吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (6): 1708-1718.doi: 10.13229/j.cnki.jdxbgxb.20220876

• 交通运输工程·土木工程 • 上一篇

考虑非均匀性的沥青混合料开裂行为细观模拟

- 沈阳建筑大学 交通与测绘工程学院,沈阳 110168

Mesoscale simulation of cracking behavior of asphalt mixture considering heterogeneity

Ya-zhen SUN( ),Bo-xin XUE,Yan SUN,Zhi-chen WANG,Jia-wei PAN

),Bo-xin XUE,Yan SUN,Zhi-chen WANG,Jia-wei PAN

- School of Transportation and Geomatics Engineering,Shenyang Jianzhu University,Shenyang 110168,China

摘要:

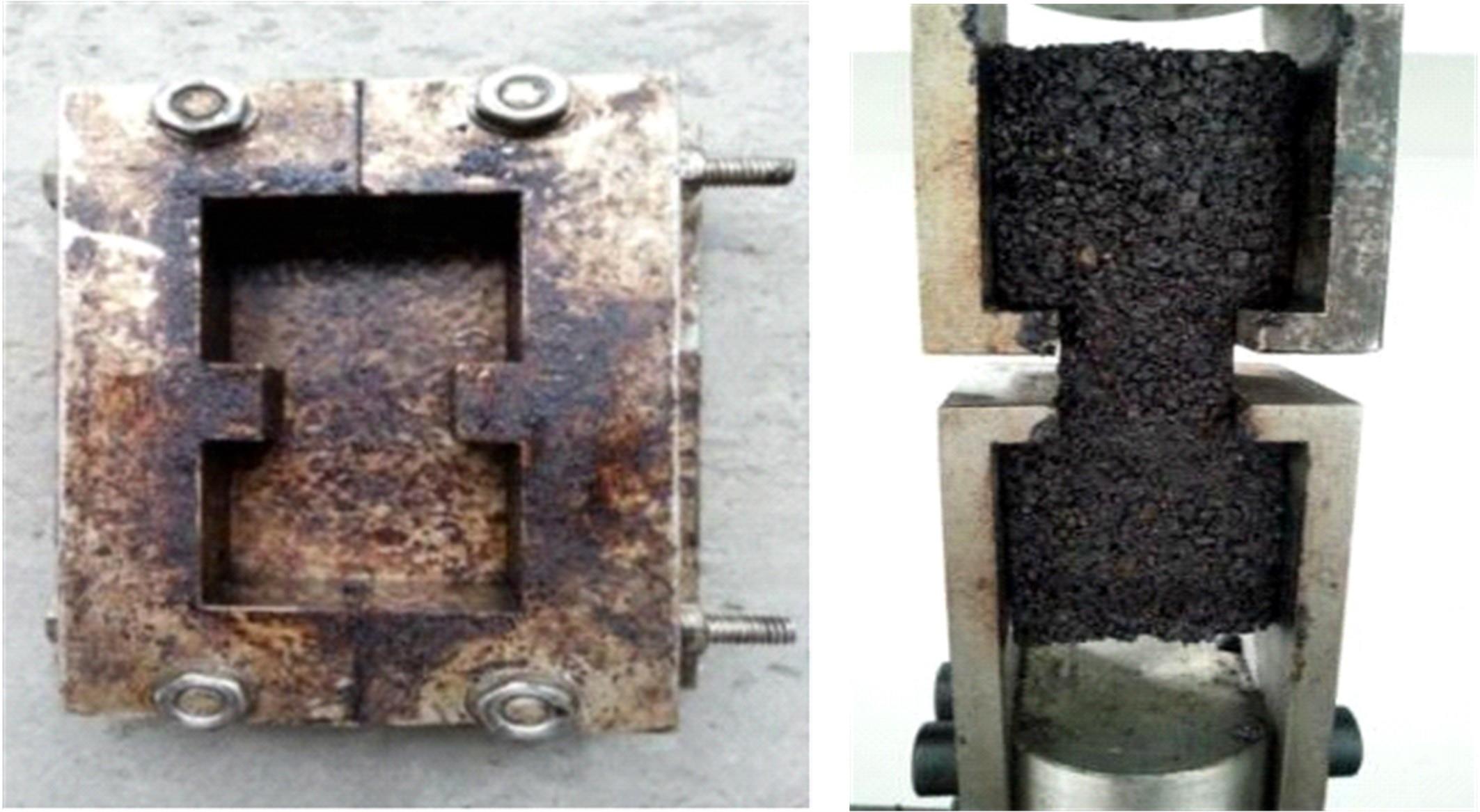

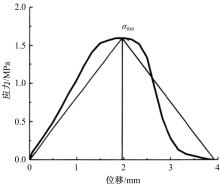

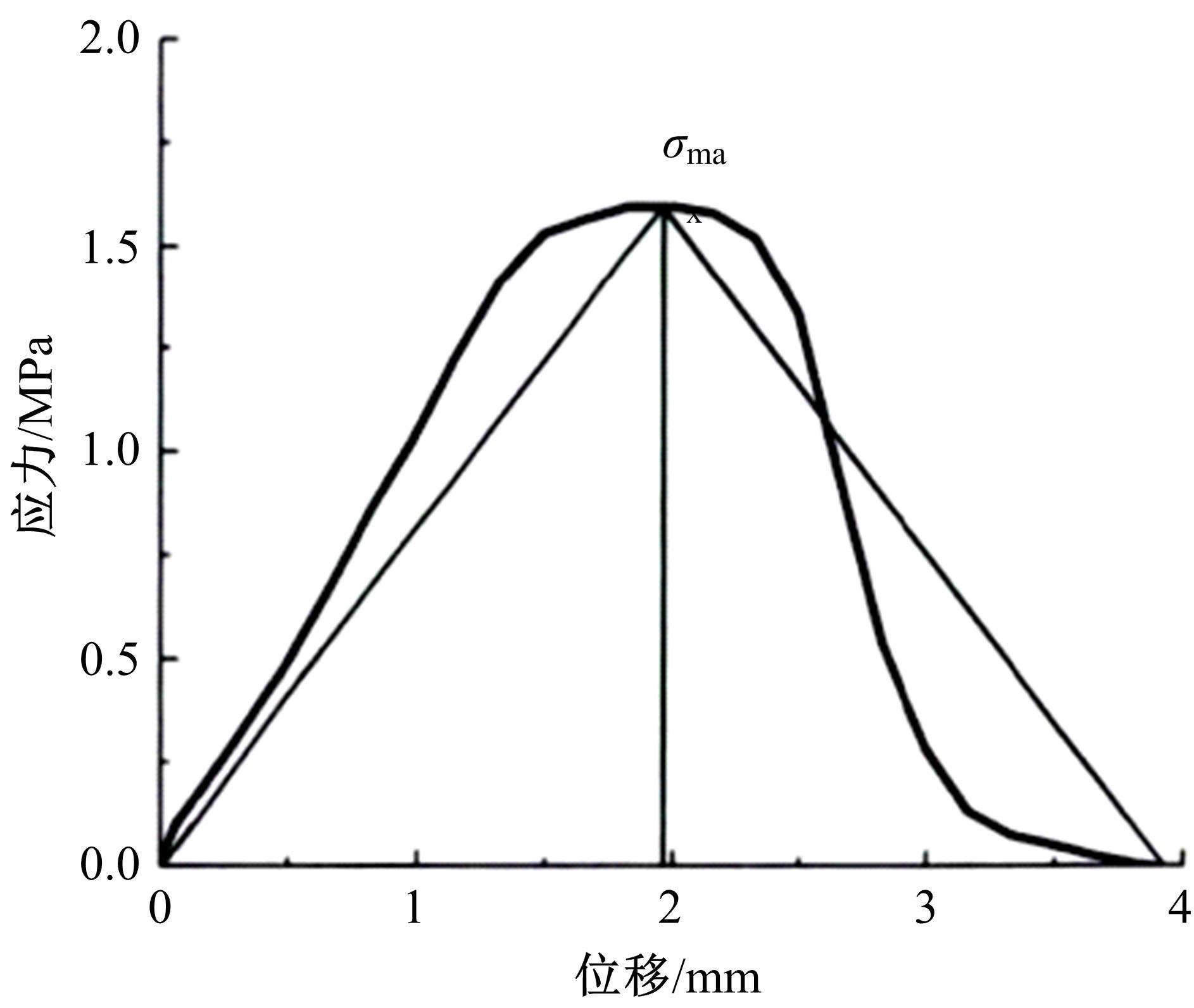

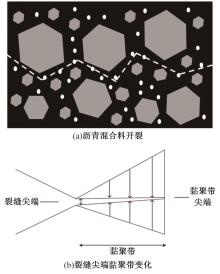

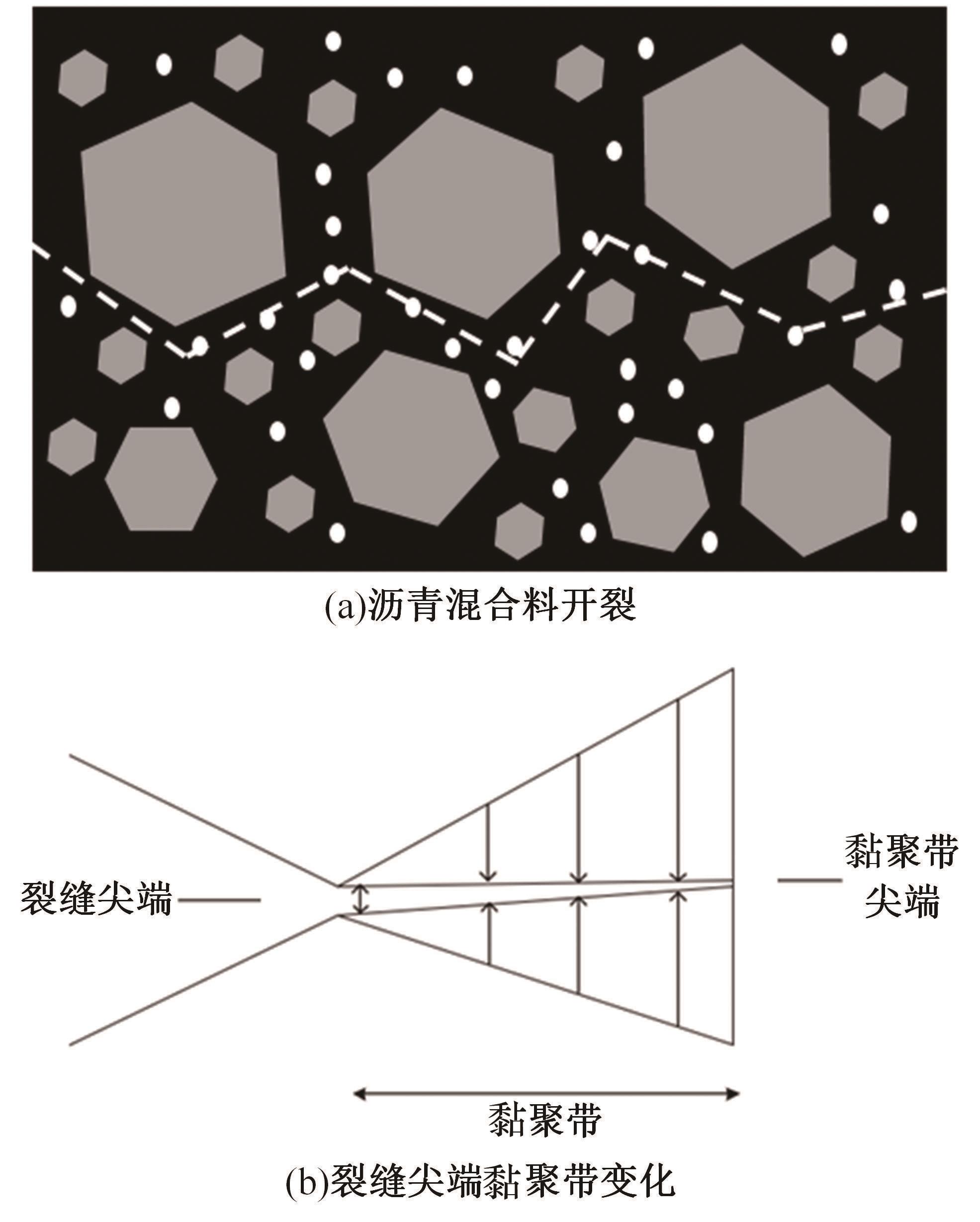

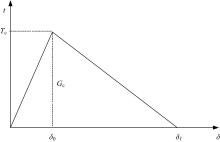

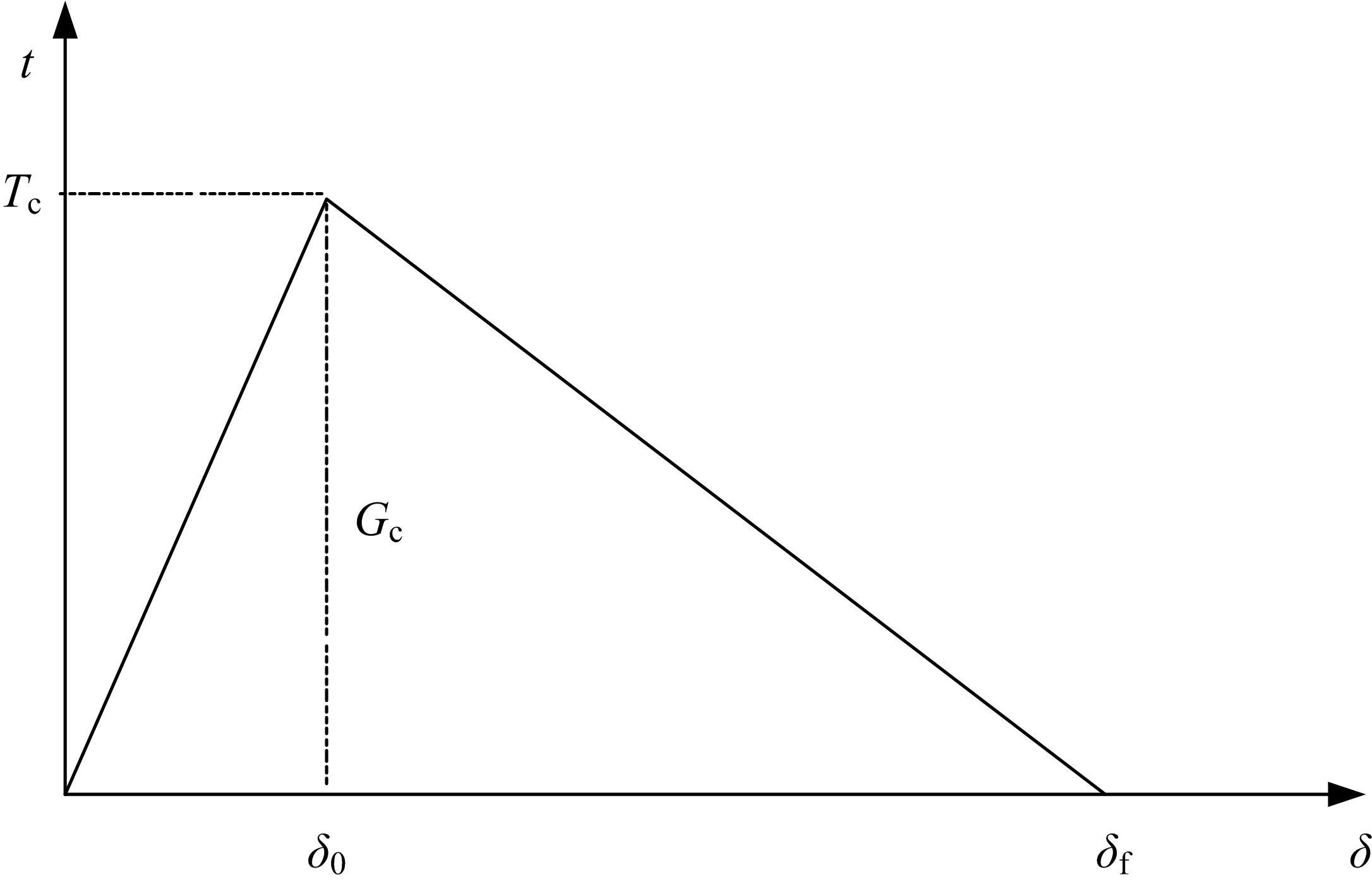

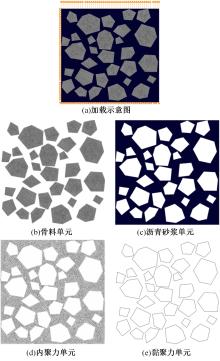

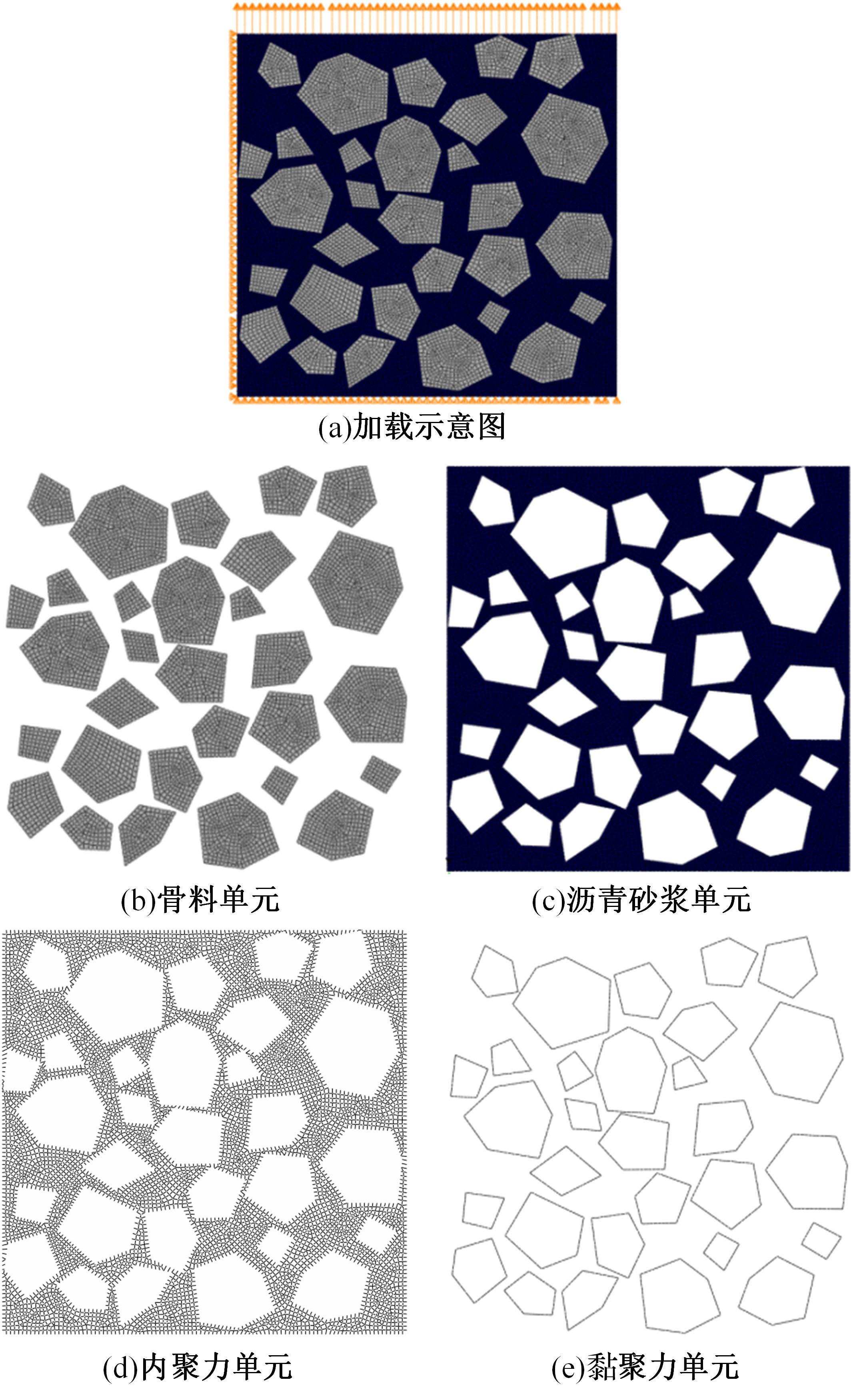

