吉林大学学报(工学版) ›› 2020, Vol. 50 ›› Issue (2): 494-503.doi: 10.13229/j.cnki.jdxbgxb20181131

• 车辆工程·机械工程 • 上一篇

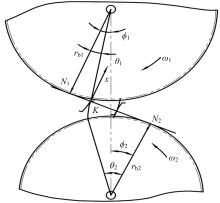

混合润滑状态下齿轮接触刚度

- 1.重庆大学 机械工程学院,重庆 400044

2.四川大学 空天科学与工程学院,成都 610065

Gear contact stiffness under mixed lubrication status

Gong CHENG1( ),Ke XIAO1(

),Ke XIAO1( ),Jia-xu WANG1,2,Wei PU2,Yan-feng HAN1

),Jia-xu WANG1,2,Wei PU2,Yan-feng HAN1

- 1.College of Mechanical Engineering,Chongqing University, Chongqing 400044,China

2.School of Aeronautics and Astronautics, Sichuan University, Chengdu 610065, China

摘要:

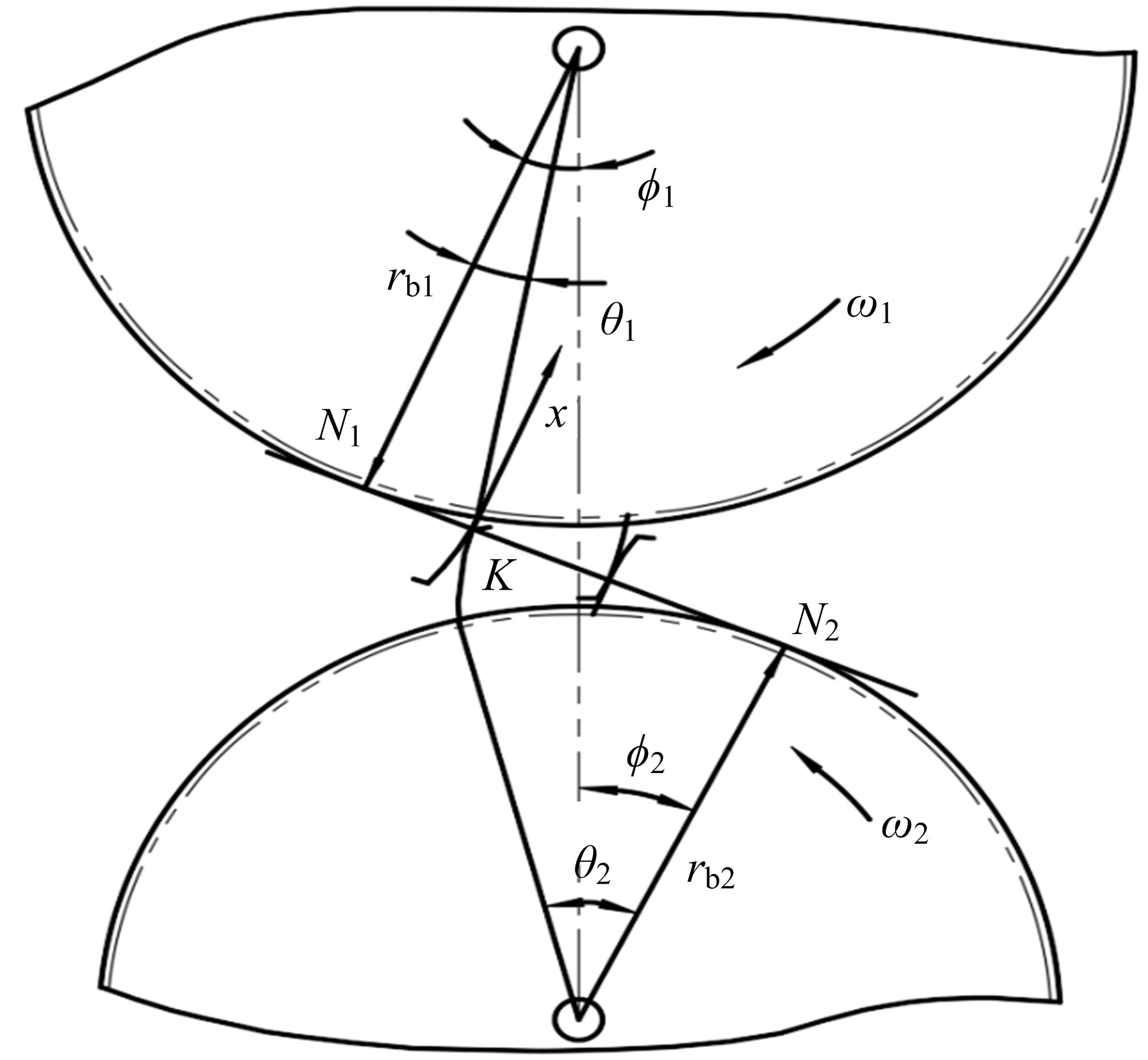

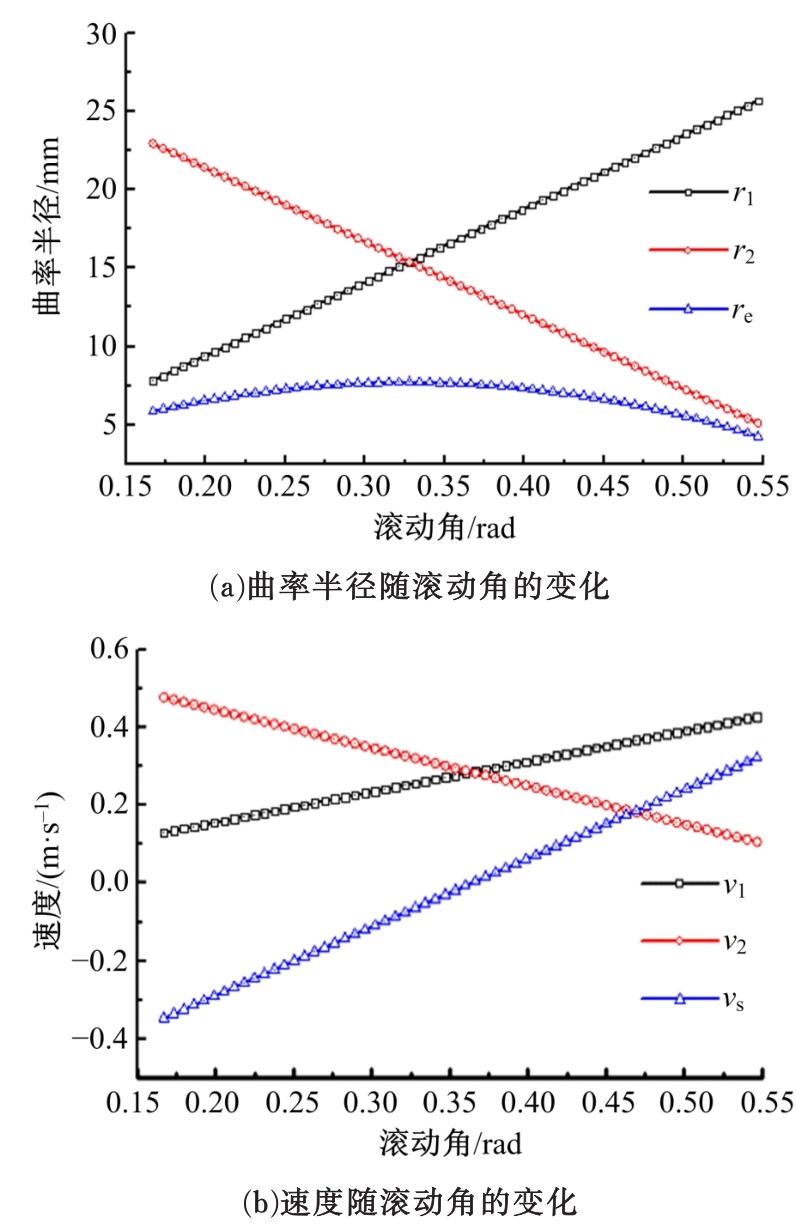

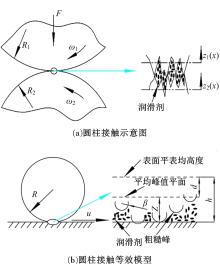

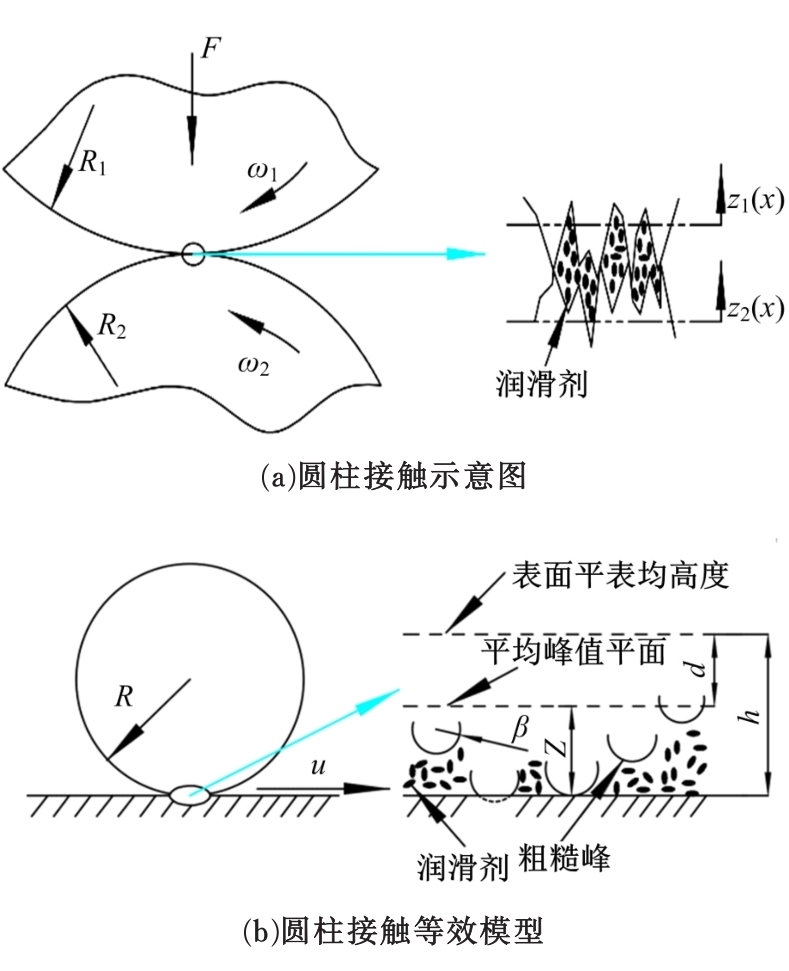

