吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (6): 1634-1642.doi: 10.13229/j.cnki.jdxbgxb.20220904

• 交通运输工程·土木工程 • 上一篇

球扁钢肋钢纤维混凝土组合桥面板正弯矩受力性能试验

- 1.同济大学 土木工程学院,上海 200092

2.上海市政工程设计研究总院(集团)有限公司,上海 200092

3.上海高性能组合结构桥梁工程技术研究中心,上海 200092

Experimental on positive bending behaviour of composite bridge decks with steel-fiber-reinforced concrete and longitudinal bulb-flat ribs

Chun-lei ZHANG1( ),Chang-yu SHAO2,3,Qing-tian SU1,3,Chang-yuan DAI2,3(

),Chang-yu SHAO2,3,Qing-tian SU1,3,Chang-yuan DAI2,3( )

)

- 1.College of Civil Engineering,Tongji University,Shanghai 200092,China

2.Shanghai Municipal Engineering Design Institute (Group) Co. ,Ltd. ,Shanghai 200092,China

3.Shanghai Engineering Research Center of High Performance Composite Bridges,Shanghai 200092,China

摘要:

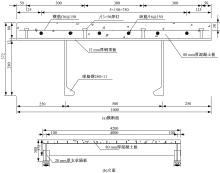

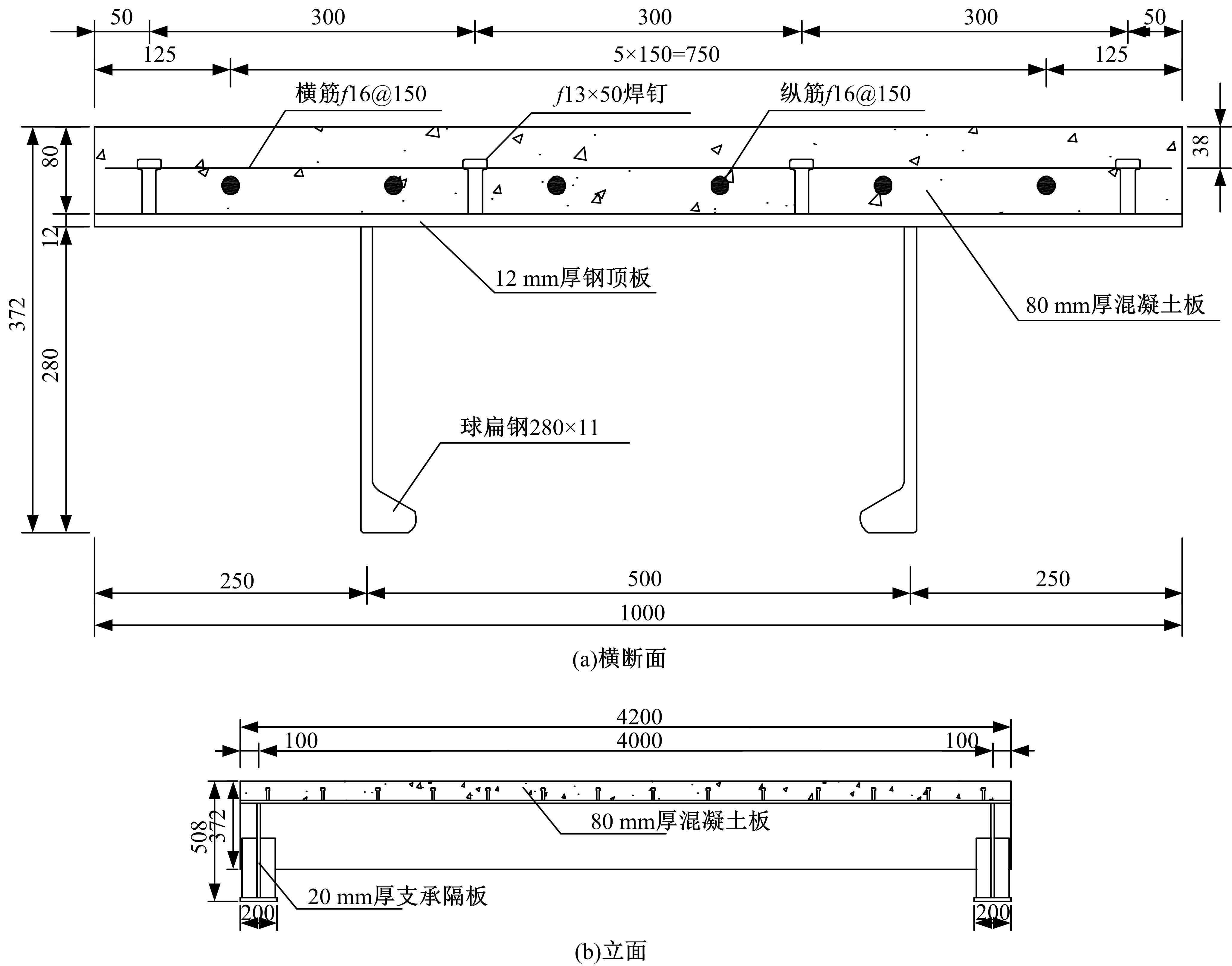

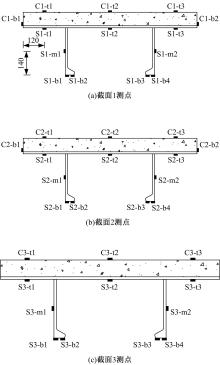

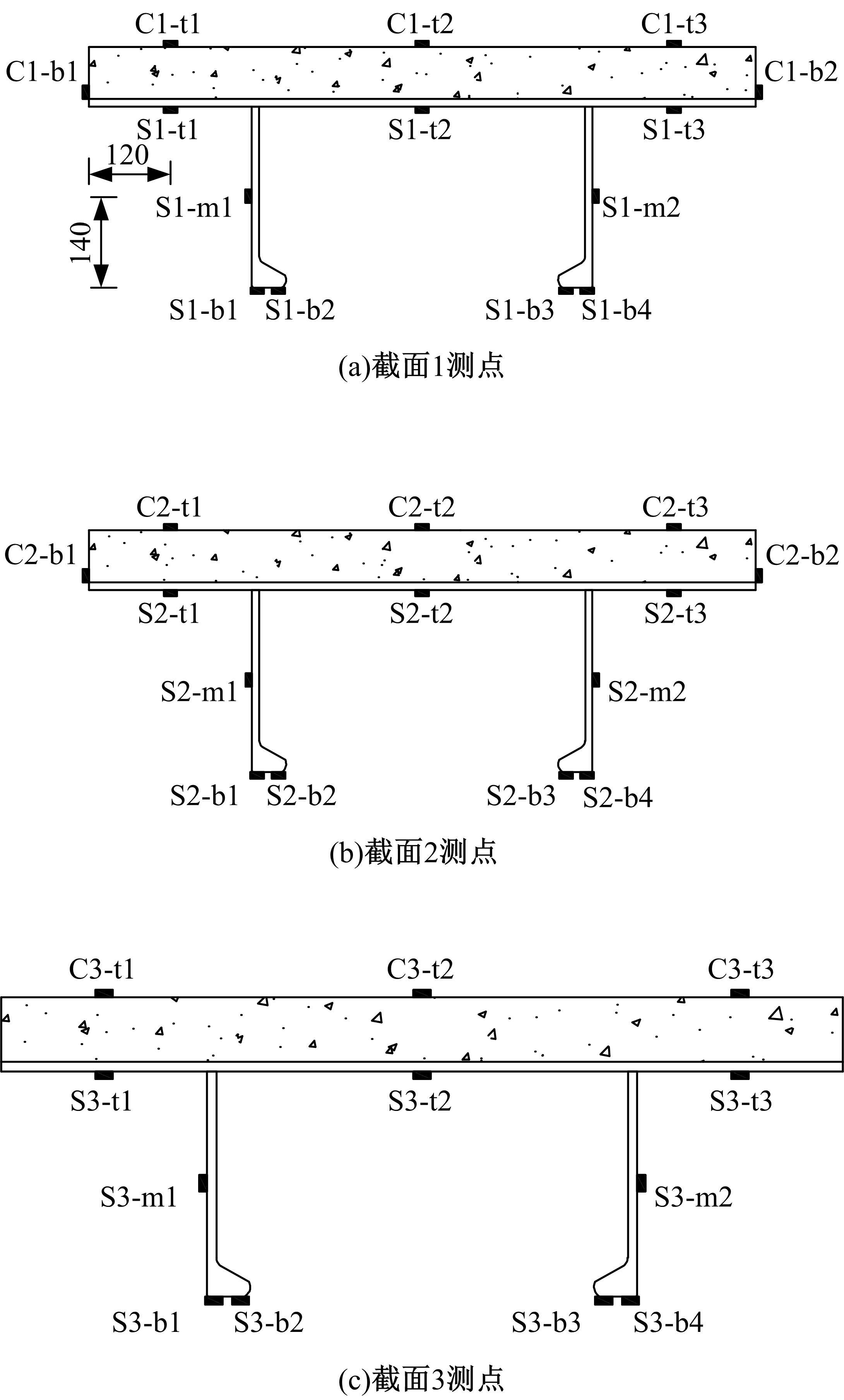

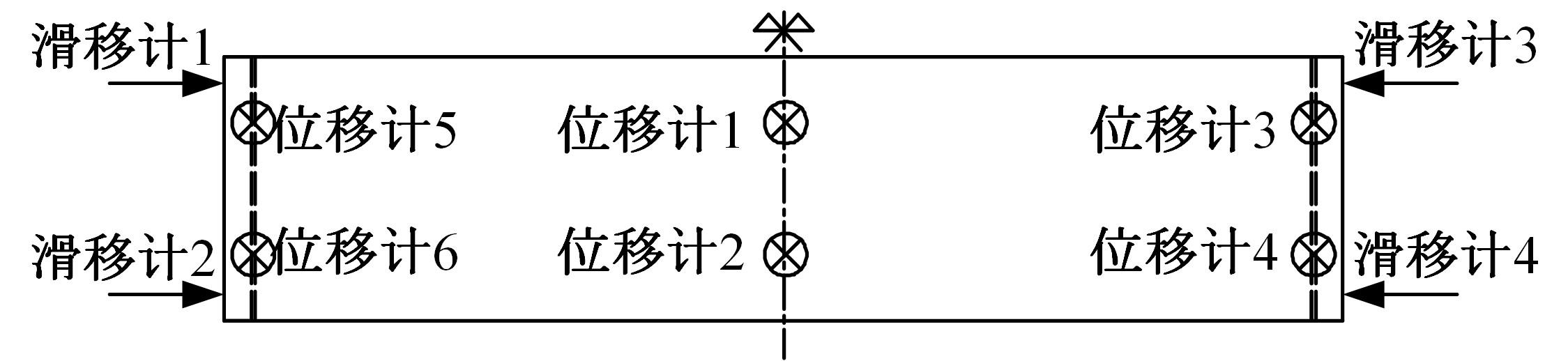

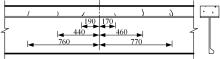

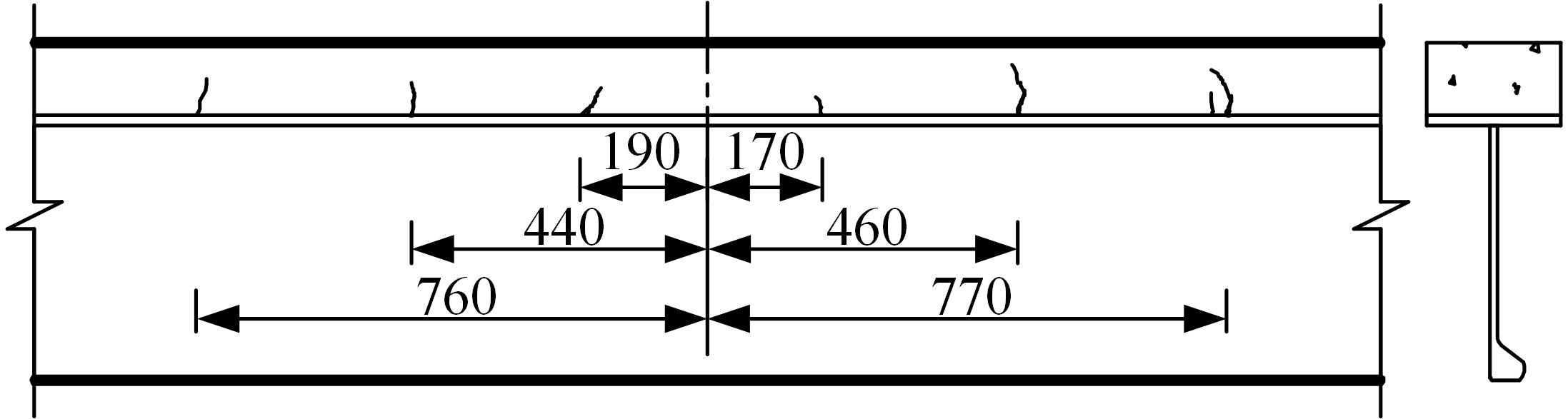

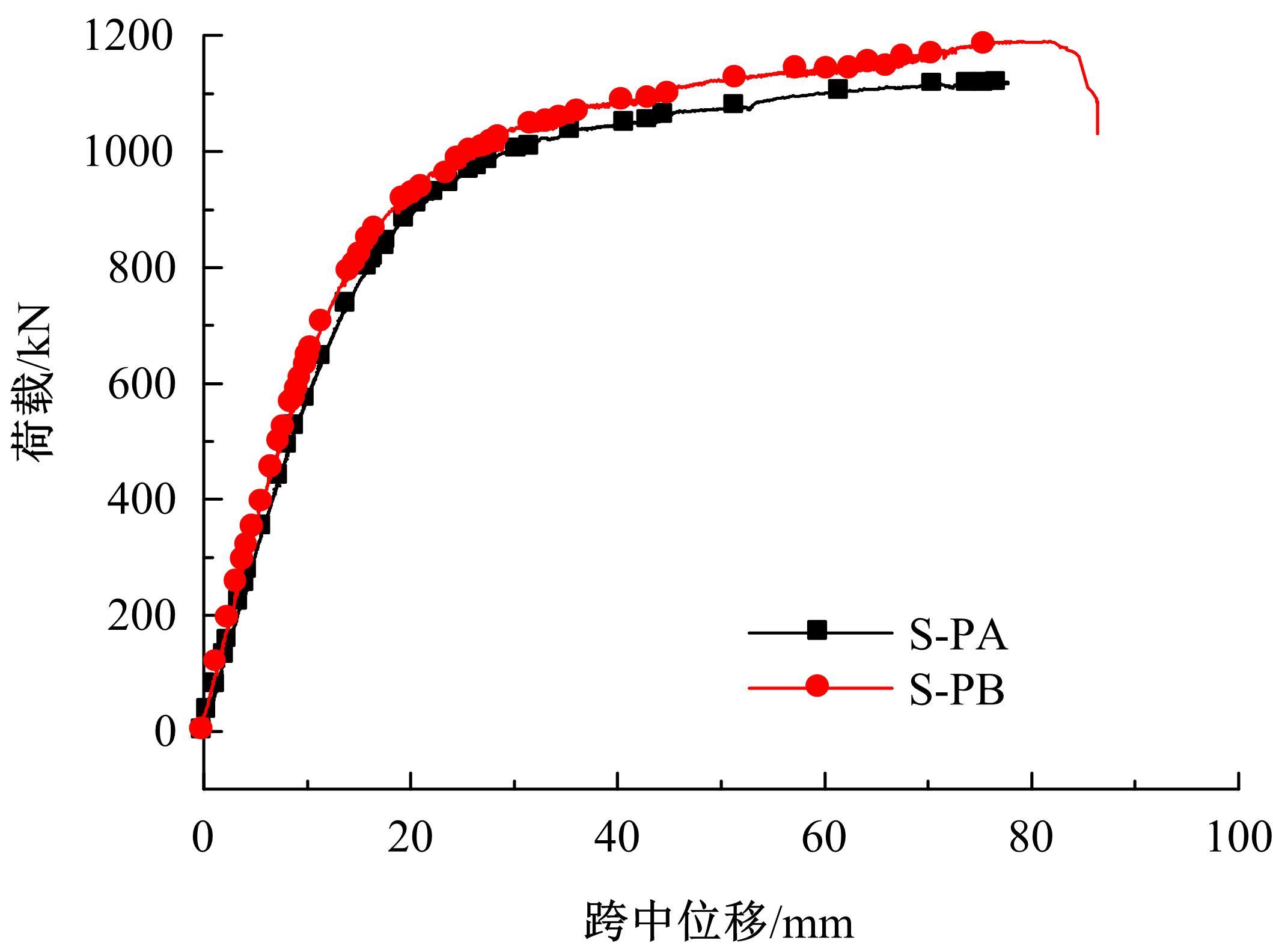

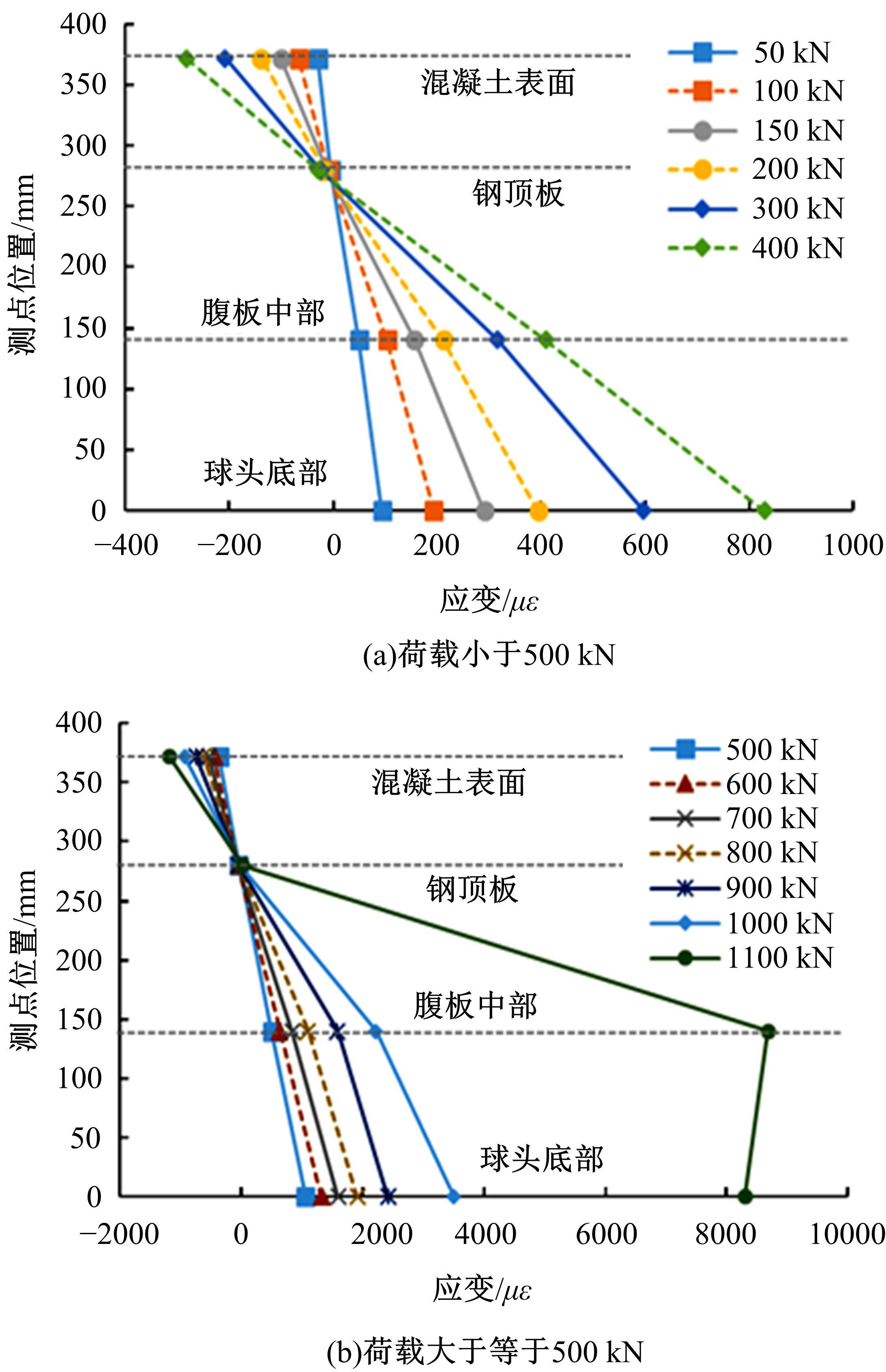

