吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (1): 86-98.doi: 10.13229/j.cnki.jdxbgxb.20220309

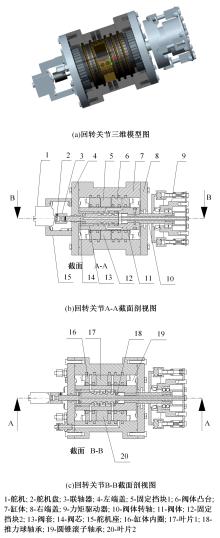

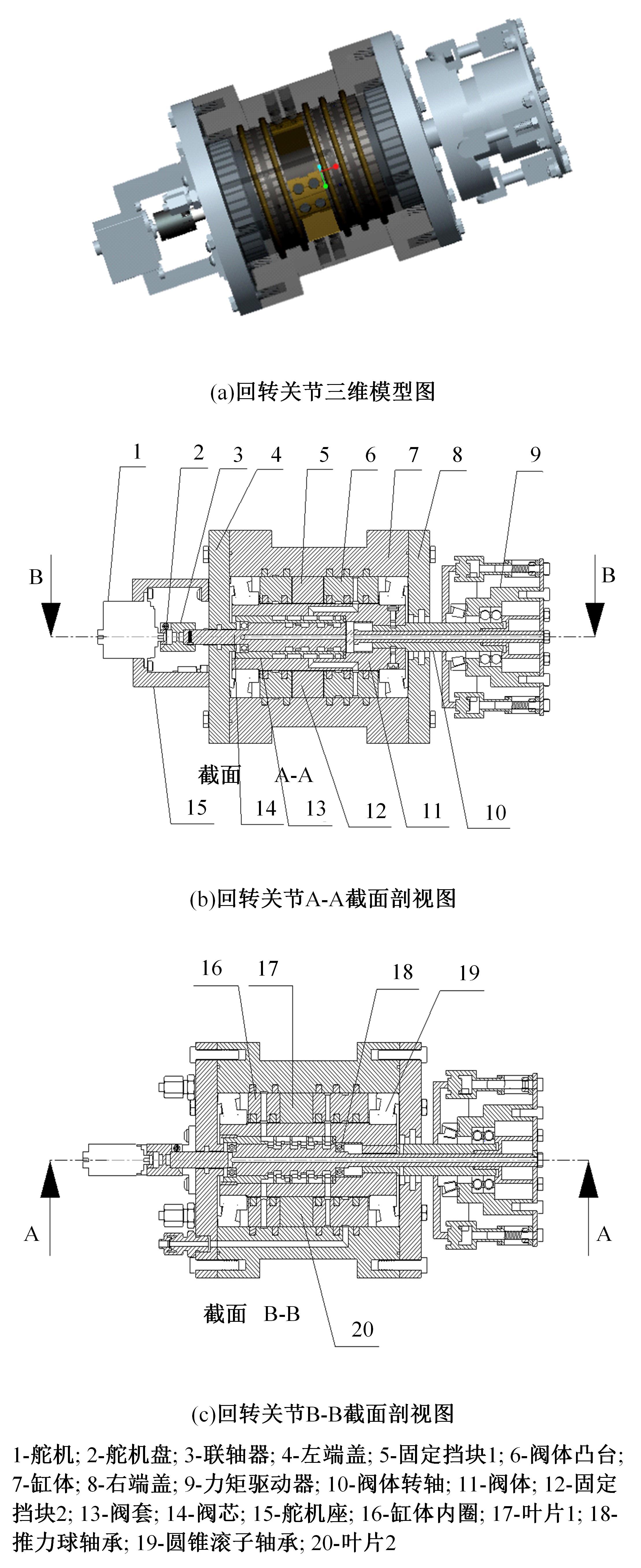

双叶片液压关节主被动联合柔顺控制分析

- 1.武汉科技大学 冶金装备及其控制教育部重点实验室,武汉 430081

2.武汉科技大学 机器人与智能系统研究院,武汉 430081

Analysis of active compliance and passive compliance combined control of double blade hydraulic joint

Hui ZHAO1,2( ),Fa-qiang ZHU1,Lin JIANG1,2(

),Fa-qiang ZHU1,Lin JIANG1,2( ),Shi-hu WANG1

),Shi-hu WANG1

- 1.Key Laboratory of Metallurgical Equipment and Control Technology of Ministry of Education,Wuhan University of Science and Technology,Wuhan 430081,China

2.Institute of Robotics and Intelligent Systems,Wuhan University of Science and Technology,Wuhan 430081,China

摘要:

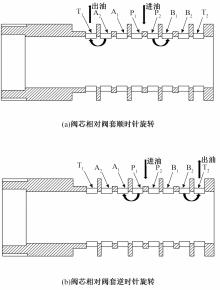

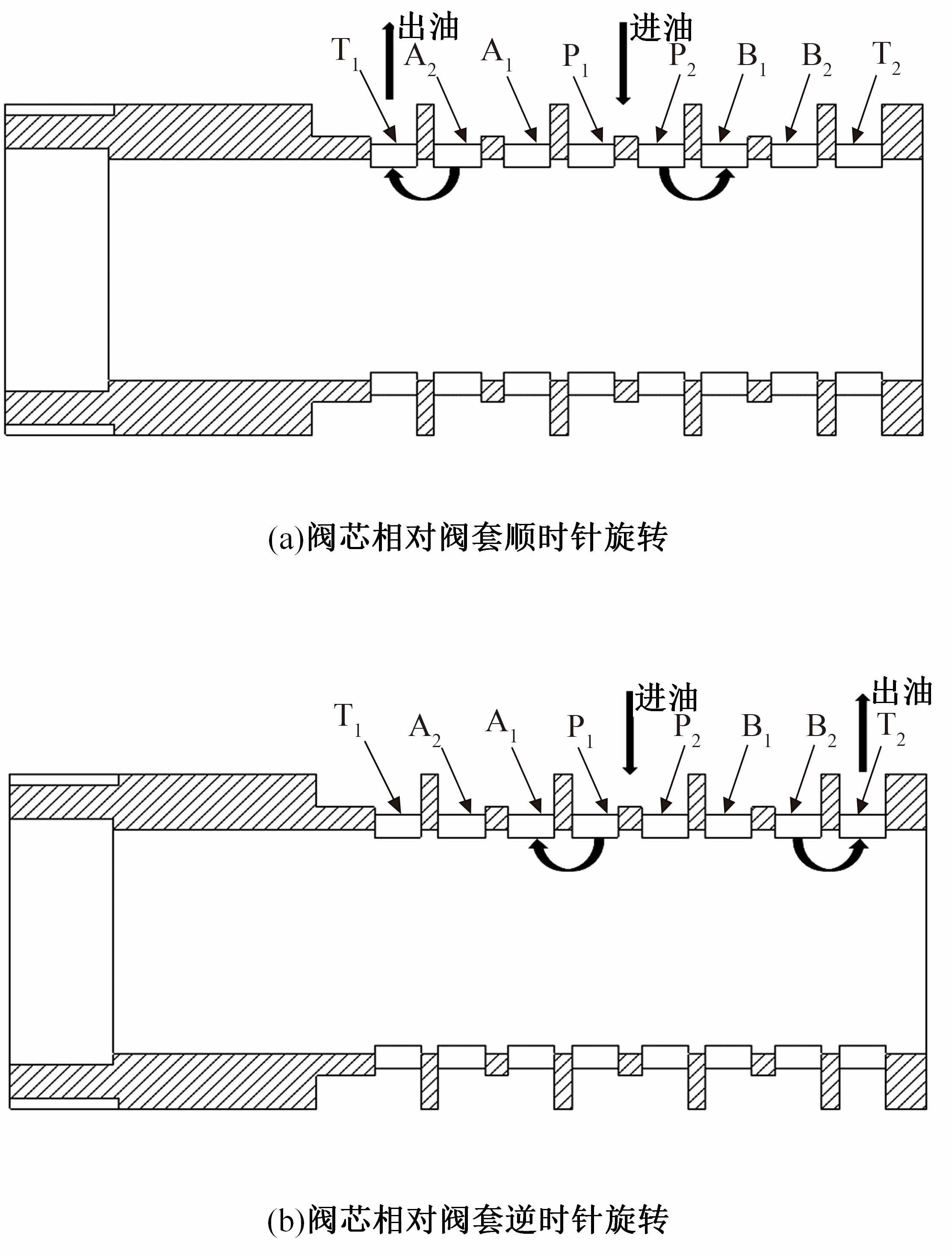

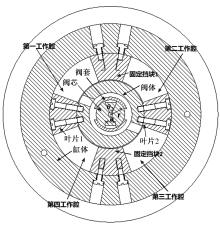

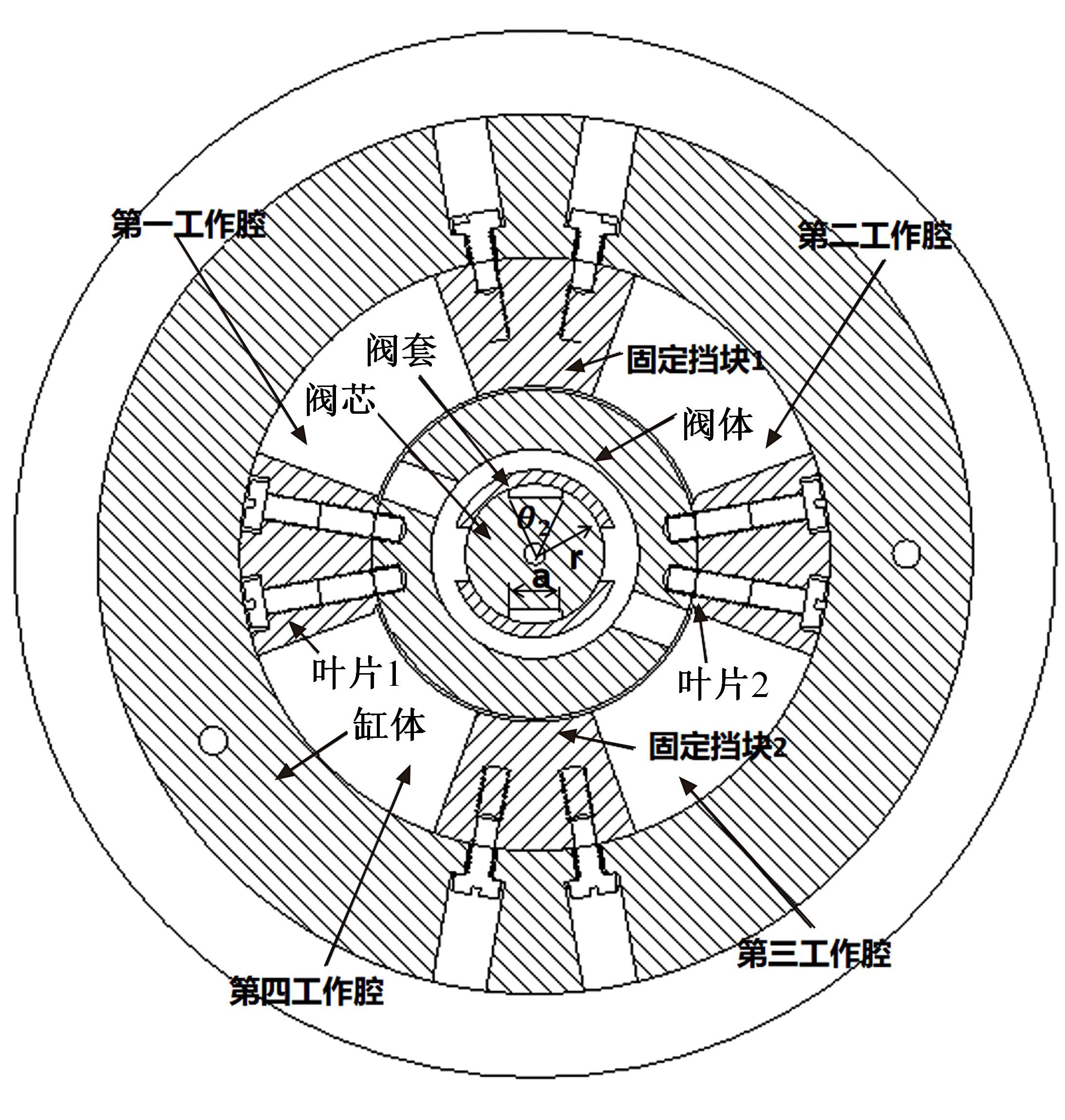

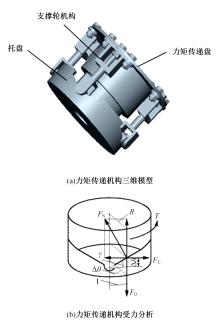

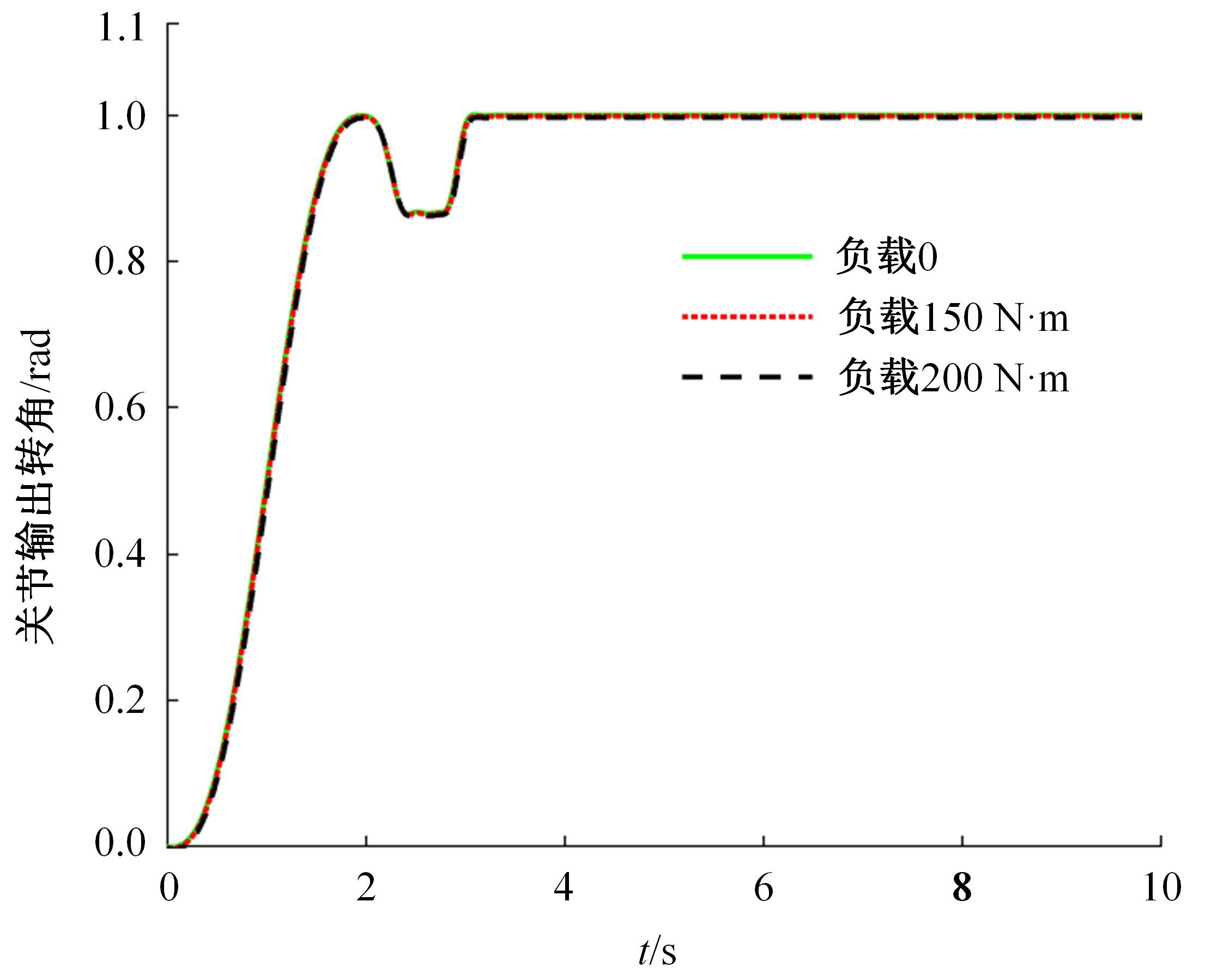

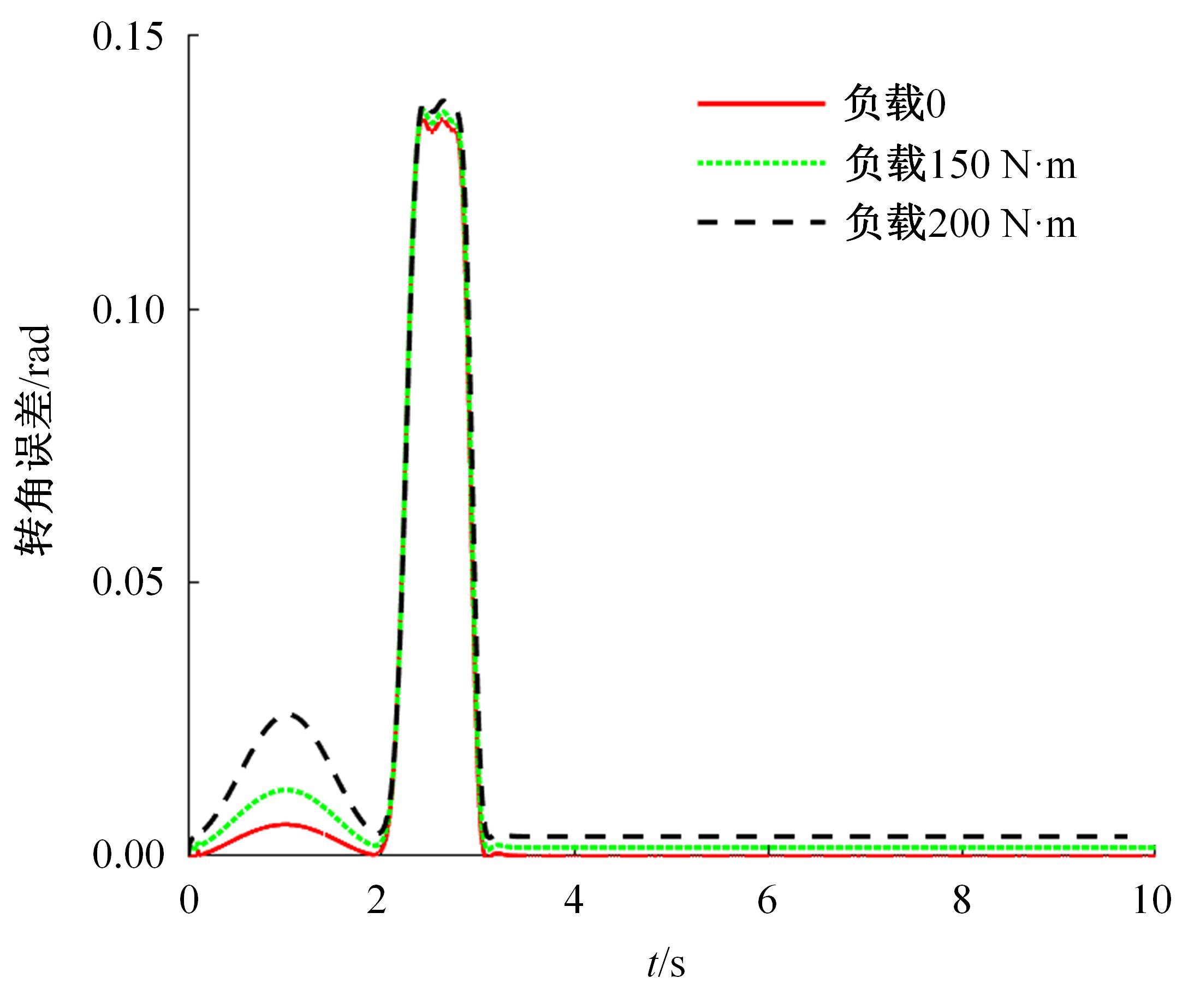

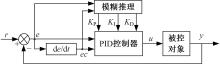

