吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (2): 333-345.doi: 10.13229/j.cnki.jdxbgxb.20221099

• 车辆工程·机械工程 • 上一篇

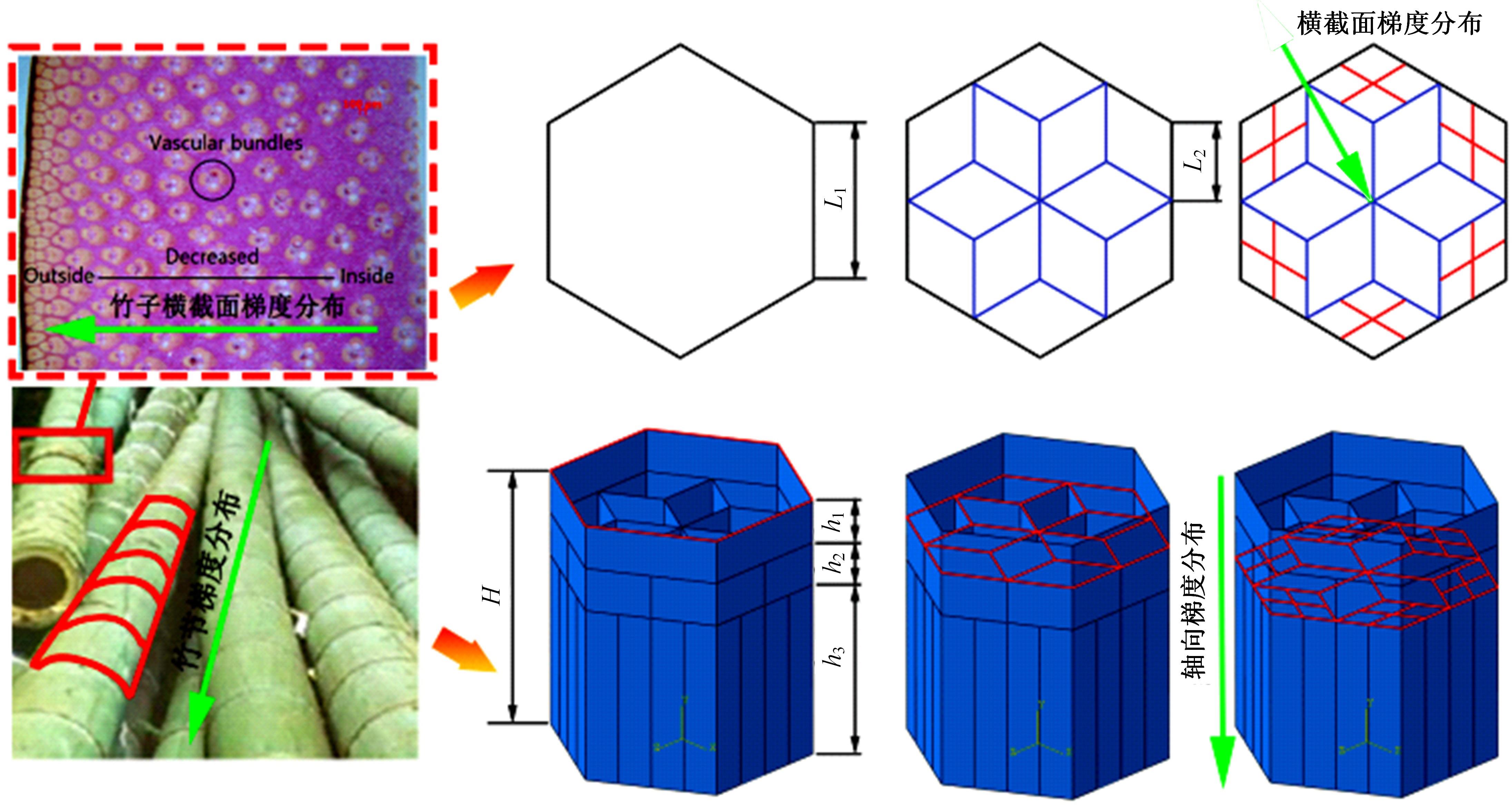

新型仿竹六边形梯度层级多胞管耐撞性对比分析

- 1.梧州学院 电子与信息工程学院,广西 梧州 543002

2.广西大学 机械工程学院,南宁 530004

Comparative analysis on crashworthiness of a novel bamboo⁃like hexagonal gradient hierarchical multicellular tube

Xiao-lin DENG1( ),Fu-mo YANG2,Shan-gan QIN2

),Fu-mo YANG2,Shan-gan QIN2

- 1.School of Electronics and Information Engineering,Wuzhou University,Wuzhou 543002,China

2.School of Mechanical Engineering,Guangxi University,Nanning 530004,China

摘要:

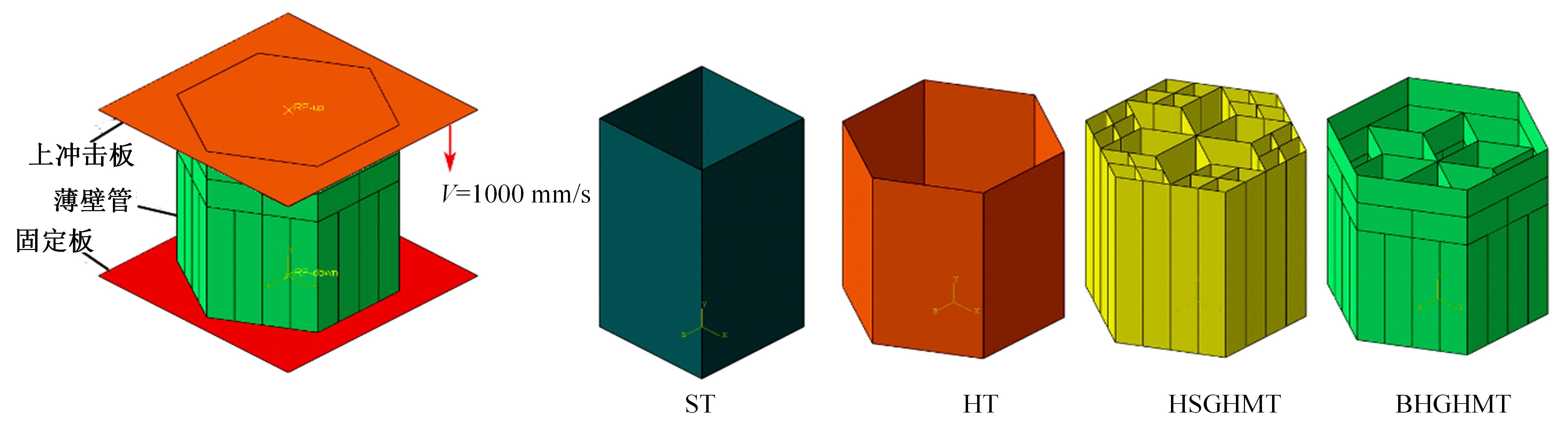

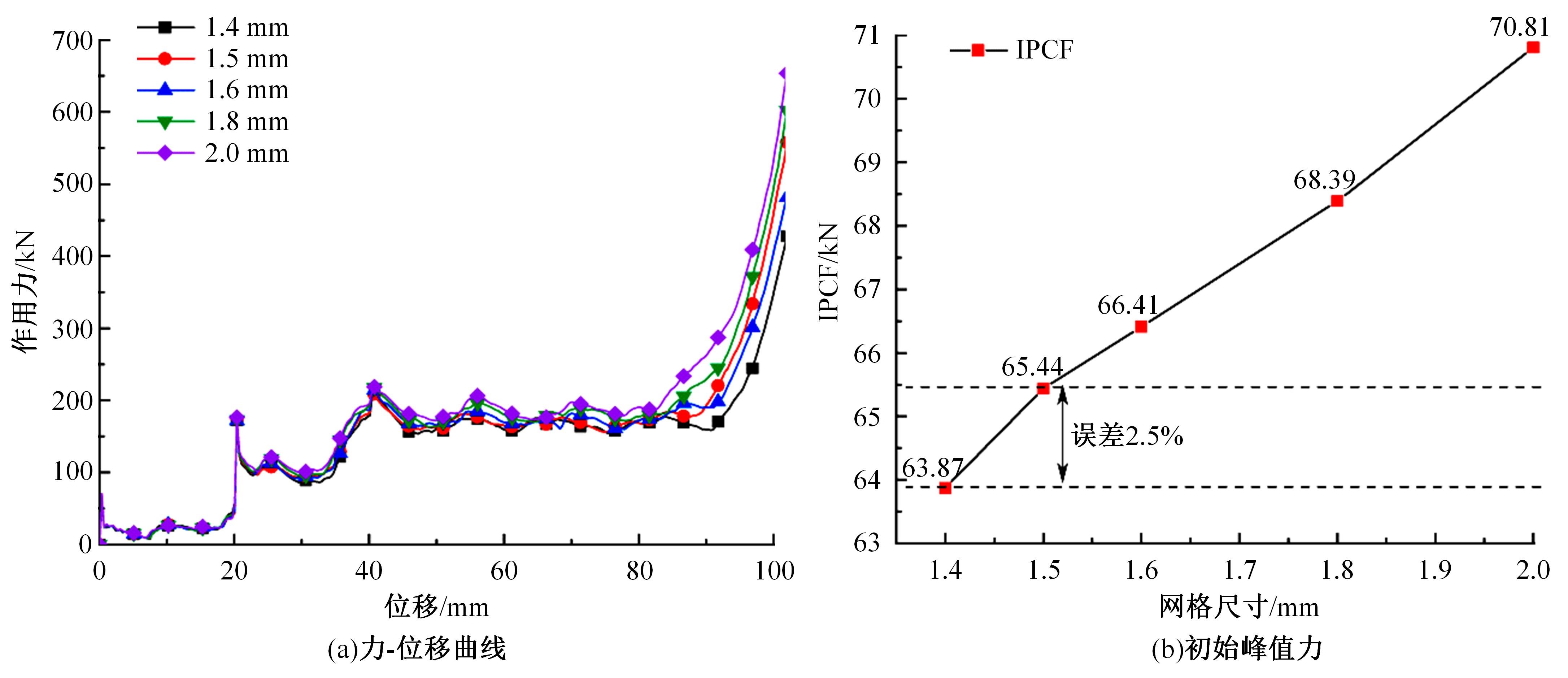

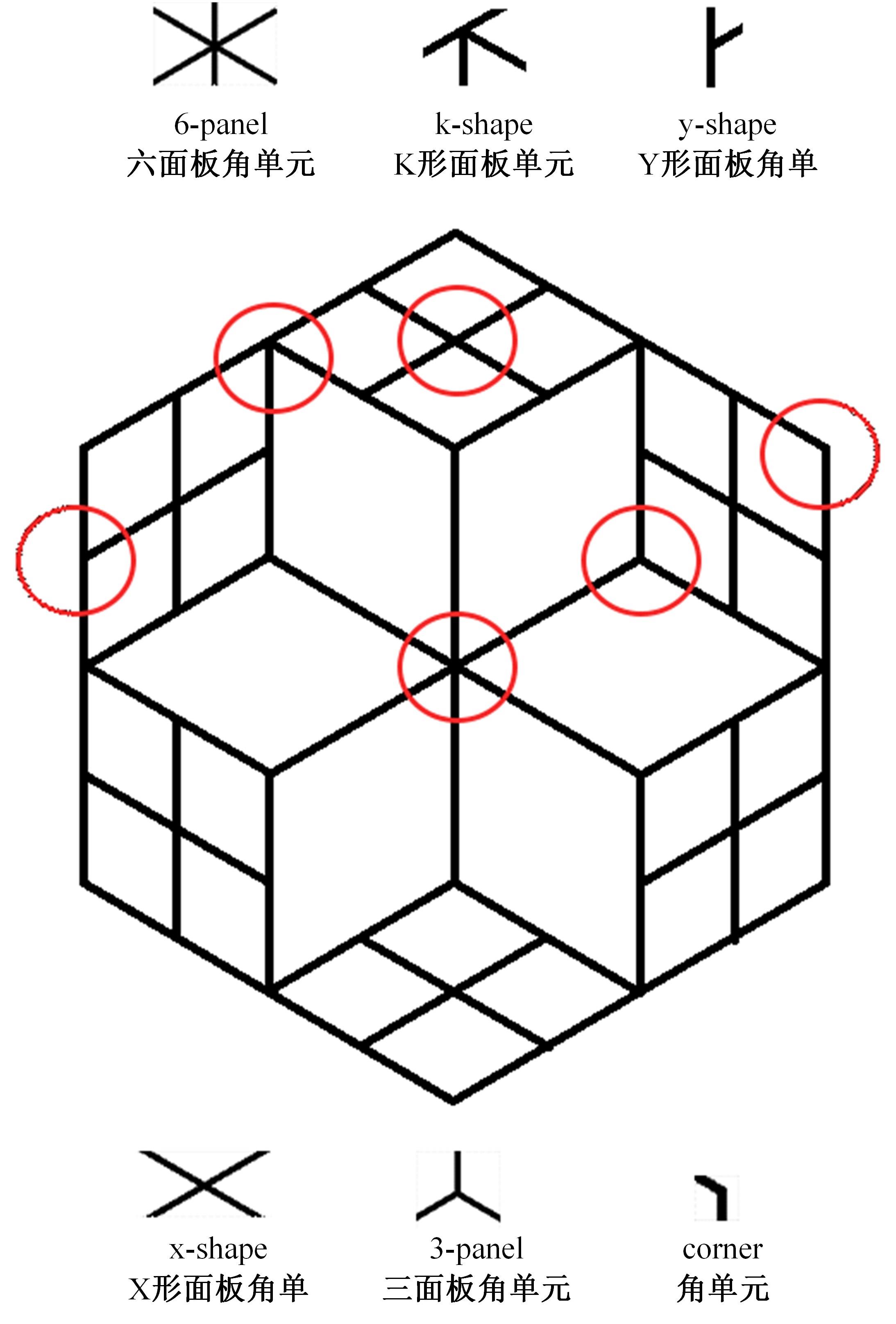

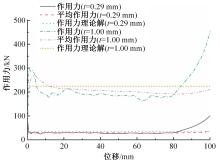

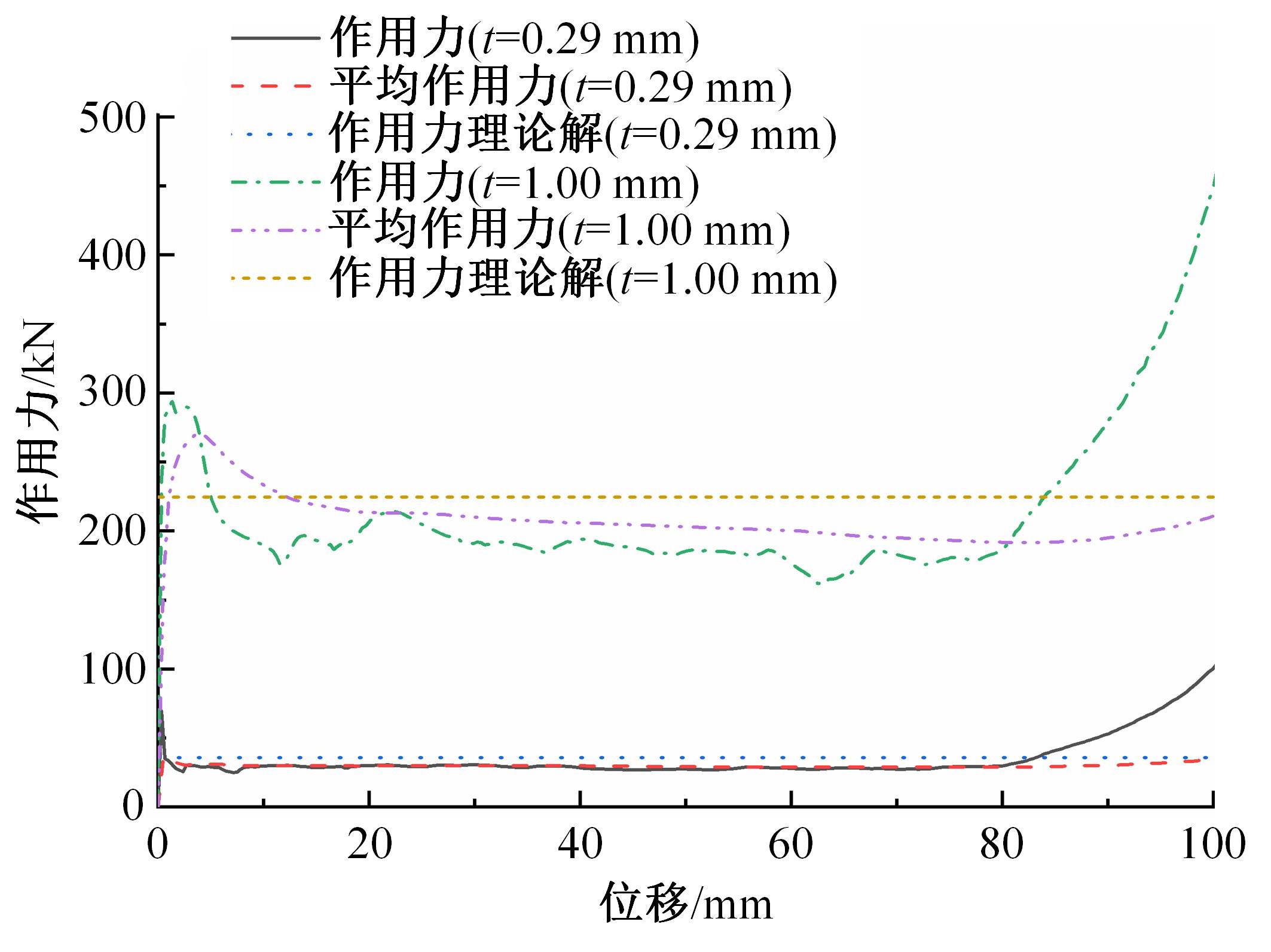

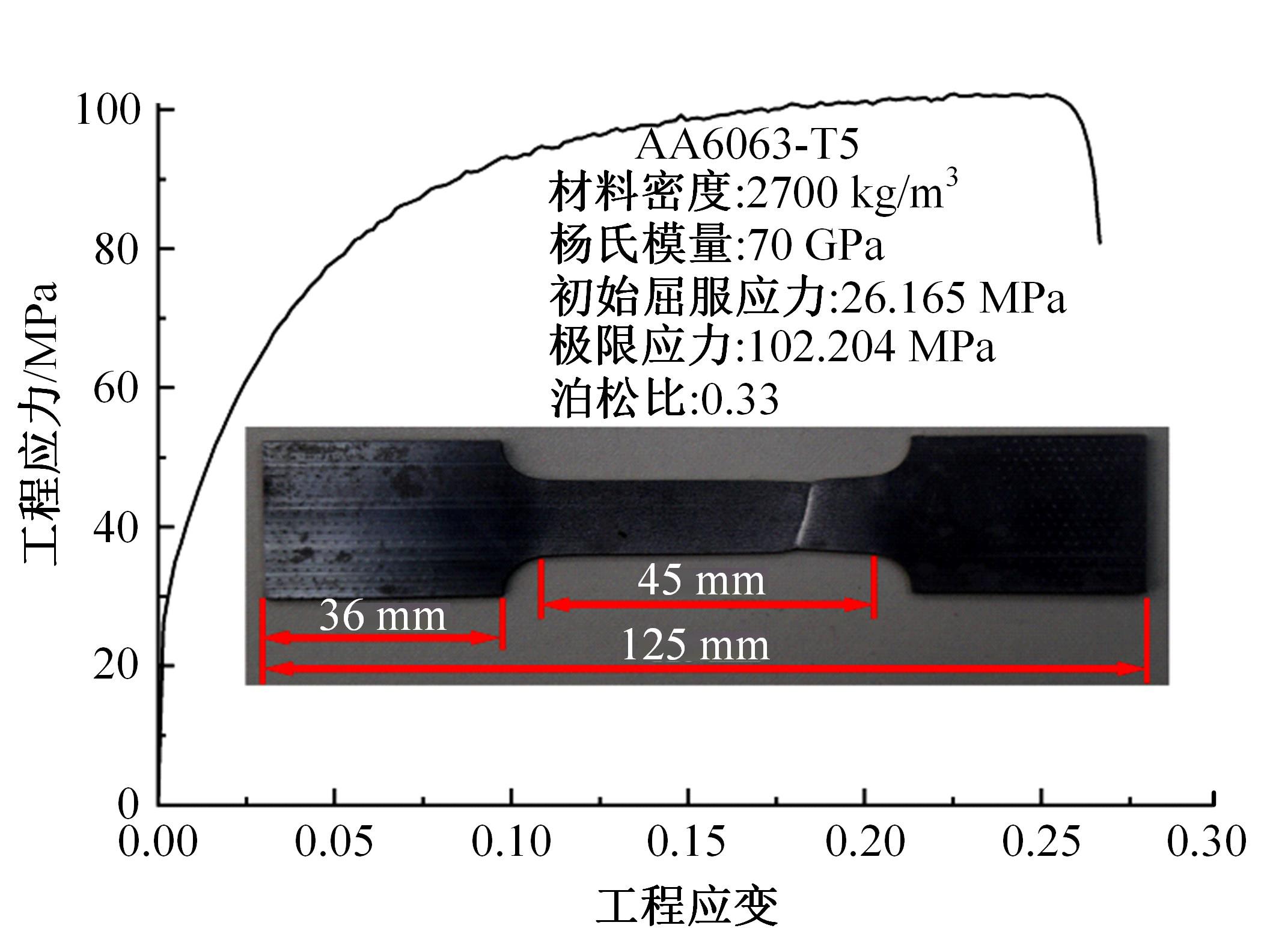

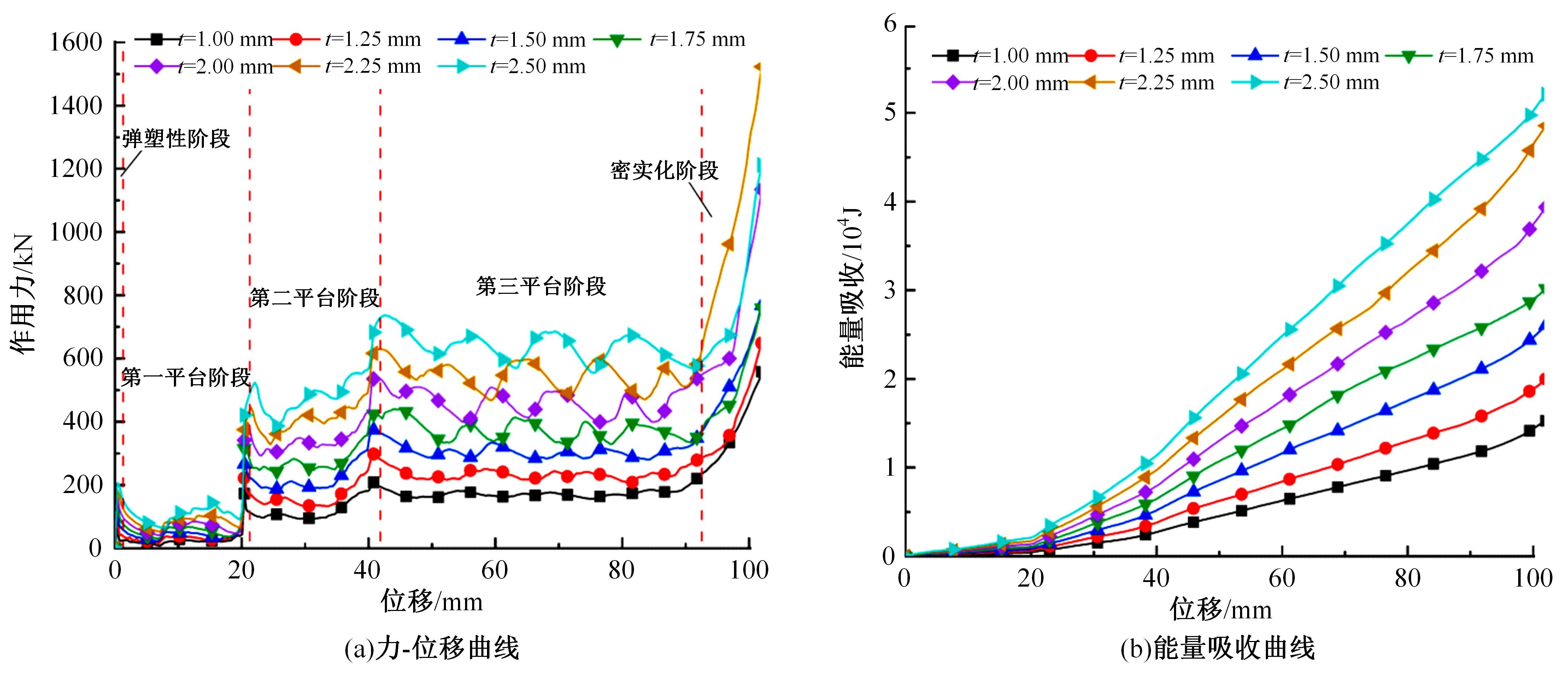

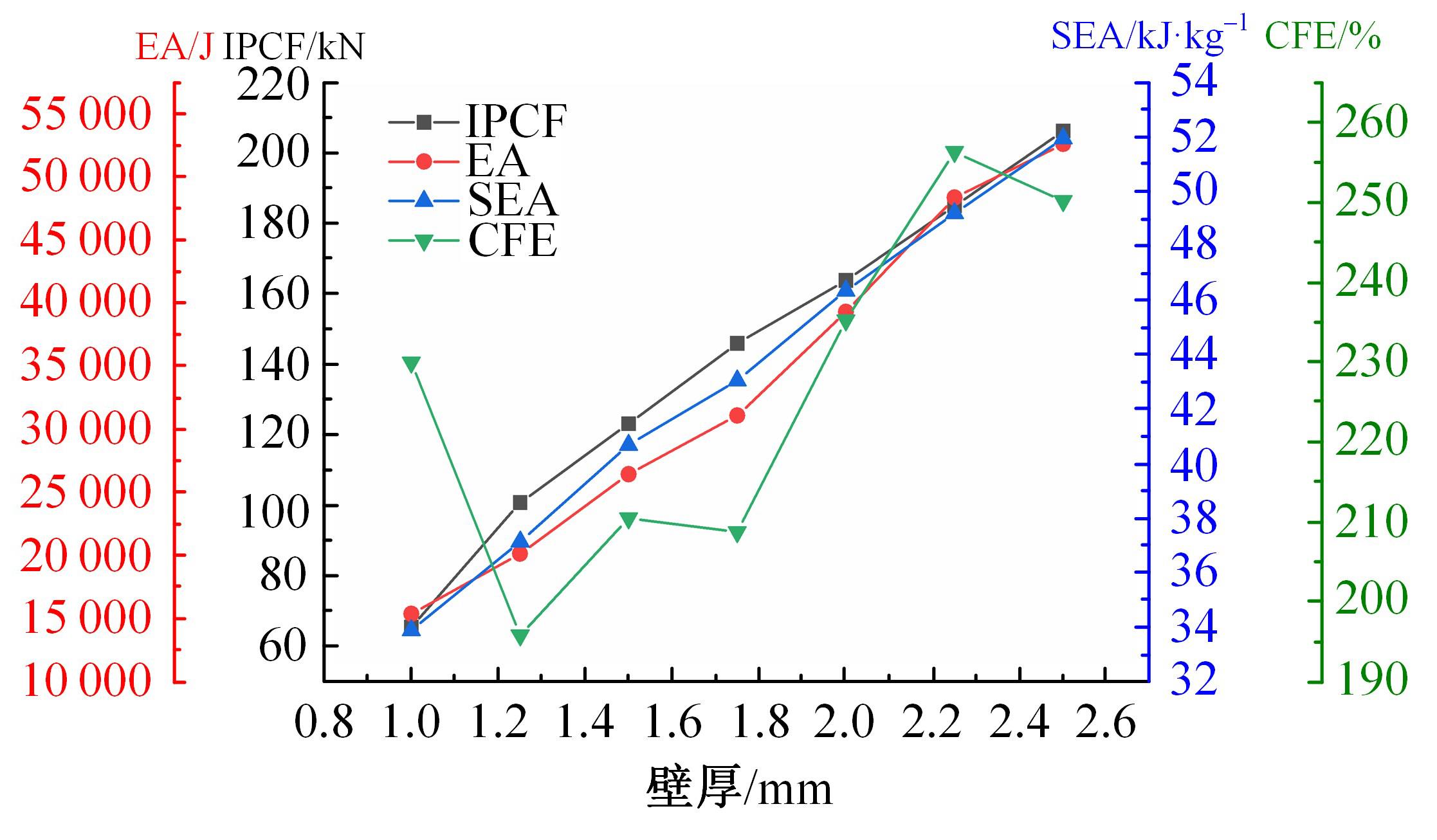

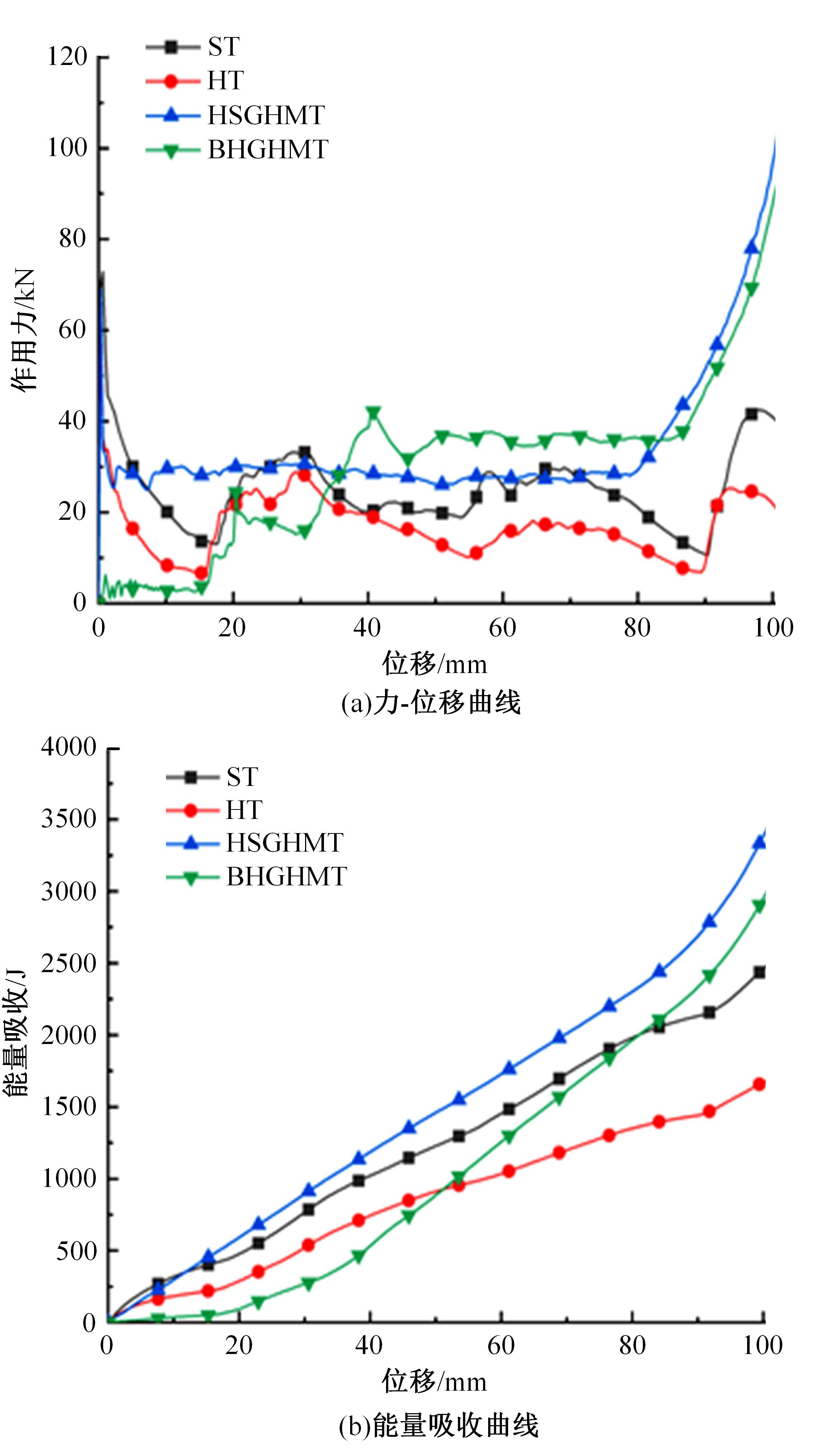

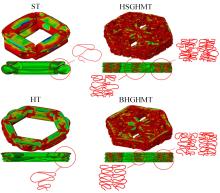

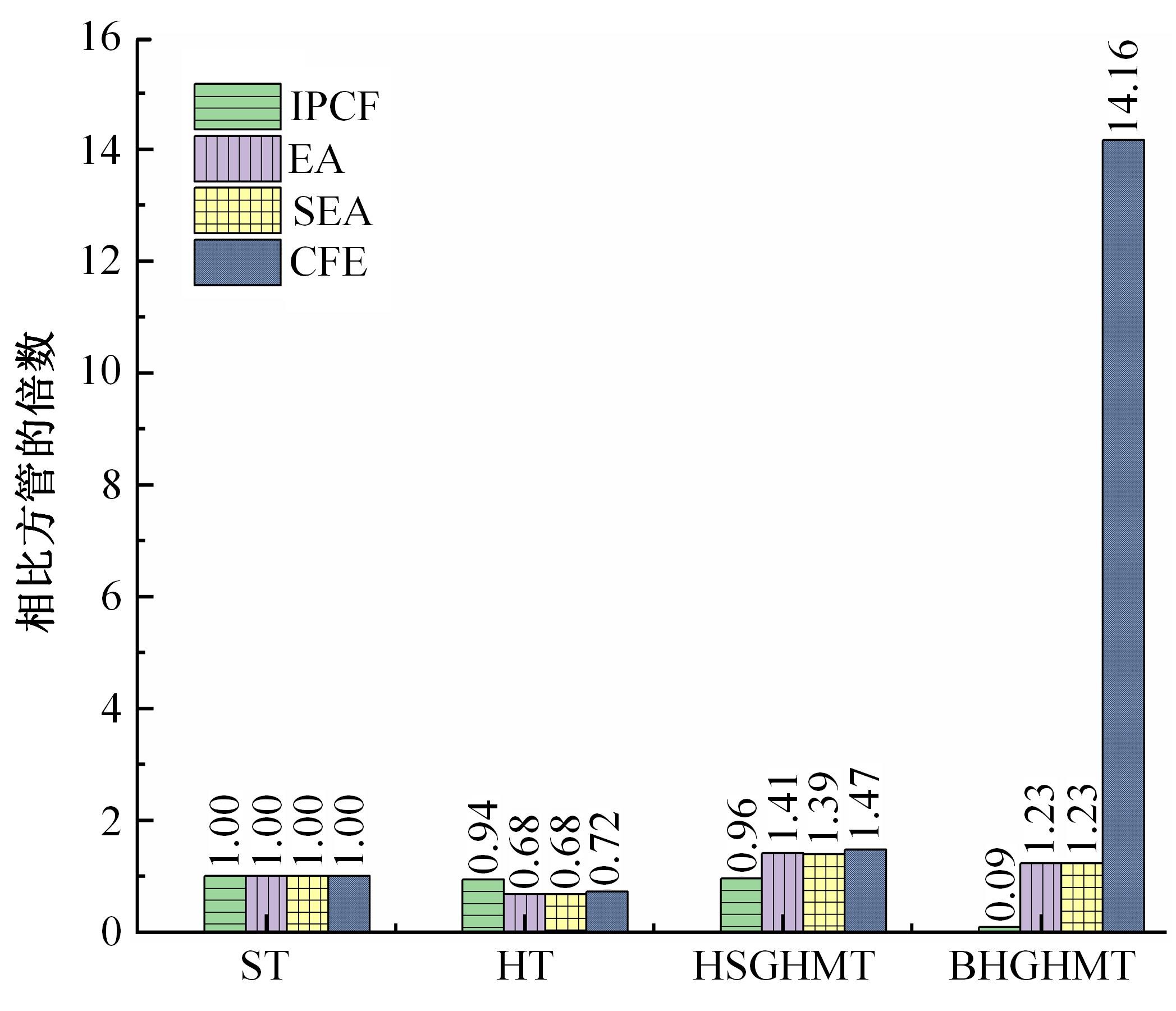

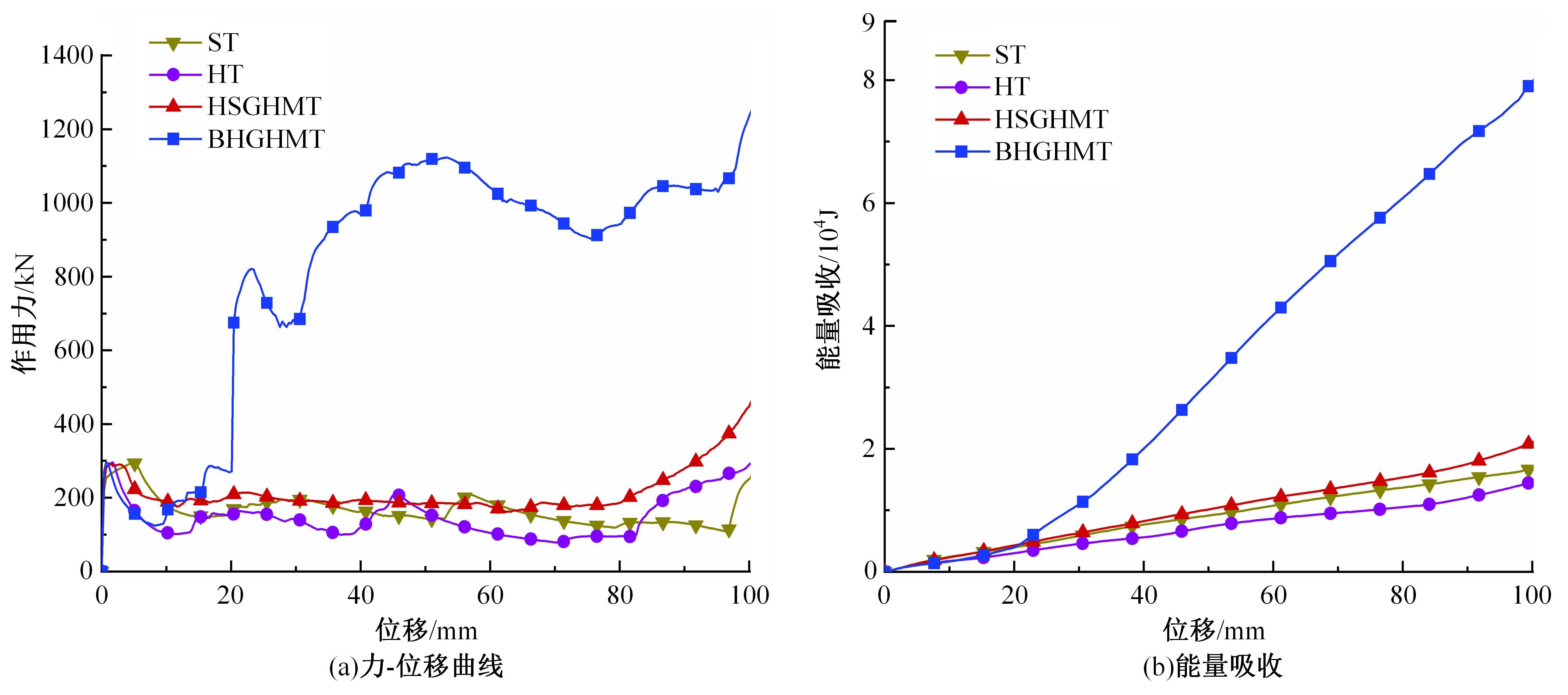

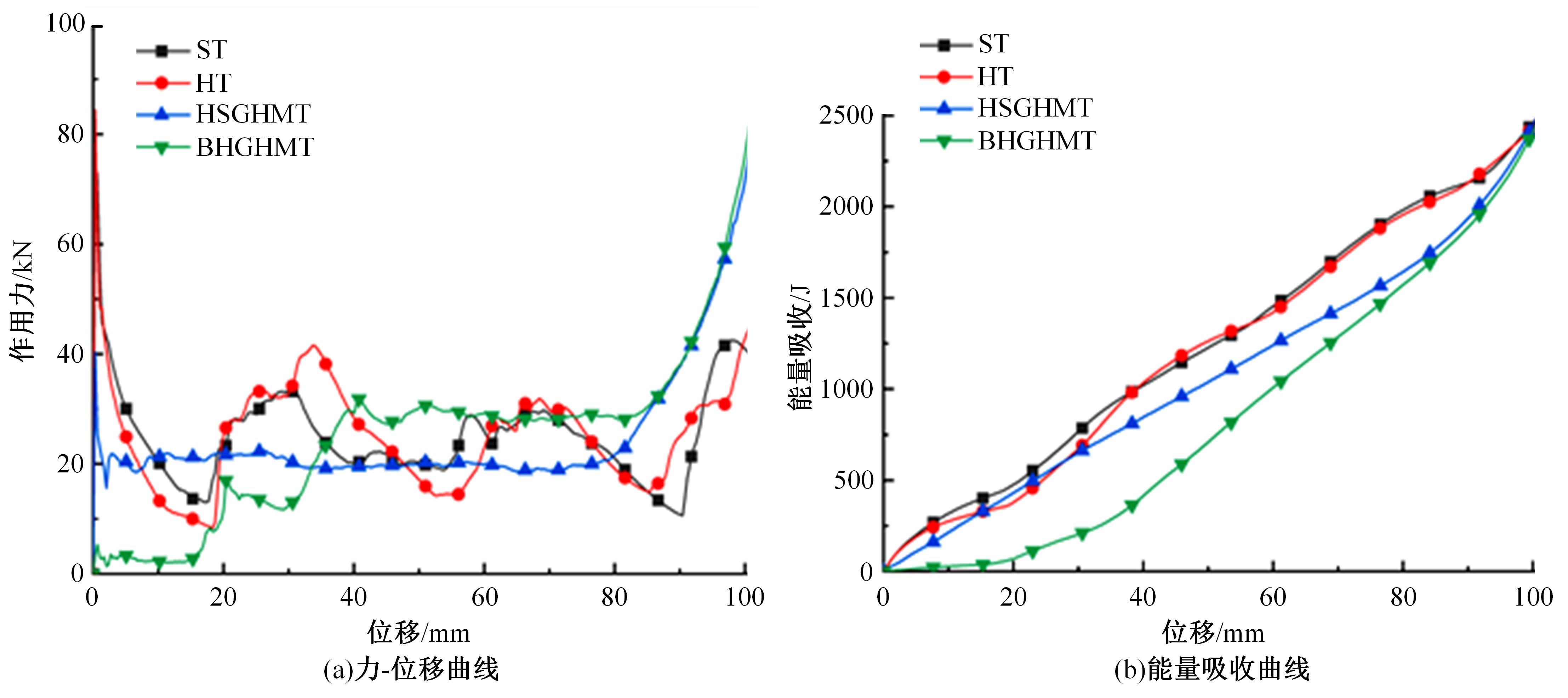

