吉林大学学报(工学版) ›› 2023, Vol. 53 ›› Issue (8): 2227-2235.doi: 10.13229/j.cnki.jdxbgxb.20211166

• 车辆工程·机械工程 • 上一篇

考虑非线性刚度的间隙球铰碰撞动力学建模与仿真

- 江苏大学 汽车与交通工程学院,江苏 镇江 212013

Impact dynamic modeling and simulation for ball joint with clearance considering nonlinear stiffness

Shu-pei ZHANG( ),Ming-yue XIA,Wei ZHANG,Zhao CHEN,Yi-xiang CHEN

),Ming-yue XIA,Wei ZHANG,Zhao CHEN,Yi-xiang CHEN

- School of Automotive and Traffic Engineering,Jiangsu University,Zhenjiang 212013,China

摘要:

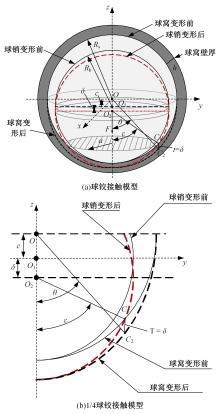

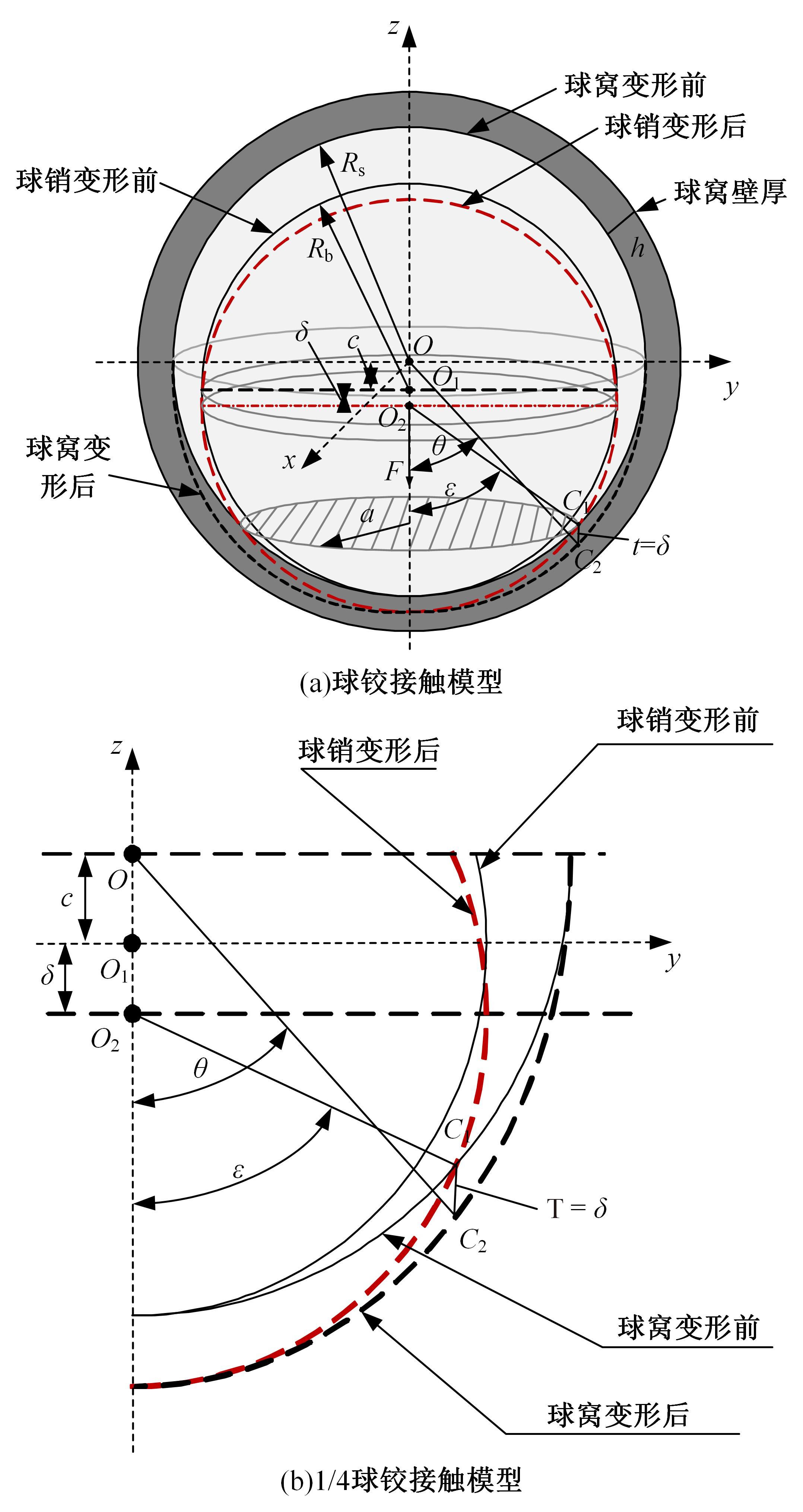

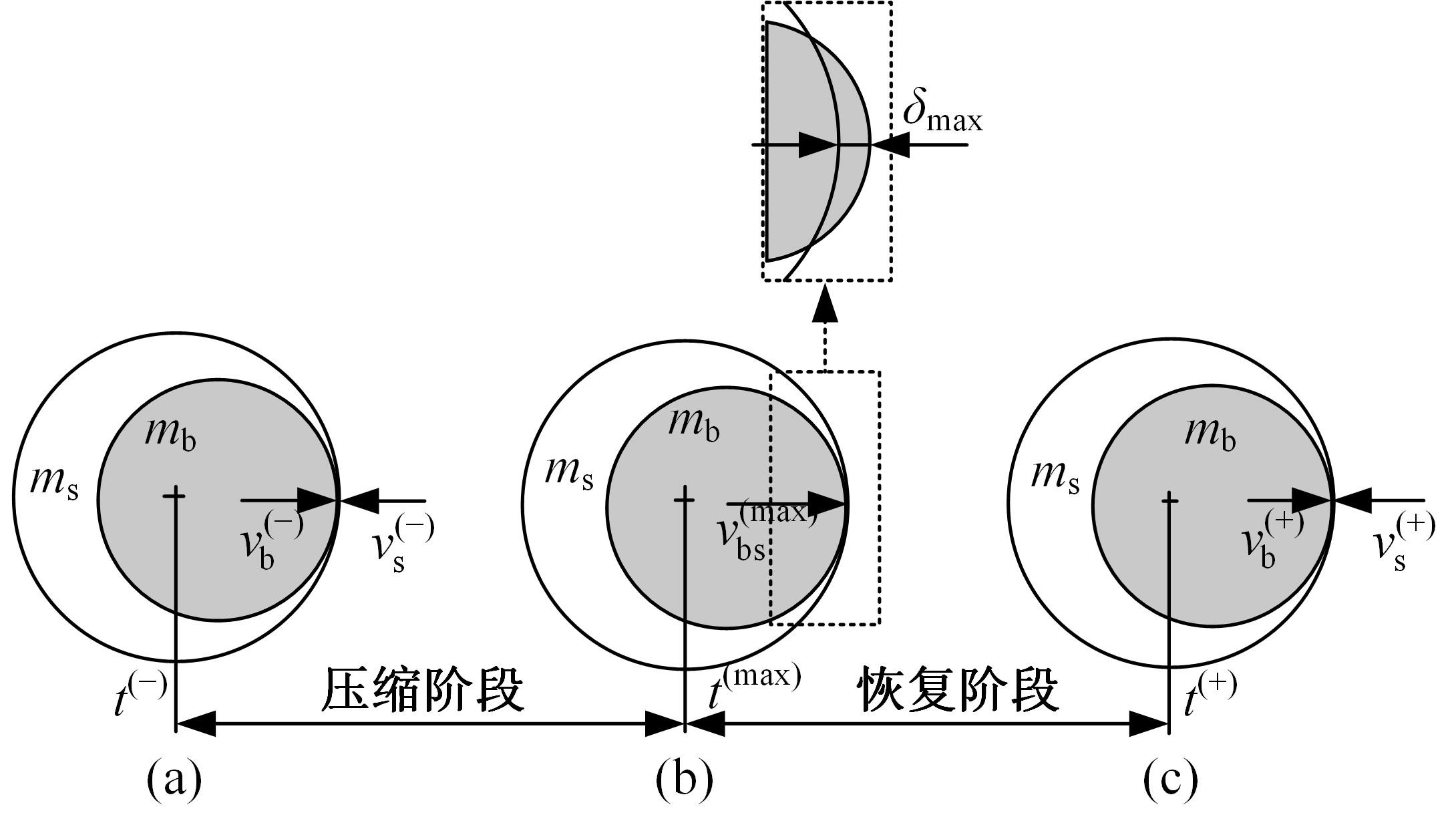

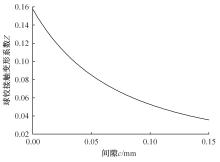

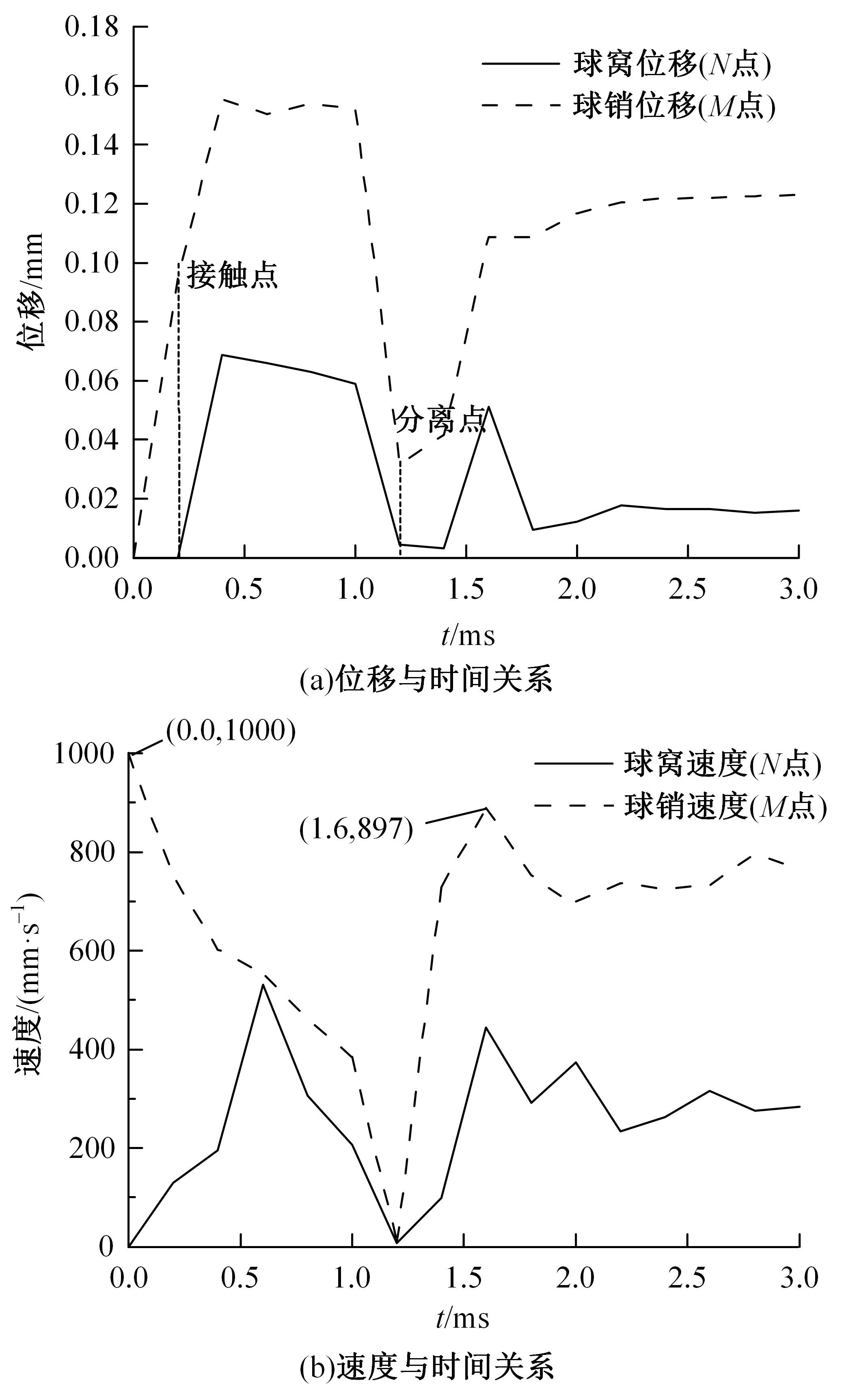

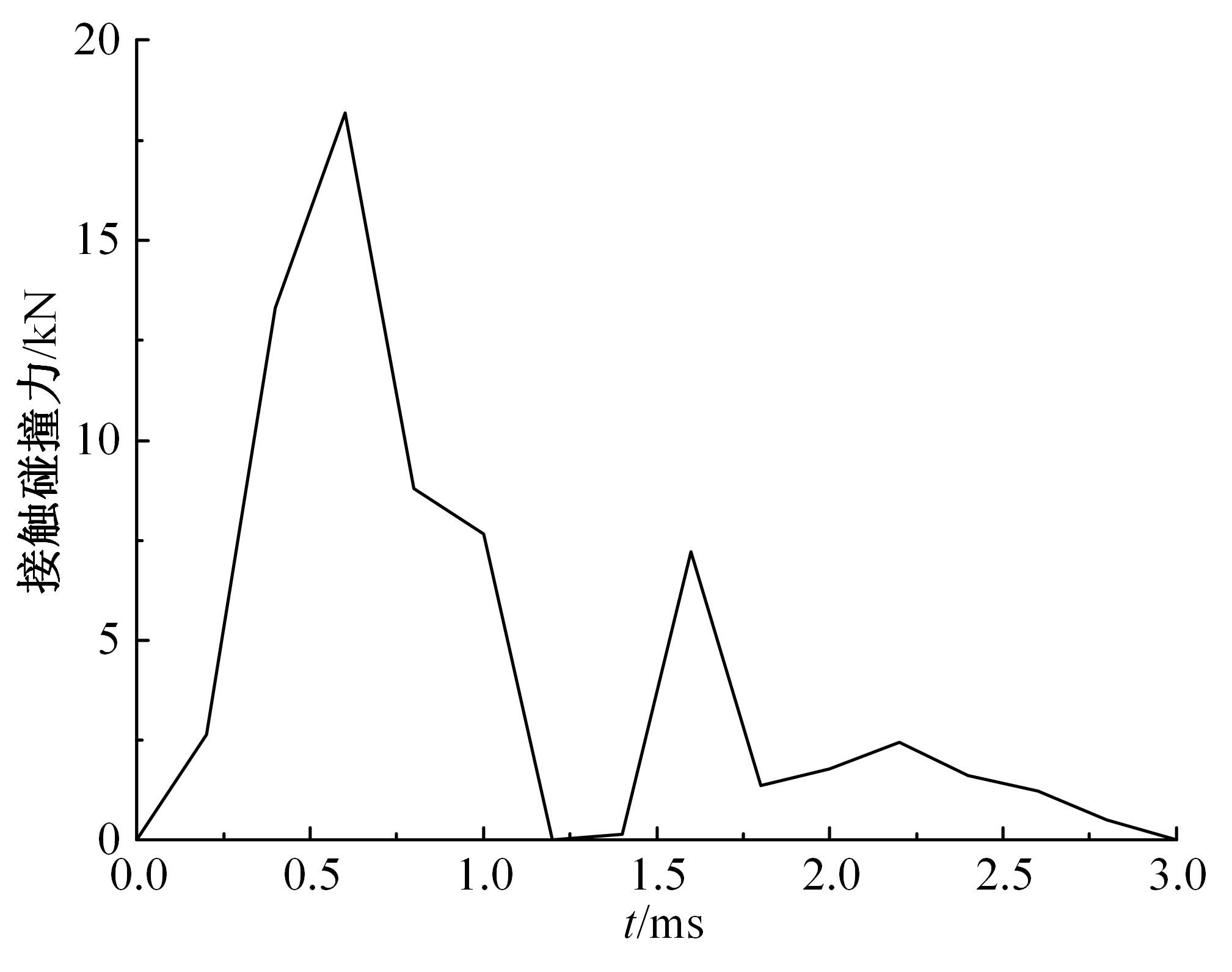

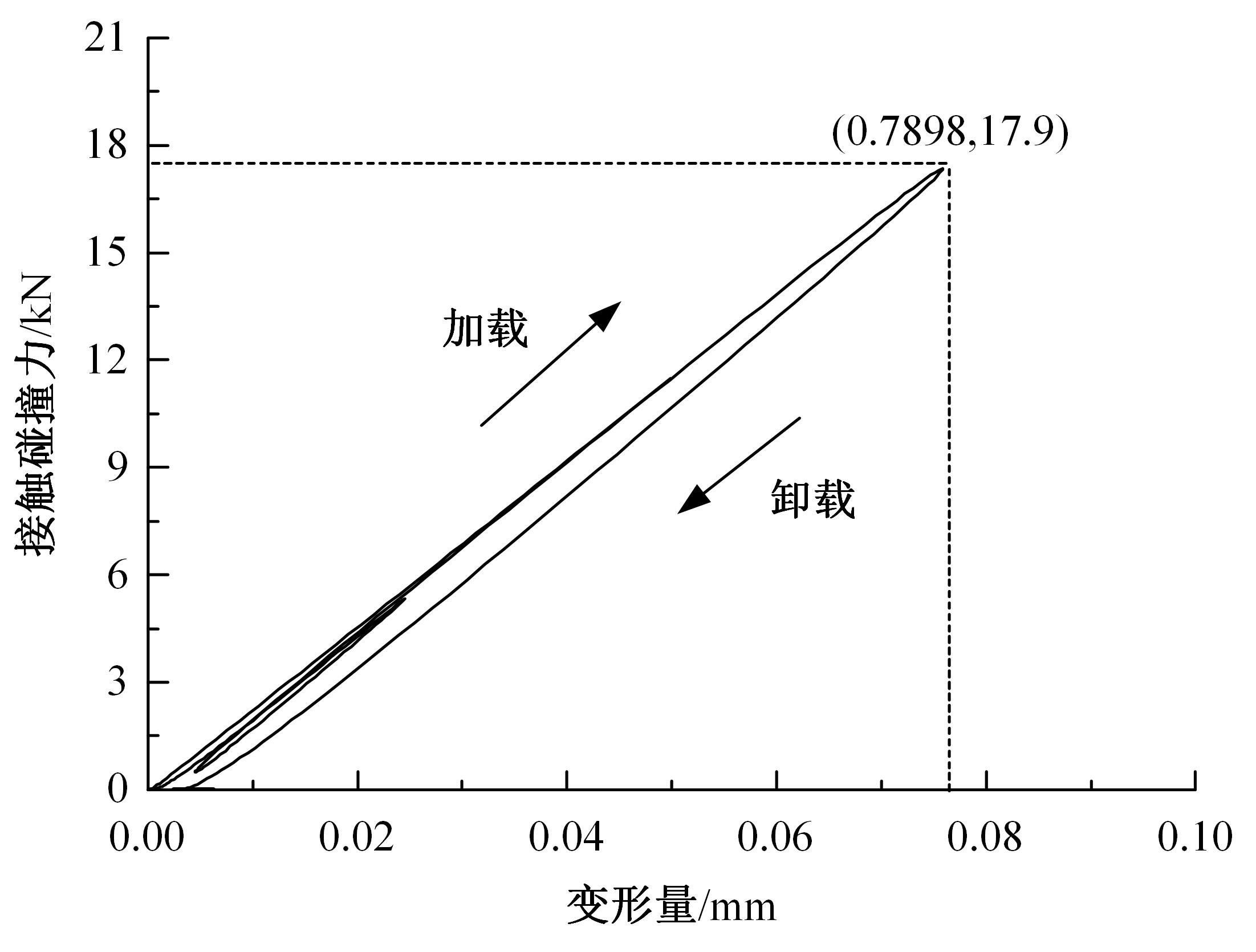

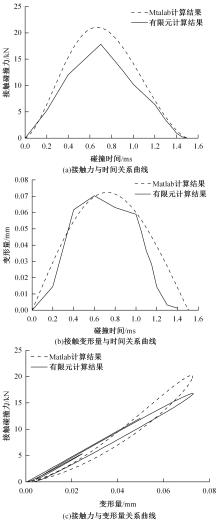

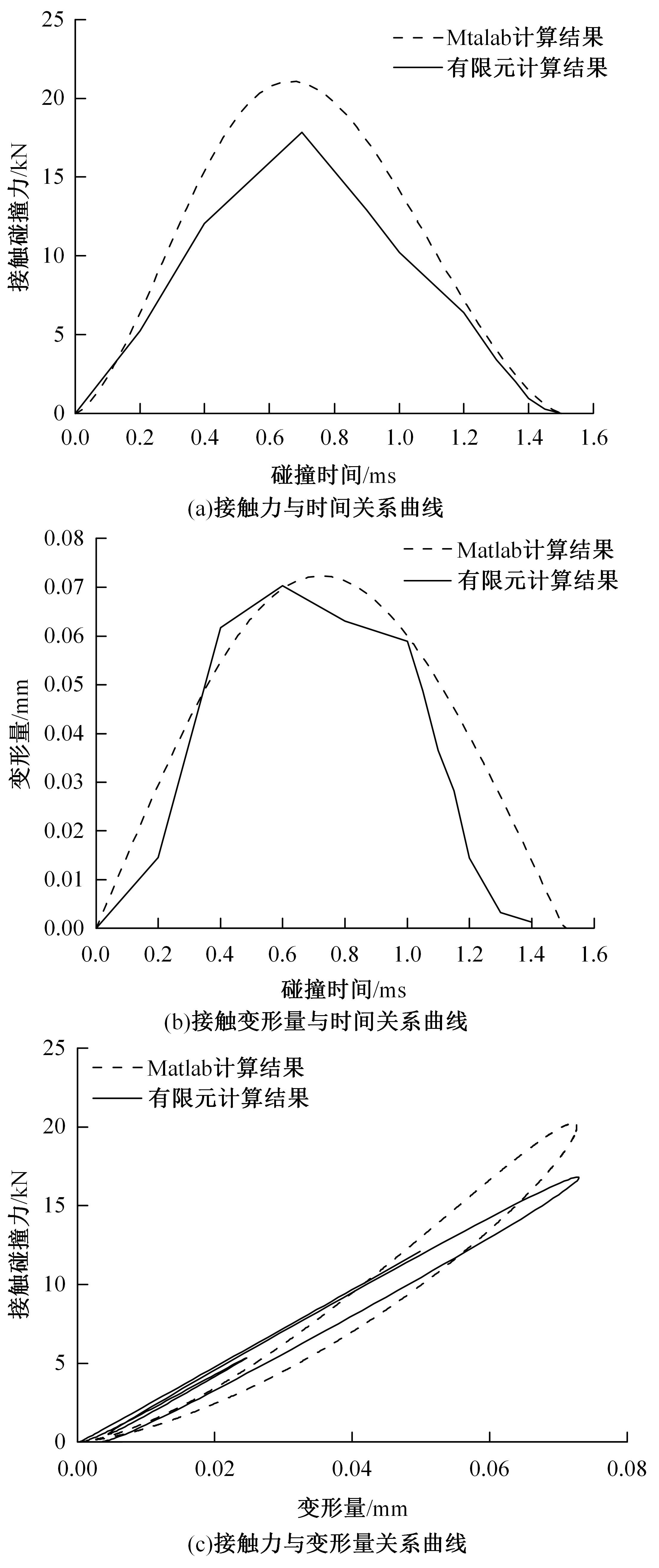

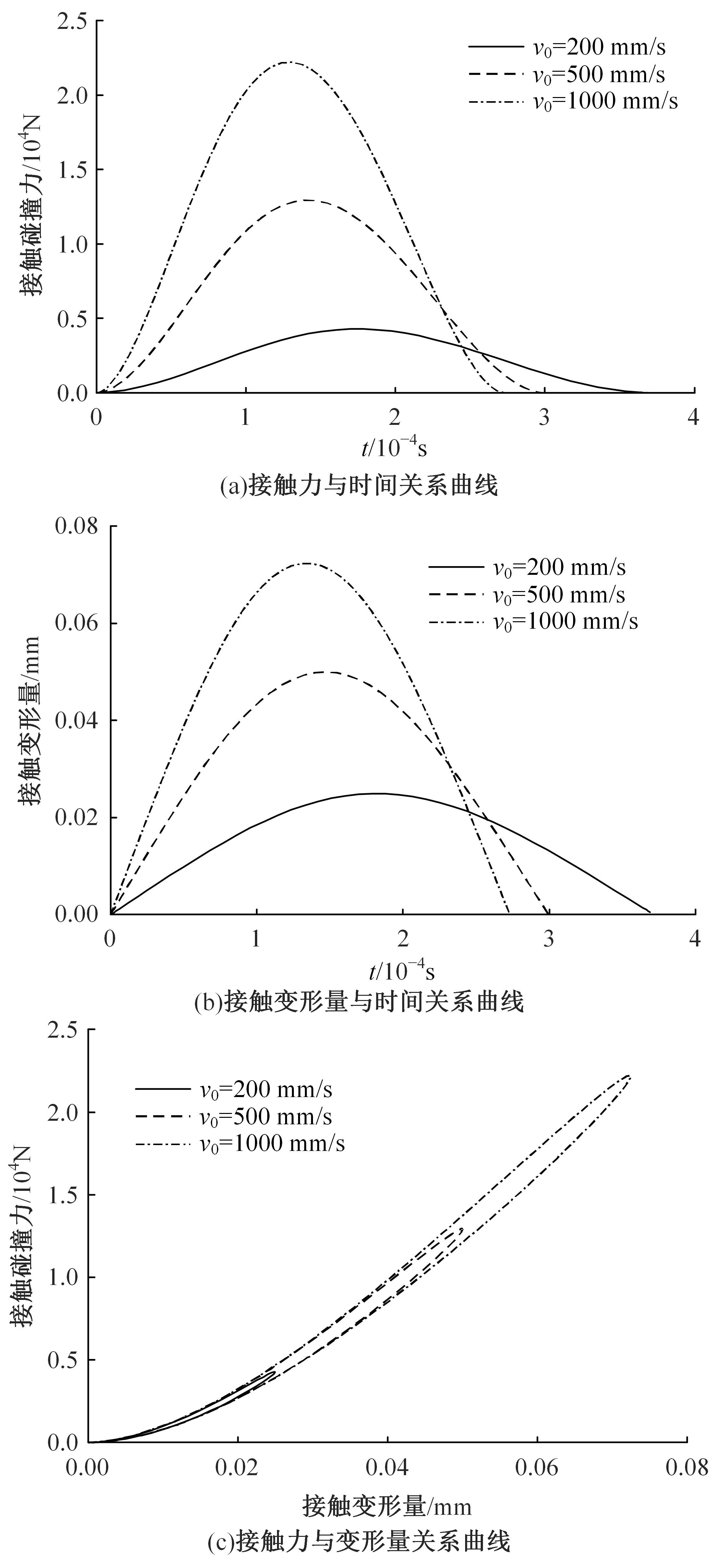

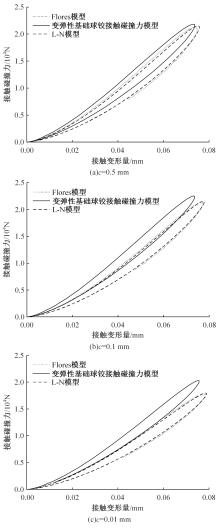

为提高间隙球铰建模分析的准确性,考虑接触体间的非线性接触刚度在碰撞中与机构的耦合特性,建模研究了不同恢复系数与碰撞初速度条件下球铰的接触碰撞特性。