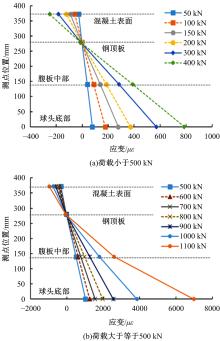

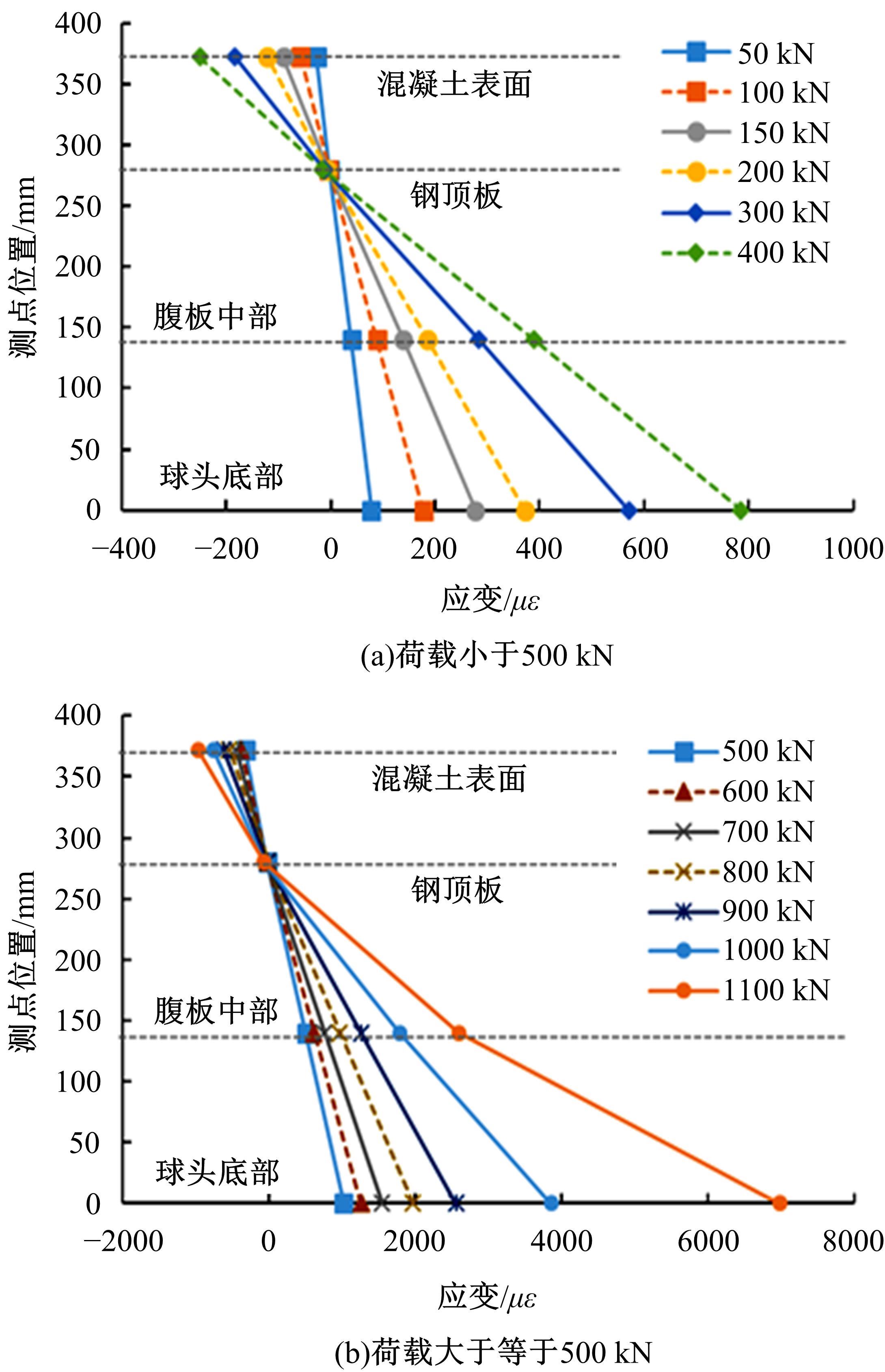

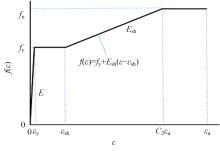

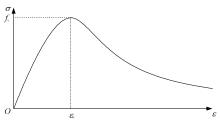

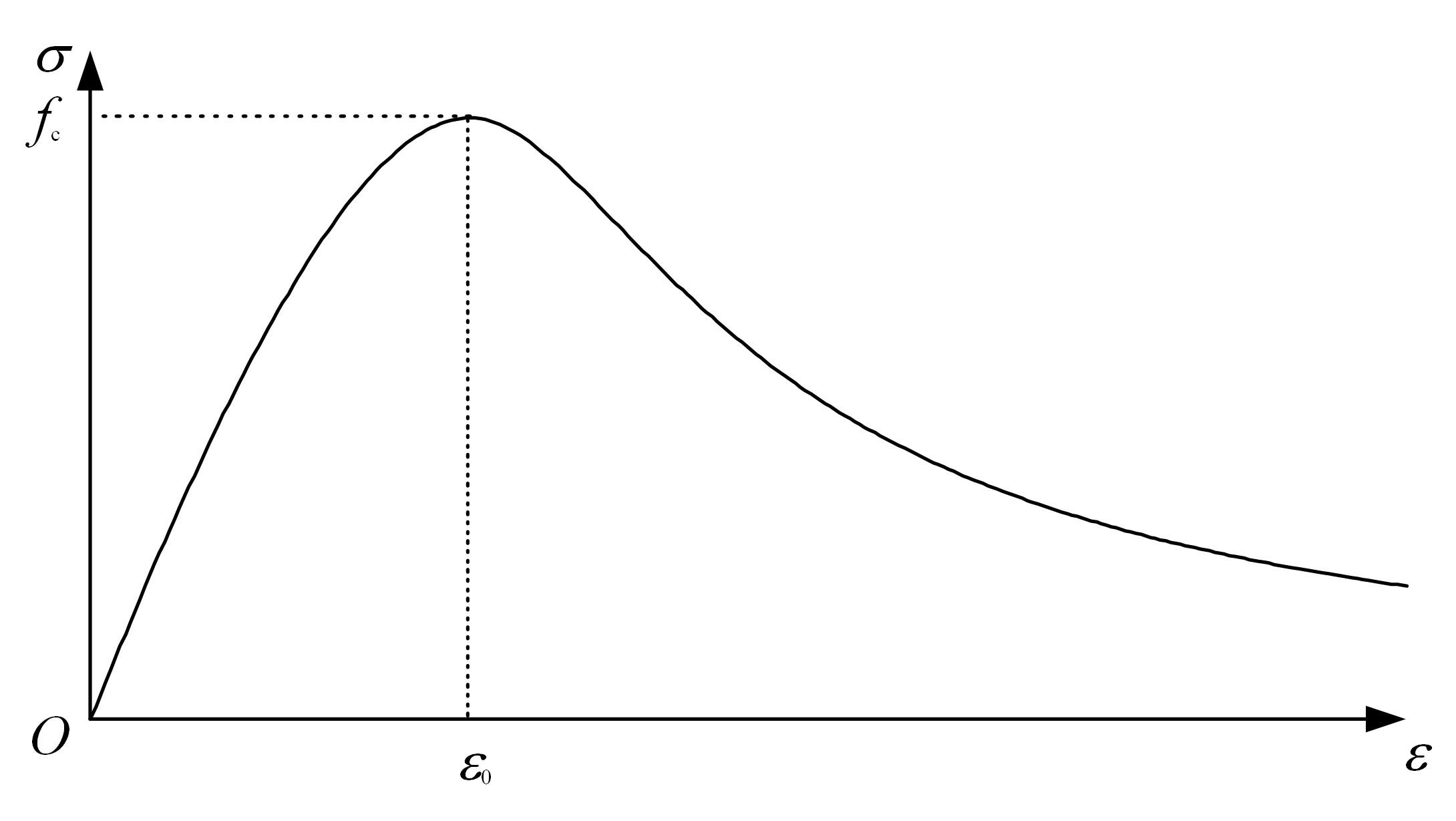

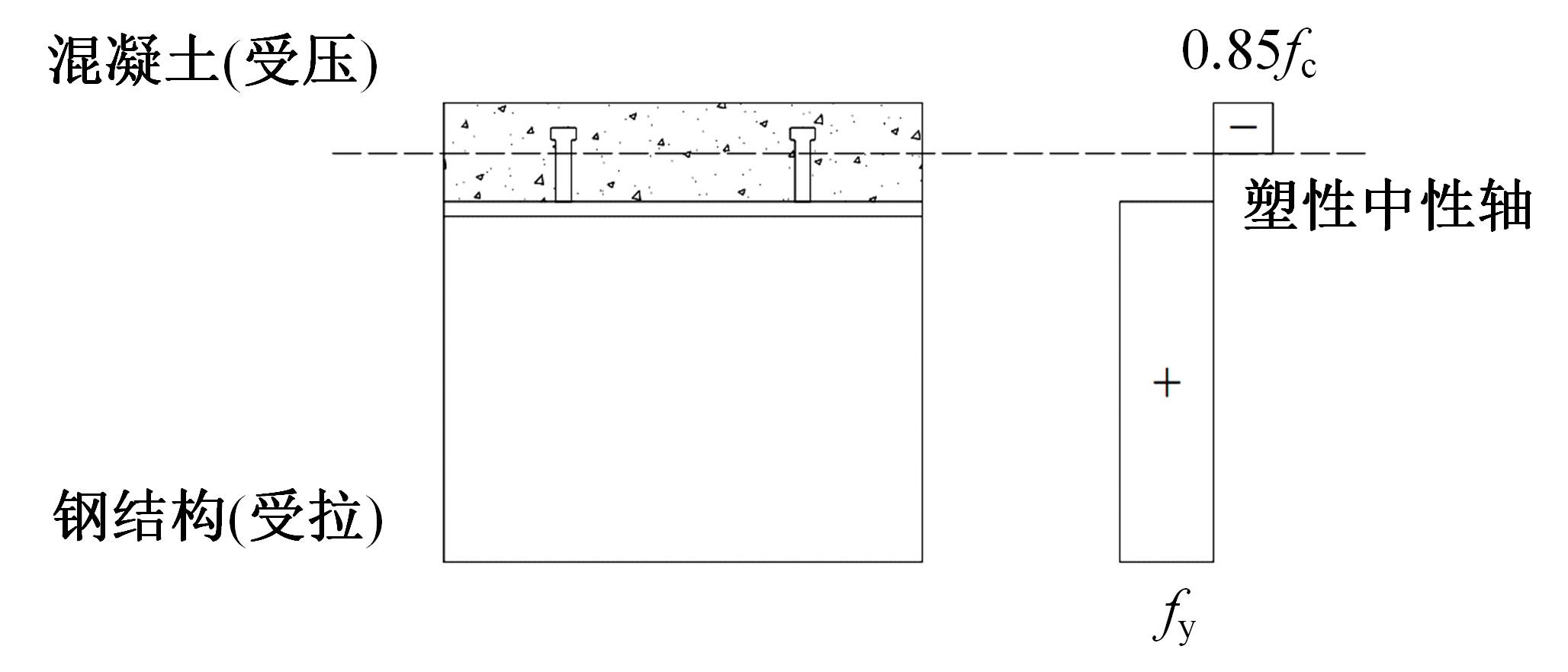

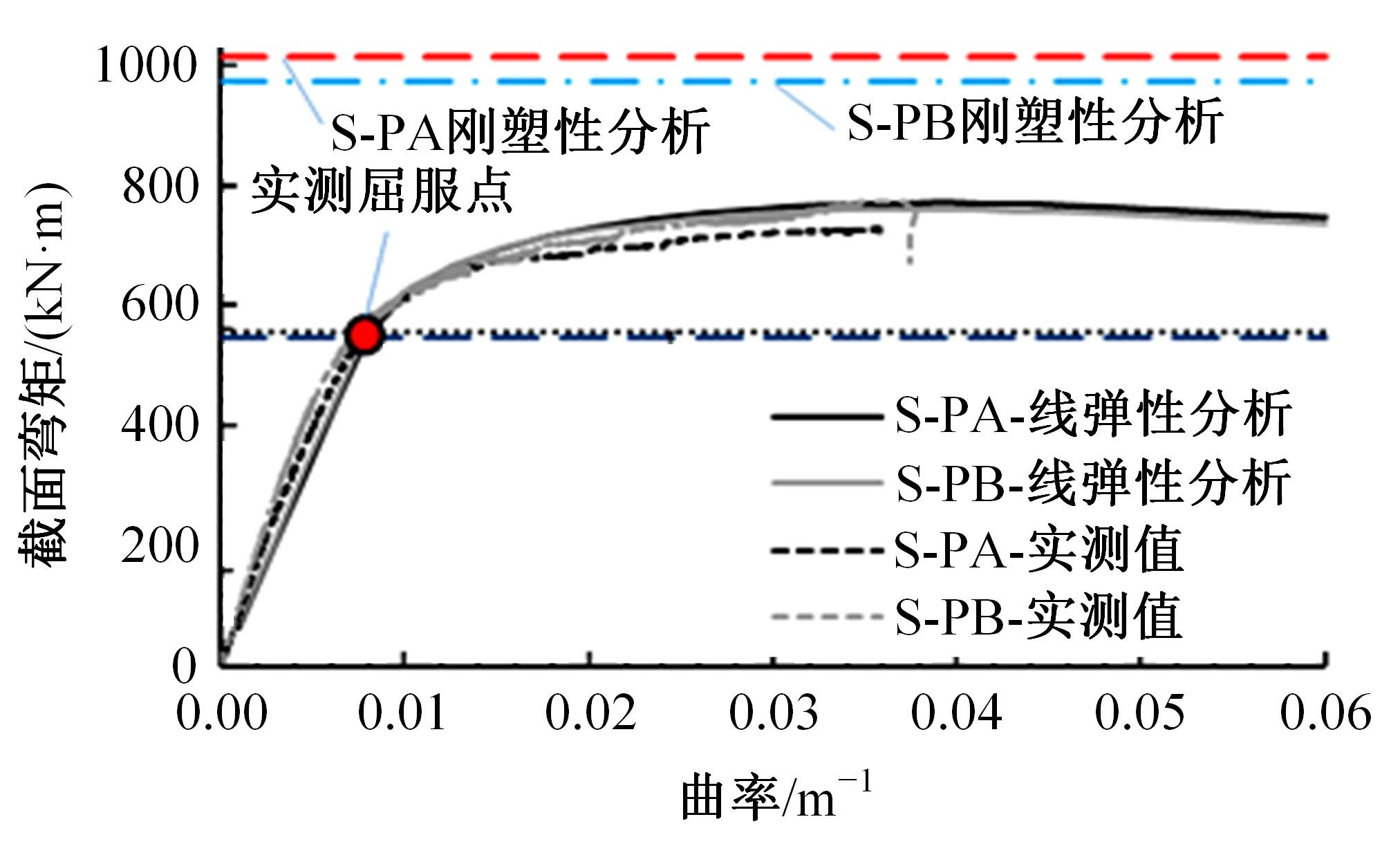

针对一种采用80 mm厚钢纤维混凝土(SFRC)和球扁钢纵肋的新型组合桥面板,设计制作了两个组合桥面板足尺模型,进行了正弯矩加载试验,测试得到加载全过程结构变形和应变变化情况。采用截面弹塑性截面分析方法、线弹性分析方法和刚塑性分析方法计算了正弯矩承载力,并与试验结果进行对比。研究结果表明:组合桥面板在承受正弯矩荷载时位移延性系数为4.90~5.77,具有较好的延性;在承载能力极限状态下,组合桥面板正弯矩承载力由球扁钢受力控制,SFRC具有充足的抗压强度,提高混凝土强度对正弯矩承载力影响很小;截面弹塑性分析能较为准确地计算正弯矩承载力,适合用于组合桥面板设计计算。

中图分类号:

- TU398

