吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (4): 890-901.doi: 10.13229/j.cnki.jdxbgxb.20221107

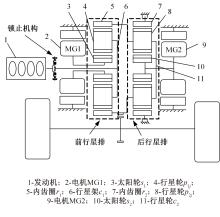

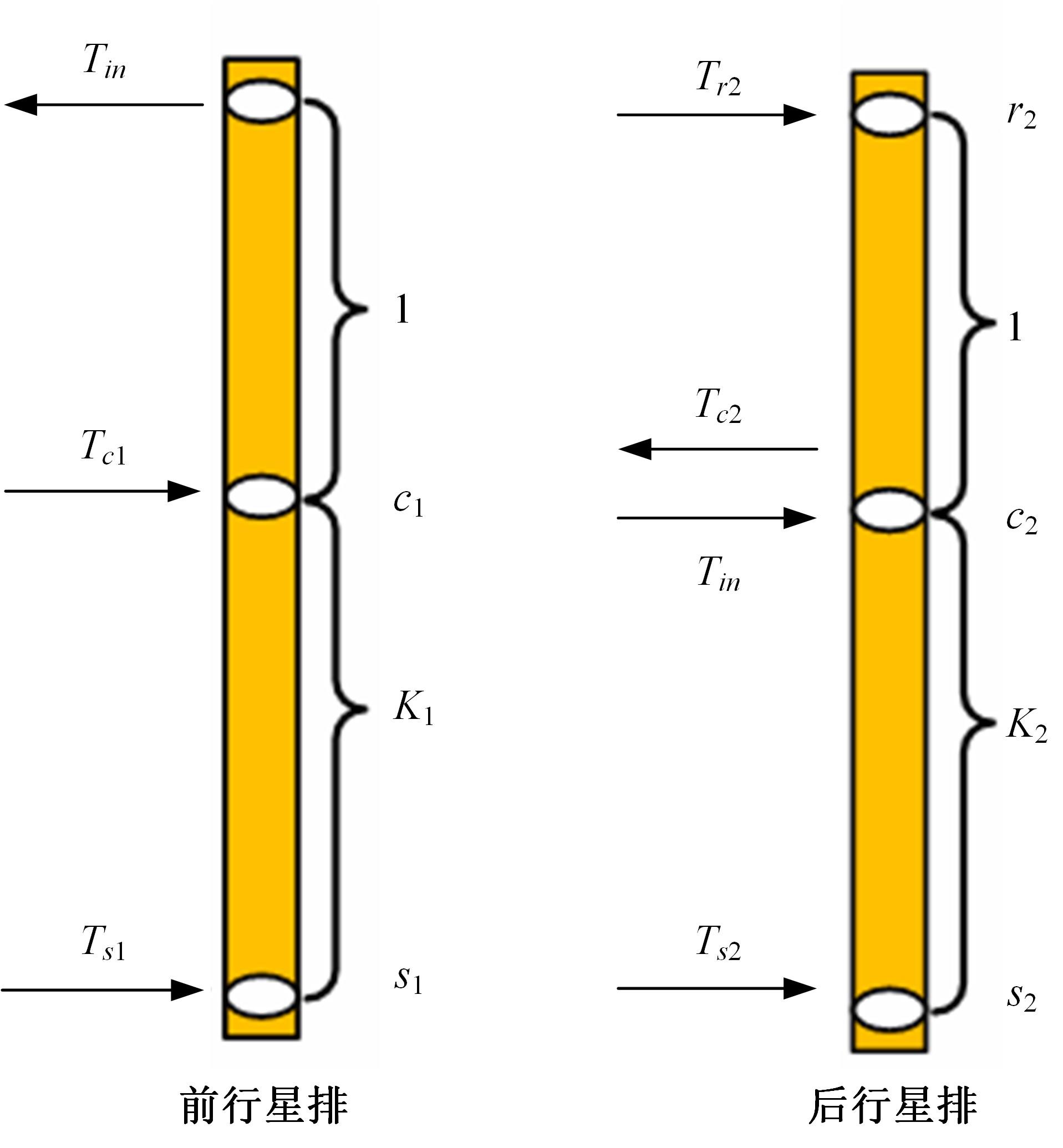

双行星排式混合动力传动系统非线性振动响应特性分析

汪少华1,2( ),张启睿1,施德华1,2(

),张启睿1,施德华1,2( ),殷春芳3,李春4

),殷春芳3,李春4

- 1.江苏大学 汽车工程研究院,江苏 镇江 212013

2.江苏省新能源汽车电驱动系统与智能控制工程研究中心,镇江 212013

3.江苏大学 电气信息工程学院,江苏 镇江 212013

4.金龙联合汽车工业(苏州)有限公司,江苏 苏州 215026

Analysis of nonlinear vibration response characteristics of hybrid transmission system with dual-planetary gear sets

Shao-hua WANG1,2( ),Qi-rui ZHANG1,De-hua SHI1,2(

),Qi-rui ZHANG1,De-hua SHI1,2( ),Chun-fang YIN3,Chun LI4

),Chun-fang YIN3,Chun LI4

- 1.Automotive Engineering Research Institute,Jiangsu University,Zhenjiang 212013,China

2.Jiangsu Province Engineering Research Center of Electric Drive System and Intelligent Control for Alternative Vehicles,Zhenjiang 212013,China

3.School of Electrical and Information Engineering,Jiangsu University,Zhenjiang 212013,China

4.Higer Bus Company Limited,Suzhou 215026,China

摘要:

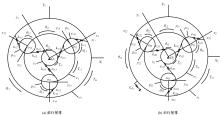

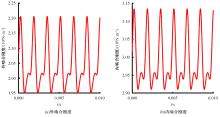

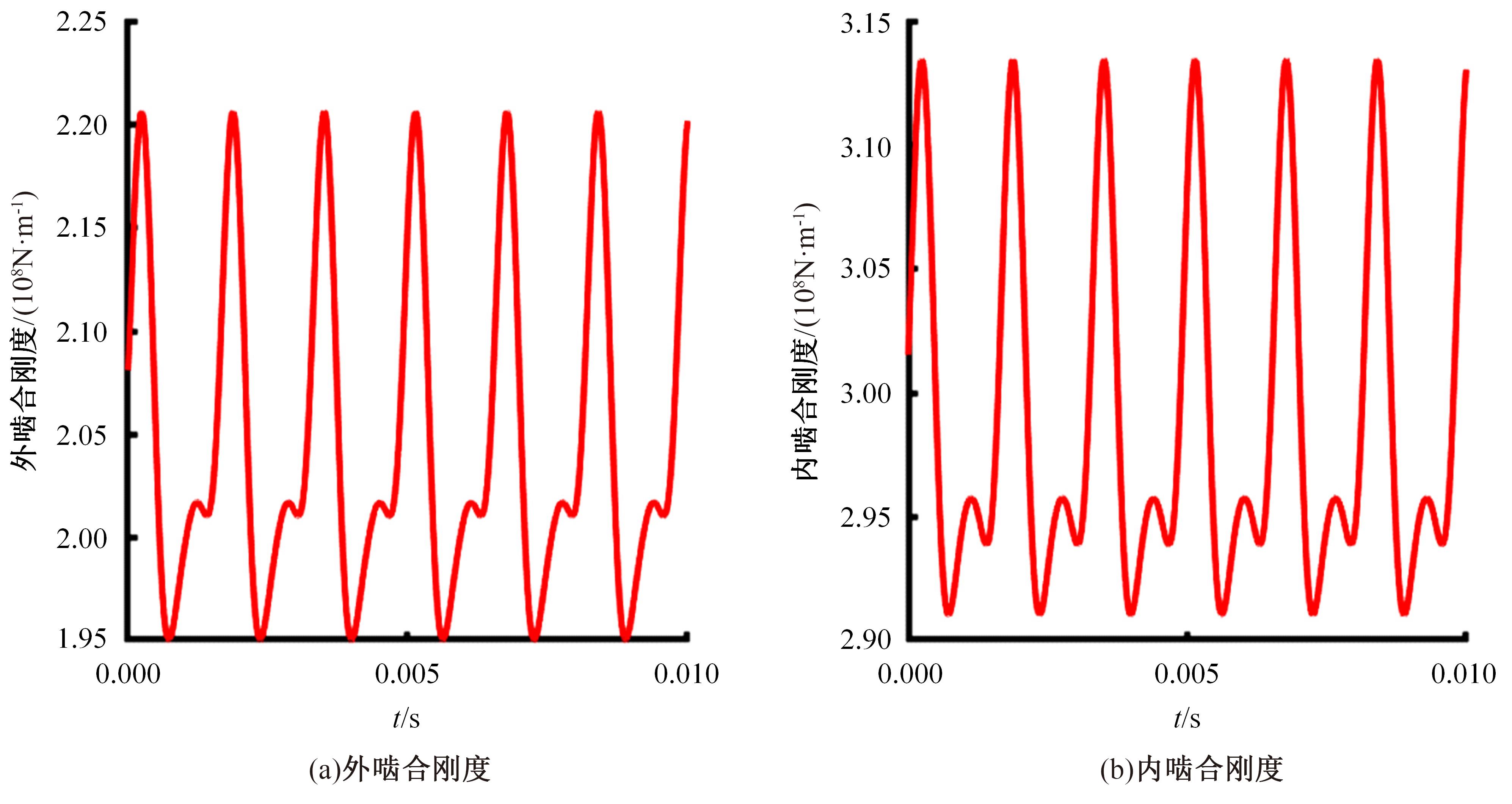

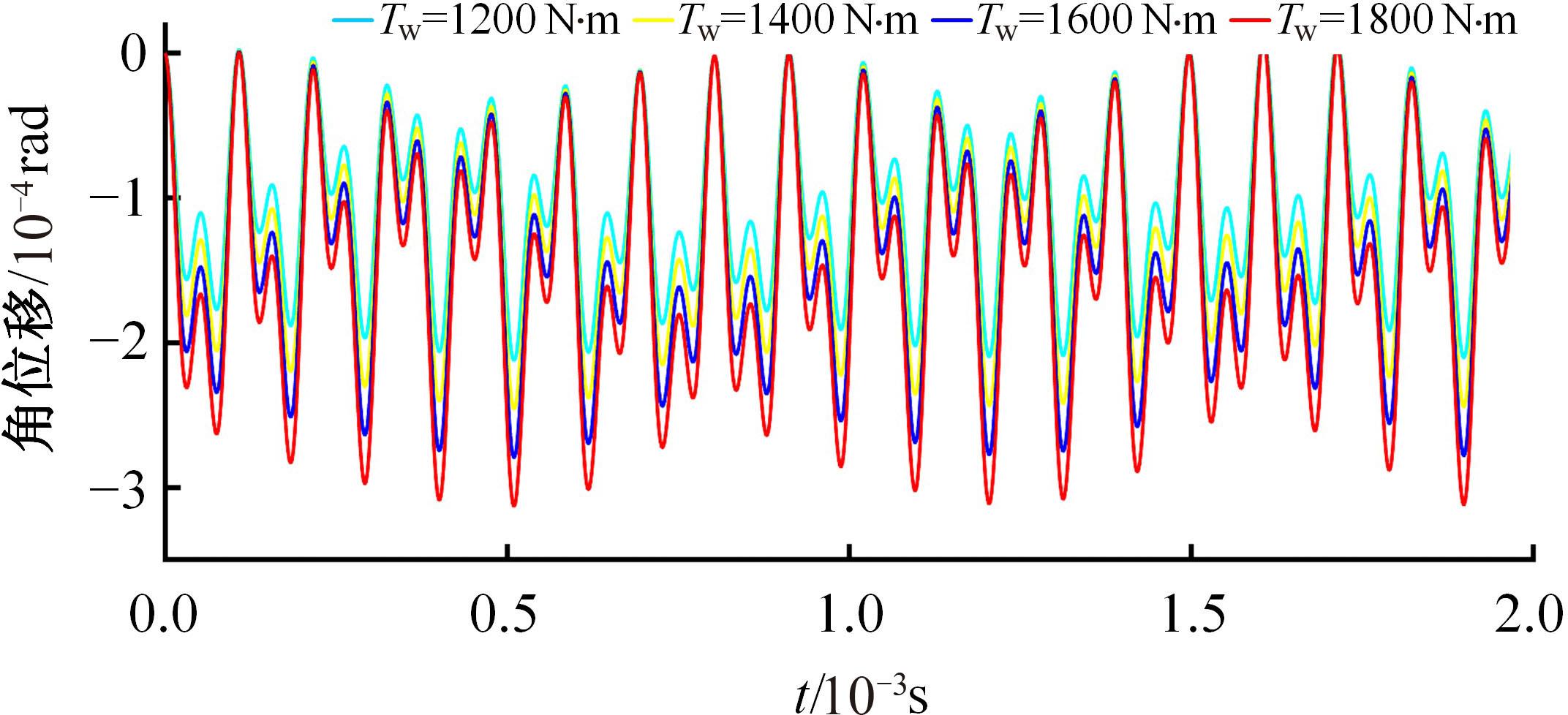

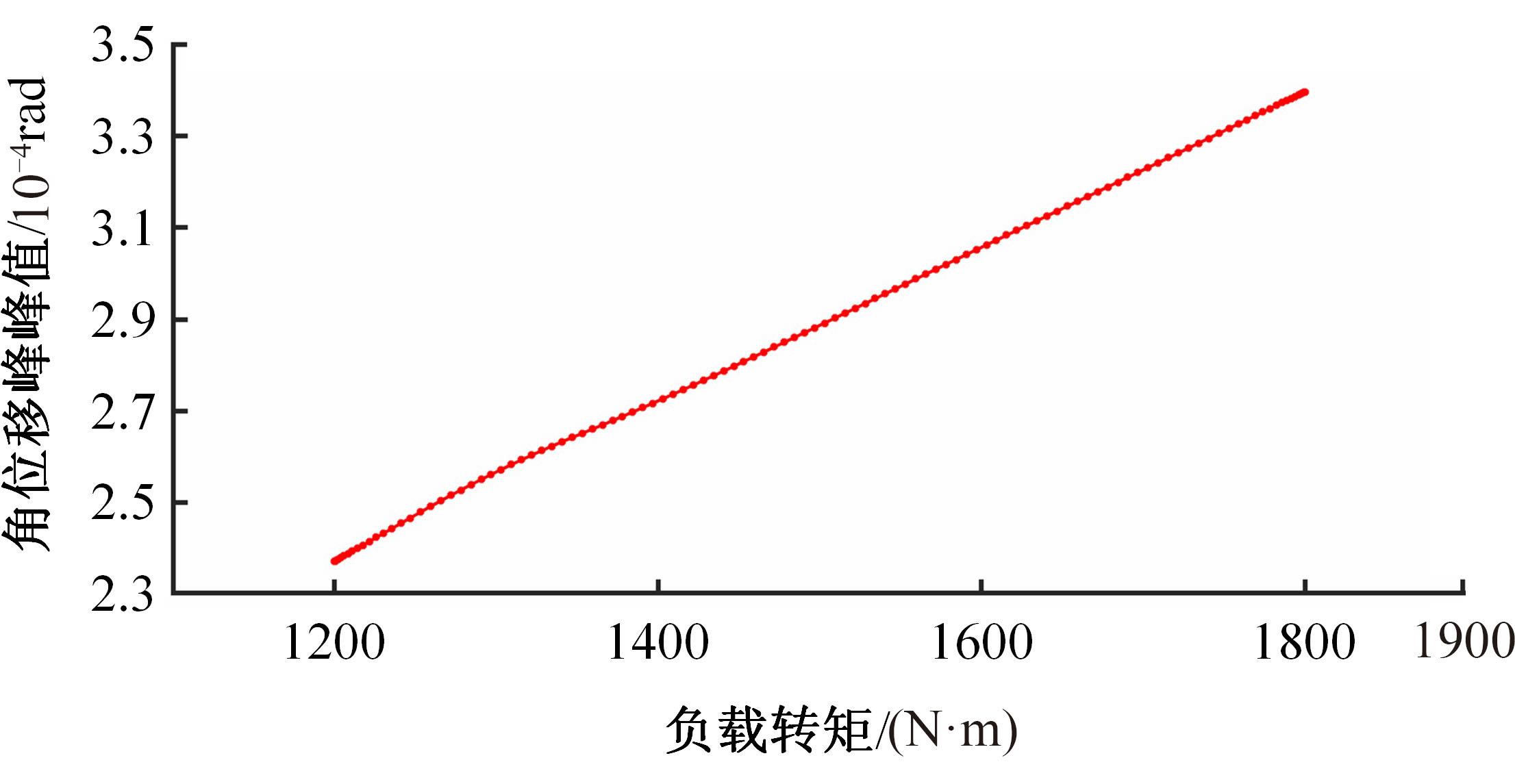

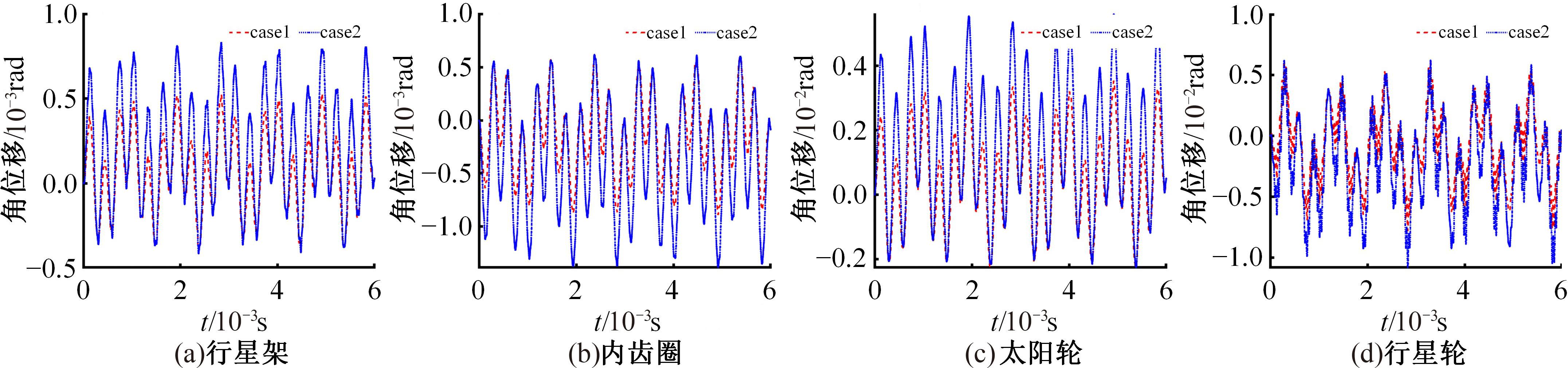

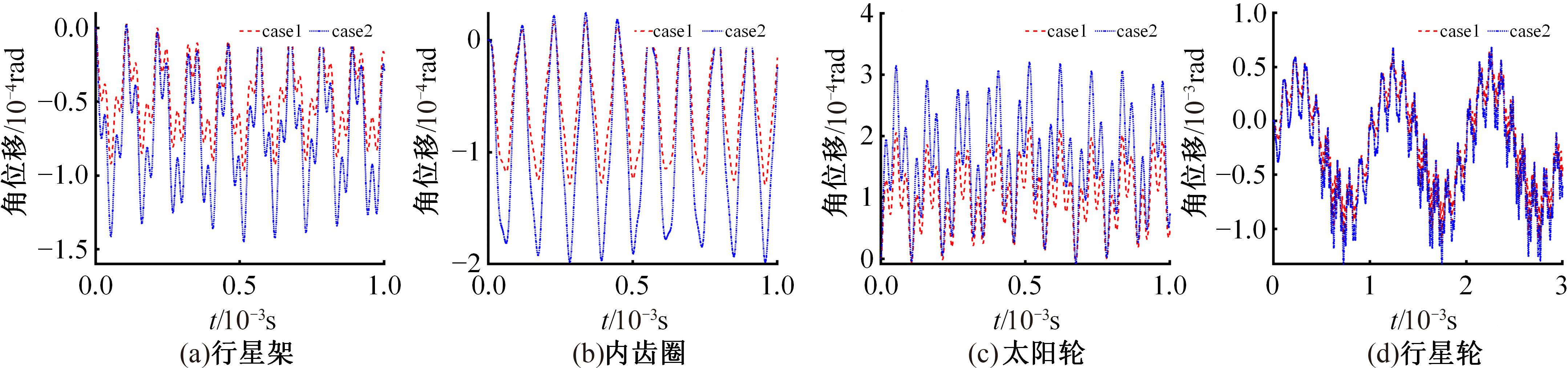

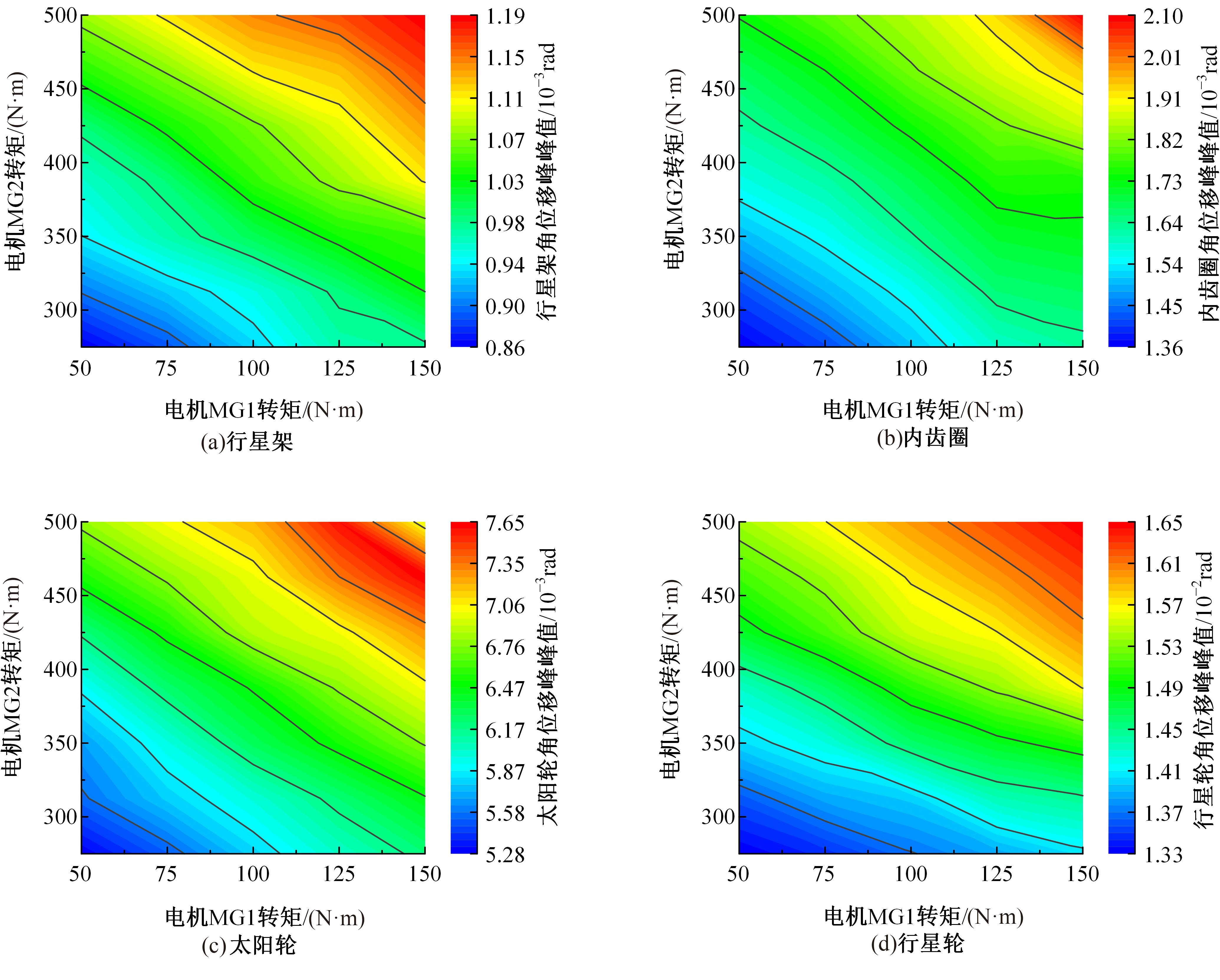

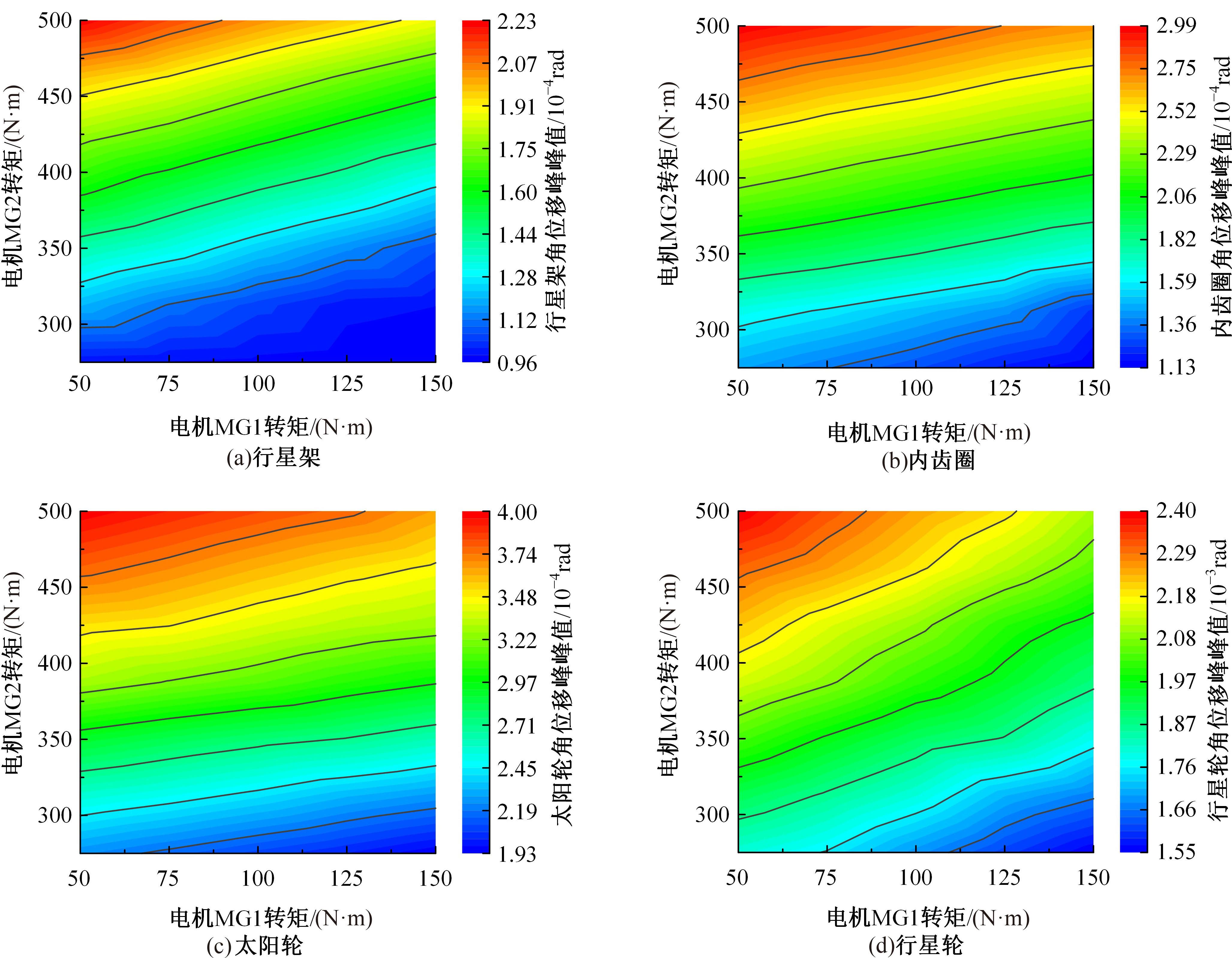

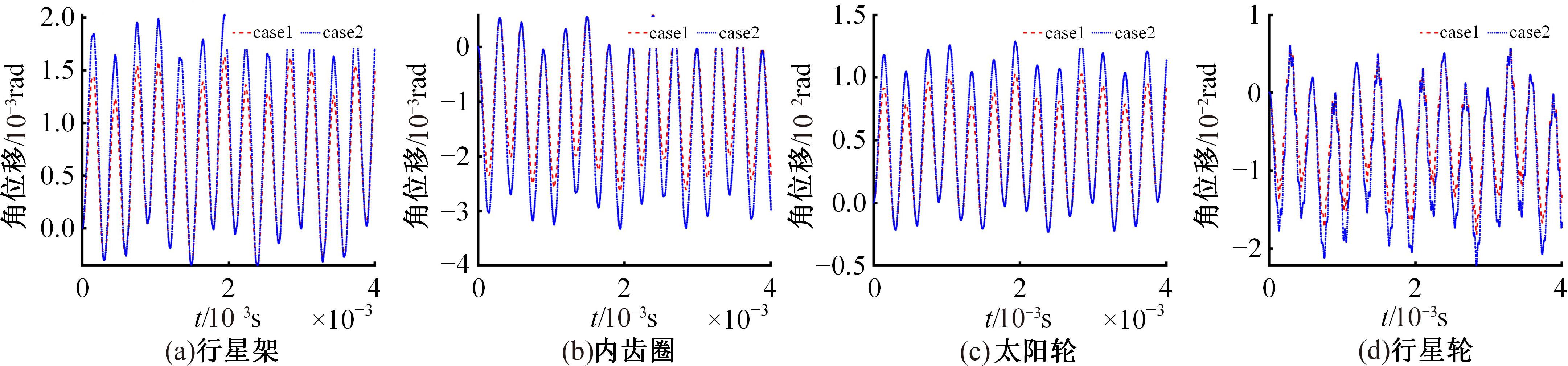

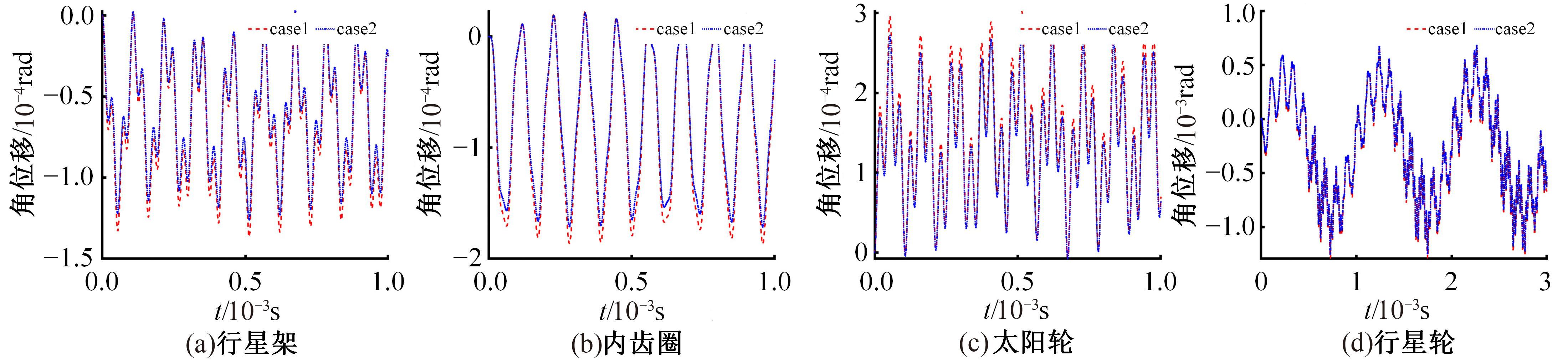

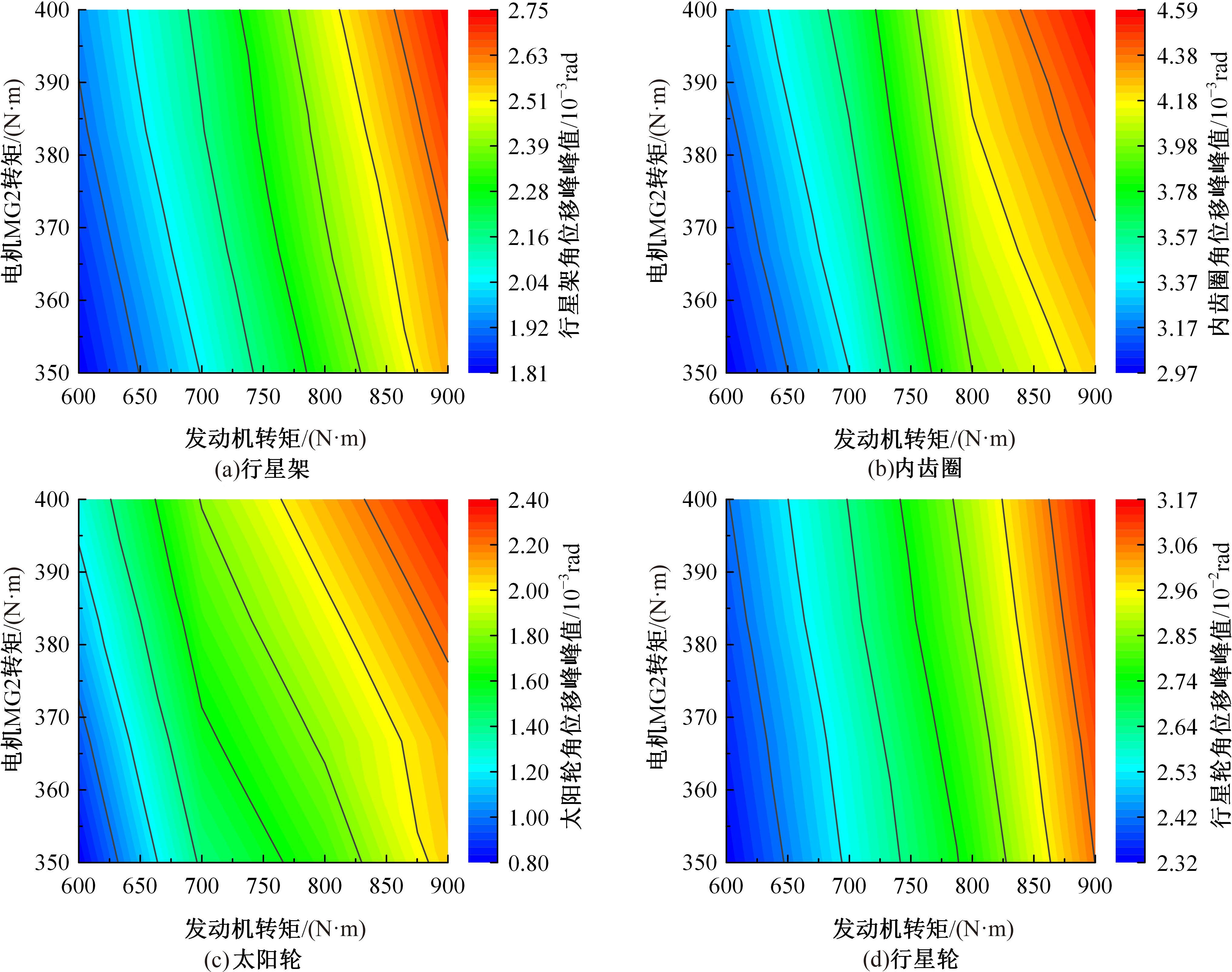

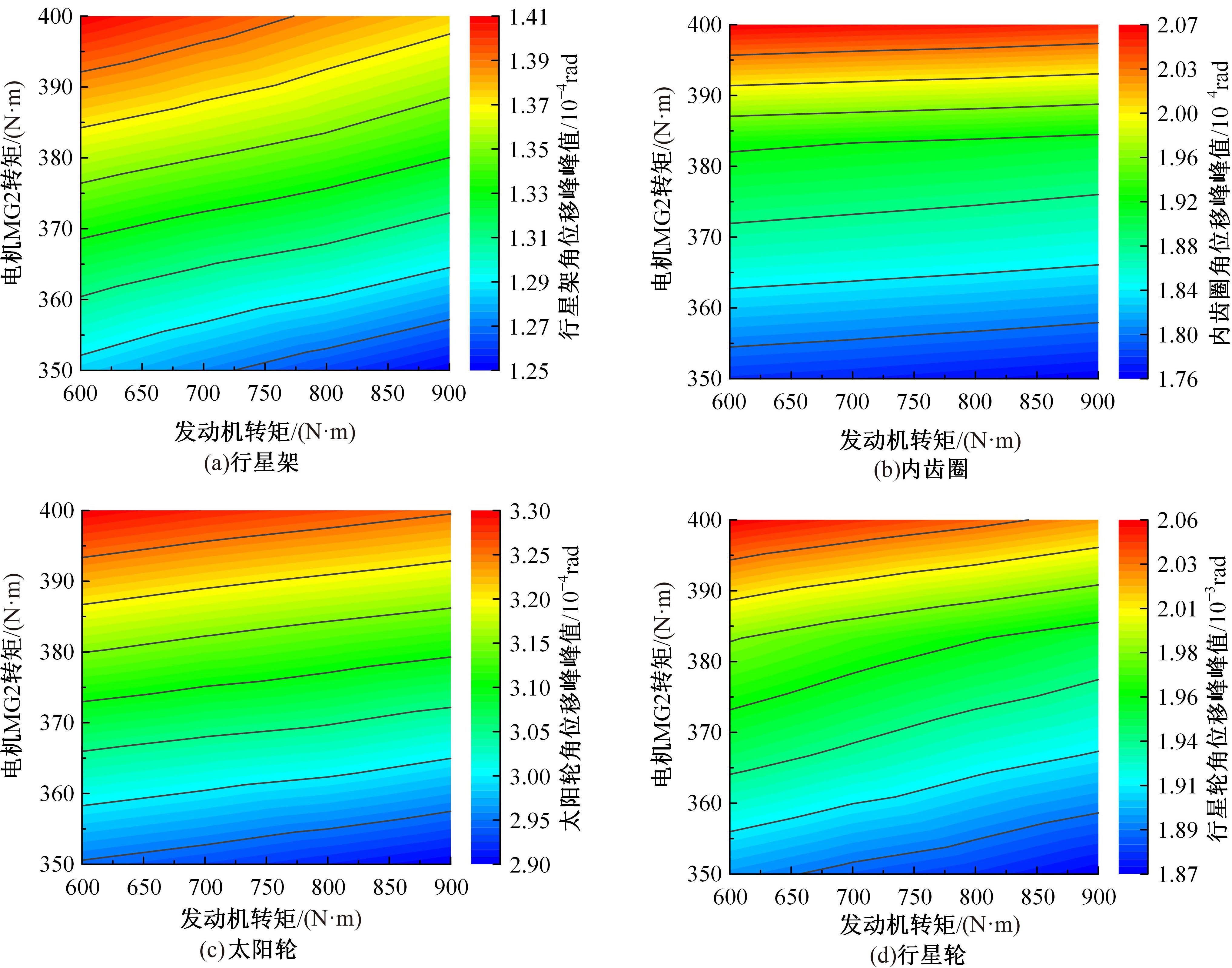

