相焱,王富玉,张勇. 基于振动成型AC-25沥青混合料力学性能及细观分析[J]. 吉林大学学报(工学版), 2021, 51(4): 1269-1276. |

| [3] | 程永春,李赫,李立顶,王海涛,白云硕,柴潮. 基于灰色关联度的矿料对沥青混合料力学性能的影响分析[J]. 吉林大学学报(工学版), 2021, 51(3): 925-935. |

| [4] | 刘寒冰,高鑫,宫亚峰,刘诗琪,李文俊. 表面处理对玄武岩纤维活性粉末混凝土力学性能的影响及断裂特性[J]. 吉林大学学报(工学版), 2021, 51(3): 936-945. |

| [5] | 王金国,王志强,任帅,闫瑞芳,黄恺,郭劲. Ti添加量对球墨铸铁组织及力学性能的影响[J]. 吉林大学学报(工学版), 2020, 50(5): 1653-1662. |

| [6] | 向红亮,陈盛涛,邓丽萍,张伟,詹土生. 微合金化2205双相不锈钢组织及性能[J]. 吉林大学学报(工学版), 2020, 50(5): 1645-1652. |

| [7] | 李明,王浩然,赵唯坚. 单向带抗剪键叠合板的受力性能试验[J]. 吉林大学学报(工学版), 2020, 50(2): 654-667. |

| [8] | 修文翠,吴化,韩英,刘云旭. 等温热处理温度对超级贝氏体组织与性能的影响[J]. 吉林大学学报(工学版), 2020, 50(2): 520-525. |

| [9] | 佟鑫,张雅娇,黄玉山,胡正正,王庆,张志辉. 选区激光熔化304L不锈钢的组织结构及力学性能分析[J]. 吉林大学学报(工学版), 2019, 49(5): 1615-1621. |

| [10] | 李明,王浩然,赵唯坚. 带抗剪键叠合板的力学性能[J]. 吉林大学学报(工学版), 2019, 49(5): 1509-1520. |

| [11] | 姜秋月,杨海峰,檀财旺. 22MnB5超高强钢焊接接头强化性能[J]. 吉林大学学报(工学版), 2018, 48(6): 1806-1810. |

| [12] | 庄蔚敏, 赵文增, 解东旋, 李兵. 超高强钢/铝合金热铆连接接头性能[J]. 吉林大学学报(工学版), 2018, 48(4): 1016-1022. |

| [13] | 刘晓波, 周德坤, 赵宇光. 不同等温热处理条件下半固态挤压Mg2Si/Al复合材料的组织和性能[J]. 吉林大学学报(工学版), 2016, 46(5): 1577-1582. |

| [14] | 李春玲, 樊丁, 王斌, 余淑荣. 5A06铝合金/镀锌钢预置涂粉对接激光熔钎焊组织与性能[J]. 吉林大学学报(工学版), 2016, 46(2): 516-521. |

| [15] | 邓成江,何晓聪,邢保英,王玉奇,曾凯,丁燕芳. 铝与铜异质板材自冲铆搭接接头的力学性能[J]. 吉林大学学报(工学版), 2015, 45(2): 473-480. |

|

||