吉林大学学报(工学版) ›› 2021, Vol. 51 ›› Issue (5): 1642-1650.doi: 10.13229/j.cnki.jdxbgxb20210466

• 车辆工程·机械工程 • 上一篇

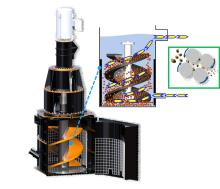

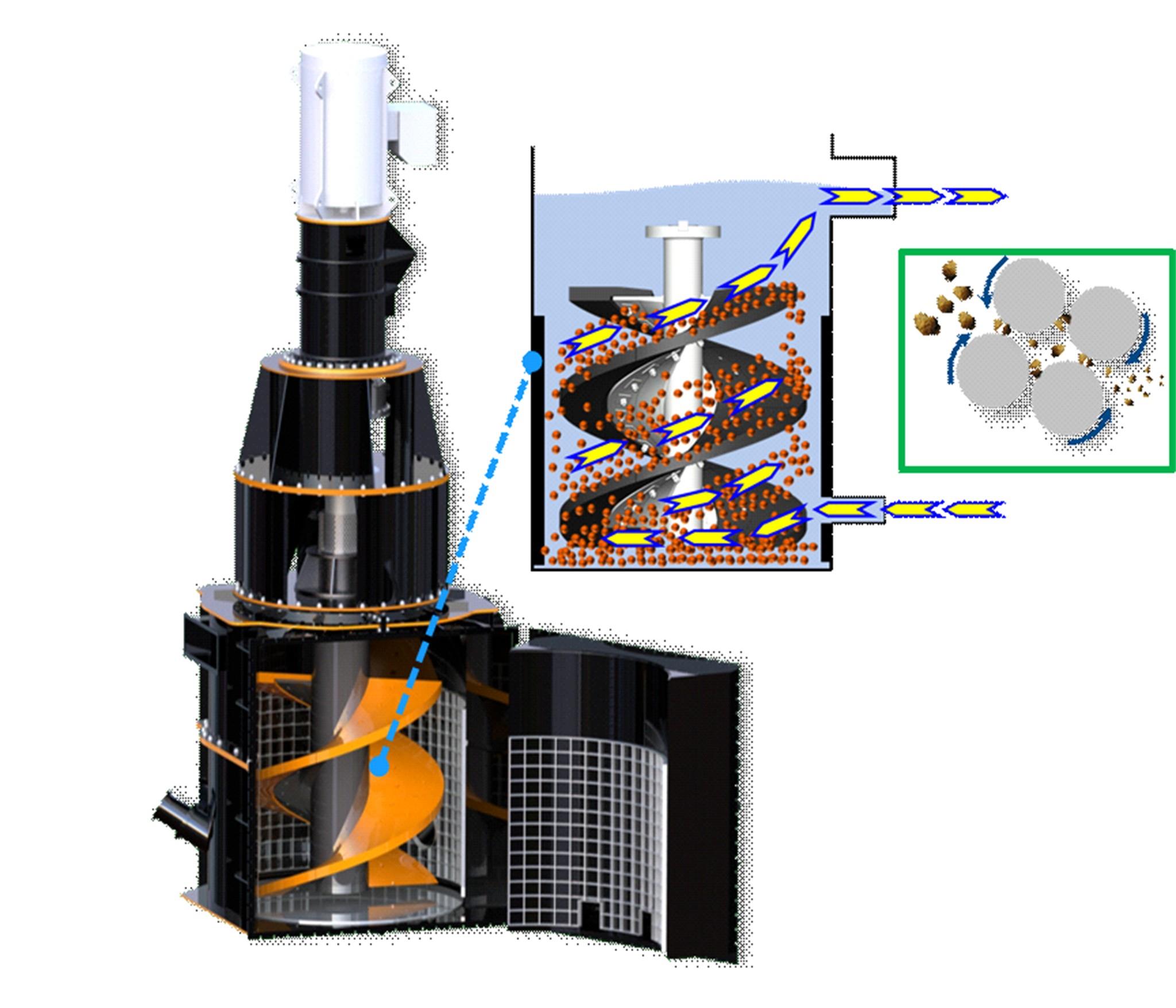

基于数值仿真的大型塔式磨机工作特性分析

- 1.吉林大学 机械与航空航天工程学院,长春 130022

2.北方重工集团有限公司,沈阳 110141

Research on working performance of vertical screw stirring mill based on numerical simulations

Zong-wei YAO1( ),Xu-dong GAO1,Gang LIU2,Qiu-shi BI1(

),Xu-dong GAO1,Gang LIU2,Qiu-shi BI1( )

)

- 1.School of Mechanical and Aerospace Engineering,Jilin University,Changchun 130022,China

2.Northern Heavy Industries Group Co. ,Ltd. ,Shenyang 110141,China

摘要:

