吉林大学学报(工学版) ›› 2025, Vol. 55 ›› Issue (2): 444-455.doi: 10.13229/j.cnki.jdxbgxb.20230347

• 车辆工程·机械工程 • 上一篇

面向汽车传动系统多挡共振的多级吸振器参数设计方法

- 吉林大学 汽车仿真与控制国家重点实验室,长春 130022

Parameter design method of multiple dynamic vibration absorbers for suppressing multi-frequency resonance of automotive powertrain

Jun-long QU( ),Wen-ku SHI,Sheng-yi XUAN(

),Wen-ku SHI,Sheng-yi XUAN( ),Zhi-yong CHEN

),Zhi-yong CHEN

- State Key Laboratory of Automotive Simulation and Control,Jilin University,Changchun 130022,China

摘要:

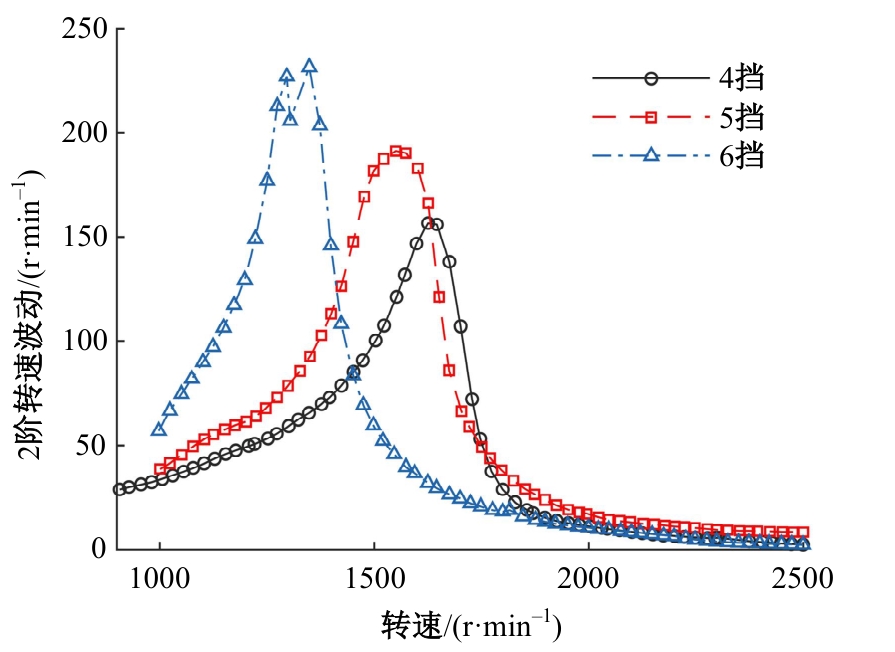

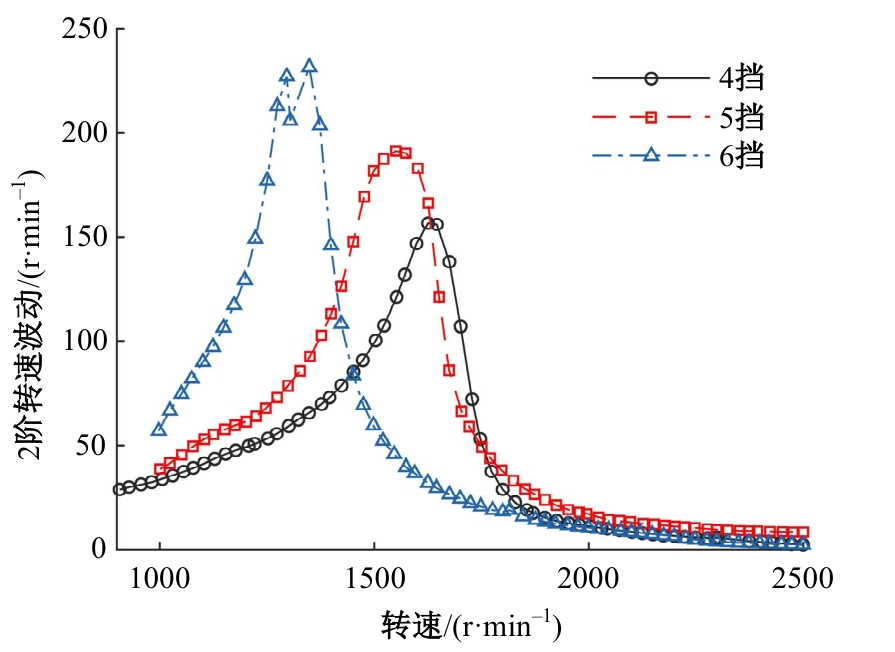

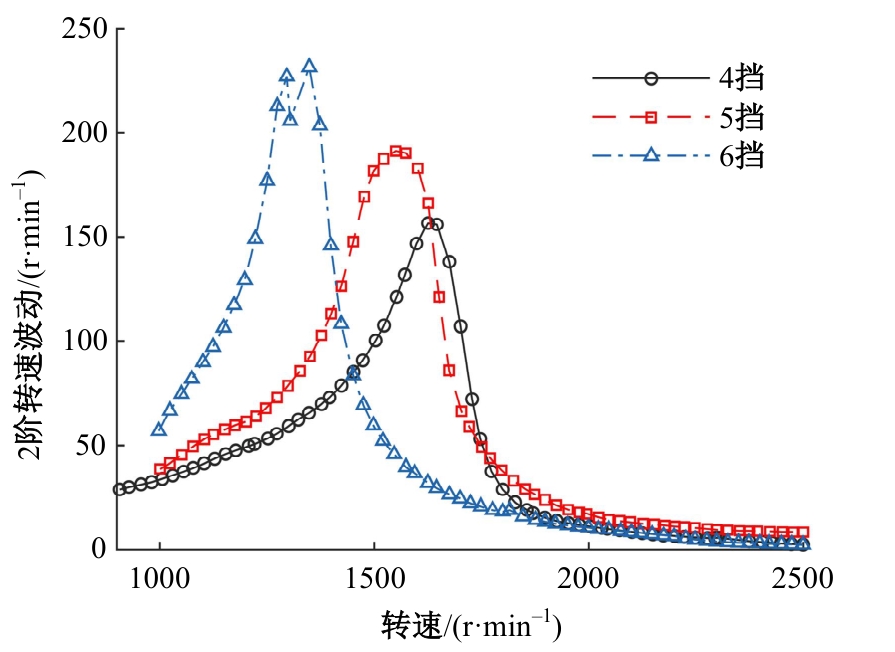

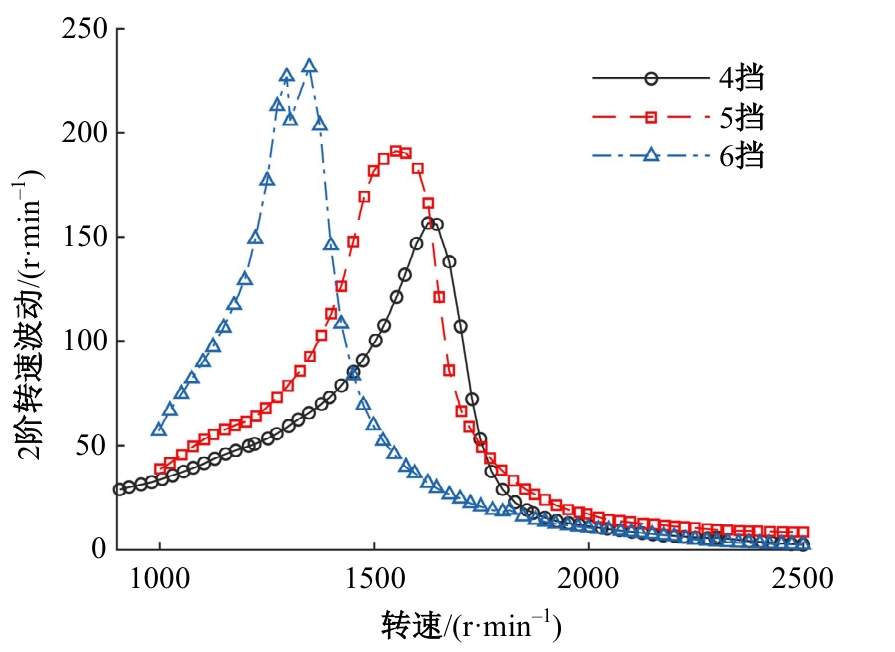