结果表明:接触刚度与迟滞阻尼系数避免了在真实接触过程中保持恒定的情况;改进的碰撞力模型更加精确地描述了球铰关节碰撞特性;恢复系数越大,接触力以及变形量的峰值越大,达到峰值时间越长,完成一次碰撞的时间越短;接触碰撞力和变形量随碰撞初速度的增加而迅速增大,完成碰撞的时间减小,更加准确地获得了球铰关节的碰撞特性,为汽车操纵稳定性的精确控制提供了力学基础。

中图分类号:

- U463.46

| 1 | 赵洪志,杨刚,孟庆海,等.转向球铰球面加工机床及误差分析[J].吉林大学学报:工学版,2008,38(3):548-551. |

| Zhao Hong-zhi, Yang Gang, Meng Qing-hai, et al. Design of machine tool for surface of spherical hinge and error analysis[J]. Journal of Jilin University (Engineering and Technology Edition), 2008,38(3): 548-551. | |

| 2 | 李研彪,徐涛涛,郑航,等. 含球面副间隙的空间并联机构动态特性[J]. 浙江大学学报:工学版,2020,54(2):348-356. |

| Li Yan-biao, Xu Tao-tao, Zheng Hang, et al. Dynamic characteristics of spatial parallel mechanism with spherical joint clearance[J]. Journal of Zhejiang University (Engineering Science),2020,54(2):348-356. | |

| 3 | Askari E. Mathematical models for characterizing non-Hertzian contacts[J]. Applied Mathematical Modelling, 2021, 90 : 432-447. |

| 4 | Lankarani H M, Nikravesh P E. A contact force model with hysteresis damping for impact analysis of multibody systems[J]. Journal of Mechanical Design, 1990,112(3):369-376. |

| 5 | 韩雪艳,李富娟,高振辉,等. 考虑摩擦与刚度的空间机构动力学特性[J].机械工程学报, 2020, 56(15): 170-180. |