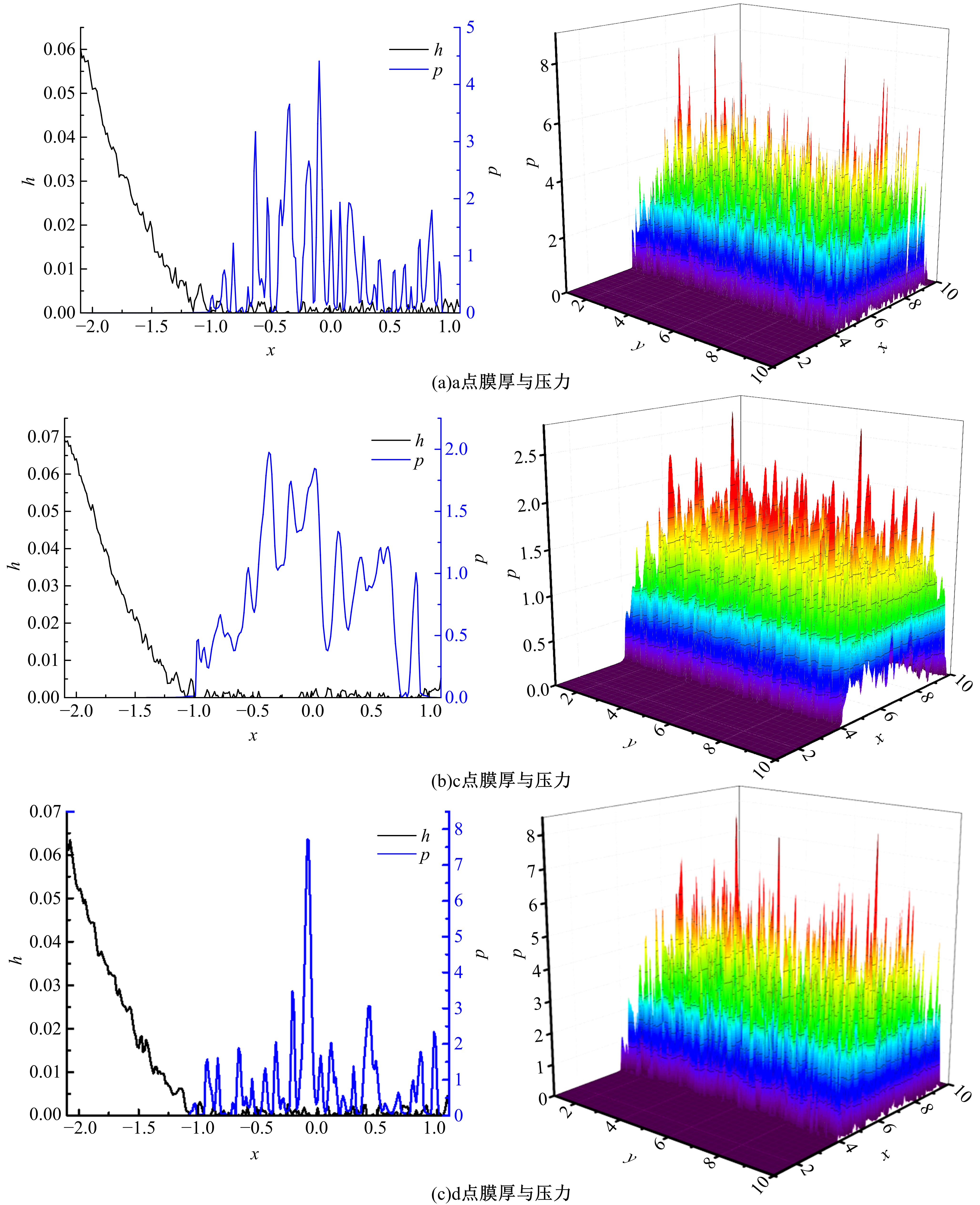

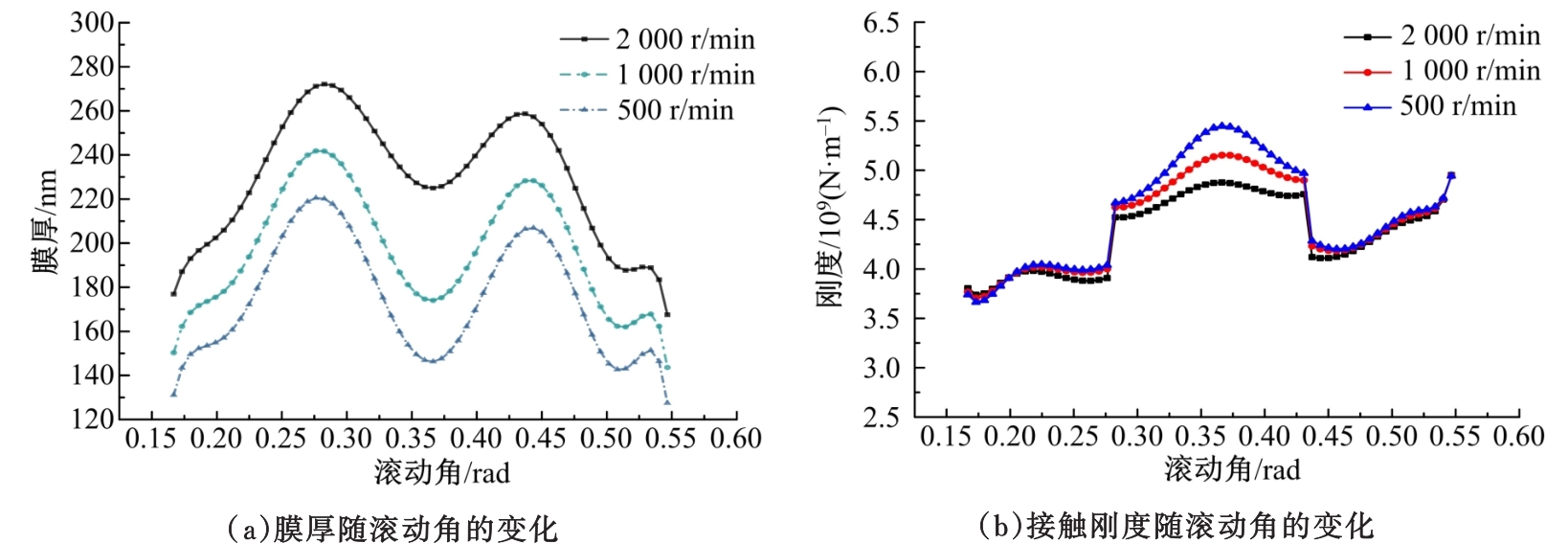

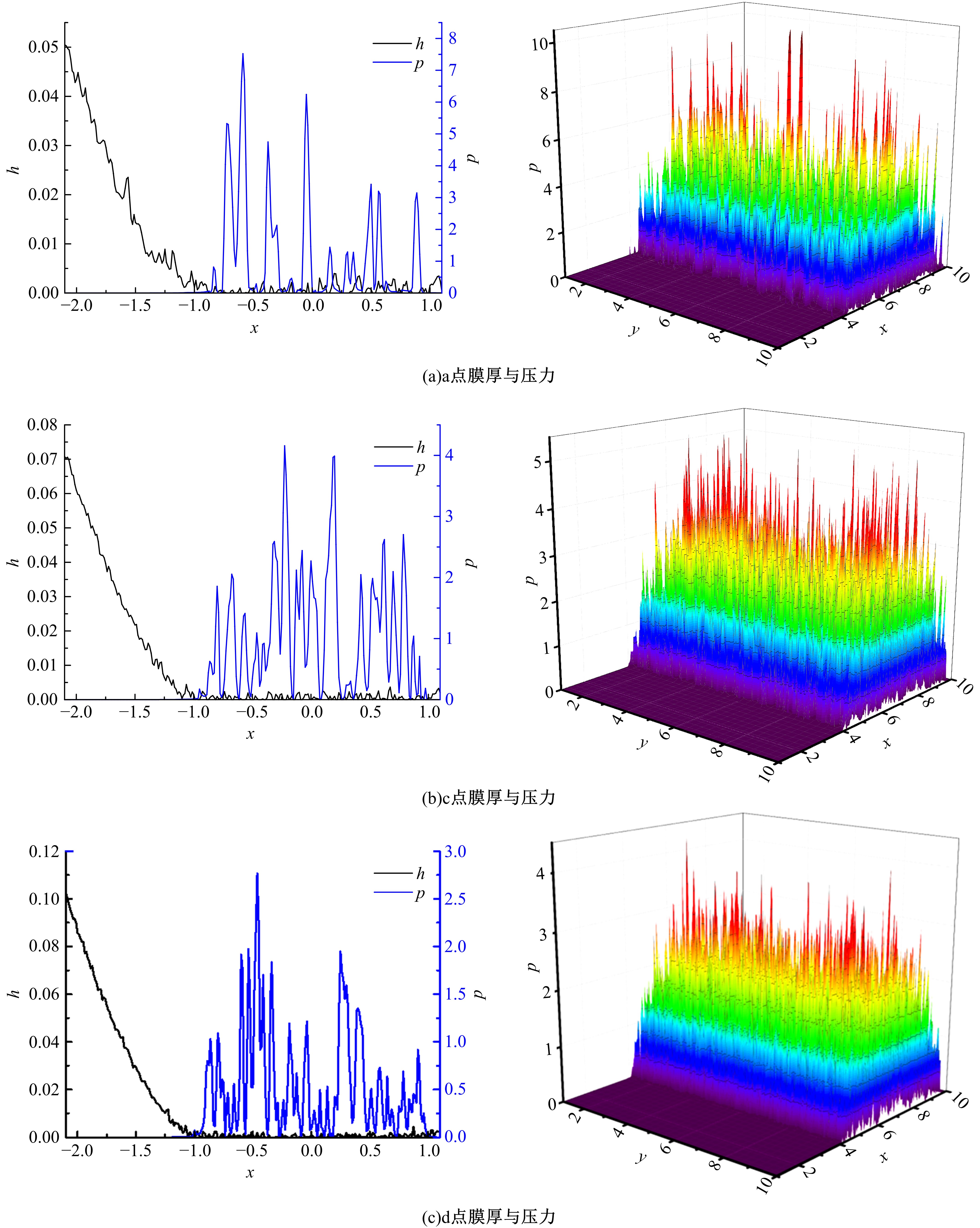

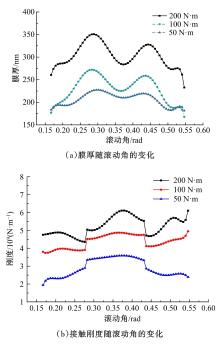

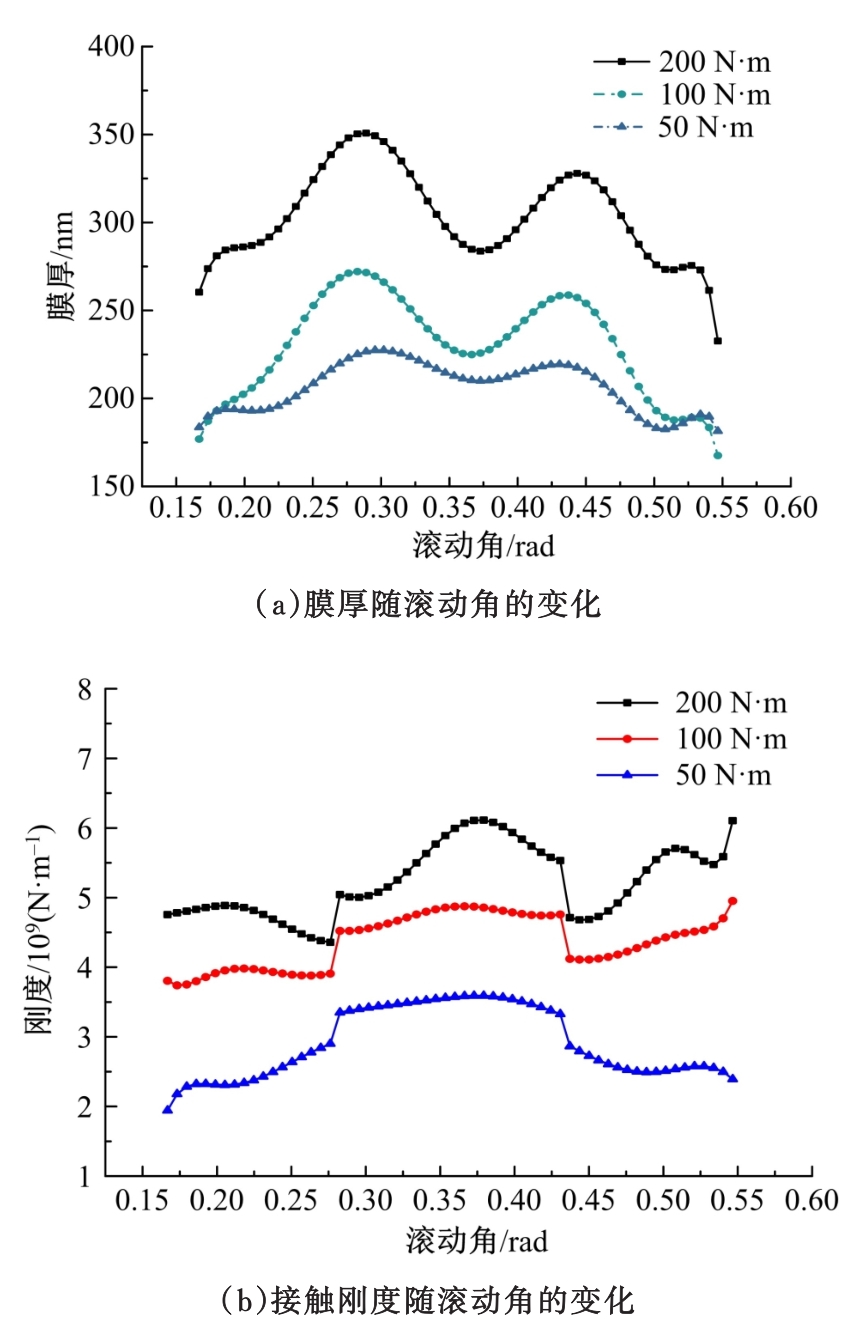

为研究混合润滑状态下齿轮的接触刚度,提出了一种计算齿轮接触刚度的方法。首先计算出齿轮啮合过程中运动参数和受力情况,然后采用混合弹流润滑方法求解得到不同时刻粗糙齿面啮合处的膜厚与压力分布,将结果代入接触刚度计算式,得到不同时刻齿轮啮合的接触刚度。讨论了不同工况对齿轮啮合接触刚度的影响,并将光滑表面接触刚度与粗糙表面接触刚度进行了对比。