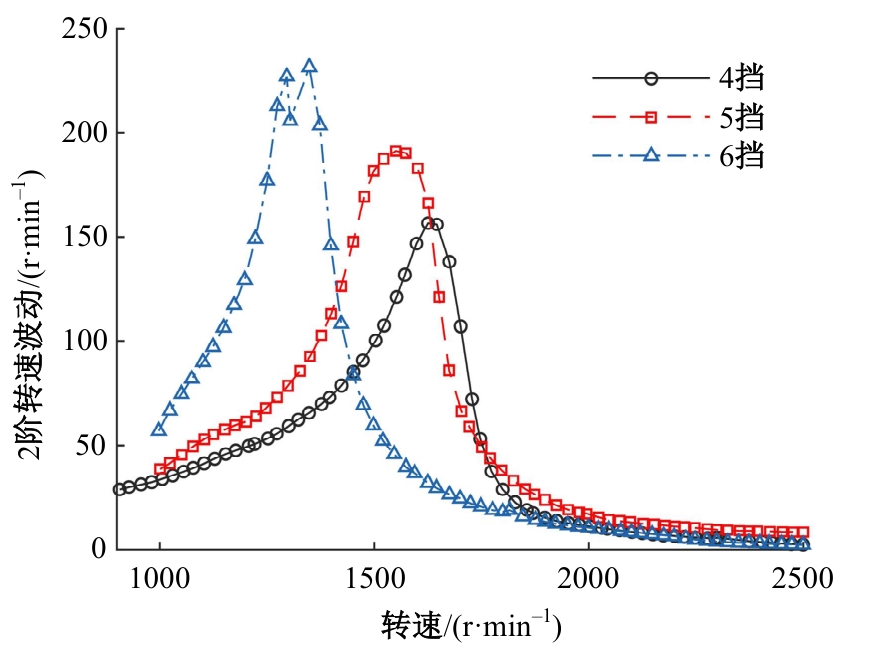

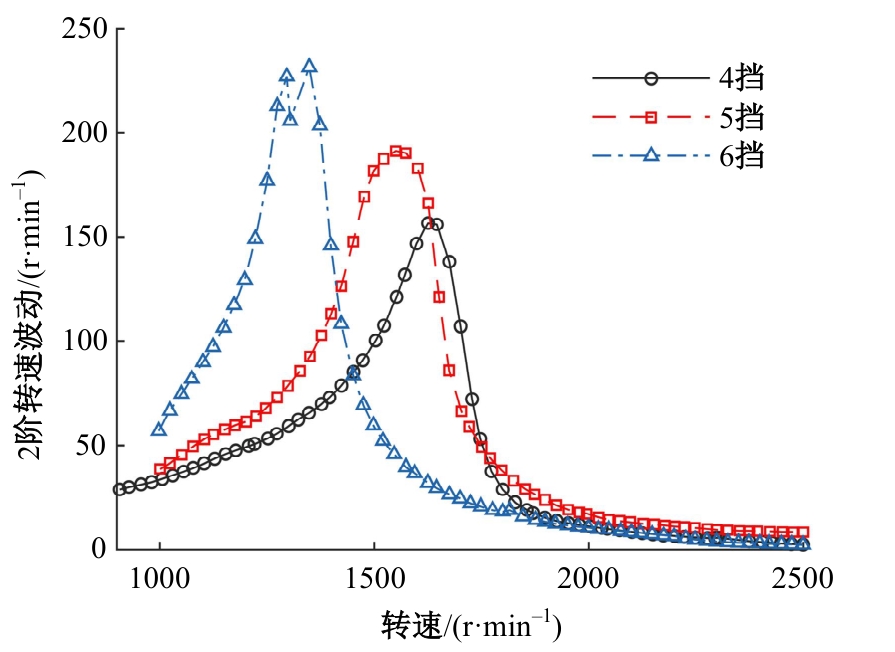

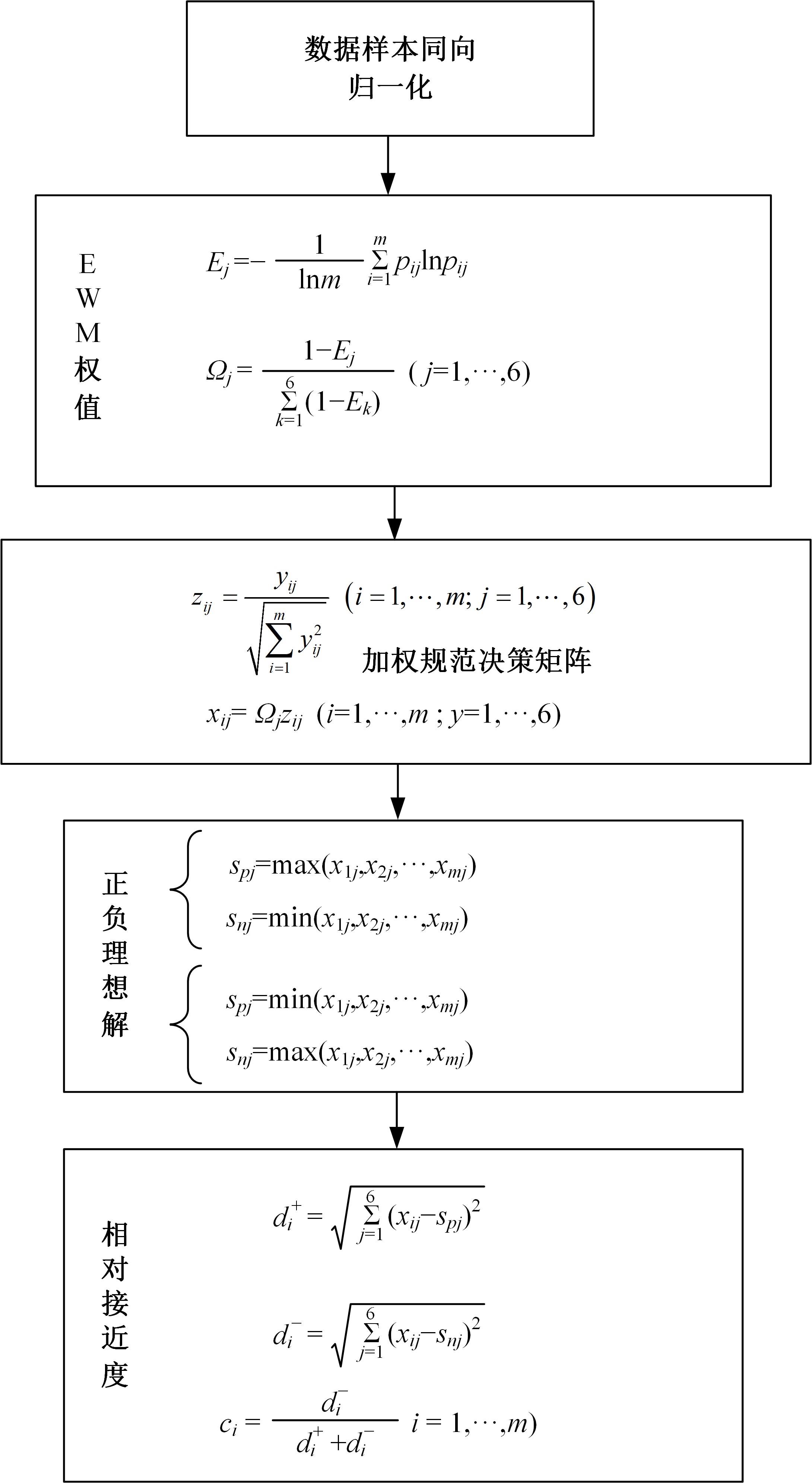

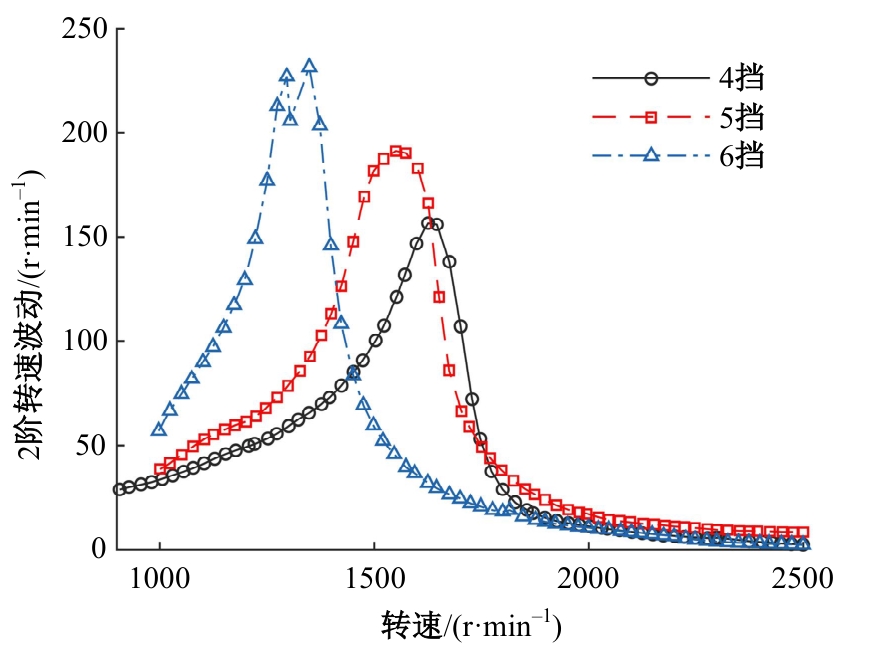

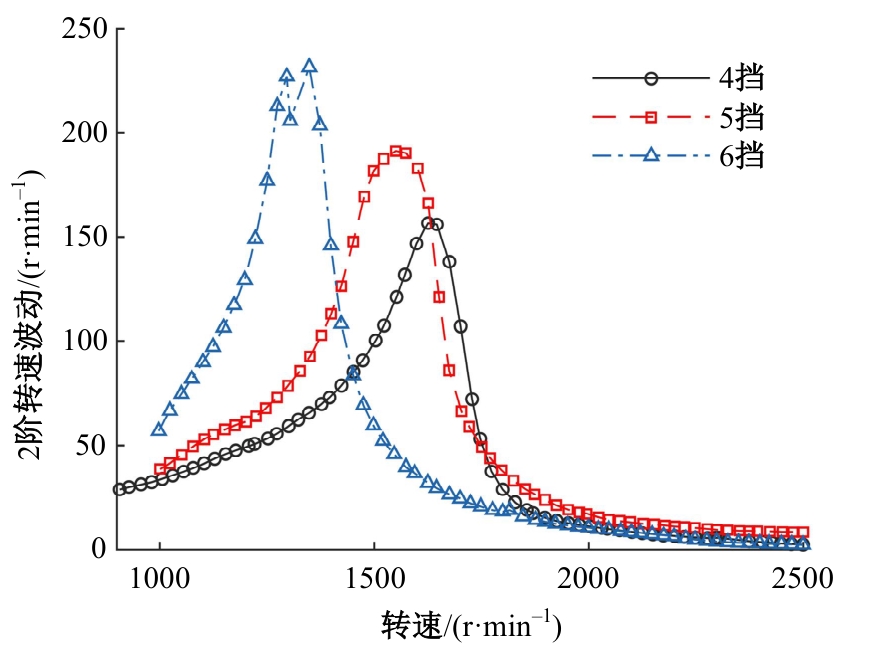

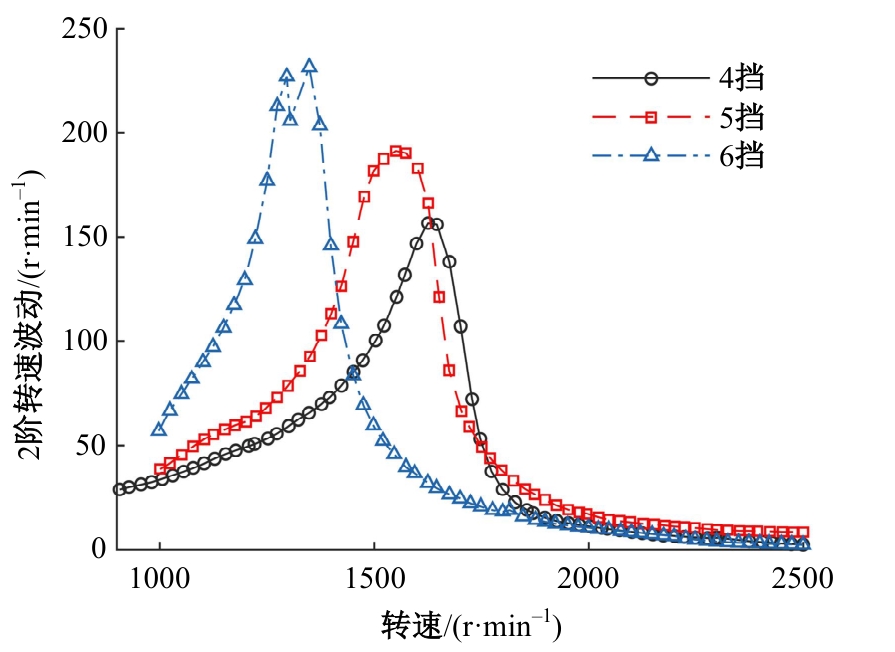

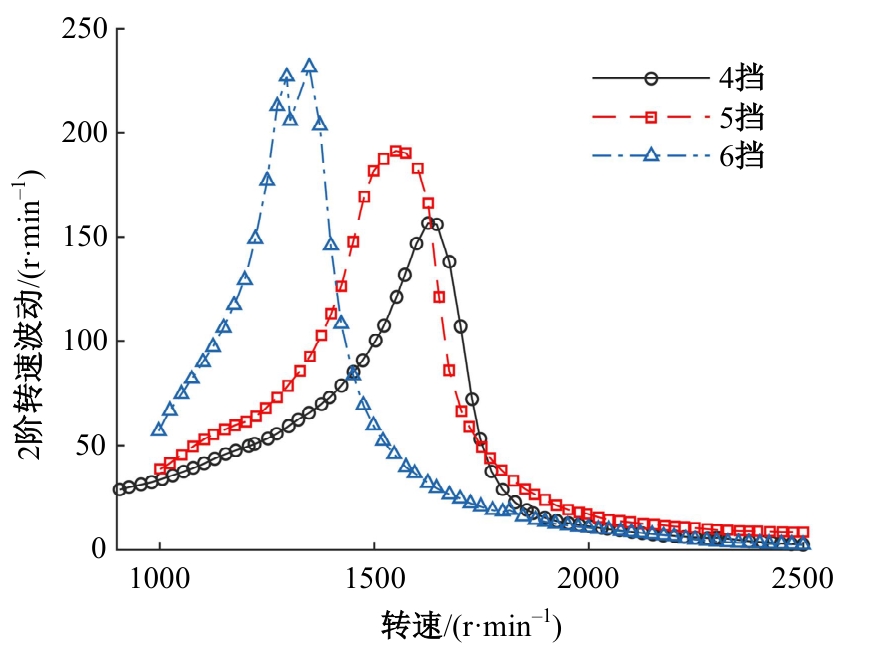

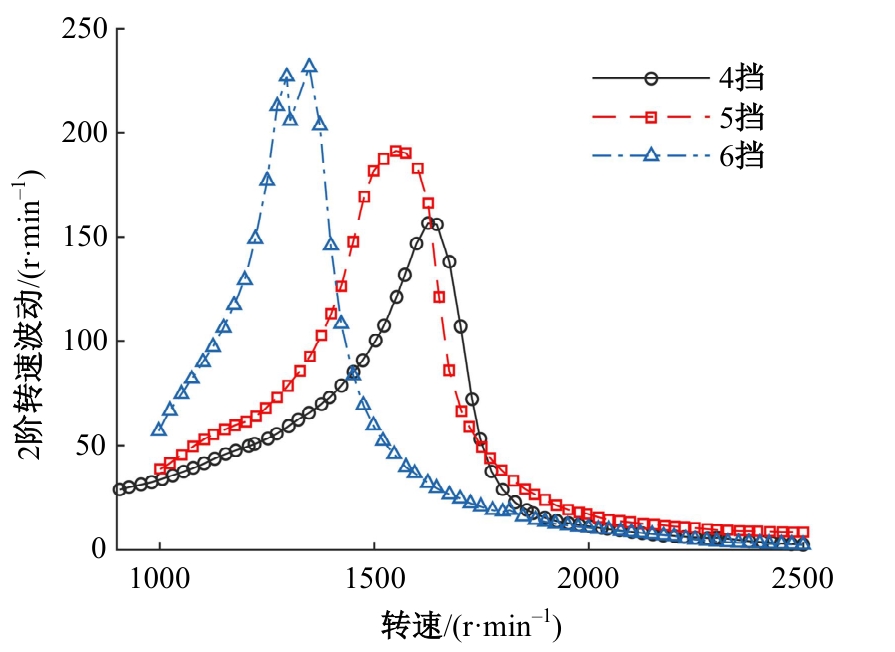

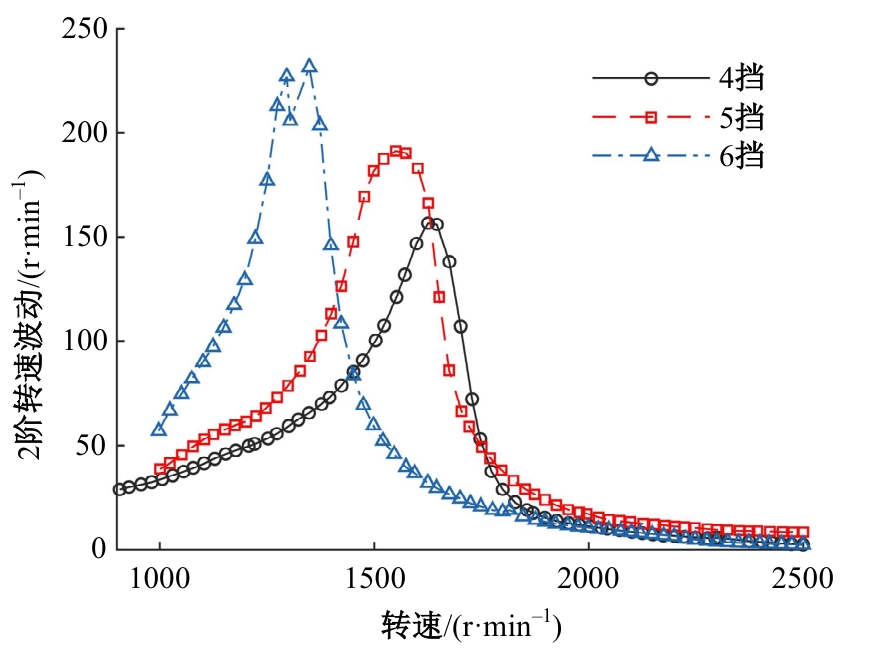

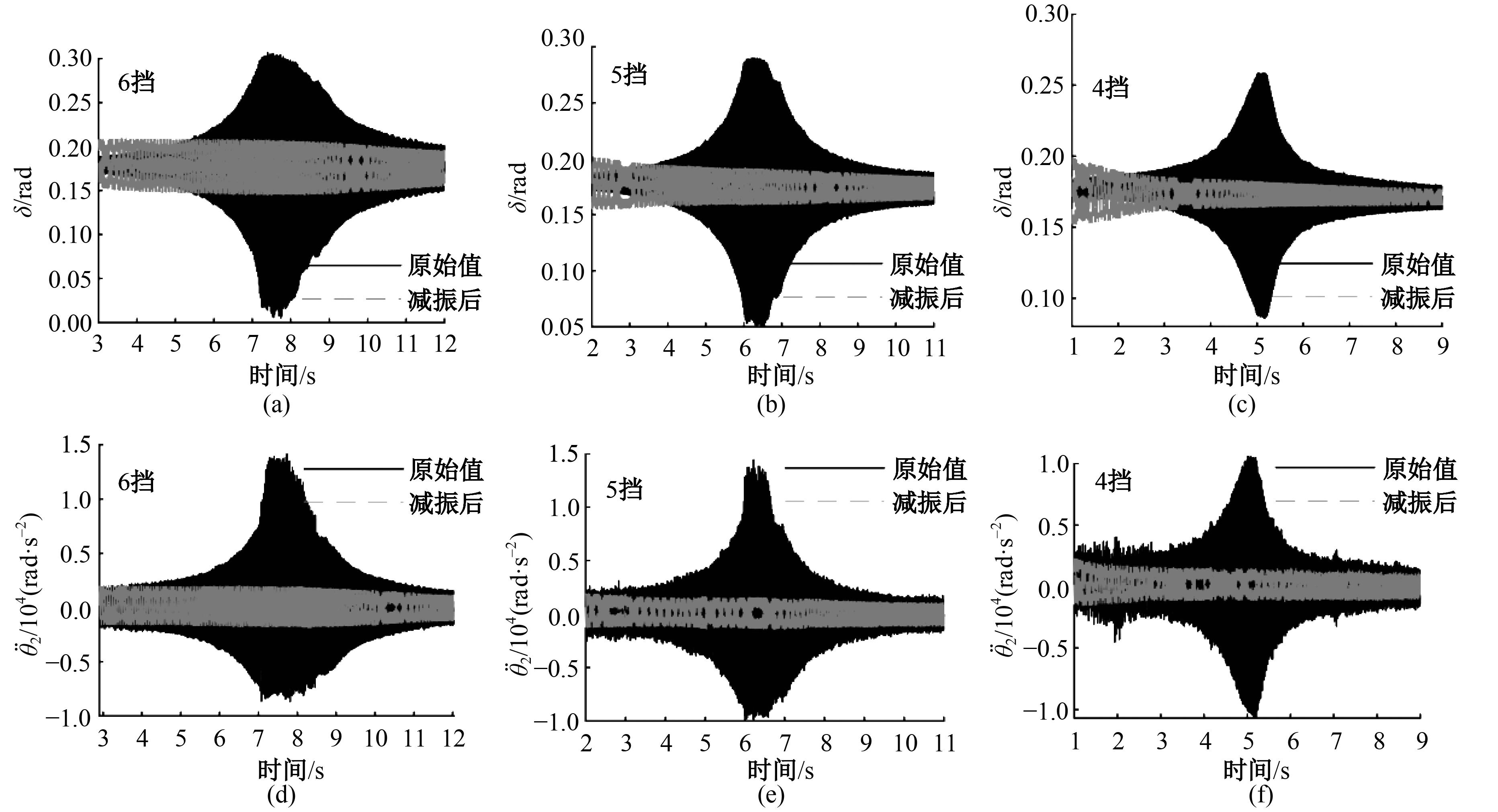

针对汽车动力传动系统多个挡位存在扭转共振的问题,本文提出了一种多级并联动力吸振器的参数设计方法。首先,建立四自由度动力传动系统扭振模型并进行模态分析,基于共振模态的等效系统推导了n级并联动力吸振器的频响函数;然后,以4级并联动力吸振器为例,将传动系统3个挡位的振动角位移和振动角加速度作为优化目标,采用改进的非支配排序遗传算法对吸振器组的定调比和阻尼比进行优化,利用熵值法联合逼近理想解的排序法对Pareto解进行排序;最后,通过与3种传统的动力吸振器优化方法进行对比,并进行时域和频域仿真分析,验证了本文设计方案的有效性。本文方法可为固有频率可变振动系统的动力吸振器优化设计提供参考。