| Han Xue-yan, Li Fu-juan, Gao Zhen-hui, et al. Dynamic characteristics of space mechanism considering friction and stiffness[J]. Journal of Mechanical Engineering, 2020, 56(15):170-180. | |

| 6 | Flores P, Machado M, Silva M T, et al. On the continuous contact force models for soft materials in multibody dynamics[J]. Multibody System Dynamics, 2011,25(3): 357-375. |

| 7 | 王庚祥,刘宏昭. 考虑球面副间隙的4-SPS/CU并联机构动力学分析[J].机械工程学报,2015,51(1):43-51. |

| Wang Geng-xiang, Liu Hong-zhao. Dynamics analysis of 4-SPS /CU parallel mechanism with spherical joint clearance[J]. Journal of Mechanical Engineering,2015,51(1):43-51. | |

| 8 | Wang G, Liu H, Deng P. Dynamics analysis of spatial multibody system with spherical joint wear[J]. Journal of Tribology, 2015, 137(2):021605. |

| 9 | Chen X, Jia Y. Wear analysis of spatial parallel mechanisms with multiple 3D spherical clearance joints[J]. Journal of Tribology, 2019, 141(10):4044295. |

| 10 | Liu C S, Zhang K, Yang L. Normal force-displacement relationship of spherical joints with clearances[J]. Journal of Computational & Non-linear Dynamics, 2006, 1(2):160-167. |

| 11 | 王旭鹏,刘更,马尚君.含间隙运动副机构的动力学特性研究[J]. 振动与冲击,2016,35(7):110-115. |

| Wang Xu-peng, Liu Geng, Ma Shang-jun. Dynamic characteristics of mechanisms with revolute clearance joints[J]. Vibration and Shock, 2016,35(7):110-115. | |

| 12 | Tian Q, Flores P, Lankarani H M. A comprehensive survey of the analytical, numerical and experimental methodologies for dynamics of multibody mechanical systems with clearance or imperfect joints[J]. Mechanism & Machine Theory, 2018, 122:1-57. |