结果表明:转速和载荷对接触刚度影响很大,速度越快,接触刚度越小;载荷越大,接触刚度越大。

中图分类号:

- TH117.2

| 1 | Greenwood J A, Williamson J B P. Contact of nominally flat surfaces[J]. Proceedings of the Royal Society of London, Series A, 1966, 295( 1442): 300- 319. |

| 2 | 张学良, 黄玉美, 傅卫平, 等. 粗糙表面法向接触刚度的分形模型[J]. 应用力学学报, 2000, 17( 2): 31- 35. |

| Zhang Xue-liang, Huang Yu-mei, Fu Wei-ping, et al. Fractal model of normal contact stiffness between rough surfaces[J]. Chinese Journal of Applied Mechanics, 2000, 17( 2): 31- 35. | |

| 3 | Akarapu S, Sharp T, Robbins M O. Stiffness of contacts between rough surfaces[J]. Physical Review Letters, 2011, 106( 20): 204- 301. |

| 4 | 尤晋闽, 陈天宁. 基于分形接触理论的结合面法向接触参数预估[J]. 上海交通大学学报, 2011, 45( 9): 1275- 1280. |

| You Jin-min, Chen Tian-ning. Estimation for normal parameters of joint surfaces based on fractal theory[J]. Journal of Shanghai Jiaotong University, 2011, 45( 9): 1275- 1280. | |

| 5 | Hyun S, Robbins M O. Elastic contact between rough surfaces: effect of roughness at large and small wavelengths[J]. Tribology International, 2007, 40( 10-12): 1413- 1422. |