针对一种双行星排混合动力传动系统,建立包含综合时变啮合刚度和啮合误差等内部激励以及不同动力源输出转矩和负载转矩等外部激励的纯轴向扭转非线性动力学模型。在此基础上,针对纯电动和混合动力驱动模式,采用四阶Runge-Kutta法研究系统在不同转矩激励下的非线性高频振动特性,获取不同动力源转矩分配对行星排各构件振动响应行为的影响。研究结果表明,在双电机联合驱动模式下,前行星排振动响应量大于后行星排,后行星排的振动响应波动范围大于前行星排,电机MG2应优先工作在转矩较大且较为恒定的工作区间;混合动力驱动模式下,前行星排受电机MG1影响较大,振动响应量及振动响应波动范围大于后行星排,电机MG1应保持在较为恒定的工作区间,电机MG2优先工作在较大的转矩区间。研究结果将为基于双行星排构型的功率分流式混合动力汽车系统动力学行为分析与转矩决策优化提供理论基础。

中图分类号:

- U463.2

| 1 | Shi T Z, Zhao F Q, Hao H, et al. Development trends of transmissions for hybrid electric vehicles using an optimized energy management strategy[J]. Automotive Innovation, 2018, 1(4): 291-299. |

| 2 | 宋大凤, 高福旺, 曾小华, 等. 基于虚拟样机模型行星混动系统受迫振动响应分析[J]. 吉林大学学报:工学版, 2020, 50(6): 1974-1982. |

| Song Da-feng, Gao Fu-wang, Zeng Xiao-hua,et al. Analysis of forced vibration response of planetary hybrid system based on virtual prototype model[J]. Journal of Jilin University (Engineering and Technology Edition), 2020, 50(6): 1974-1982. | |

| 3 | Kahraman A. Planetary gear train dynamics[J]. ASME Journal of Mechanical Design, 1994, 116(3): 714-720. |

| 4 | Ahmet K. Free torsional vibration characteristics of compound planetary gear sets[J]. Mechanism and Machine Theory, 2001, 36(6): 953-971. |