中图分类号:

- U461.1

| 1 | Wang Y L, Qin X P, Huang S, et al. Design and analysis of a multi-stage torsional stiffness dual mass flywheel based on vibration control[J]. Applied Acoustics, 2016, 104: 172-181. |

| 2 | Idehara S J, Flach F L, Lemes D. Modeling of nonlinear torsional vibration of the automotive powertrain[J]. Journal of Vibration and Control, 2018, 24(9): 1774-1786. |

| 3 | 刘耀宗, 郁殿龙, 赵宏刚, 等. 被动式动力吸振技术研究进展[J]. 机械工程学报, 2007, 43(3): 15-21. |

| Liu Yao-zong, Yu Dian-long, Zhao Hong-gang, et al. Research progress of passive dynamic vibration absorption technology[J]. Chinese Journal of Mechanical Engineering, 2007, 43(3): 15-21. | |

| 4 | Gao P, Xiang C L, Liu H, et al. Reducing variable frequency vibrations in a powertrain system with an adaptive tuned vibration absorber group[J]. Journal of Sound and Vibration, 2018, 425(1): 82-101. |

| 5 | 李学斌. 动力吸振器的多目标优化和多属性决策研究[J]. 振动工程学报, 2009, 22(3): 319-324. |

| Li Xue-bin. Research on multi-objective optimization and multi- attribute decision-making of dynamic vibration absorber[J]. Journal of Vibration Engineering, 2009, 22(3): 319-324. | |

| 6 | 王淳, 陈雅菊. 基于多目标粒子群算法的动力吸振器参数优化和决策研究[J]. 舰船科学技术, 2009, 31(11): 46:50. |

| Wang Chun, Chen Ya-ju. Multi-objective particle optimization and multi-attribute decision making study of dynamic vibration absorber[J]. Ship Science and Technology, 2009, 31(11): 46-50. | |