| 6 | 李辉光, 刘恒, 虞烈. 粗糙机械结合面的接触刚度研究[J]. 西安交通大学学报, 2011, 45( 6): 69- 74. |

| Li Hui-guang, Liu Heng, Yu Lie. Contact stiffness of rough mechanical joint surface[J]. Journal of Xi'an Jiaotong University, 2011, 45( 6): 69- 74. | |

| 7 | Pohrt R, Popov V L. Normal contact stiffness of elastic solids with fractal rough surfaces[J]. Physical Review Letters, 2012, 108( 10): 1- 12. |

| 8 | Pohrt R, Popov V L. Contact stiffness of randomly rough surfaces[J/OL].[ 2018-11-13]. |

| 9 | 庄艳, 李宝童, 洪军, 等. 一种结合面法向接触刚度计算模型的构建[J]. 上海交通大学学报, 2013, 47( 2): 180- 186. |

| Zhuang Yan, Li Bao-tong, Hong Jun, et al. A normal contact stiffness model of the interface [J]. Journal of Shanghai Jiaotong University, 2013, 47( 2): 180- 186. | |

| 10 | 田小龙, 王雯, 傅卫平, 等. 考虑微凸体相互作用的机械结合面接触刚度模型[J]. 机械工程学报, 2017, 53( 17): 149- 159. |

| Tian Xiao-long, Wang Wen, Fu Wei-Ping, et al. Contact stiffness model of mechanical joint surfaces considering the asperity interactions[J]. Journal of Mechanical Engineering, 2017, 53( 17): 149- 159. | |

| 11 | 王雯, 吴洁蓓, 傅卫平, 等. 机械结合面法向动态接触刚度理论模型与试验研究[J]. 机械工程学报, 2016, 52( 13): 123- 130. |

| Wang Wen, Wu Jie-bei, Fu Wei-ping, et al. Theoretical and experimental research on normal dynamic contact stiffness of machined joint surfaces[J]. Journal of Mechanical Engineering, 2016, 52( 13): 123- 130. | |

| 12 | 傅卫平, 娄雷亭, 高志强, 等. 机械结合面法向接触刚度和阻尼的理论模型[J]. 机械工程学报, 2017, 53( 9): 73- 82. |

| Fu Wei-ping, Lou Lei-ting, Gao Zhi-qiang, et al. Theoretical model for the contact stiffness and damping of mechanical joint surface[J]. Journal of Mechanical Engineering, 2017, 53( 9): 73- 82. | |

| 13 | 赵韩, 陈奇, 黄康. 两圆柱体结合面的法向接触刚度分形模型[J]. 机械工程学报, 2011, 47( 7): 53- 58. |

| Zhao Han, Chen Qi, Huang Kang. Fractal model of normal contact stiffness between two cylinders’ joint interfaces[J]. Journal of Mechanical Engineering, 2011, 47( 7): 53- 58. | |

| 14 | Chen Q, Xu F, Liu P, et al. Research on fractal model of normal contact stiffness between two spheroidal joint surfaces considering friction factor[J]. Tribology International, 2016, 97: 253- 264. |

| 15 | 刘鹏, 赵韩, 黄康, 等. 线段齿轮法向接触刚度的改进分形模型研究[J]. 机械工程学报, 2018, 54( 7): 114- 122. |

| Liu Peng, Zhao Han, Huang Kang, et al. Research on normal contact stiffness of micro-segments gear based on improved fractal model[J]. Journal of Mechanical Engineering, 2018, 54( 7): 114- 122. | |

| 16 | 欧阳天成, 陈南, 牛亚峰. 不同粗糙面渐开线齿轮混合弹流润滑[J]. 吉林大学学报: 工学版, 2016, 46( 6): 1933- 1939. |

| Ouyang Tian-cheng, Chen Nan, Niu Ya-feng. Mixed elastohydrodynamic lubrication for involute gear with different rough surfaces[J]. Journal of Jilin University (Engineering and Technology Edition), 2016, 46( 6): 1933- 1939. | |

| 17 | 张阔, 谭庆昌, 王顺, 等. 表面粗糙度幅值对点接触混合润滑的影响[J]. 吉林大学学报: 工学版, 2012, 42( 2): 377- 381. |

| Zhang Kuo, Tan Qing-chang, Wang Shun, et al. Effect of surface roughness amplitude on point contact mixed lubrication condition[J]. Journal of Jilin University (Engineering and Technology Edition), 2012, 42( 2): 377- 381. | |

| 18 | Dwyer-joyce R S, Reddyhoff T, Zhu J. Ultrasonic measurement for film thickness and solid contact in elastohydrodynamic lubrication[J]. Journal of Tribology, 2011, 133( 3): 031501. |