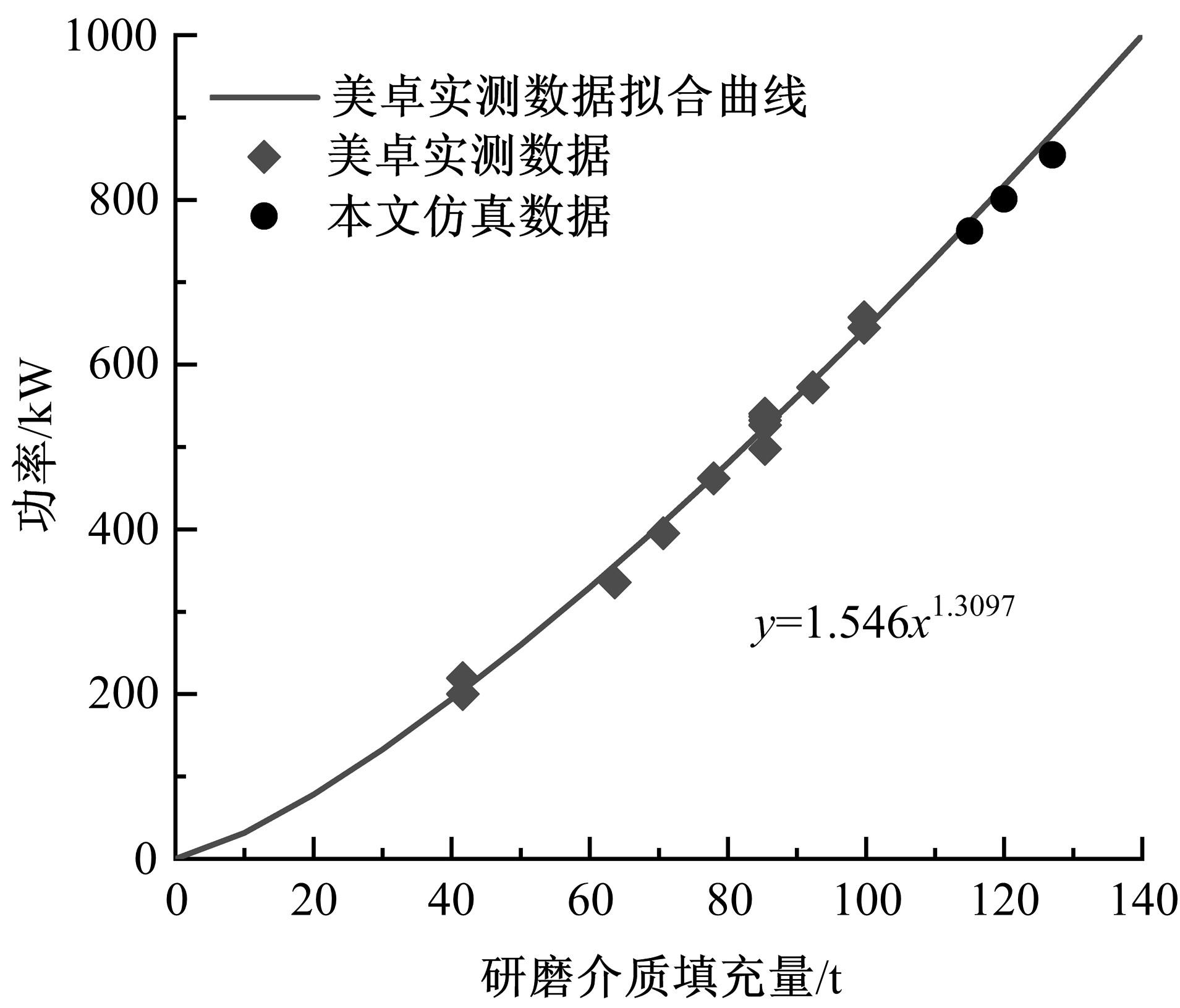

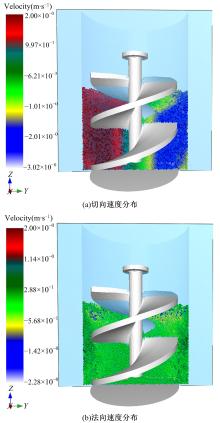

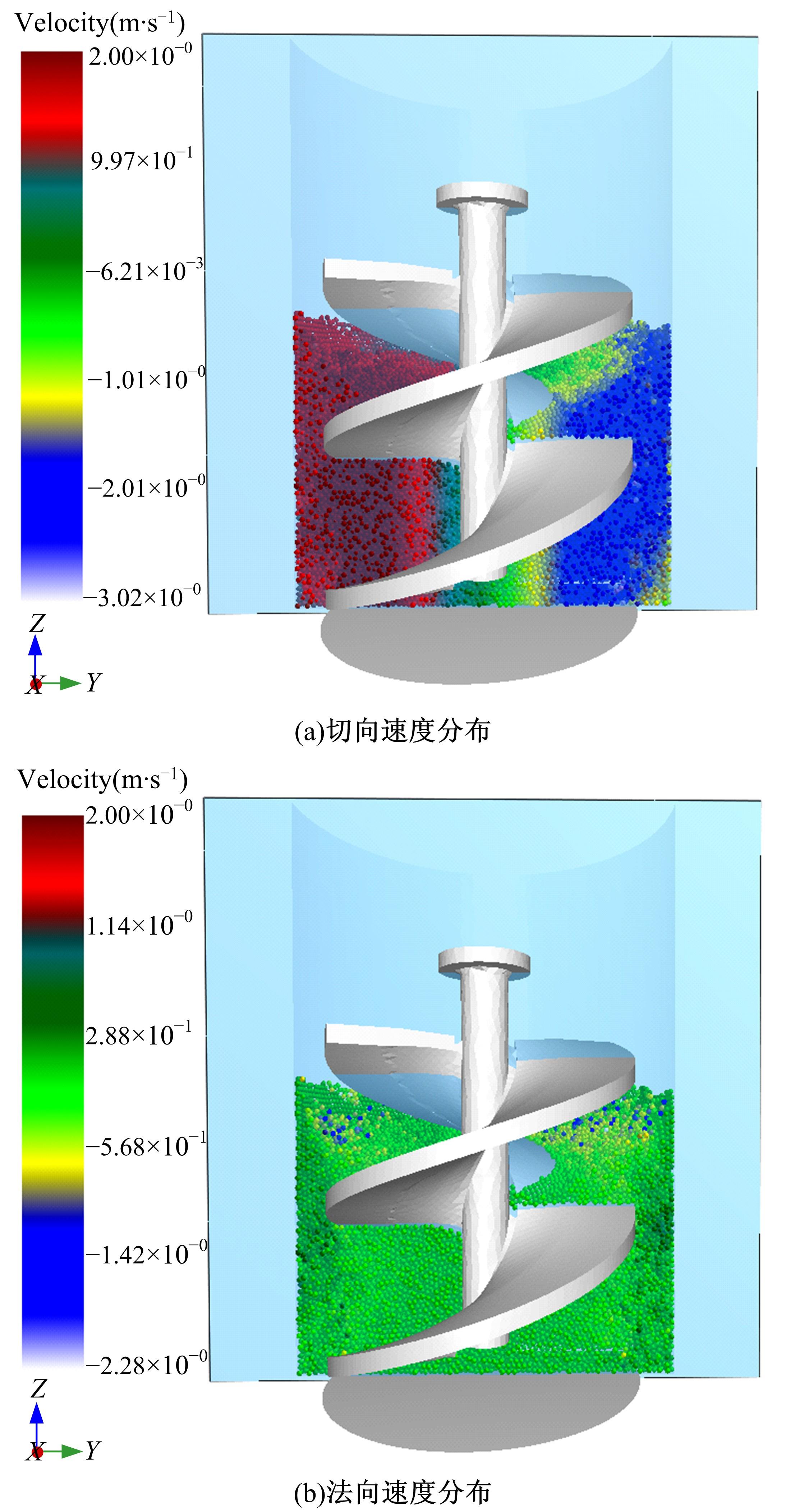

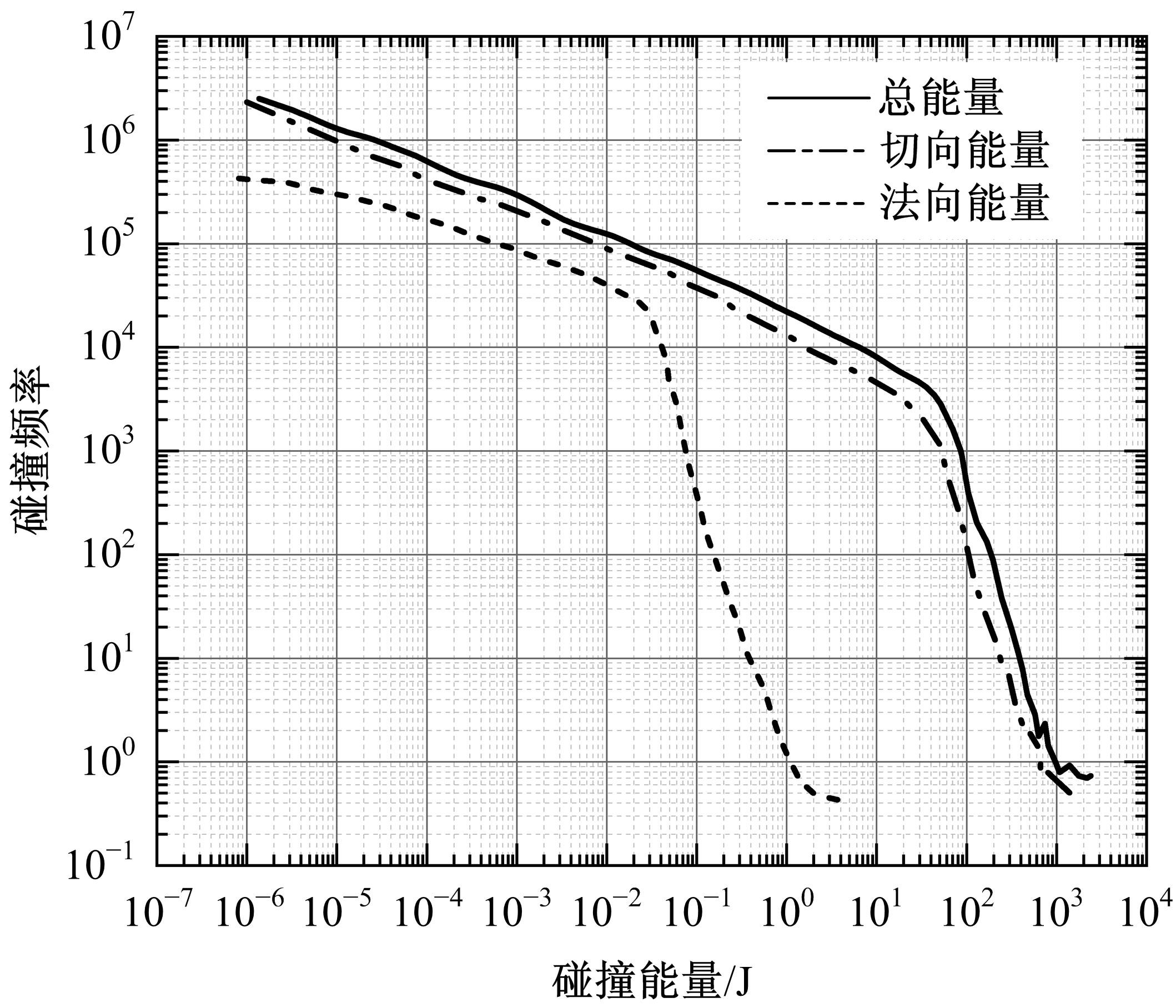

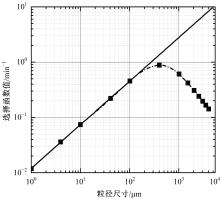

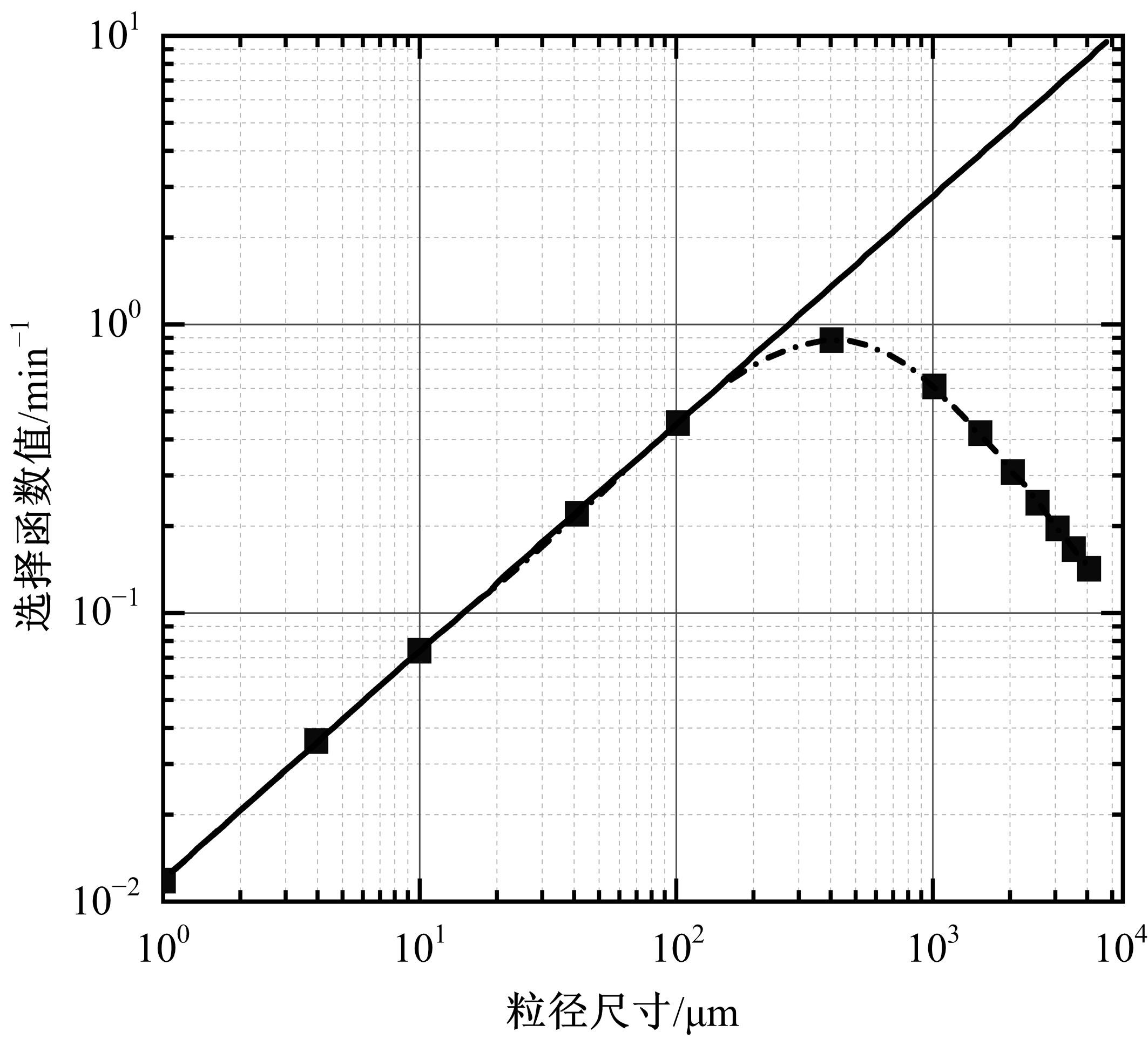

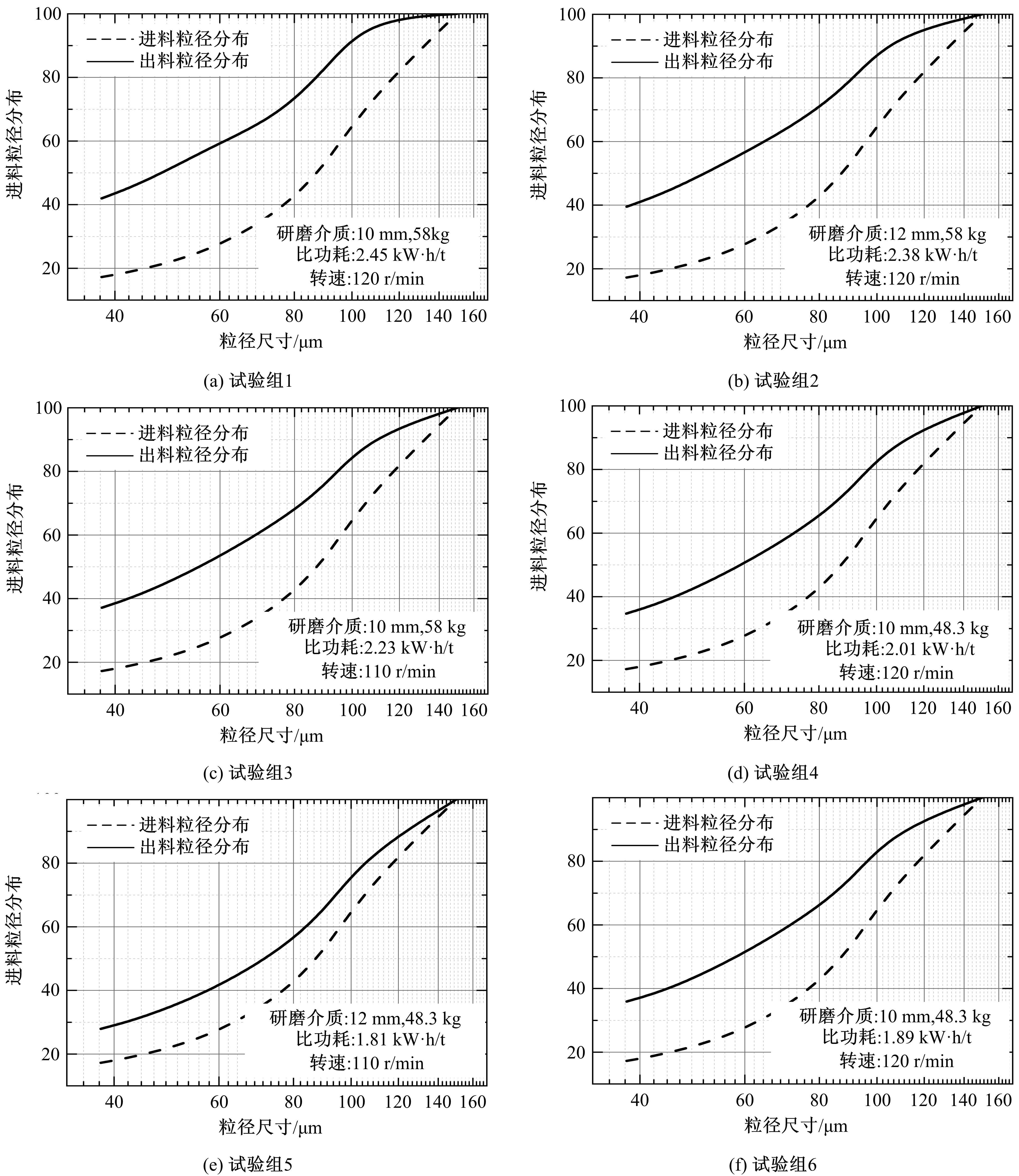

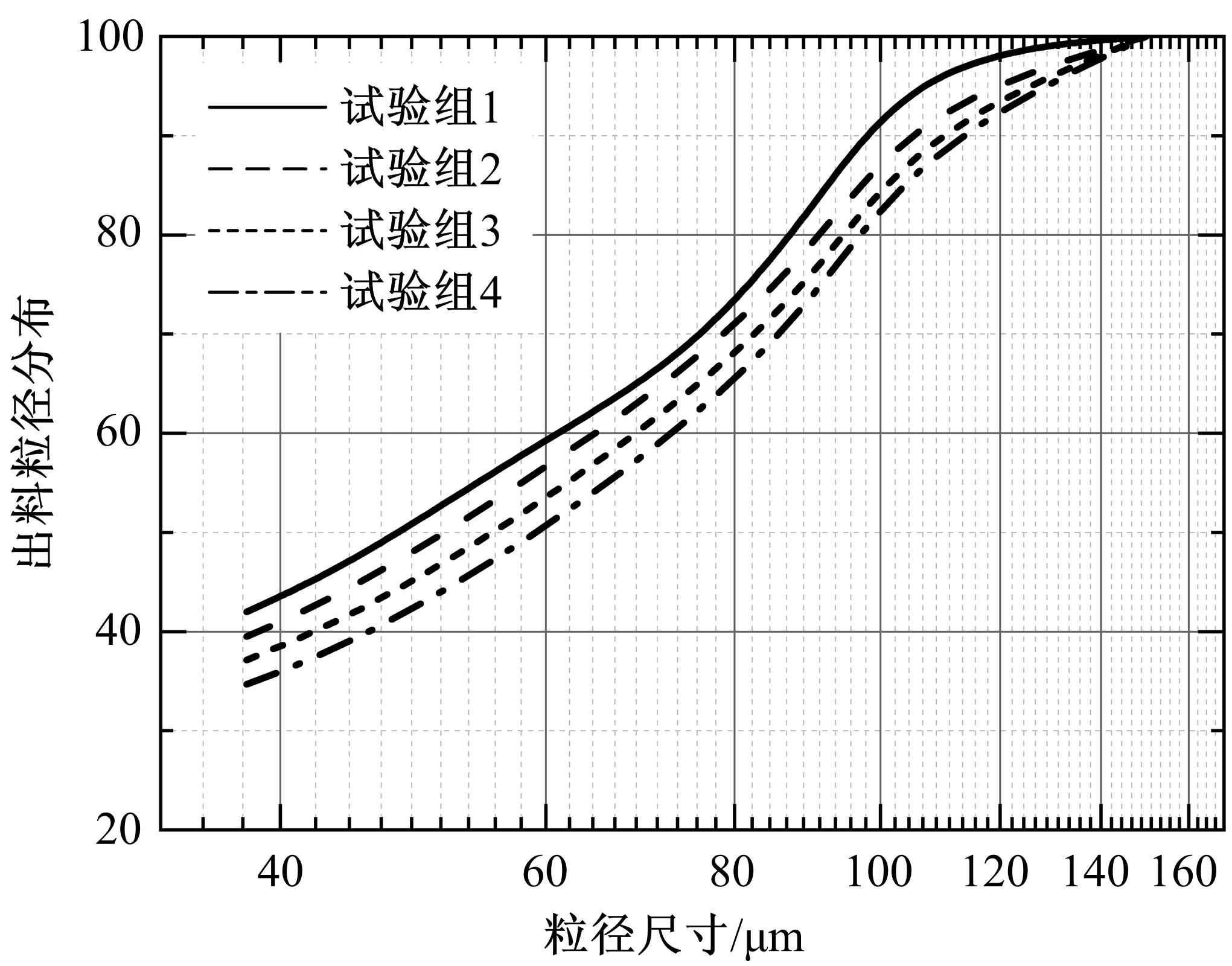

针对大型塔式磨机在设计阶段驱动功率、螺旋主轴应力和出料粒度分布(PSD)等指标的预测不准确问题,提出了基于流固耦合(CFD-DEM)联合仿真的塔式磨机工作过程数值模拟方法,对工作过程中研磨介质运动分布、力链分布、碰撞谱以及驱动功率进行分析,并将载荷信息作用到有限元模型中对磨机螺旋主轴应力状态及分布进行计算;此外,建立塔式磨机磨矿过程的数学模型,以分析不同工艺参数对磨矿效果的影响。通过实测不同装球量条件下的驱动功率验证了流固耦合仿真结果的正确性,并通过一系列磨矿试验确定了数学模型中的关键参数。分析结果表明:研磨介质尺寸、填充量以及螺旋搅拌器速度等参数是影响塔式磨机作业性能的主要因素。