| 7 | Brown B, Singh T. Minimax design of vibration absorbers for linear damped systems[J]. Journal of Sound and Vibration, 2011, 330(11): 2437-2448. |

| 8 | Cheung Y L, Wong W O. H2 optimization of a non- traditional dynamic vibration absorber for vibration control of structures under random force excitation[J]. Journal of Sound and Vibration, 2011, 330(6): 1039-1044. |

| 9 | 郝耀东, 何智成, 李光耀, 等. 考虑公差的扭转动力吸振器不确定性优化设计[J]. 中国机械工程, 2018, 29(14): 1645-1652. |

| Hao Yao-dong, He Zhi-cheng, Li Guang-yao, et al. Uncertain optimization of torsional vibration damper considering tolerant design[J]. China Mechanical Engineering, 2018, 29(14): 1645-1652. | |

| 10 | Wang X, Yang B T, Yu H, et al. Transient vibration analytical modeling and suppressing for vibration absorber system under impulse excitation[J]. Journal of Sound and Vibration, 2017, 394: 90-108. |

| 11 | Haris A, Motato E, Mohammadpour M, et al. On the effect of multiple parallel nonlinear absorbers in palliation of torsional response of automotive drivetrain[J]. International Journal of Non-Linear Mechanics, 2017, 96: 22-35. |

| 12 | 高普, 项昌乐, 刘辉, 等. 被动吸振器组在传动系统宽频减振中的应用研究[J]. 汽车工程, 2019, 41(2): 191-197. |

| Gao Pu, Xiang Chang-le, Liu Hui, et al. A study on the application of passive vibration absorber group on powertrain system wideband vibration reduction[J]. Automotive Engineering, 2019, 41(2): 191-197. | |

| 13 | 上官文斌, 牛立志, 黄兴. 发动机曲轴多级橡胶阻尼式扭转减振器的设计[J]. 汽车工程, 2007, 29(11): 991-994. |

| Shangguan Wen-bin, Niu Li-zhi, Huang Xing. Design of multi-rubber-element torsional vibration dampers for engine crankshaft[J]. Automotive Engineering, 2007, 29(11): 991-994. | |

| 14 | 王媛文, 董大伟, 孙梅云, 等. 多级扭振减振器在降低车内噪声中的应用[J]. 内燃机工程, 2017, 38(3): 123-130. |

| Wang Yuan-wen, Dong Da-wei, Sun Mei-yun, et al. Application of multi-dof torsional vibration absorber to reduce interior noise[J]. Chinese Internal Combusting Engine Engineering, 2017, 38(3): 123-130. | |