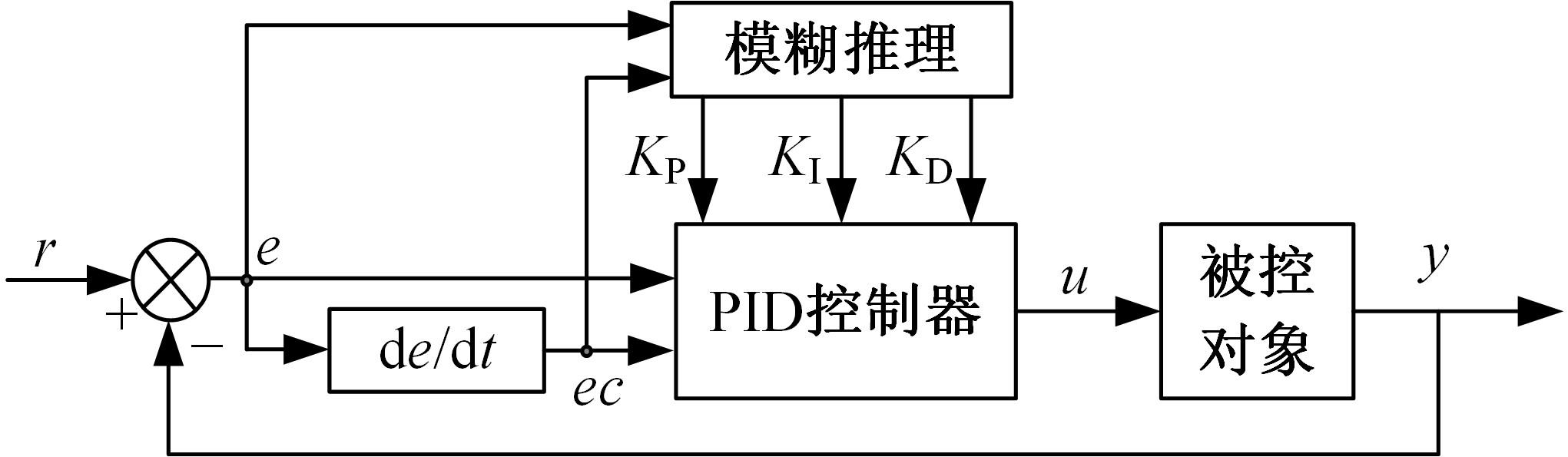

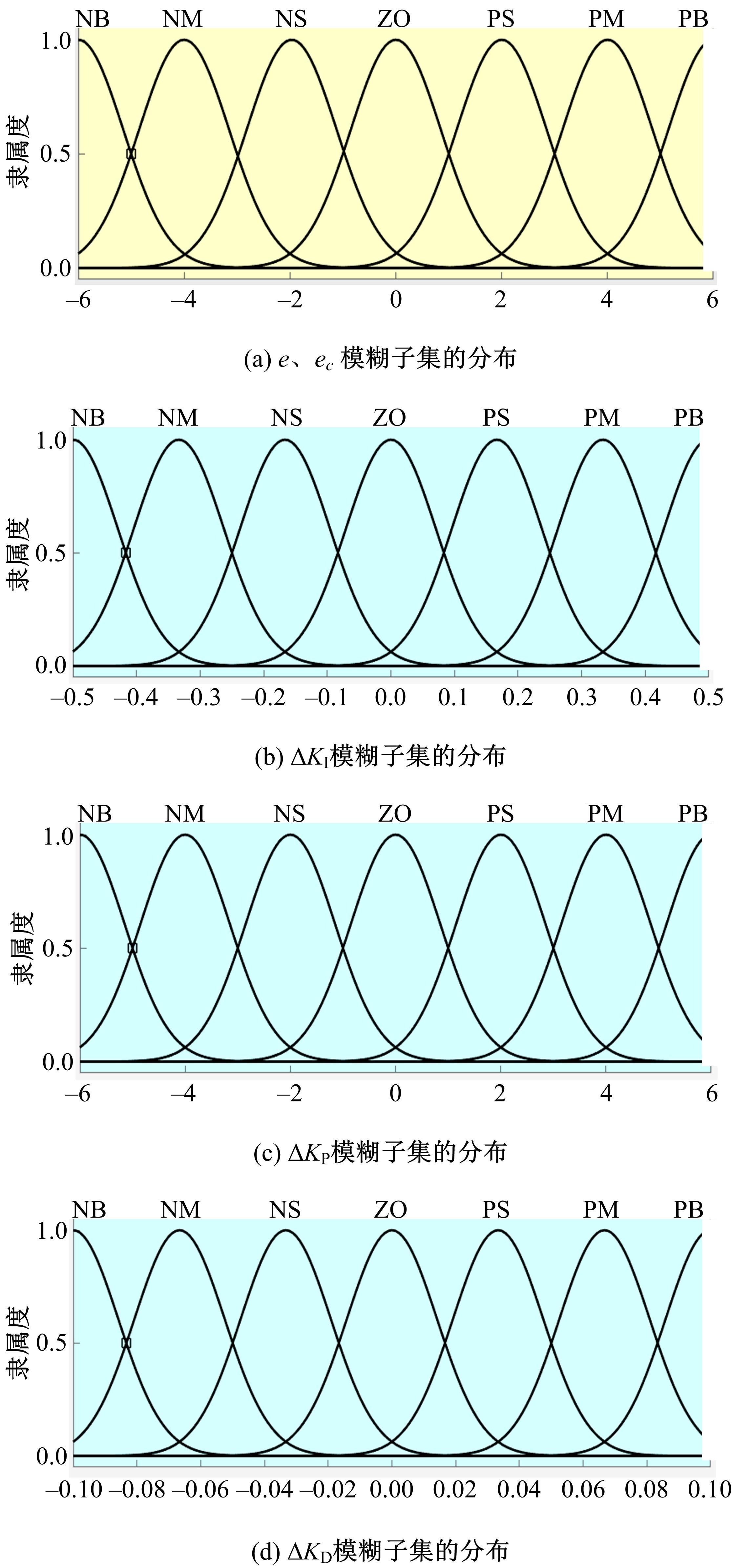

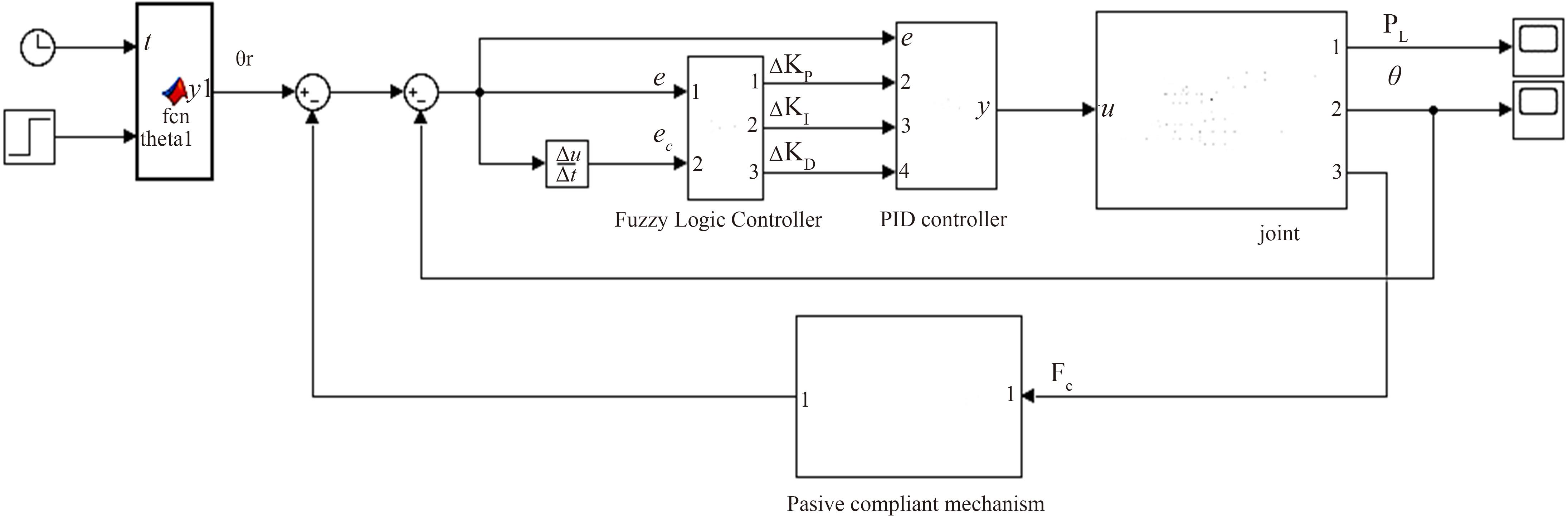

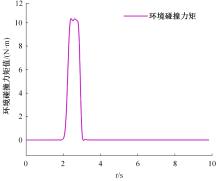

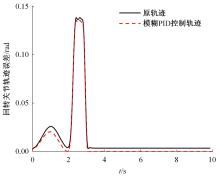

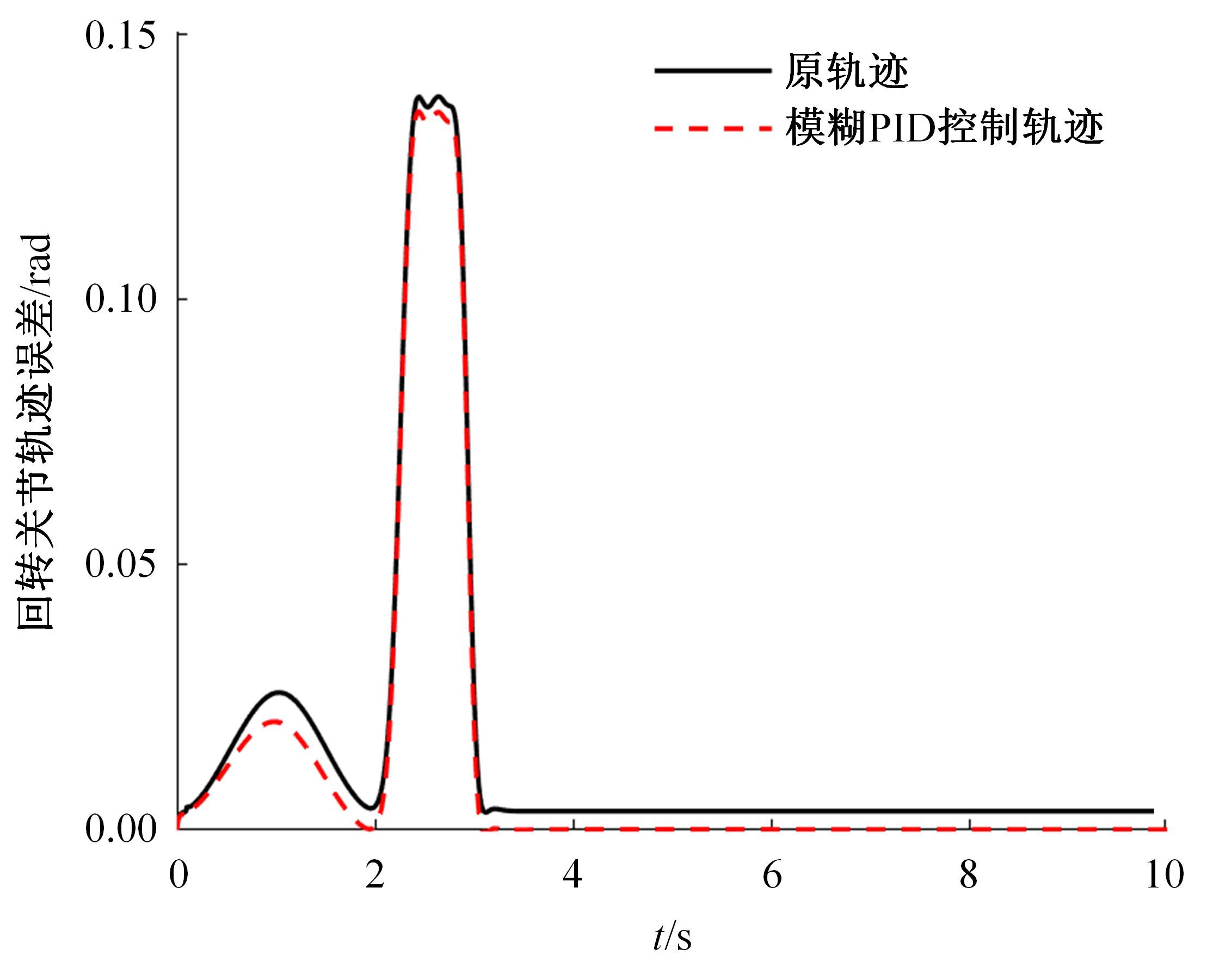

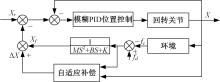

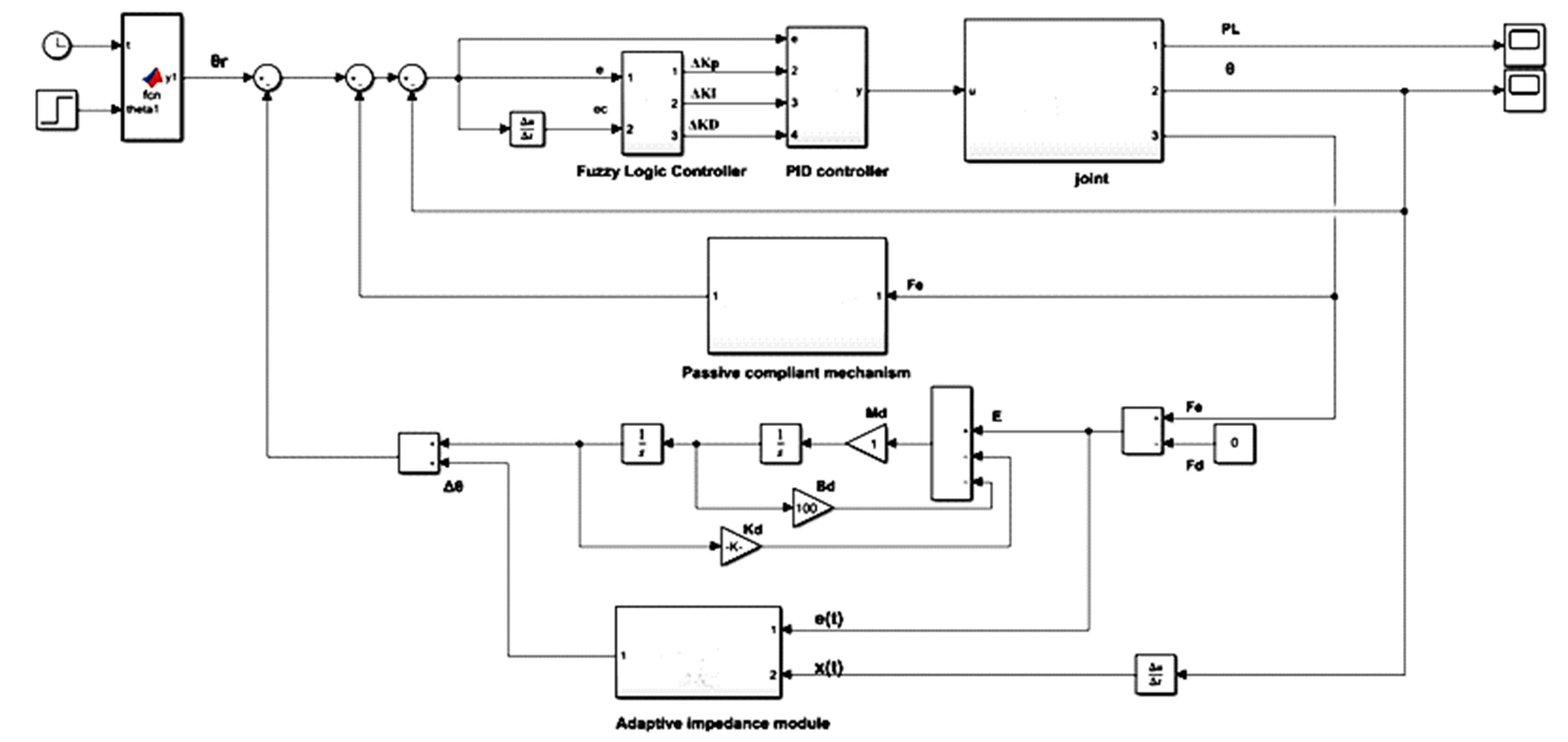