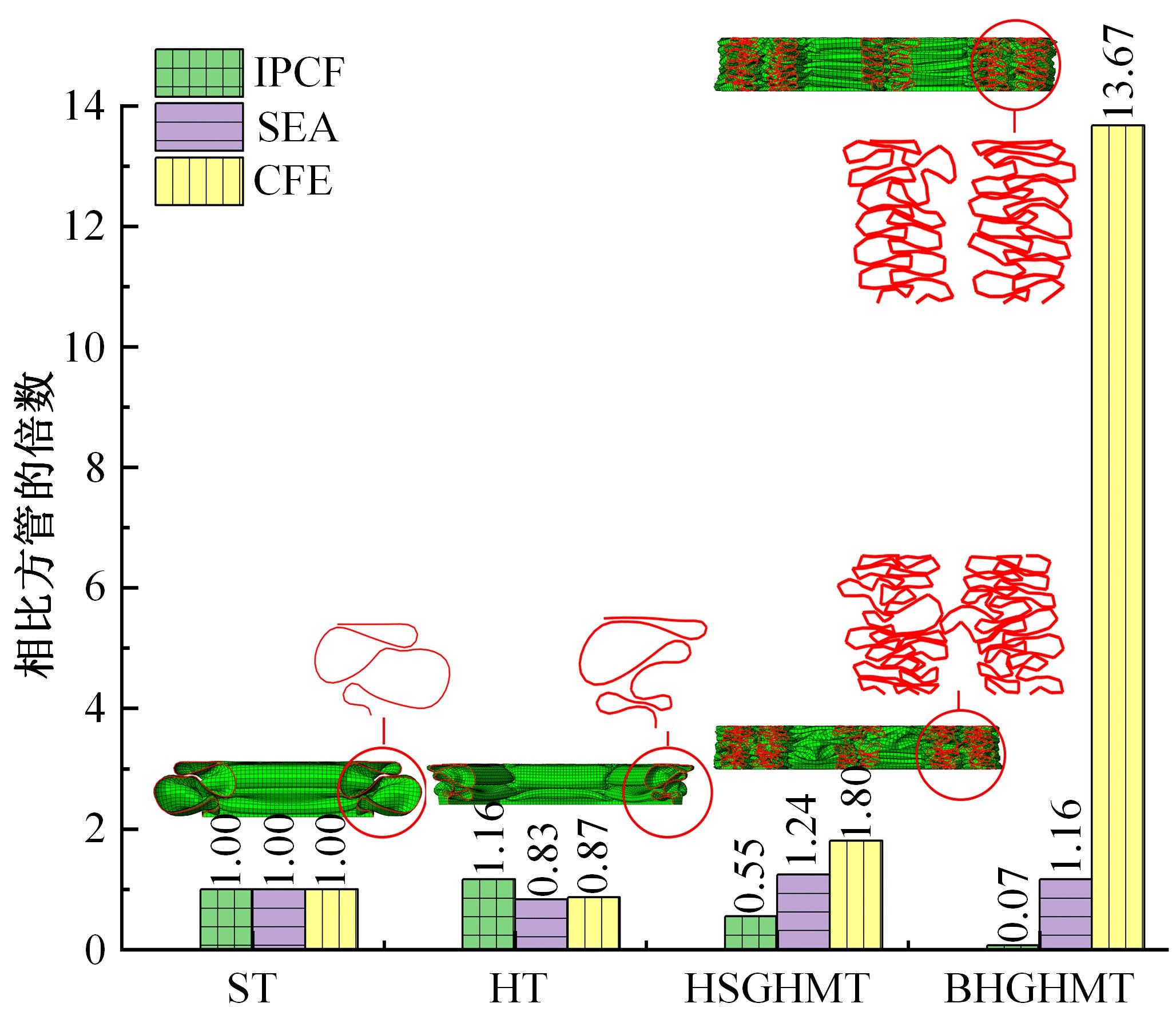

设计并提出了一种新型的仿竹六边形梯度层级多胞管。首先,采用超折叠单元方法推导了六边形单梯度层级多胞管的平均冲击力的理论解,开展了方管的实验研究,利用理论解及实验结果对有限元数值模型的精确性进行了验证。其次,利用验证后的数值模型分析了不同壁厚的仿竹六边形梯度层级多胞管的耐撞性能。最后,系统地研究了仿竹六边形梯度层级多胞管相比常规方管、六边形管、六边形单梯度层级多胞管在相同质量、相同初始峰值力和相同能量吸收条件下的耐撞性能。研究结果表明:提出的仿竹六边形梯度层级多胞管能有效降低结构的初始峰值力和提高结构的冲击力效率,在相同质量、相同初始峰值力和相同能量吸收条件下,仿竹六边形梯度层级多胞管的综合耐撞性能都要优于常规方管、六边形管和六边形单梯度层级多胞管。研究结果能为新型梯度层级多胞管的结构创新设计提供参考。

中图分类号:

- U463.8

| 1 | Patel V, Tiwari G, Dumpala R, et al. Review of the crushing response of collapsible tubular structures[J]. Frontiers of Mechanical Engineering, 2020, 15(3): 438-474. |