| 1 | Buitelaar P, Braam R. Heavy reinforced ultra thin white topping of high performance concrete for re-strengthening and rehabilitation of structures and pavements[C]∥8th International Symposium on Utilization of High-Strength and High-Performance Concrete, Tokyo, Japan, 2008: 1262-1269. |

| 2 | De Jong F B P, Kolstein M H. Strengthening a bridge deck with high performance concrete[C]∥2004 Orthotropic Bridge Conference, Sacramento, California, USA, 2004: 328-347. |

| 3 | Terada H, Maeno H, Nakamura M, et al. An experimental study on SFRC composite steel deck[J]. Structural Eng/Earthquake Eng,1986, 3(2): 469-476. |

| 4 | Hayama M, Sekiya H, Nagai M. Verification of the reinforcement effect of an SFRC pavement under a live load based on visualization of deformation of a trough rib of an orthotropic steel deck using MEMS IMUs and contact displacement gauges[J]. Journal of Bridge Engineering, 2022, 27(5): No.4022030. |

| 5 | 李林波,张锋,丁庆军. SFRC在日本钢桥面铺装工程中的研究与应用[J]. 公路交通技术, 2012(1): 36-39. |

| Li Lin-bo, Zhang Feng, Ding Qing-jun. Research and application of SFRC in paving projects of steel decks in Japan[J]. Technology of Highway and Transport,2012(1): 36-39. | |