| 5 | Wu X H, Robert G P. Modal properties of planetary gears with an elastic continuum ring gear[J]. Journal of Applied Mechanics, 2008, 75(3):No. 031014. |

| 6 | 孙涛, 沈允文. 行星齿轮传动非线性动力学模型与方程[J]. 机械工程学报, 2002, 38(3): 6-9. |

| Sun Tao, Shen Yun-wen. Nonlinear dynamic model and equation of planetary gear transmission[J]. Journal of Mechanical Engineering, 2002, 38(3): 6-9. | |

| 7 | Sheng D P, Zhu R P, Jin G H, et al. Dynamic load sharing characteristics and sun gear radial orbits of double-row planetary gear train[J]. Journal of Central South University, 2015, 22(10): 3806-3816. |

| 8 | Mo S, Zhang Y D, Wu Q, et al. Load sharing behavior analysis method of wind turbine gearbox in consideration of multiple-errors[J]. Renewable Energy, 2016, 97(11): 481-491. |

| 9 | 林何, 王三民, 董金城. 斜齿行星齿轮传动系统振动模式与动载特性[J]. 航空动力学报, 2015, 30(9): 2298-2304. |

| Lin He, Wang San-min, Dong Jin-cheng. Vibration mode and dynamic load characteristics of helical planetary gear transmission system[J]. Journal of Aerodynamics, 2015, 30(9): 2298-2304. | |

| 10 | 李思千, 巫世晶, 王晓笋. 两级行星齿轮传动系统动态均载特性分析[J]. 机械传动, 2016, 40(10) : 11-16. |

| Li Si-qian, Wu Shi-jing, Wang Xiao-sun. Analysis of dynamic load sharing characteristics of two-stage planetary gear transmission system[J]. Mechanical transmission, 2016, 40(10): 11-16. | |

| 11 | 胡鹏, 路金昌, 张义民. 含时变刚度及侧隙的多级齿轮系统非线性动力学特性分析[J]. 振动与冲击, 2014, 33(15): 150-156. |

| Hu Peng, Lu Jin-chang, Zhang Yi-min. Nonlinear dynamic characteristics analysis of multistage gear system with time-varying stiffness and backlash[J]. Vibration and Shock, 2014, 33(15): 150-156. | |