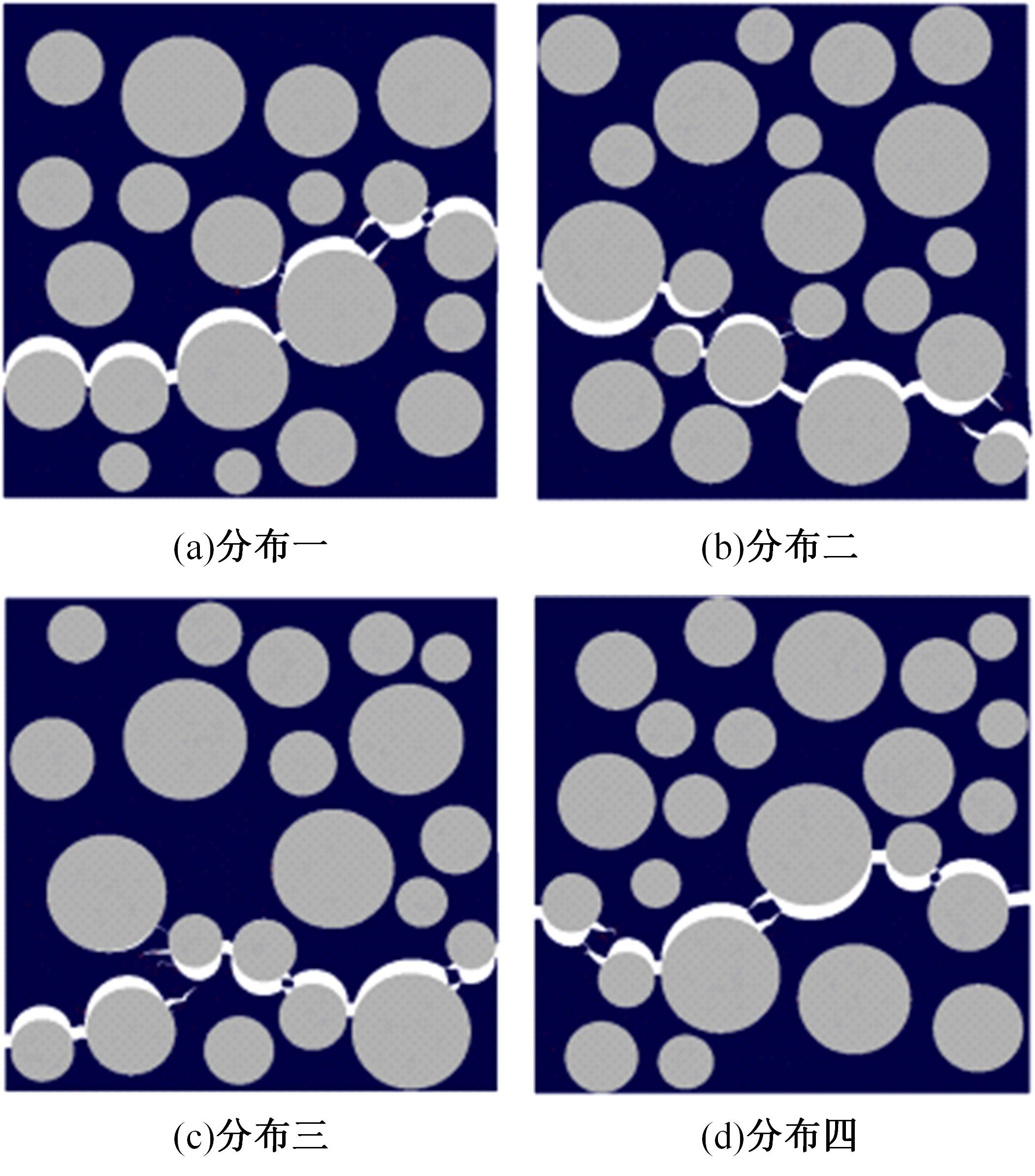

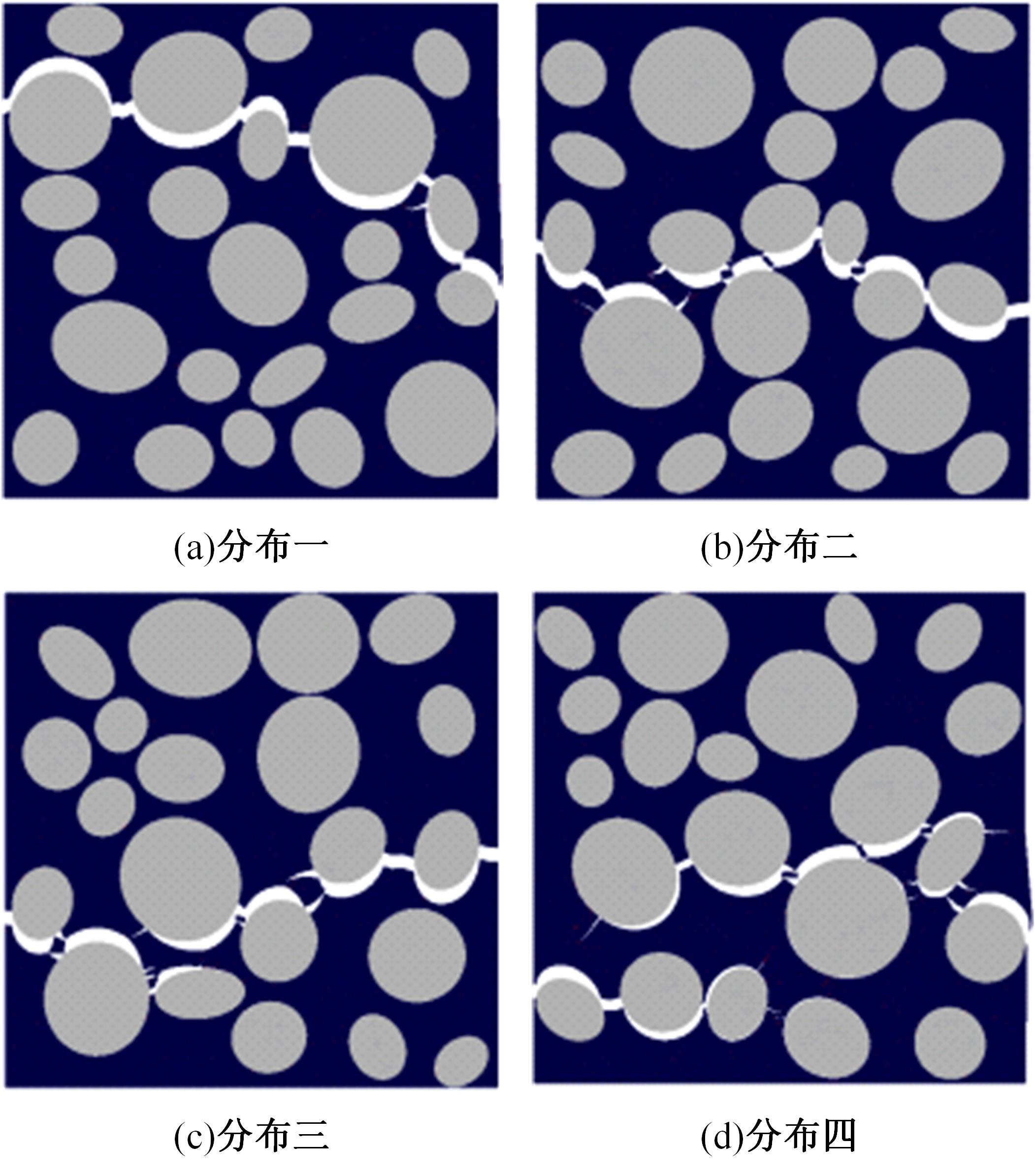

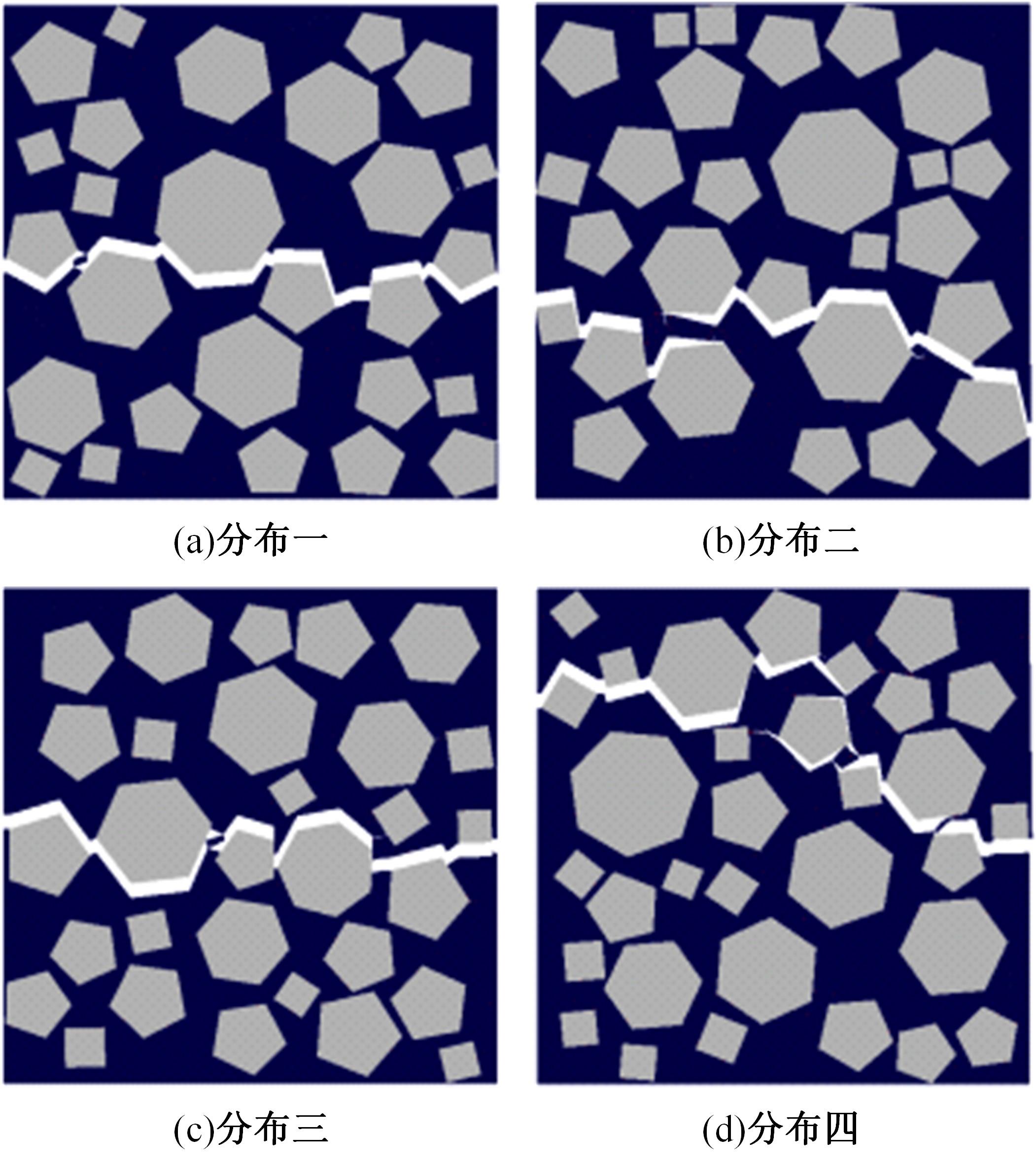

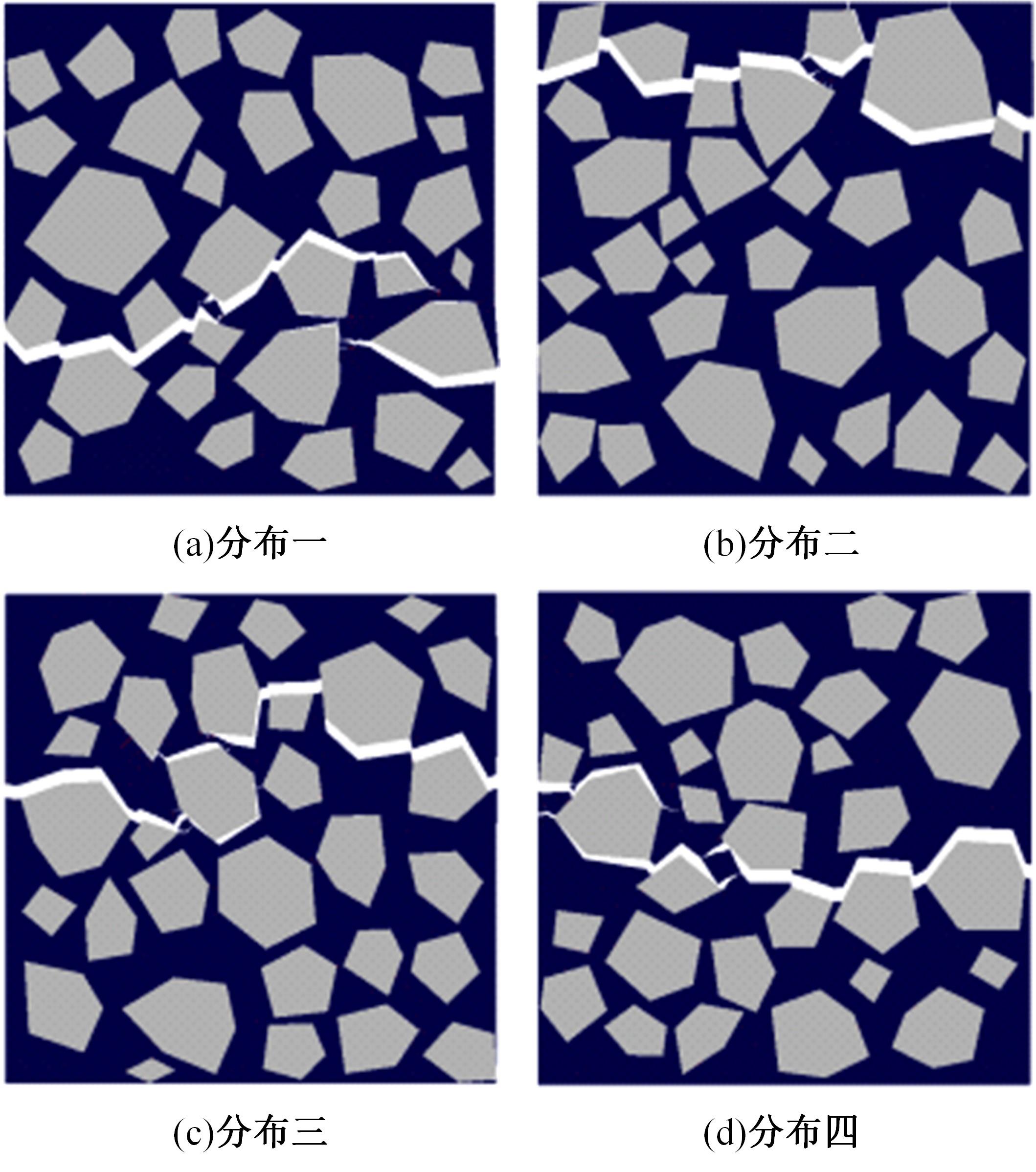

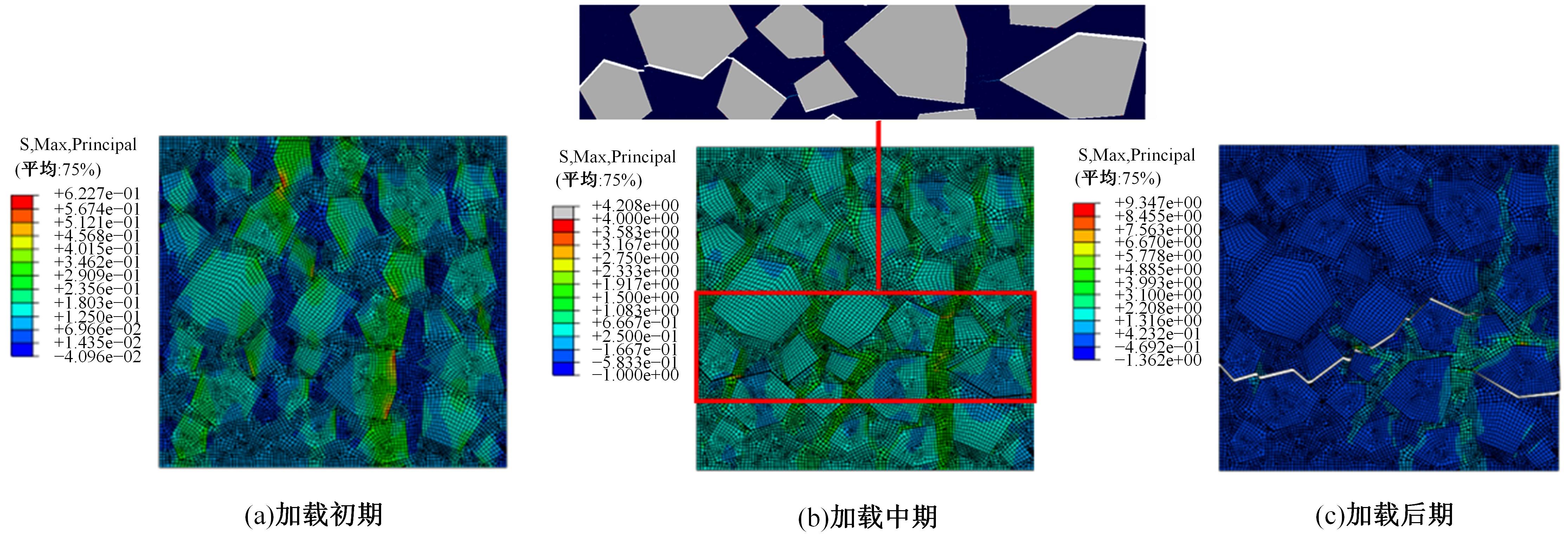

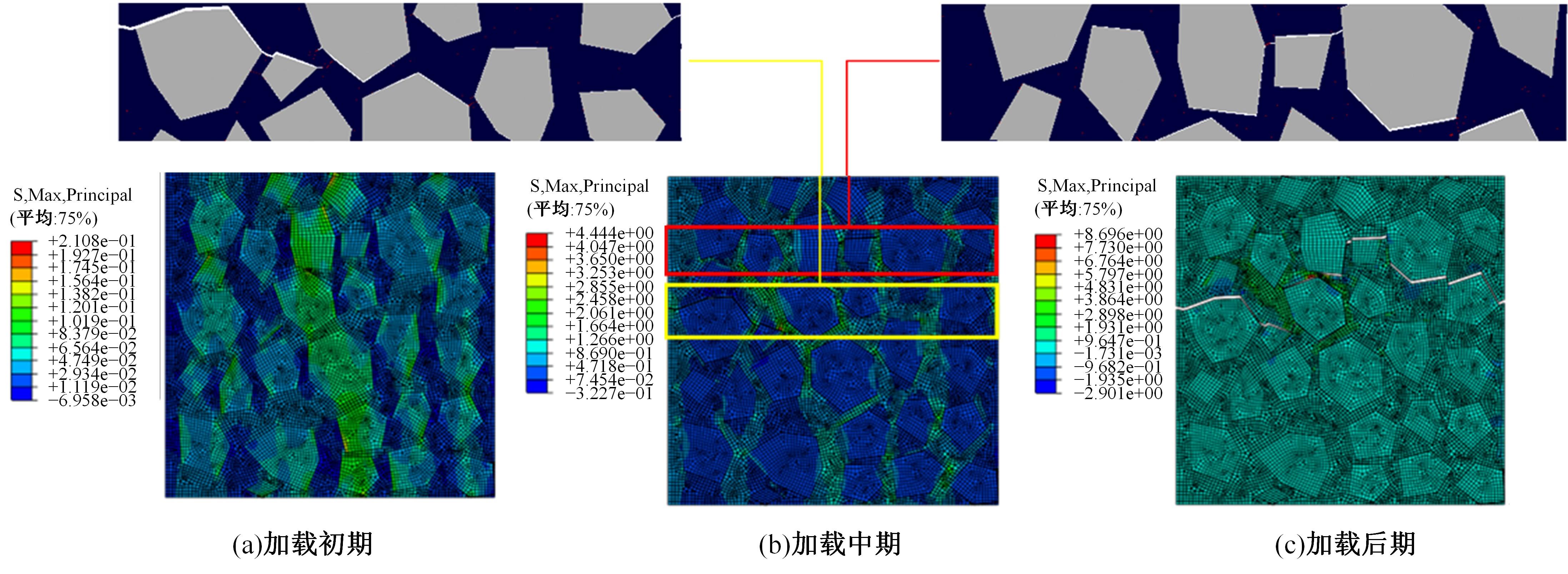

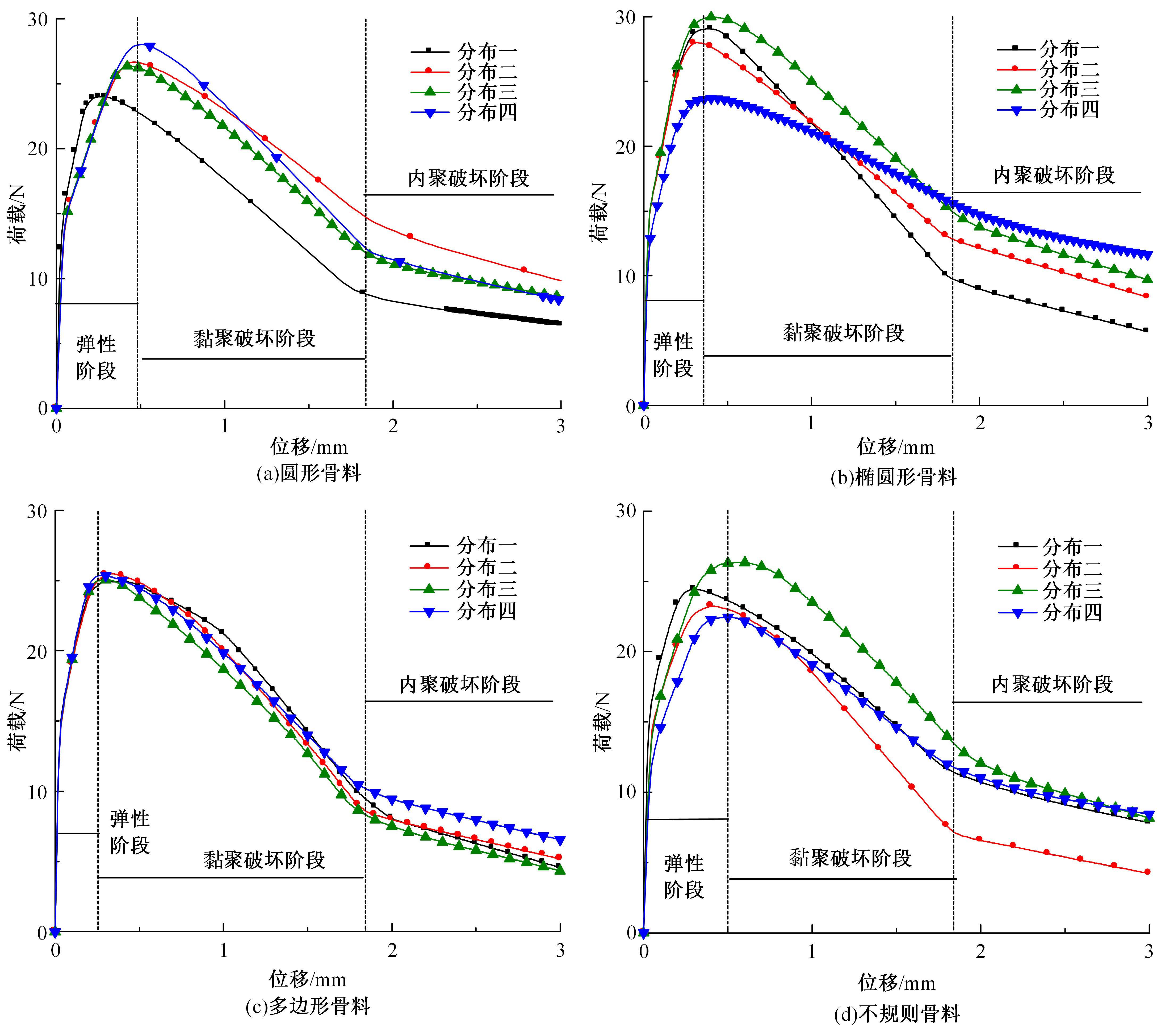

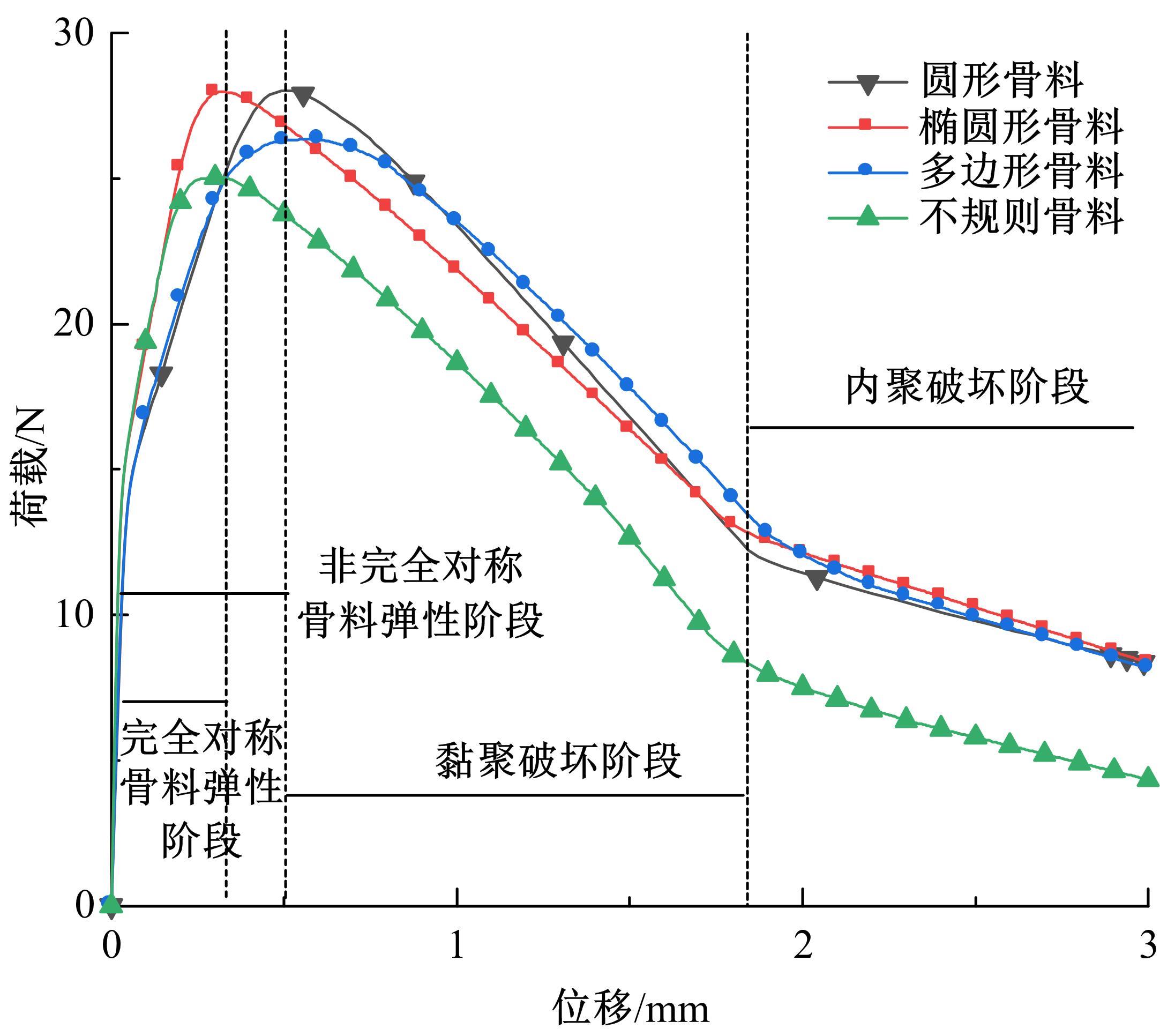

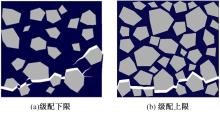

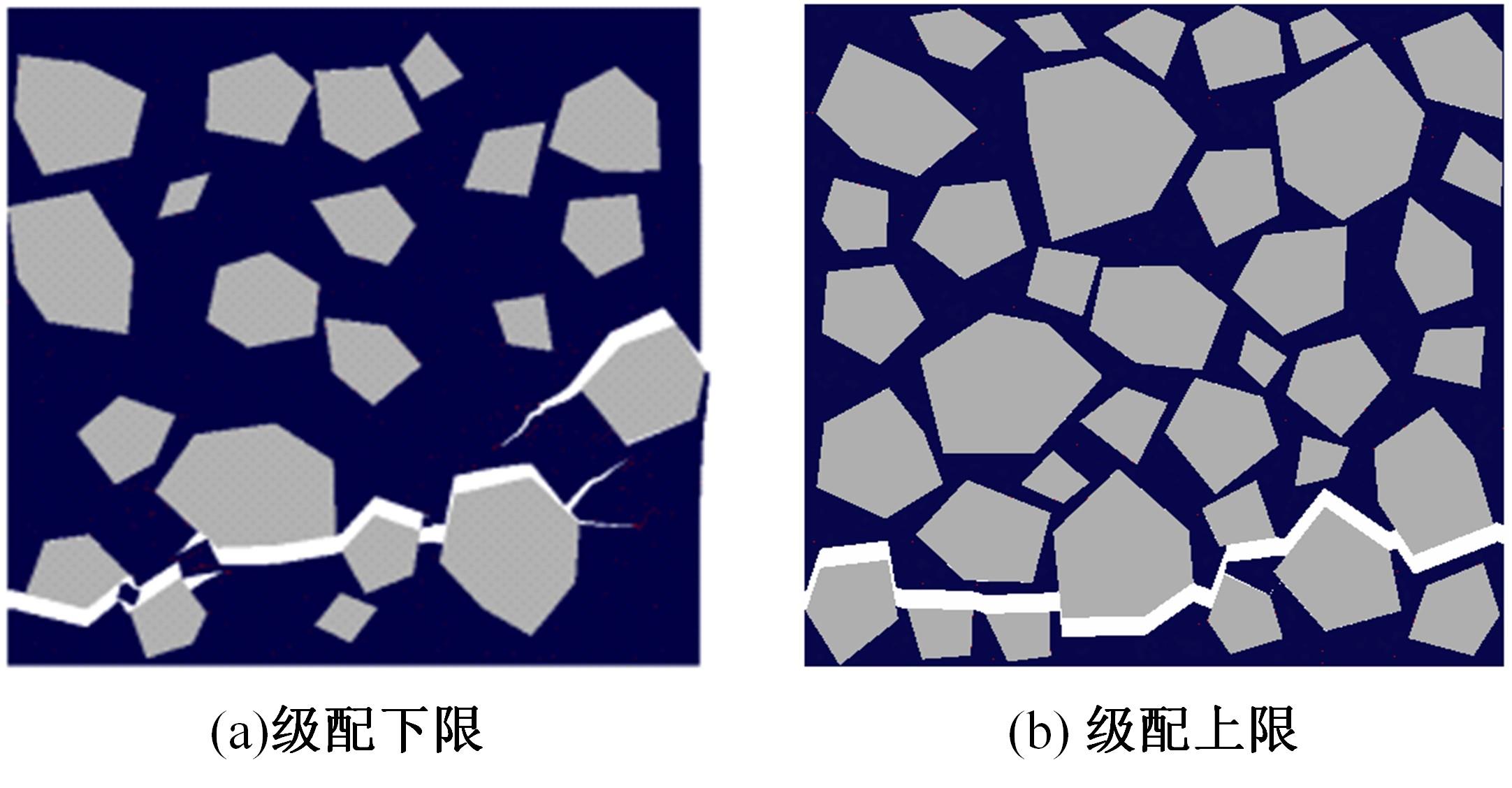