| 6 | 陈开利. 正交异性钢桥面板的疲劳裂纹处治[J]. 世界桥梁,2016(1): 70-76. |

| Chen Kai-li. Treatment for fatigue cracks of orthotropic steel decks[J]. World Bridges,2016(1): 70-76. | |

| 7 | Cao J, Shao X, Zhang Z, et al. Retrofit of an orthotropic steel deck with compact reinforced reactive powder concrete[J]. Structure and Infrastructure Engineering, 2015, 12(3): 411-429. |

| 8 | Wang S, Ke Z, Gao Y, et al. Long-term in situ performance investigation of orthotropic steel bridge deck strengthened by SPS and RPC solutions[J]. Journal of Bridge Engineering, 2019, 24(6): 4019051-4019054. |

| 9 | Zhang S, Shao X, Cao J, et al. Fatigue performance of a lightweight composite bridge deck with open ribs[J]. Journal of Bridge Engineering, 2016, 21(7): No.4016039. |

| 10 | Jung R, Mansperger T. The ortho-composite-slab of the elbebridge wittenberge[C]∥IABSE Symposium Report: Engineering for Progree Nature and People, Madrid, Spain, 2014: 1186-1191. |

| 11 | Jiang X, Su Q, Han X, et al. Experimental study and numerical analysis on mechanical behavior of T-shape stiffened orthotropic steel-concrete composite bridge decks[J]. International Journal of Steel Structures, 2017, 17(3): 893-907. |