中图分类号:

- TD453

| 1 | Oliveira A L R, Rodriguez V A, de Carvalho R M, et al. Mechanistic modeling and simulation of a batch vertical stirred mill[J]. Minerals Engineering, 2020, 156: 106487. |

| 2 | Daraio D, Villoria J, Ingram A, et al. Investigating grinding media dynamics inside a vertical stirred mill using the discrete element method: effect of impellerarm length[J]. Powder Technology, 2020, 364: 1049-1061. |

| 3 | Larsson S, Palsson B I, Parian M, et al. A novel approach for modelling of physical interactions between slurry, grinding media and mill structure in wet stirred media mills[J]. Minerals Engineering, 2020, 148: 106180. |

| 4 | Prziwara P, Breitung-Faes S, Kwade A. Impact of the powder flow behavior on continuous fine grinding in dry operated stirred media mills[J]. Minerals Engineering, 2018, 128: 215-223. |

| 5 | Flach F, Breitung-Faes S, Kwade A. Model based process optimization of nanosuspension preparation via wet stirred media milling[J]. Powder Technology, 2018, 331: 146-154. |

| 6 | 毕秋实, 王国强, 黄婷婷, 等. 基于DEM-FEM耦合的双齿辊破碎机辊齿强度分析[J]. 吉林大学学报: 工学版, 2018, 48(6): 1770-1776. |