| 13 | 张静. 铰链及含铰折展桁架非线性动力学建模与分析[D]. 哈尔滨:哈尔滨工业大学机电工程学院,2014. |

| Zhang Jing. Modeling and analysis of nonlinear dynamics for joint and deployable structure[D]. Harbin:School of Mechatronics Engineering, Harbin Institute of Technology, 2014. | |

| 14 | 李忠洪. 考虑铰链间隙的空气舵传动机构动力学建模及分析[D]. 哈尔滨:哈尔滨工业大学机电工程学院,2015. |

| Li Zhong-hong. Dynamic modeling and analysis of transmission mechanism with joint clearances for air rudder[D]. Harbin:School of Mechatronics Engineering, Harbin Institute of Technology, 2015. | |

| 15 | 迟华瑞. 考虑涂层的间隙转动副接触碰撞力模型及其应用[D].秦皇岛:燕山大学机械工程学院,2019. |

| Chi Hua-rui. The contact-impact force model of coated revolute joints with clearance and its application[D]. Qinhuangdao:School of Mechanical Engineering, Yanshan University, 2019. |

| [1] | 刘平义,李晓婷,高偌霖,李海涛,魏文军,王亚. 车辆侧倾驱动机构设计与试验[J]. 吉林大学学报(工学版), 2023, 53(8): 2185-2192. |

| [2] | 黄学劲,钟锦星,路京雨,赵霁,肖伟,袁新枚. 基于用户画像的电动汽车充电负荷预测方法[J]. 吉林大学学报(工学版), 2023, 53(8): 2193-2200. |

| [3] | 马涛,马源,黄晓明. 基于多元非线性回归的智能压实关键参数最优解[J]. 吉林大学学报(工学版), 2023, 53(7): 2067-2077. |

| [4] | 李崛,张安顺,张军辉,钱俊峰. 级配碎石基层结构动力响应模型测试及数值分析[J]. 吉林大学学报(工学版), 2023, 53(6): 1782-1789. |

| [5] | 陈磊,王杨,董志圣,宋亚奇. 一种基于转向意图的车辆敏捷性控制策略[J]. 吉林大学学报(工学版), 2023, 53(5): 1257-1263. |

| [6] | 李九一,周丰峻,刘建华,孙云厚,朱精忠,邱明坤. 扭转荷载下螺旋形螺纹连接件的IWAN改进模型[J]. 吉林大学学报(工学版), 2023, 53(5): 1305-1314. |

| [7] | 陈鑫,张冠宸,赵康明,王佳宁,杨立飞,司徒德蓉. 搭接焊缝对铝合金焊接结构轻量化设计的影响[J]. 吉林大学学报(工学版), 2023, 53(5): 1282-1288. |

| [8] | 张勇,毛凤朝,刘水长,王青妤,潘神功,曾广胜. 基于Laplacian算法的汽车外流场畸变网格优化[J]. 吉林大学学报(工学版), 2023, 53(5): 1289-1296. |

| [9] | 汪少华,储堃,施德华,殷春芳,李春. 基于有限时间扩张状态观测的HEV鲁棒复合协调控制[J]. 吉林大学学报(工学版), 2023, 53(5): 1272-1281. |

| [10] | 于贵申,陈鑫,武子涛,陈轶雄,张冠宸. AA6061⁃T6铝薄板无针搅拌摩擦点焊接头结构及性能分析[J]. 吉林大学学报(工学版), 2023, 53(5): 1338-1344. |

| [11] | 田彦涛,黄兴,卢辉遒,王凯歌,许富强. 基于注意力与深度交互的周车多模态行为轨迹预测[J]. 吉林大学学报(工学版), 2023, 53(5): 1474-1480. |

| [12] | 尹燕莉,黄学江,潘小亮,王利团,詹森,张鑫新. 基于PID与Q⁃Learning的混合动力汽车队列分层控制[J]. 吉林大学学报(工学版), 2023, 53(5): 1481-1489. |

| [13] | 赵睿,李云,胡宏宇,高镇海. 基于V2I通信的交叉口车辆碰撞预警方法[J]. 吉林大学学报(工学版), 2023, 53(4): 1019-1029. |

| [14] | 杨红波,史文库,陈志勇,郭年程,赵燕燕. 基于NSGA⁃II的斜齿轮宏观参数多目标优化[J]. 吉林大学学报(工学版), 2023, 53(4): 1007-1018. |

| [15] | 陈小波,陈玲. 定位噪声统计特性未知的变分贝叶斯协同目标跟踪[J]. 吉林大学学报(工学版), 2023, 53(4): 1030-1039. |

|

||