吉林大学学报(工学版) ›› 2023, Vol. 53 ›› Issue (4): 1231-1244.doi: 10.13229/j.cnki.jdxbgxb.20210767

• 农业工程·仿生工程 • 上一篇

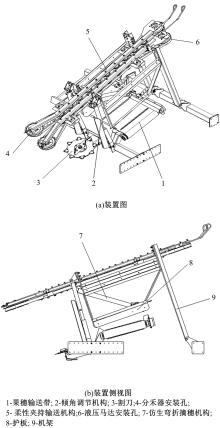

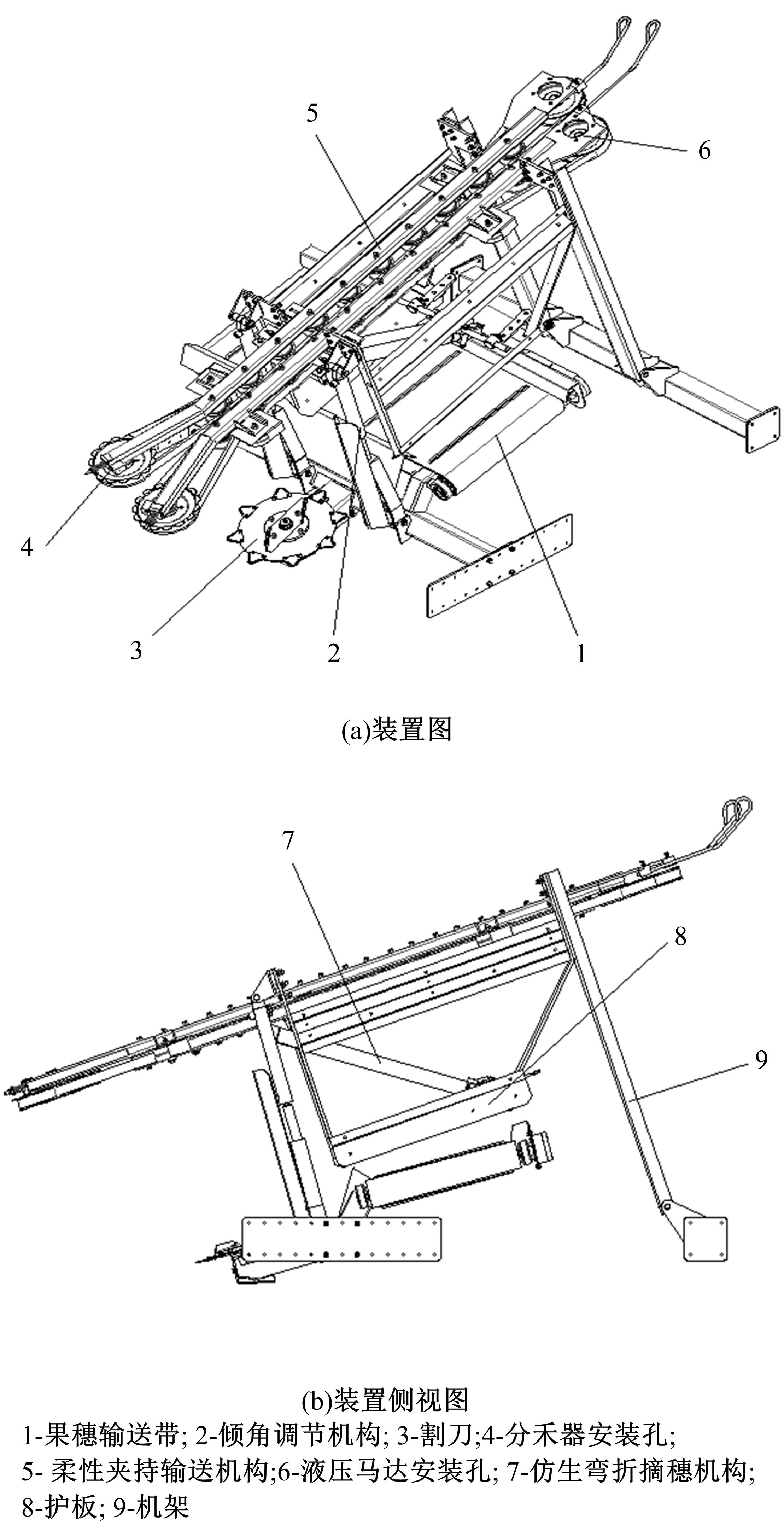

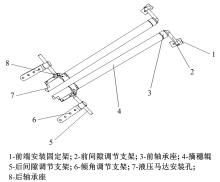

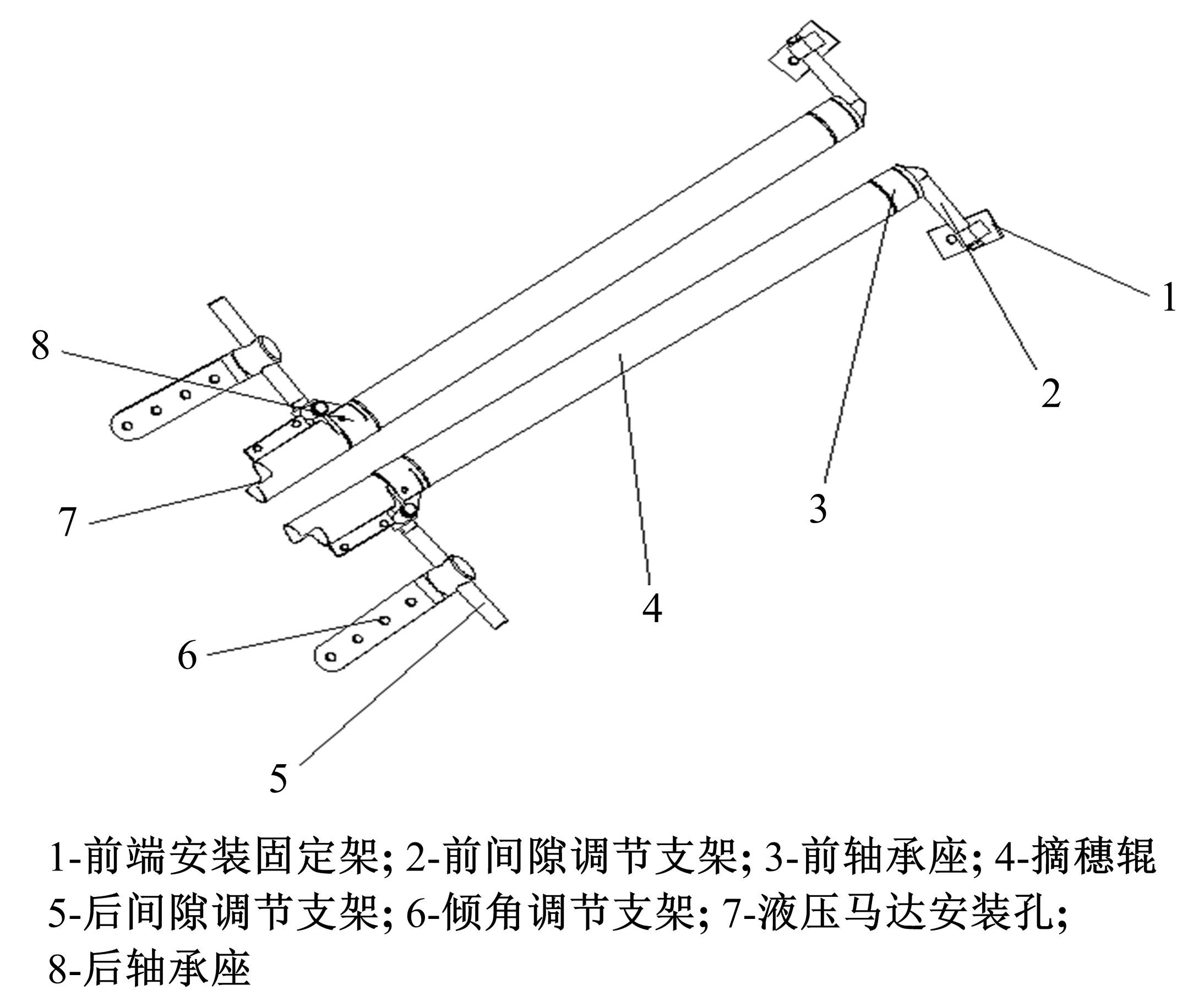

鲜食玉米仿生摘穗装置设计与试验

- 1.东北农业大学 工程学院, 哈尔滨 150030

2.北部湾大学 机械与船舶海洋工程学院, 广西 钦州 535011

3.黑龙江科技大学 机械工程学院, 哈尔滨 150020

Design and experiment of bionic ear picking device for fresh corn

Guang-qiang ZHU1( ),Tian-yu LI1,Fu-jun ZHOU2(

),Tian-yu LI1,Fu-jun ZHOU2( ),Wen-ming WANG3

),Wen-ming WANG3

- 1.College of Engineering,Northeast Agricultural University,Harbin 150030,China

2.College of Mechanical and Marine Engineering,Beibu Gulf University,Qinzhou 535011,China

3.School of Mechanical Engineering,Heilongjiang University of Science and Technology,Harbin 150020,China

摘要:

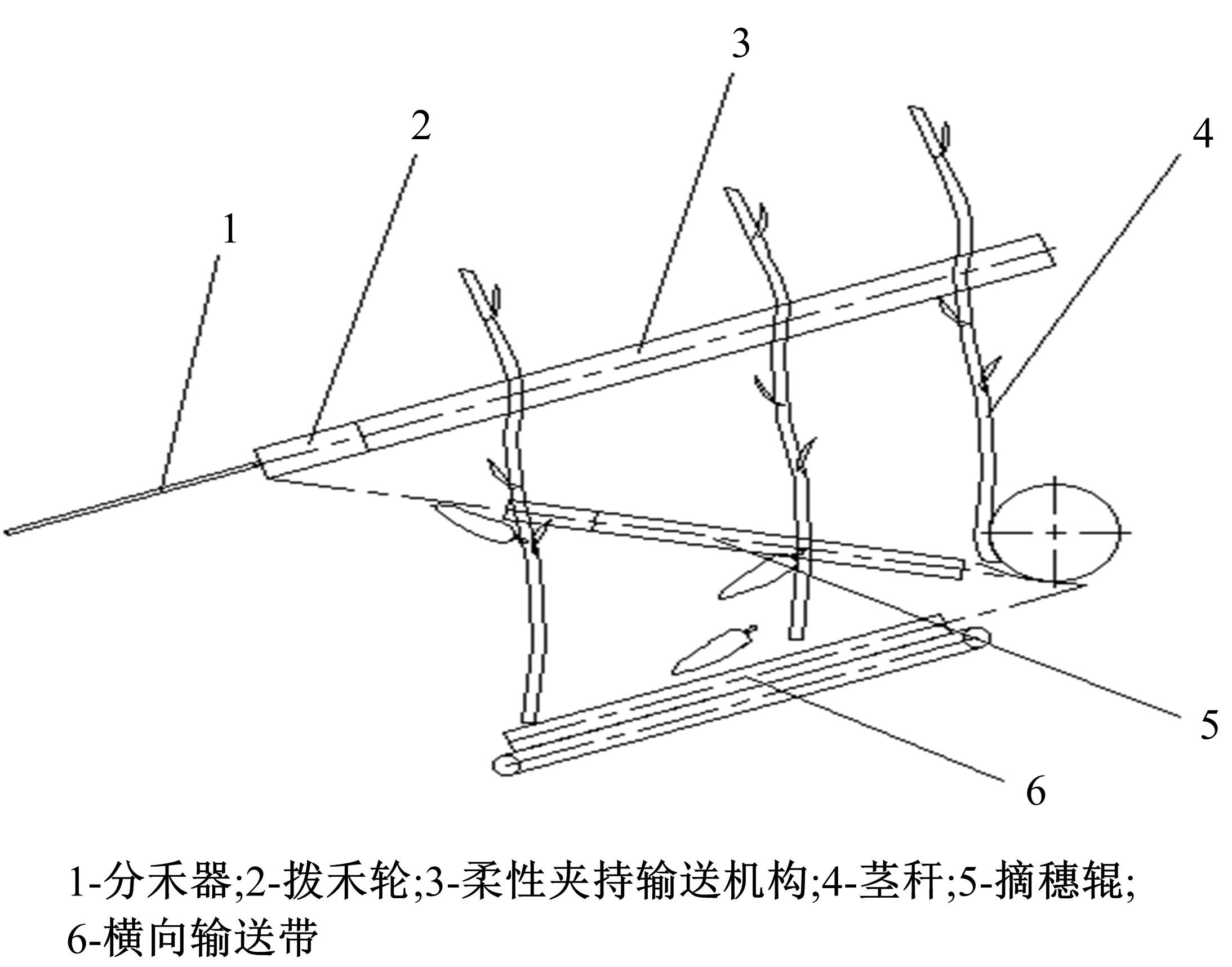

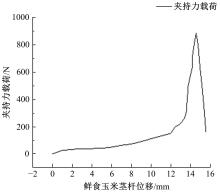

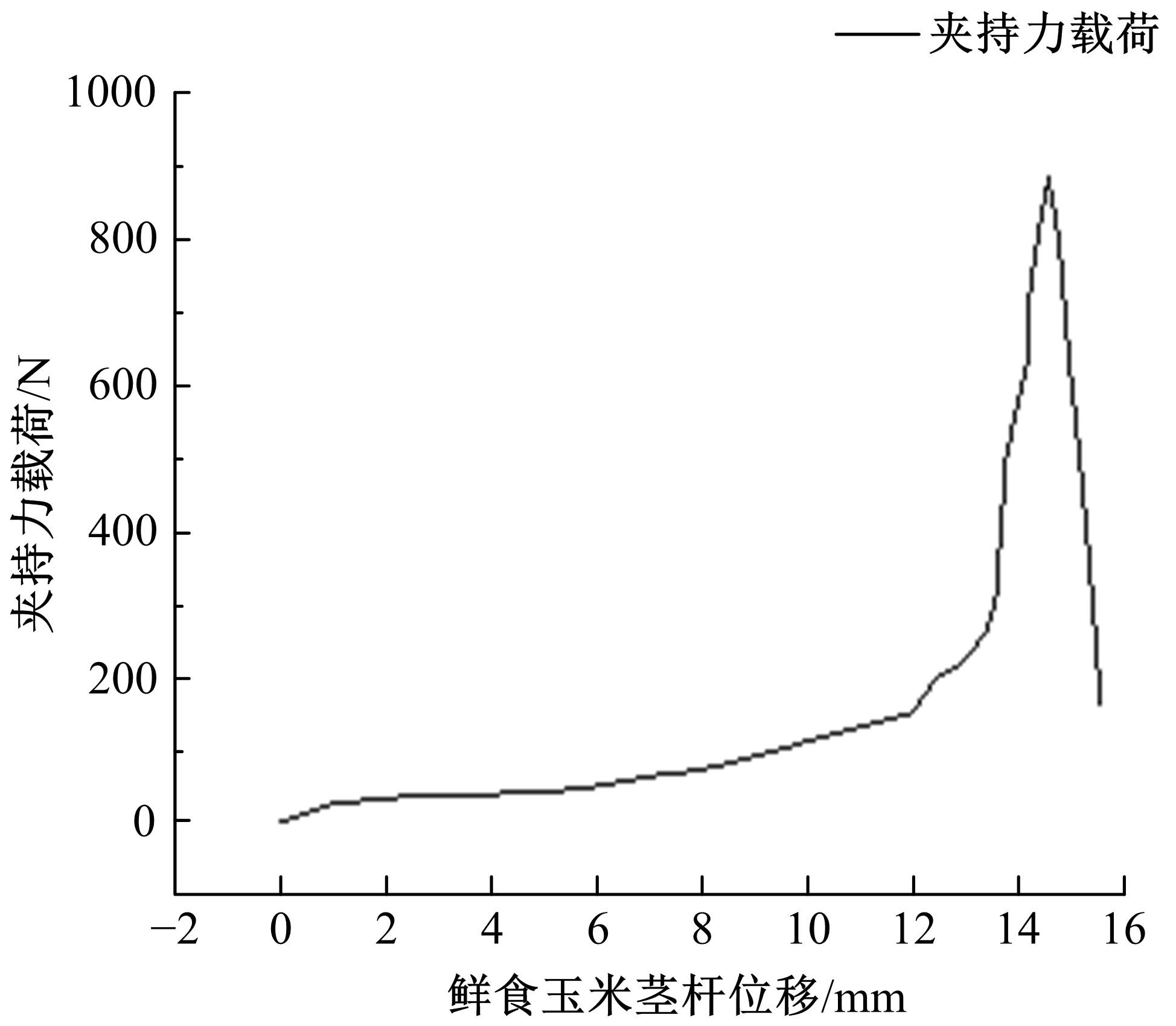

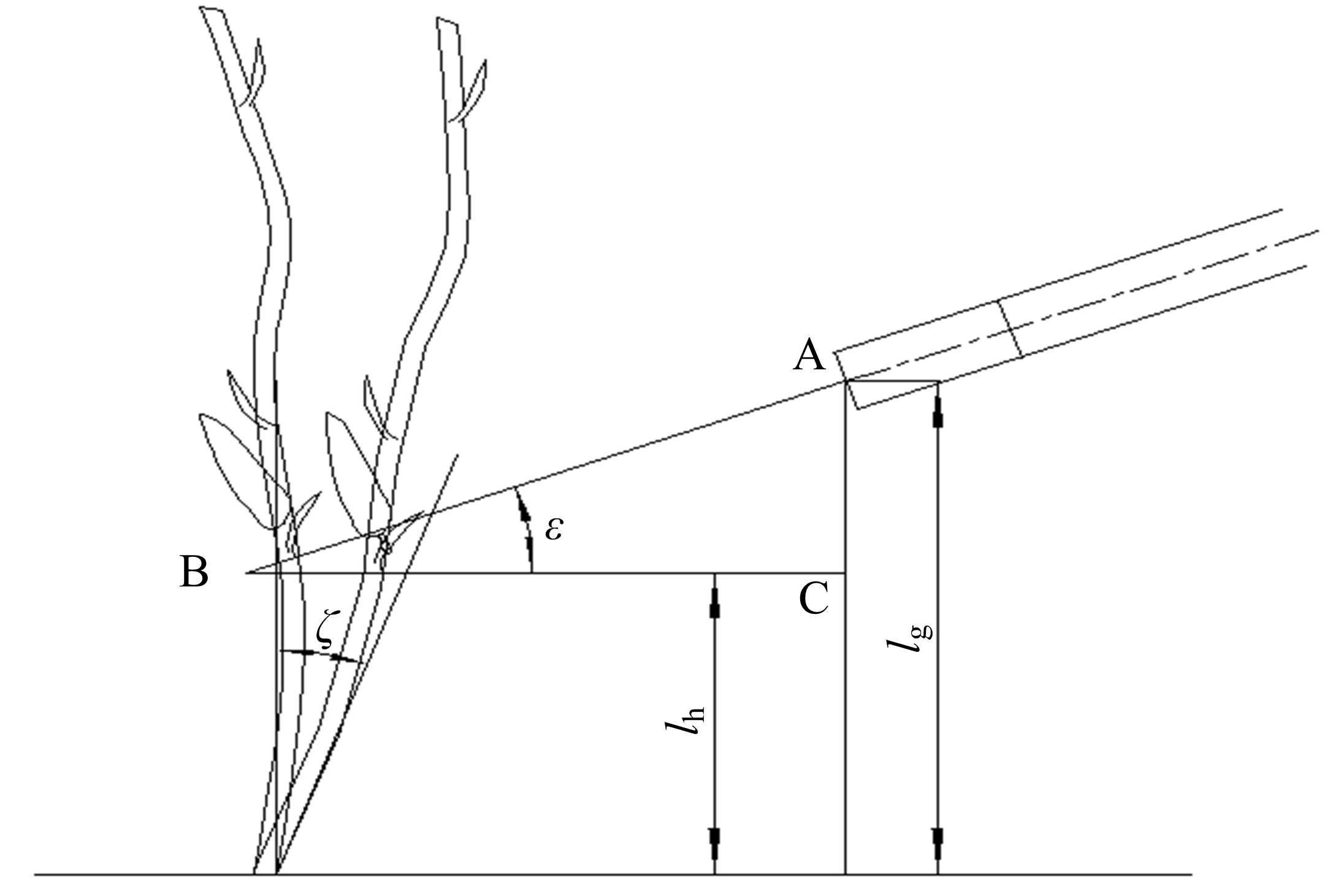

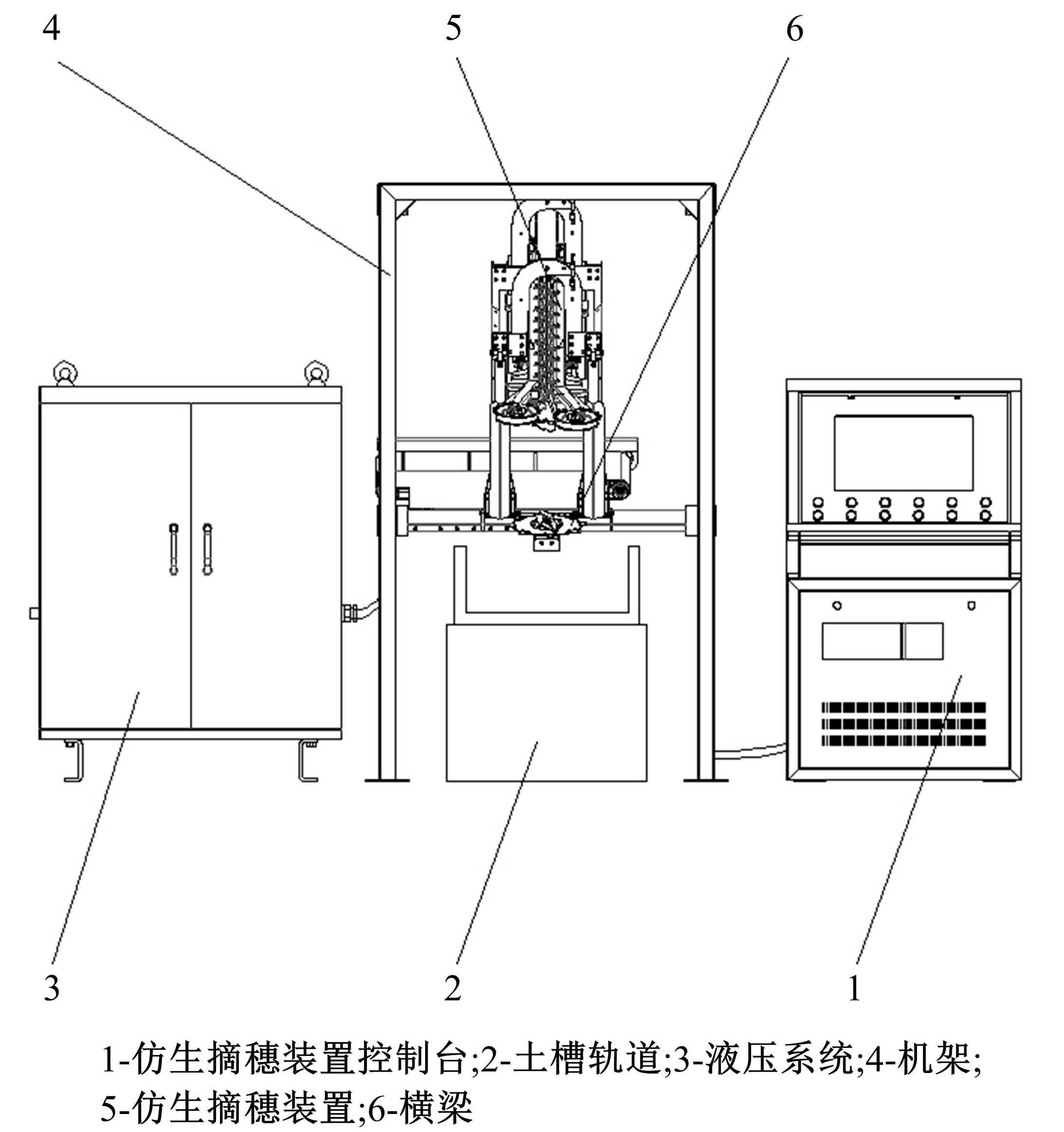

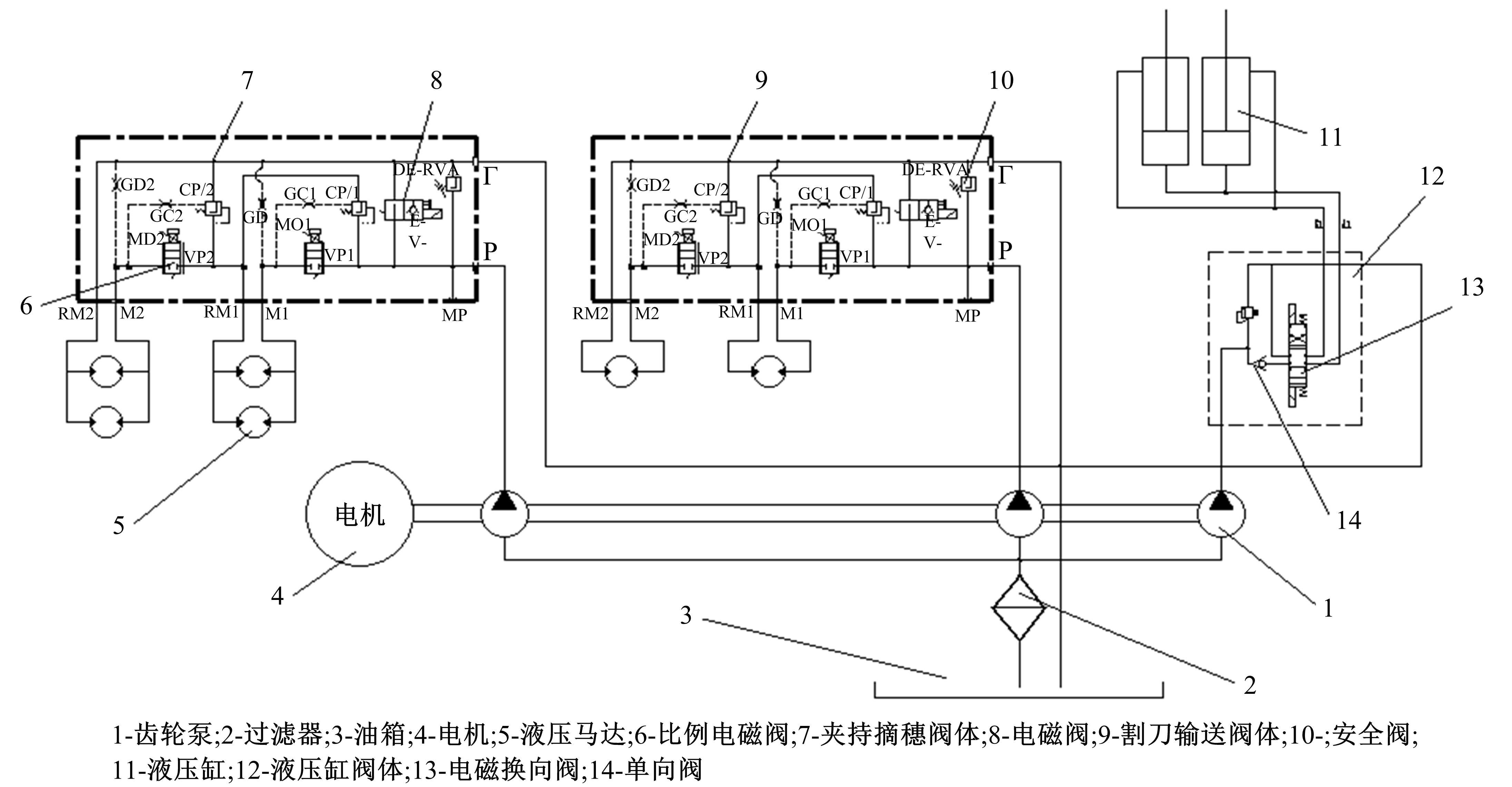

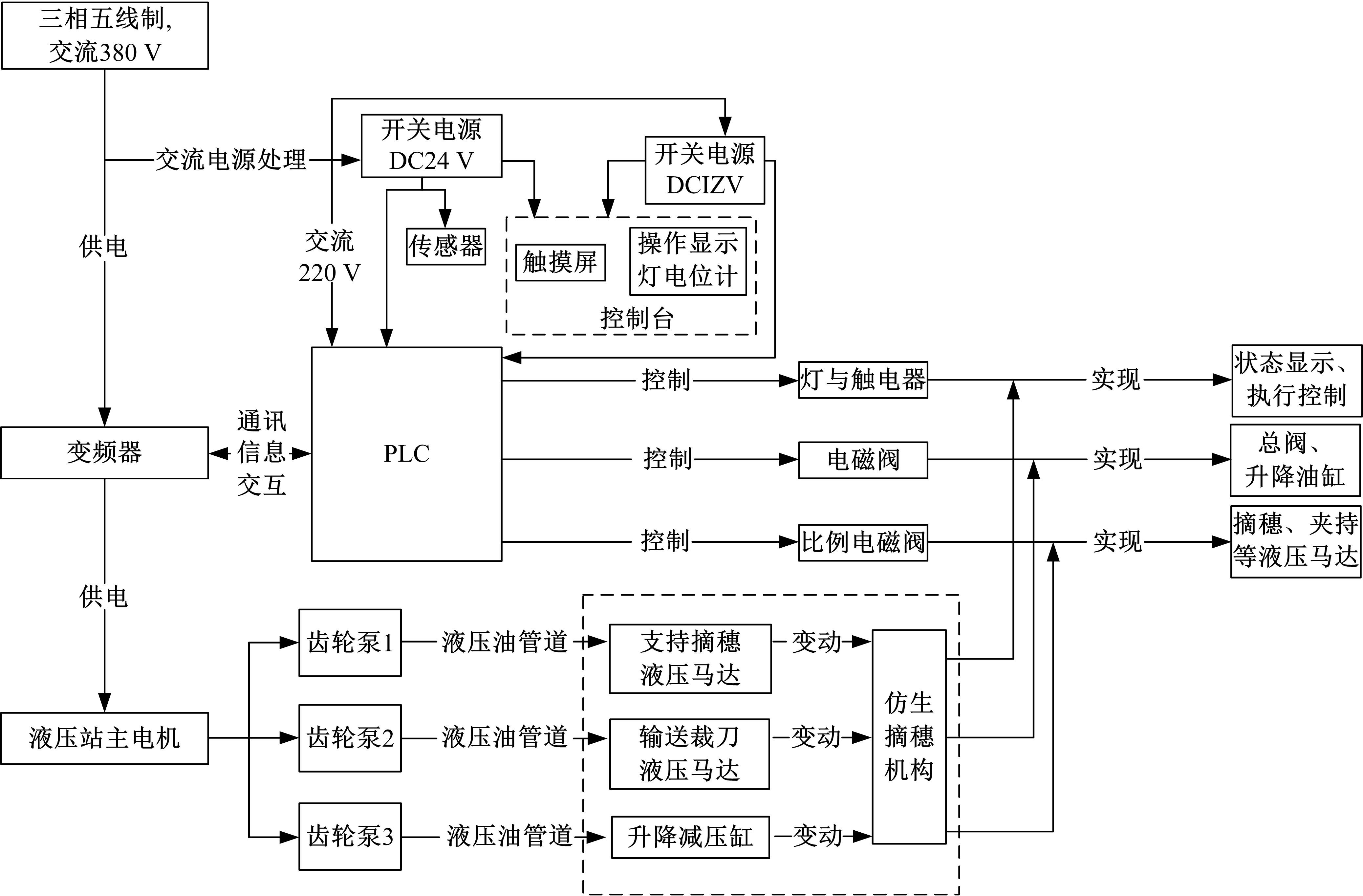

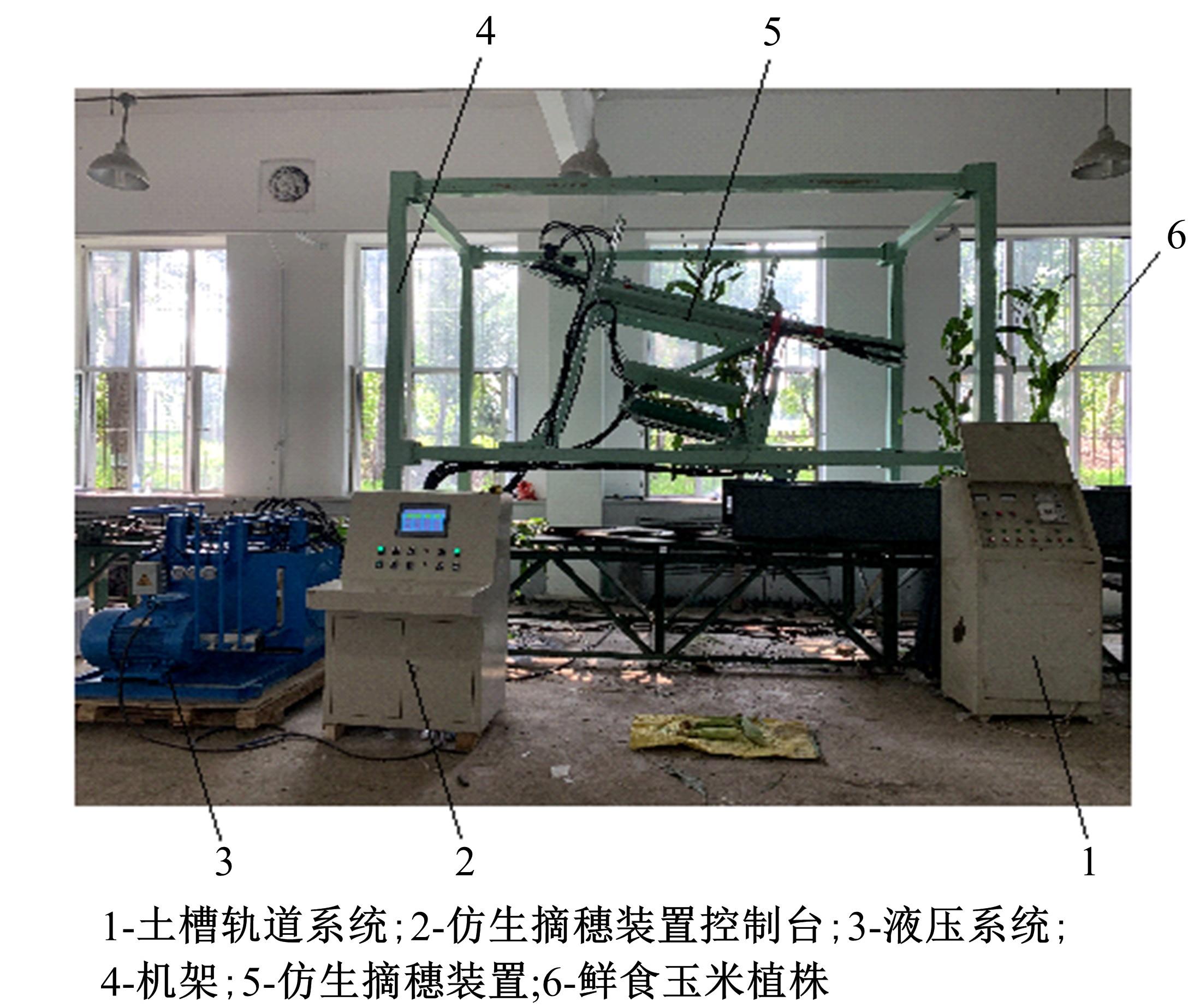

针对现有鲜食玉米摘穗作业收获后果穗籽粒破损、掺杂茎叶等问题,模仿玉米果穗人工掰穗收获姿态,设计了一种鲜食玉米仿生摘穗装置,以降低果穗上籽粒损伤,减少功耗,提高收获质量,并对该摘穗装置进行了结构设计及参数分析。采用二次正交旋转组合试验,以摘穗辊转速、夹持机构倾角、夹持机构间隙、机组前进速度为影响因素,以籽粒破碎率、果穗含杂率、功耗为试验指标,并运用Design-Expert软件对试验数据进行方差和响应曲面分析,得到影响因素和响应曲面之间的数学模型及因素贡献率,并对模型进行试验验证。结果表明,当摘穗辊转速为465 r/min、夹持机构倾角为19°、夹持机构间隙为8 mm、机组前进速度为1.2 m/s时,对应的试验指标籽粒破碎率均值为0.88%、果穗含杂率均值为1.3%、功耗均值为3.1 kW,装置作业稳定性良好。