| Bi Qiu-shi, Wang Guo-qiang, Huang Ting-ting, et al. Tooth strength analysis of mineral sizer by coupling discrete element method and finite element method[J] Journal of Jilin University(Engineering and Technology Edition), 2018, 48(6): 1770-1776. | |

| 7 | 于向军, 槐元辉, 李学飞, 等. 基于克里金和粒子群算法的装载机铲掘轨迹规划[J]. 吉林大学学报: 工学版, 2020, 50(2): 437-444. |

| Yu Xiang-jun, Huai Yuan-hui, Li Xue-fei, et al. Shoveling trajectory planning method for wheel loader based on kriging and particle swarm optimization[J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 437-444. | |

| 8 | 王同建, 杨书伟, 谭晓丹, 等. 基于DEM-MBD联合仿真的液压挖掘机作业性能分析[J/OL]. [2021-05-28]. |

| 9 | 石立, 张国旺, 肖骁. 立式螺旋搅拌磨机的启动力矩研究[J]. 矿山机械, 2013, 41(7): 68-71. |

| Shi Li, Zhang Guo-wang, Xiao Xiao. Study on staring torque of vertical screw stirring mill[J] Mining & Processing Equipment, 2013, 41(7): 68-71. | |

| 10 | 张国旺, 黄圣生. 超细搅拌磨机的流场模拟和应用[J].矿山机械, 2008, 36(21): 78-83. |

| Zhang Guo-wang, Huang Sheng-sheng. Flow-field numerical simulation and application of ultra-fine stirred mill[J]. Mining & Processing Equipment, 2008, 36(21): 78-83. | |

| 11 | 宁晓斌, 孙新明, 佘翊妮, 等. 搅拌磨DEM-CFD耦合仿真研究及搅拌器强度分析[J]. 有色金属工程, 2016, 6(4): 63-67, 72. |

| Ning Xiao-bin, Sun Xin-ming, She Yi-ni, et al. Research on multidisciplinary coupling simulation of the vertical stirred mill based on DEM-CFD and analysis of the screw agitator structural strength[J]. Nonferrous Metals Engineering, 2016, 6(4): 63-67, 72. | |

| 12 | 母福生, 董方, 史金东, 等. 塔式磨机磨矿机理及关键参数研究[J]. 中国机械工程, 2011, 22(7): 815-817. |

| Mu Fu-sheng, Dong Fang, Shi Jin-dong, et al. Analysis of DEM numerical simulation of media movement for a stirred mill[J]. China Mechanical Engineering, 2011, 22(7): 815-817. | |