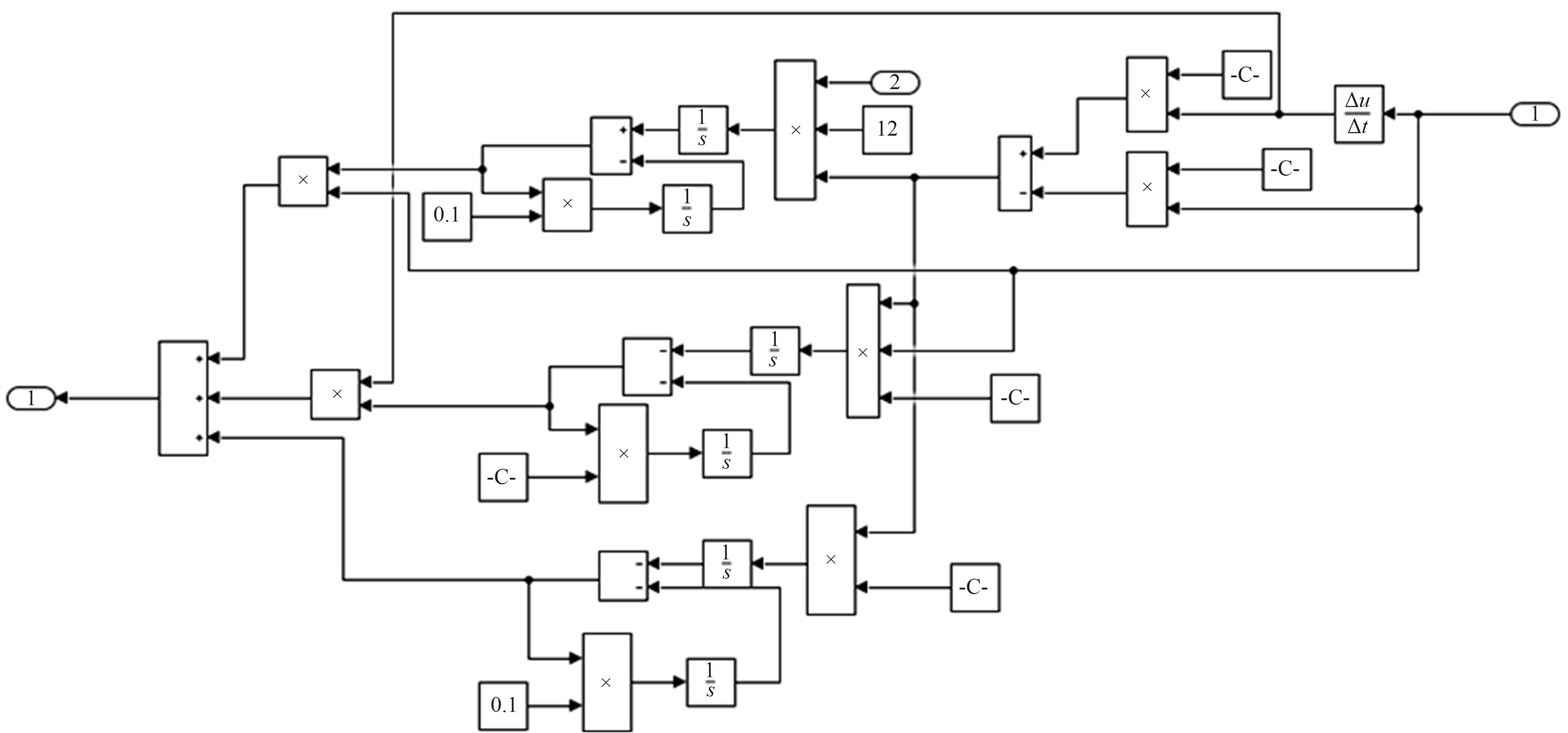

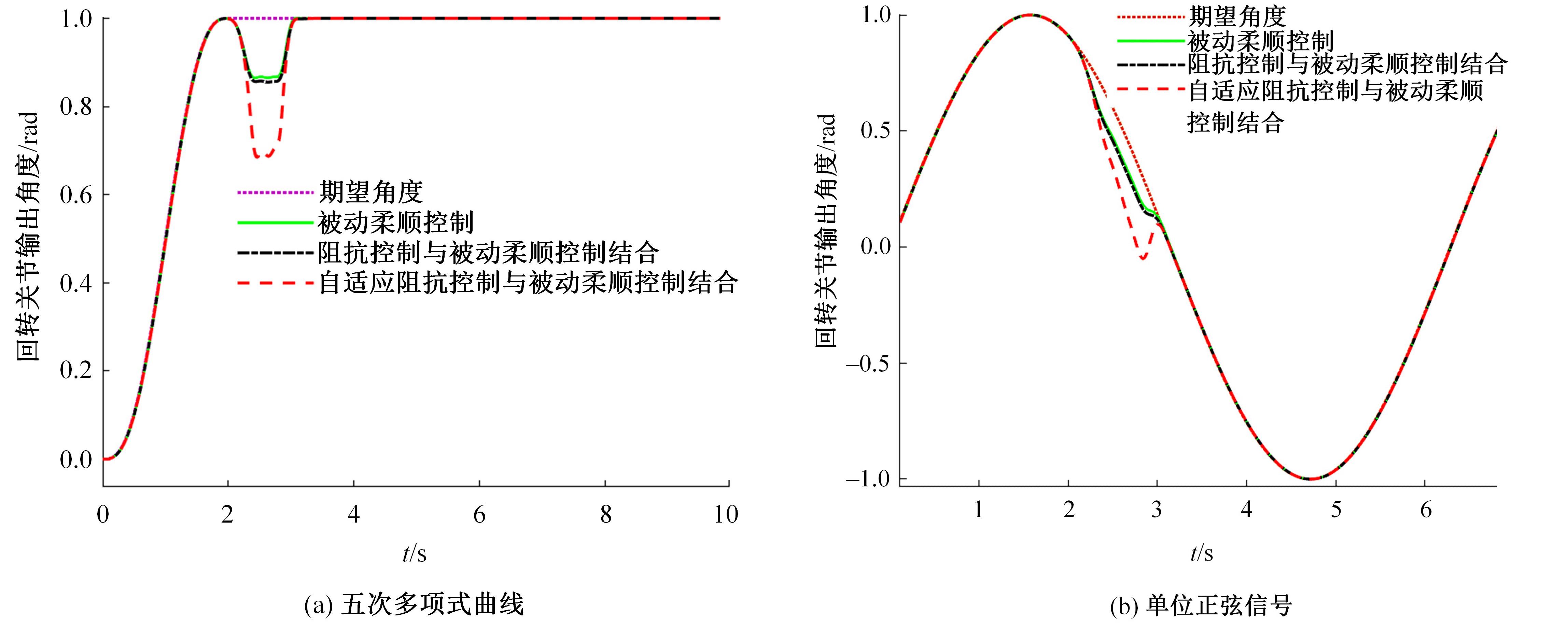

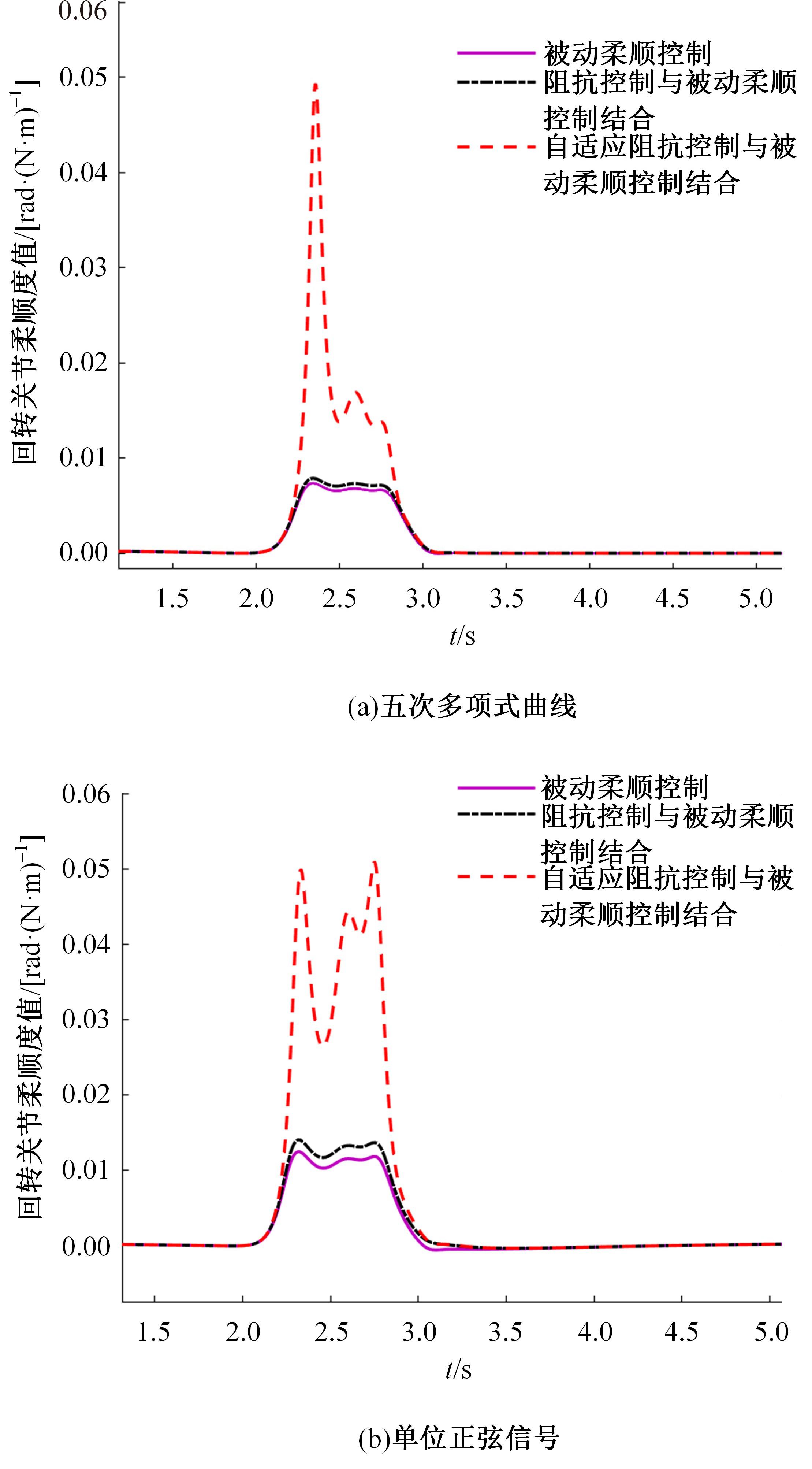

双叶片液压被动柔顺回转关节在受到外界环境的碰撞时,关节的被动柔顺性会使关节阀体输出转角产生回调,碰撞结束后,输出转角又会迅速恢复。为了有效吸收剩余的冲击能量,本文将自适应阻抗控制作为回转关节的主动柔顺控制,与关节的被动柔顺控制相结合,实现对关节的主被动联合柔顺控制,增大了回转关节在受到碰撞时的回调角度,能够更好地化解环境碰撞力。