| 12 | 孙智民, 季林红, 沈允文. 2K-H行星齿轮传动非线性动力学[J]. 清华大学学报: 自然科学版, 2003(5):636-639. |

| Sun Zhi-min, Ji Lin-hong, Shen Yun-wen. Nonlinear dynamics of 2K-H planetary gear transmission [J]. Journal of Tsinghua University (Natural Science Edition), 2003(5): 636-639. | |

| 13 | 唐友福, 王磊, 邹龙庆. 变转速风电行星齿轮传动系统动力学特性[J]. 江苏大学学报:自然科学版, 2018, 39(5): 550-555. |

| Tang You-fu, Wang Lei, Zou Long-qing. Dynamic characteristics of variable speed wind power planetary gear transmission system[J]. Journal of Jiangsu University(Natural Science Edition), 2018, 39 (5): 550-555. | |

| 14 | 向玲, 刘随贤, 张军华. 风电齿轮箱两级行星齿轮传动系统的非线性动力学特性[J]. 振动与冲击, 2020, 39(15): 193-199, 229. |

| Xiang Ling, Liu Sui-xian, Zhang Jun-hua. Nonlinear dynamic characteristics of two-stage planetary gear transmission system of wind power gearbox[J]. Vibration and Shock, 2020, 39(15): 193-199, 229. | |

| 15 | 刘辉, 蔡仲昌, 项昌乐. 发动机激励下行星传动非线性合力的动态特性研究[J]. 振动、测试与诊断, 2014, 34(1): 83-89. |

| Liu Hui, Cai Zhong-chang, Xiang Chang-le. Research on dynamic characteristics of nonlinear resultant force of planetary transmission under engine excitation[J]. Vibration, Testing and Diagnosis, 2014, 34(1): 83-89. | |

| 16 | 蔡仲昌, 刘辉, 项昌乐, 等. 车辆多级行星传动系统强迫扭转振动与动载特性[J]. 吉林大学学报: 工学版, 2012, 42(1): 19-26. |

| Cai Zhong-chang, Liu Hui, Xiang Chang-le, et al. Forced torsional vibration and dynamic load characteristics of vehicle multi-stage planetary transmission system[J]. Journal of Jilin University (Engineering and Technology Edition), 2012, 42(1): 19-26. | |

| 17 | 曹火. 含内斜齿圈的行星齿轮系动力学建模与分析[D]. 合肥:合肥工业大学机械工程学院, 2013. |

| Cao Huo. Dynamic modeling and analysis of planetary gear train with internal helical gear ring[D]. Hefei: School of Mechanical Engineering, Hefei University of Technology, 2013. | |

| 18 | Wang F, Zhang J, Xu X,et al. New method for power allocation of multi-power sources considering speed-up transient vibration of planetary power-split HEVs driveline system[J]. Mech Syst Signal Process, 2019,128:1-18. |

| [1] | 高镇海,蔡荣贵,孙天骏,于桐,赵浩源,班浩. 人机共驾下的驾驶行为数据滤波方法[J]. 吉林大学学报(工学版), 2024, 54(3): 589-599. |

| [2] | 谢宪毅,王禹涵,金立生,赵鑫,郭柏苍,廖亚萍,周彬,李克强. 基于改变控制时域时间步长的智能车轨迹跟踪控制[J]. 吉林大学学报(工学版), 2024, 54(3): 620-630. |

| [3] | 邓小林,杨馥模,覃善甘. 新型仿竹六边形梯度层级多胞管耐撞性对比分析[J]. 吉林大学学报(工学版), 2024, 54(2): 333-345. |

| [4] | 王毅刚,王玉鹏,张昊,赵思安. 高速列车转向架区域气动噪声源识别与分析[J]. 吉林大学学报(工学版), 2024, 54(2): 346-355. |

| [5] | 聂建军,侯军凯,解晓琳,鄢鸿桢. 新型巡检机器人移动底盘设计及越障性能分析[J]. 吉林大学学报(工学版), 2024, 54(2): 356-364. |

| [6] | 胡宏宇,张慧珺,姚荣涵,陈国迎,高菲. L3级自动驾驶接管过程驾驶员情景意识研究[J]. 吉林大学学报(工学版), 2024, 54(2): 410-418. |

| [7] | 吴骁,史文库,郭年程,赵燕燕,陈志勇,李鑫鹏,孙卓,刘健. 基于Ease off的准双曲面齿轮多目标优化[J]. 吉林大学学报(工学版), 2024, 54(1): 76-85. |

| [8] | 王铁,李旭东,田程,赵宏伟. 基于多轴载荷投影构建轮辋双轴疲劳损伤模型[J]. 吉林大学学报(工学版), 2024, 54(1): 99-104. |

| [9] | 李旭东,王新宇,田程,张新峰,牛治慧,赵志强. 基于用户关联的车辆耐久性载荷谱编制[J]. 吉林大学学报(工学版), 2024, 54(1): 66-75. |

| [10] | 陈兆玮,蒲前华. 弹性车轮对大跨斜拉桥车桥耦合振动的抑制特性[J]. 吉林大学学报(工学版), 2023, 53(9): 2519-2532. |

| [11] | 刘平义,李晓婷,高偌霖,李海涛,魏文军,王亚. 车辆侧倾驱动机构设计与试验[J]. 吉林大学学报(工学版), 2023, 53(8): 2185-2192. |

| [12] | 黄学劲,钟锦星,路京雨,赵霁,肖伟,袁新枚. 基于用户画像的电动汽车充电负荷预测方法[J]. 吉林大学学报(工学版), 2023, 53(8): 2193-2200. |

| [13] | 张树培,夏明悦,张玮,陈钊,陈义祥. 考虑非线性刚度的间隙球铰碰撞动力学建模与仿真[J]. 吉林大学学报(工学版), 2023, 53(8): 2227-2235. |

| [14] | 陈辉,邵亚军. 基于惯性基准多传感器耦合的路面谱测量方法[J]. 吉林大学学报(工学版), 2023, 53(8): 2254-2262. |

| [15] | 田国红,代鹏杰. 基于单亲遗传算法的无人驾驶汽车主动避撞方法[J]. 吉林大学学报(工学版), 2023, 53(8): 2404-2409. |

|

||