田间试验结果表明,籽粒破碎率均值为0.87%、果穗含杂率均值为1.22%、功耗均值为3.0 kW,降低了果穗含杂率和损伤,减少了功耗,其性能满足鲜食玉米收获作业要求。

中图分类号:

- S233.4

| 1 | 王中林. 鲜食玉米发展前景及关键栽培技术[J]. 科学种养,2018(12): 20-21. |

| Wang Zhong-lin. Development prospect and key cultivation techniques of fresh corn[J]. KeXue ZhongYang, 2018(12): 20-21. | |

| 2 | Cheng Yong-hui, Huang Biao, Chu Ao, et al. Research progress of corn harvest mechanization technology[J]. Mechanical Engineering and Technology, 2021, 10(1): 83-91. |

| 3 | Rogovskii I L, Liubarets B S, Voinash S A, et al. Research of diagnostic of combine harvesters at levels of hierarchical structure of systems and units of hydraulic system[J]. Journal of Physics: Conference Series, 2020, 1679(4): No. 042038. |

| 4 | 王优,张强,于路路. 玉米摘穗装置的应用现状与展望[J]. 农机化研究,2011, 33(1): 228-231. |

| Wang You, Zhang Qiang, Yu Lu-lu. Application status and prospect of maize maize picking device[J]. Journal of Agricultural Mechanization Research, 2011, 33(1): 228-231. | |

| 5 | 陈美舟,程修沛,贾晓东,等. 仿生手掰穗玉米收获装置结构及运行参数优化[J]. 农业工程学报,2018, 34(5): 15-22. |

| Chen Mei-zhou, Cheng Xiu-pei, Jia Xiao-dong, et al. Optimization of operating parameter and structure for corn ear picking device by bionic breaking ear hand[J]. Transactions of the Chinese Society of Agricultural Engineering, 2018, 34(5):15-22. | |

| 6 | 张丽萍, 李其昀. 仿生玉米掰穗装置掰穗速度与功耗试验[J]. 农业工程学报,2015, 31(19):9-14. |