同时在关节的控制系统中设计并添加了一个模糊自适应PID(比例-积分-微分)控制器,作为自适应阻抗控制中的位置控制器,能够减小回转关节输出转角恢复后的稳态误差,提高了关节与外界接触时的安全性。

中图分类号:

- TH12

| 1 | 杨嘉伟. 液压机器人关节柔顺控制的研究与实现[D]. 黑龙江: 哈尔滨工业大学机电工程学院,2015. |

| Yang Jia-wei. Research and implementation of joint compliance control of hydraulic robot[D]. Heilongjiang: School of Mechanical and Electrical Engineering, Harbin Institute of Technology, 2015 | |

| 2 | Peng J, Yang Z, Ma T. Position/force tracking impedance control for robotic systems with uncertainties based on adaptive Jacobian and neural network[J]. Complexity, 2019: No.1406534. |

| 3 | 张程博. 液压驱动足式机器人单腿关节柔顺控制研究[D]. 哈尔滨: 哈尔滨工业大学机电工程学院,2019. |

| Zhang Cheng-bo. Research on compliance control of single leg joint of hydraulically driven foot robot[D]. Harbin: School of Mechanical and Electrical Engineering, Harbin Institute of technology, 2019. | |

| 4 | Hogan N. Impedance control: an approach to manipulation: part I-theory, implementation and applications[J]. Journal of Dynamic Systems, Measurement, and Control, 1985,107(1): 1-24. |