| 19 | Xiao H, Sun Y, Xu J. Investigation into the normal contact stiffness of rough surface in line contact mixed elastohydrodynamic lubrication[J]. Tribology Transactions, 2018, 41( 4): 742- 753. |

| 20 | Zhou C, Xiao Z, Chen S, et al. Normal and tangential oil film stiffness of modified spur gear with non-Newtonian elastohydrodynamic lubrication[J]. Tribology International, 2017, 109: 319- 327. |

| 21 | Zhou C, Xiao Z. Stiffness and damping models for the oil film in line contact elastohydrodynamic lubrication and applications in the gear drive[J]. Applied Mathematical Modeling, 2018, 61: 634- 649. |

| 22 | Ren N, Zhu D, Chen W W, et al. A three-dimensional deterministic model for rough surface line-contact EHL problems[J]. Journal of Tribology, 2009, 131( 1): 011501. |

| 23 | Masjedi M, Khonsari M M. Film thickness and asperity load formulas for line-contact elastohydrodynamic lubrication with provision for surface roughness[J]. Journal of Tribology, 2012, 134( 1): 011503. |

| [1] | 毛艳,成凯. 基于Hopfield神经网络的单缸插销式伸缩臂伸缩路径优化[J]. 吉林大学学报(工学版), 2020, 50(1): 53-65. |

| [2] | 郭震,于红英,滑忠鑫,赵娣. 刚性折纸机构运动分析及折叠过程仿真[J]. 吉林大学学报(工学版), 2020, 50(1): 66-76. |

| [3] | 贾富淳,孟宪皆,雷雨龙. 基于多目标遗传算法的二自由度动力吸振器优化设计[J]. 吉林大学学报(工学版), 2019, 49(6): 1969-1976. |

| [4] | 谢志江,王昆,皮阳军,吴小勇,郭映位. 新的6⁃PSS型并联机构正向运动学求解方法[J]. 吉林大学学报(工学版), 2019, 49(6): 1977-1985. |

| [5] | 曹恩国,刘坤,吉硕,孙震源,徐洪伟,骆星吉. 减重站起康复训练系统机械结构设计与优化[J]. 吉林大学学报(工学版), 2019, 49(5): 1558-1566. |

| [6] | 李俊烨,刘洋,卢慧,孟文卿,杨兆军,张心明. 基于分子动力学的磨粒微切削单晶铁数值分析[J]. 吉林大学学报(工学版), 2019, 49(5): 1567-1574. |

| [7] | 张艳芹,冯雅楠,孔鹏睿,于晓东,孔祥滨. 基于热油携带的静压支承油膜温度场及试验[J]. 吉林大学学报(工学版), 2019, 49(4): 1203-1211. |

| [8] | 杨成,赵永胜,刘志峰,蔡力钢. 基于多尺度理论的栓接结合部动力学建模[J]. 吉林大学学报(工学版), 2019, 49(4): 1212-1220. |

| [9] | 王兴野,张进秋,李国强,彭志召. 惯性质量对齿轮齿条式作动器阻尼特性的影响[J]. 吉林大学学报(工学版), 2019, 49(3): 881-887. |

| [10] | 王家序,倪小康,韩彦峰,向果,肖科. 轴向往复运动下微槽轴承混合润滑数值模型[J]. 吉林大学学报(工学版), 2019, 49(3): 888-896. |

| [11] | 刘坤,吉硕,孙震源,徐洪伟,刘勇,赵静霞. 多功能坐站辅助型如厕轮椅机械结构设计与优化[J]. 吉林大学学报(工学版), 2019, 49(3): 872-880. |

| [12] | 毕秋实,王国强,黄婷婷,毛瑞,鲁艳鹏. 基于DEM-FEM耦合的双齿辊破碎机辊齿强度分析[J]. 吉林大学学报(工学版), 2018, 48(6): 1770-1776. |

| [13] | 朱伟,王传伟,顾开荣,沈惠平,许可,汪源. 一种新型张拉整体并联机构刚度及动力学分析[J]. 吉林大学学报(工学版), 2018, 48(6): 1777-1786. |

| [14] | 刘建芳, 王记波, 刘国君, 李新波, 梁实海, 杨志刚. 基于PMMA内嵌三维流道的压电驱动微混合器[J]. 吉林大学学报(工学版), 2018, 48(5): 1500-1507. |

| [15] | 毛宇泽, 王黎钦. 鼠笼支撑一体化结构对薄壁球轴承承载性能的影响[J]. 吉林大学学报(工学版), 2018, 48(5): 1508-1514. |

|

||