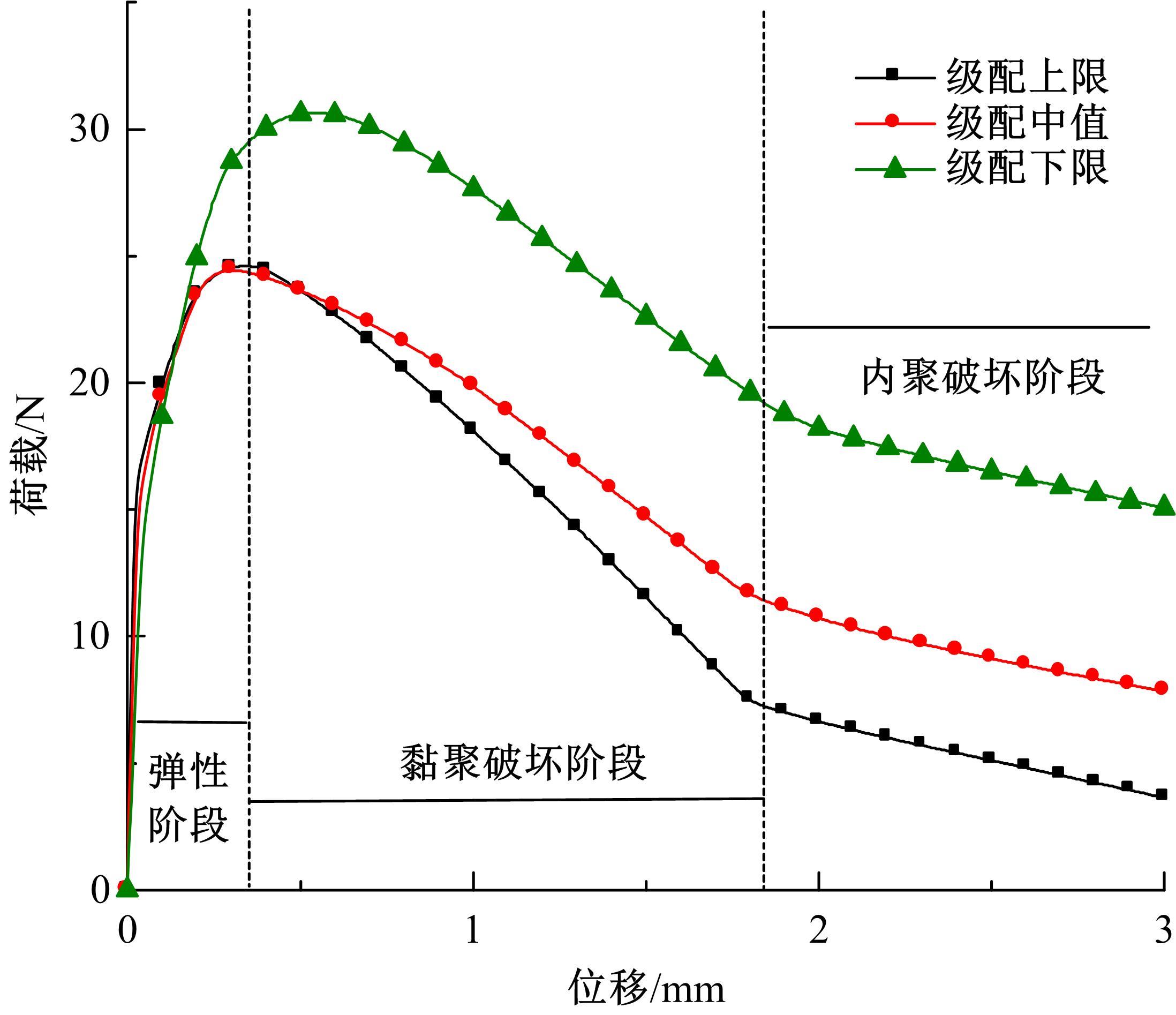

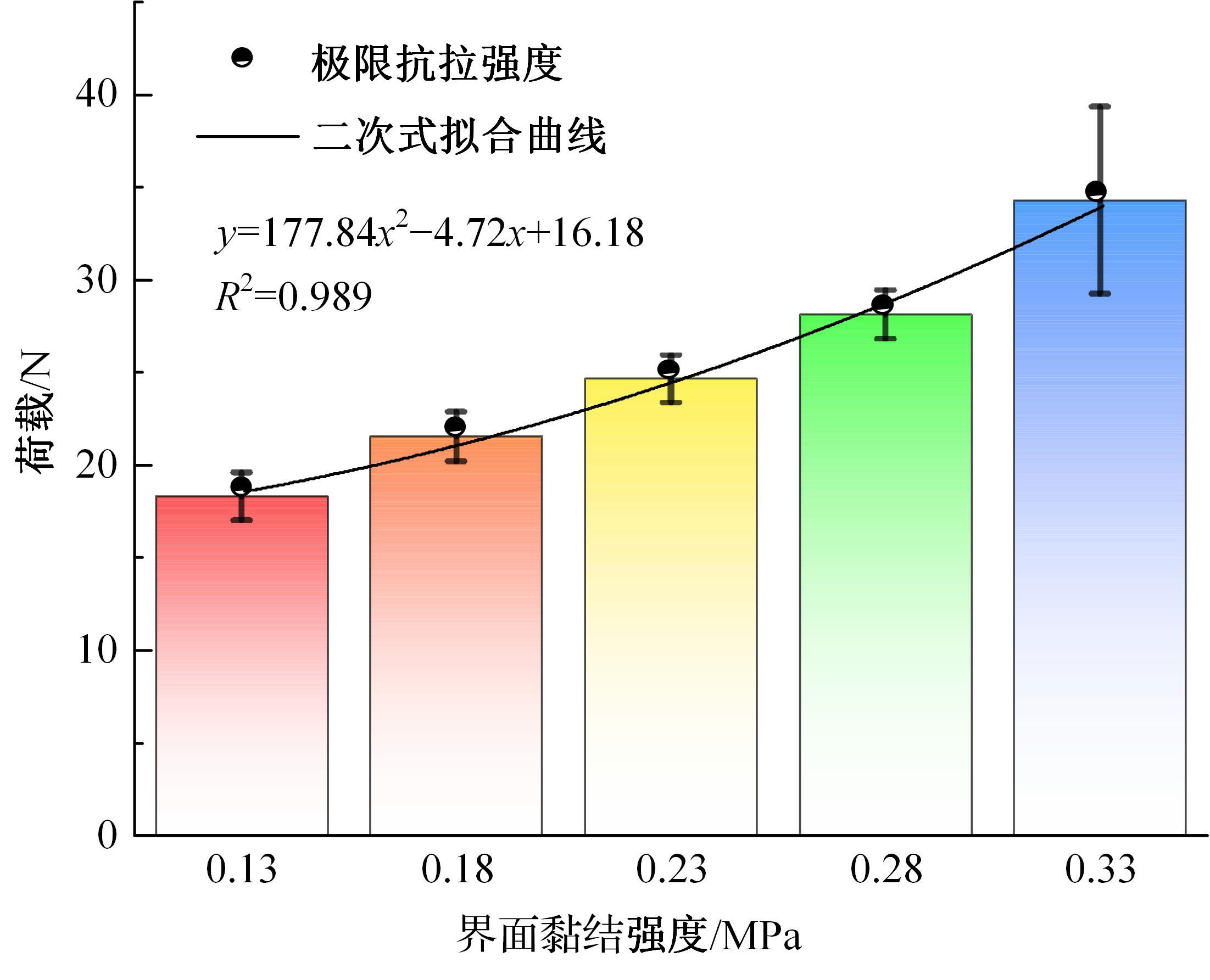

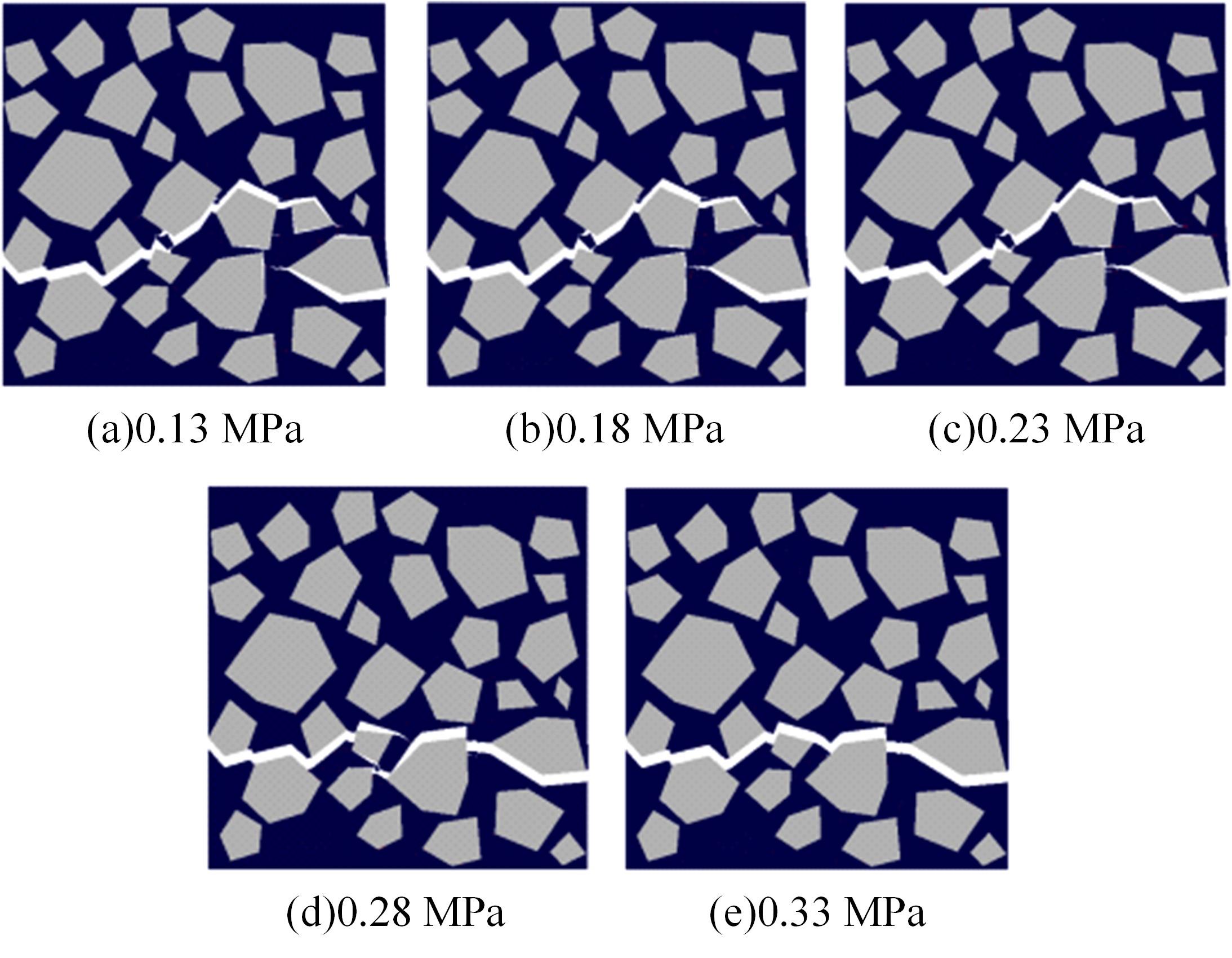

为探究沥青混合料内部非均匀性对其开裂行为的影响,通过室内试验获取有限元模型所需参数;使用插件实现骨料随机投放,并分别在骨料-砂浆界面处和沥青砂浆单元间插入内聚力单元,基于内聚力模型对细观尺度下沥青混合料中裂缝的萌生、扩展和失效全过程进行模拟;探讨了骨料物理力学性质和界面黏结强度对沥青混合料抵抗拉伸开裂性能的影响。本文研究成果可为沥青混合料的设计提供理论和数据支撑。

中图分类号:

- U416.2

| 1 | 赵延庆,谭忆秋,王国忠,等. 黏弹性对沥青路面疲劳开裂的影响[J]. 吉林大学学报:工学版, 2010, 40(3): 683-687. |