| 5 | 李扬. 主被动相融合的抗冲击柔性关节及其控制研究[D]. 哈尔滨: 哈尔滨工业大学机电工程学院,2017. |

| Li Yang. Research on impact resistant flexible joint with active passive fusion and its control[D]. Harbin: School of Mechanical and Electrical Engineering, Harbin Institute of Technology, 2017. | |

| 6 | 尹正乾.上肢康复机器人主被动控制研究[D]. 哈尔滨: 哈尔滨工程大学机电工程学院, 2014. |

| Yin Zheng-qian. Research on active and passive control of upper limb rehabilitation robot[D]. Harbin: School of Mechanical and Electrical Engineering, Harbin Engineering University, 2014. | |

| 7 | 邢宏军.基于主被动柔顺的机器人旋拧阀门作业研究[D]. 哈尔滨: 哈尔滨工业大学机电工程学院,2017. |

| Xing Hong-jun. Research on robot screwing valve operation based on active passive compliance[D]. Harbin: School of Mechanical and Electrical Engineering, Harbin Institute of Technology, 2017. | |

| 8 | 柯贤锋, 王军政, 何玉东, 等.基于力反馈的液压足式机器人主/被动柔顺性控制[J]. 机械工程学报,2017, 53(1): 13-20. |

| Ke Xian-feng, Wang Jun-zheng, He Yu-dong, et al. Active/passive compliance control of hydraulic foot robot based on force feedback[J]. Journal of Mechanical Engineering, 2017, 53(1): 13-20. | |

| 9 | 刘纯键, 蒋林, 任利胜, 等. 液压伺服被动柔顺关节的柔顺特性分析[J]. 武汉科技大学学报: 自然科学版, 2021, 44(4): 270-276. |

| Liu Chun-jian, Jiang Lin, Ren Li-sheng, et al. Analysis of compliance characteristics of hydraulic servo passive compliant joint[J]. Journal of Wuhan University of science and Technology (Natural Science Edition), 2021, 44 (4): 270-276. | |

| 10 | Dong J, Xu J, Zhou Q, et al. Physical human-robot interaction force control method based on adaptive variable impedance[J]. Journal of the Franklin Institute, 2020, 357(12): 7864-7878. |

| 11 | 刘董, 李京慧, 迟宗涛, 等. 基于模糊PID控制的控温箱设计[J]. 传感器与微系统, 2021, 40(3): 73-76. |

| Liu Dong, Li Jing-hui, Chi zong-tao, et al. Design of temperature control box based on fuzzy PID control[J]. Sensors and Microsystems, 2021, 40 (3): 73-76. | |

| 12 | 金光哲, 段科俊, 王璐. 基于模糊PID控制的恒压浇灌系统研究[J]. 安徽农业科学, 2021, 49(2): 206-210. |

| Jin Guang-zhe, Duan Ke-jun, Wang Lu. Research on constant pressure irrigation system based on Fuzzy PID control[J]. Anhui Agricultural Science, 2021,49(2): 206-210. | |

| 13 | 李焕, 王奉文, 徐世杰, 等. 基于阻抗控制的机械臂末端工具的柔顺控制[J]. 空间控制技术与应用,2019, 45(1): 20-26. |

| Li Huan, Wang Feng-wen, Xu Shi-jie, et al. Compliance control of manipulator end tool based on impedance control[J]. Space Control Technology and Application, 2019, 45 (1): 20-26. | |

| 14 | Chen P, Zhao H, Yan X, et al. Force control polishing device based on fuzzy adaptive impedance control[C]//International Conference on Intelligent Robotics and Applications, Shanghai, China, 2019: 181-194. |

| 15 | 王懂. 基于阻抗控制的机械臂力/位置控制关键技术研究[D]. 济南: 山东大学机械工程学院, 2018. |

| Wang Dong. Research on key technologies of force/position control of manipulator based on impedance control[D]. Jinan: School of Mechanical Engineering, Shandong University, 2018. |

| [1] | 陈淑江,徐春望,路长厚,王康. 嵌入控制油腔的静压主轴轴心运动主动控制分析与试验[J]. 吉林大学学报(工学版), 2023, 53(4): 973-981. |

| [2] | 蒋林,杨立,张文俊,张琼玉,吴艳霞. 在障碍物检测时对斜坡点云的检测处理算法[J]. 吉林大学学报(工学版), 2023, 53(11): 3221-3228. |

| [3] | 蒋林,周玲,赵慧. 液压伺服柔驱机构设计及其刚度连续可调分析[J]. 吉林大学学报(工学版), 2022, 52(7): 1499-1508. |

| [4] | 杨志军,高忠义,王丽君,黄观新,危宇泰. 面向刚柔耦合定位平台的模型预测控制算法[J]. 吉林大学学报(工学版), 2022, 52(12): 2806-2815. |

| [5] | 胡鹏,朱建新,刘昌盛,张大庆. 液压挖掘机动臂势能交互回收利用系统特性[J]. 吉林大学学报(工学版), 2022, 52(10): 2256-2264. |

| [6] | 冯建鑫,王强,王雅雷,胥彪. 基于改进量子遗传算法的超声电机模糊PID控制[J]. 吉林大学学报(工学版), 2021, 51(6): 1990-1996. |

| [7] | 李学勇,赵仲秋,张春松,路长厚. 基于有限元的人体⁃机械手交互力计算方法[J]. 吉林大学学报(工学版), 2021, 51(5): 1612-1619. |

| [8] | 施昕昕,黄家才,高芳征. 基于分数阶BICO滤波器的运动控制测量噪声抑制[J]. 吉林大学学报(工学版), 2021, 51(5): 1873-1878. |

| [9] | 于萍,穆特,朱黎辉,周子业,宋杰. 钻具输送装置非线性动力学分析及稳定性控制[J]. 吉林大学学报(工学版), 2021, 51(3): 820-830. |

| [10] | 姜继海,赵存然,张冠隆,车明阳. 航空煤油柱塞泵摩擦副涂层材料摩擦性能[J]. 吉林大学学报(工学版), 2021, 51(1): 147-153. |

| [11] | 胡明伟,王洪光,潘新安. 基于正交设计的协作机器人全域结构优化设计[J]. 吉林大学学报(工学版), 2021, 51(1): 370-378. |

| [12] | 张茹斌, 占礼葵, 彭伟, 孙少明, 刘骏富, 任雷. 心肺功能评估训练系统的恒功率控制[J]. 吉林大学学报(工学版), 2018, 48(4): 1184-1190. |

| [13] | 靳立强, 刘刚, 陈鹏飞. 汽车电子稳定控制系统的分层控制策略及试验[J]. 吉林大学学报(工学版), 2016, 46(6): 1765-1771. |

| [14] | 彭贝, 高宇, 冯培恩, 邱清盈. 液压挖掘机回转启动过程节能技术[J]. 吉林大学学报(工学版), 2016, 46(6): 1912-1921. |

| [15] | 刘昌盛, 何清华, 张大庆, 李铁辉, 龚俊, 赵喻明. 混合动力挖掘机势能回收系统参数优化与试验[J]. 吉林大学学报(工学版), 2014, 44(2): 379-386. |

|

||