| 2 | Wang Z, Lei Z, Li Z, et al. Mechanical reinforcement mechanism of a hierarchical Kagome honeycomb[J]. Thin-Walled Structures, 2021, 167: 108235. |

| 3 | Tan H L, He Z C, Li K X, et al. In-plane crashworthiness of re-entrant hierarchical honeycombs with negative Poisson's ratio[J]. Composite Structures, 2019, 229: 111415. |

| 4 | Lu Q, Qi D, Li Y, et al. Impact energy absorption performances of ordinary and hierarchical chiral structures[J]. Thin-Walled Structures, 2019, 140: 495-505. |

| 5 | 邹猛, 于用军, 张荣荣, 等. 仿牛角结构薄壁管吸能特性仿真分析[J]. 吉林大学学报: 工学版, 2015, 45(6): 1863-1868. |

| Zou Meng, Yu Yong-jun, Zhang Rong-rong, et al. Simulation analysis of energy-absorption properties of thin-wall tube based on horn structure[J]. Journal of Jilin University (Engineering and Technology Edition), 2015, 45(6): 1863-1868. | |

| 6 | 黄晗, 闫庆昊, 向枳昕, 等. 基于虾螯的仿生多胞薄壁管耐撞性分析及优化[J]. 吉林大学学报: 工学版, 2022, 52(3): 716-724. |

| Huang Han, Yan Qing-hao, Xiang Zhi-xin, et al. Crashworthiness investigation and optimization of bionic multi-cell tube based on shrimp chela[J]. Journal of Jilin University (Engineering and Technology Edition), 2022, 52(3): 716-724. | |

| 7 | Xu S, Li W, Li L, et al. Crashworthiness design and multi-objective optimization for bio-inspired hierarchical thin-walled structures[J]. Computer Modeling in Engineering & Sciences, 2022, 131(2): 929-947. |

| 8 | Li W, Fan H. Crushing behavior of hierarchical hexagonal thin-walled steel tubes under oblique impact[J]. International Journal of Steel Structures, 2020, 21(1): 202-212. |

| 9 | Wang Z, Li Z, Shi C, et al. Mechanical performance of vertex-based hierarchical vs square thin-walled multi-cell structure[J]. Thin-Walled Structures, 2019, 134: 102-110. |

| 10 | Zhang S, Fan T. Impact behaviour of hexagonal hierarchical honeycombs[J]. Journal of Sandwich Structures & Materials, 2022, 24(3): 1597-1610. |

| 11 | Zhang X, Shen Z, Wu H, et al. In-plane dynamic crushing behaviors of joint-based hierarchical honeycombs with different topologies[J]. Journal of Sandwich Structures & Materials, 2021, 23(8): 4218-4251. |