| 15 | Phuc V D, Tran V T. Optimization design for multiple dynamic vibration absorbers on damped structures using equivalent linearization method[J]. Proceedings of the Institution of Mechanical Engineers, Part K: Journal of Multi-body Dynamics, 2022, 236(1): 41-50. |

| 16 | 背户一登, 任明章. 动力吸振器及其应用[M]. 北京: 机械工业出版社, 2013. |

| 17 | Deb K, Pratap A, Agarwal S, et al. A fast and elitist multiobjective genetic algorithm: NSGA-II[J]. IEEE Transactions on Evolutionary Computation, 2002, 6(2): 182-197. |

| 18 | 贾富淳, 孟宪皆, 雷雨龙. 基于多目标遗传算法的二自由度动力吸振器优化设计[J]. 吉林大学学报: 工学版, 2019, 49(6): 1969-1976. |

| Jia Fu-chun, Meng Xian-jie, Lei Yu-long. Optimal design of two degrees of freedom dynamic vibration absorber based on multi-objective genetic algorithm[J]. Journal of Jilin University (Engineering and Technology Edition), 2019, 49(6): 1969-1976. | |

| 19 | Rezeka S F, Henein N A. A new approach to evaluate instantaneous friction and its components in internal combustion engines[J]. SAE Transactions, 1984, 93: 932-944. |

| 20 | Wu H W, Wu G Q. Driveline torsional analysis and clutch damper optimization for reducing gear rattle[J]. Shock and Vibration, 2016, 2016(1): 1-24. |

| 21 | Chen L, Shi W K, Chen Z Y. Research on damping performance of dual mass flywheel based on vehicle transmission system modeling and multi-condition simulation[J]. IEEE Access, 2020, 8: 28064-28077. |

| 22 | Yoon J Y, Yoon H S. Nonlinear frequency response analysis of a multistage clutch damper with multiple nonlinearities[J]. Journal of Computational and Nonlinear Dynamics, 2014, 9(3): 031007. |

| [1] | 王军年,曹宇靖,罗智仁,李凯旋,赵文伯,孟盈邑. 基于双目视觉的道路水深在线检测算法[J]. 吉林大学学报(工学版), 2025, 55(1): 175-184. |

| [2] | 谭草,任浩鑫,葛文庆,宋亚东,陆佳瑜. 直驱阀控液压振动平台改进自抗扰控制[J]. 吉林大学学报(工学版), 2025, 55(1): 84-92. |

| [3] | 胡宏宇,张争光,曲优,蔡沐雨,高菲,高镇海. 基于双分支和可变形卷积网络的驾驶员行为识别方法[J]. 吉林大学学报(工学版), 2025, 55(1): 93-104. |

| [4] | 李寿涛,杨路,屈如意,孙鹏鹏,于丁力. 基于模型预测控制的滑移率控制方法[J]. 吉林大学学报(工学版), 2024, 54(9): 2687-2696. |

| [5] | 吴量,顾义凡,邢彪,马芳武,倪利伟,贾微微. 基于线性二次型调节器的四轮转向与分布式集成控制方法[J]. 吉林大学学报(工学版), 2024, 54(9): 2414-2422. |

| [6] | 王玉海,李晓之,李兴坤. 面向高速工况的混合动力卡车预见性节能算法[J]. 吉林大学学报(工学版), 2024, 54(8): 2121-2129. |

| [7] | 常胜,刘宏飞,邹乃威. 汽车变曲率路径循迹H∞回路成形鲁棒控制[J]. 吉林大学学报(工学版), 2024, 54(8): 2141-2148. |

| [8] | 刘建泽,柳江,李敏,章新杰. 基于最小二乘的车速解耦路面辨识方法[J]. 吉林大学学报(工学版), 2024, 54(7): 1821-1830. |

| [9] | 谢宪毅,张明君,金立生,周彬,胡涛,白宇飞. 考虑舒适度的智能汽车人工蜂群轨迹规划方法[J]. 吉林大学学报(工学版), 2024, 54(6): 1570-1581. |

| [10] | 刘从臻,陈高,刘洪柱,马强,徐成伟,孟辉,王国林. 湿滑路面轮胎接地力学特性模型[J]. 吉林大学学报(工学版), 2024, 54(6): 1501-1511. |

| [11] | 黄玲,崔躜,游峰,洪佩鑫,钟浩川,曾译萱. 适用于多车交互场景的车辆轨迹预测模型[J]. 吉林大学学报(工学版), 2024, 54(5): 1188-1195. |

| [12] | 郭洪艳,王连冰,赵旭,戴启坤. 考虑侧向运动的整车质量与道路坡度估计[J]. 吉林大学学报(工学版), 2024, 54(5): 1175-1187. |

| [13] | 陆玉凯,袁帅科,熊树生,朱绍鹏,张宁. 汽车漆面缺陷高精度检测系统[J]. 吉林大学学报(工学版), 2024, 54(5): 1205-1213. |

| [14] | 陈涛,周志刚,雷楠南. 粒子群算法下汽车机械式自动变速系统参数多目标优化[J]. 吉林大学学报(工学版), 2024, 54(5): 1214-1220. |

| [15] | 汪少华,张启睿,施德华,殷春芳,李春. 双行星排式混合动力传动系统非线性振动响应特性分析[J]. 吉林大学学报(工学版), 2024, 54(4): 890-901. |

|

||