| Zhao Yan-qing, Tan Yi-qiu, Wang Guo-zhong, et al. Effect of viscoelasticity on fatigue cracking of asphalt pavement[J]. Journal of Jilin University (Engineering and Technology Edition), 2010, 40(3): 683-687. | |

| 2 | 马泽欣,刘黎萍,孙立军. 基于加速加载的在役沥青混合料 损伤与疲劳性能[J]. 吉林大学学报:工学版, 2019, 49(2): 384-391. |

| Ma Ze-xin, Liu Li-ping, Sun Li-jun. Damage and failure performance of in-service asphalt mixture based on accelerated loading test[J]. Journal of Jilin University (Engineering and Technology Edition), 2019, 49(2): 384-391. | |

| 3 | 孙雅珍,郑直,黄伟明,等. 基于状态空间法的含裂缝水泥路面结构分[J].吉林大学学报:工学版, 2023, 53(1): 188-196. |

| Sun Ya-zhen, Zheng Zhi, Huang Wei-ming, et al. Structural analysis of cement pavement with cracks based on state⁃space method[J]. Journal of Jilin University (Engineering and Technology Edition), 2023, 53(1): 188-196. | |

| 4 | Dong Z J, Gong X B, Zhao L D, et al. Mesostructural damage simulation of asphalt mixture using microscopic interface contact models[J]. Construction and Building Materials, 2014, 53: 665-673. |

| 5 | Qiu X, Xiao S L, Yang Q, et al. Meso-scale analysis on shear failure characteristics of asphalt–aggregate interface[J]. Materials and Structures, 2017, 50(5): 1-14. |

| 6 | 孙艳丽, 邹桢, 崔长青, 等. ICF掺合料对混凝土抗压性能及微观结构的影响[J].沈阳建筑大学学报: 自然科学版, 2023, 39(1): 104-111. |