| 13 | 黄胤淇. 磨矿条件对立式搅拌磨磨矿产品粒度特性的影响及应用[D]. 昆明: 昆明理工大学国土资源工程学院, 2019. |

| Huang Yin-qi. Influence and application of influence of grinding conditions on particle characters of vertical stirred mill[D] Kunming: Kunming University of Science and Technology, Faculty of Land Resource Engineering of KUST, 2019. | |

| 14 | Sousani M, Hobbs A M, Anderson A, et al. Accelerated heat transfer simulations using coupled DEM and CFD[J]. Powder Technology, 2019, 357: 367-376. |

| 15 | Jankovic A, Valery W, Clarke G. Design and implementation of an AVC grinding circuit at BHP billiton cannington[C]∥Fourth International Conference on Autogenous and Semiautogenous Grinding Technology(SAG 2006). Vancouver: University of British Columbia, 2006: 290-300. |

| 16 | King R P. Modeling and Simulation of Mineral Processing Systems[M]. Elsevier, 2001. |

| 17 | Hasan M, Palaniandy S, Hilden M, et al. Simulating product size distribution of an industrial scale VertiMill® using a time-based population balance model[J]. Minerals Engineering, 2018, 127: 312-317. |

| 18 | Hasan M, Palaniandy S, Hilden M, et al. Calculating breakage parameters of a batch vertical stirred mill[J]. Minerals Engineering, 2017, 111: 229-237. |

| [1] | 胡晶,李聪,张邦成,乔晓利,张心明,周笑平. 考虑离心膨胀的双级串联轴承油膜刚度和阻尼[J]. 吉林大学学报(工学版), 2021, 51(5): 1601-1611. |

| [2] | 陈魏,雷雨龙,李兴忠,付尧,扈建龙,侯利国. 低速工况下渐开线圆柱直齿轮齿面粘着磨损计算[J]. 吉林大学学报(工学版), 2021, 51(5): 1628-1634. |

| [3] | 李卫,张怀亮,瞿维. 随机振动环境下液压直管道设计方法[J]. 吉林大学学报(工学版), 2021, 51(4): 1222-1229. |

| [4] | 李晓韬,任金鹏,李晓旭,杨航. 双压电振子反相模态驱动的直线驱动器机理[J]. 吉林大学学报(工学版), 2021, 51(2): 468-471. |

| [5] | 侯才生,刘涛,郭李先. 一种新型变壁厚涡旋型线的构建理论[J]. 吉林大学学报(工学版), 2020, 50(5): 1627-1634. |

| [6] | 程功,肖科,王家序,蒲伟,韩彦峰. 混合润滑状态下齿轮接触刚度[J]. 吉林大学学报(工学版), 2020, 50(2): 494-503. |

| [7] | 毛艳,成凯. 基于Hopfield神经网络的单缸插销式伸缩臂伸缩路径优化[J]. 吉林大学学报(工学版), 2020, 50(1): 53-65. |

| [8] | 郭震,于红英,滑忠鑫,赵娣. 刚性折纸机构运动分析及折叠过程仿真[J]. 吉林大学学报(工学版), 2020, 50(1): 66-76. |

| [9] | 贾富淳,孟宪皆,雷雨龙. 基于多目标遗传算法的二自由度动力吸振器优化设计[J]. 吉林大学学报(工学版), 2019, 49(6): 1969-1976. |

| [10] | 谢志江,王昆,皮阳军,吴小勇,郭映位. 新的6⁃PSS型并联机构正向运动学求解方法[J]. 吉林大学学报(工学版), 2019, 49(6): 1977-1985. |

| [11] | 胡兴军,惠政,郭鹏,张扬辉,张靖龙,王靖宇,刘飞. 基于流固耦合的汽车气动特性[J]. 吉林大学学报(工学版), 2019, 49(5): 1414-1419. |

| [12] | 曹恩国,刘坤,吉硕,孙震源,徐洪伟,骆星吉. 减重站起康复训练系统机械结构设计与优化[J]. 吉林大学学报(工学版), 2019, 49(5): 1558-1566. |

| [13] | 李俊烨,刘洋,卢慧,孟文卿,杨兆军,张心明. 基于分子动力学的磨粒微切削单晶铁数值分析[J]. 吉林大学学报(工学版), 2019, 49(5): 1567-1574. |

| [14] | 曲昭伟,潘昭天,陈永恒,陶鹏飞,孙迪. 基于最优速度模型的改进安全距离跟驰模型[J]. 吉林大学学报(工学版), 2019, 49(4): 1092-1099. |

| [15] | 张艳芹,冯雅楠,孔鹏睿,于晓东,孔祥滨. 基于热油携带的静压支承油膜温度场及试验[J]. 吉林大学学报(工学版), 2019, 49(4): 1203-1211. |

|

||