| 12 | Huang W, Zhang Y, Xu Y, et al. Out-of-plane mechanical design of bi-directional hierarchical honeycombs[J]. Composites Part B: Engineering, 2021, 221: 109012. |

| 13 | Zhang D, Fei Q, Liu J, et al. Crushing of vertex-based hierarchical honeycombs with triangular substructures[J]. Thin-Walled Structures, 2020, 146: 106436. |

| 14 | Tao Y, Li W, Cheng T, et al. Out-of-plane dynamic crushing behavior of joint-based hierarchical honeycombs[J]. Journal of Sandwich Structures & Materials, 2020, 23(7): 2832-2855. |

| 15 | Ha N S, Pham T M, Hao H, et al. Energy absorption characteristics of bio-inspired hierarchical multi-cell square tubes under axial crushing[J]. International Journal of Mechanical Sciences, 2021, 201: 106464. |

| 16 | Ha N S, Pham T M, Chen W, et al. Crashworthiness analysis of bio-inspired fractal tree-like multi-cell circular tubes under axial crushing[J]. Thin-Walled Structures, 2021, 169: 108315. |

| 17 | Wu J, Zhang Y, Zhang F, et al. A bionic tree-liked fractal structure as energy absorber under axial loading[J]. Engineering Structures, 2021, 245: 112914. |

| 18 | He Q, Wang Y, Gu H, et al. The dynamic behavior of fractal-like tubes with Sierpinski hierarchy under axial loading[J]. Engineering with Computers, 2021(1): 012756. |

| 19 | Deng X, Qin S, Huang J. Crashworthiness analysis of gradient hierarchical multicellular columns evolved from the spatial folding[J]. Materials & Design, 2022, 215: 110435. |

| 20 | Deng X, Qin S, Huang J. Multiobjective optimization of axially varying thickness lateral corrugated tubes for energy absorption[J]. Mechanics of Advanced Materials and Structures, 2021(1): 1924901. |

| 21 | Zhou J, Qin R, Chen B. Energy absorption properties of multi-cell thin-walled tubes with a double surface gradient[J]. Thin-Walled Structures, 2019, 145: 106386. |

| 22 | Zheng J, Qin Q, Wang T J. Impact plastic crushing and design of density-graded cellular materials[J]. Mechanics of Materials, 2016, 94: 66-78. |

| 23 | Karagiozova D, Alves M. Propagation of compaction waves in cellular materials with continuously varying density[J]. International Journal of Solids and Structures, 2015, 71: 323-337. |

| 24 | Zou M, Xu S, Wei C, et al. A bionic method for the crashworthiness design of thin-walled structures inspired by bamboo[J]. Thin-Walled Structures, 2016, 101: 222-230. |

| 25 | Pirmohammad S, Saravani S A. Crashworthiness performance of stiffened foam-filled tapered structures under axial and oblique dynamic loads[J]. Latin American Journal of Solids and Structures, 2018, 15(5): 1-15. |

| 26 | Zhang Y, He N, Song X, et al. On impacting mechanical behaviors of side fractal structures[J]. Thin-Walled Structures, 2020, 146: 1-9. |

| 27 | Ha N S, Pham T M, Hao H, et al. Energy absorption characteristics of bio-inspired hierarchical multi-cell square tubes under axial crushing[J]. International Journal of Mechanical Sciences, 2021, 201: 17-25. |

| 28 | Zheng G, Wu S, Sun G, et al. Crushing analysis of foam-filled single and bitubal polygonal thin-walled tubes[J]. International Journal of Mechanical Sciences, 2014, 87: 226-240. |

| 29 | Zhang L, Bai Z, Bai F. Crashworthiness design for bio-inspired multi-cell tubes with quadrilateral, hexagonal and octagonal sections[J]. Thin-Walled Structures, 2018, 122: 42-51. |

| 30 | Zhang X, Cheng G, Zhang H. Theoretical prediction and numerical simulation of multi-cell square thin-walled structures[J]. Thin-Walled Structures, 2006, 44(11): 1185-1191. |

| [1] | 王铁,李旭东,田程,赵宏伟. 基于多轴载荷投影构建轮辋双轴疲劳损伤模型[J]. 吉林大学学报(工学版), 2024, 54(1): 99-104. |

| [2] | 李旭东,王新宇,田程,张新峰,牛治慧,赵志强. 基于用户关联的车辆耐久性载荷谱编制[J]. 吉林大学学报(工学版), 2024, 54(1): 66-75. |

| [3] | 吴骁,史文库,郭年程,赵燕燕,陈志勇,李鑫鹏,孙卓,刘健. 基于Ease off的准双曲面齿轮多目标优化[J]. 吉林大学学报(工学版), 2024, 54(1): 76-85. |

| [4] | 陈兆玮,蒲前华. 弹性车轮对大跨斜拉桥车桥耦合振动的抑制特性[J]. 吉林大学学报(工学版), 2023, 53(9): 2519-2532. |

| [5] | 刘平义,李晓婷,高偌霖,李海涛,魏文军,王亚. 车辆侧倾驱动机构设计与试验[J]. 吉林大学学报(工学版), 2023, 53(8): 2185-2192. |

| [6] | 黄学劲,钟锦星,路京雨,赵霁,肖伟,袁新枚. 基于用户画像的电动汽车充电负荷预测方法[J]. 吉林大学学报(工学版), 2023, 53(8): 2193-2200. |

| [7] | 张树培,夏明悦,张玮,陈钊,陈义祥. 考虑非线性刚度的间隙球铰碰撞动力学建模与仿真[J]. 吉林大学学报(工学版), 2023, 53(8): 2227-2235. |

| [8] | 陈辉,邵亚军. 基于惯性基准多传感器耦合的路面谱测量方法[J]. 吉林大学学报(工学版), 2023, 53(8): 2254-2262. |

| [9] | 陈磊,王杨,董志圣,宋亚奇. 一种基于转向意图的车辆敏捷性控制策略[J]. 吉林大学学报(工学版), 2023, 53(5): 1257-1263. |

| [10] | 陈鑫,张冠宸,赵康明,王佳宁,杨立飞,司徒德蓉. 搭接焊缝对铝合金焊接结构轻量化设计的影响[J]. 吉林大学学报(工学版), 2023, 53(5): 1282-1288. |

| [11] | 张勇,毛凤朝,刘水长,王青妤,潘神功,曾广胜. 基于Laplacian算法的汽车外流场畸变网格优化[J]. 吉林大学学报(工学版), 2023, 53(5): 1289-1296. |

| [12] | 汪少华,储堃,施德华,殷春芳,李春. 基于有限时间扩张状态观测的HEV鲁棒复合协调控制[J]. 吉林大学学报(工学版), 2023, 53(5): 1272-1281. |

| [13] | 于贵申,陈鑫,武子涛,陈轶雄,张冠宸. AA6061⁃T6铝薄板无针搅拌摩擦点焊接头结构及性能分析[J]. 吉林大学学报(工学版), 2023, 53(5): 1338-1344. |

| [14] | 田彦涛,黄兴,卢辉遒,王凯歌,许富强. 基于注意力与深度交互的周车多模态行为轨迹预测[J]. 吉林大学学报(工学版), 2023, 53(5): 1474-1480. |

| [15] | 尹燕莉,黄学江,潘小亮,王利团,詹森,张鑫新. 基于PID与Q⁃Learning的混合动力汽车队列分层控制[J]. 吉林大学学报(工学版), 2023, 53(5): 1481-1489. |

|

||