| Zhang Li-ping, Li Qi-yun. Speed of bionic breaking corn ear hand and experiment on power consumption[J]. Transactions of the Chinese Society of Agricultural Engineering, 2015, 31(19): 9-14. | |

| 7 | 王显仁,耿令新,李心平,等. 鲜食玉米低损伤摘穗试验台设计与试验[J]. 农业工程, 2017, 7(1): 68-71. |

| Wang Xian-ren, Geng Ling-xin, Li Xin-ping, et al. Design and experiment of low-injury picking test table for fresh-esting maize[J]. Agricultural Engineering, 2017, 7(1): 68-71. | |

| 8 | 刘宪军. 新型玉米摘穗装置的研究[D]. 长春:吉林大学生物与农业工程学院,2014. |

| Liu Xian-jun. Study on a new type of corn ear picking device[D]. Changchun: College of Biological and Agricultural Engineering, Jilin University, 2014. | |

| 9 | 曹彪. 弯曲折断式玉米摘穗机构研究[D]. 长春: 吉林大学生物与农业工程学院, 2012. |

| Cao Biao. Study on corn snapping mechanism with mode of bending and breaking[D]. Changchun: College of Biological and Agricultural Engineering, Jilin University, 2012. | |

| 10 | Hanna H M, Kohl K D, Haden D A. Machine losses from conventional versus narrow row corn harvest[J]. Applied Engineering in Agriculture, 2002, 18(4): 405-409. |

| 11 | 徐文腾,赵静,崔欣,等. 上拉切茎式仿生玉米掰穗装置设计与分析[J]. 农机化研究,2018, 40(7): 81-86. |

| Xu Wen-teng, Zhao Jing, Cui Xin, et al. The bionics design and analysis on device of corn picking with dragging and cutting stem[J]. Journal of Agricultural Mechanization Research, 2018, 40(7): 81-86. | |