| 12 | 苏庆田,韩旭,姜旭,等. U形肋正交异性组合桥面板力学性能[J]. 哈尔滨工业大学学报,2016, 48(9): 14-19. |

| Su Qing-tian, Han Xu, Jiang Xu, et al. Performance of the orthotropic composite bridge deck with U-shape stiffener[J]. Journal of Harbin Institute of Technology,2016, 48(9): 14-19. | |

| 13 | 苏庆田,贺欣怡,曾明根,等. T形肋正交异性组合桥面板力学性能[J]. 同济大学学报:自然科学版, 2016, 44(3): 341-347. |

| Su Qing-tian, He Xin-yi, Zeng Ming-gen, et al. Performance of the composite bridge deck with concrete slab and orthotropic steel plate with T-shape stiffener[J]. Journal of Tongji University (Natural Science), 2016, 44(3): 341-347. | |

| 14 | Zhou W, Chen L, Shao C, et al. A long-span network arch bridge for road and rail traffic[J]. Structural Engineering International : Journal of the International Association for Bridge and Structural Engineering (IABSE). 2022, 32(2): 211-215. |

| 15 | . 公路桥涵设计通用规范 [S]. |

| 16 | 范立础,卓卫东. 桥梁延性抗震设计[M]. 北京: 人民交通出版社, 2001. |

| 17 | 张利梅,赵顺波,黄承逵. 预应力高强混凝土梁延性性能分析与试验研究[J]. 工程力学, 2005(3): 166-171. |

| Zhang Li-mei, Zhao Shun-bo, Huang Cheng-kui. Experimental study of ductility of prestressed high-strength concrete beams[J]. Engineering Mechanics, 2005(3): 166-171. | |

| 18 | Yang F, Liu Y, Xin H. Positive bending capacity prediction of composite girders based on elastoplastic cross-sectional analysis[J]. Engineering Structures, 2018, 167: 327-339. |

| 19 | . 公路钢结构桥梁设计规范 [S]. |

| 20 | Eurocode 4. Design of composite steel and concrete structures, part 2 [S]. |

| 21 | Yun X, Gardner L. Stress-strain curves for hot-rolled steels[J]. Journal of Constructional Steel Research, 2017, 133: 36-46. |

| 22 | Walraven J. FIB model code for concrete structures 2010: mastering challenges and encountering new ones[J]. Structural Concrete: Journal of the FIB, 2013, 14(1): 3-9. |

| [1] | 邵长江,崔皓蒙,漆启明,庄卫林. 近断层大跨RC轻柔拱桥纵向阻尼器减震研究[J]. 吉林大学学报(工学版), 2024, 54(5): 1355-1367. |

| [2] | 赵秋,陈鹏,赵煜炜,余澳. 台后设置拱形结构的无缝桥梁整体受力性能[J]. 吉林大学学报(工学版), 2024, 54(4): 1016-1027. |

| [3] | 张洪,朱志伟,胡天宇,龚燕峰,周建庭. 基于改进YOLOv5s的桥梁螺栓缺陷识别方法[J]. 吉林大学学报(工学版), 2024, 54(3): 749-760. |

| [4] | 韩智强,谢刚,卓亚娟,骆佐龙,李华腾. 基于车轮-桥面相干激励的大跨连续梁桥振动响应[J]. 吉林大学学报(工学版), 2024, 54(2): 436-444. |

| [5] | 杨国俊,齐亚辉,石秀名. 基于数字图像技术的桥梁裂缝检测综述[J]. 吉林大学学报(工学版), 2024, 54(2): 313-332. |

| [6] | 谭国金,欧吉,艾永明,杨润超. 基于改进DeepLabv3+模型的桥梁裂缝图像分割方法[J]. 吉林大学学报(工学版), 2024, 54(1): 173-179. |

| [7] | 龙关旭,张修石,辛公锋,王涛,杨干. 融合机器视觉的桥梁动态称重方法[J]. 吉林大学学报(工学版), 2024, 54(1): 188-197. |

| [8] | 卫星,高亚杰,康志锐,刘宇辰,赵骏铭,肖林. 低温环境下栓钉环焊缝焊接残余应力场数值模拟[J]. 吉林大学学报(工学版), 2024, 54(1): 198-208. |

| [9] | 安然,王有志. 剪力钉连接件拉剪共同作用抗剪性能[J]. 吉林大学学报(工学版), 2023, 53(9): 2554-2562. |

| [10] | 左新黛,张劲泉,赵尚传. 在役混凝土T梁疲劳刚度退化及寿命预测方法[J]. 吉林大学学报(工学版), 2023, 53(9): 2563-2572. |

| [11] | 顾正伟,张攀,吕东冶,吴春利,杨忠,谭国金,黄晓明. 基于数值仿真的简支梁桥震致残余位移分析[J]. 吉林大学学报(工学版), 2023, 53(6): 1711-1718. |

| [12] | 吴春利,黄诗茗,李魁,顾正伟,黄晓明,张炳涛,杨润超. 基于数值仿真和统计分析的洪水作用下桥墩作用效应分析[J]. 吉林大学学报(工学版), 2023, 53(6): 1612-1620. |

| [13] | 谭国金,孔庆雯,何昕,张攀,杨润超,朝阳军,杨忠. 基于动力特性和改进粒子群优化算法的桥梁冲刷深度识别[J]. 吉林大学学报(工学版), 2023, 53(6): 1592-1600. |

| [14] | 江辉,李新,白晓宇. 桥梁抗震结构体系发展述评:从延性到韧性[J]. 吉林大学学报(工学版), 2023, 53(6): 1550-1565. |

| [15] | 王峰,刘双瑞,王佳盈,宋佳玲,王俊,张久鹏,黄晓明. 尺寸和形状效应对多孔结构风阻系数的影响[J]. 吉林大学学报(工学版), 2023, 53(6): 1677-1685. |

|

||