| Sun Yan-li, Zou Zhen, Cui Chan-qing, et al. Effect of ICF admixture on compressive properties and microstructure of concrete[J]. Journal of Shenyang Jianzhu University (Natural Science), 2023, 39(1): 104-111. . | |

| 7 | Ziaei-Rad V, Nouri N, Ziaei-Rad S, et al. A numerical study on mechanical performance of asphalt mixture using a meso-scale finite element model[J]. Finite Elements in Analysis and Design, 2012, 57: 81-91. |

| 8 | 谷凡, 王凯, 包忠彬, 等. 聚乙烯醇(PVA)纤维增强水泥基复合材料单纤维拔出细观机理研究[J]. 沈阳建筑大学学报: 自然科学版, 2023, 39(6): 1092-1099. |

| Gu Fan, Wang Kai, Bao Zhong-bin, et al. Micro-mechanism study on the single fiber pullout of PVA engineered cementitious composite[J]. Journal of Shenyang Jianzhu University (Natural Science), 2023, 39(6): 1092-1099. | |

| 9 | Shi L W, Wang D Y, Xiao X, et al. Meso-structural characteristics of asphalt mixture main skeleton based on meso-scale analysis[J]. Construction and Building Materials, 2020, 232: 1-12. |

| 10 | 王志臣, 孙雅珍, 桑海军, 等. 沥青与矿粉的交互作用评价及影响机理分析[J]. 沈阳建筑大学学报: 自然科学版), 2023, 39(2): 339-347. |

| Wang Zhi-chen, Sun Ya-zhen, Sang Hai-jun, et al. Evaluation of the interaction between asphalt and mineral powder and analysis of its influence mechanism[J]. Journal of Shenyang Jianzhu University (Natural Science), 2023, 39(2): 339-347. | |

| 11 | Zhao Y J, Ni F J, Zhou L, et al. Heterogeneous fracture simulation of asphalt mixture under SCB test with cohesive crack model[J]. Road Materials and Pavement Design, 2017, 18(6): 1411-1422. |

| 12 | Chen X Q, Yuan J W, Dong Q, et al. Meso-scale cracking behavior of cement treated base material[J]. Construction and Building Materials, 2020, 239: 1-12. |

| 13 | 熊学玉,肖启晟. 基于内聚力模型的混凝土细观拉压统一数值模拟方法[J]. 水利学报, 2019, 50(4): 448-462. |

| Xiong Xue-yu, Xiao Qi-sheng. A unified meso-scale simulation method for concrete under both tension and compression based on cohesive zone model[J]. Journal of Hydraulic Engineering, 2019, 50(4): 448-462. | |

| 14 | 梁何浩. 基于细观力学性能的抗裂型沥青混合料研究[D]. 广州: 华南理工大学土木与交通工程学院, 2019. |

| Liang He-hao. Investigation of anti-cracking asphalt mixture based on mesomechanical property[D]. Guangzhou: School of Civil Engineering and Transportation, South China University of Technology, 2019. | |

| 15 | Kim H, Buttlar W G. Finite element cohesive fracture modeling of airport pavements at low temperatures[J]. Cold Regions Science & Technology, 2009, 57(2/3): 123-130. |

| 16 | Yin A Y, Yang X H, Yang Z J. 2D and 3D fracture modeling of asphalt mixture with randomly distributed aggregates and embedded cohesive cracks[J]. Procedia IUTAM, 2013, 6: 114-122 |

| 17 | Wang H, Wang J, Chen J Q. Micromechanical analysis of asphalt mixture fracture with adhesive and cohesive failure[J]. Engineering Fracture Mechanics, 2014, 132: 104-119. |

| 18 | 郭永祥. 半刚性基层沥青混凝土路面病害分析与路面结构设计参数研究[D]. 长沙:中南大学土木工程学院, 2012. |

| Guo Yong-xiang. Disease analysis and structural design parameters studies of semi-rigid base asphalt concrete pavement[D]. Changsha: School of Civil Engineering, Central South University, 2012. | |

| 19 | 牛冬瑜. 基于细观力学的沥青砂浆及骨架结构沥青混合料性能研究[D]. 西安:长安大学材料工程与科学学院, 2015. |

| Niu Dong-yu. Study on performance of asphalt mortar and framework structured asphalt mixture based on meso-mechanics[D]. Xi´an: School of Materials Engineering and Science, Chang 'an University, 2015. | |

| 20 | 尹安毅. 沥青混合料开裂破坏行为的细观尺度模拟[D]. 武汉:华中科技大学土木工程与力学学院, 2013. |

| Yin An-yi. Mesoscale fracture simulation of asphalt mixture considering material heterogeneity[D]. Wuhan: School of Civil Engineering and Mechanics, Huazhong University of Science and Technology, 2013. | |

| 21 | 万蕾. 基于内聚力模型和三维离散元法沥青混合料劈裂试验研究[D]. 杭州:浙江大学建筑工程学院, 2016. |

| Wan Lei. Study on asphalt mixture splitting test using cohesive zone model and three-dimensional discrete element method[D]. Hangzhou: School of Civil Engineering and Architecture, Zhejiang University, 2016. | |

| 22 | 张争奇,李平,王秉纲. 纤维和矿粉对沥青胶浆性能的影响[J]. 长安大学学报:自然科学版, 2005, 25(5): 15-18. |

| Zhang Zheng-qi, Li Ping, Wang Bing-gang. Effect of fiber and mineral filler on asphalt mortar performance[J]. Journal of Chang'an University (Natural Science Edition), 2005, 25(5): 15-18. | |

| 23 | 张东,黄晓明,赵永利. 基于内聚力模型的沥青混合料劈裂试验模拟[J].东南大学学报: 自然科学版, 2010, 40(6): 1276-1281. |

| Zhang Dong, Huang Xiao-ming, Zhao Yong-li. Simulation of indirect tension test of asphalt mixtures based on cohesive zone model[J]. Journal of Southeast University(Natural Science Edition), 2010, 40(6): 1276-1281. | |

| 24 | 林震寰. 沥青混合料低温抗裂性能数值模拟研究[D]. 沈阳: 沈阳建筑大学土木工程学院, 2021. |

| Lin Zhen-huan. Numerical simulation of low temperature crack resistance of asphalt mixture[D]. Shenyang: School of Civil Engineering, Shenyang Jianzhu University, 2021. |

| [1] | 徐永丽,杨煦兰,周吉森,杨松翰,孙明刚. 温拌沥青的沥青烟成分及温拌剂抑烟性能[J]. 吉林大学学报(工学版), 2024, 54(6): 1701-1707. |

| [2] | 赵晓康,胡哲,牛振兴,张久鹏,裴建中,温永. 基于非均质模型的水稳碎石材料细观开裂行为[J]. 吉林大学学报(工学版), 2024, 54(5): 1258-1266. |

| [3] | 万铜铜,汪海年,郑文华,冯珀楠,陈玉,张琛. 级配碎石层协调沥青混合料层温度收缩变形行为[J]. 吉林大学学报(工学版), 2024, 54(4): 1045-1057. |

| [4] | 陈俊,孙振浩,赵成,吴欣怡,王俊鹏. 相变沥青混凝土复合结构降温效果试验分析[J]. 吉林大学学报(工学版), 2024, 54(1): 180-187. |

| [5] | 唐乃膨,薛晨阳,刘少鹏,朱洪洲,李睿. 胶粉改性沥青老化机理及表征评价研究综述[J]. 吉林大学学报(工学版), 2024, 54(1): 22-43. |

| [6] | 王壮,冯振刚,姚冬冬,崔奇,沈若廷,李新军. 导电沥青混凝土研究进展[J]. 吉林大学学报(工学版), 2024, 54(1): 1-21. |

| [7] | 赵胜前,丛卓红,游庆龙,李源. 沥青-集料黏附和剥落研究进展[J]. 吉林大学学报(工学版), 2023, 53(9): 2437-2464. |

| [8] | 马涛,马源,黄晓明. 基于多元非线性回归的智能压实关键参数最优解[J]. 吉林大学学报(工学版), 2023, 53(7): 2067-2077. |

| [9] | 杨柳,王创业,王梦言,程阳. 设置自动驾驶小客车专用车道的六车道高速公路交通流特性[J]. 吉林大学学报(工学版), 2023, 53(7): 2043-2052. |

| [10] | 周正峰,于晓涛,陶雅乐,郑茂,颜川奇. 基于灰色关联分析的树脂与弹性体高黏沥青高温性能评价[J]. 吉林大学学报(工学版), 2023, 53(7): 2078-2088. |

| [11] | 张青霞,侯吉林,安新好,胡晓阳,段忠东. 基于车辆脉冲响应的路面不平度识别方法[J]. 吉林大学学报(工学版), 2023, 53(6): 1765-1772. |

| [12] | 姜屏,陈业文,陈先华,张伟清,李娜,王伟. 改性石灰土在干湿和冻融循环下的无侧限抗压性能[J]. 吉林大学学报(工学版), 2023, 53(6): 1809-1818. |

| [13] | 司春棣,崔亚宁,许忠印,凡涛涛. 层间粘结失效后桥面沥青铺装层细观力学行为分析[J]. 吉林大学学报(工学版), 2023, 53(6): 1719-1728. |

| [14] | 李岩,张久鹏,陈子璇,黄果敬,王培. 基于PCA-PSO-SVM的沥青路面使用性能评价[J]. 吉林大学学报(工学版), 2023, 53(6): 1729-1735. |

| [15] | 刘状壮,郑文清,郑健,李轶峥,季鹏宇,沙爱民. 基于网格化的路表温度感知技术[J]. 吉林大学学报(工学版), 2023, 53(6): 1746-1755. |

|

||