| 12 | 耿端阳, 李玉环,孟凡虎,等.玉米收获机多棱立辊式摘穗装置设计与试验[J]. 农业机械学报,2017, 48(3): 84-91. |

| Geng Duan-yang, Li Yu-huan, Meng Fan-hu, et al. Design and experiment of corn harvester polygonal vertical-rollers snapping means[J]. Transactions of the Chinese Society for Agricultural Machinery, 2017, 48(3): 84-91. | |

| 13 | 陈美舟, 孙雪峰, 程修沛, 等. 卧辊式摘穗机构摘穗辊高度差对玉米籽粒损失的影响[J]. 农业工程学报, 2017, 33(4): 63-68. |

| Chen Mei-zhou, Sun Xue-feng, Cheng Xiu-pei, et al.Effect of height difference of horizontal corn snapping rollers device on grain loss[J]. Transactions of the Chinese Society of Agricultural Engineering, 2017, 33(4):63-68. | |

| 14 | 中国农业机械化科学研究院.农业机械设计手册:上册[M]. 北京: 中国农业科学技术出版社, 2007. |

| 15 | Igathinathane C, Pordesimo L O, Schilling M W, et al. Fast and simple measurement of cutting energy requirement of plant stalk and prediction model development[J]. Industrial Crops and Products, 2011, 33(2): 518-523. |

| 16 | Lisowski A, Swiatek K, Klonowski J, et al. Movement of chopped material in the discharge spout of forage harvester with a flywheel chopping unit:measurements using maize and numerical simulation[J]. Biosystems Engineering, 2012, 111(4): 381-391. |

| 17 | 张道林,孙永进,赵洪光,等. 立辊式玉米摘穗与茎秆切碎装置的设计[J]. 农业机械学报,2005, 36(7): 50-52, 76. |

| Zhang Dao-lin, Sun Yong-jin, Zhao Hong-guang,et al.Design of a vertical-roll type of corn picker and stalk chopper[J]. Transactions of the Chinese Society for Agricultural Machinery, 2005, 36(7): 50-52, 76. | |

| 18 | 纪晓琦,耿端阳,姚艳春,等.玉米收获机激振摘穗装置设计与试验[J].农业机械学报,2020,51():126-133. |

| Ji Xiao-qi, Geng Duan-yang, Yao Yan-chun, et al. Design and test of the corn harvester's excitation vibration ear picking device[J]. Transactions of the Chinese Society for Agricultural Machinery, 2020, 51(Sup.2): 126-133. | |

| 19 | 耿端阳,李玉环,何珂,等. 立辊式玉米收获机割台间隙夹持输送装置设计与试验[J].农业机械学报,2017,48(11): 130-136. |

| Geng Duan-yang, Li Yu-huan, He Ke,et al. Design and experiment on gripping delivery mechanism for vertical-rollers type of corn harvester[J]. Transactions of the Chinese Society for Agricultural Machinery, 2017,48(11): 130-136. | |

| 20 | 吴鸿欣,陈志,韩增德,等. 玉米植株抗弯特性对分禾器结构的影响分析[J]. 农业机械学报,2011, 42(): 6-9. |

| Wu Hong-xin, Chen Zhi, Han Zeng-de, et al. Effect analysis of bending properties of corn plants on divider structure[J]. Transactions of the Chinese Society for Agricultural Machinery, 2011, 42(Sup.1): 6-9. | |

| 21 | 刘静,刁培松,张道林,等. 玉米收获机分禾器的研究[J]. 农机化研究,2007, 28(11): 145-149. |

| Liu Jing, Diao Pei-song, Zhang Dao-lin. Research on the nearside divider of corn harvest[J]. Journal of Agricultural Mechanization Research, 2007, 28(11): 145-149. | |

| 22 | 李慧,李丽.采摘机械手末端控制系统的设计——基于PLC和MCGS组态软件[J]. 农机化研究,2020, 42(6): 202-206. |

| Li Hui, Li Li. Design of picking manipulator terminal control system―based on PLC and MCGS configuration software[J]. Journal of Agricultural Mechanization Research, 2020, 42(6): 202-206. | |

| 23 | Wang Heng, Cao Shu-kun, Xu Xiang-qian, et al. Design of picking roller for corn harvester picking machine and selection of hydraulic motor[J]. IOP Conference Series: Materials Science and Engineering, 2018, 439(4): No. 042028. |

| 24 | 刘国梁,李新,伍梁,等. 宽范围输入输出电压LCC谐振变换器的分析设计[J]. 浙江大学学报: 工学版, 2018, 52(9): 1762-1770. |

| Liu Guo-liang, Li Xin, Wu Liang,et al. Analysis and design-optimization of LCC resonant converter operating under wide range input and output voltage [J].Journal of Zhejiang University(Engineering Science),2018, 52(9): 1762-1770. | |

| 25 | 肖戟,杨光,牛云鹏,等. 4YL-2型玉米收获机性能指标及测试技术[J]. 长春工业大学学报: 自然科学版, 2009, 30(1): 83-87. |

| Xiao Ji, Yang Guang, Niu Yun-ping, et al. Performance test techniques for 4YL-2type harvest machine[J]. Journal of Changchun University of Technology(Natural Science Edition), 2009, 30(1): 83-87. | |

| 26 | 赵淑红,谭贺文,王加一,等. 多功能集成式播种开沟器的设计与试验[J].农业工程学报, 2018, 34(11): 58-67. |

| Zhao Shu-hong, Tan He-wen, Wang Jia-yi, et al. Design and experiment of multifunctional integrated seeding opener[J]. Transactions of the Chinese Society of Agricultural Engineering, 2018, 34(11): 58-67. | |

| 27 | 肖宝兰,俞小莉,韩松,等. 翅片参数对车用中冷器流动传热性能的影响[J]. 浙江大学学报:工学版, 2010, 44(11): 2164-2168, 2178. |

| Xiao Bao-lan, Yu Xiao-li, Han Song, et al. The study of effects of fin parameters on thermal hydraulic performance of a vehicular charged air cooler[J]. Journal of Zhejiang University (Engineering Science), 2010,44(11): 2164-2168, 2178. | |

| 28 | 陈洋,连永祥,李新. 二次回归正交旋转组合设计优化废橡胶辊筒粉碎机效率[J]. 沈阳化工大学学报,2012, 26(3): 251-254. |

| Chen Yang, Lian Yong-xiang, Li Xin. Rubber roller mill efficiency with the method of quadratic regression orthogonal rotation[J]. Journal of Shenyang University of Chemical Technology, 2012, 26(3): 251-254. | |

| 29 | 徐仲儒.试验回归设计[M].哈尔滨:黑龙江科技出版社,1998. |

| 30 | . 玉米收获机械技术条件 [S]. |

| [1] | 曾山,黄登攀,杨文武,刘伟健,文智强,曾力. 三角履带式再生稻收割机底盘的设计与试验[J]. 吉林大学学报(工学版), 2022, 52(8): 1943-1950. |

| [2] | 魏国粱,张青松,王彪,何坤,廖庆喜. 油菜直播机扣垡犁体参数分析与试验[J]. 吉林大学学报(工学版), 2022, 52(7): 1709-1718. |

| [3] | 刘佳杰,马兰,向伟,颜波,文庆华,吕江南. 4QM-4.0型麻类青饲料联合收获机研制[J]. 吉林大学学报(工学版), 2022, 52(12): 3039-3048. |

| [4] | 曾百功,黎奎良,叶进,任丽丽,Rashidov Jaloliddin,张明. 工厂化上海青流水线收割装置的设计与试验[J]. 吉林大学学报(工学版), 2022, 52(11): 2756-2764. |

| [5] | 万星宇,廖庆喜,蒋亚军,单伊尹,周宇,廖宜涛. 饲用油菜机械化收获切碎过程离散元仿真与试验[J]. 吉林大学学报(工学版), 2022, 52(11): 2735-2745. |

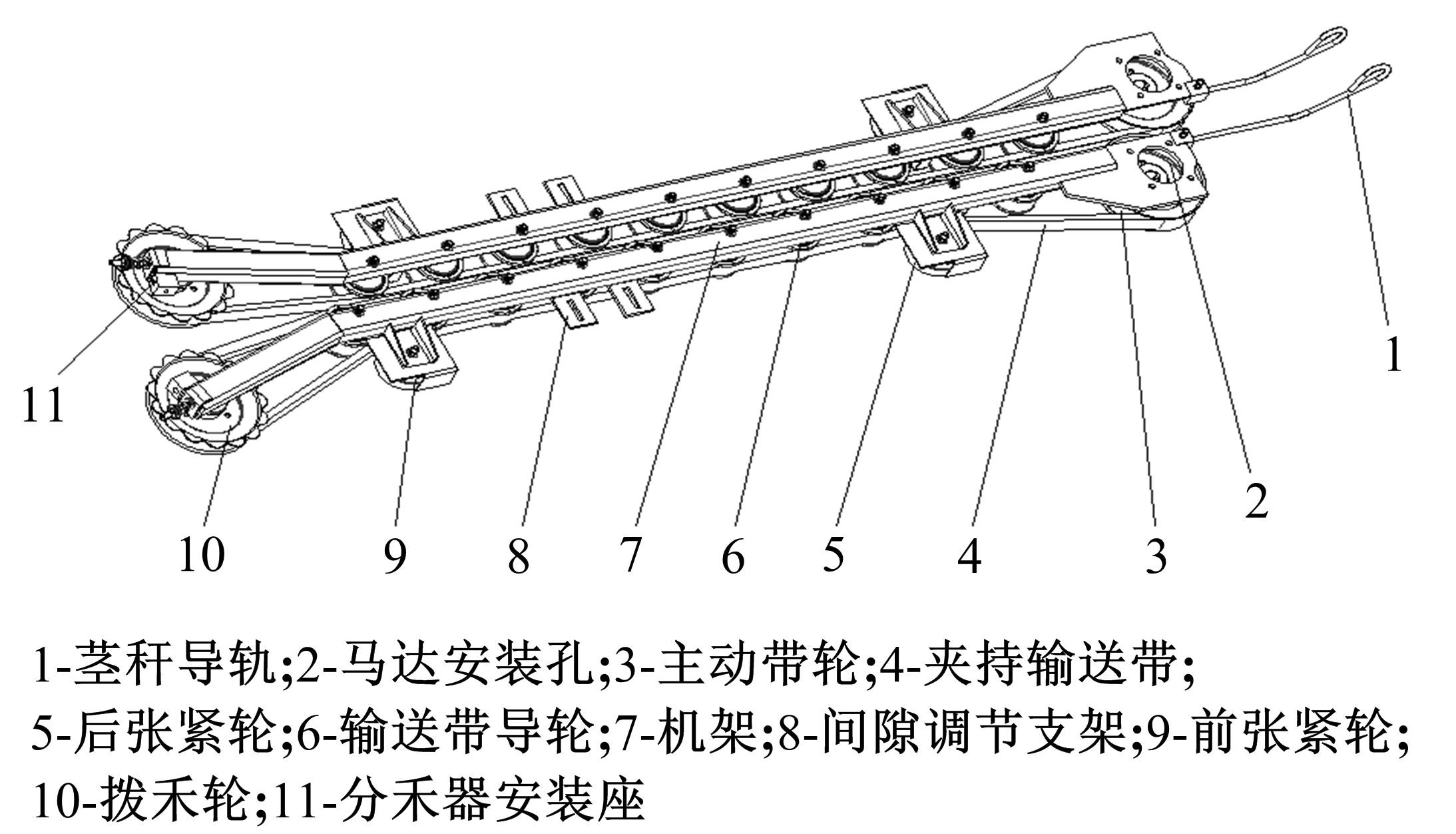

| [6] | 朱光强,李天宇,周福君. 鲜食玉米仿生摘穗柔性夹持输送装置设计与试验[J]. 吉林大学学报(工学版), 2022, 52(10): 2486-2500. |

| [7] | 梁荣庆,钟波,蒙贺伟,孙志民,坎杂. 4QJ⁃3型青贮燕麦捡拾割台的研制[J]. 吉林大学学报(工学版), 2021, 51(5): 1887-1896. |

| [8] | 袁佳诚,王昌,何坤,万星宇,廖庆喜. 油菜联合收获机筛下物组分质量比对清选性能的影响[J]. 吉林大学学报(工学版), 2021, 51(5): 1897-1907. |

| [9] | 王刚,刘慧力,贾洪雷,郭春江,丛永健,屈明浩. 触碰定位式玉米行间除草装置的设计与试验[J]. 吉林大学学报(工学版), 2021, 51(4): 1518-1527. |

| [10] | 付君,张屹晨,程超,陈志,唐心龙,任露泉. 刚柔耦合式小麦脱粒弓齿设计及试验[J]. 吉林大学学报(工学版), 2020, 50(2): 730-738. |

| [11] | 薛钊,付君,陈志,王锋德,韩少平,任露泉. 青饲玉米收获机械切碎装置参数优化试验[J]. 吉林大学学报(工学版), 2020, 50(2): 739-748. |

| [12] | 程超,付君,郝付平,陈志,周德义,任露泉. 清选筛运动参数对玉米芯轴堵筛规律的影响[J]. 吉林大学学报(工学版), 2020, 50(1): 351-360. |

| [13] | 程超,付君,唐心龙,陈志,任露泉. 振动形式对水稻脱出物界面粘附规律的影响[J]. 吉林大学学报(工学版), 2019, 49(4): 1228-1235. |

| [14] | 付君,钱志辉,尹维,王甲甲,任露泉. 小麦摩擦与拉伸性能[J]. 吉林大学学报(工学版), 2015, 45(2): 501-507. |

|

||